Automobile pipeline and method for producing automobile pipeline

A technology for automobile pipelines and pipelines, applied in the direction of chemical instruments and methods, pipes/fittings/fittings, pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

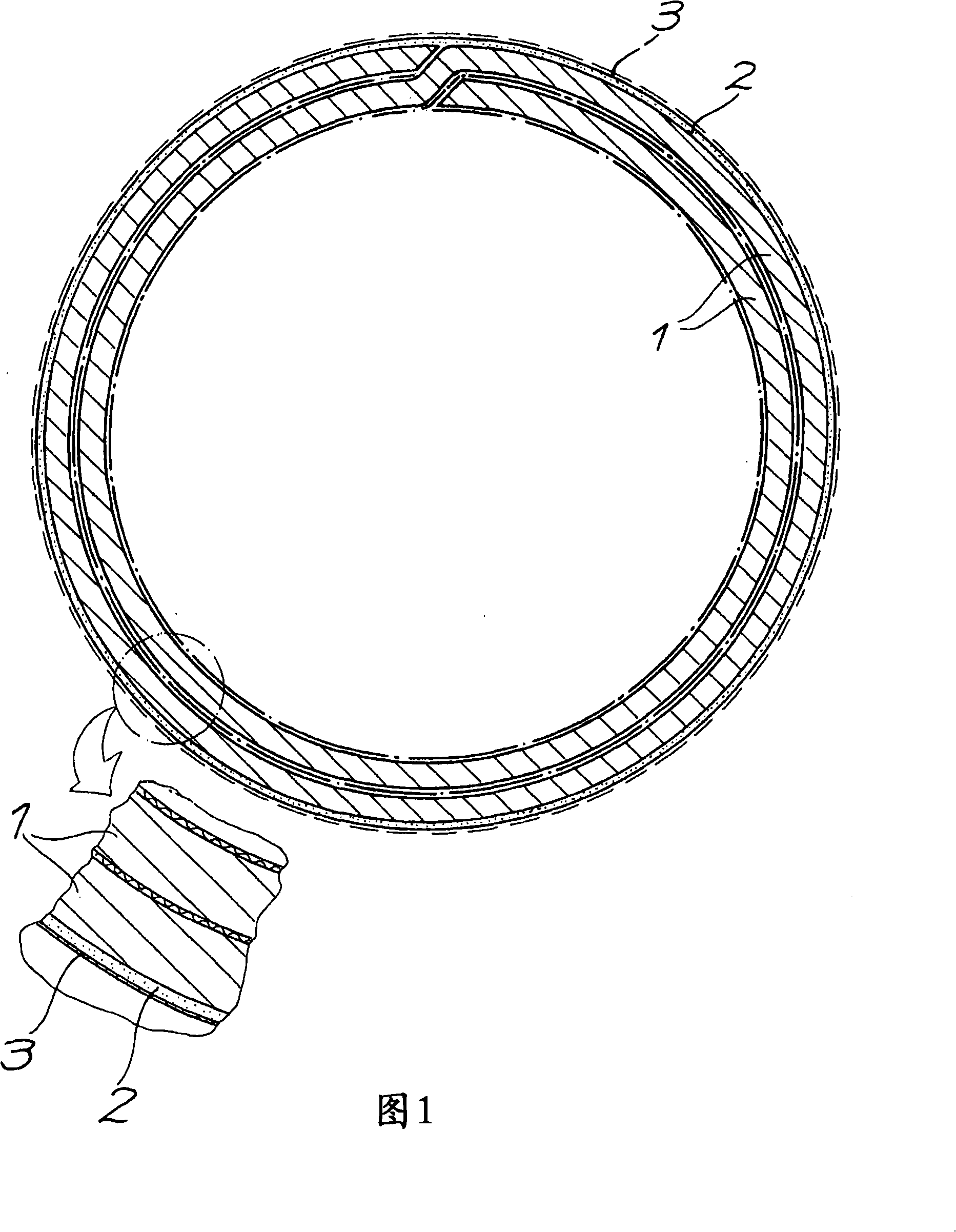

[0031] In the first embodiment according to FIG. 1 , the initially uncoated outer surface of the double-walled steel pipe 1 has been coated with an aluminum layer 2 . In this case, the aluminum layer 2 is expediently coated according to a hot-dipping process. Directly on the aluminum layer 2 is arranged an aluminum oxide layer 3 which forms the outer surface of the vehicle conduit.

