Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Increase input current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric energy feedback type electronic load

InactiveCN104052079AImprove machine efficiencyReduce the temperatureSingle network parallel feeding arrangementsPower supply testingPower qualityMOSFET

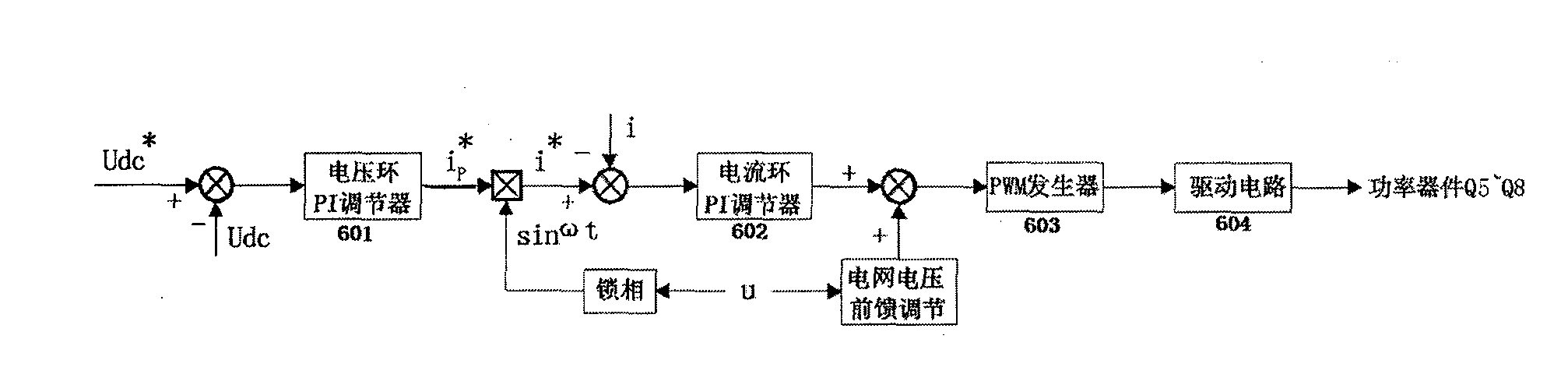

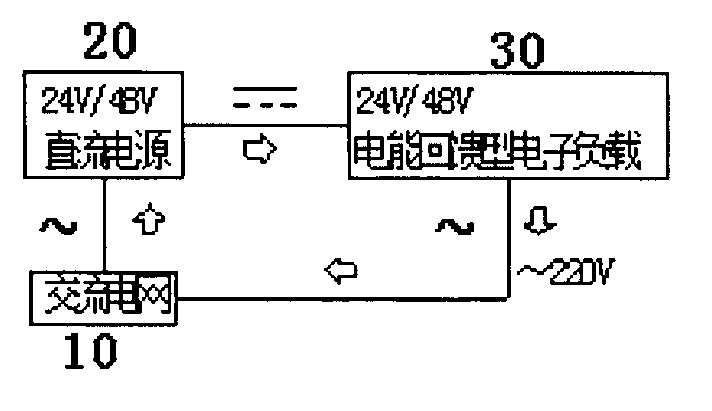

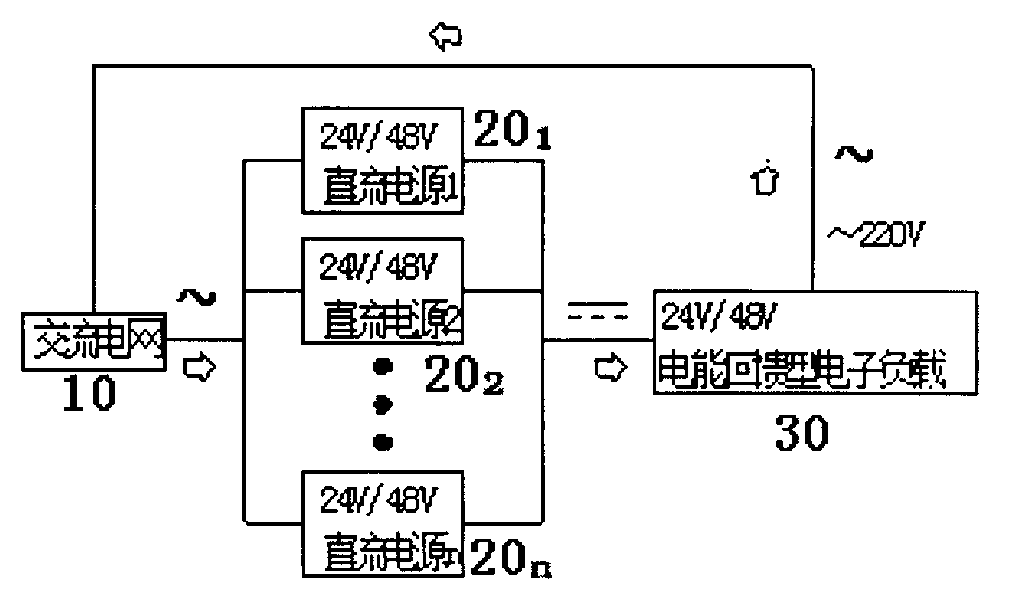

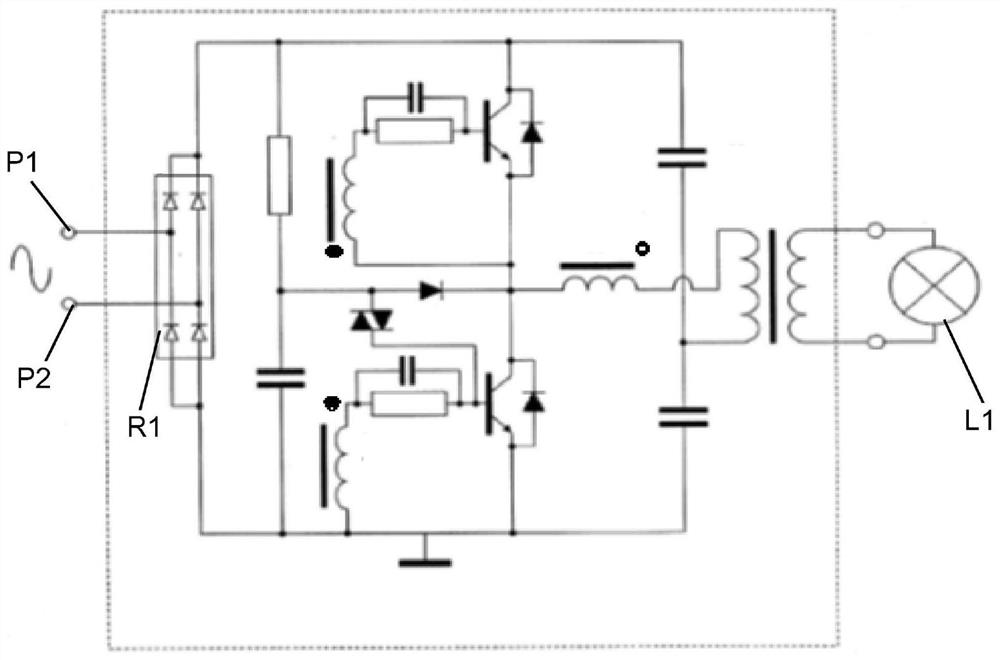

The invention relates to an electric energy feedback type electronic load. The input end of the electronic load employs a large-current single-channel access mode. A main circuit mainly comprises a DC / DC conversion circuit, a DC / AC inverter circuit, and an AC filter output circuit, wherein the DC / DC conversion circuit employs a phase-shifted full-bridge circuit to achieve the control of DC input, and boosts DC input voltage. In order to adapt to large-current input, a switching device is formed by parallel connection of a plurality of MOSFETs. The DC / DC conversion circuit is connected with the DC / AC inverter circuit through a DC bus. The DC / AC inverter circuit employs a single-phase full-bridge inverter circuit to control AC output current so as to stabilize the voltage of the DC bus and feeds the AC current back to a power network by a unit power factor. The DC / AC inverter circuit employs an IGBT module as a power device. The AC filter circuit can employ an LC low-pass filter circuit so as to eliminate the higher harmonic waves in the output current of the DC / AC inverter circuit and improve the quality of grid-connected electric energy.

Owner:余名俊

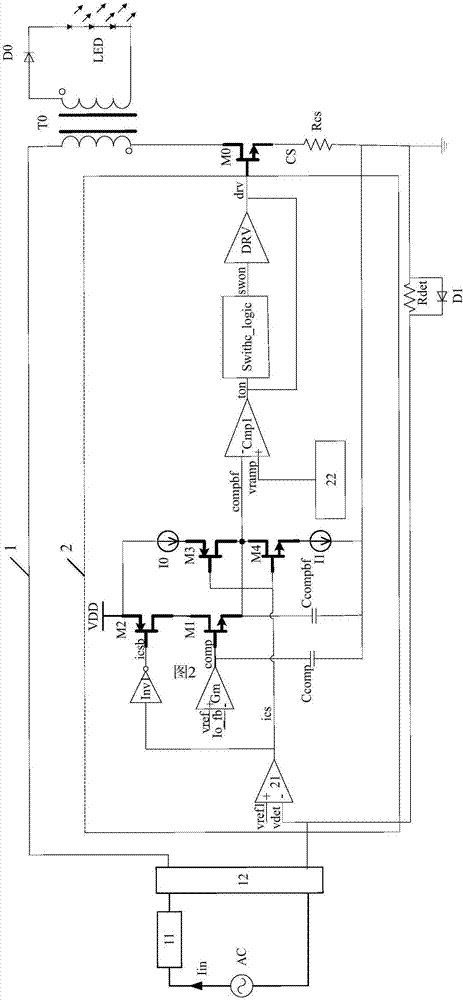

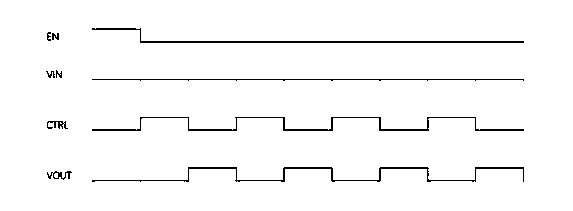

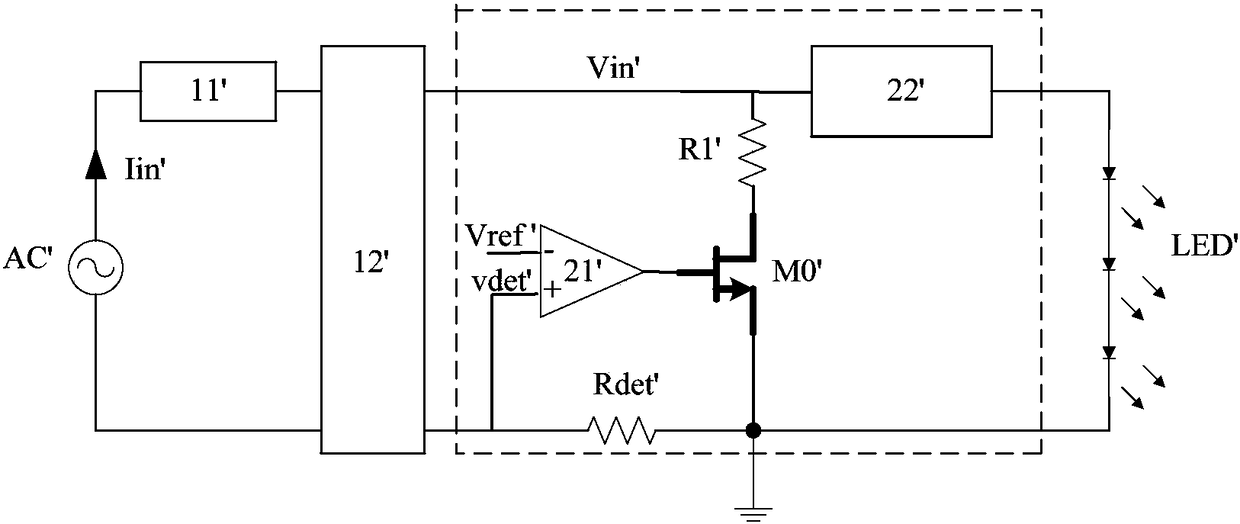

LED drive chip capable of improving thyristor dimmer compatibility and circuit

ActiveCN107046748ALow costIncrease input currentElectrical apparatusElectroluminescent light sourcesCapacitanceEngineering

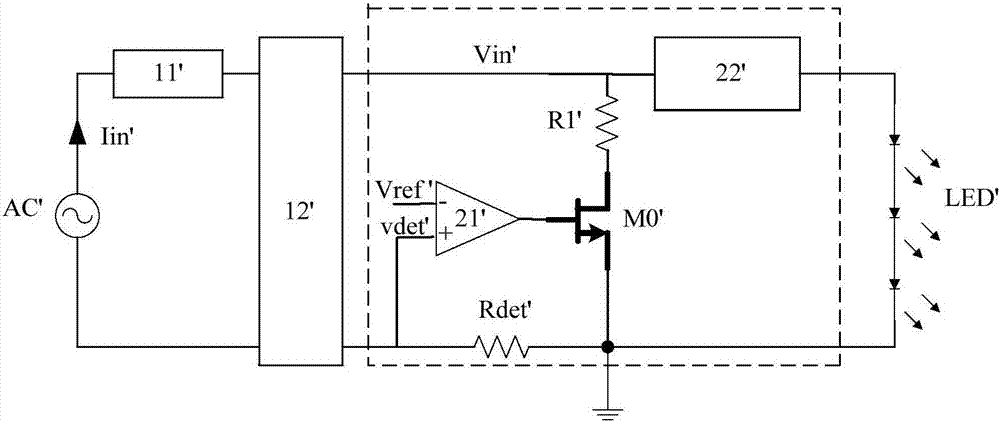

The invention provides an LED drive chip capable of improving the thyristor dimmer compatibility and a circuit. The chip is connected with a peripheral circuit including a thyristor dimmer and an input current sampling resistor. The chip comprises a hysteresis comparator, a transconductance module, a first NMOS tube, a first PMOS tube, a second PMOS tube, a second NMOS tube, a compensation capacitor, an isolation capacitor, a first comparator and a drive module. According to the invention, the input current is increased without directly pulling down the bus voltage Vin; a part where the input current is increased is used as a part of output current; compared with the figure 1 in the prior art, the chip has remarkably improved efficiency, and particularly in the case of small output current, the efficiency is remarkably improved; and in addition, the cost is reduced without using a high voltage MOS tube and additionally increasing chip pins.

