Laser power automatic control system

A technology of automatic power control and laser, which is applied to lasers, laser components, phonon exciters, etc., can solve problems such as complex circuit structure diagrams, and achieve the effect of reducing input current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

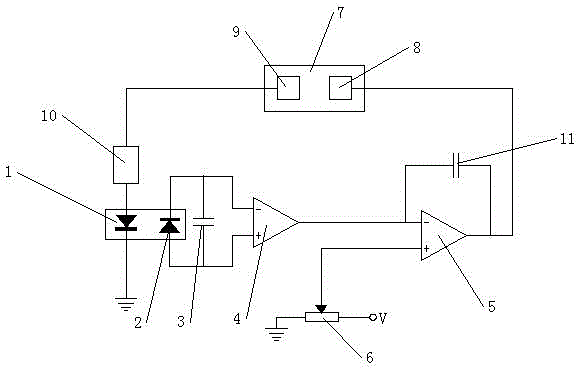

[0017] A laser power automatic control system, comprising a PIN tube 2 for detecting the backlight of the laser 1, the PIN tube 2 is installed on the side of the laser 1, the PIN tube 2 is connected with an operational amplifier 4, and the output terminal of the operational amplifier 4 is connected with a comparator 5 The negative terminal of the comparator 5 is connected to the DC reference voltage branch, the DC reference voltage branch is the current limiting resistor 6 set between the ground and the high potential of the reference voltage, and the middle tap of the current limiting resistor 6 is connected to At the positive end of the comparator 5, the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com