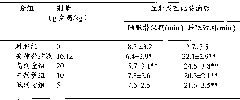

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Increase labor productivity and" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

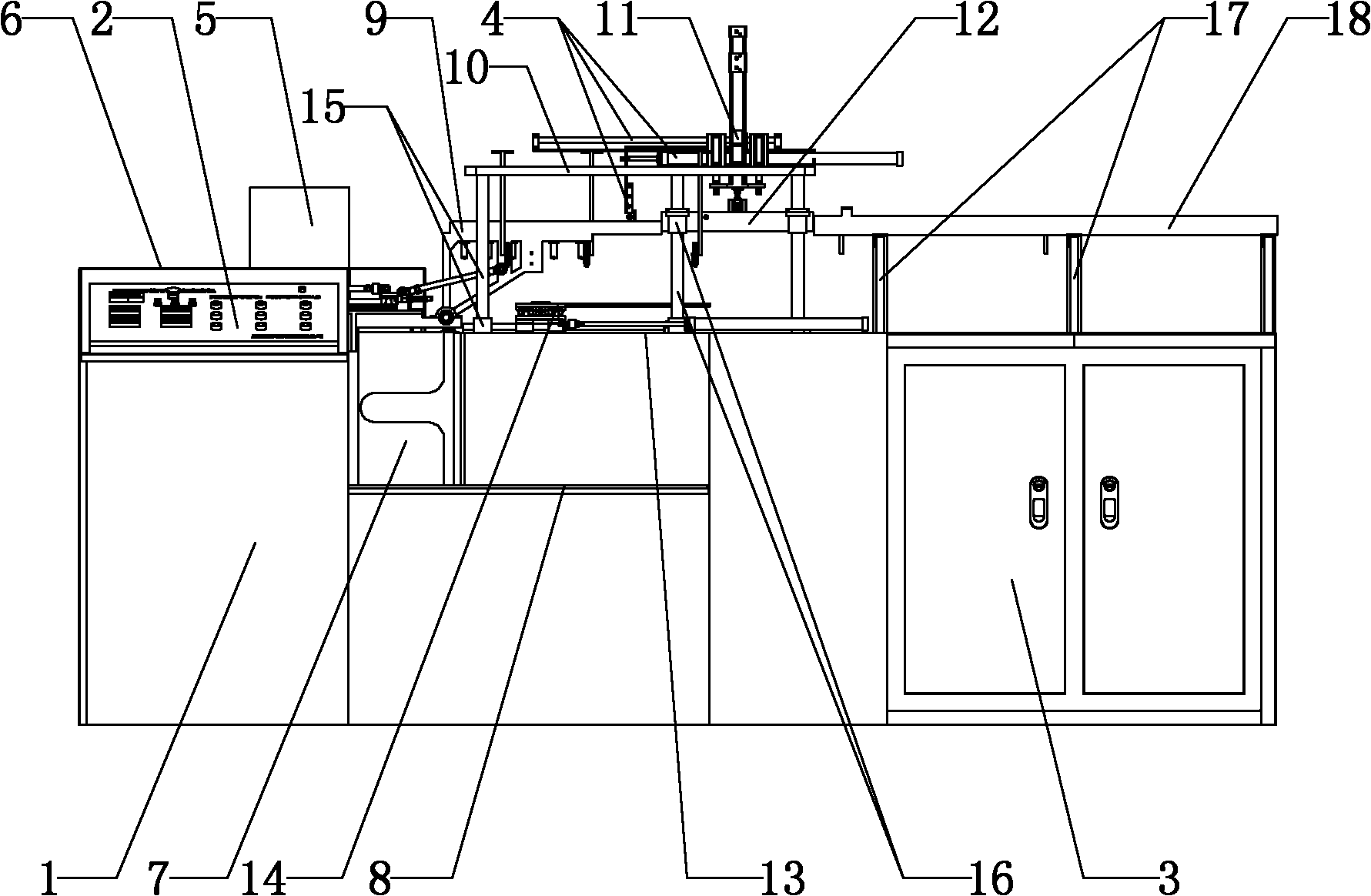

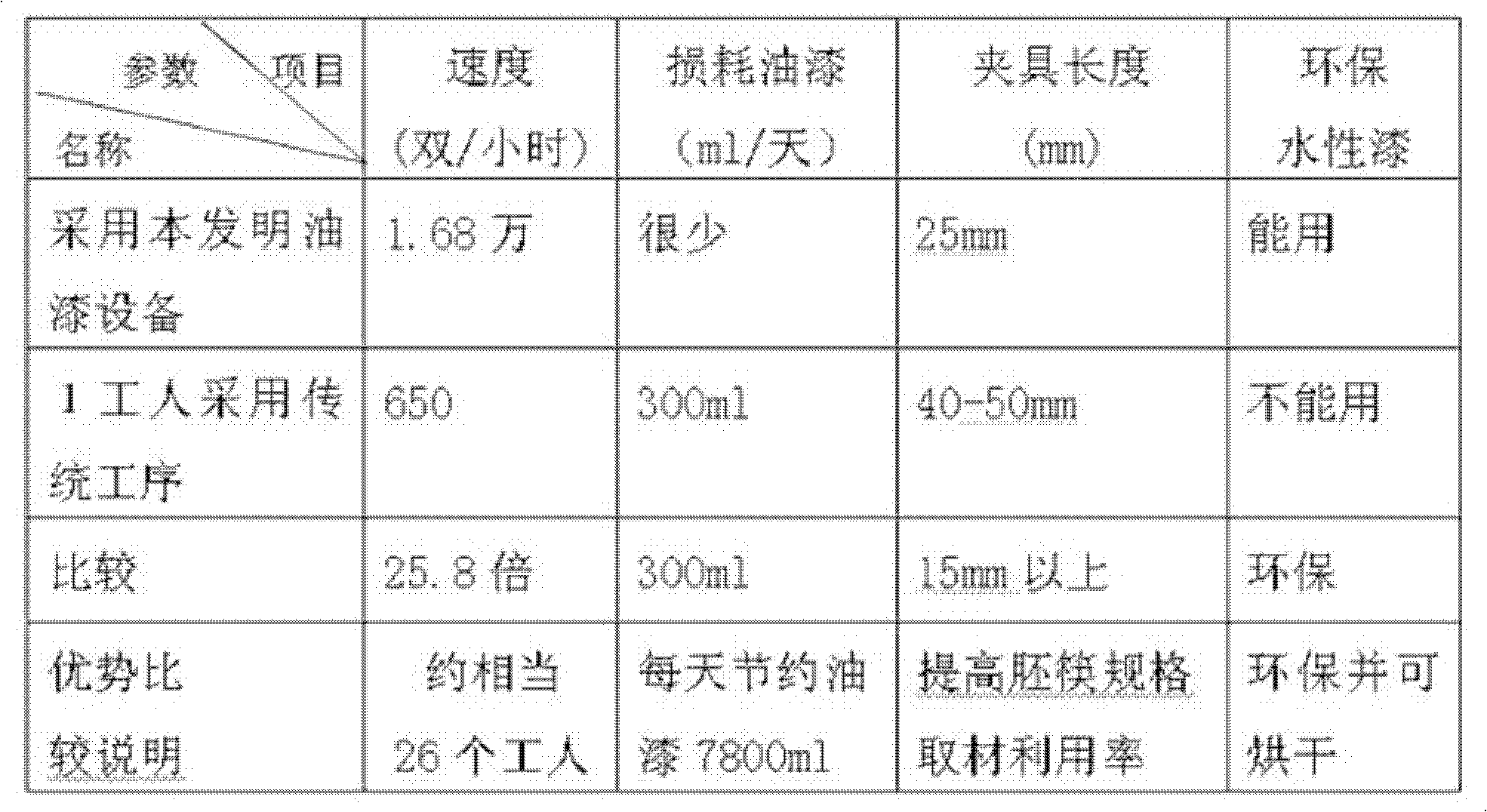

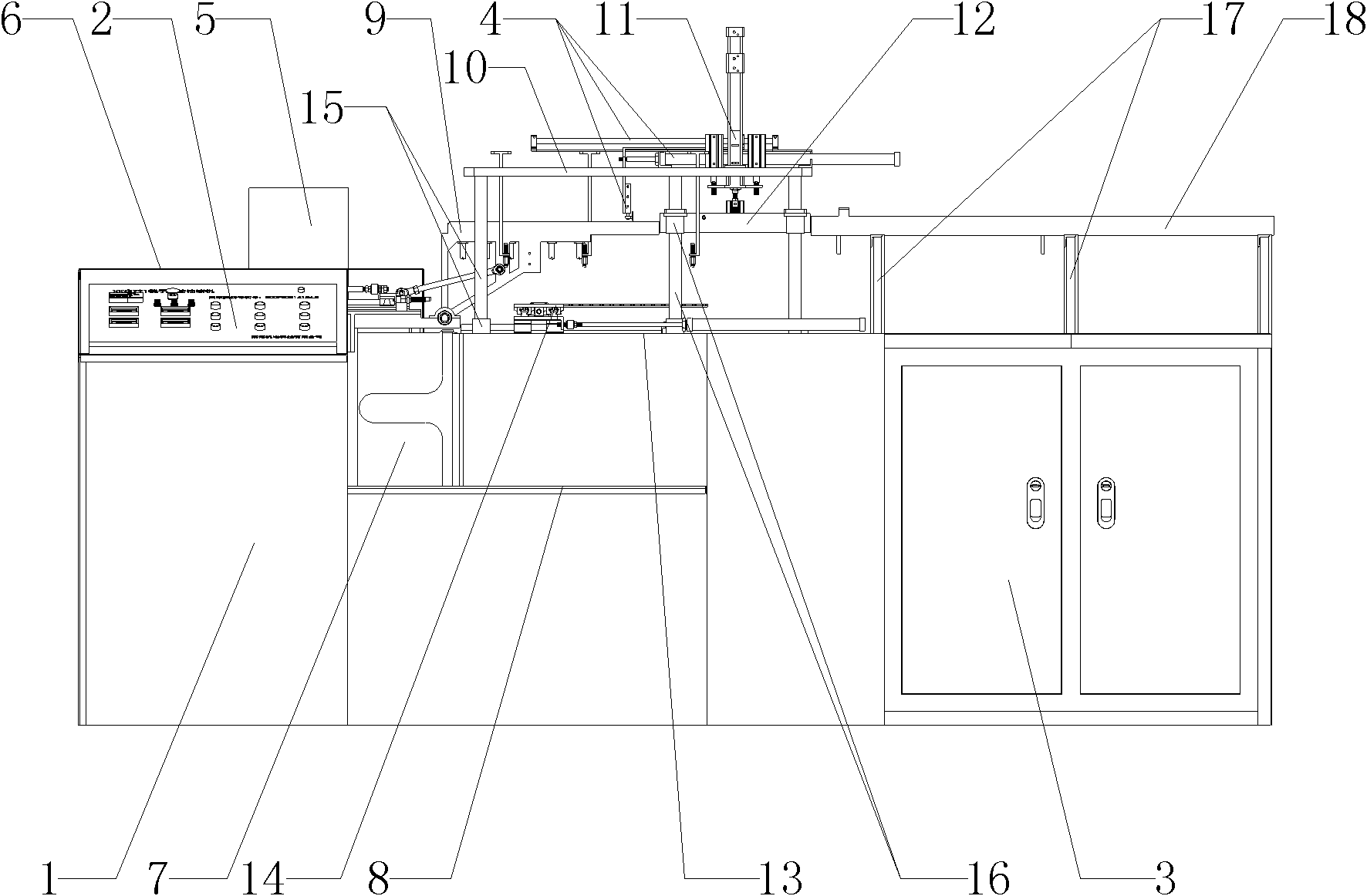

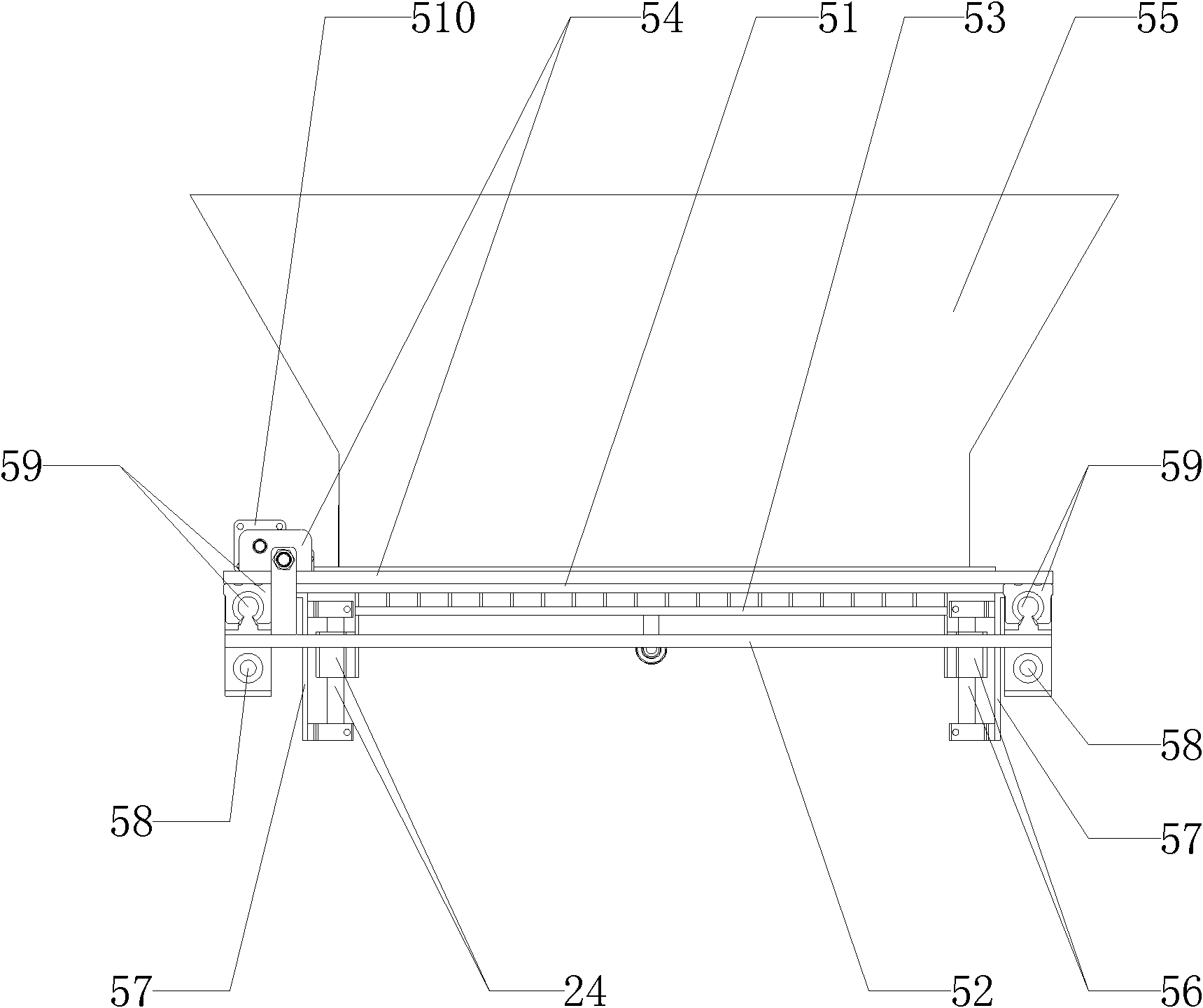

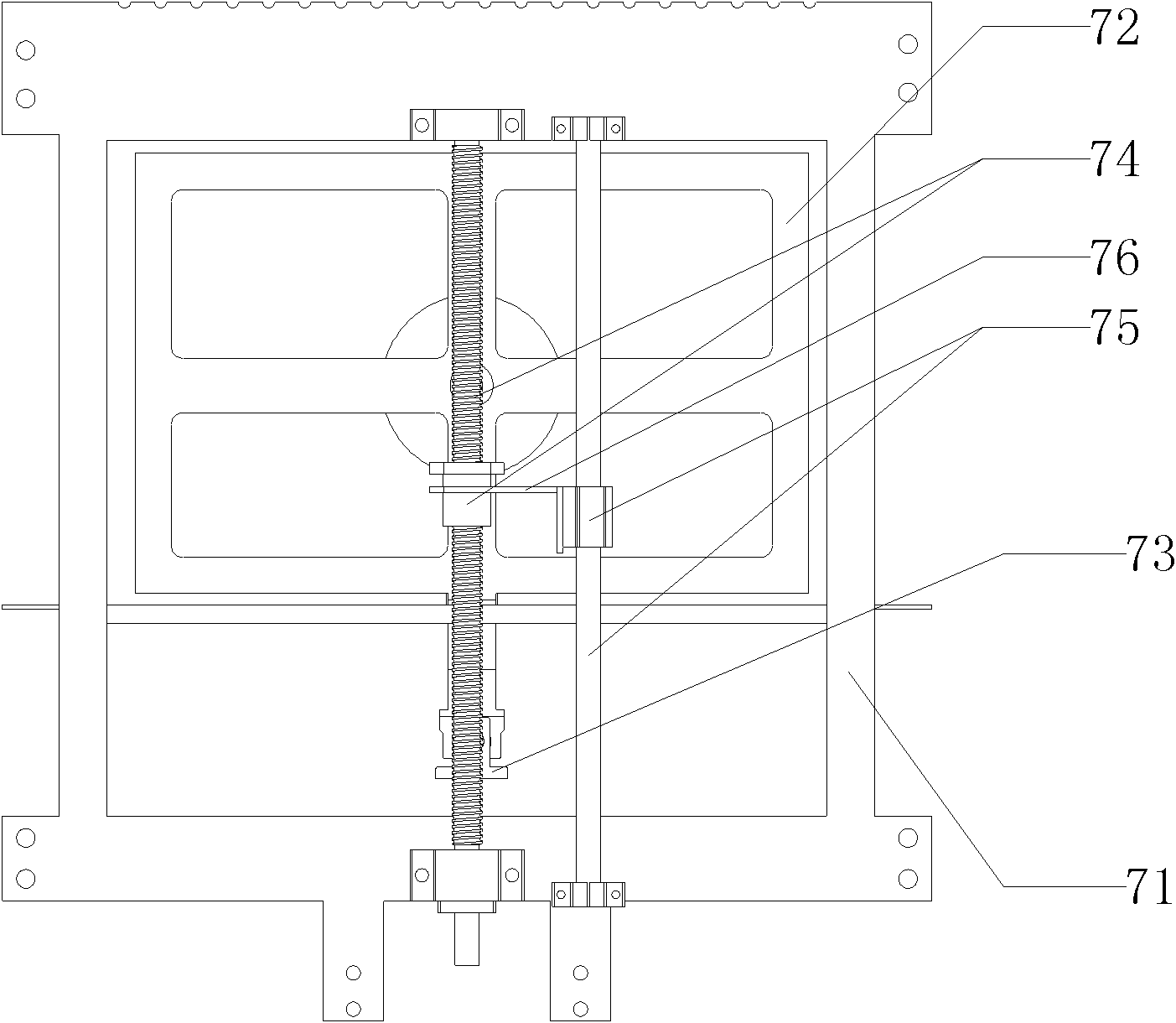

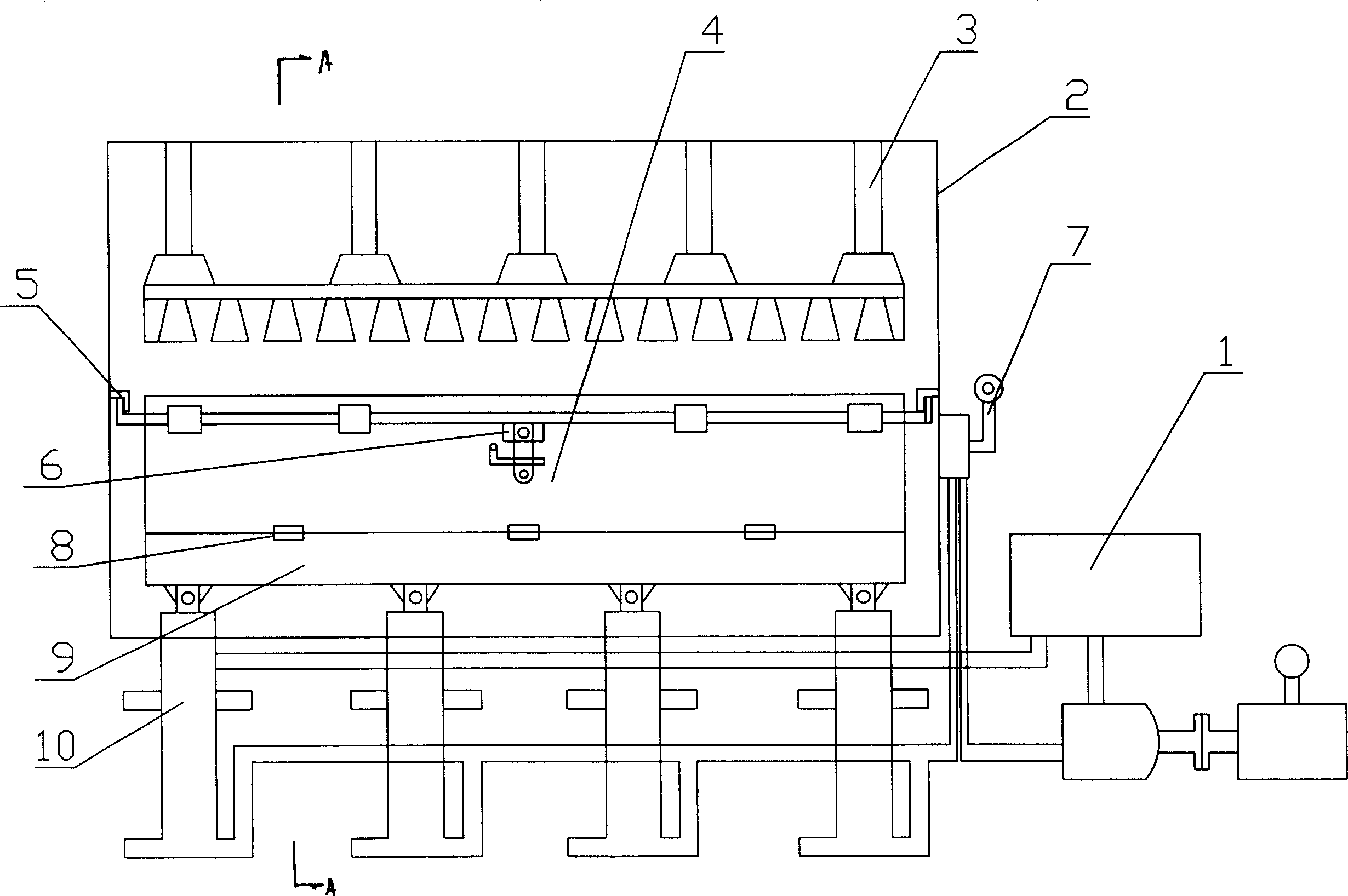

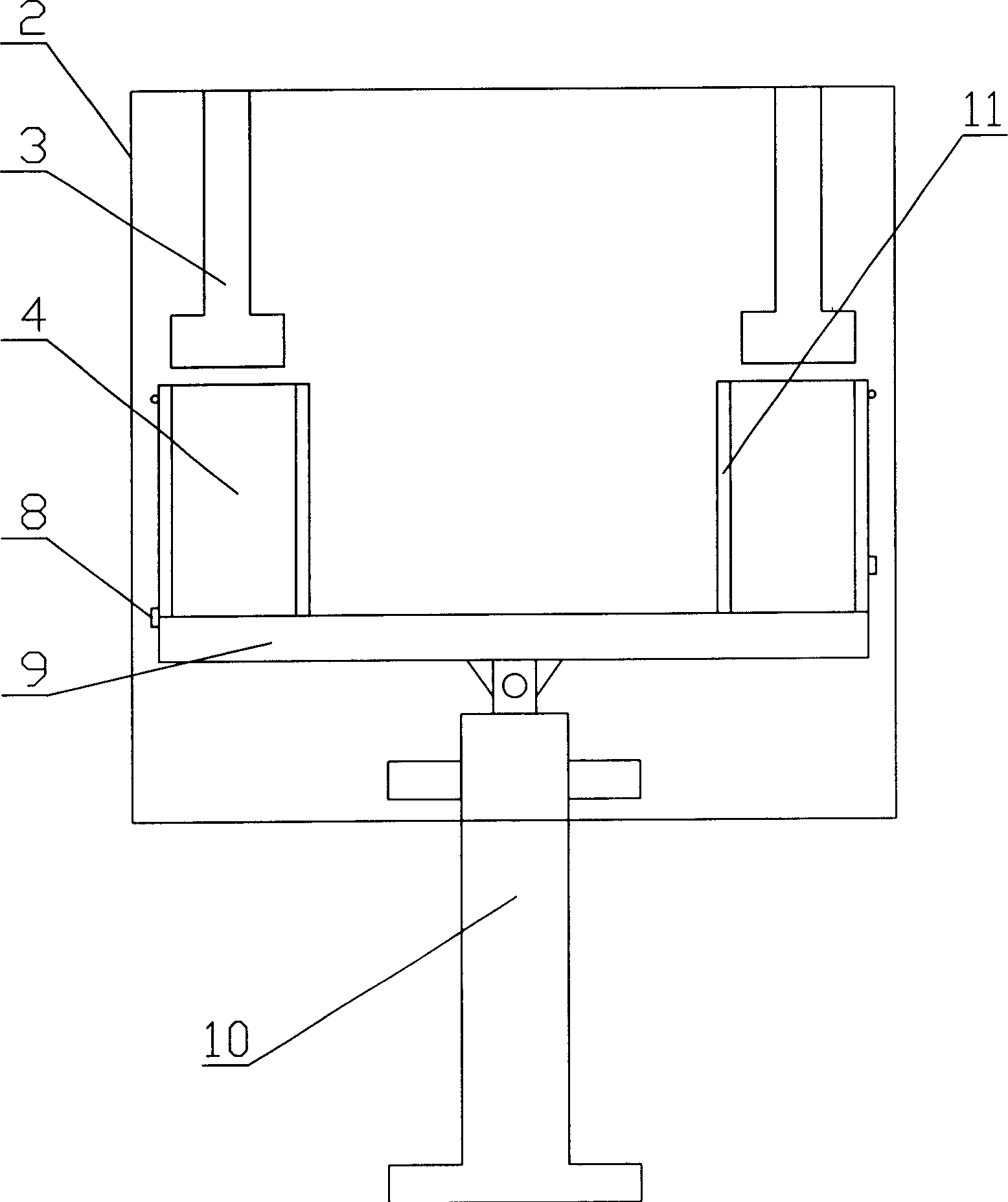

Multi-specification automatic chopstick painting equipment and method

InactiveCN101811109AShorten the lengthReduce labor intensityLiquid surface applicatorsCoatingsLacquerEngineering