Owner:SHANGHAI ORIENT CHIP TECH CO LTD

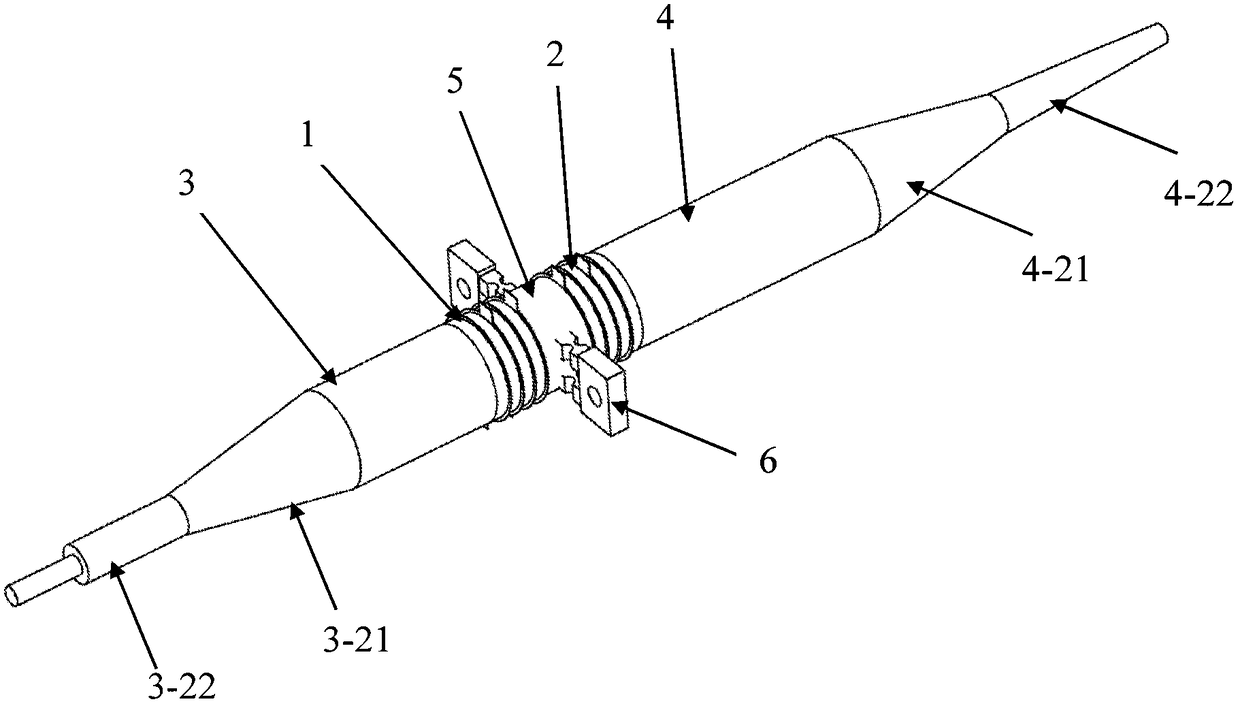

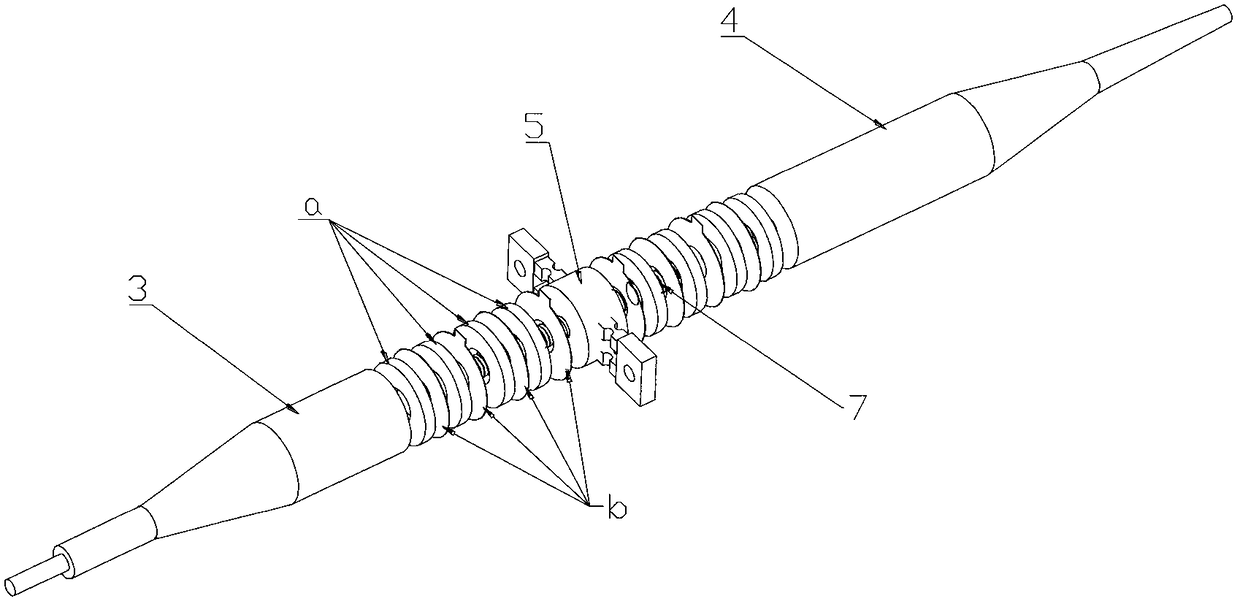

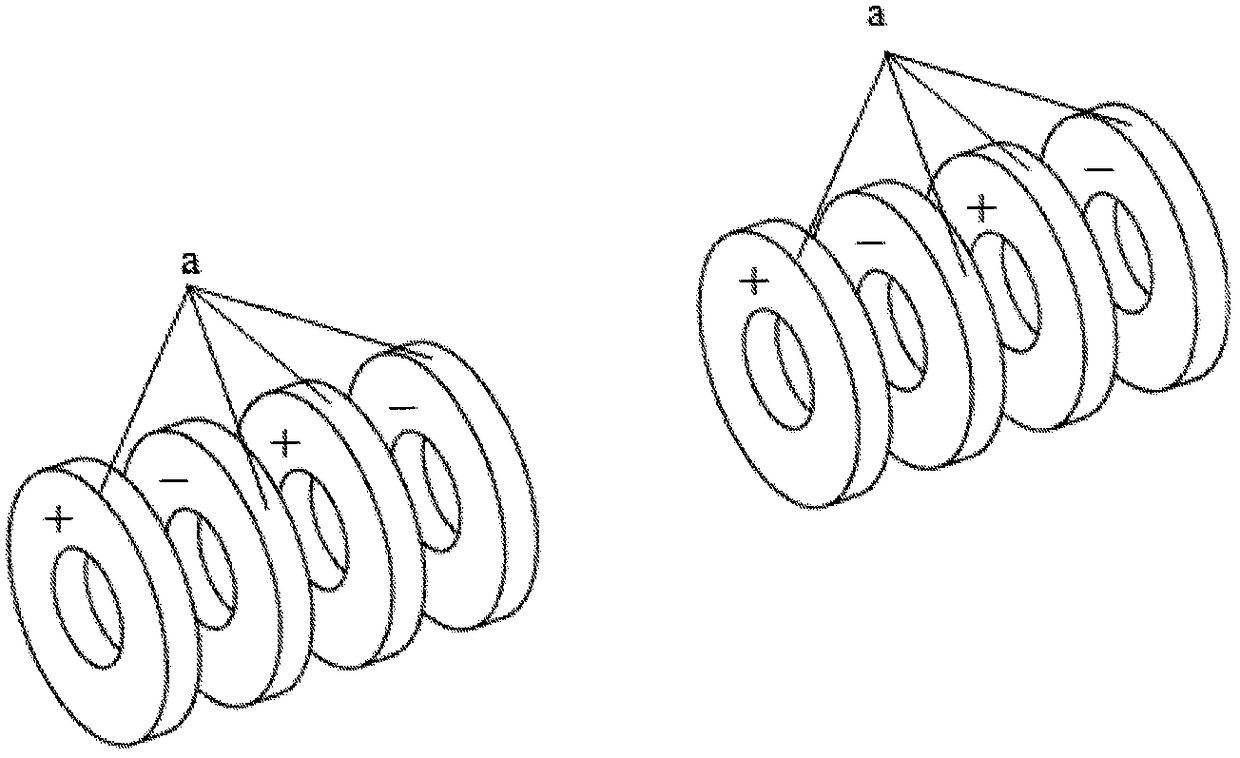

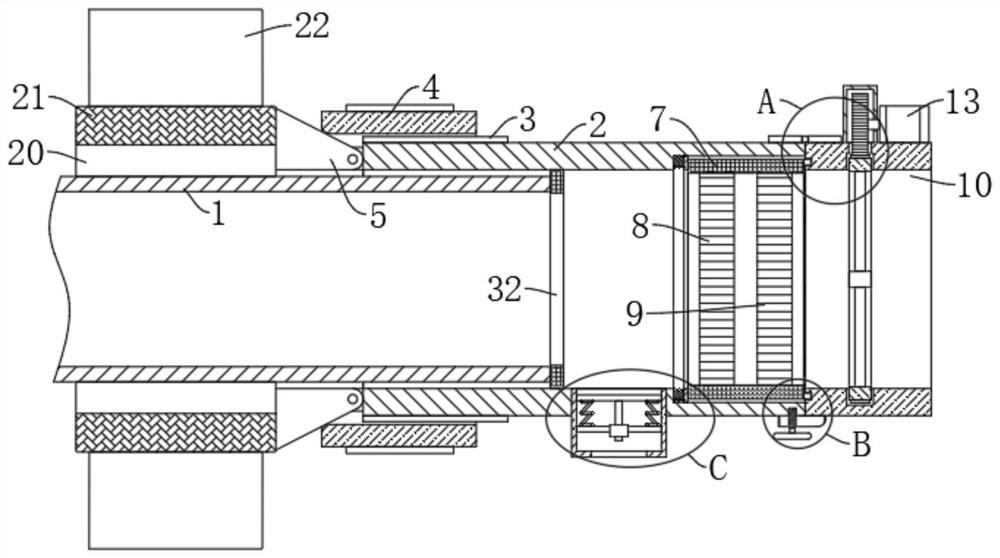

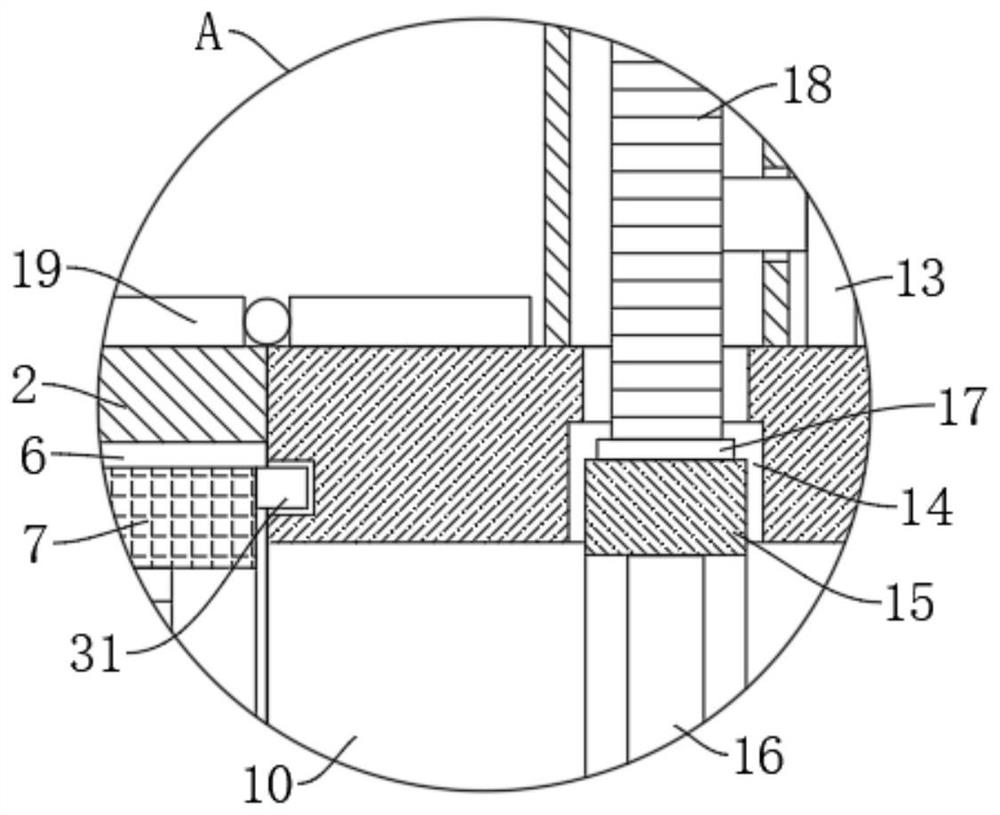

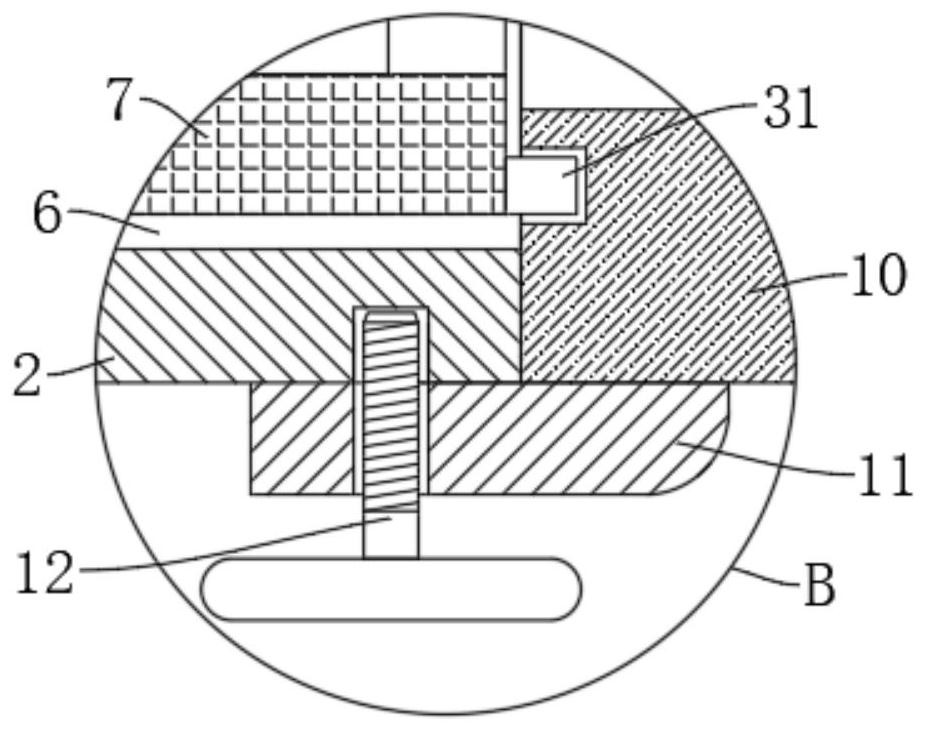

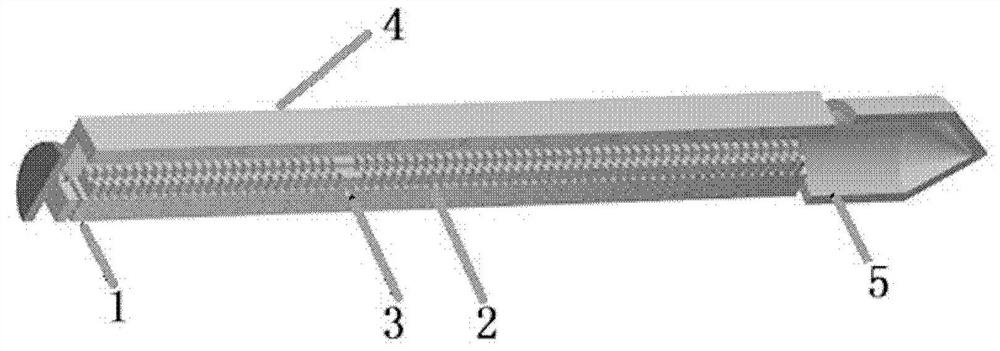

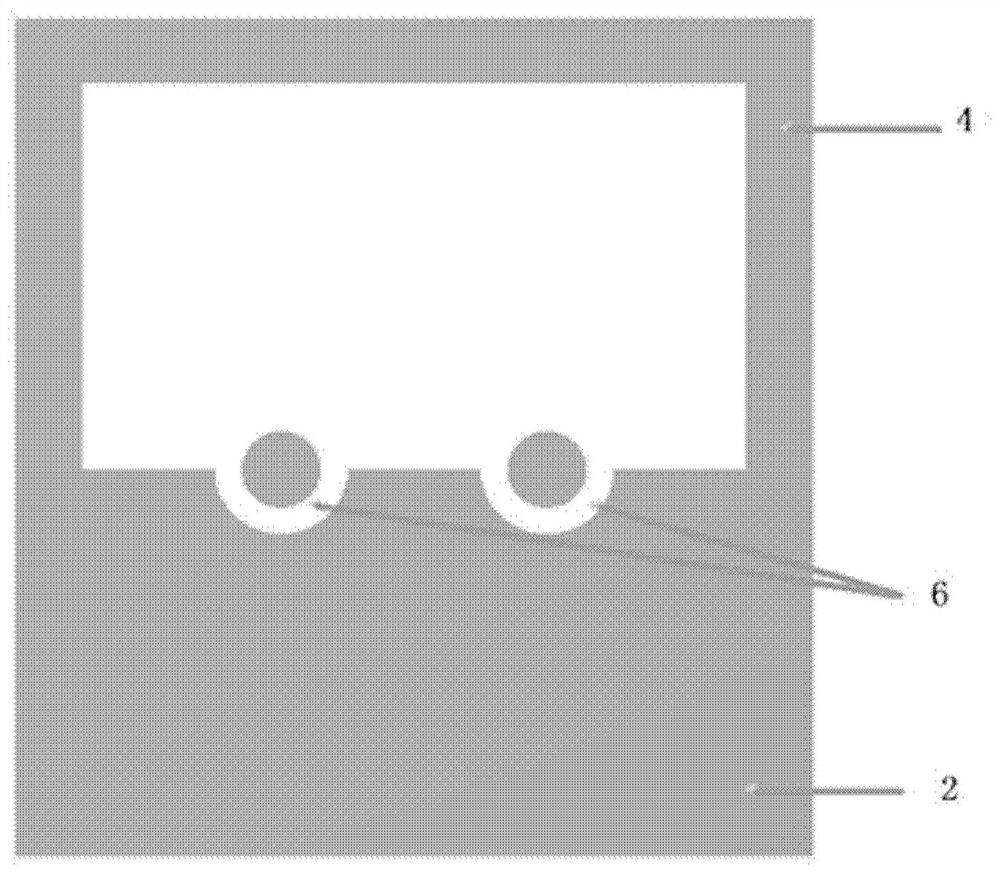

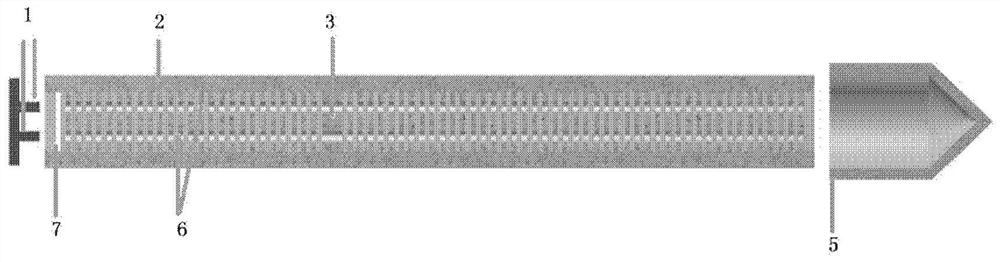

Series composite structure double-frequency multi-amplitude piezoelectric ultrasonic transducer

InactiveCN108176574AReduced service lifeReduce energy consumptionMechanical vibrations separationUltrasonic wire bondingUltrasonic transmission

The invention discloses a series composite structure double-frequency and multi-amplitude piezoelectric ultrasonic transducer applied to a thermal ultrasonic wire bonding and sealing process of an integrated circuit chip. The transducer is composed of two sets of double-ended radiating piezoelectric oscillators and two two-stage mechanical variable-amplitude poles with different amplification factors. The transducer can work at the frequency near the frequency of 60 kHz or 120 kHz and has three driving modes. Under simple harmonic excitation signals with the same frequency, the transducer canobtain multiple amplitude outputs to meet the different requirements of the wire bonding process of the integrated circuit chip and improve the bonding connection efficiency and reliability. Meanwhile, clamping mechanisms of the composite structure ultrasonic transducer adopt flexible flange clamping mechanisms formed by circular arc hinges, the influence of the clamping rack disturbance torque onthe ultrasonic transmission efficiency in the axial ultrasonic transmission process of the variable-amplitude pole can be effectively lowered, and the utilization rate of ultrasonic energy is increased.

Owner:TIANJIN POLYTECHNIC UNIV

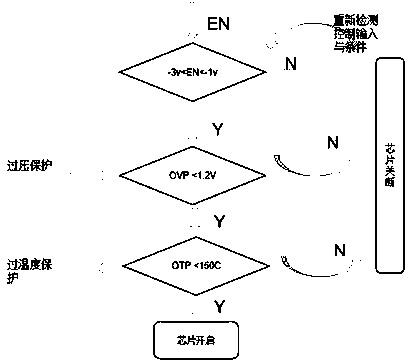

Modulation method of drain electrode power supply modulation chip of GaN power amplifier

InactiveCN109981057AImplementing Power SequencingIncreased power capacityPower amplifiersAmplifier modifications to raise efficiencyElectricityModulation function

The invention discloses a modulation method of a drain electrode power supply modulation chip of a GaN power amplifier, and belongs to the field of chip design. The modulation method of a drain electrode power supply modulation chip of a GaN power amplifier comprises a linear voltage stabilizer, a comparator, a charge pump, a high-power N-channel switch tube, a negative electricity detection control unit, an over-temperature and over-voltage protection unit, a power supply modulation unit and an output rapid discharge channel. On-off of drain electrode input of the GaN power amplifier is controlled by detecting whether negative voltage exists in a grid electrode of the GaN power amplifier or not, and therefore power supply time sequence control over the GaN power amplifier is achieved. On-off of the switch tube is controlled by controlling the gate-source voltage of the power switch tube in the chip, so that pulse modulation of drain electrode power supply of the GaN power amplifier isrealized. The design of a monolithic integrated circuit is adopted, so that the hardware layout area is reduced; while integrating the drain electrode modulation function, the invention also providesa perfect GaN power amplifier protection function, including drain electrode negative pressure enabling and over-temperature and over-voltage protection.

Owner:南京固德芯科技有限公司

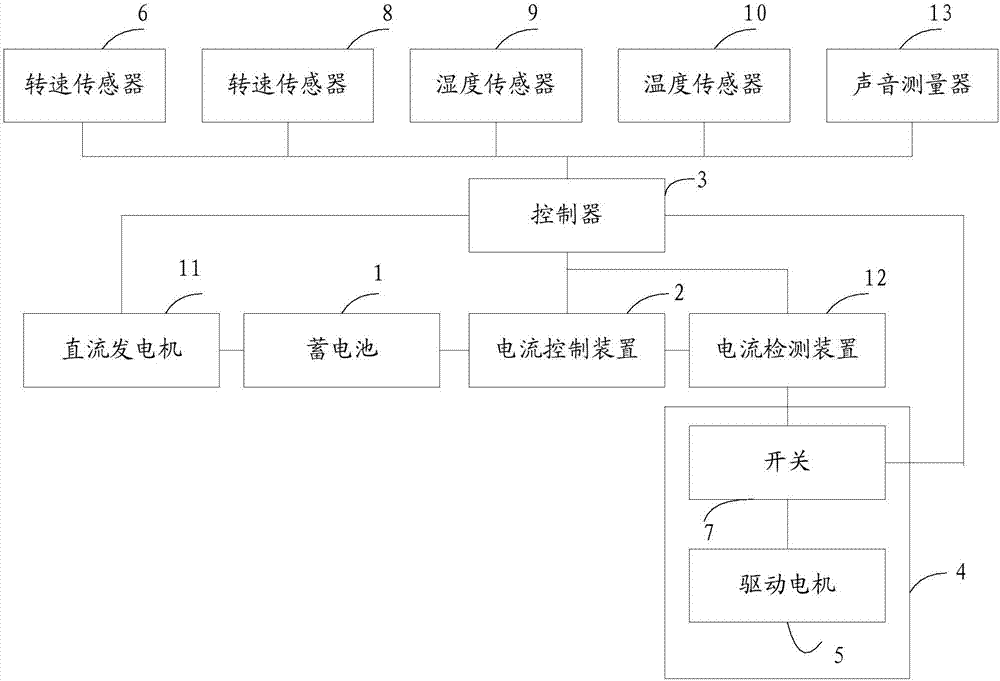

Mower

PendingCN106856799AIncrease input currentAdjust the input currentMowersField or armature current controlMotor speedElectric machine

The invention provides a mower. The mower comprises a storage battery, a current control device, a controller and mowing equipment, wherein the storage battery is electrically connected with the mowing equipment through the current control device; the mowing equipment comprises a driving motor, and the driving motor comprises a rotation speed sensor which is arranged on an output shaft of the driving motor; the rotation speed sensor is connected with the current control device through the controller; the controller is used for obtaining a rotation speed value of the rotation speed sensor, and when the rotation speed value is smaller than a preset rotation speed threshold value, the output current of the current control device is increased. The mower has the advantages that the mowing efficiency is high, the output power of the mower can be intelligently adjusted, the rotation speed of the driving motor is adjusted, the waste of energy is avoided, and the energy-saving and environment-friendly effects are realized.