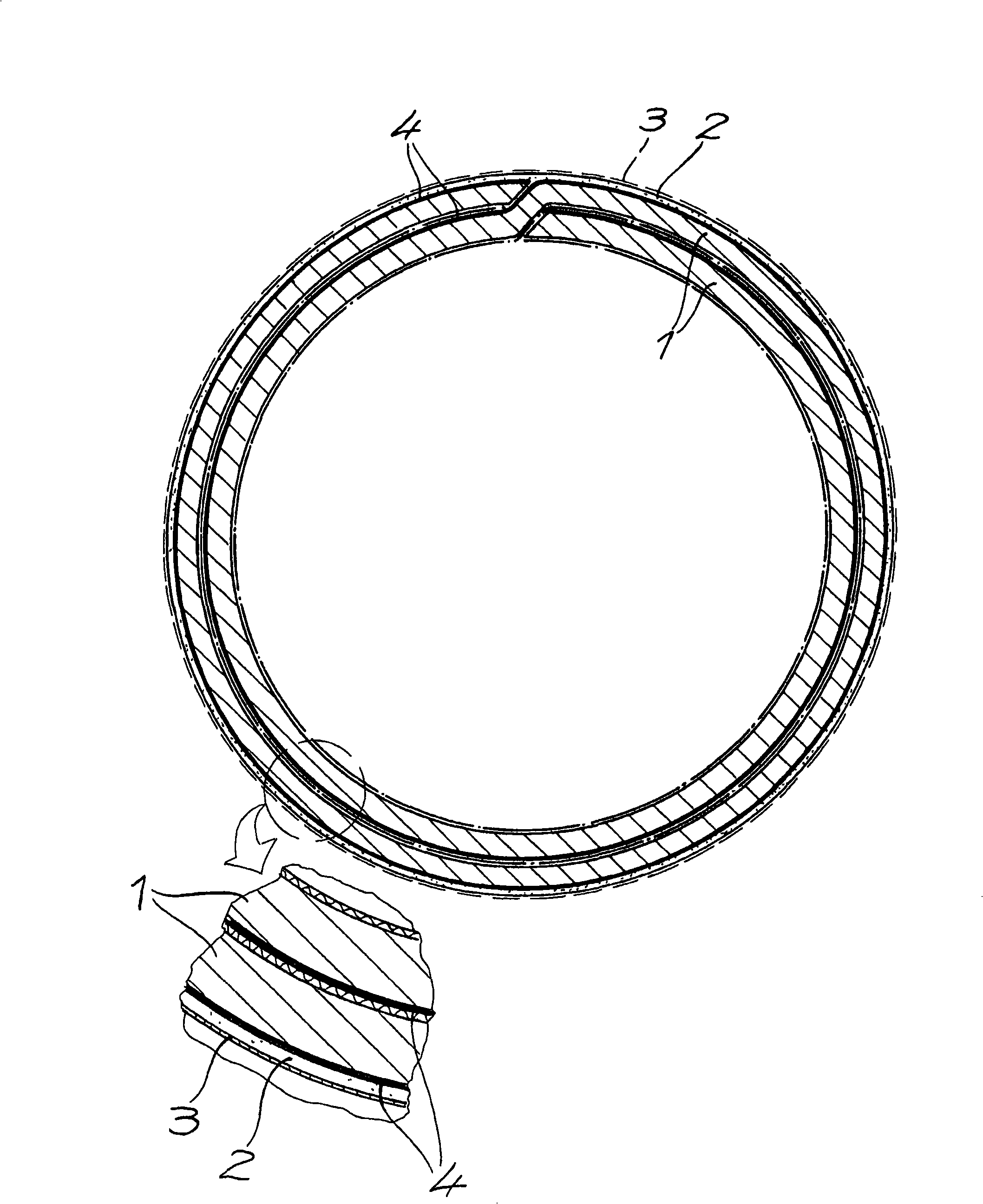

[0032] in accordance with figure 2 In the second embodiment, a nickel layer 4 is firstly plated on the outer surface of the double-walled steel pipe 1 . The aluminum layer 2 is arranged on the nickel layer 4 , wherein the aluminum layer 2 is expediently likewise applied using a hot-dipping process. The aluminum oxide layer 3 is in contact with the aluminum layer 2 on the outside, and the aluminum oxide layer 3 is in accordance with figure 2 In the embodiment of the same, the outer surface of the automobile pipeline is formed. in manufacturing based on figure 2 For the double-walled steel pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com