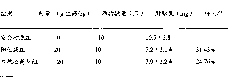

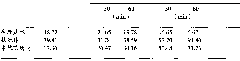

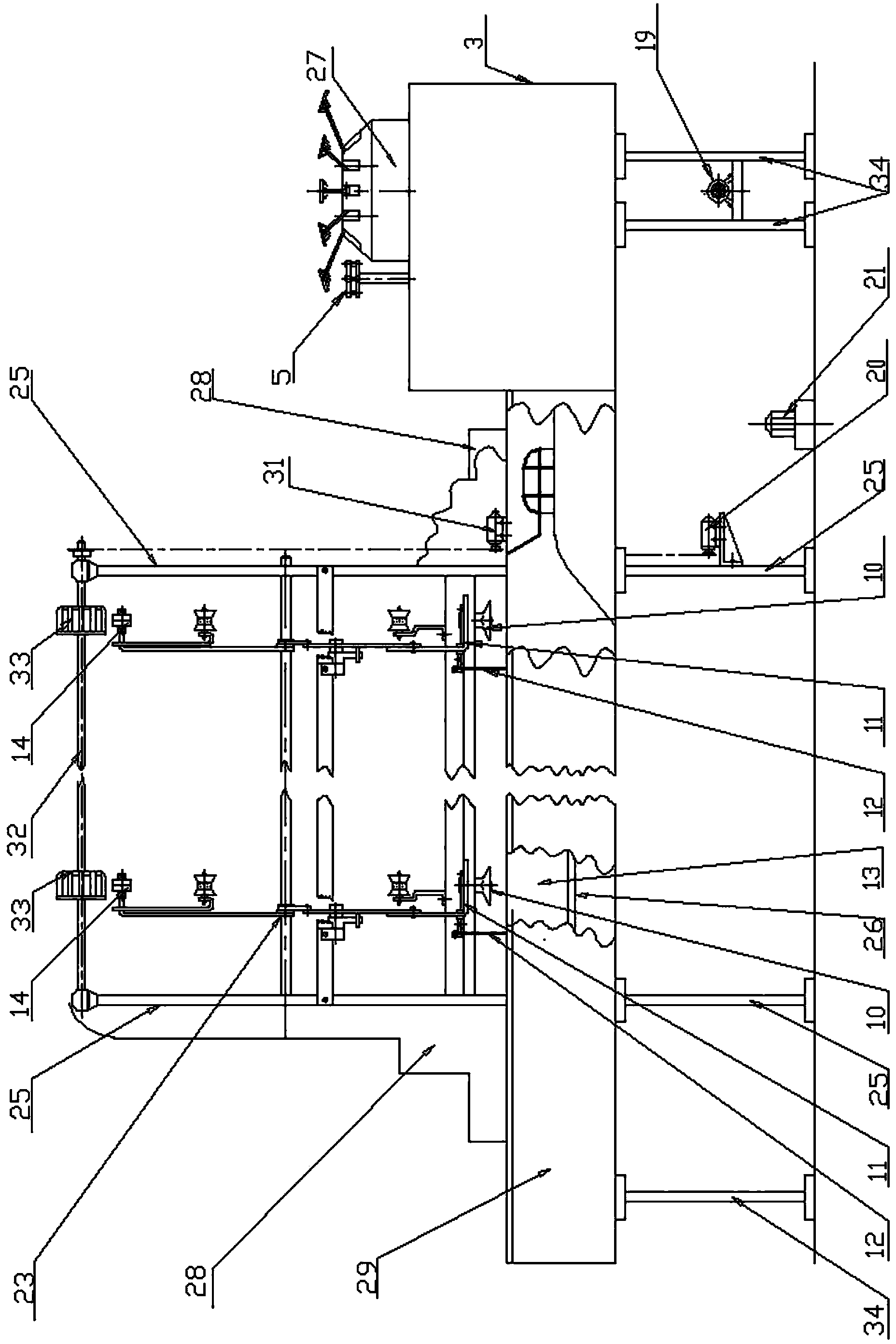

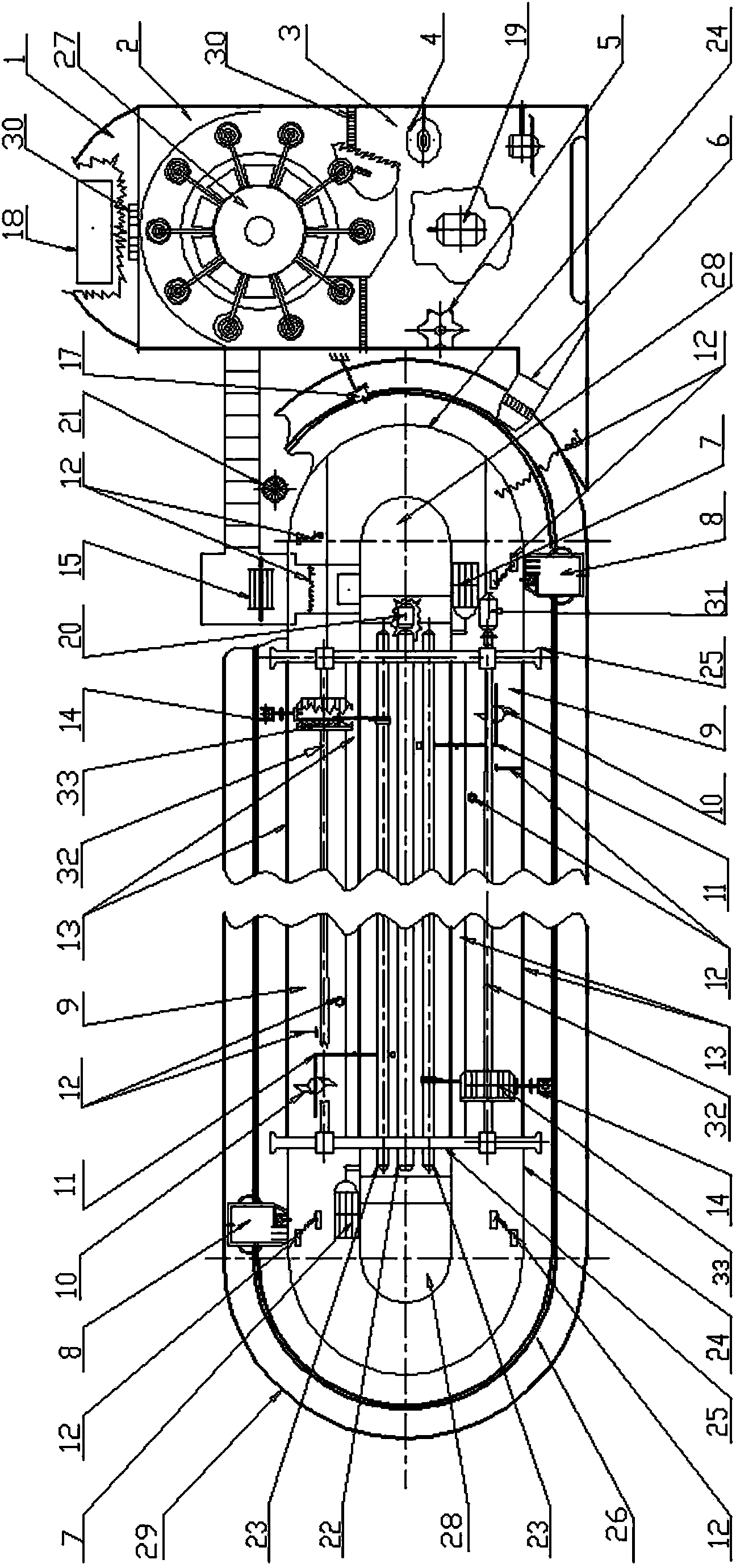

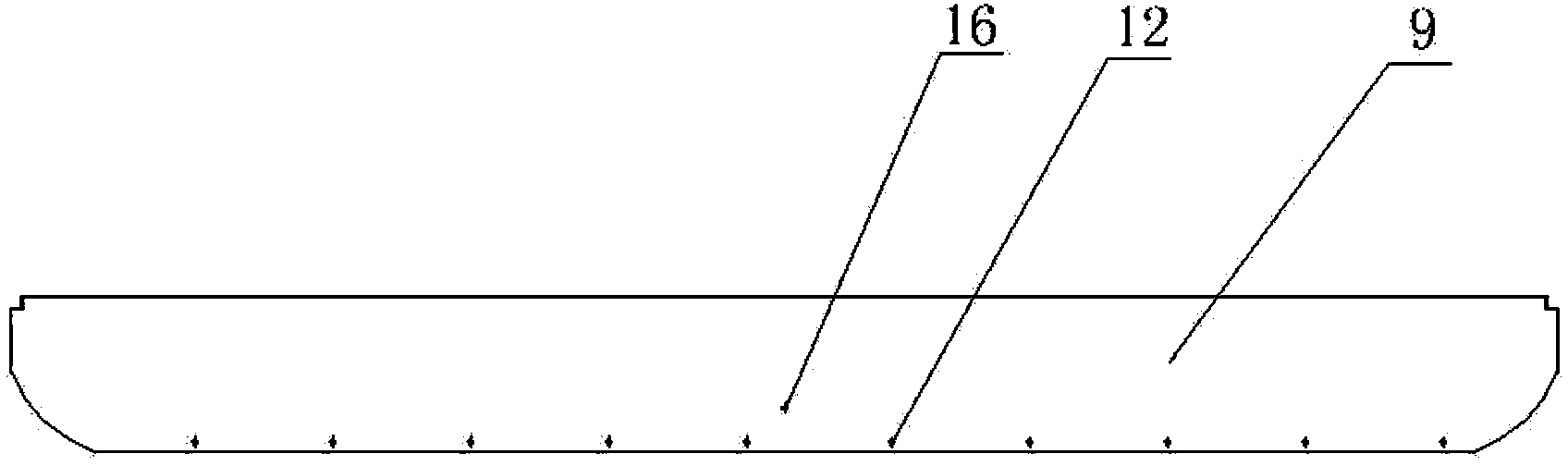

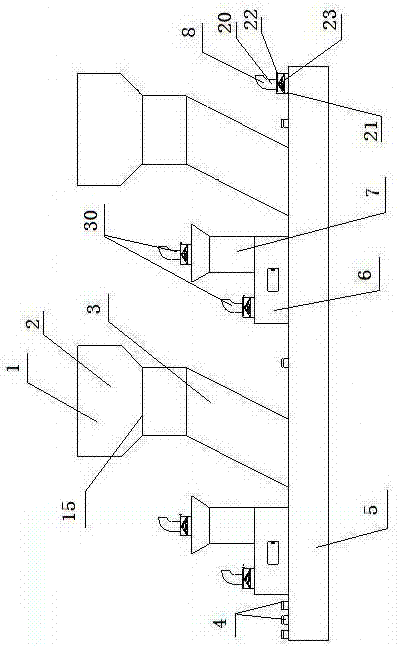

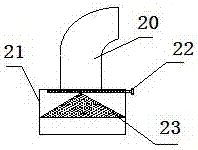

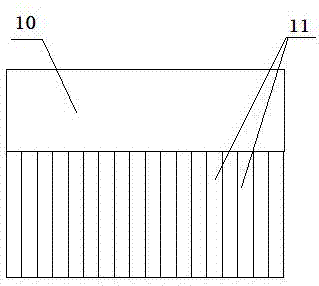

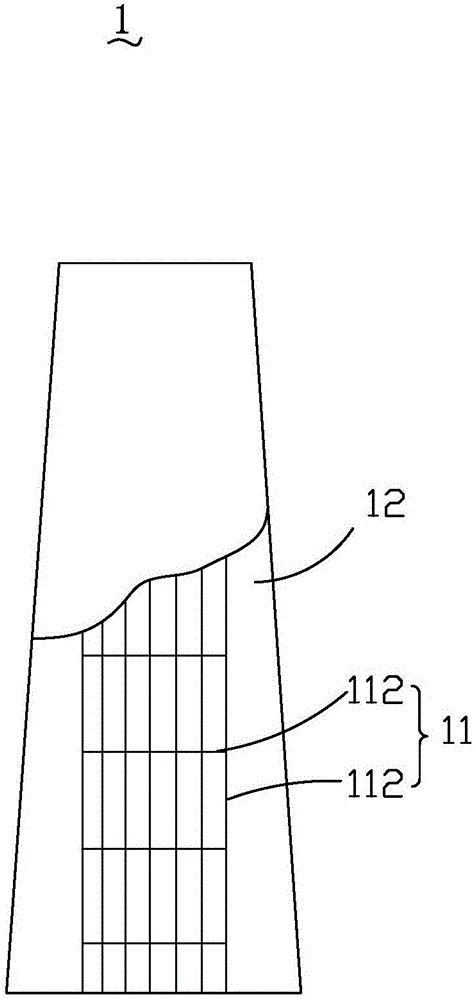

The invention relates to multi-specification automatic chopstick painting equipment and method. The method comprises the steps of: (1) inserting chopsticks in boards in rows in a vibrating way; (2) supplying the boards in an automatic stepping way and supplying empty boards by pressure; (3) overturning the boards and moving the chopstick boards in a positioning way; (4) vertically immersing in paint and guiding and correcting chopsticks; (5) supplying paint by circulating pressure; and (6) moving the chopstick boards upward and scraping paint off at a rubber opening. The invention has the advantages that one set of equipment can make work load of 26 workers and can replace manual painting operation efficiently, reduce labor intensity and greatly improve labor productive power; the consumption of paint raw material is saved; the length of the blank of the chopstick is shortened; the utilization rate of specification draw material is improved; the bottleneck effect of the output improvement of the chopstick enterprises can be broken down; production output can be improved; product quality can be stabilized; and labor cost and raw material cost can be reduced.

Owner:徐峰

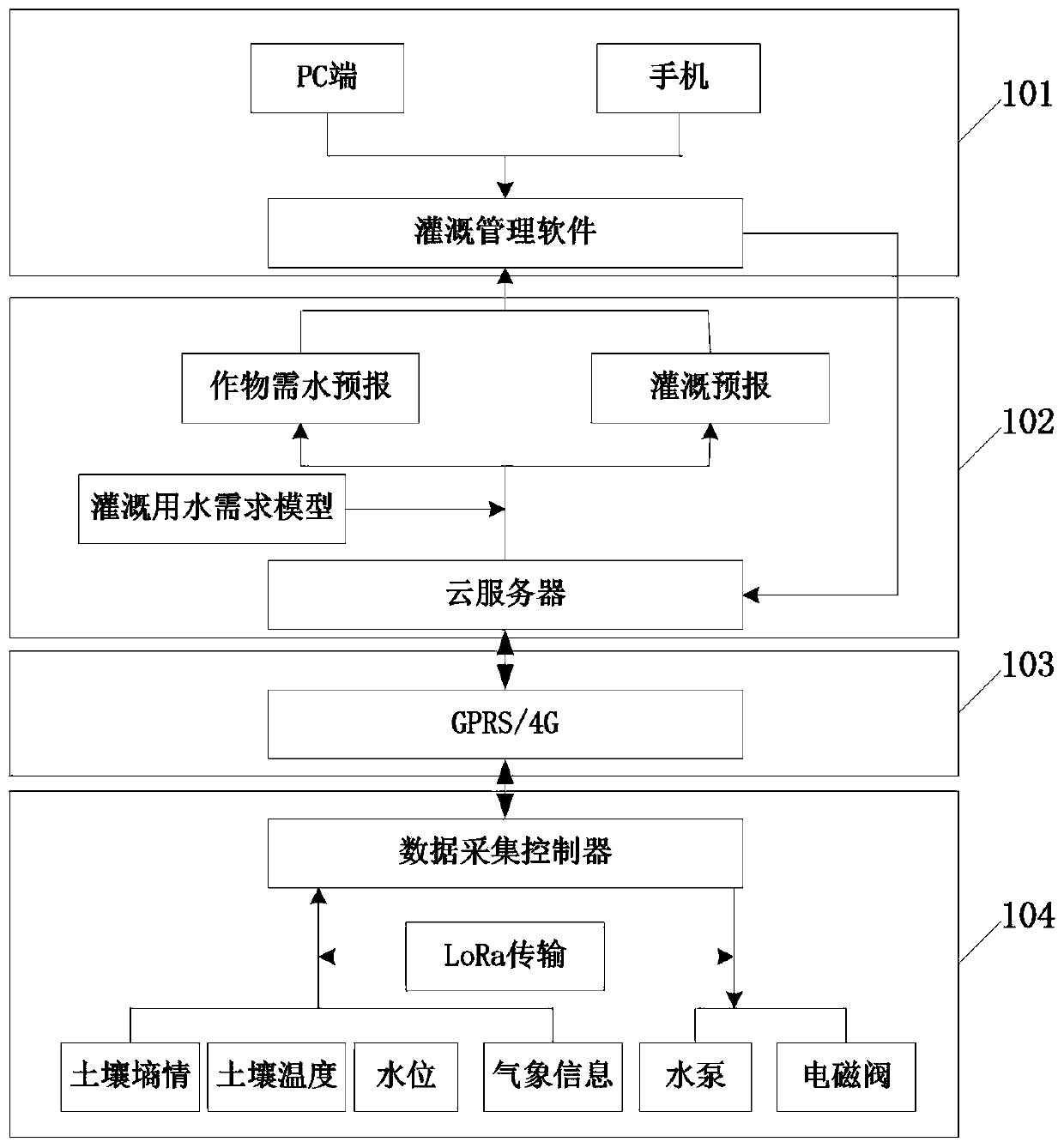

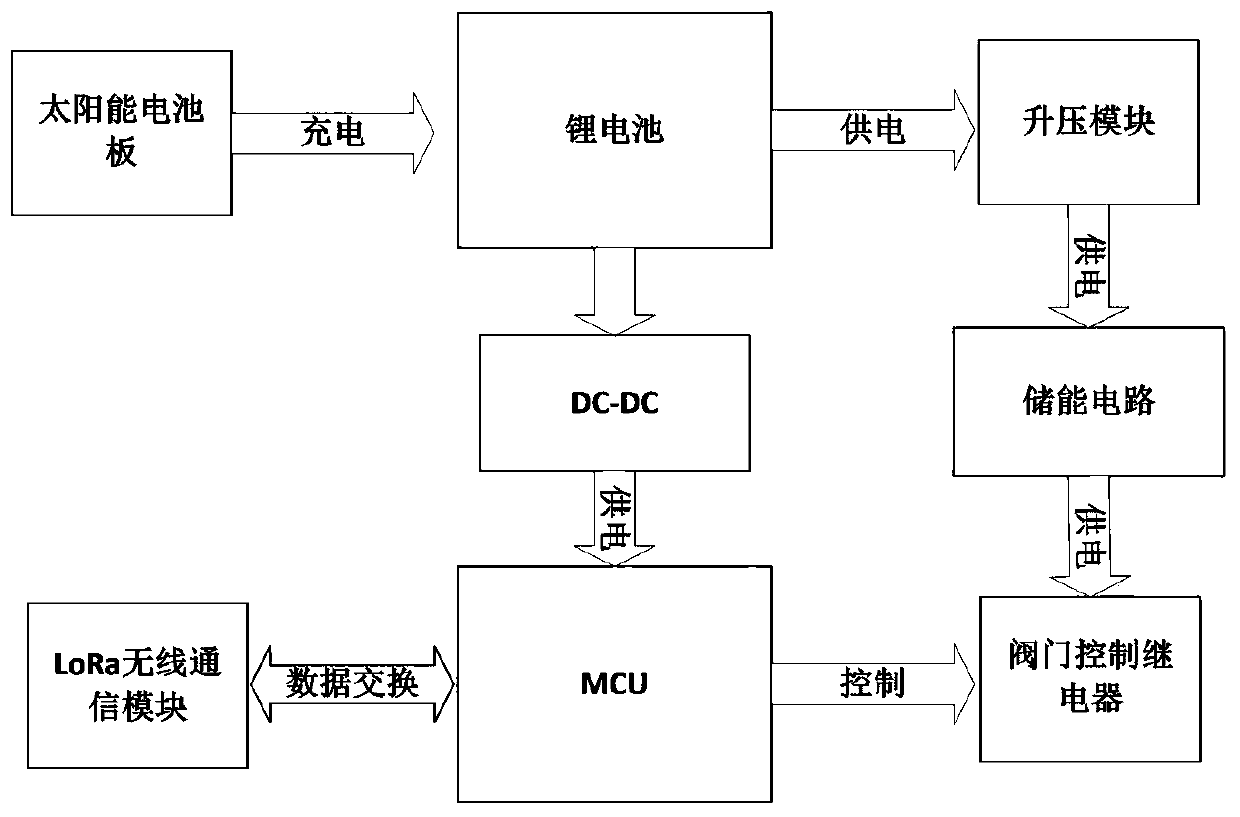

Intelligent irrigation management system

PendingCN110050673AEase of accessThere are many types of reliefWatering devicesCultivating equipmentsData acquisitionEngineering

The invention provides an intelligent irrigation management system, comprising an application management platform, a cloud data center, a wireless transmission platform and an intelligent sensing platform; the application management platform comprises an intelligent terminal and irrigation management software; the intelligent sensing platform comprises a data acquisition controller, a LoRa transmission module, a soil moisture sensor, a soil temperature sensor, a water level sensor, a meteorological environment sensor, a water pump and an electromagnetic valve; the cloud data center comprises acloud server; the cloud data center receives the information, collected by the intelligent sensing platform, by means of the wireless transmission platform, generates crop water demand forecast and irrigation forecast according to the collected information and a preset irrigation water demand model, and transmits the generated crop water demand forecast and irrigation forecast to the irrigation management software; the irrigation management software generates a corresponding irrigation strategy. The intelligent irrigation management system provided by the invention can avoid the problems in the prior art, and can set different irrigation strategies according to the different requirements of the crops for watering, thus realizing personalized watering.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