Owner:FUJIAN EVERSTRONG LEGA POWER EQUIP CO LTD

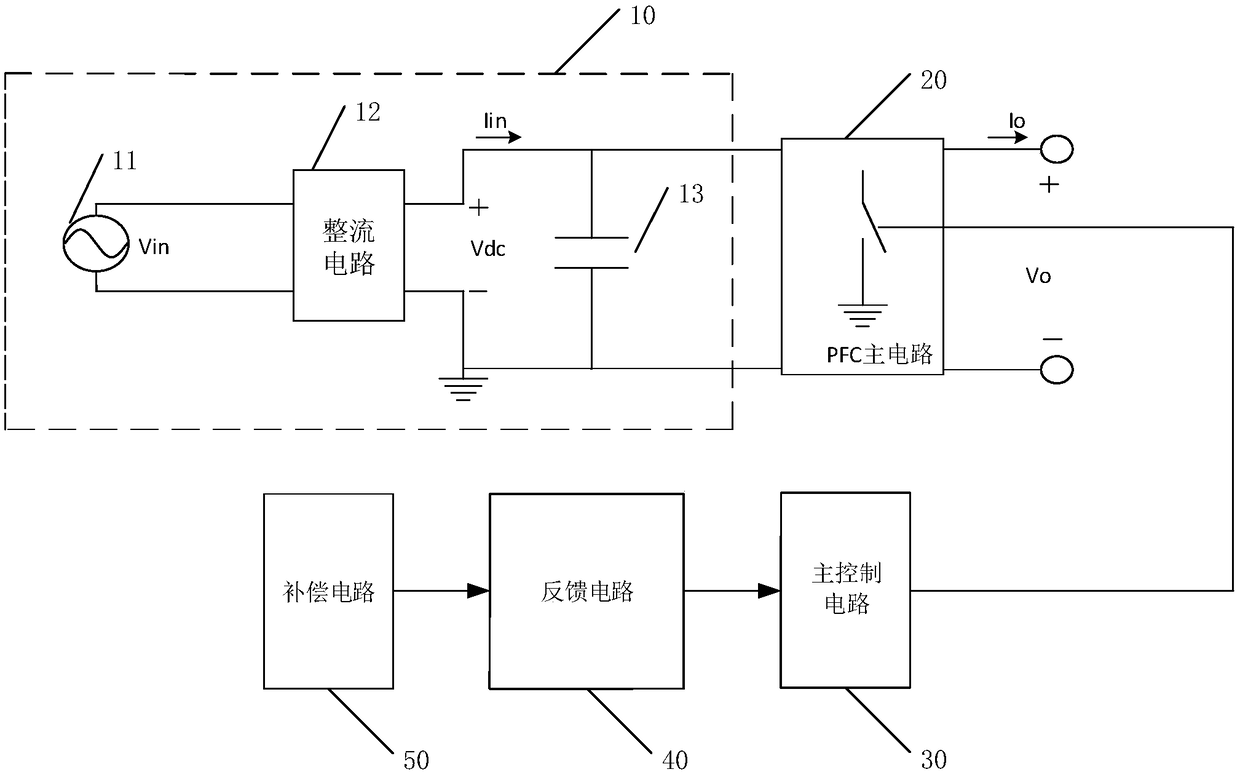

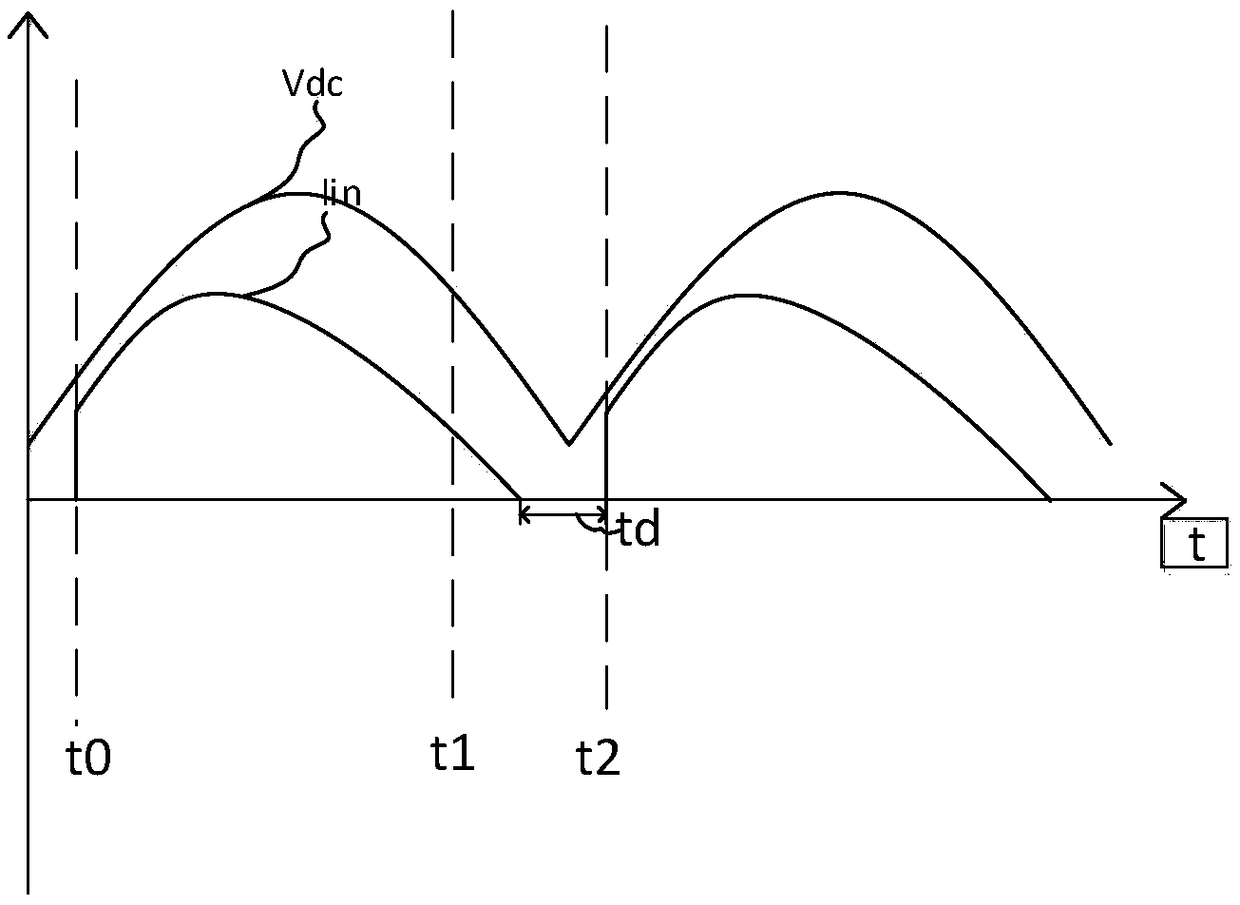

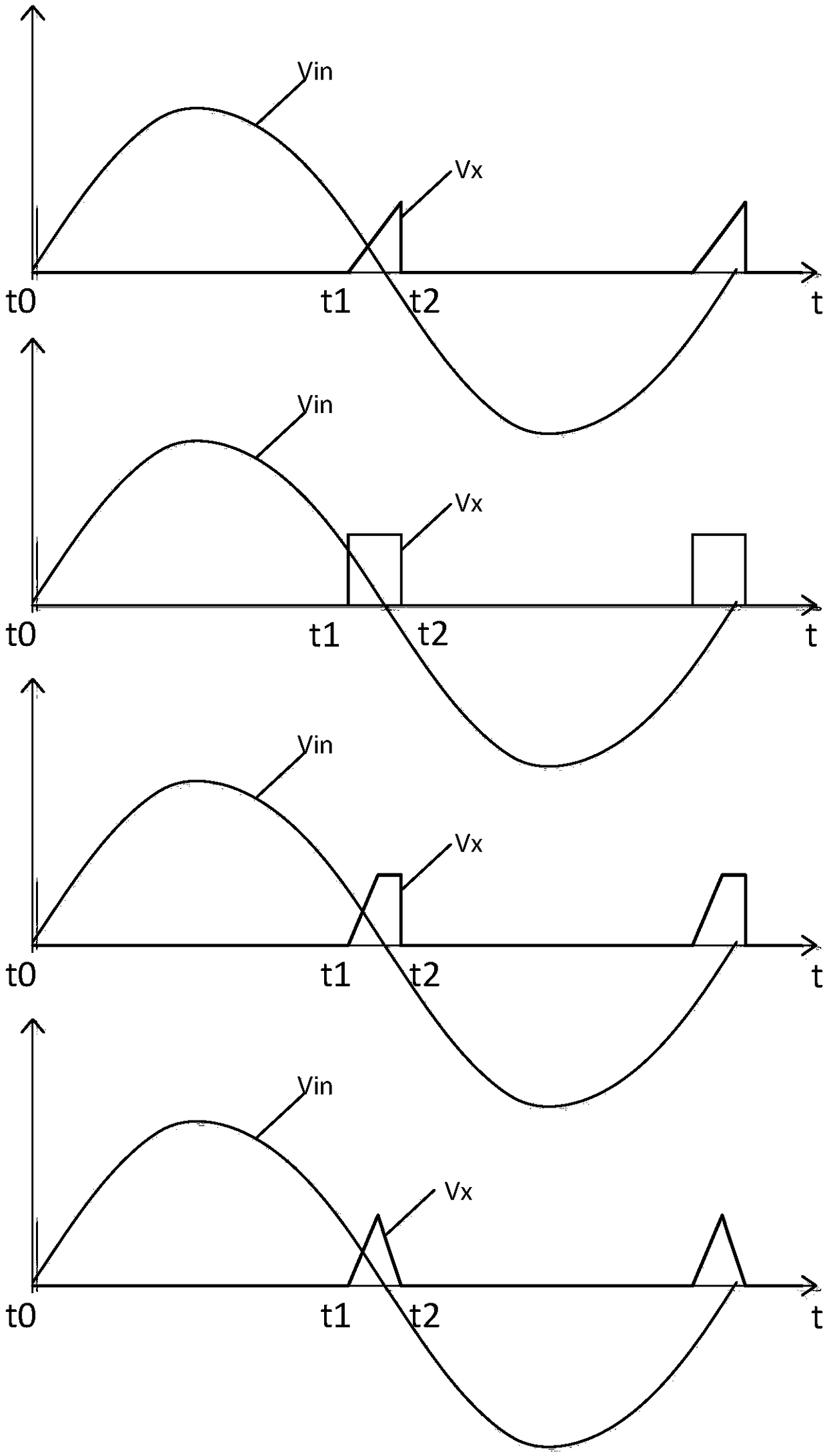

Power supply equipment and power factor correction circuit thereof

PendingCN108768156AIncrease input currentAvoid abnormal currentEfficient power electronics conversionPower conversion systemsCapacitanceHarmonic

Owner:INVENTRONICS HANGZHOU

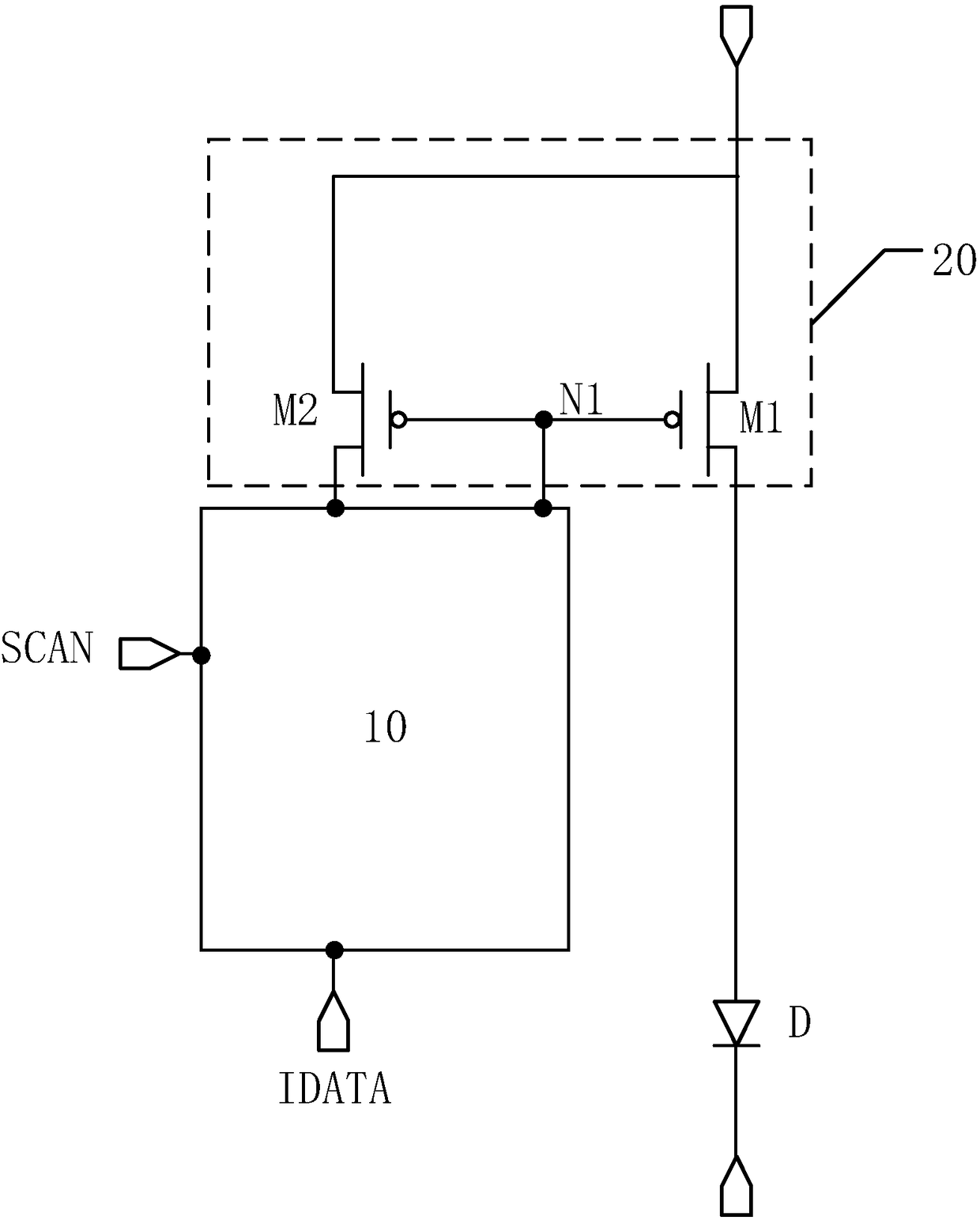

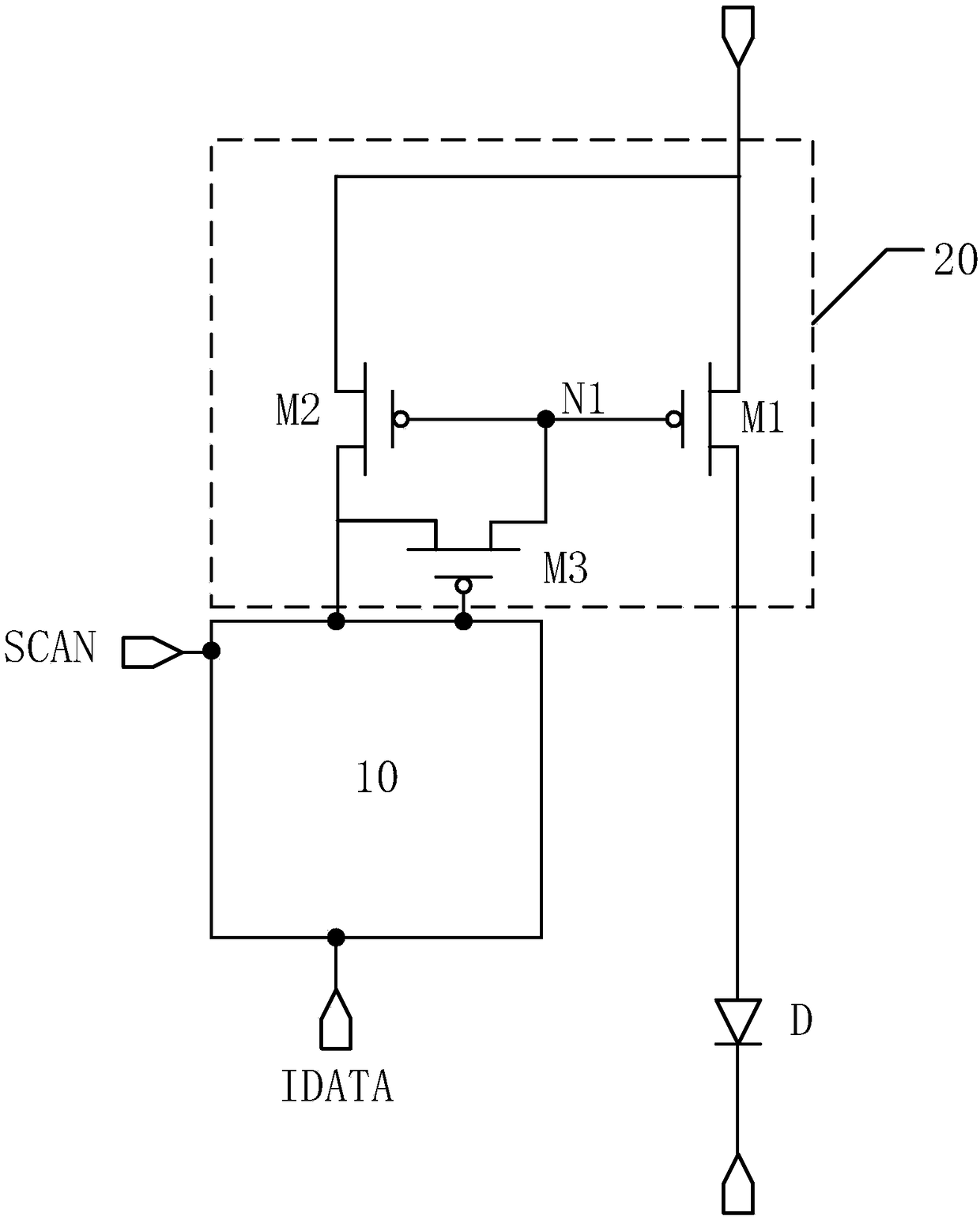

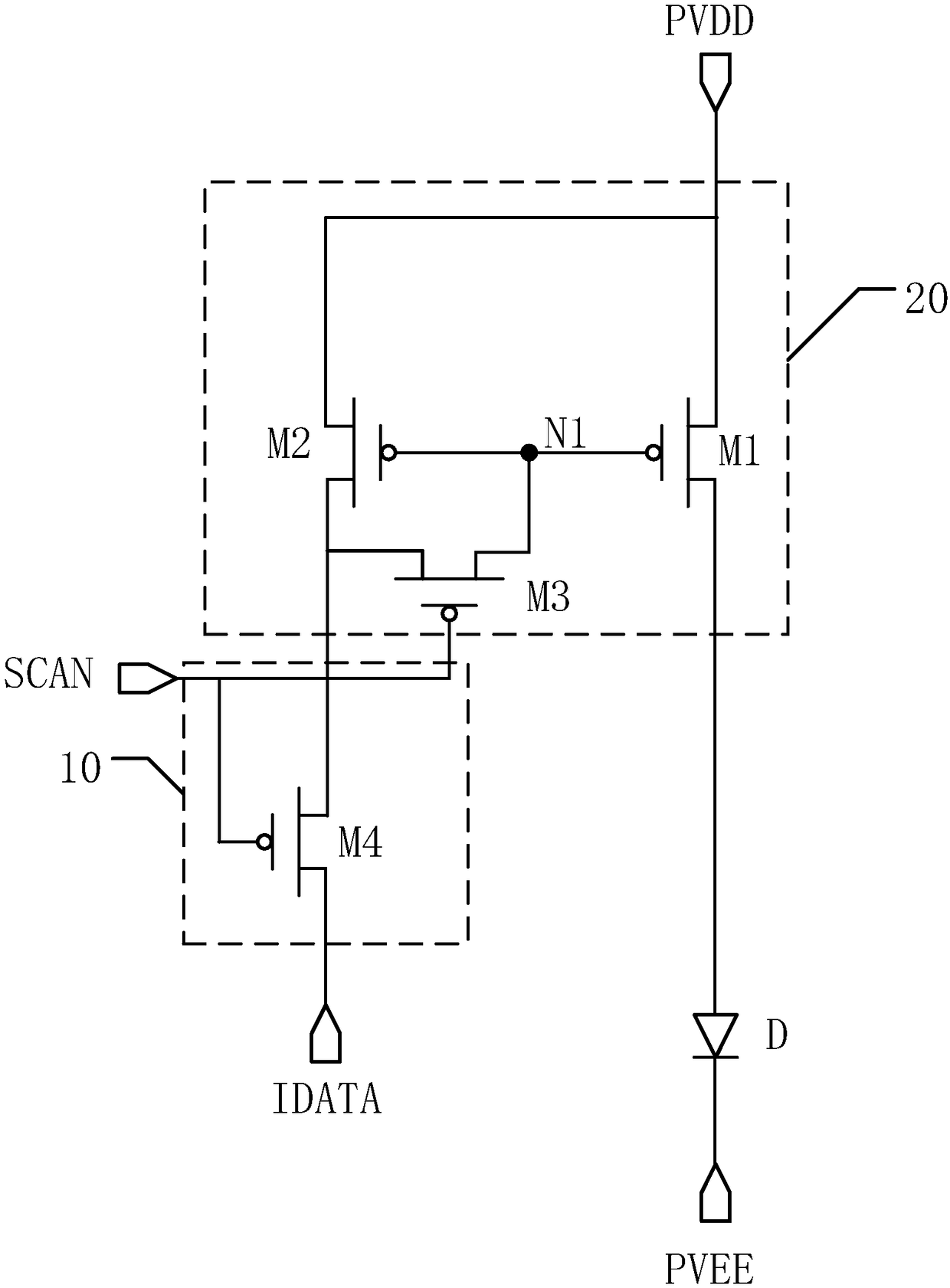

A pixel drive circuit and a drive method thereof, a display panel and a display device

InactiveCN108538242AImprove work efficiencyImprove work performanceStatic indicating devicesElectricityDriving current

The invention provides a pixel drive circuit and a drive method thereof, a display panel and a display device and belongs to the technical field of display. The pixel drive circuit comprises a data write-in module, a mirror drive module and a light-emitting element. The mirror drive module comprises a first transistor and a second transistor; the gate of the first transistor and the gate of the second transistor are electrically connected to a first node; a first electrode of the first transistor and a first electrode of the second transistor are electrically connected; the threshold voltage of the first transistor equals the threshold voltage of the second transistor; the width-length ratio of the first transistor is A and the width-length ratio of the second transistor is B, wherein A<B<=20A; the light-emitting element is used for emitting light in response to a drive current. Compared with the prior art, the charging speed of data signals can be increased, the working efficiency ofthe pixel drive circuit is increased, the influence of a leak current on a drive current can be greatly reduced and the working performance of the pixel drive circuit is improved.

Owner:SHANGHAI TIANMA AM OLED

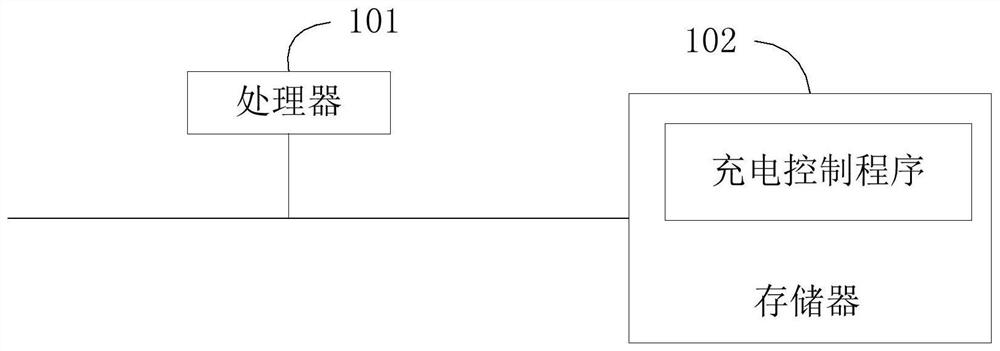

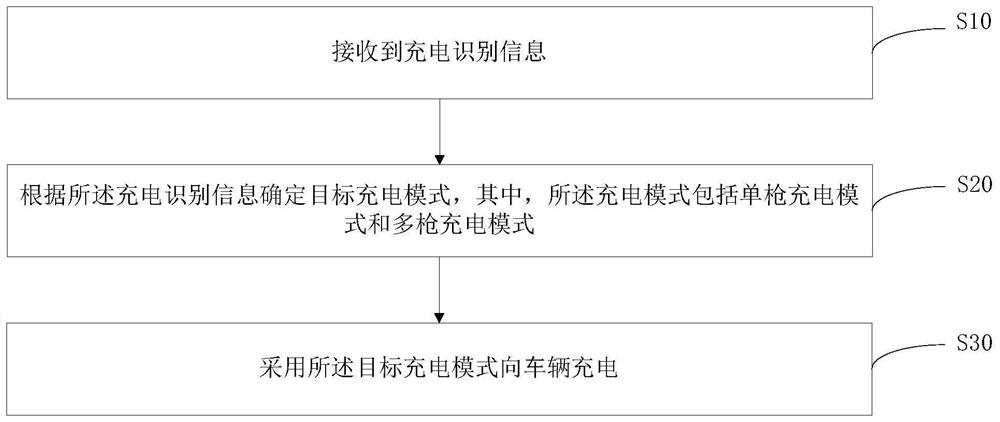

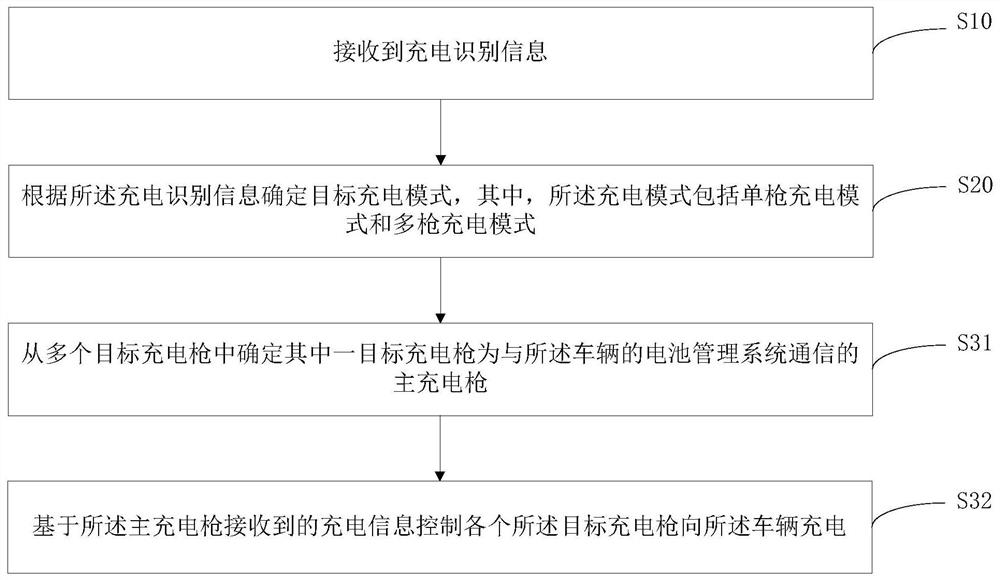

Charging method, charging device and computer readable storage medium

InactiveCN113147443AWide applicabilityIncrease input currentCharging stationsElectric vehicle charging technologyEngineeringElectrical and Electronics engineering

The invention discloses a charging method. The method comprises the following steps of receiving charging identification information, determining a target charging mode according to the charging identification information, wherein the charging mode comprises a single-gun charging mode and a multi-gun charging mode, and charging the vehicle by adopting the target charging mode. The invention further discloses a charging device and a computer readable storage medium. According to the embodiment of the invention, different charging modes are adapted based on different requirements of vehicles, so that the charging efficiency of different types of vehicles can achieve a better effect.

