Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Increase fermentation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

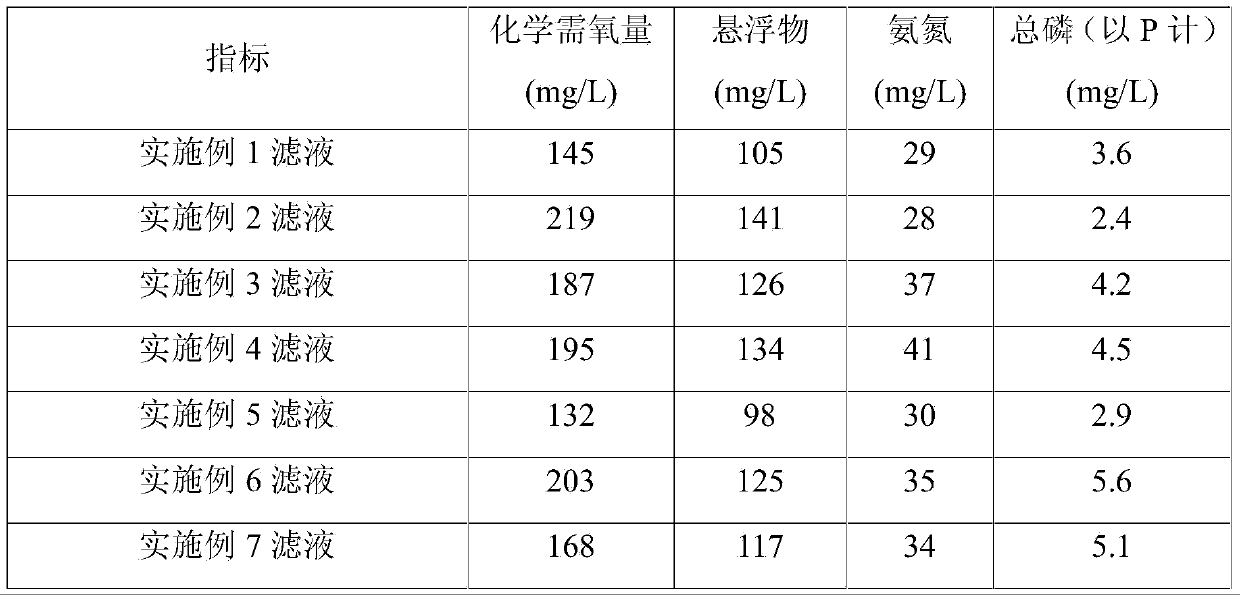

Deep dehydration recycling method for livestock and poultry feces

ActiveCN103723906AWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningAnimal fecesFilter press

The invention relates to the field of livestock and poultry feces treatment methods, and in particular relates to a deep dehydration recycling method for livestock and poultry feces. The method specifically comprises the following steps: adjusting the pH value of the livestock and poultry feces to be 2-4, adding ferrite or ferric salt into the livestock and poultry feces with the adjusted pH value, uniformly stirring, subsequently adding hydrogen peroxide into the livestock and poultry feces, stirring for 50-180 minutes, adding a phosphorus curing agent into the treated livestock and poultry feces, adjusting the pH value to be 8.5-10.5, uniformly stirring, and performing filter pressing on the treated livestock and poultry feces by a filer press for dehydration. The method is high in speed, short in period, high in solid recycling rate, high in dehydration degree, low in energy consumption and low in cost.

Owner:HUNAN UNIV

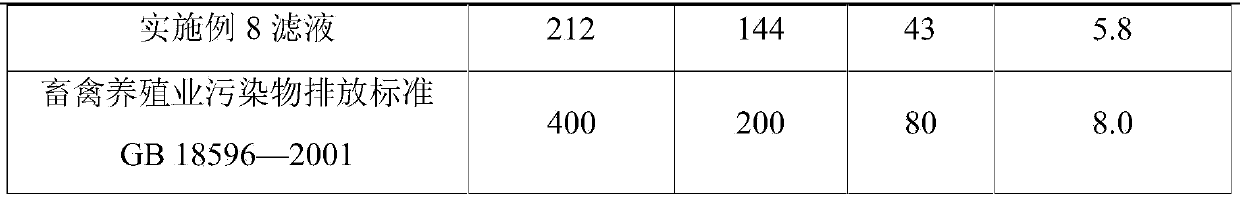

Method of producing zinc vitriol using indium extraction raffinate and zinc oxide

A process for preparing heptahydrated zinc sulfate from the residual liquid after extracting indium and zinc oxide includes such steps as preparing the extracting liquid from said residual liquid and sulfuric acid, heating, extracting zinc oxide while stirring, laying aside, filtering, oxidizing the filtrate by potassium permangnate for removing Fe and Mn, cleaning by using zn powder for displacement, concentrating, crystallizing, separating and drying.