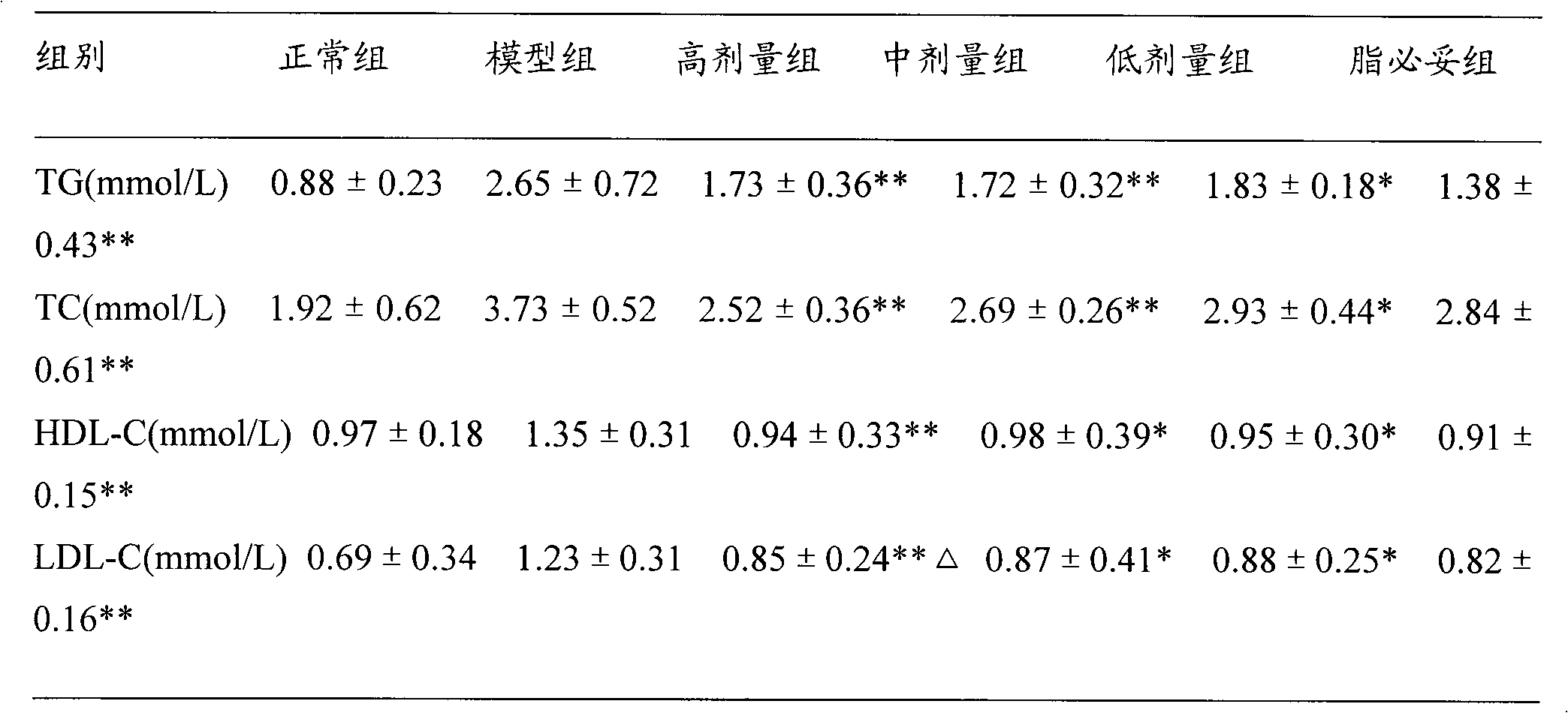

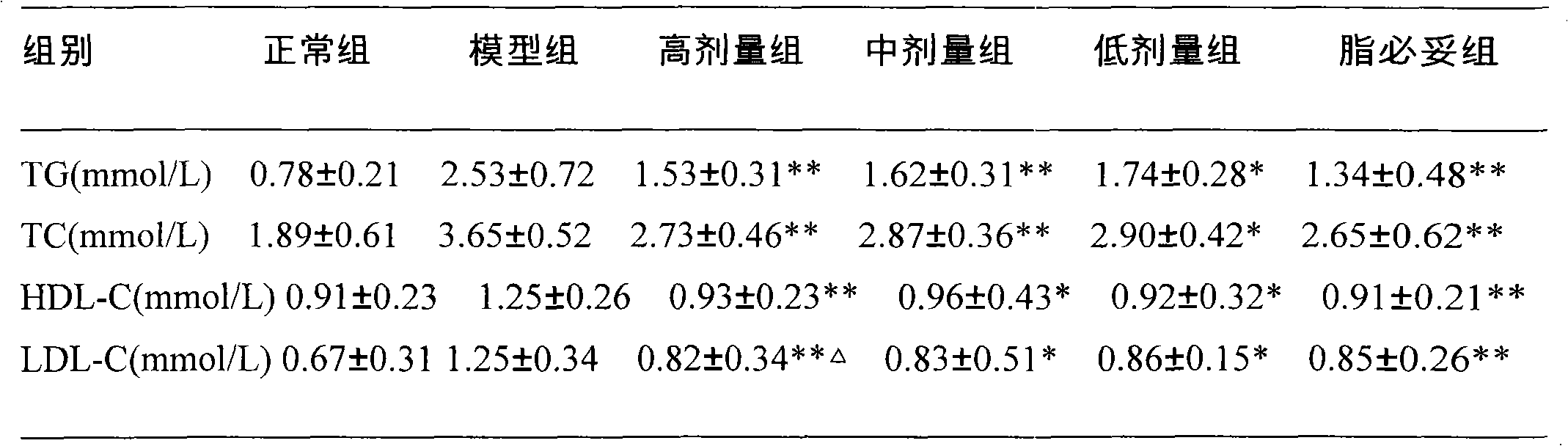

Chinese medicinal composition for treating fatty liver and preparation method and application thereof

InactiveCN102139084AAccurate analysisCompatibility is reasonableDigestive systemPlant ingredientsFatty liverBULK ACTIVE INGREDIENT

The invention provides a Chinese medicinal composition, which fulfills the aims of treating fatty liver diseases by helping digestion, removing food retention and reducing blood fat. In order to fulfill the aims, the technical scheme is that: the Chinese medicinal composition comprises the following active ingredients serving as raw materials in part by weight: 10 to 30 parts of root of red-rooted salvia, 10 to 30 parts of lotus leaf, 10 to 30 parts of hawthorn, 10 to 30 parts of oriental waterplantain rhizome, 10 to 30 parts of prepared tuber fleeceflower root, 10 to 30 parts of turmeric root-tuber and 10 to 30 parts of stringy stonecrop herb. The Chinese medicinal composition has the effects of helping digestion, removing food retention and reducing blood fat and an effect of treating fatty liver by a corresponding preparation method.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Multi-specification automatic chopstick painting equipment and method

InactiveCN101811109BShorten the lengthHarm reductionLiquid surface applicatorsCoatingsEngineeringUltimate tensile strength

The invention relates to multi-specification automatic chopstick painting equipment and method. The method comprises the steps of: (1) inserting chopsticks in boards in rows in a vibrating way; (2) supplying the boards in an automatic stepping way and supplying empty boards by pressure; (3) overturning the boards and moving the chopstick boards in a positioning way; (4) vertically immersing in paint and guiding and correcting chopsticks; (5) supplying paint by circulating pressure; and (6) moving the chopstick boards upward and scraping paint off at a rubber opening. The invention has the advantages that one set of equipment can make work load of 26 workers and can replace manual painting operation efficiently, reduce labor intensity and greatly improve labor productive power; the consumption of paint raw material is saved; the length of the blank of the chopstick is shortened; the utilization rate of specification draw material is improved; the bottleneck effect of the output improvement of the chopstick enterprises can be broken down; production output can be improved; product quality can be stabilized; and labor cost and raw material cost can be reduced.