Owner:SUNGROW POWER SUPPLY CO LTD

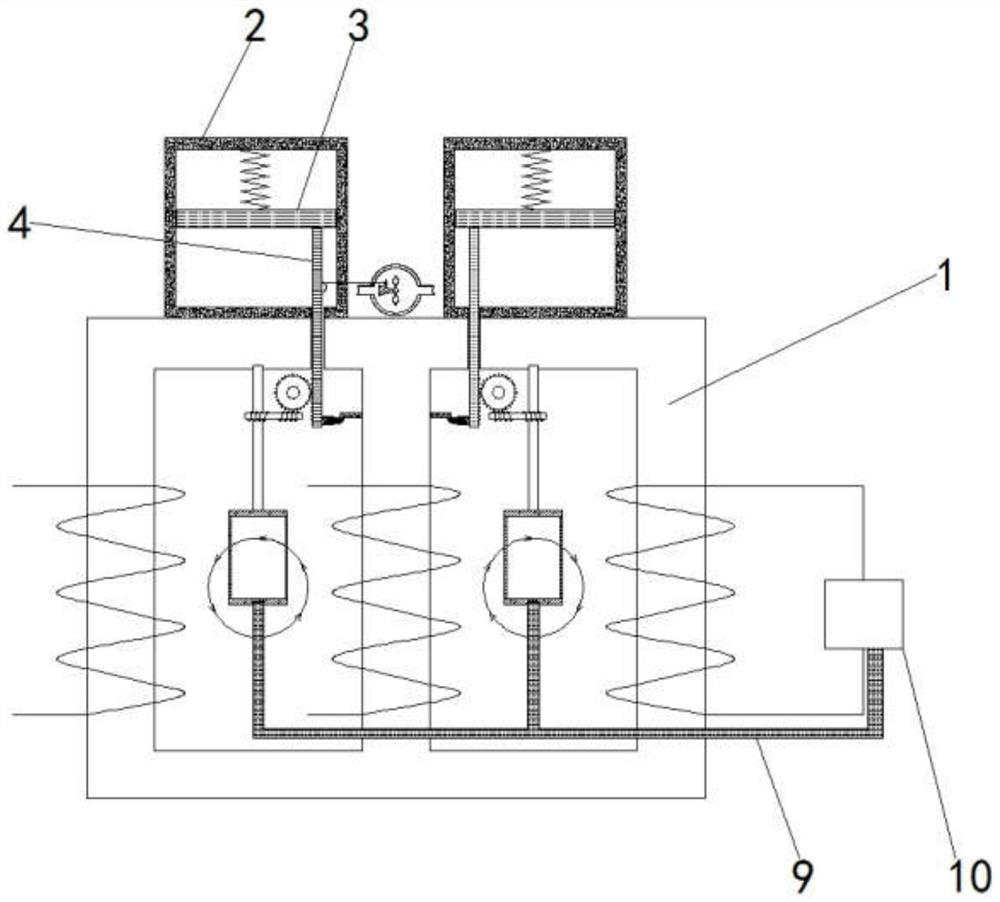

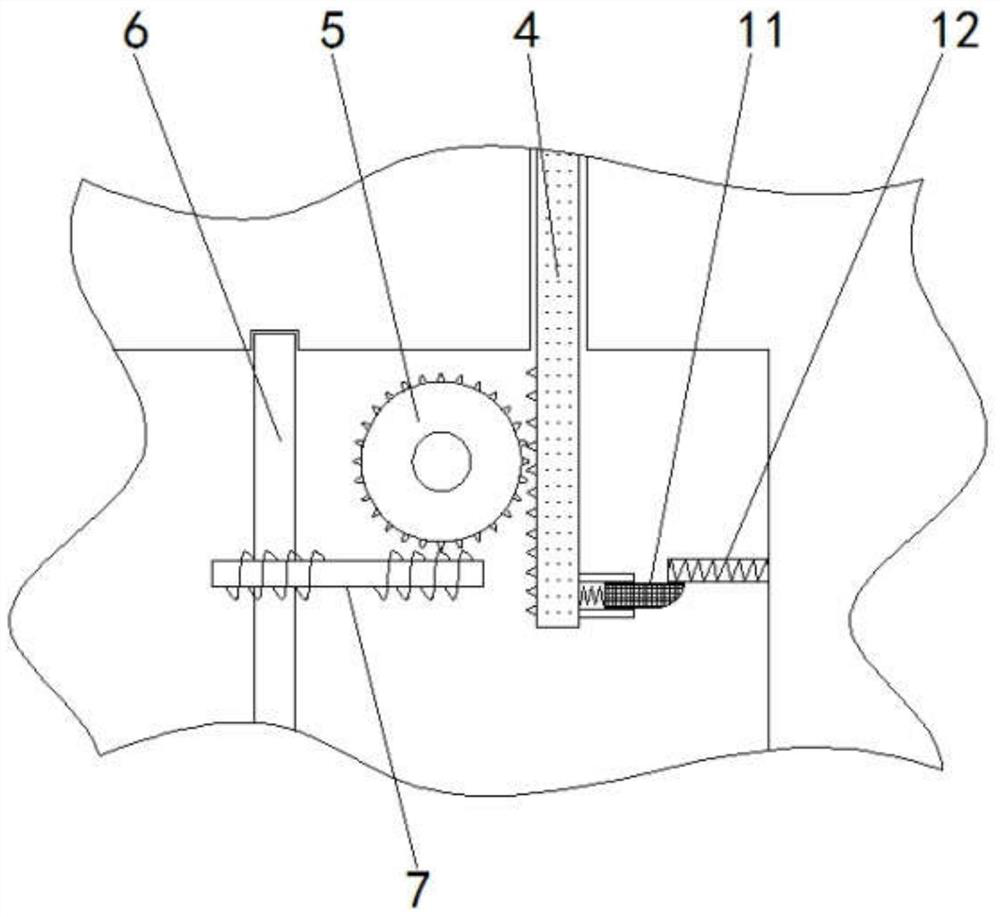

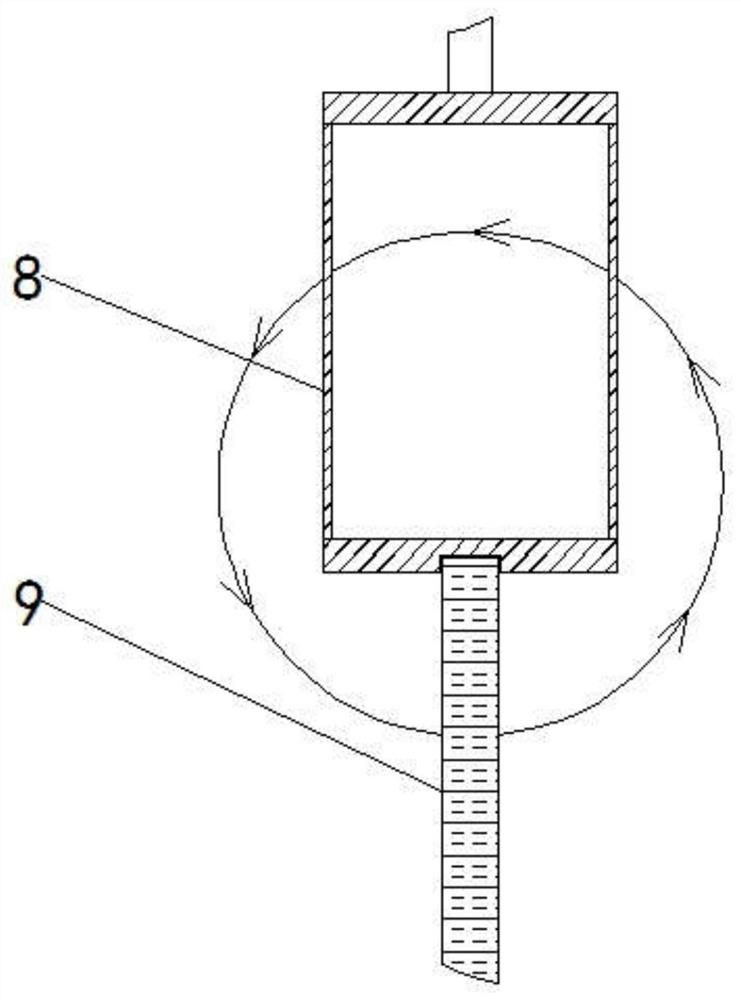

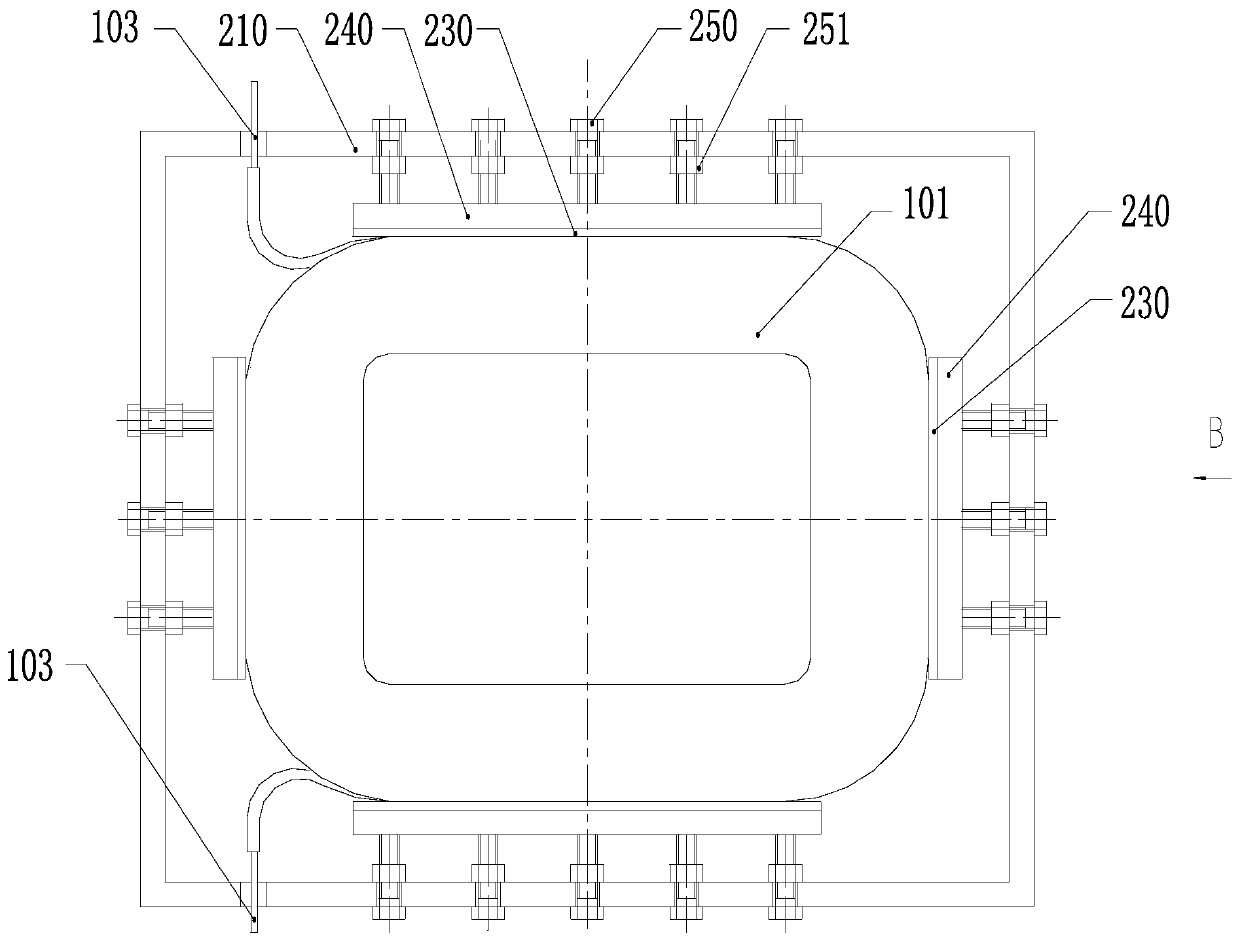

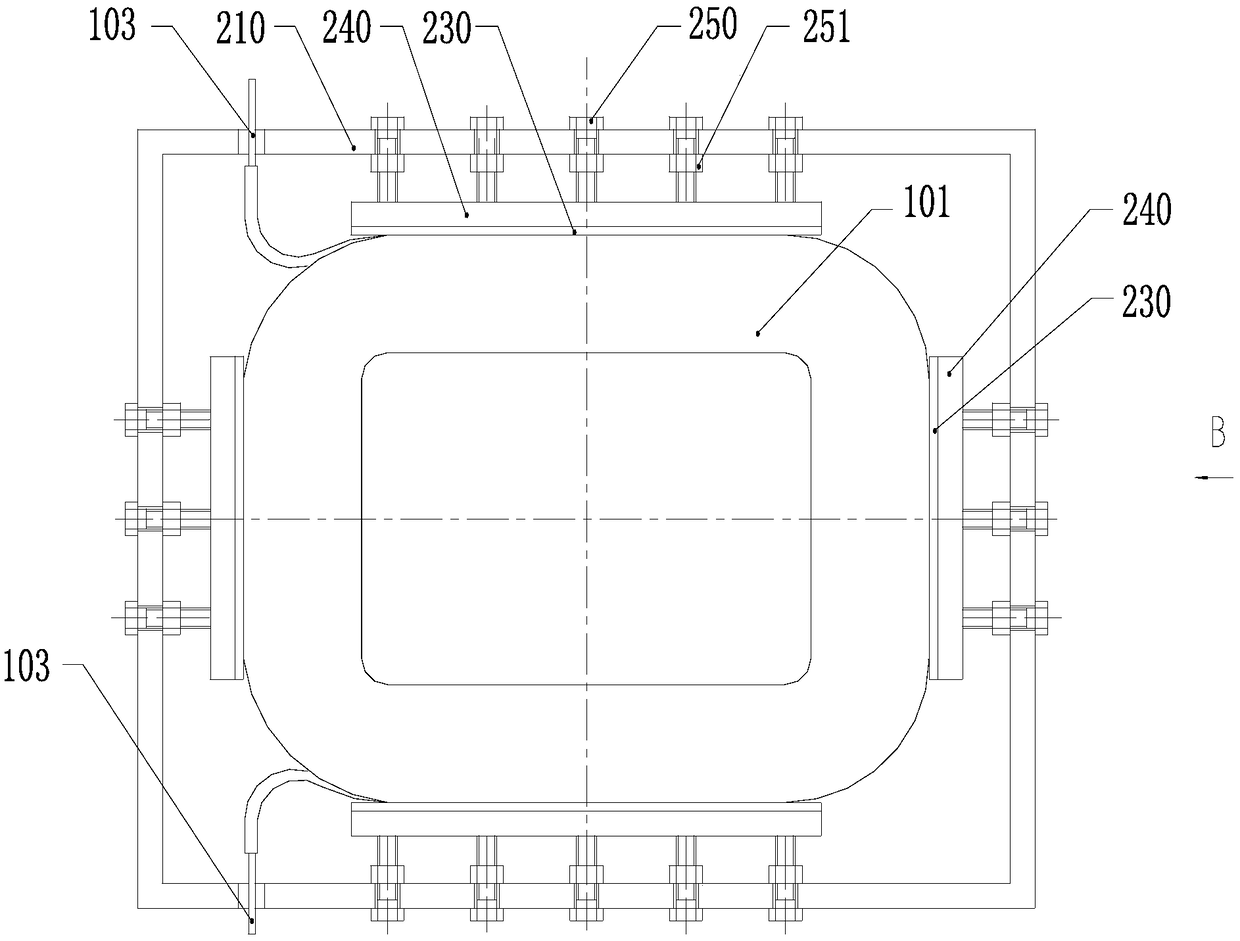

Winding mechanism for concentric winding of oil-immersed transformer and application of winding mechanism

ActiveCN111933415AIncrease input currentImprove cooling effectTransformers/inductances coolingUnwanted magnetic/electric effect reduction/preventionWinding machineDrive wheel

The invention relates to the technical field of oil-immersed transformers, and discloses a winding mechanism for a concentric winding of an oil-immersed transformer and application of the winding mechanism. The winding mechanism comprises an iron core, wherein the top of the iron core is fixedly connected with a mercury box; an extrusion plate is connected into the mercury box in a sliding manner;the bottom of the extrusion plate is fixedly connected with a force storage rod; the side face of the force storage rod is in engaged connection with a bearing wheel; the surface of the bearing wheelis connected with a screw in a meshed mode; the side face of the screw is connected with a rotating shaft in a meshed mode; the side face of the force storage rod is slidably connected with an extrusion rod; the right side of the extrusion rod is rotatably connected with a driving wheel; a meshing rod is arranged on the side face of the driving wheel in a penetrating mode; and a conical shaft isarranged below the driving wheel. According to the winding mechanism for the concentric winding of the oil-immersed transformer and the application of the winding mechanism, through cooperative use ofthe mercury box and a cutting frame, the effect of automatically compensating leaked electric energy for a load when the magnetic flux leakage phenomenon affects work of the transformer is achieved.

Owner:江西广变电气有限公司

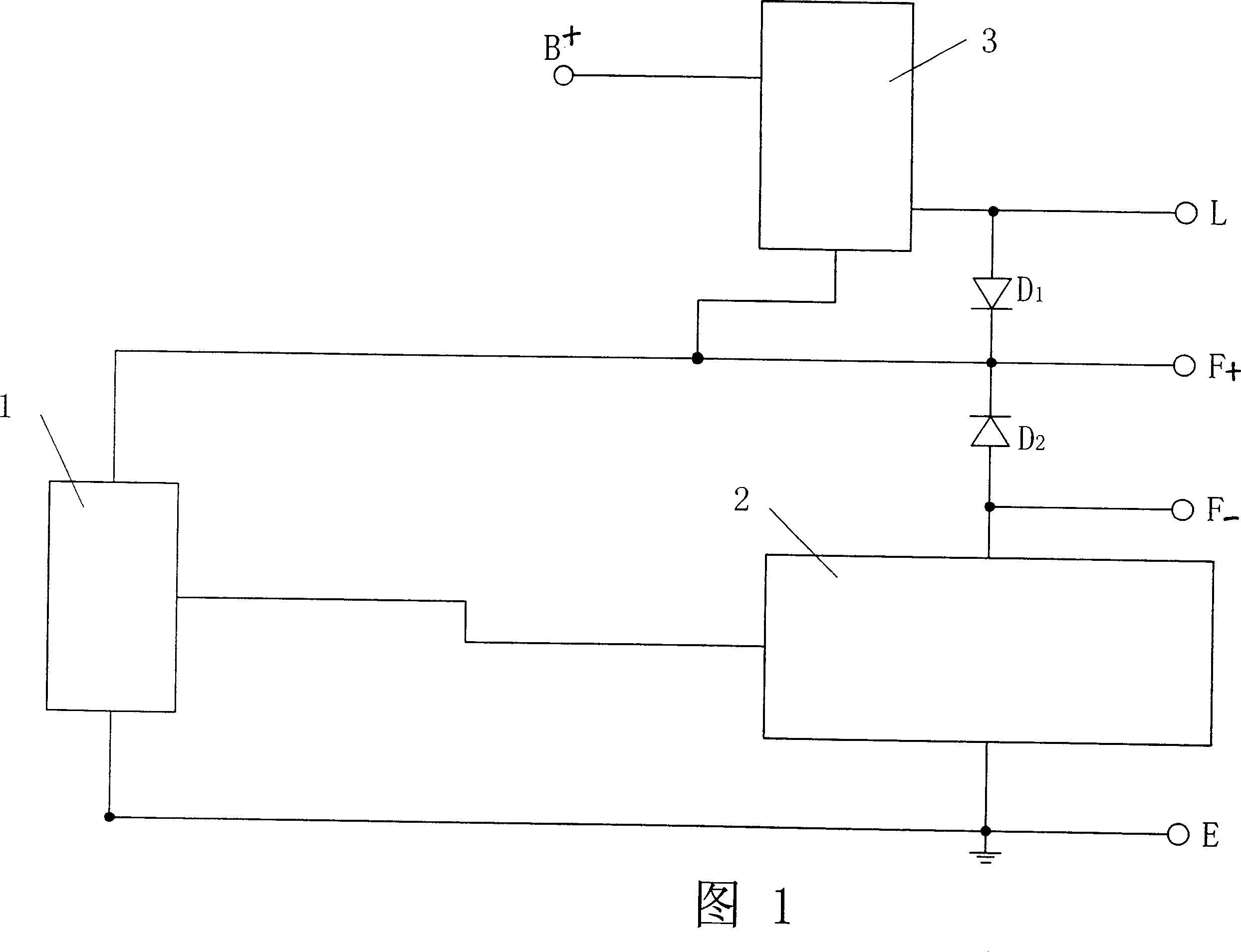

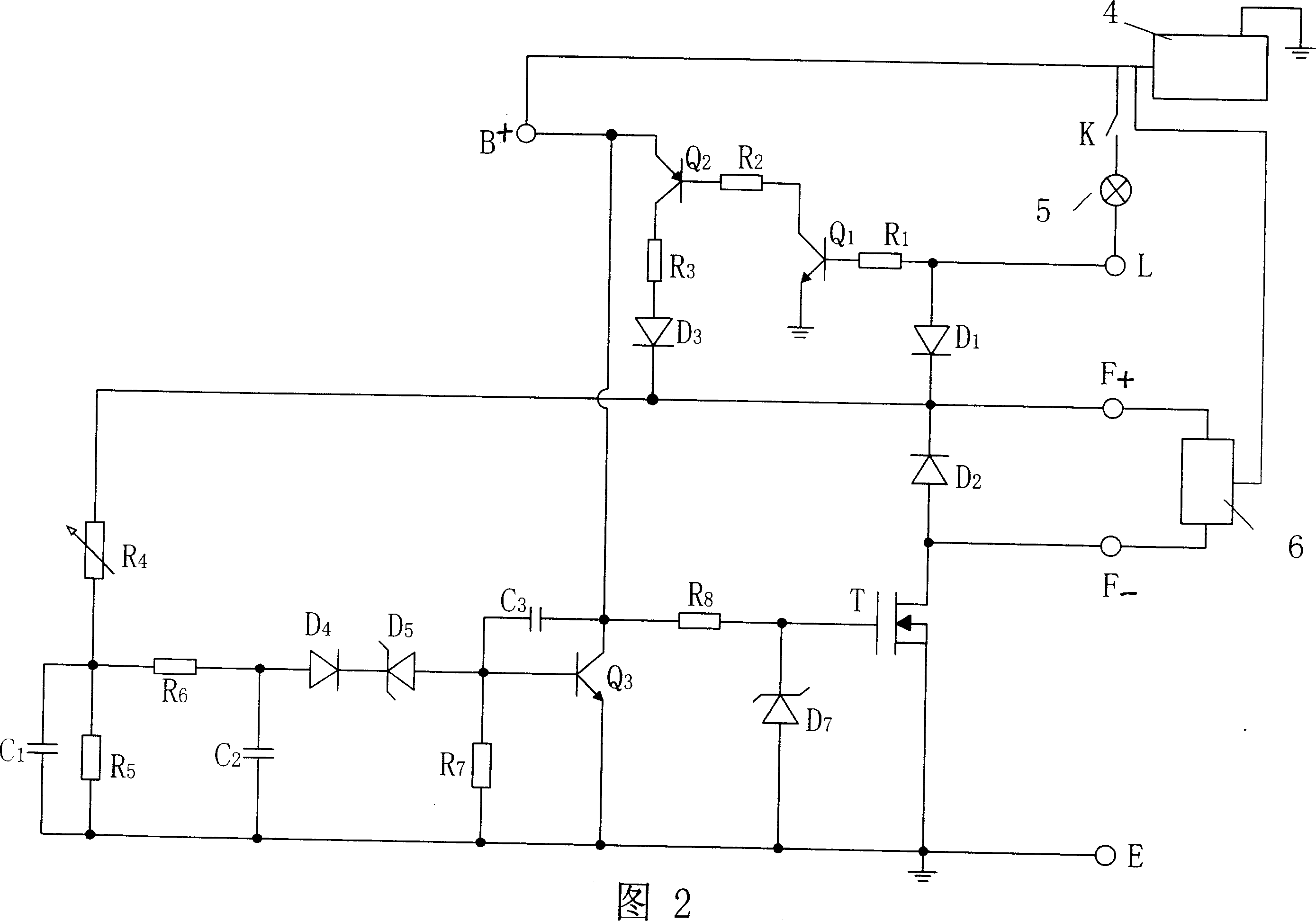

Voltage regulator for vehicle alternating current generator

InactiveCN1921290ASimple structureGuaranteed power generationBatteries circuit arrangementsElectric powerVoltage regulationAlternating current

The invention relates to a voltage adjuster of alternative-current generator of vehicle. Wherein, it comprises power anode, generating instruction lamp wiring terminal, generator winding wiring terminal, and ground end; the generating instruction lamp wiring terminal is connected to sampling circuit; the generator winding wiring terminal and the ground end have switch circuit between them; the output of sampling is connected to the input of switch circuit. The invention is characterized in that: there are current amplifiers between the instruction lamp wiring terminal, the power anode and the generator winding wiring terminal. The invention has simple structure and wide application.

