Reinforcing net structure for geotechnical applications, use of the reinforcing net structure, and a method for production of the reinforcing net structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

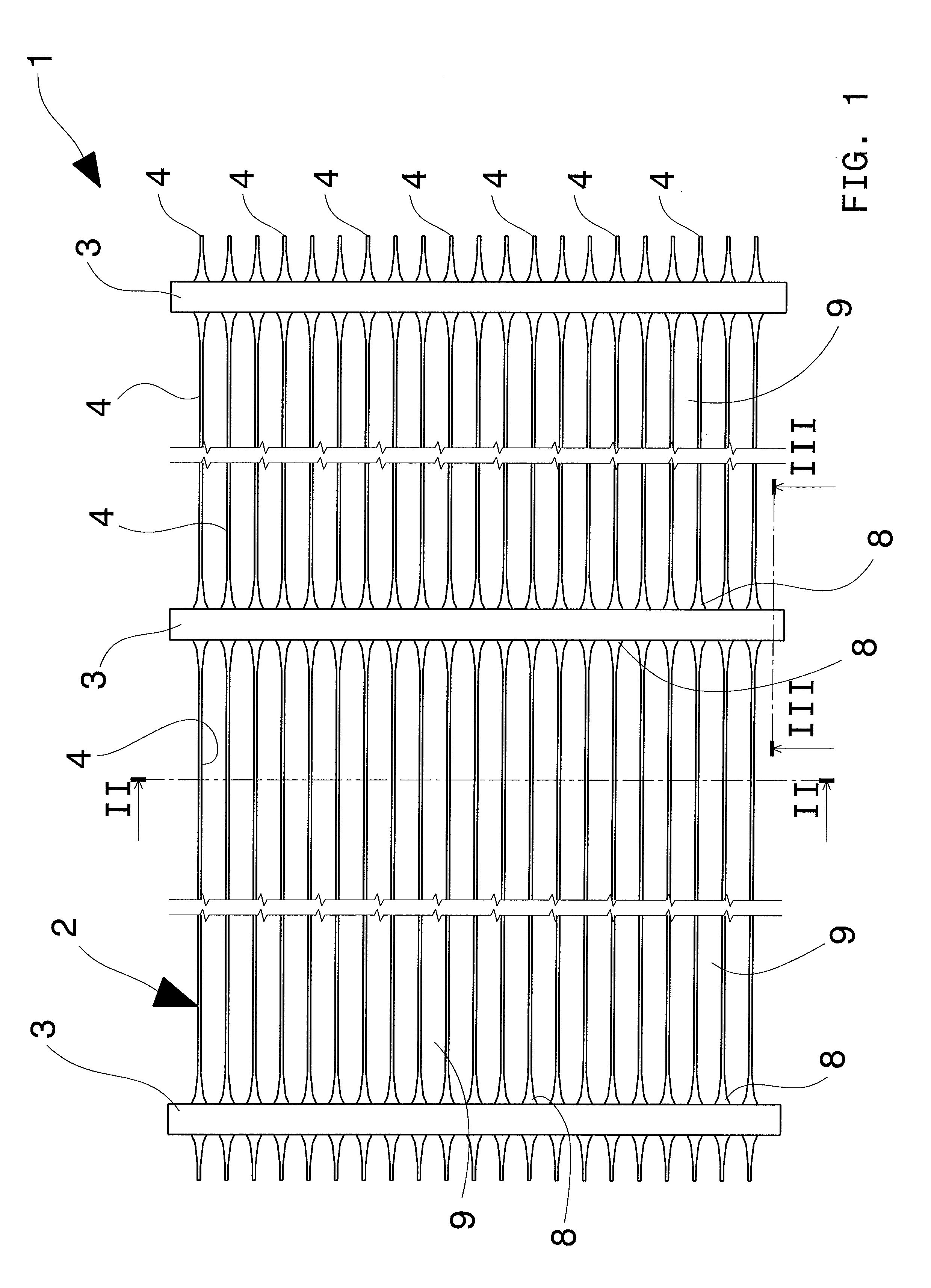

[0065]With reference to the accompanying figures of the drawings, 1 denotes in its entirety a product for reinforcing terrain, which can for example be used for retaining slopes or for reinforcing terrains requiring structural strengthening.

[0066]The product 1 comprises a net structure 2 made of a plastic material; for example, the structure 2 made of a plastic material can be realized using one or more of the following polymers: polyethylene, high density polyethylene (HDPE), polypropylene. The net structure 2 may optionally be obtained by a continuous process of formation as will be more fully described herein below, or by discontinuous processes such as injection molding.

[0067]The net structure 2 product 1 exhibits a plurality of bars 3, distanced from one another, which are substantially rigid structural elements able to offer a considerable resistance to traction in the longitudinal direction of development thereof, but also considerable resistance to shear, torsion and flexion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com