Adjustable constant-proportion division device

A fixed-ratio scaler and adjustable technology, applied in the field of scalers and adjustable fixed-ratio scalers, can solve the problems of low efficiency and great influence of scale reduction, avoid human error and improve labor productivity , the effect of convenient sample disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

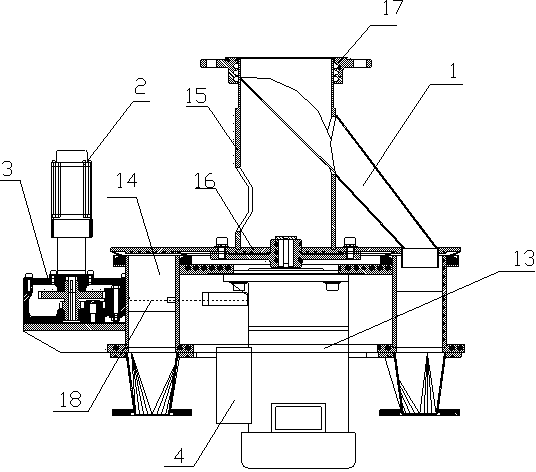

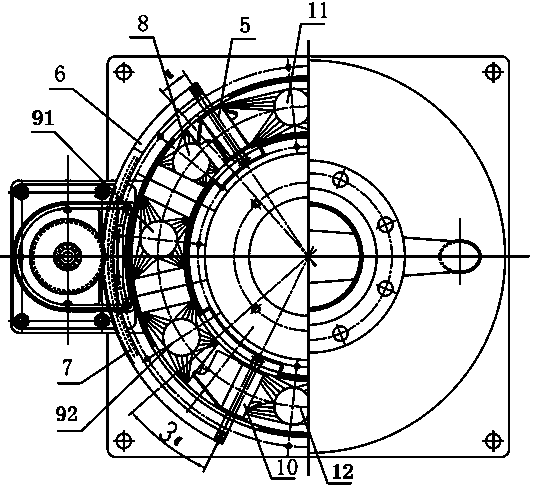

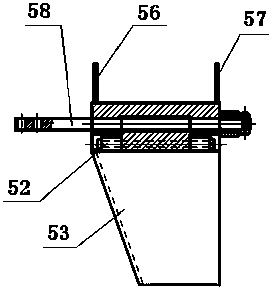

[0027] Such as figure 1 , figure 2 As shown, the adjustable fixed-ratio splitter of the present invention includes a swing hopper 1, a drive device (spindle motor 4 and a reducer), a distribution disc 13 and several drop hoppers distributed along the circumference, and the swing hopper 1 is located on the distribution disc 13 above and connected to the driving device, the distribution disc 13 is provided with feed holes corresponding to each drop hopper, and each drop hopper is connected to the bottom of the distribution disc 13 in turn, and the shrink divider is also provided with two sets of loose-leaf deflectors, respectively It is A loose-leaf deflector 5 and B loose-leaf deflector 10. Both loose-leaf deflectors are arranged above the discharge hopper and connected with the transmission rack. The discharge hopper is divided into a sample retention hopper and a sample discard hopper. The loose-leaf deflector Located between the sample retention hopper and the sample disc...

Embodiment 2

[0033] This example is on the basis of implementing one, and the quantity of loose-leaf deflectors, racks and hoppers can also be set as required.

[0034]

[0035] Working process of the present invention:

[0036] A rack and B rack move in opposite directions, and the radians of movement are in a 1:3 relationship, such as figure 2 Radians a and 3a in .

[0037] The stepping motor drives the gear box to rotate, and the gear box respectively drives the A rack and the B rack to move in a circular arc. The direction of the A rack and the B rack is opposite, and the motion arc is 1:3. Therefore, in the material receiving area Sa :Sb=1:3;

[0038] When designing, the ratio of the area SA of the sample A hopper to the area SB of the sample B hopper is 1:3, and the formula is SA: SB=1:3;

[0039] So there is: (SA+Sa) / (SB +Sb)=1 / 3;

[0040] Therefore, the reduction ratio of the A reduction sample and the B reduction sample is always a fixed value, and the fixed ratio reduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com