Owner:锦州万得汽车电器电子科技有限公司

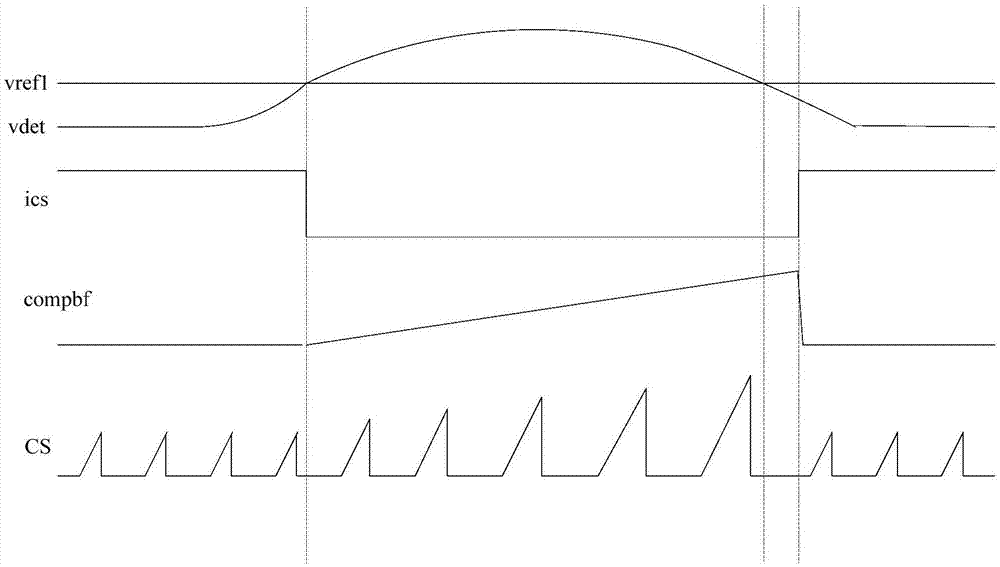

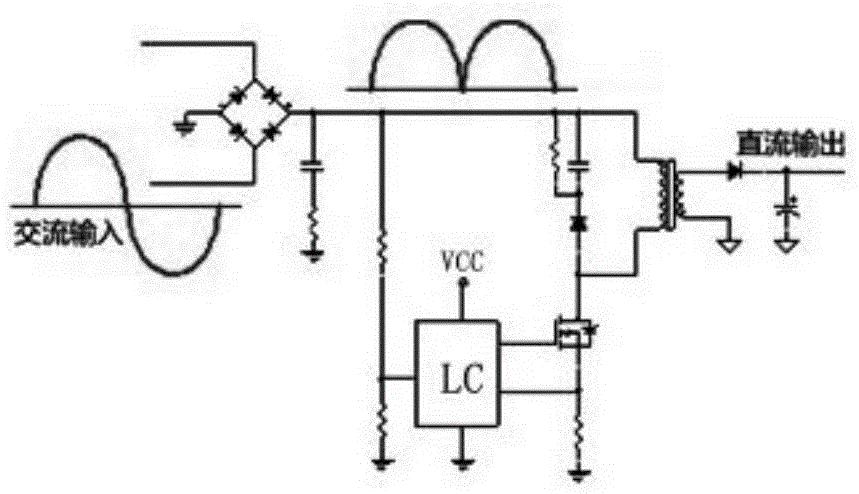

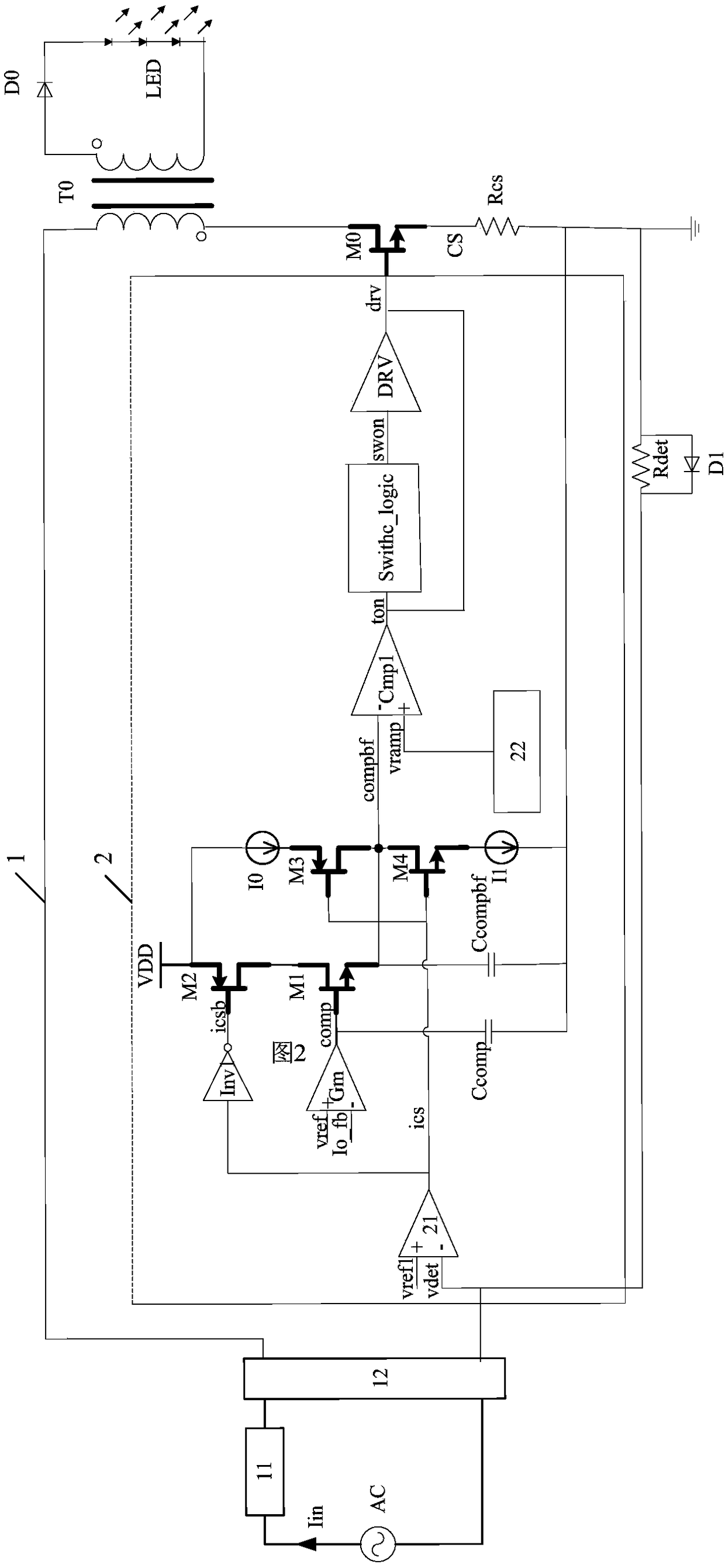

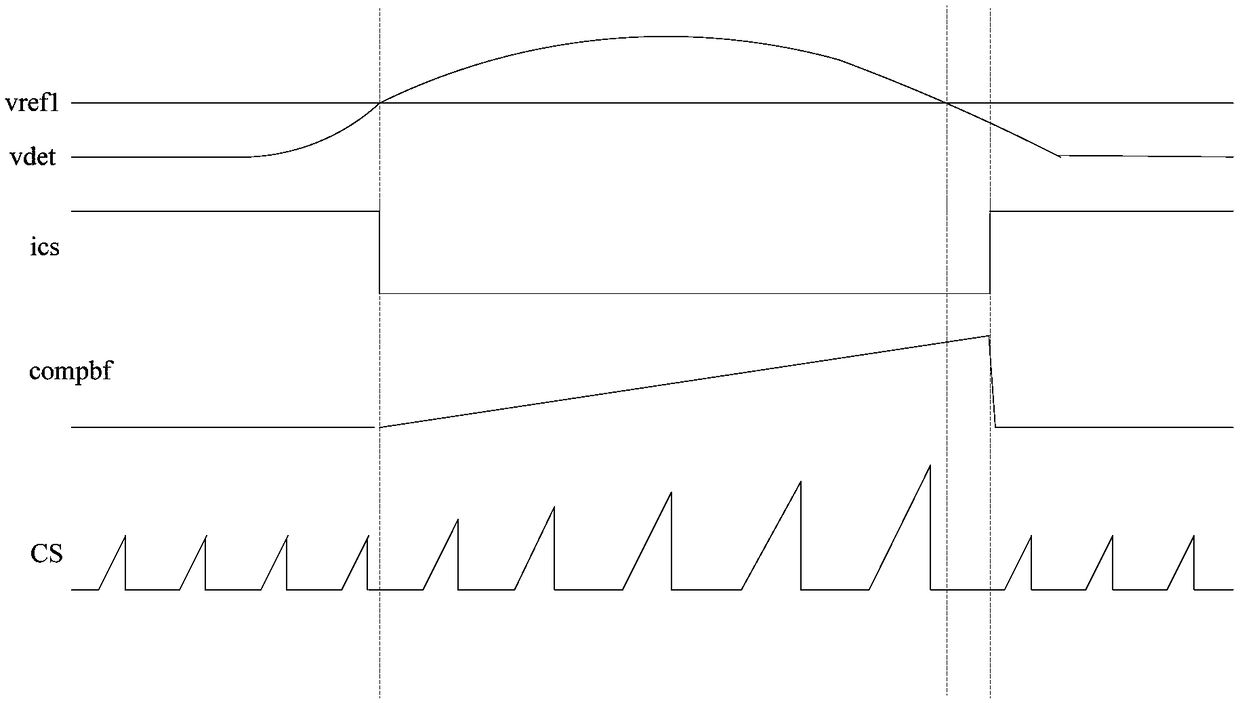

LED drive power source self-discharge method and circuit module applicable to alternating-current dimmers

ActiveCN105472806AIncrease input currentElectrical apparatusElectroluminescent light sourcesCurrent meterDimmer

The invention discloses an LED drive power source self-discharge method and a circuit module applicable to alternating-current dimmers. The LED drive power source self-discharge method applicable to alternating-current dimmers comprises the following steps: adjusting the switching frequency and duty ratio of a main switching device, and generating an additional load current on the input side of an LED drive circuit to meet the need of a dimmer for the holding current. According to the invention, the switching frequency of the main switching device is increased to enable the LED drive circuit to generate a certain current on the input side to meet the need of the dimmer, without increasing the power on the output side. The LED drive power source self-discharge method and the circuit module of the invention are applicable to a variety of power electronic topologies including boosting, bucking, forward activation and reverse activation.

Owner:JIANGSU LIGEN ELECTRIC POWER ELECTRONICS TECH CO LTD

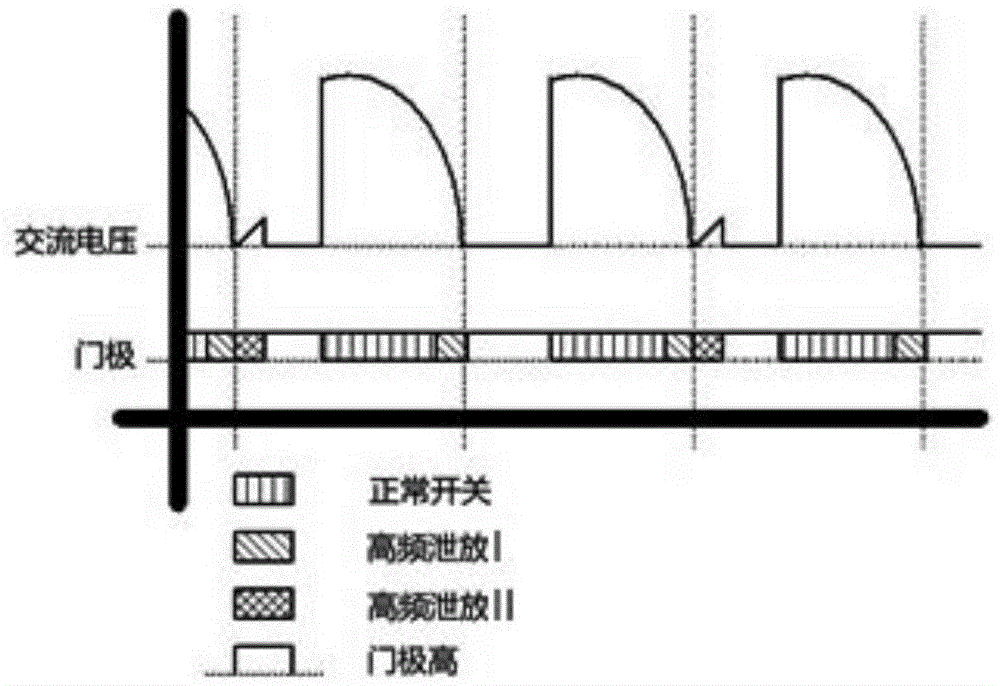

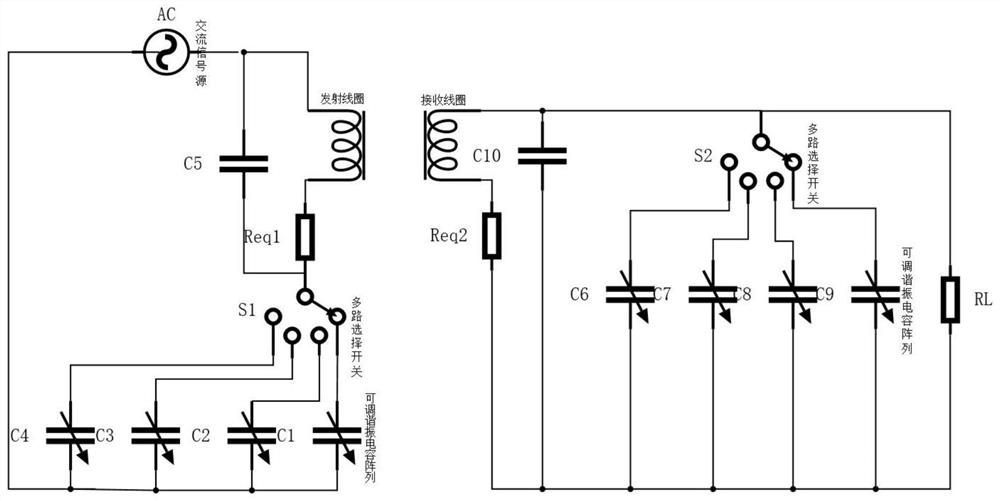

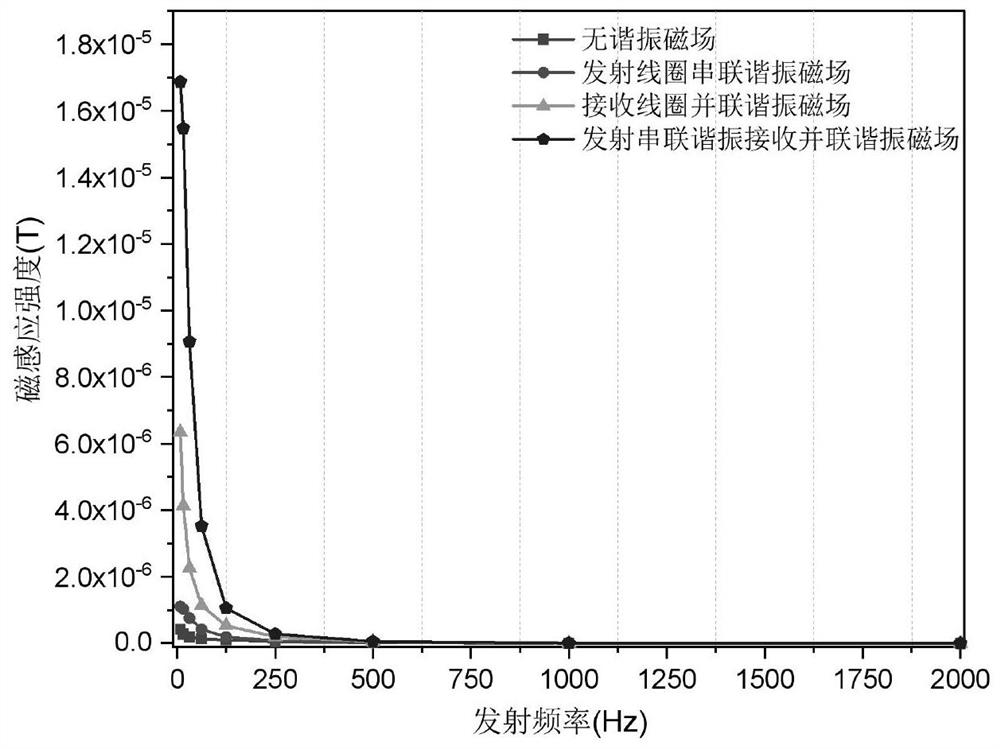

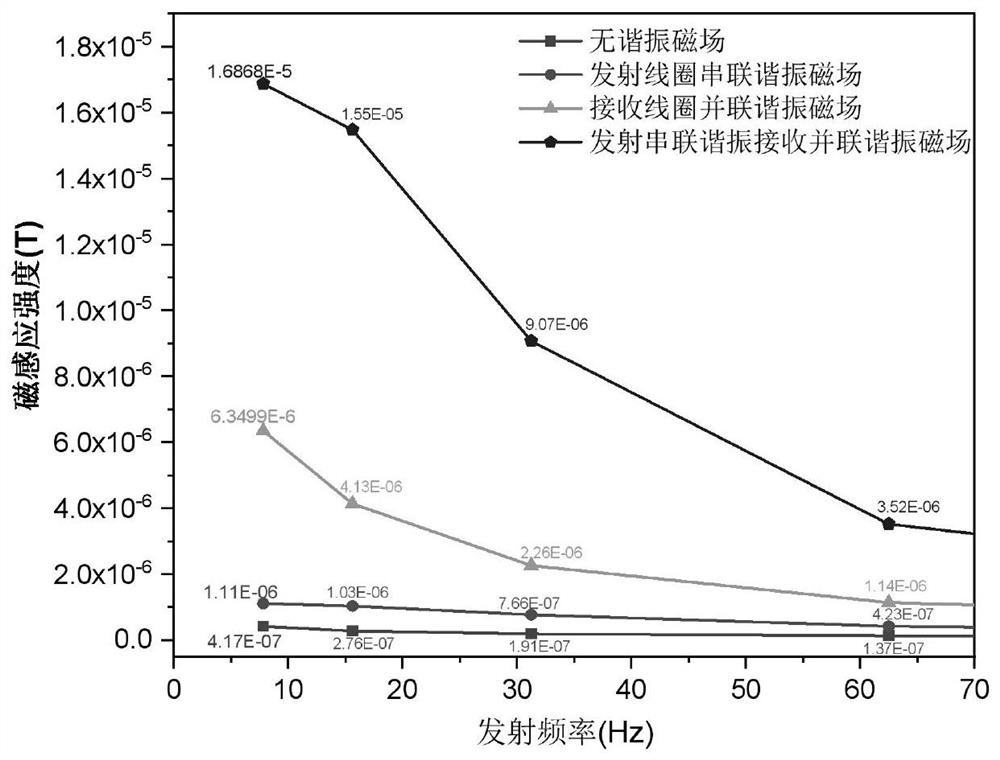

Optimization system and method for cross-well electromagnetic remote detection transceiving antenna

ActiveCN113109878AMake up for the reduced problemLaunch implementationRadiating elements structural formsDetection using electromagnetic wavesTransmitter coilCapacitance

The invention relates to the technical field of geophysical exploration and development, in particular to an optimization system and method for a cross-well electromagnetic remote detection transceiving antenna. The system comprises a transmitting antenna circuit and a receiving antenna circuit. The transmitting antenna circuit comprises a transmitting coil L1, and the transmitting coil L1 is connected in series with a first tunable capacitor array through a first multiplexer switch S1; the receiving antenna circuit comprises a receiving coil L2, and the receiving coil L2 is connected in parallel with a second tunable capacitor array through a second multiplexer switch S2. According to the invention, the inter-well detection distance can be effectively increased, and the inter-well long-distance exploration and development capability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

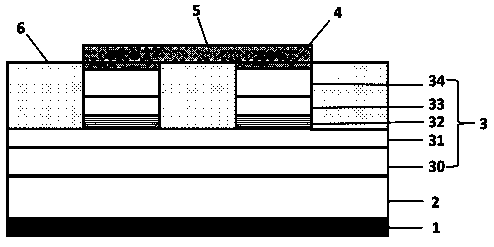

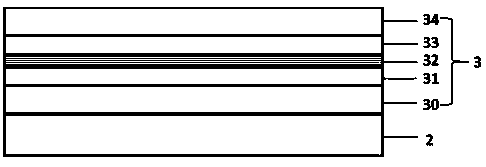

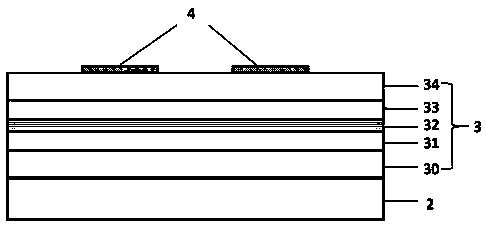

Multi-ridge type semiconductor laser capable of reducing inter-bridge crosstalk and preparation method thereof

InactiveCN109494567AReduce thermal crosstalkIncrease output powerOptical wave guidanceHigh resistanceLower limit

The invention discloses a multi-ridge type semiconductor laser capable of reducing inter-bridge crosstalk and a preparation method thereof. The multi-ridge type semiconductor laser comprises a substrate and an epitaxial structure including a lower limit layer, a lower waveguide layer, an active layer, an upper waveguide layer, an upper limit layer and the like. The epitaxial structure includes a plurality of ridge portions; each ridge portion reaches the space below the active layer from the top of the epitaxial layer; and gaps among the ridge portions are filled with high-resistance low-thermal-conductivity low-refractive-index materials, so that active regions of all ridge portions are isolated mutually. And then ohmic contact electrodes are arranged at the upper parts of the ridge portions in a one-to-one correspondence manner and are provided with top electrodes for connection. With the multi-ridge type semiconductor laser, the mutual independence of electricity and light between the ridge portions is realized; and the thermal crosstalk among the ridges is reduced effectively. Therefore, a solution idea is provided for obtaining a high power laser.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