Owner:徐峰

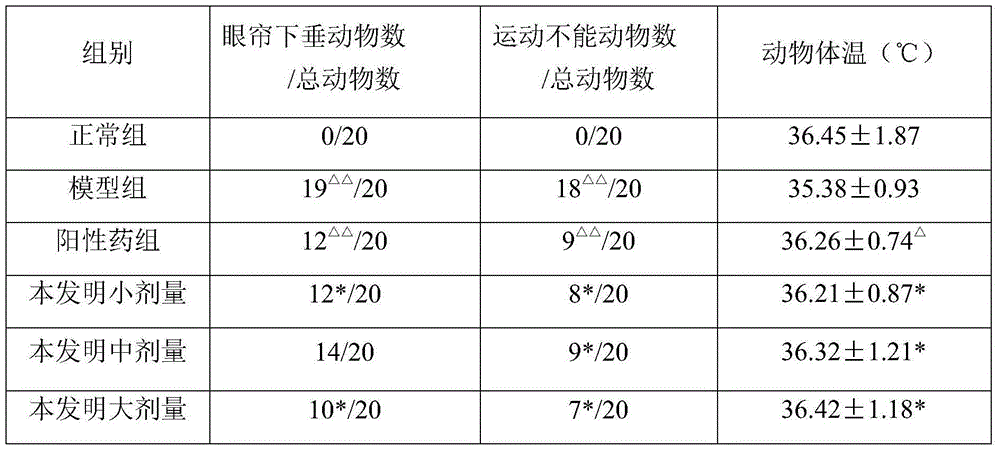

Traditional Chinese medicinal composition for treating depression as well as preparation method and application thereof

InactiveCN104367765AImprove the quality of lifeProtect healthNervous disorderFungi medical ingredientsStylophorum lasiocarpumRaw material

The invention provides a traditional Chinese medicinal composition for treating depression. The traditional Chinese medicinal composition is prepared from the following raw materials: Japanese mulberry root, root of tangut cacalia, stylophorum lasiocarpum fedde, rose myrtle flower and the like. The traditional Chinese medicinal composition disclosed by the invention can be used for treating depression.

Owner:李洋

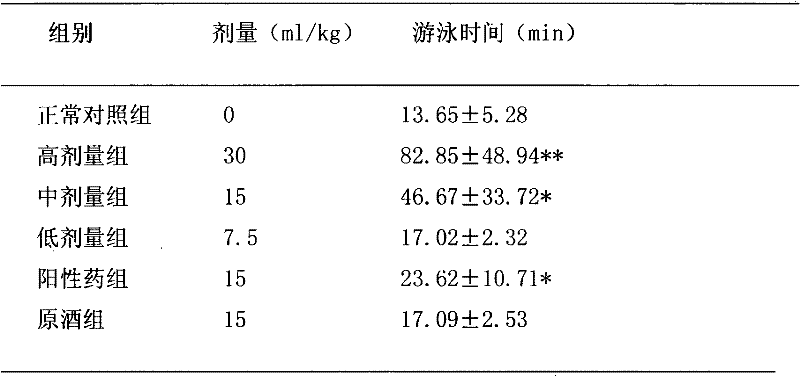

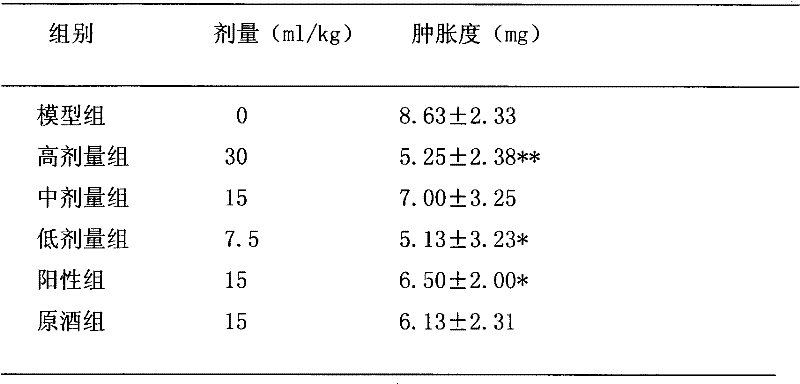

A kind of deer antler wine with anti-fatigue and immune regulation effect and preparation method thereof

InactiveCN102258734ASignificant effectImprove the quality of lifeAntinoxious agentsAlcoholic beverage preparationWhite liquorEpimedium

The invention provides cartialgenous wine having antifatigue and immunity-regulating effects and a preparation method thereof. For achieving the aim, the invention adopts a technical scheme that: the active ingredients of the cartialgenous wine are prepared from the following raw materials in part by weight: 10 to 30 parts of cartialgenous, 10 to 30 parts of ginseng, 10 to 30 parts of astragalus,10 to 30 parts of medlar, 10 to 30 parts of epimedium herb, 10 to 30 parts of Chinese magnoliavine fruit, 10 to 30 parts of alpinia oxyphylla, 10 to 30 parts of seed of Chinese dodder and 800 to 2,400 parts of 30-to-50-degree white liquor; and the corresponding preparation method is adopted. The cartialgenous wine has antifatigue and immunity-regulating effects.

Owner:淮安市淮安区古神梅花鹿养殖场

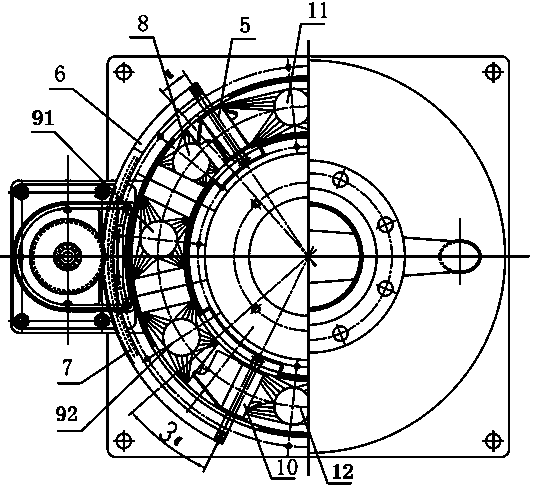

Adjustable constant-proportion division device

ActiveCN104198250AInnovative designEasy to addPreparing sample for investigationCircular discElectric machinery

The invention provides an adjustable constant-proportion division device. The adjustable constant-proportion division device comprises a swinging hopper, a driving device, a distributing circular disc and a plurality of blanking hoppers, wherein the blanking hoppers are distributed along the circumference, the swinging hopper is located above the distributing circular disc and is connected with the driving device, material holes corresponding to the blanking hoppers are formed in the distributing circular disc, and each blanking hopper is connected to the bottom of the distributing circular disc; the adjustable constant-proportion division device is further provided with a group of loose-leaf flow guiding plates, the loose-leaf flow guiding plates are arranged above the blanking hoppers, are connected with driving racks and respectively correspond to the blanking hoppers when the swinging hopper rotates. According to the adjustable constant-proportion division device, a stepping motor is controlled to drive the loose-leaf flow guiding plates so as to adjust the division proportion, and a manual adjusting manner of a conventional division device is avoided, so that the personal error is avoided, and the labor productivity is increased.

Owner:南京南环自动化技术有限公司

Interplanting cultivation method for marigold and konjak

InactiveCN106034598AReduce soft rot diseaseIncrease productionPlant cultivationCultivating equipmentsEconomic benefitsBud

The invention relates to the field of cultivation technology of konjak, in particular to an interplanting cultivation method for marigold and konjak.The method comprises following steps: selecting healthy seed konjak of 10-20 kg and sowing them on planting land with the moisture surface of 1.2-1.8 m in width, ridge height of22-28 cm and furrow width of 28-35 cm at the row distance of 22-28 cm, plant distance of 40-45 cm; placing bud eyes of seeds upward and covering them with shallow soil of 5-10 cm in thickness during sowing; and transplanting marigold seedlings to available rows between konjak after sowing of konjak for 1-2 months and marigold seedlings with 3-4 main leaves and at plant height of 15-20 cm appear and planting 2 rows of marigold at each moisture.The interplanting cultivation method for marigold and konjak is low in soft rot diseases and good in economic benefit.

Owner:富源县中安街道农业综合服务中心

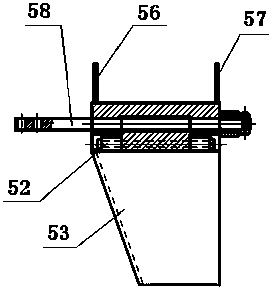

Hydraulic machine for producing grass mat and its grass mat production method

InactiveCN1736677ANeat appearanceQuality improvementWood working apparatusFlat articlesHydraulic pumpEngineering

The invention belongs to the art of preparation of supporting-pad for transporting goods, and especially relates to a hydraulic pad-making device for straw supporting-pad and the method for preparation the pad, the pad-making device comprising a electric hydraulic pump, a hydro-cylinder, a main frame, a die for supporting-pad, and a fixed rammer equipped with the top beam of the main frame, the hydro-cylinder being equipped with the cross beam in the bottom of the main frame and connecting with the hydro-cylinder, and the die for supporting-pad being made up of two side of the bottom board linked with the top end of the piston of the hydro-cylinder, the active gate hinged with the active bottom board, and the inside formwork. The gate of the die is equipped with a door opening unit, which contains a fixed gate-pole and a door opening spanner. The method for preparing pad is: closing the active gate to form the die, adding pad material uniformly into the die, pressing, tying, and opening the gate to take out the product supporting-pad. The structure of the device is simple, the technique reasonable and the operation convenient, and it can prepare two straw supporting-pads or combination supporting-pads one time.

Owner:章金华

Chinese medicinal pillow core for treating cervical spondylosis and preparation method thereof

InactiveCN101797293APreventionPrevention and developmentPillowsSkeletal disorderCervical spondylosisPeppermints

The invention provides a Chinese medicinal pillow core, which achieves the aim of treating cervical spondylosis by making the fragrant penetrate, stimulating the circulation of the blood and causing the muscles and joints to relax, activating blood and removing blood stasis, promoting the circulation of qi and relieving pain. For achieving the aim, the following technical scheme is adopted that the active components in the Chinese medicinal pillow core for treating cervical spondylosis are prepared from the following raw materials in part by weight in a certain proportion: 60 to 120 parts of kudzu-vine root, 60 to 120 parts of peppermint, 10 to 50 parts of mulberry twig, 10 to 50 parts of cassia twig, 40 to 80 parts of Chinese angelica, 40 to 80 parts of garden balsam stem, 40 to 80 parts of safflower, 40 to 80 parts of clematis root and 40 to 80 parts of gambir plant; and a corresponding preparation method is adopted.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Chinese medical pillow inner for curing insomnia and preparation method thereof

InactiveCN101797292AHeadache improves or disappearsFatigue improves or disappearsPillowsNervous disorderMedicineFlos chrysanthemi

The invention provides a Chinese medical pillow inner for curing insomnia and a preparation method thereof. The Chinese medical pillow inner reaches the purpose of curing insomnia by soothing the liver, eliminating stasis, calming the heart and tranquilizing the mind, and alleviating fatigue. In order to reach the purpose, the invention adopts the technical scheme that the active constituent of the Chinese medical pillow inner for curing insomnia is prepared from the materials of 60-120 parts of mulberry leaves, 60-120 parts of flos rosae rugosae, 10-50 parts of lotus leaf, 10-50 parts of flos chrysanthemi indici, 40-80 parts of flower of silktree albizzia, 40-80 parts of spina date seed and 40-80 parts of vine of multiflower knotweed by weight, and a corresponding preparation method is adopted.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

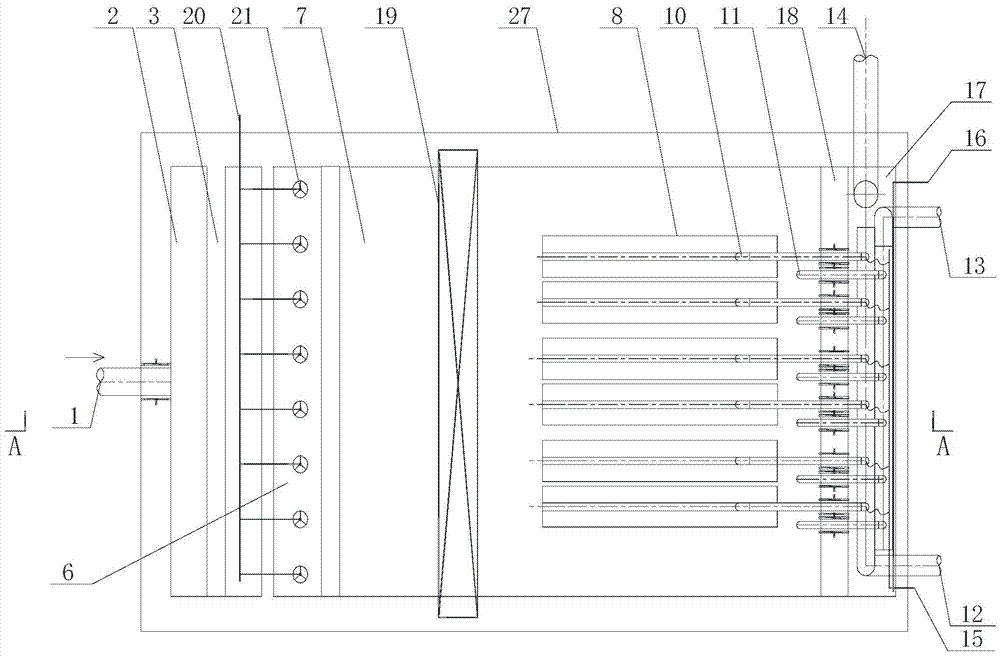

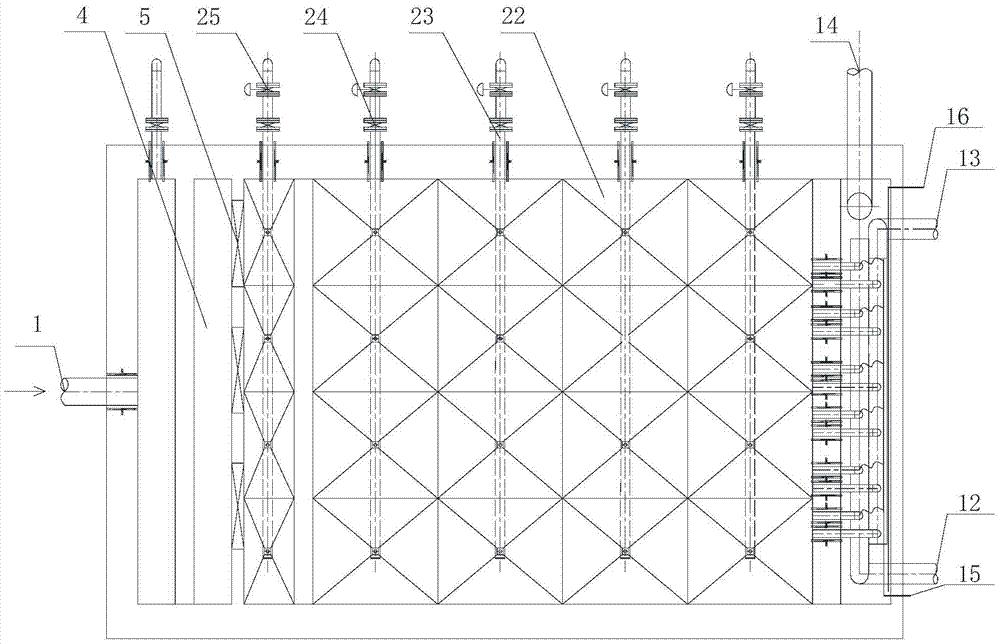

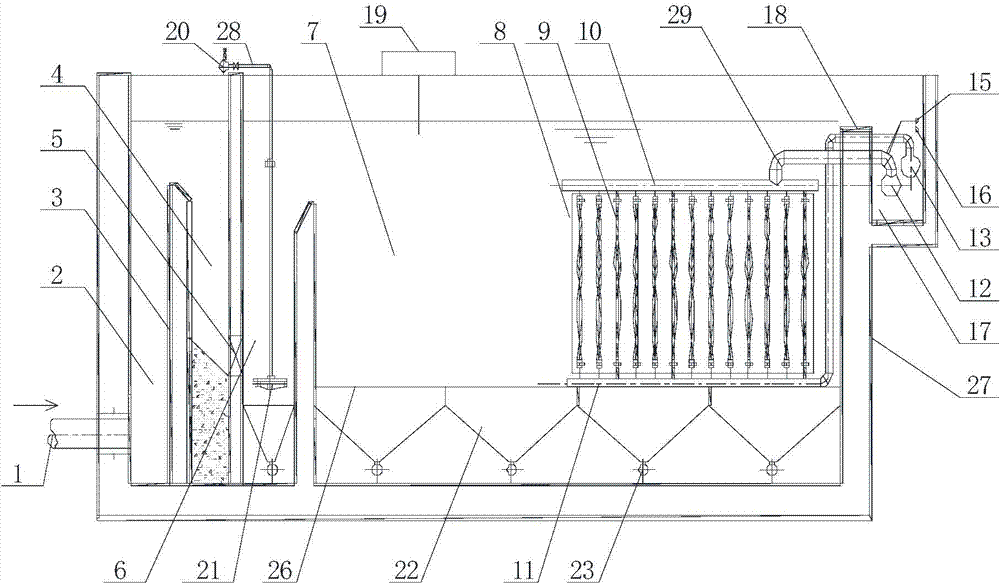

Air-flotation and membrane-filtration purification system

InactiveCN103663820AImprove effluent qualityImprove anti-pollution performanceWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentAutomatic controlMicro bubble

The invention relates to water conditioning constructional work in a water purification plant and particularly relates to an air-flotation and membrane-filtration purification system which is divided into a water buffering region, a water distribution region, an air-flotation contact region and an air-flotation separation and membrane-filtration water outlet region, wherein a micro-bubble generating device and a gas-solublized water conveying pipeline are connected and distributed in the air-flotation contact region; the air-flotation separation and membrane-filtration water outlet region is provided with a conical mud bucket, a supporting beam and an immersed membrane module from bottom to top; a slag scraping machine is capable of walking on a guide rail distributed on the side wall of a pool; a slagging groove is formed on a side wall opposite to the water inlet of the pool. The air-flotation and membrane-filtration purification system has the advantages of organically combining an air-flotation process with an ultrafiltration membrane filtration process, being capable of treating low-turbidity or high-algae water, and meanwhile being small in occupied space, simple in structure, low in civil engineering construction cost, high in load resistance capacity, low in auxiliary water ratio, low in operating cost and simple in automatic control.

