Bamboo shoot shelling machine

A bamboo shoot peeling machine and transmission mechanism technology, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of reducing labor intensity, high labor intensity, slow speed, etc., so as to improve labor productivity and reduce labor. Strength, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

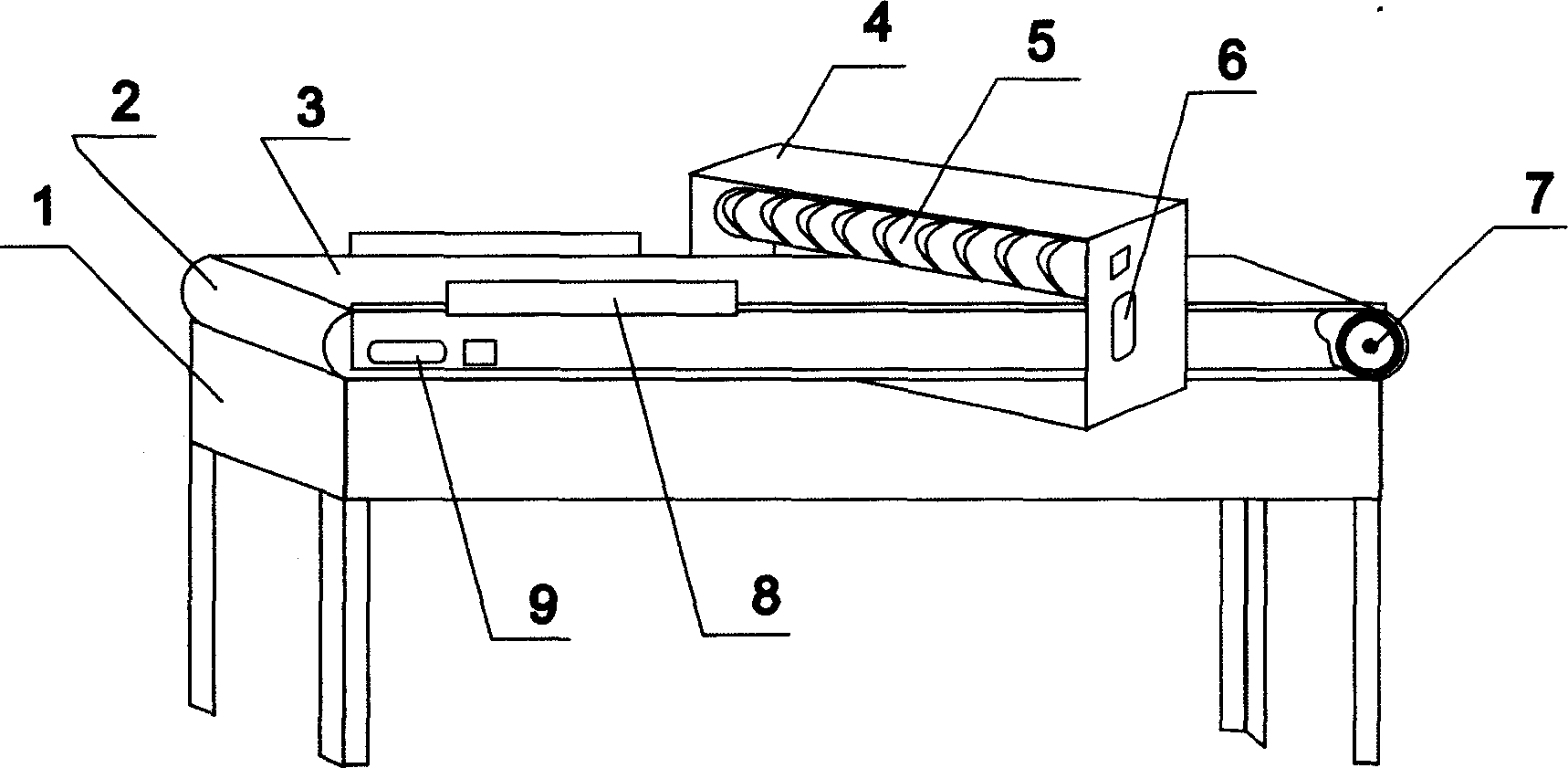

[0010] combined with figure 1 The present invention is further described.

[0011] A bamboo shoot peeling machine of the present invention is composed of a support 1, a front roller 2, a conveyor belt 3, a rear roller 7, a main roller frame 4 and a main roller 5. The rollers 2 and 7 are fixed on the two ends of the support, and the rollers are tangent to the surface of the support. The conveyor belt is made of rubber and plastic material with texture on the surface, which is a closed annular belt, and is tightly sleeved on the front and rear rollers and the surface of the support. The rear roller is driven by a motor through a transmission mechanism, and a left and right adjustment mechanism 9 is arranged at the connection between the front roller 2 and the support 1, which is used to adjust the tightness of the conveyor belt; the main roller frame 4 is fixed on the surface of the support 1, and its axial direction Forming an angle with the axial direction of the bracket, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com