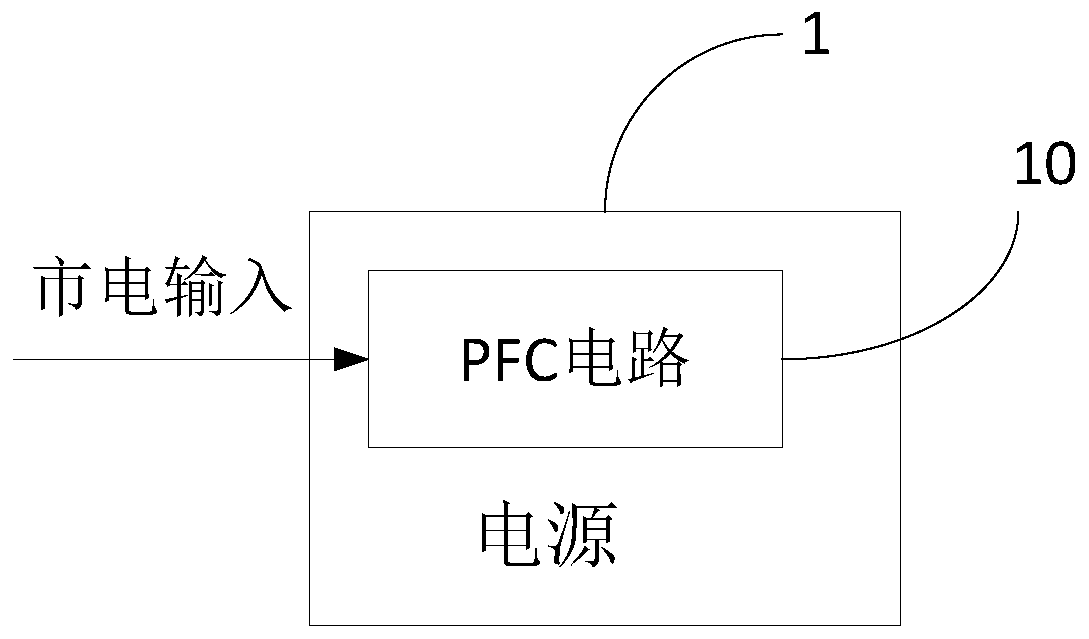

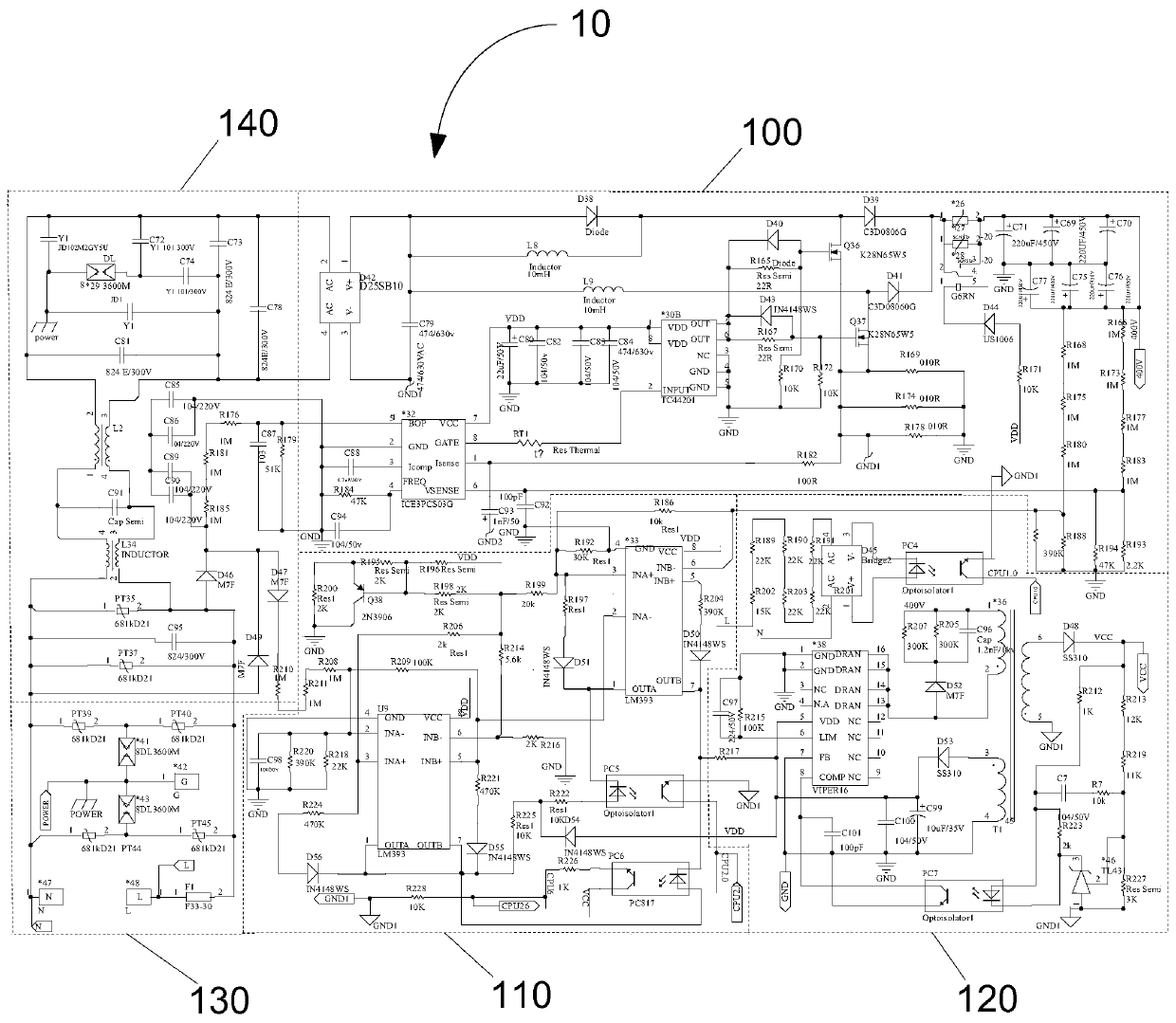

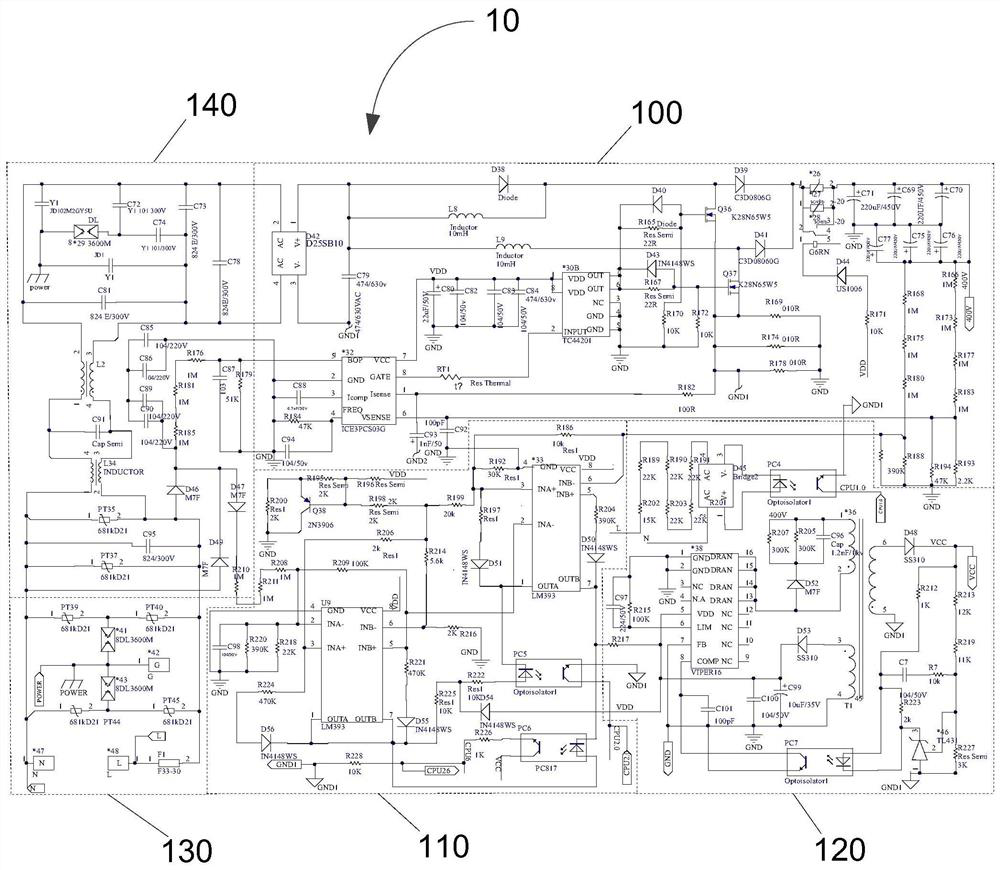

Power supply of 5G communication base station with high driving power

ActiveCN111564968AIncrease input currentImprove power factor valueEfficient power electronics conversionPower conversion systemsPower factorHemt circuits

The invention provides a power supply of a 5G communication base station with high driving power. The power supply for the 5G communication base station comprises a PFC circuit connected with power supply equipment, the PFC circuit comprises a power amplification module, the power amplification module drives two MOS transistors to be conducted through an IC chip so as to increase input current, and a power factor value is effectively improved on the premise of controlling cost.

Owner:SHENZHEN ADTEK TECH CO LTD

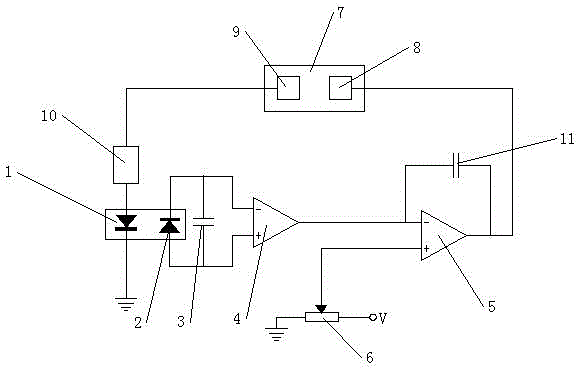

Laser power automatic control system

PendingCN106410594AIncrease input currentReduce input currentLaser detailsAutomatic controlCurrent limiting

The present invention provides a laser power automatic control system. The system comprises a PIN tube configured to detect the backlight of the laser, wherein the PIN tube is installed at the side of the laser and is connected in parallel with an operational amplifier; the output end of the operational amplifier is connected with the negative end of a comparator, and the positive end of the comparator is connected with a direct current reference voltage branch which is a current-limiting resistor arranged between the grounding and the high level with reference voltage; the center tap of the current-limiting resistor is connected with the positive end of the comparator, and the output end of the comparator is connected with a central control unit; and the laser is further connected with a switch power supply convertor, the central control unit includes an ADC convertor and a DAC convertor, and the pin of the DAC convertor of the central control unit is connected with the feedback voltage pin of the switch power supply convertor. The laser power automatic control system is simple in structure and can automatically control the power of the laser to allow the output power of the laser to keep basic constant.

Owner:JIANGSU JUNLONG ELECTRIC TECH

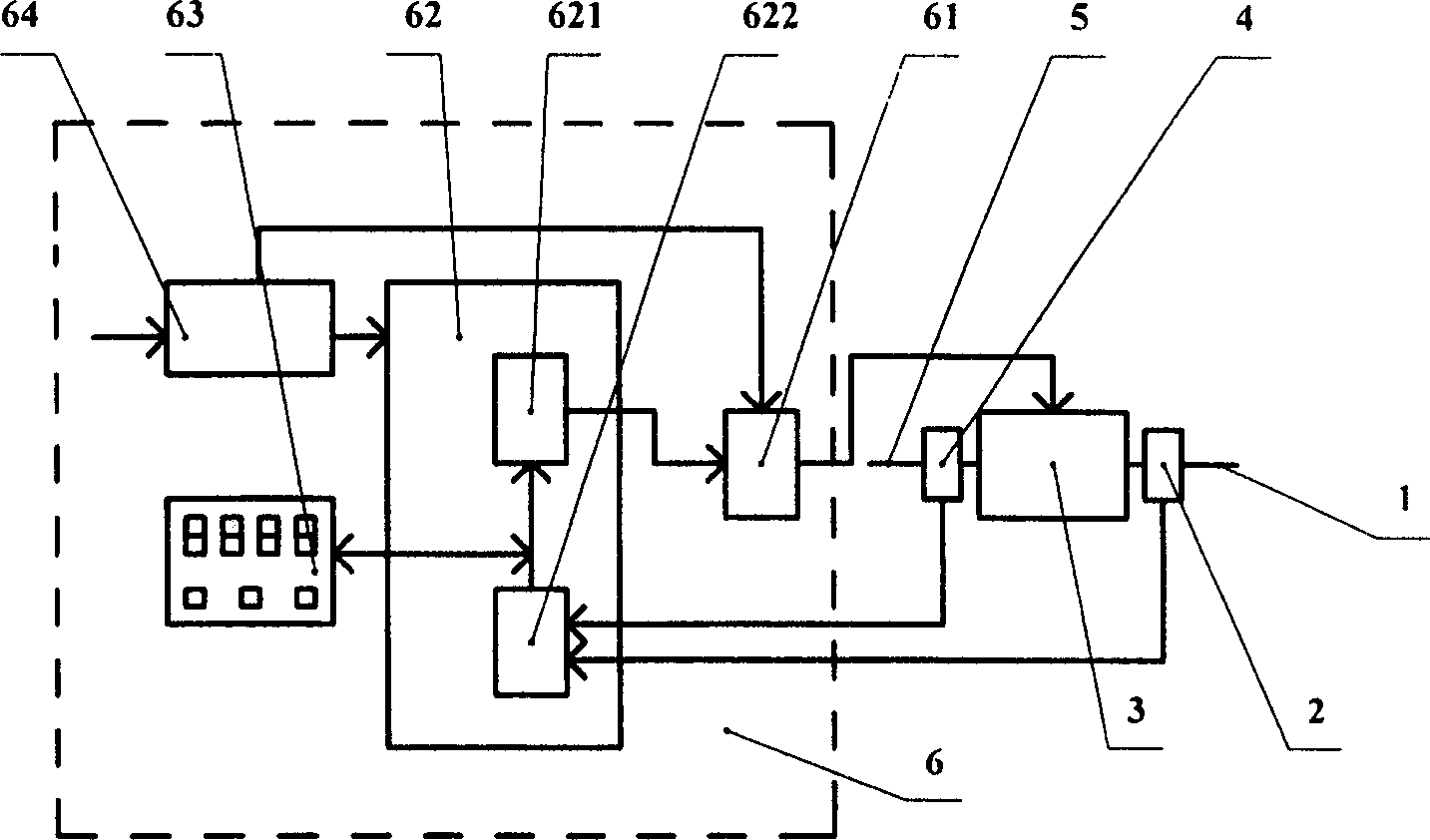

Magnetic powder clutched stepless speed regulator

InactiveCN1805267AIncrease input currentReduce input currentElectric motor controlDynamo-electric brake controlAudio power amplifierEngineering

The invention relates to a magnetic powder clutch step-less speed regulation device, which comprises a power input axle, a speed-detecting sensor, a magnetic powder clutch, a power output axle, and a control part. Wherein, the power input and output axles are individually mounted at two sides of magnetic powder clutch, while they are mounted with speed-detecting sensors; the control part comprises a power amplifier, a control unit, and a display and button box; the magnetic powder clutch is connected to the power amplifier; the speed-detecting sensor is connected to the control unit; the control unit via using the speed-detecting sensor to detect the rotational speeds of power input and output axles to set the input current of magnetic powder clutch to adjust the output torque of magnetic powder clutch, to step-less regulate the rotational speed of power output axle.

Owner:田国荣

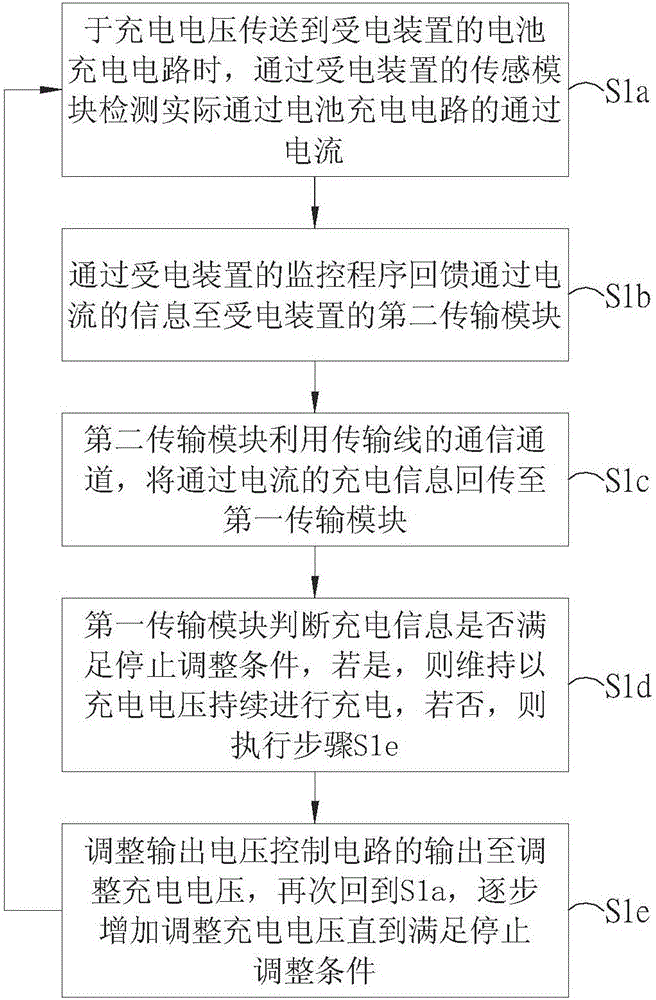

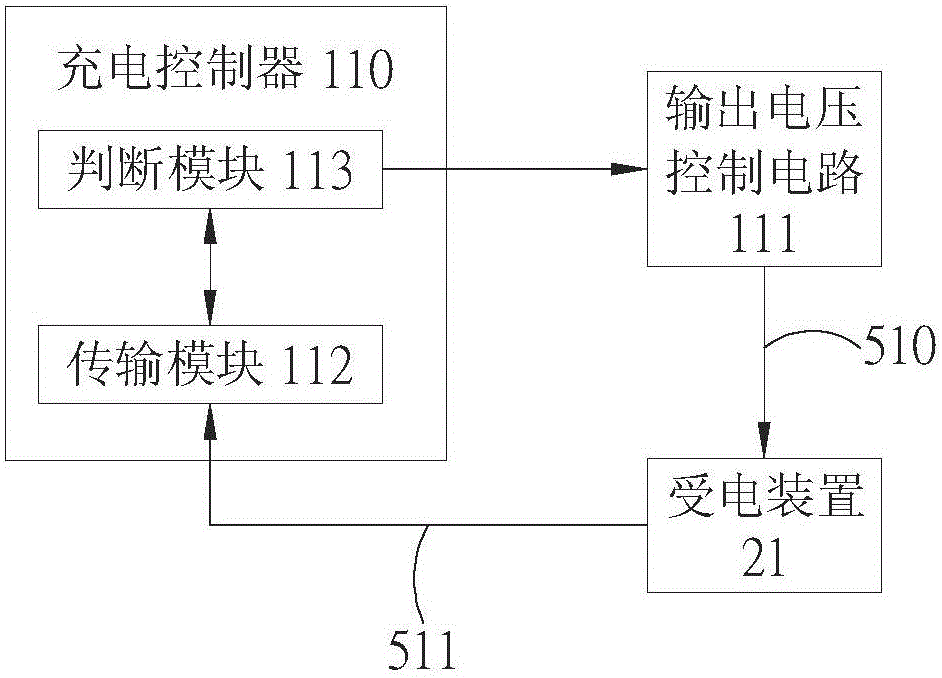

Charging method, charging controller and charging system

InactiveCN106486715AIncrease input currentShorten the timeSecondary cells charging/dischargingElectric powerElectricityBattery charge

Owner:NUVOTON

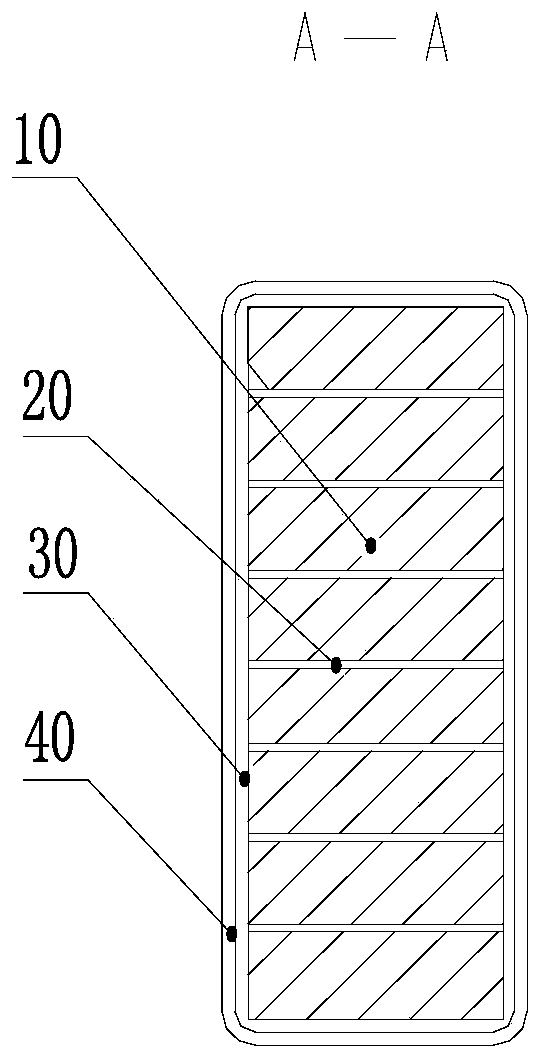

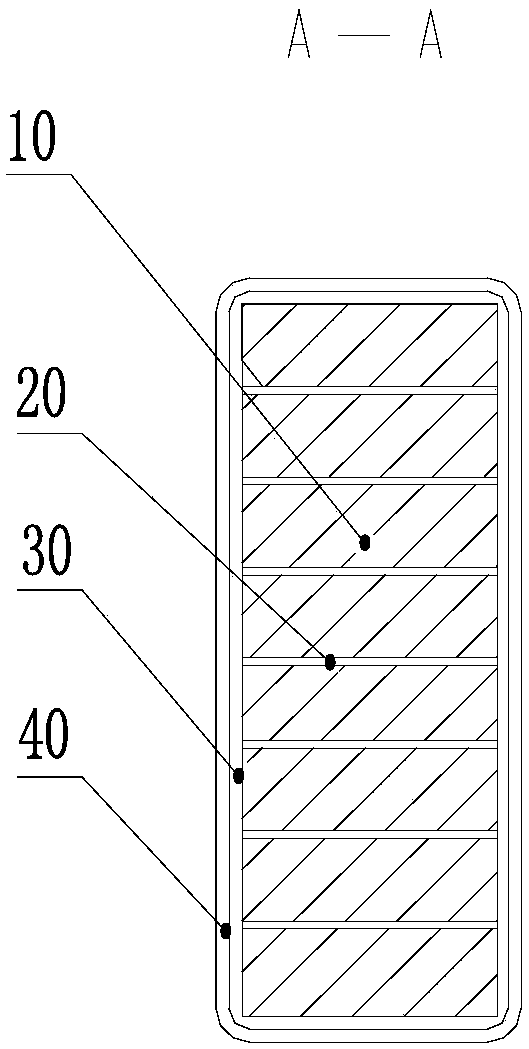

Stator Coil Insulation Integrated Method

ActiveCN108448770BIncrease input currentIncrease powerWindings insulation shape/form/constructionApplying solid insulationElectric machineStator coil

The invention provides a stator coil of a direct current motor and a stator coil insulation integration method, and relates to the technical field of the direct current motor. The stator coil of the direct current motor comprises multiple numbers of turns of buses, insulating paper bands and a silicone rubber insulating band, wherein the multiple numbers of turns of buses are configured into the coil appearance of the stator coil of the direct current motor; the insulating paper bands are placed between adjacent two turns of buses in a cushion manner; and the outer sides of multiple numbers ofturns of buses are bundled with the silicone rubber insulating band. The stator coil insulation integration method is used for manufacturing the stator coil of the direct current motor; and by virtueof the stator coil of the direct current motor, the motor input current can be highly increased without changing the motor appearance, so that the motor can output higher power and torsion, and the service life of the motor is not shortened.