Owner:大连宏博水科技有限公司

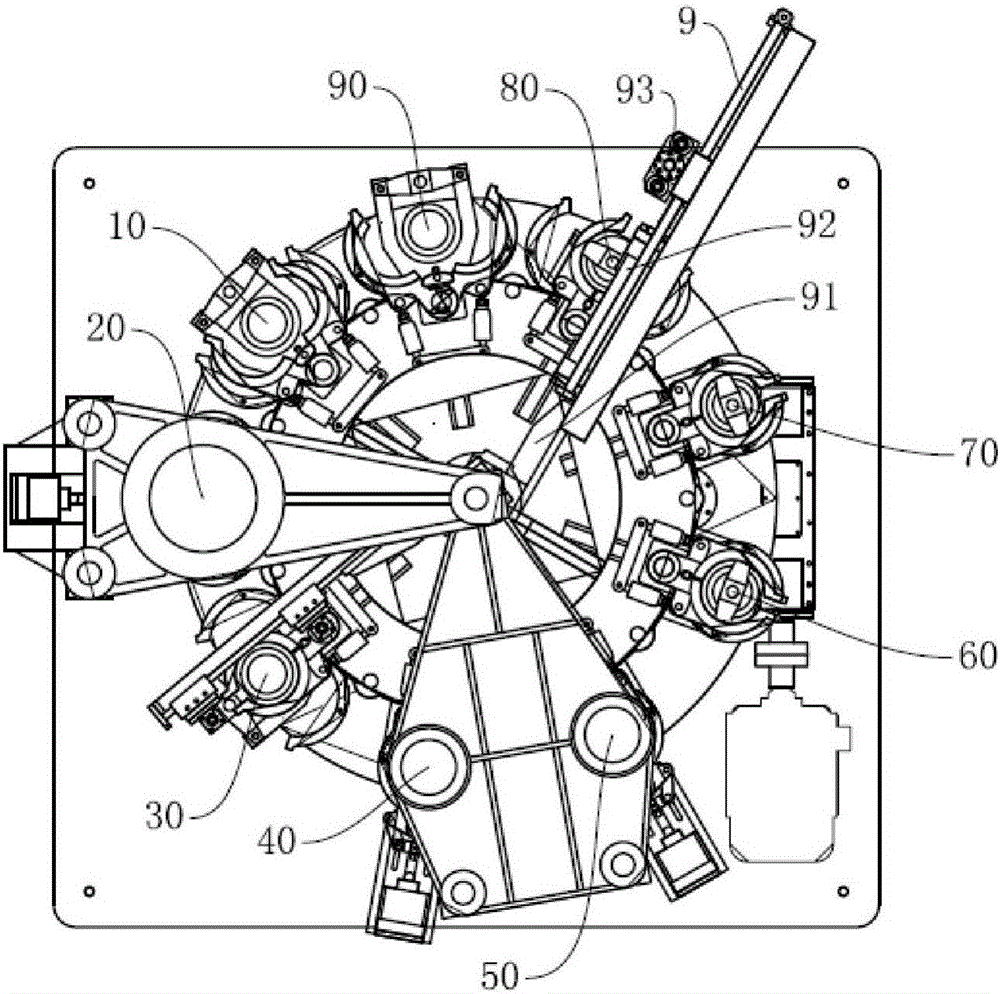

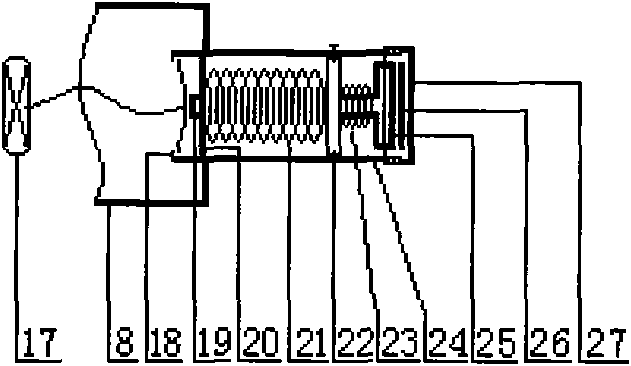

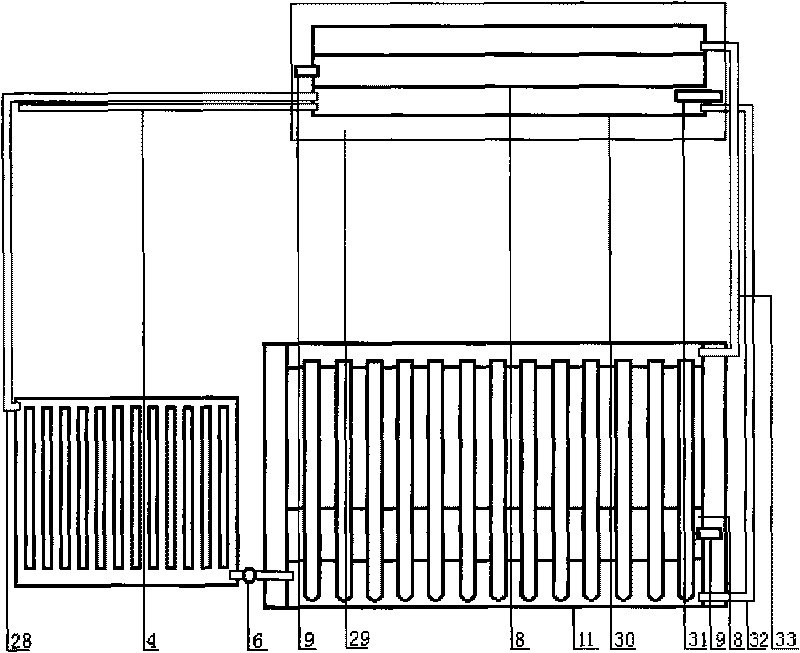

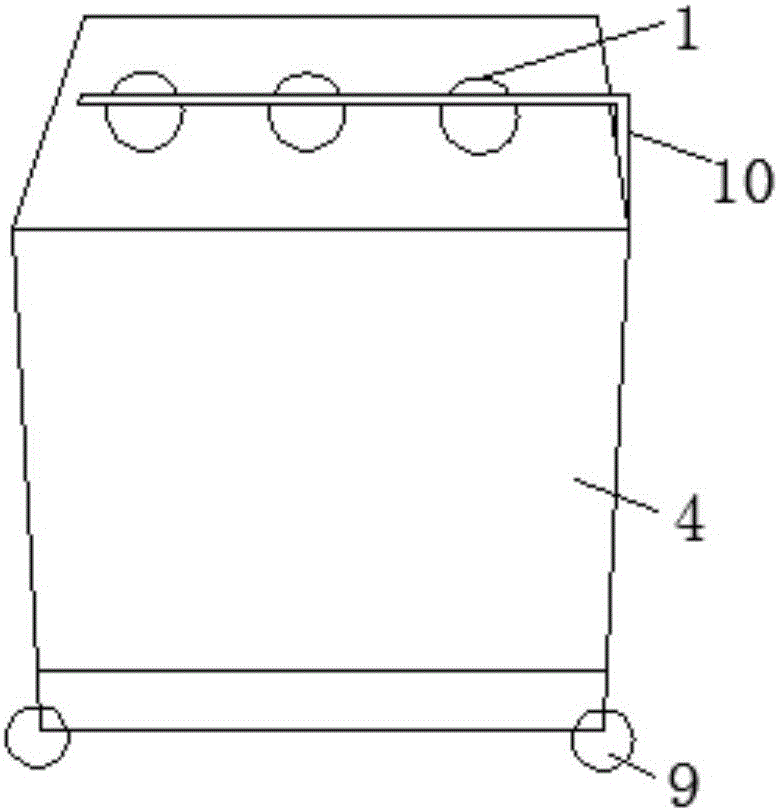

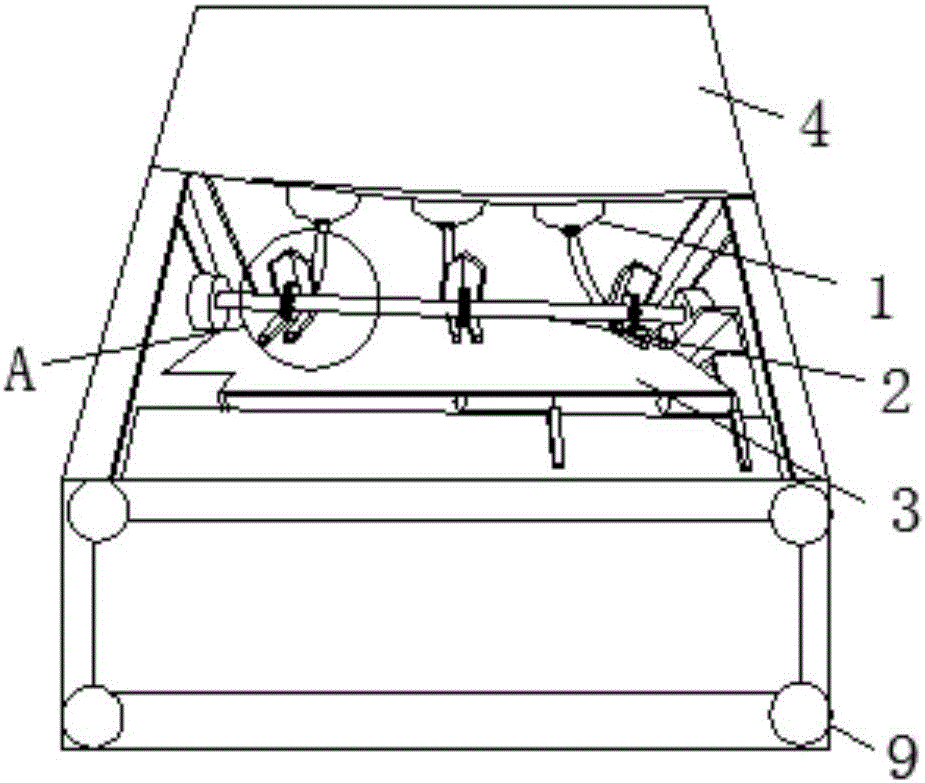

Energy-saving and environmentally-friendly automatic tussah silk reeling machine

ActiveCN103938279AHigh recovery rateEasy to separateSilk reelingTextile/flexible product manufactureAgricultural engineeringElectric machinery

Provided is an energy-saving and environmentally-friendly automatic tussah silk reeling machine. An automatic production line is composed of a cocoon preparing basin, an automatic end groping basin, an automatic end picking bath, an automatic cocoon feeding opening, a reeling basin, automatic cocoon discharging catchers, rotating wings, an automatic end feeding device, an automatic size-fixing device, an automatic basin-residue separating device, a cocoon detecting device, a variable frequency control cabinet, a variable frequency motor, an automatic cocoon feeder and the like. Because cocoon supporting boards and drag horizontal thread interrupters are arranged in the machine, the problem of separation of dropping end cocoons and the problem of drag horizontal threads are well solved, and automatic end groping, automatic end picking, automatic cocoon feeding, automatic sensing, automatic end feeding, automatic winding, automatic cocoon discharging and automatic basin-residue separating are achieved. Thus, labor productivity is improved, labor intensity of operators is reduced, the working environment of the operators is improved, hands of the operators do not need to be soaked in alkaline water for a long time, and the output per man shift is 2.5 times that of a multi-end reeling machine. Meanwhile, the quality of raw silk is higher than the level of 2A, and the recovery rate of reeled silk of tussah cocoons is increased by more than 3%.

Owner:辽宁柞蚕丝绸科学研究院有限责任公司

Bud injury preventing system for sugarcane cutting

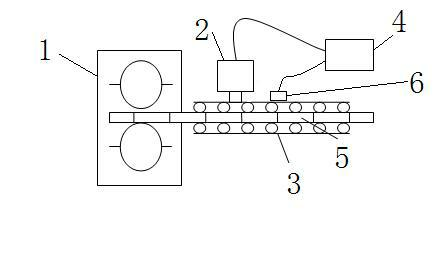

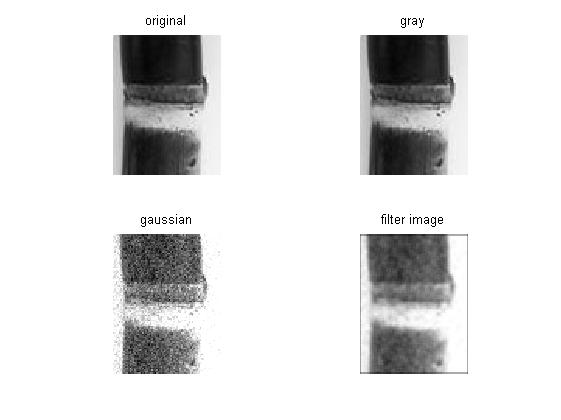

InactiveCN102630429AReduce manufacturing costReduce the rate of damaged budsHarvestersCharacter and pattern recognitionEngineeringBud

The invention discloses a bud injury preventing system for sugarcane cutting, comprising a cutter and a clamping conveying mechanism driven by a motor controller, wherein the distance between the clamping conveying mechanism and the cutter is fixed; a camera is arranged above the clamping conveying mechanism; the distance from the center position of the camera to the cutting position of sugarcane is just the length of the sugarcane after being cut off; an output end of the camera is connected with a computer equipped with a MATLAB (MATrix LABoratory) software; and an output end of the computer is connected with the motor controller of the clamping conveying mechanism. According to the invention, accurate shutter triggering time interval is matched according to the rotating speed of the cutter and the conveying speed of the sugarcane to ensure that image collecting positions are consistent with actual cutting positions; and filtering, noise reduction and binarization processing are carried out on the collected images to judge whether sugarcane joints are cut by the cutter or not. The bud injury preventing system disclosed by the invention has the advantages that the rapid and accurate judgment on the sugarcane positions cut by the cutter is realized; the bud injury rate of the sugarcane seed stem joints and the production cost of the sugarcane are reduced; the sugarcane seed is saved; and the labour productivity is improved.

Owner:GUANGXI UNIV

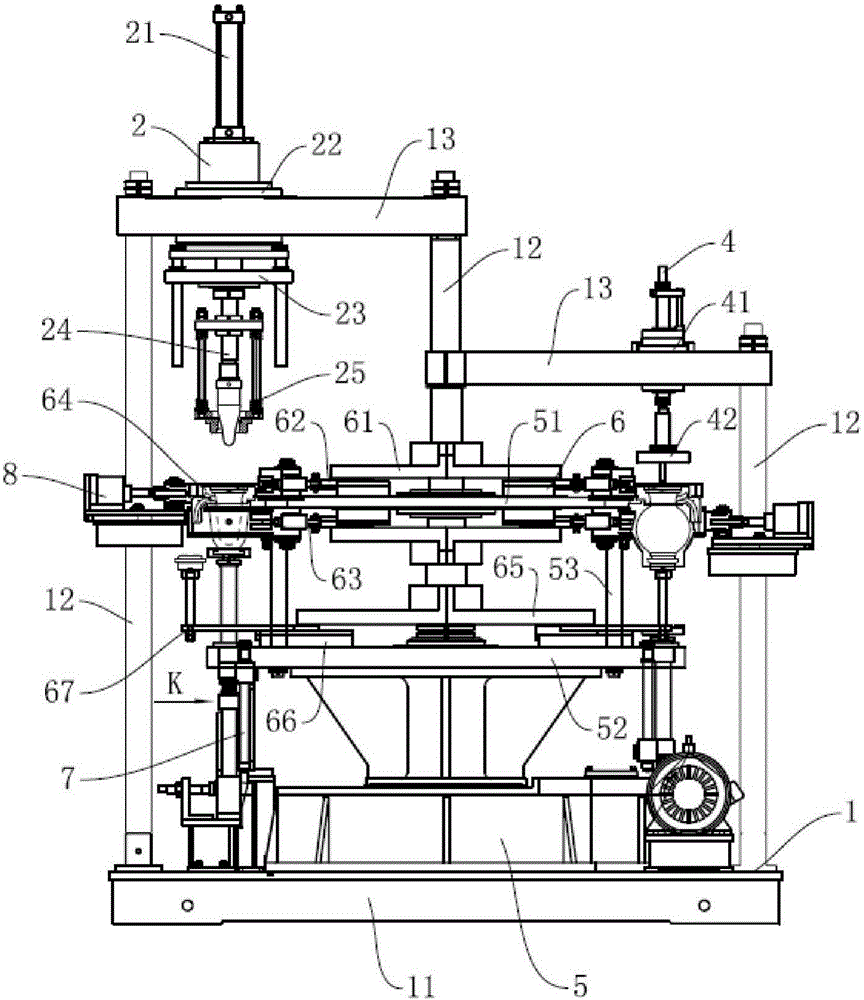

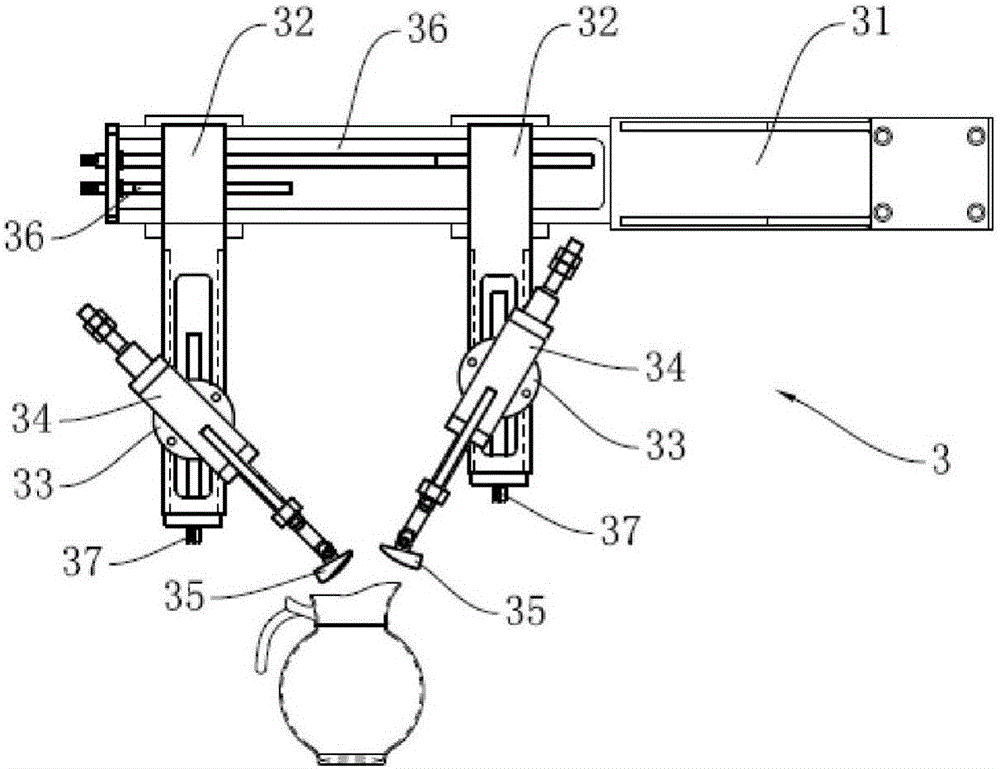

Glass kettle molding machine

InactiveCN105906188AChange the artificial production methodRealize automated productionGlass pressing apparatusWater-boiling vesselsBlow moldingMolding machine

The invention discloses a glass kettle molding machine. The glass kettle molding machine comprises a rack and a pressing molding device arranged on the rack, the rack is further provided with a nozzle molding device and a blowing molding device, the nozzle molding device comprises a transverse moving arm arranged on the rack, the transverse moving arm is provided with two vertical moving dragging plates which can move on the transverse moving arm in the horizontal direction, each vertical moving dragging plate is provided with an air cylinder rotary table seat, the air cylinder rotary table seats can move on the vertical moving dragging plates in the vertical direction, each air cylinder rotary table seat is provided with a spout molding air cylinder, the top end of a piston rod of each spout molding air cylinder is fixedly provided with a spout pushing mold, and the two spout pushing molds can push and press a molded kettle nozzle to form a spout. According to the glass kettle molding machine, pressing molding, nozzle molding and blowing molding are completed on one molding machine, the manual manufacture and production mode of simple equipment is changed, automated production is achieved, the labor productivity is increased, the labor intensity is lowered, and the production cost is reduced.

Owner:TAICANG HUANG FA JI MACHINERIES & MOLDS

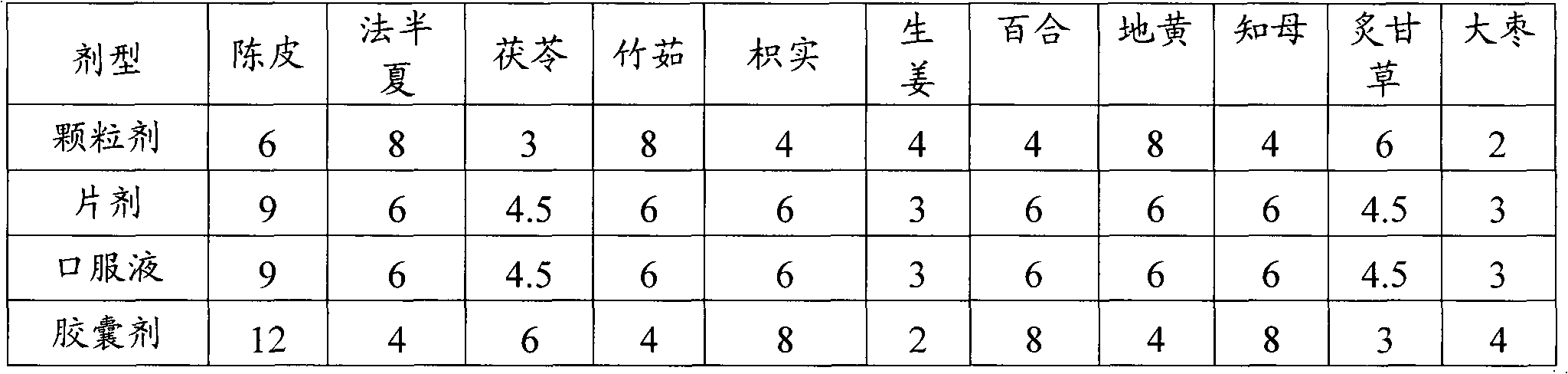

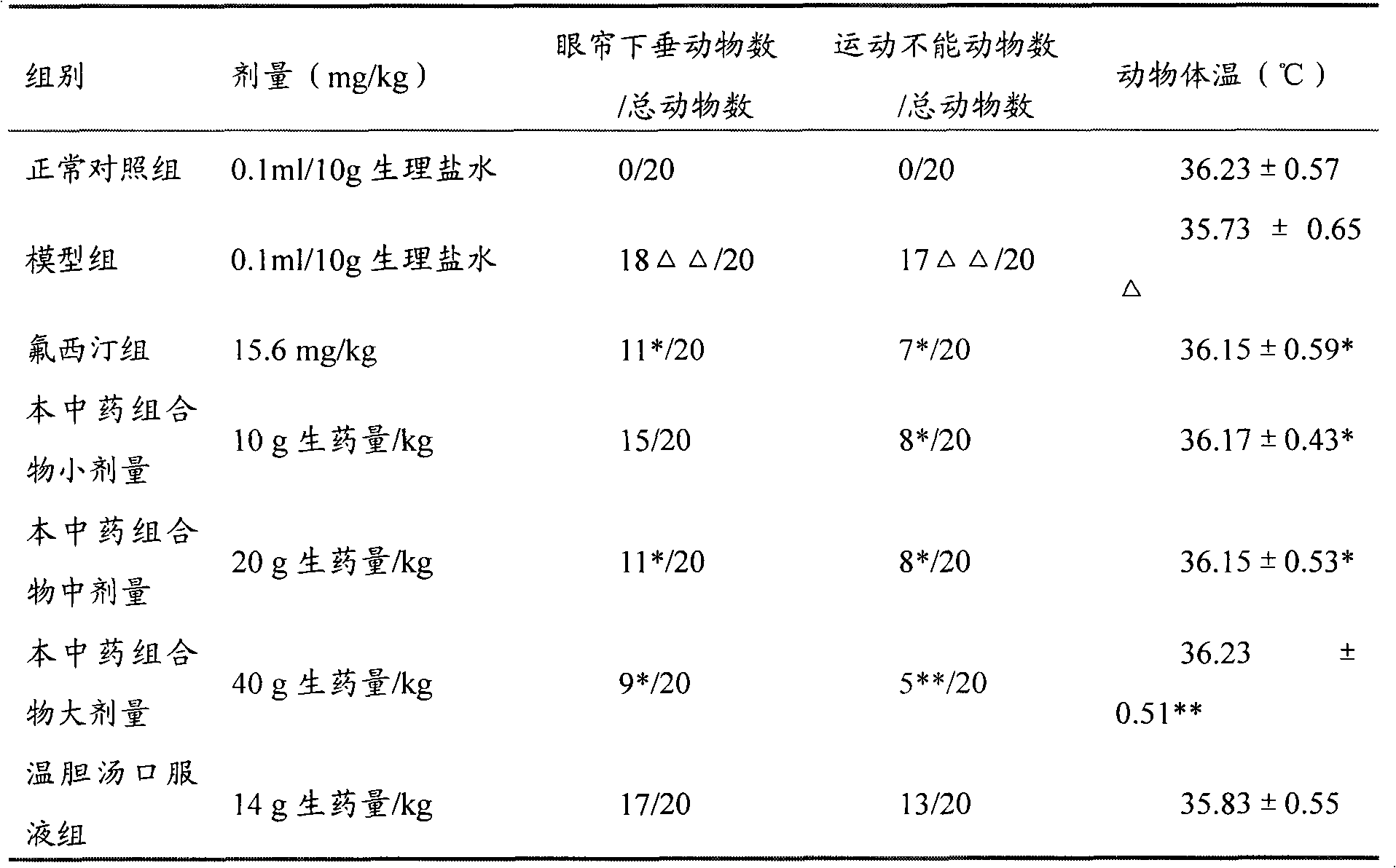

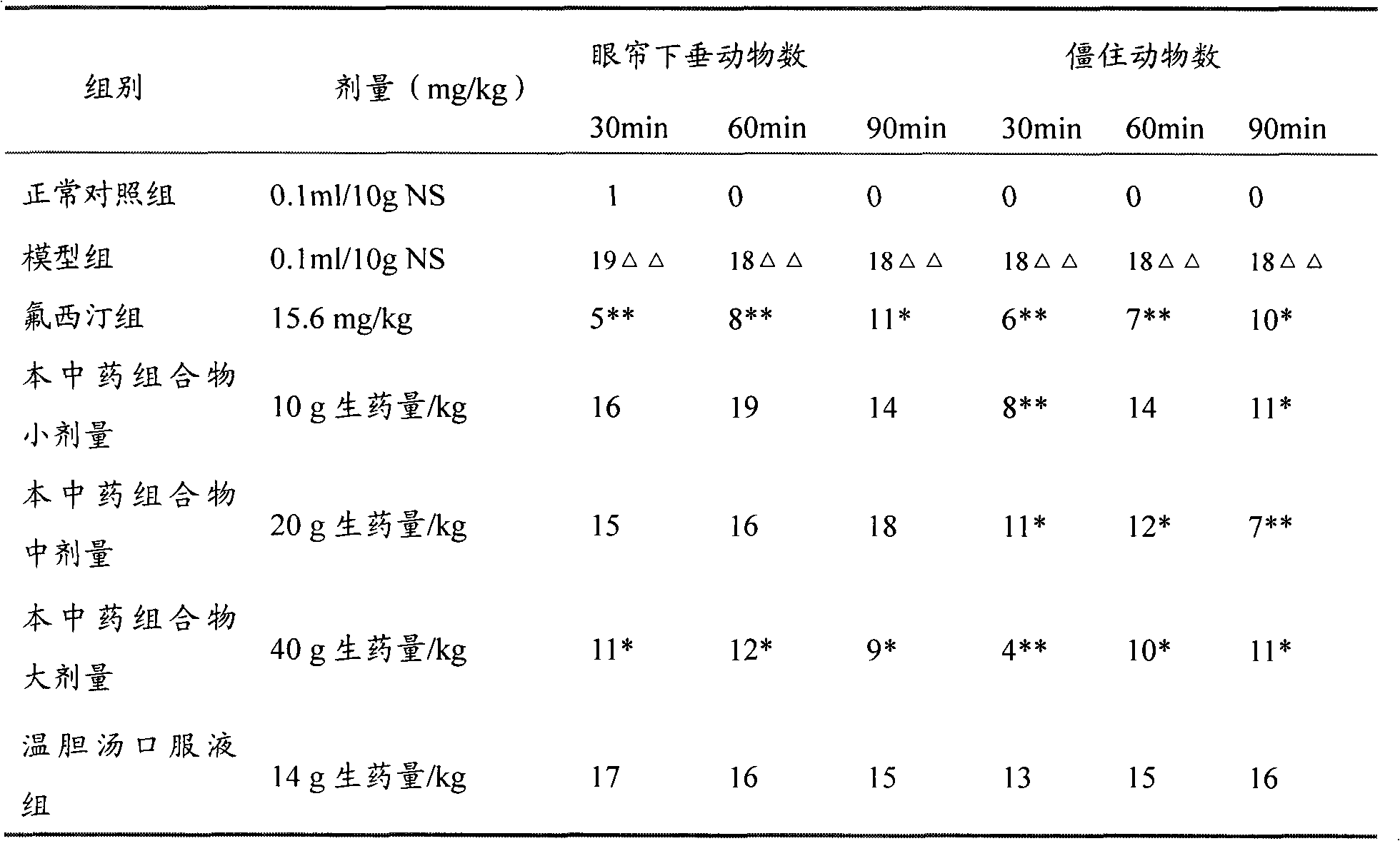

Chinese medicine composition for treating depression and preparation method and application thereof

InactiveCN102139090ARestore physical functionImprove general conditionNervous disorderPlant ingredientsActive componentRemove blood

The invention provides a Chinese medicine composition to achieve the purpose of treating depression through clearing heat, eliminating phlegm, promoting blood circulation, removing blood stasis, soothing liver, regulating qi, restoring consciousness, improving the blood circulation, quickly improving depressive symptoms, and effectively controlling depressive illnesses. In order to achieve the purpose, the following technical scheme is adopted: active components contained in the Chinese medicine composition are prepared by the following raw materials in parts by weight: 6-12 parts of orange peel, 4-8 parts of rhizoma pinellinae praeparata, 3-6 parts of poria cocos, 4-8 parts of bamboo shavings, 4-8 parts of fruit of immature citron, 2-4 parts of ginger, 4-8 parts of lily, 4-8 parts of rehmannia, 4-8 parts of rhizoma anemarrhenae, 3-6 parts of radix glycyrrhizae preparata and 2-4 parts of jujubes; and a corresponding preparation method is adopted. The Chinese medicine composition has the function of treating depression.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

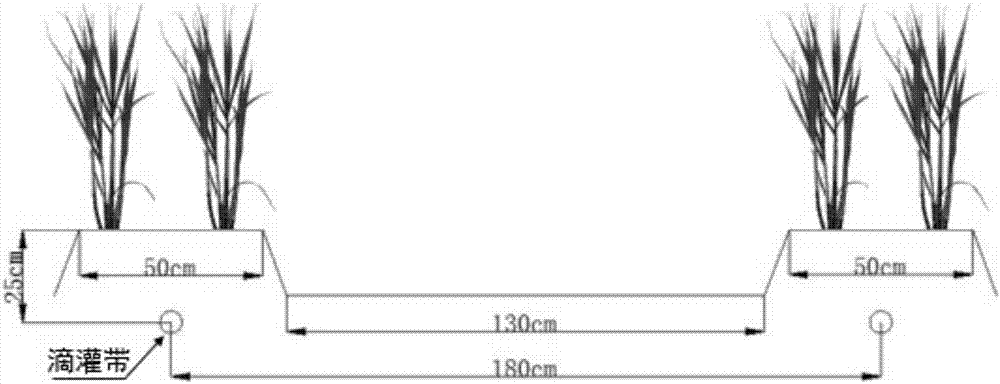

Efficient sugar cane cultivation method based on long-acting underground drip irrigation system

InactiveCN107996340AIncrease the length of useful lifeExtended rootSugarcane cultivationClimate change adaptationDrip irrigationSugar cane

The invention relates to an efficient sugar cane cultivation method based on a long-acting underground drip irrigation system. A sugar cane underground drip irrigation system arrangement form and a sugar cane wide-narrow row planting mode are provided, the service life of an the underground drip irrigation system is prolonged, labor intensity is remarkably relieved, and labor productivity is improved. A field management water-fertilizer-air-pesticide integrated technique used with the sugar cane underground drip irrigation system is further provided to make full use of the underground drip irrigation full-pipeline system for irrigation, fertilizer and pesticide application and aeration, and accordingly sugar cane yield is effectively increased, early growth and quick tillering of sugar canes are promoted, yield increase and quality improvement are realized, and increasing of yield and incomes of peasant households is promoted. By providing of a capillary pipe arrangement matched underground drip irrigation system filter type selection and combination mode, an irrigation device blockage control method and an underground insect and mouse gnaw damage prevention method, normal and stable operation of the underground drip irrigation system in a sugarcane ratoon crop period is guaranteed, irrigation uniformity of the underground drip irrigation system is improved, and the service life of the underground drip irrigation system is prolonged.