Owner:NEW UNITED RAIL TRANSIT TECH

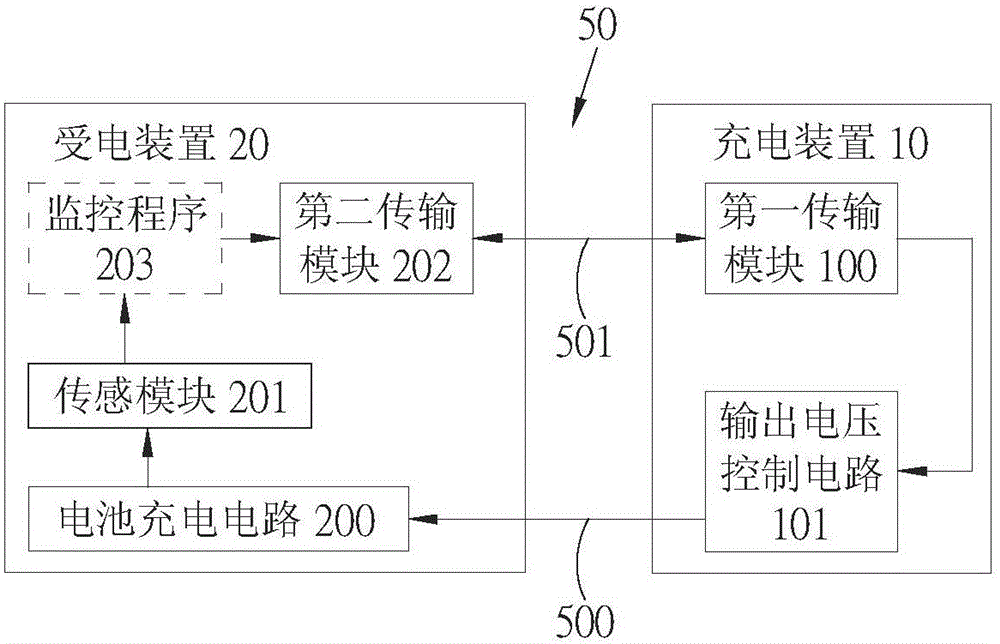

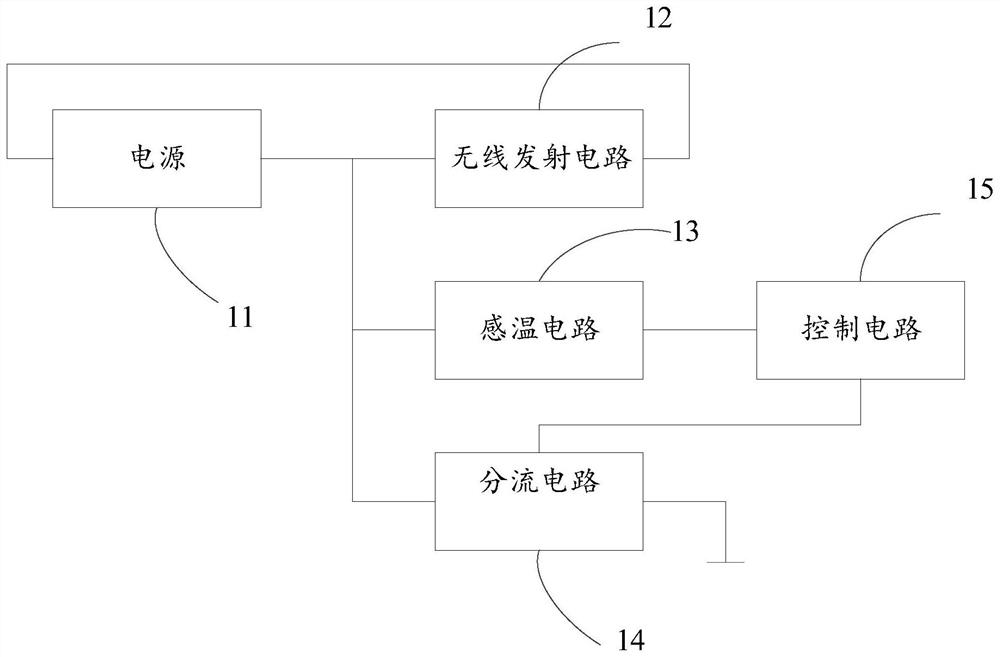

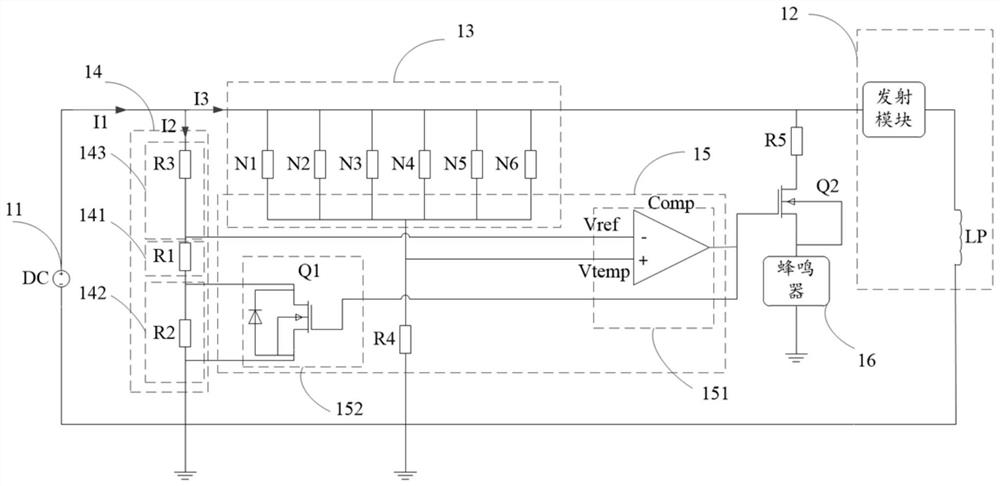

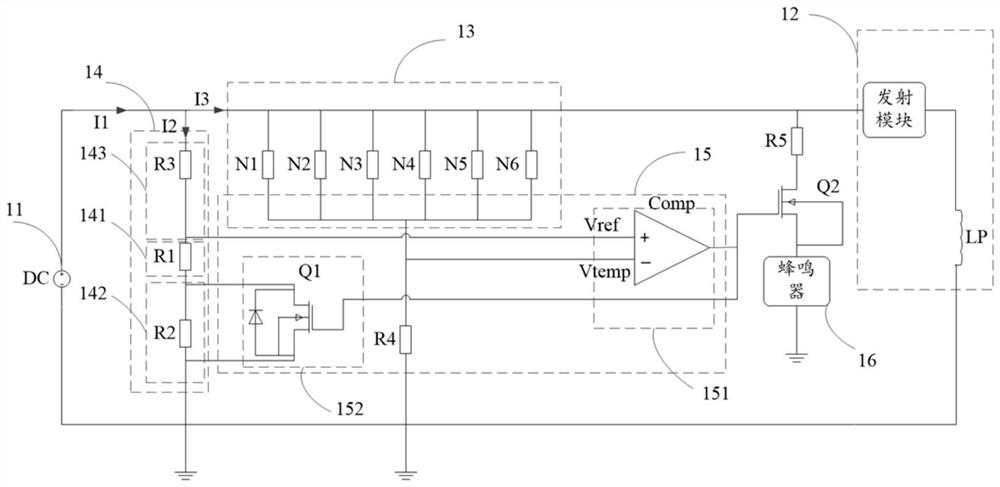

A wireless charging control circuit and wireless charging device

ActiveCN111030267BIncrease input currentReduce input currentBatteries circuit arrangementsElectric powerTelecommunicationsWireless transmission

The present invention provides a wireless charging control circuit and a wireless charging device, including: a power supply and a wireless transmitting circuit, the first end of the wireless transmitting circuit is connected to the input terminal of the power supply, the second end of the wireless transmitting circuit is connected to the grounding terminal of the power supply, and the wireless The charging control circuit also includes: a temperature sensing circuit, the temperature sensing circuit includes at least one thermistor, the first end of the temperature sensing circuit is connected to the power input end; a shunt circuit, the first end of the shunt circuit is connected to the power input end, and the shunt circuit The second end of the control circuit is grounded; the control circuit, the first end of the control circuit is connected to the second end of the temperature sensing circuit, the second end of the control circuit is connected to the third end of the shunt circuit; the control circuit is used for the resistance of the temperature sensing circuit When the value is greater than the first target resistance value or less than the second target resistance value, the resistance of the shunt circuit is adjusted to increase the input current of the shunt circuit and decrease the current of the wireless transmitting circuit. The embodiments of the present invention can improve the safety of the wireless charging device.

Owner:VIVO MOBILE COMM CO LTD

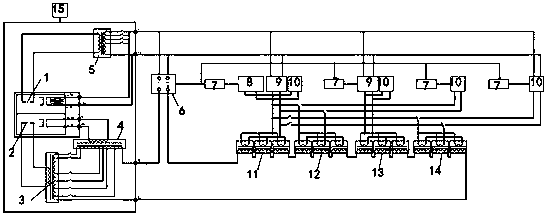

Device for 1600 A electric energy meter detection based on parallel CTs

InactiveCN110275128AFulfilling verification requirementsIncrease input currentElectrical measurementsTransformerVoltage source

The invention discloses a device for 1600 A electric energy meter detection based on parallel CTs. The device includes a computer, a voltage source, a current source, a booster, a first converter, a second converter, a standard meter, an error calculation unit, a detected electric energy meter and a first transformer, a second transformer, a third transformer and a fourth transformer which are connected in parallel. The detected electric energy meter includes a first calibrated meter, a second calibrated meter and a third calibrated meter which are connected in parallel. The device of the invention adopts a mode of parallel CTs, that is, the first transformer, the second transformer, the third transformer and the fourth transformer are connected in parallel, to increase output current without increasing input current. The maximum output current of the device is 1600 A, and the device can realize verification requirements of multiple different types and different meters.

Owner:周晓辉

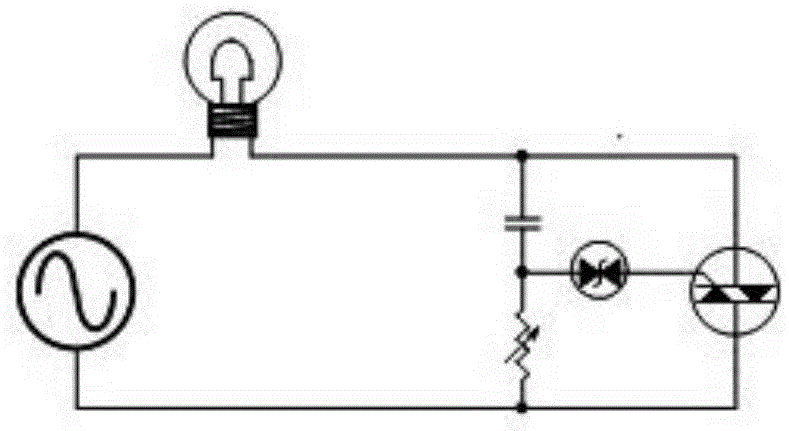

A LED driver chip and circuit for improving compatibility with thyristor dimmer

ActiveCN107046748BLow costIncrease input currentElectrical apparatusElectroluminescent light sourcesCapacitanceSilicon-controlled rectifier

The present invention provides an LED drive chip and circuit that improves the compatibility with a thyristor dimmer, the chip is connected to a peripheral circuit including a thyristor dimmer and an input current sampling resistor, including a hysteresis comparator, a Transconductance module, a first NMOS transistor, a first PMOS transistor, a second PMOS transistor, a second NMOS transistor, a compensation capacitor, an isolation capacitor, a first comparator, and a driving module. The present invention does not increase the input current by directly pulling down the bus voltage Vin, and the increased input current is still part of the output current, so compared with the prior art shown in Figure 1, the efficiency is significantly improved, especially when the output current is small In addition, the present invention does not need to use high-voltage MOS tubes and does not need to add additional chip pins, thereby reducing costs.

Owner:SHANGHAI ORIENT CHIP TECH CO LTD

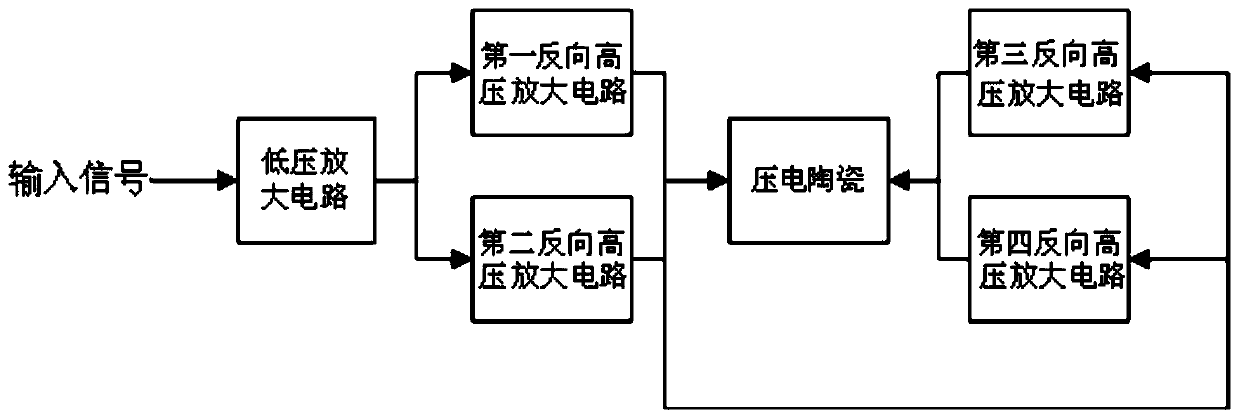

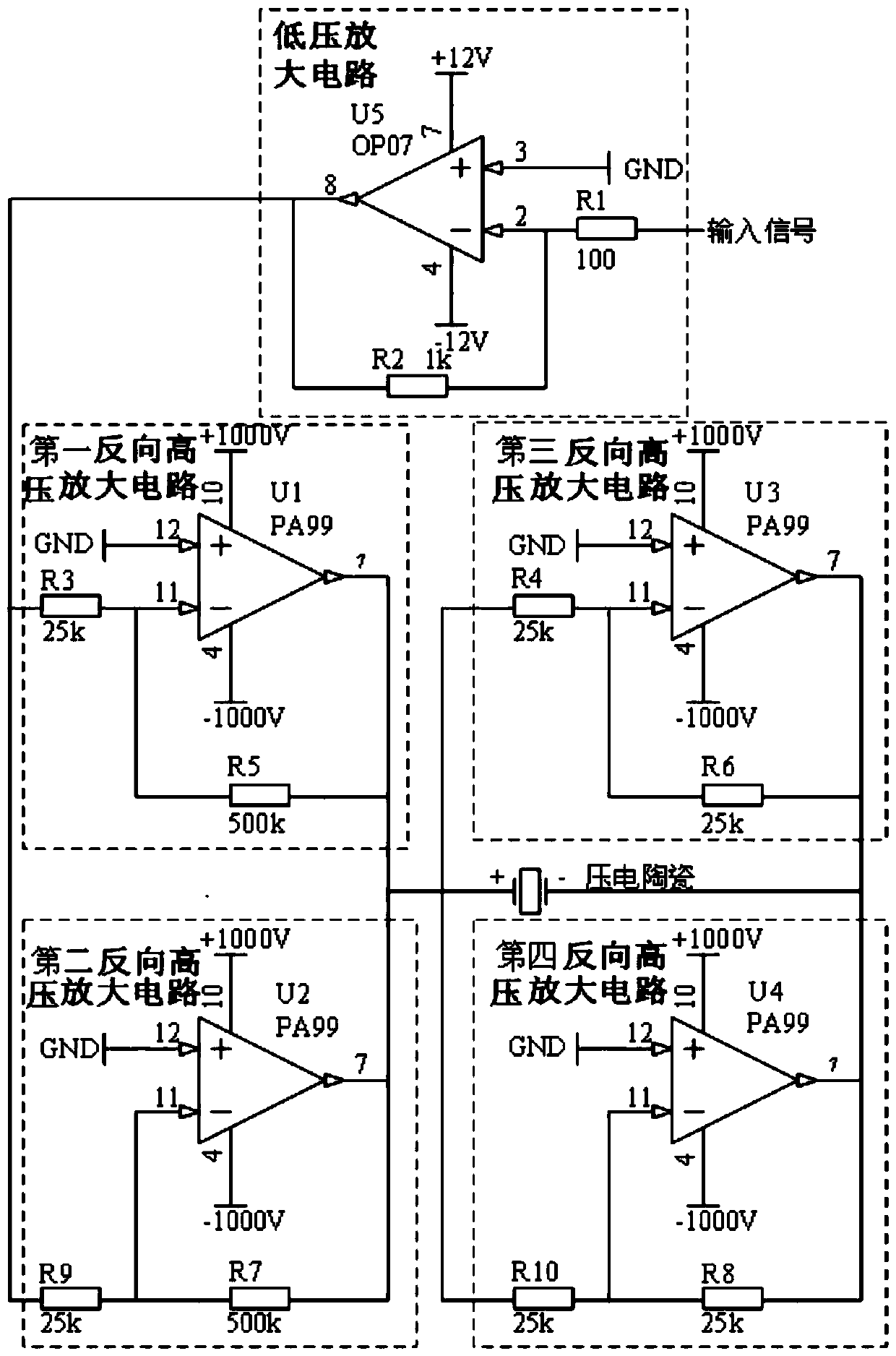

A piezoelectric ceramic driving device and driving method

InactiveCN107508489BReduce thermal power consumptionIncrease input currentPiezoelectric/electrostriction/magnetostriction machinesElectricityAudio power amplifier

The invention discloses a piezoelectric ceramic driving device. The piezoelectric ceramics driving device comprises a low voltage amplification circuit and four reverse high voltage operation amplification circuits. The output of the low voltage amplification circuit is connected to input terminals of a first reverse high voltage amplification circuit and a second reverse high voltage amplification circuit. The output terminals of the first reverse high voltage amplification circuit and the second reverse high voltage amplification circuit are connected to a positive electrode of the piezoelectric ceramic input terminals of a third reverse high voltage amplification circuit and a fourth high voltage amplification circuit. The output terminals of the third reverse high voltage amplification circuit and the fourth reverse high voltage amplification circuit are connected to the negative electrode of the piezoelectric ceramic. An input signal flows out through amplification by the low voltage amplification circuit and is inputted into the first reverse high voltage amplification circuit and the second reverse high voltage amplification circuit to go through reverse high voltage amplification and then is inputted into the positive electrode of the piezoelectric ceramic and the input terminals of the third reverse high voltage amplification circuit and the fourth reverse high voltage amplification circuit to go through reverse high voltage amplification and then the input signal is inputted into the negative electrode of the piezoelectric ceramic. As a result, amplified signals which are amplified for hundreds of times are formed on two sides of the piezoelectric ceramics. The piezoelectric ceramics driving device and driving method adopt multiple high voltage operation amplifiers which are connected in parallel to perform output in order to improve output current and reduce the amount of heat generated by each high voltage operation amplifier.

Owner:TIANJIN UNIV

Stator coil of direct current motor and stator coil insulation integration method

ActiveCN108448770AIncrease input currentIncrease powerWindings insulation shape/form/constructionApplying solid insulationElectric machineStator coil

The invention provides a stator coil of a direct current motor and a stator coil insulation integration method, and relates to the technical field of the direct current motor. The stator coil of the direct current motor comprises multiple numbers of turns of buses, insulating paper bands and a silicone rubber insulating band, wherein the multiple numbers of turns of buses are configured into the coil appearance of the stator coil of the direct current motor; the insulating paper bands are placed between adjacent two turns of buses in a cushion manner; and the outer sides of multiple numbers ofturns of buses are bundled with the silicone rubber insulating band. The stator coil insulation integration method is used for manufacturing the stator coil of the direct current motor; and by virtueof the stator coil of the direct current motor, the motor input current can be highly increased without changing the motor appearance, so that the motor can output higher power and torsion, and the service life of the motor is not shortened.

Owner:NEW UNITED RAIL TRANSIT TECH

Automobile exhaust emission purification device convenient to disassemble and assemble

InactiveCN112746887AEasy to fixReduce pollutionInternal combustion piston enginesExhaust apparatusDouble filtrationStructural engineering

The invention discloses an automobile exhaust emission purification device convenient to disassemble and assemble, and belongs to the field of automobiles. The automobile exhaust emission purification device convenient to disassemble and assemble comprises an exhaust pipe and a purification pipe, wherein external threads are arranged on the outer wall of the left end of the purification pipe, the outer wall of the external threads is sleeved with a threaded sleeve, the left end of the purification pipe is fixedly connected with a plurality of trapezoidal clamping plates distributed circumferentially, and a containing groove is formed in the inner wall of the right end of the purification pipe; and an annular sleeve is arranged in the containing groove, a first filter plate and a second filter plate are fixedly installed in the annular sleeve, the right end of the purification pipe is rotationally connected with an exhaust sleeve matched with the left end of the purification pipe, the exhaust sleeve is connected with the purification pipe through a positioning mechanism, and a power-assisted exhaust device is arranged in the exhaust sleeve. According to the invention, tail gas of an automobile is purified through the double filter plates, so that a good purification effect is achieved; and the exhaust capacity of the exhaust pipe can be effectively improved through the arranged power-assisted exhaust device, so that resistance of the filter plates to the exhaust pipe is reduced.