Owner:CHINA AGRI UNIV

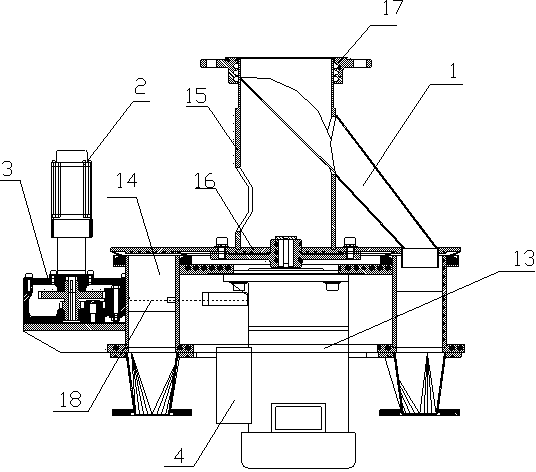

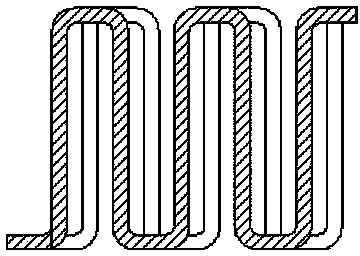

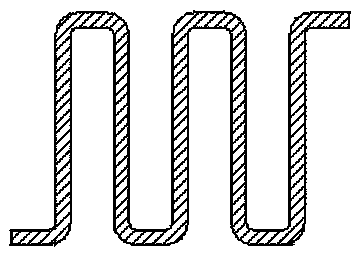

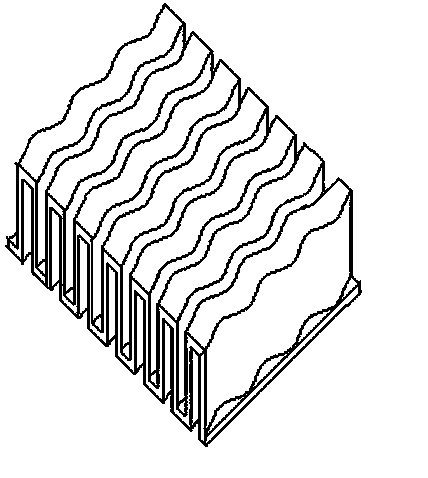

Automatic numerical control fin formation preparing method

ActiveCN103433403AIncrease labor productivity andHeat exchange apparatusNumerical controlProduction line

The invention relates to an automatic numerical control fin formation preparing method, which is characterized in that an automatic numerical control fin formation production line of integrating work procedures including aluminum foil uncoiling, hole punching, forming, fin finishing, fixed length cutting of a plurality of teeth and automatic framing into a flow process is adopted. Aiming at overcoming the defects of the prior art, the invention provides the automatic numerical control fin formation preparing method with the advantages that the manufacturing processes of multiple work procedures such as uncoiling, hole punching, punching forming, finishing, fixed length cutting and stacking and framing are combined into an automatic flow process production line by the numerical control technique via mechanical-electrical integration, the labor productivity can be greatly improved, and in addition, the foundation is laid for realizing the digital management in the machinery manufacturing industry.

Owner:HANGZHOU HANGYANG

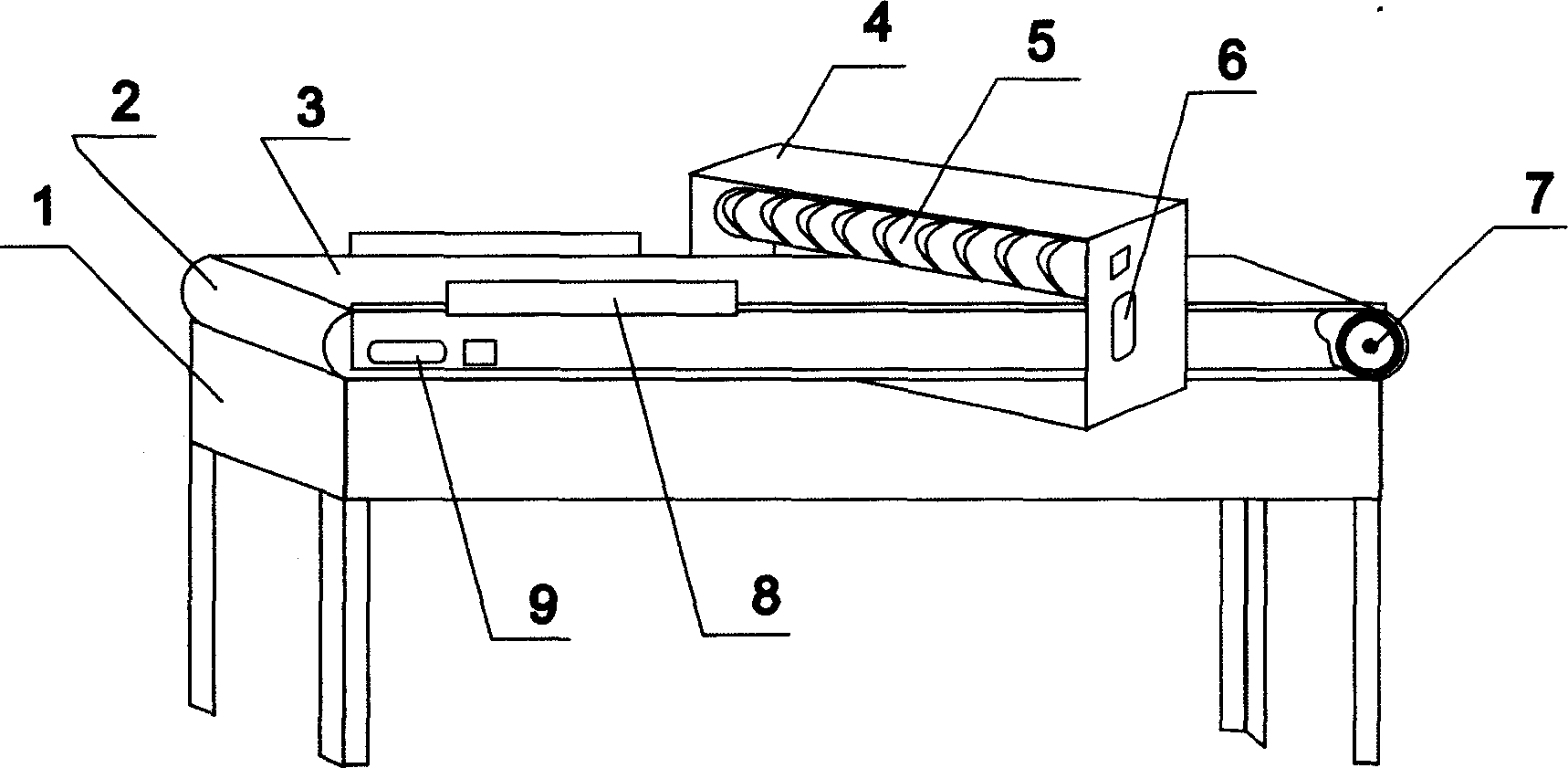

Bamboo shoot shelling machine

InactiveCN1739408AEasy to useReduce labor intensityVegetable peelingPlastic materialsAgricultural engineering

The bamboo shoot shelling machine consists of frame, conveying belt, front roller, back roller, main roller rack and main roller. The frame is one steel structure with upper steel plate, the front and back rollers are fixed on two ends of the frame, the back roller is driven with one motor, the conveying belt is one closed belt of rubber-plastic material and around the front and back rollers and the frame, the main roller rack is fixed on the frame, and the main roller fixed on the main roller rack is made of rubber-plastic material and driven with one motor. The present invention has high production efficiency.

Owner:安吉竹子科技有限公司 +1

Pueraria root wine for preventing and treating cardiovascular and cerebrovascular diseases, its preparation method and application

ActiveCN102266484ASignificant effectDilated blood vesselsAlcoholic beverage preparationBlood disorderBiotechnologyDisease

The invention aims to provide a pueraria wine capable of preventing and treating cardiovascular and cerebrovascular diseases as well as a preparation method and application thereof. In order to achieve the purpose, the invention provides the following technical schemes: the active ingredients of the pueraria wine are prepared from the following raw materials in parts by weight: 40-60 parts of pueraria, 10-30 parts of Astragalus root, 5-15 parts of hawthorn, 10-30 parts of dried tangerine peel, 10-30 parts of Polygonatum, 5-15 parts of cinnamon, 10-30 parts of Allium macrostemon and 5-15 partsof licorice; and a corresponding preparation method is utilized. The pueraria wine has the functions of nourishing myocardium, dilating blood vessels, promoting blood circulation and removing blood stasis, and preventing and treating cardiovascular and cerebrovascular diseases.

Owner:南通康威尔生物化工有限公司

Traditional Chinese medicine composition for treating hyperlipidemia and preparation method and application thereof

InactiveCN102068521AEnhanced digestive stagnation effectIncrease coronary flowMetabolism disorderPlant ingredientsDiseaseSecondary hyperlipidemia

Owner:南京苏美瑞医药科技有限公司

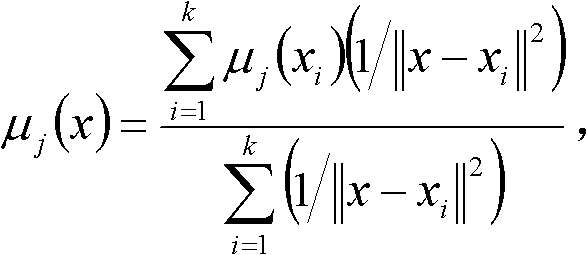

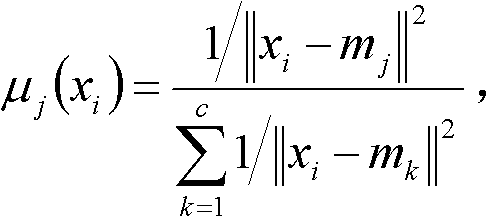

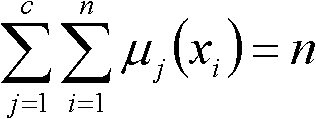

Cane stalk recognition method

InactiveCN102663434AReduce manufacturing costQuick judgmentCharacter and pattern recognitionImaging processingAlgorithm

The invention discloses a cane stalk recognition method which is based on computer vision. The method includes that after k adjacent given samples [xi, i=1,2,...,k] of a cane image sample x containing stalk joints and stalk sections to be sorted are obtained, membership degree value of the sample x on each category is calculated; then total sum of the membership degree of all samples on each category is calculated to be n, membership degree of a sample xi to be sorted on j category according to mu j(x) is calculated and compared, a category where the maximum membership degree belongs is selected so as to judge whether a sample is a stalk joint or a stalk section. The method provides reference for cane planting machinery which is not provided with a bud-damage resisting device yet at home and abroad, fills an application gap of image processing technology in cane seed stalk cutting at home and abroad, uses the computer image processing technology to achieve fast and accurate judgment of a cutter for cutting cane portions, reduces bud damaging rate of cane seeds and stalks and cane production cost, saves cane seeds, and improves labor productive power.

Owner:GUANGXI UNIV

Water mist dust falling and material guide device and dust falling method

PendingCN107265143AImprove working environmentProtect your healthCombination devicesLoading/unloadingEngineeringCoal

The invention discloses a water mist dust falling and material guide device and a dust falling method. A lot of coal dust is produced in a coal transportation process. The water mist dust falling and material guide device comprises a material guide trough (5), wherein multiple coal falling devices (1) are mounted on the material guide trough; a pressure reduction device (15) is mounted at the left end of each coal falling device; electrostatic sealing curtains (4) are mounted between every two adjacent coal falling devices and at two ends of all the multiple coal falling devices; a water mist dust remover (8) is mounted at the right end of the material guide trough; each pressure reduction device consists of a first-stage pressure reduction box (6), a second-stage pressure reduction box (7) and two pressure reduction box water mist dust removers (30); the second-stage pressure reduction boxes are mounted on the first-stage pressure reduction boxes; and the two pressure reduction box water mist dust removers are respectively mounted on each first-stage pressure reduction box and each second-stage pressure reduction box. The invention is applied to the water mist dust falling and material guide device and the dust falling method.

Owner:大唐黑龙江发电有限公司哈尔滨第一热电厂

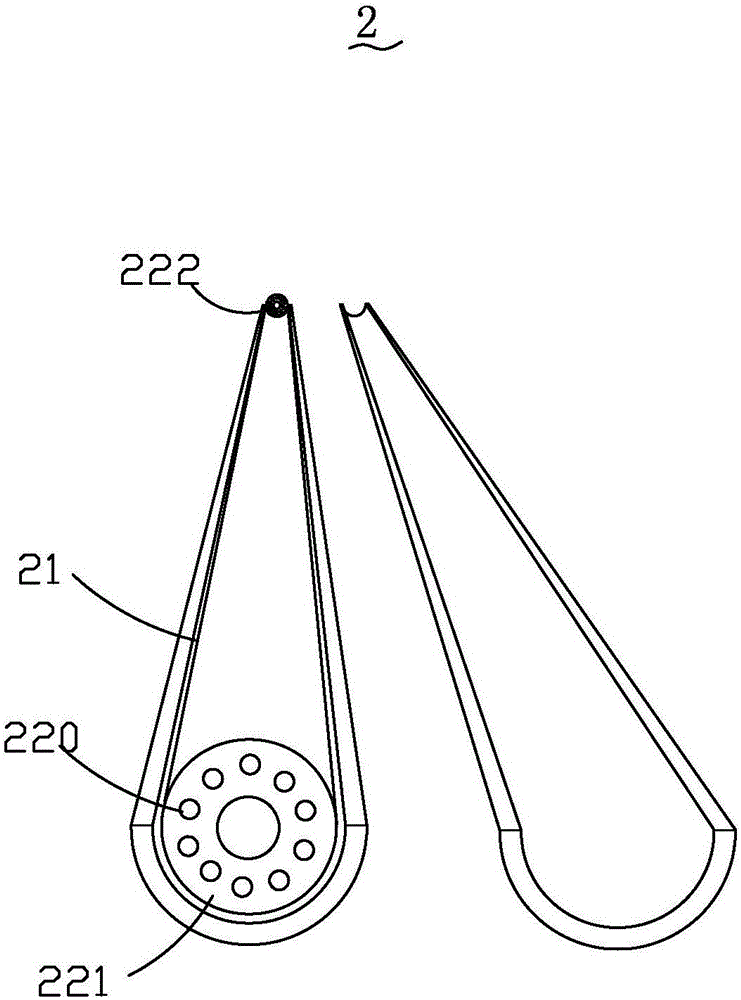

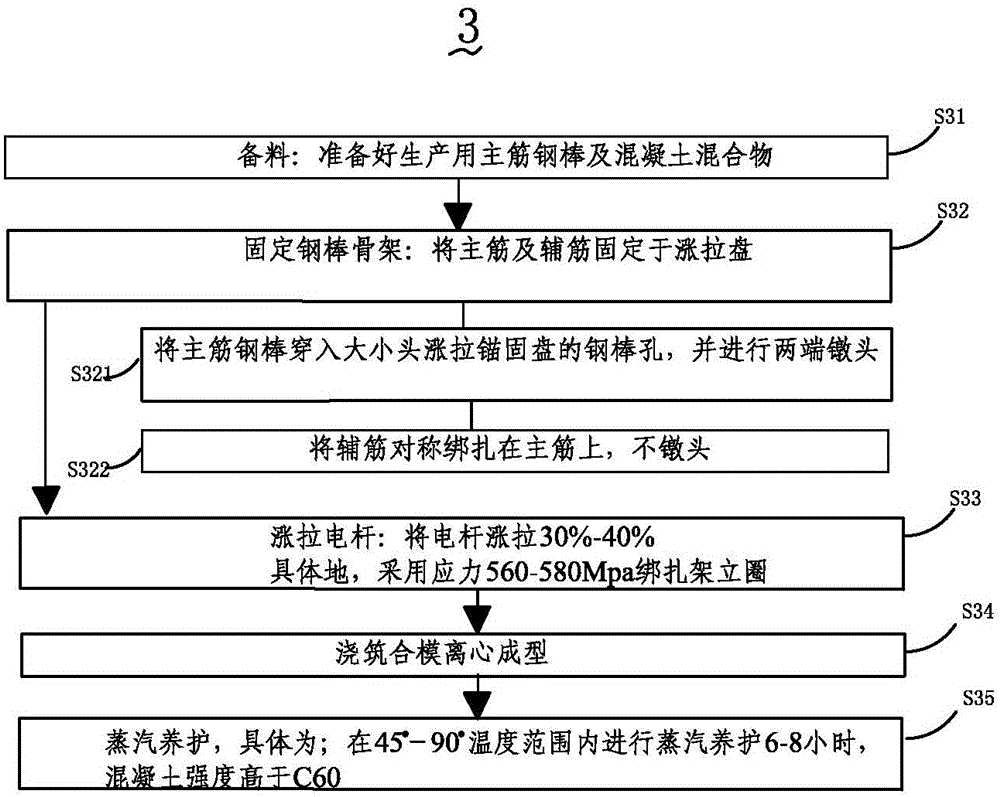

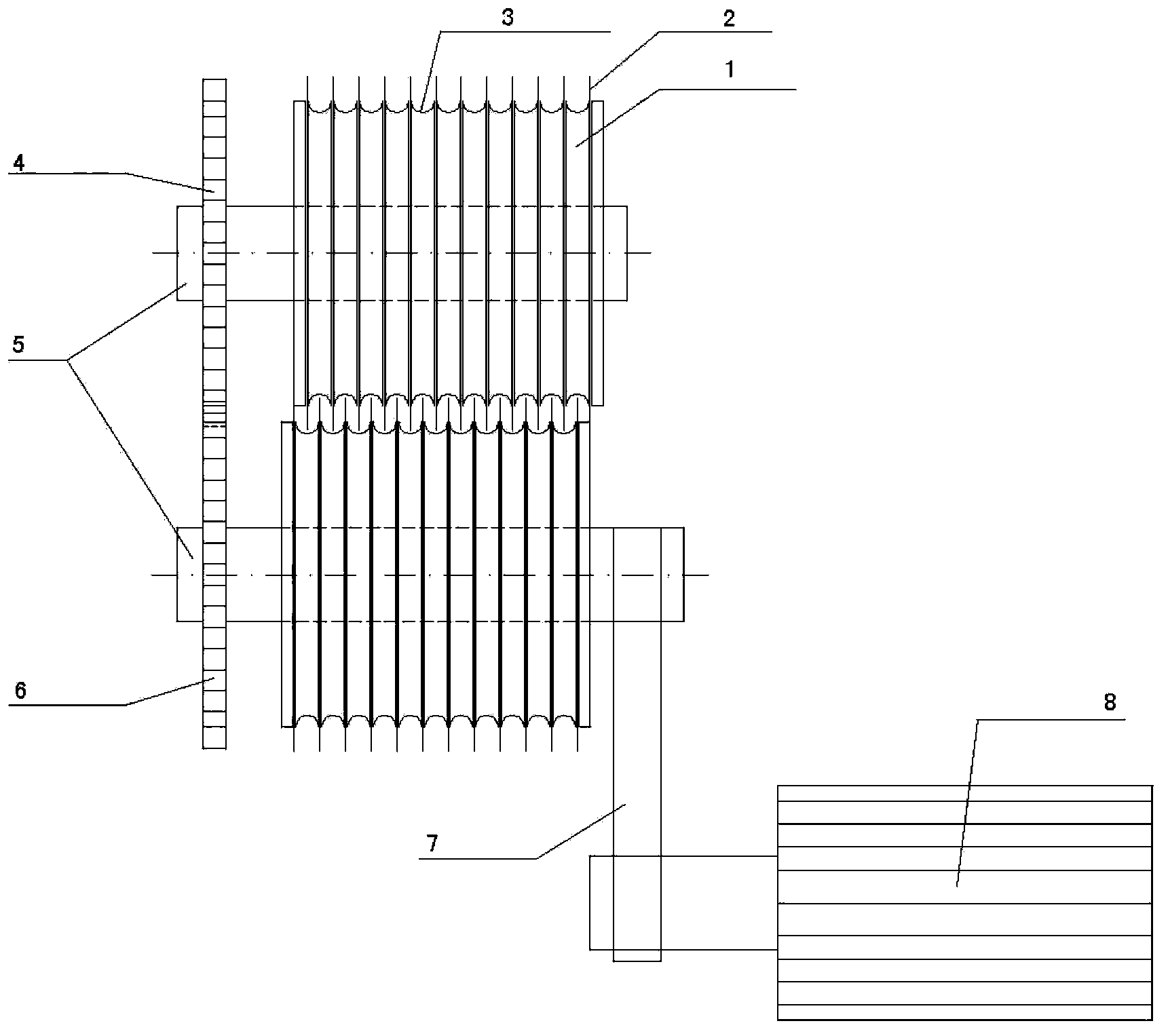

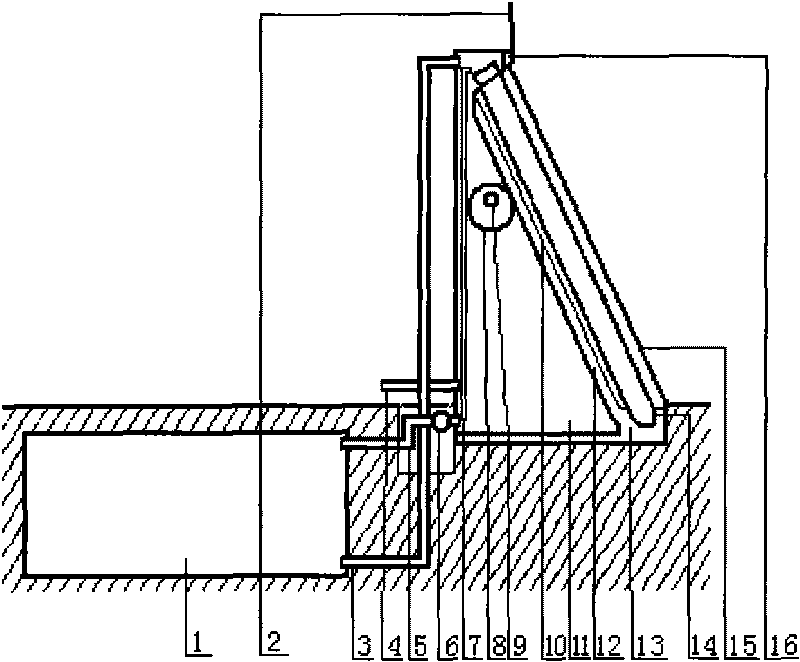

Small-bending-moment steel bar concrete pole as well as production device and manufacturing process thereof

InactiveCN105715093ASolve the ring crack problemExtensiveMouldsShaping reinforcementsPre stressRebar

The invention provides a small-bending-moment steel bar concrete pole as well as a production device and a manufacturing process thereof. The small-bending-moment steel bar concrete pole comprises a steel bar framework and a concrete layer; the concrete layer wraps the steel bar framework; the steel bar framework comprises multiple main ribs and multiple auxiliary ribs; the main ribs and the auxiliary ribs are steel bars for prestressed concrete; the multiple main ribs are axially and annularly arranged in the small-bending-moment steel bar concrete pole; the auxiliary ribs are symmetrically bound to the main ribs. The small-bending-moment steel bar concrete pole provided by the invention is widely applied to all 10kV integral electric pole types on state grid lines; the steel bars for prestressed concrete are adopted for replacing steel bar HRB concrete to upgrade electric poles, so that the ring shake problem of the electric poles is fundamentally solved, the labor productivity is improved, and the yield is free from limitation of a reinforcing mesh, and the product production quantity is improved to the greatest extent.

Owner:WENGNIUTEQI SHUANGYUAN ELECTRIC CEMENT PROD CO LTD

Earthworm mechanization preliminary processing method and special device thereof

ActiveCN104069132AHigh speedIncrease labor productivity andUnknown materialsMetal working apparatusMaterial qualityEngineering

The invention discloses an earthworm mechanization preliminary processing device. The device comprises two rollers which have the same length and are arranged in parallel, wherein the two rollers are provided with multiple U-shaped grooves; each roller is provided with a disk stainless steel knife in relation to another U-shaped groove; the two rollers are mounted on a fixed bearing through a central shaft; the central shaft is connected with a motor through a belt so that the two rollers rotate in opposite directions; flat-shaped funnels are arranged above the two rollers; prolate funnels are arranged below the two rollers. The invention also discloses an earthworm mechanization preliminary method using the special device. The total ash of an earthworm medicinal material prepared by processing is less than 10%, which conforms to the requirement of total ash of earthworm specified by National Pharmacopoeia of People's Republic of China. According to the device disclosed by the invention, the sectioning rate and the sectioning speed of earthworms are increased, the labor productivity is improved, the medicinal material quality of earthworms is improved and the device has a relatively great application value.

Owner:上海康桥中药饮片有限公司

Greenhouse solar energy storage water heater wall panel and building solar energy storage water heater wall panel

InactiveCN101736865AIncrease heightIncrease volumeRoof covering using slabs/sheetsRoof covering using tiles/slatesSolar energy storageGreenhouse

The invention discloses a greenhouse solar energy storage water heater wall panel and a building solar energy storage water heater wall panel, and belongs to the fields of agricultural production equipment and housing construction. A water tank is arranged on the inner side of a heat-collecting glass tube, and the inside of the water tank is provided with an energy storage tank which is filled with energy storage liquid prepared by mixing salt, ferric oxide, acetic acid and water; one end of the energy storage tank is provided with an energy storage liquid crystallizing exciter which is provided with magnetic exciting plates; and when the exciting plates vibrate, the energy storage liquid is crystallized under the excitation of the exciting plates and releases heat to heat the water outside the energy storage tank. The greenhouse solar energy storage water heater wall panel and the building solar energy storage water heater wall panel have the advantages that: the energy storage tank realizes two-time solar energy utilization; and the inner side face of a main water tank can be embedded with an insulation board or ventilating board so as to realize free change of heat insulation and direct heat dissipation. The greenhouse solar energy storage water heater wall panel and the building solar energy storage water heater wall panel have important significance for protecting environment, saving energy and reducing emission, improving agricultural productivity, accelerating agricultural modernization and improving quality of life of people.

Owner:任树华

Earthworm processing device and earthworm processing method

InactiveCN105998080AFast cutting speedIncrease labor productivity andLeech/worm material medical ingredientsEngineeringSlide plate

The invention discloses an earthworm processing device. The provided earthworm processing device comprises a box body, as well as a sliding plate, a storage box and a cutting unit which are arranged in the box body, wherein sliding rails used for placing earthworms are arranged on the sliding plate; the cutting unit comprises rollers and a cutter; the cutter is fixed onto the rollers; the rollers are arranged corresponding to the sliding rails; the storage box is communicated with the sliding rails. According to the provided earthworm processing device, the earthworms are brought into the sliding rails under driving of the rollers on the sliding plate, and are thoroughly and vertically cut from the head to the tail through the cutter; the cutting rate reaches 100%, the earthworm cutting speed is greatly improved, the manpower is saved, and the labor productivity is improved; the advantages of simple structure, low cost and the like are achieved.

Owner:赵正伟

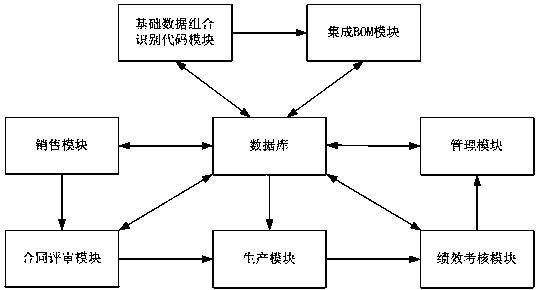

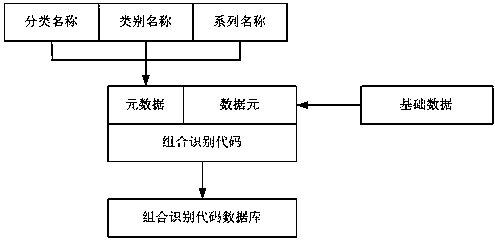

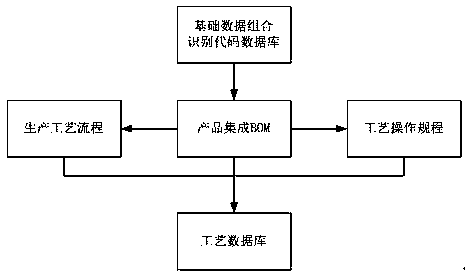

Flat enterprise management method and system

InactiveCN108846645AImprove management efficiencyQuality improvementOffice automationSpecial data processing applicationsProgram planningComputer science

The invention discloses a flat enterprise management method and system. According to the method and system, basic data recognition code modeling, integrated BOMs and technological procedure modeling,sales contracts and contract review, production plans and execution feedback, and all-staff data-based performance assessment are completed on a same flat management platform; and through uniform planmanagement, the functions, for information acquisition, analysis, decision, planning and execution feedback, of each original department are saved. According to the method and system, the enterprisemanagement efficiency and product quality are improved via a simplified management mode, the product production period is shortened, the production cost is improved, and the full-staff labor productivity of the enterprises is improved; and through an all-staff data-based performance assessment system, the effective execution of plans and technological procedures is ensured, and negative effects, in the management, of humans are reduced to the lowest.

Owner:林大统

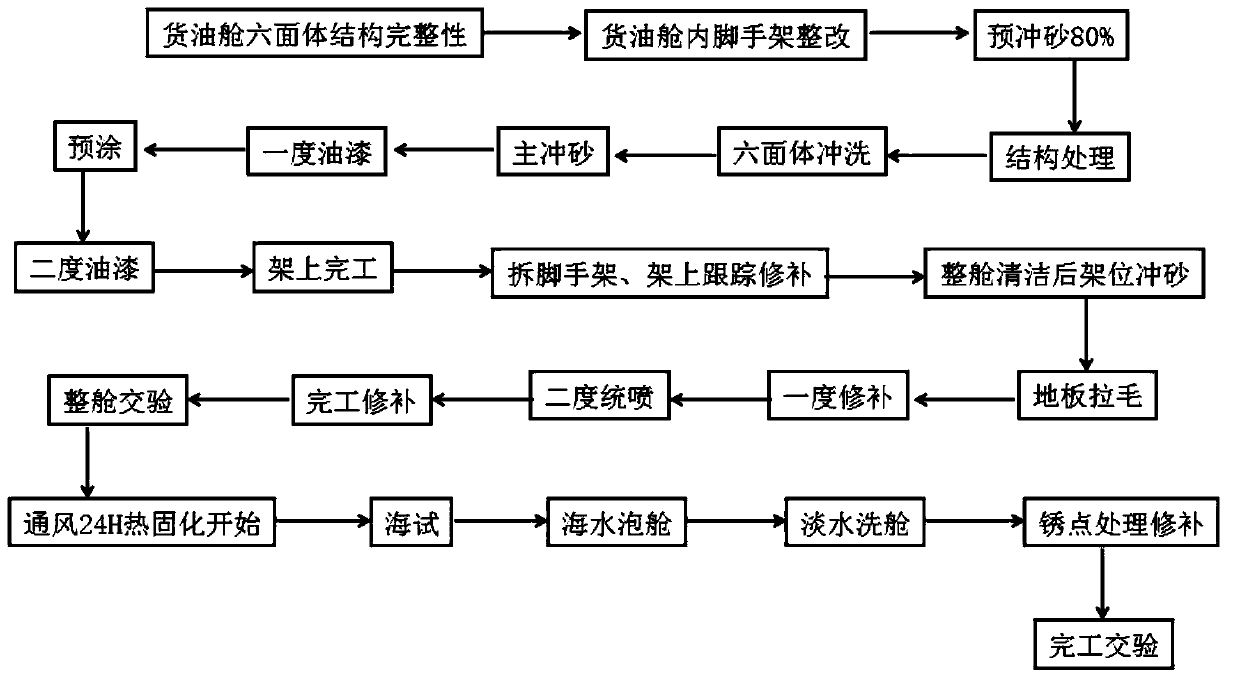

Chemical cargo ship special coating construction process

InactiveCN109701837AImprove product qualityImprove labor productivityPretreated surfacesCoatingsCargo vesselProcess engineering

The invention discloses a chemical cargo ship special coating construction process. The chemical cargo ship special coating construction process comprises following steps that firstly, a scaffold forconstruction is erected; secondly, a cabin is subjected to impurity removal and grinding, and pre-sand-removal cleaning is carried out; thirdly, cabin washing is carried out, after drying, main sand removal treatment is carried out; fourthly, cabin paint spraying and defect repair are carried out; and fifthly, cabin heat curing treatment is carried out. According to the chemical cargo ship specialcoating construction process, the process work flow can be specified, product quality is improved, labor productivity can be improved, the production cost is reduced, and the berth / pier efficiency isimproved.

Owner:WUHU SHIPYARD CO LTD

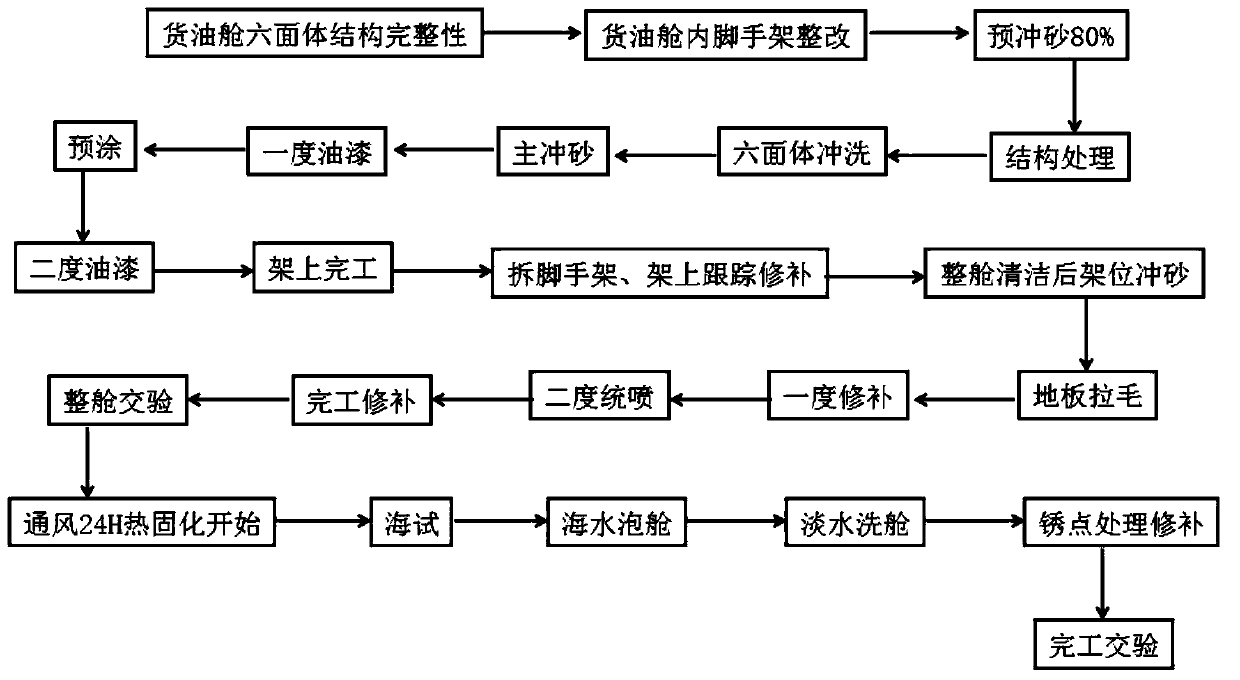

Construction engineering material price information data calculation method based on machine learning time sequence prediction algorithm

PendingCN113986869ASolve the problem of judging whether the quotation is reasonableLow costMarket predictionsForecastingPrediction algorithmsCalculation methods

The invention discloses a construction engineering material price information data calculation method based on a machine learning time sequence prediction algorithm, and the method is characterized in that the method comprises the following steps: S0, collecting and cleaning material price data through an existing standard material library, and forming a multi-dimensional material price database; S1, establishing a material composition data model by using a material price database; S2, establishing a material price historical data model; S3, establishing a material price influence factor analysis model; S4, establishing a material composition raw material price historical data model; S5, establishing a material composition raw material price fluctuation model; S6, establishing a material price reference verification mechanism; wherein the prices of future nodes and / or backtracking historical nodes of the target material are predicted through the database and / or the model in the above steps. The time dimension is broken through on the basis of the present invention, the time for backtracking and predicting the historical data has no upper limit, the time dimension is larger, and the accuracy is higher.

Owner:昆明行列科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com