Owner:付信娟

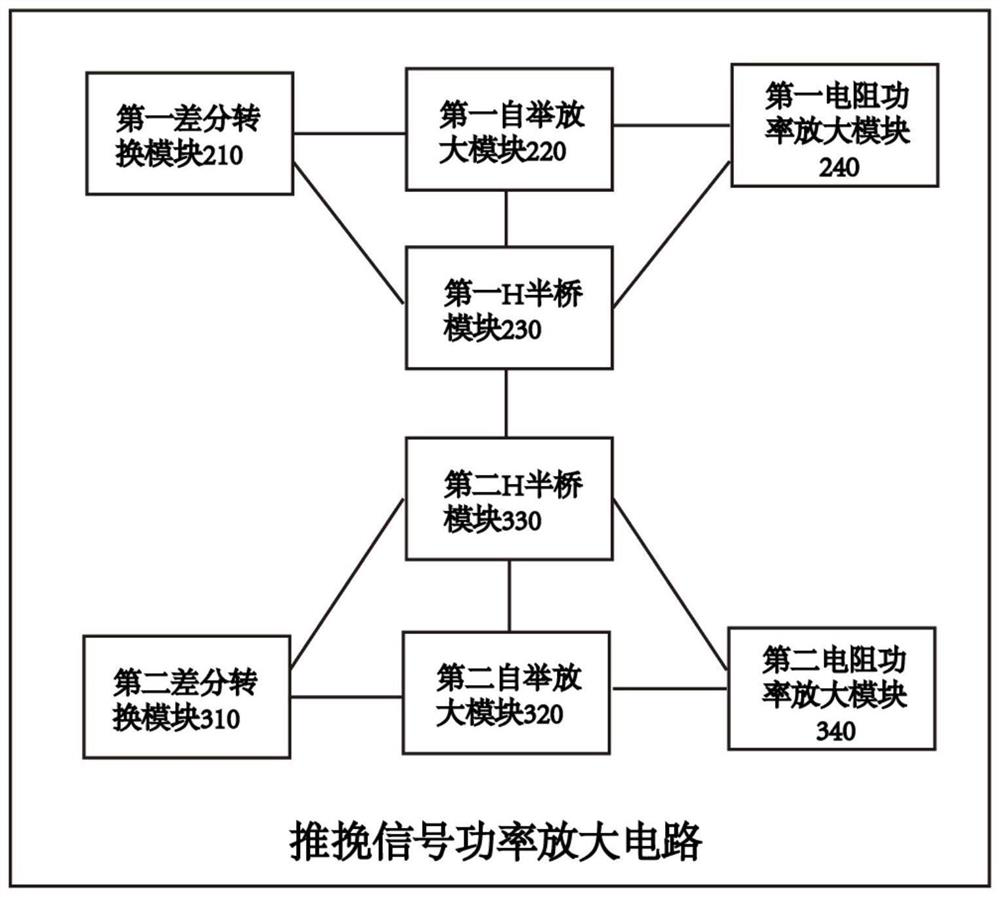

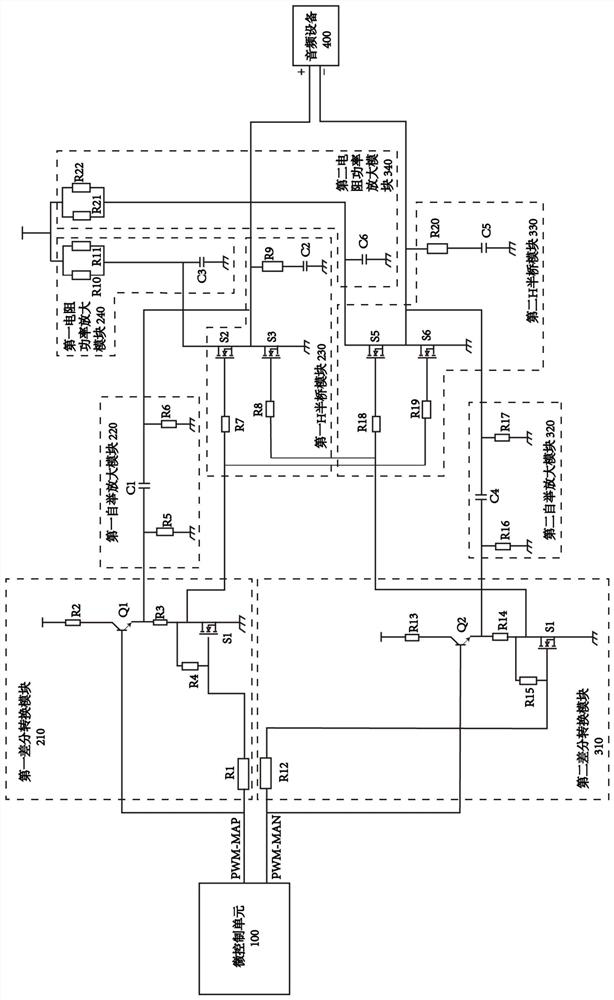

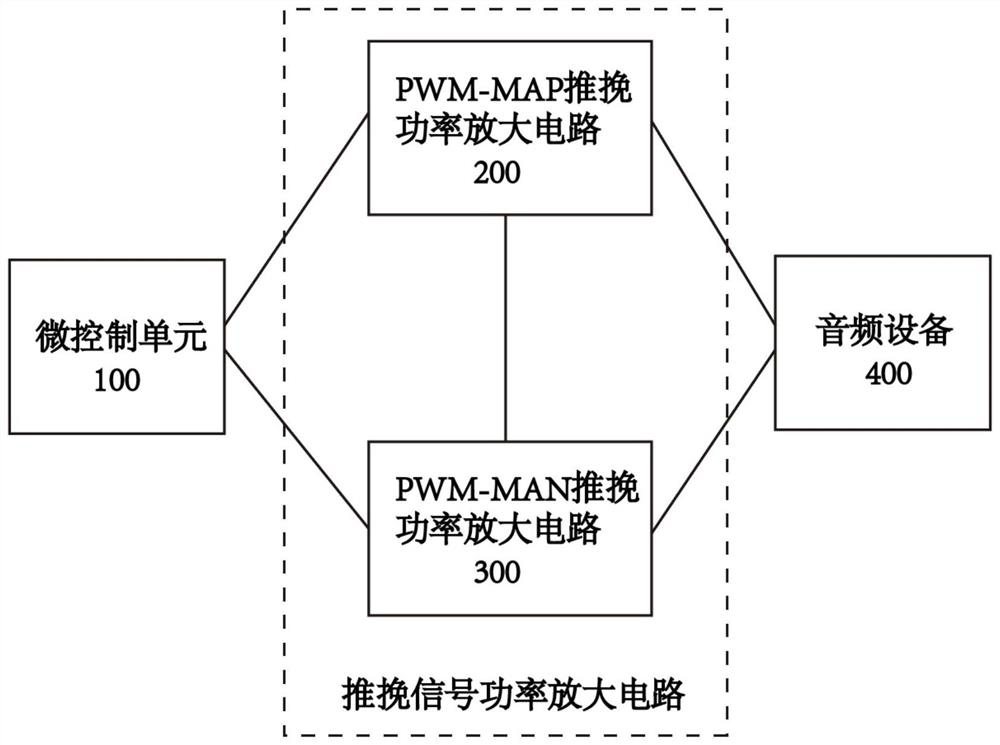

Push-pull signal power amplification circuit and system

PendingCN114157246AIncrease signal output powerStrong anti-noise abilityPush-pull amplifiersPhase-splittersTelecommunicationsAudio equipment

The invention relates to a push-pull signal power amplification circuit and system. The push-pull signal power amplification circuit comprises a PWM-MAP push-pull power amplification circuit and a PWM-MAN push-pull power amplification circuit. The PWM-MAP push-pull power amplification circuit comprises a first differential conversion module, a first bootstrap amplification module electrically connected with the first differential conversion module, a first H half-bridge module electrically connected with the first differential conversion module and the first bootstrap amplification module, and a first resistance power amplification module; the PWM-MAN push-pull power amplification circuit comprises a second differential conversion module, a second bootstrap amplification module electrically connected with the second differential conversion module, a second H half-bridge module electrically connected with the second differential conversion module and the second bootstrap amplification module, and a second resistance power amplification module; therefore, the system does not need to depend on an inherent circuit of a traditional power amplifier, power amplification can be carried out on the PWM push-pull signal, the noise interference resistance is high, and the sound quality requirement for amplification of vehicle-mounted audio equipment can be met.

Owner:智新科技股份有限公司

An Embedded Dual Electron Beam Terahertz Back-wave Oscillator

ActiveCN110416041BReduce distanceIncrease output powerTravelling-wave tubesTransit-tube circuit elementsElectron injectionGrating

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

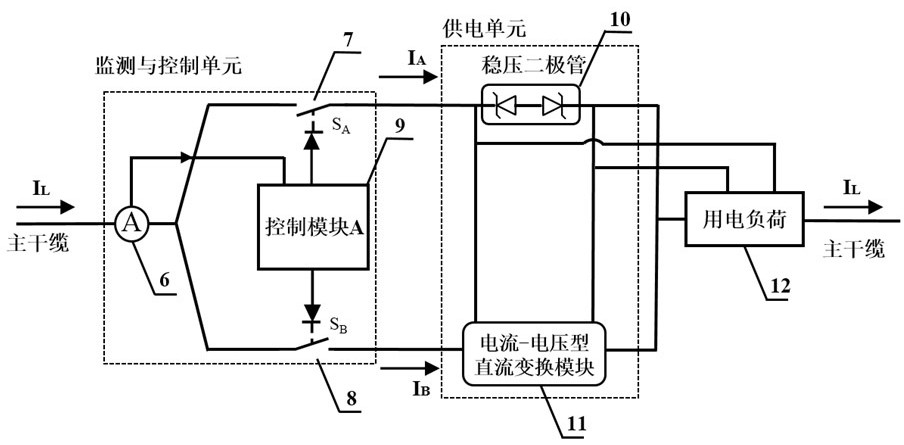

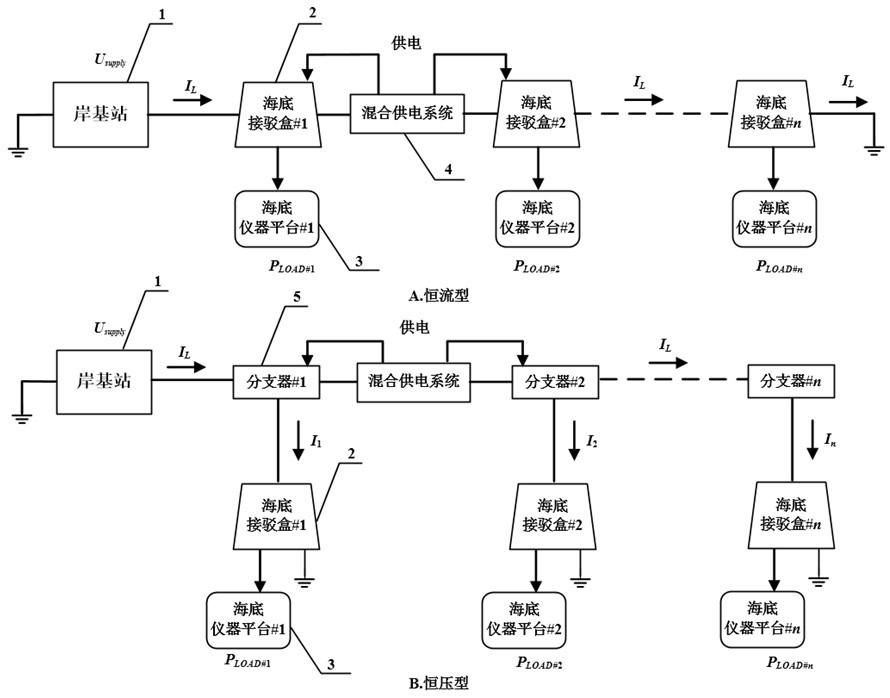

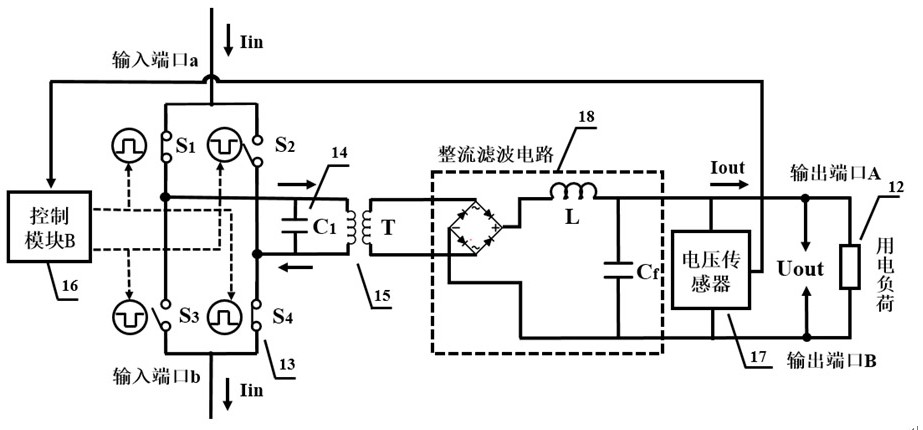

Constant voltage and constant current hybrid power supply system for submarine observation network

ActiveCN108649565BExtended service lifeReal-time monitoring of input currentAc network circuit arrangementsCurrent transducerCurrent range

Owner:TONGJI UNIV

A power supply for high driving power 5G communication base stations

ActiveCN111564968BIncrease input currentImprove power factor valueEfficient power electronics conversionPower conversion systemsPower factorHemt circuits

The invention proposes a power supply for a 5G communication base station with high driving power. The power supply for the 5G communication base station includes a PFC circuit connected to the power supply equipment. The PFC circuit includes a power amplifier module, and the power amplifier module drives two MOS transistors through the IC chip to increase the input current. Effectively improve the power factor value under the premise of low cost.

Owner:深圳市鸿星创新材料有限公司

Electronic transformer with peak current control for low power led lamps

ActiveCN111278195BSave time at workFlickering does not occurDc-dc conversionElectric variable regulationPeak currentControl theory

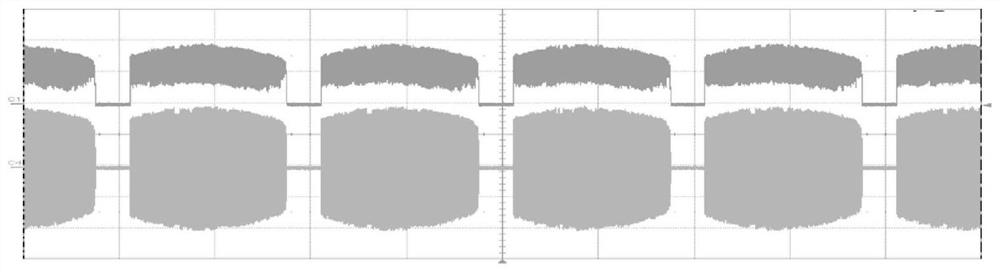

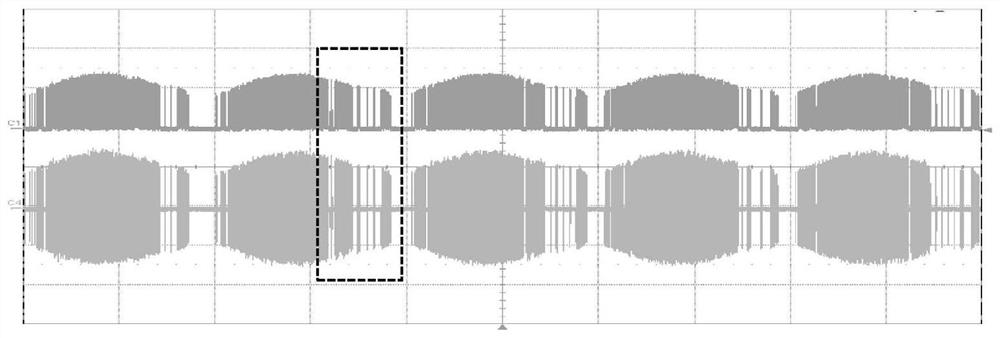

The present disclosure provides an electronic transformer and LED lamp system with peak current control for low power LED lamps. The electronic transformer (1) is configured to provide output power for operating the LED lamp (2), wherein the electronic transformer (1) comprises: voltage input ports (P1, P2) configured to connect the electronic transformer (1) to an AC power source ), a rectifier circuit (3) for converting AC power received at the voltage input ports (P1, P2) into DC power, and a boost circuit (3) comprising a boost circuit configured to generate a bus voltage (V-bus) and configured to switch boost A first stage (10) of an on / off switch circuit of the voltage circuit, wherein the switch circuit is configured to disconnect the boost circuit if the bus voltage (V-bus) is higher than a first threshold (V-bus-H) , if the bus voltage (V-bus) is lower than the second threshold (V-bus-L), the boost circuit is turned on.

Owner:LEDVANCE GMBH

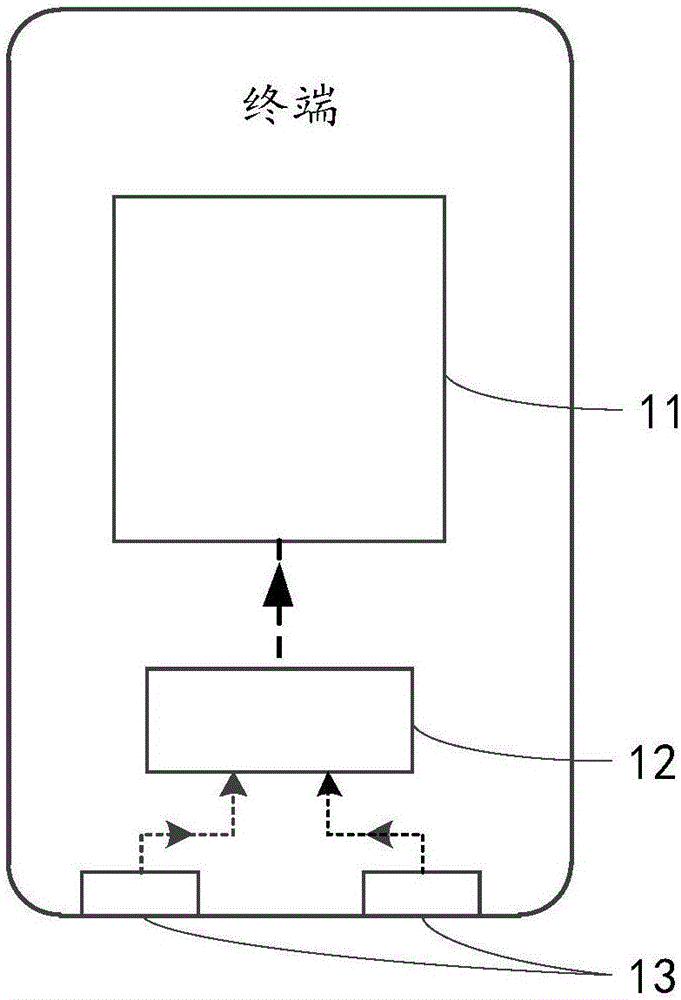

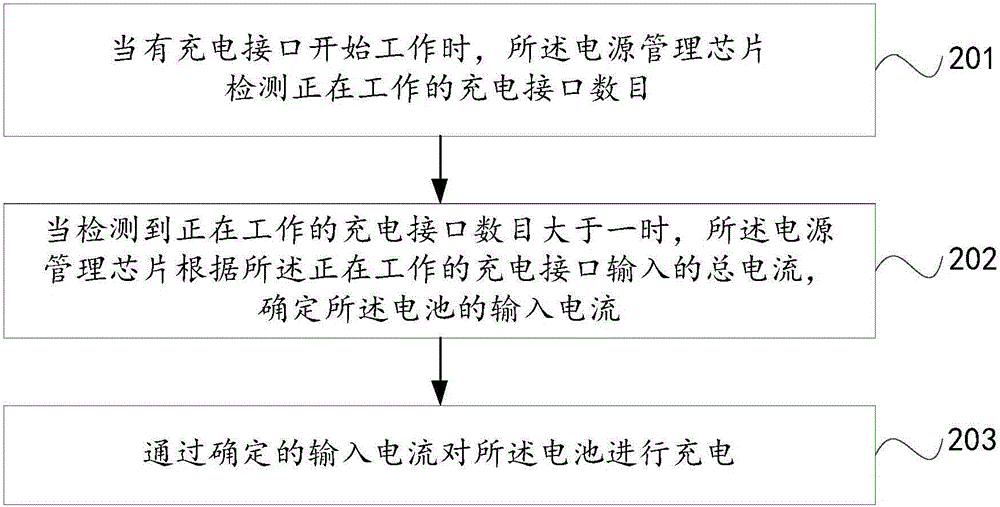

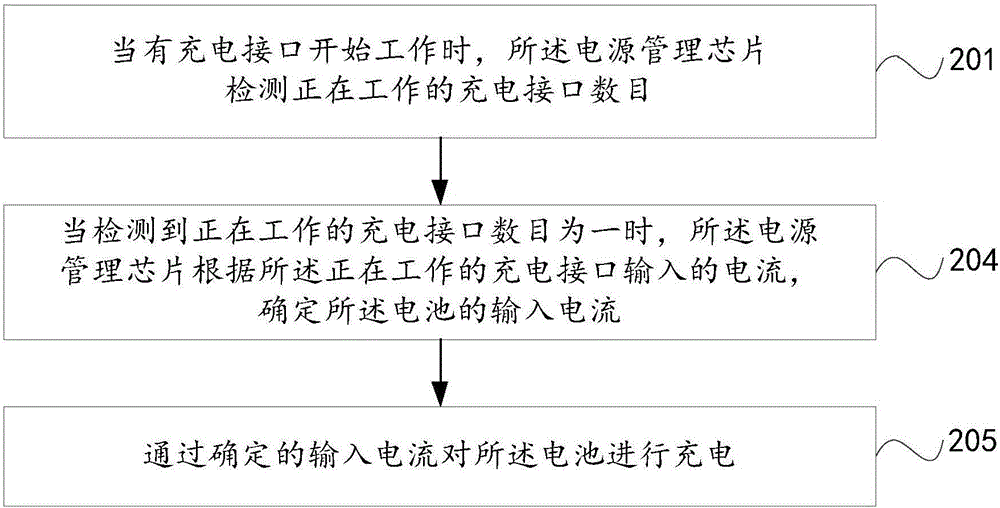

Terminal and charging method

InactiveCN106374592AShorten charging timeMeet the needs of fast chargingElectric powerCharging/discharging current/voltage regulationEngineeringPower management

The invention provides a terminal and a charging method, and relates to the field of communication technology. The terminal is provided with charging ports to meet the requirement of rapid charging of the terminal. The terminal comprises a battery, a power management chip and at least two charging ports, the charging ports are connected to the power management chip, and the power management chip manages charging of the battery. The charging method suitable for the terminal comprises that when certain charging port starts working, the power management chip detects the amount of the working charging ports; when the detected amount of the working charging port is greater than 1, the power management chip determines the input current of the battery according to the total input current of the working charging port; and the battery is charged via the determined input current. Technical schemes provided by the invention are suitable for the charging process of the terminal.

Owner:SHENZHEN TINNO WIRELESS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com