Owner:株洲冶炼集团有限责任公司

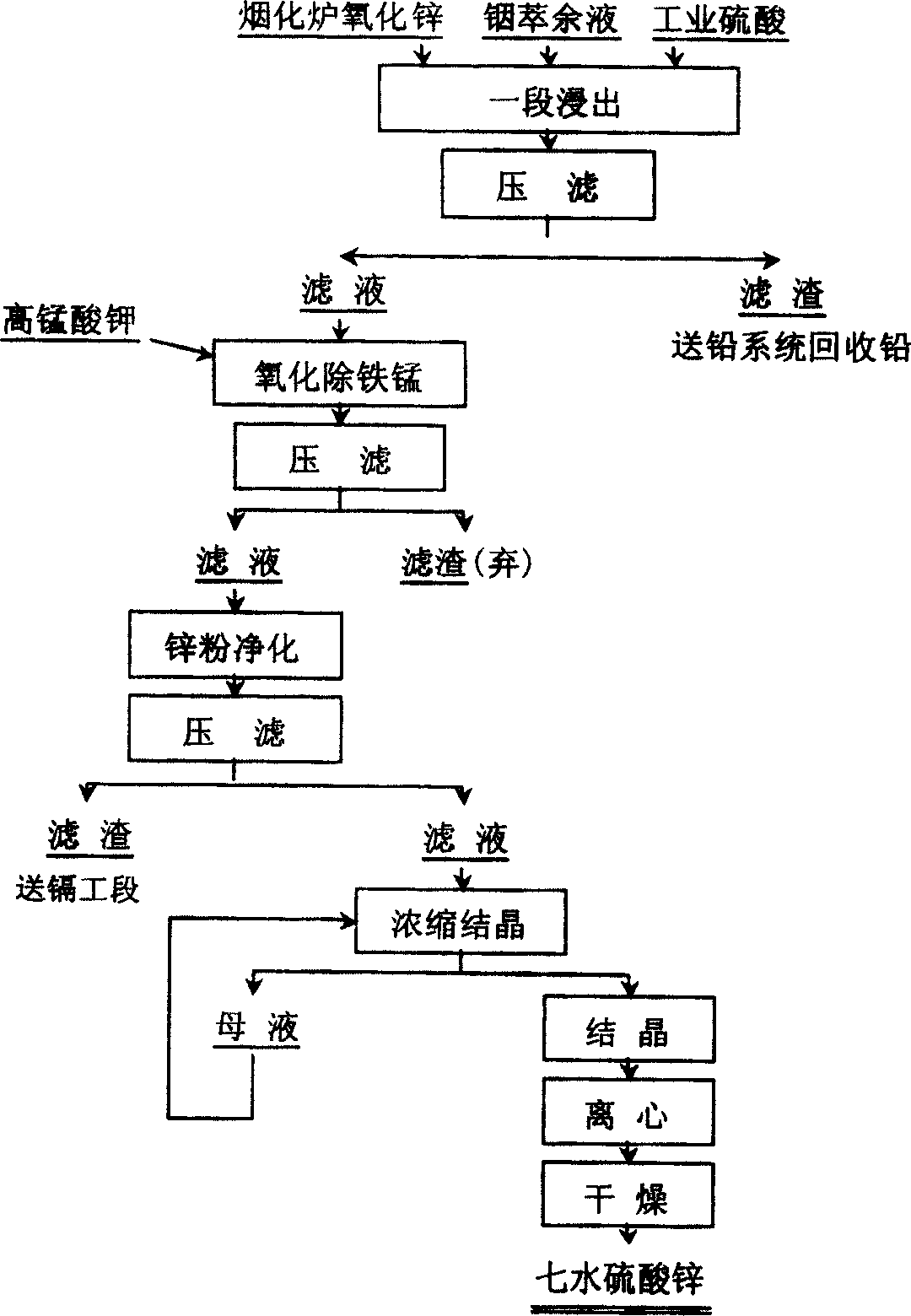

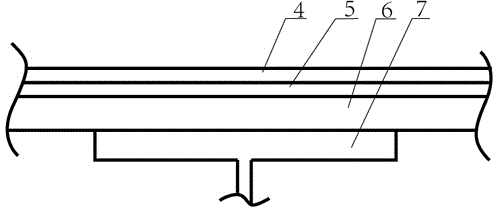

Crawler type vacuum pumping filter

InactiveCN105797462AThickened thicknessImprove the effectMoving filtering element filtersPolyesterLarge pore

The invention provides a crawler type vacuum pumping filter. The vacuum pumping filter comprises a frame, a pumping filtration part, and a distributing device; the pumping filtration part comprises a piece of filter cloth, a pumping filtration adhesive tape, a slide plate and vacuum pumping filtration boxes; the vacuum pumping filtration boxes are arranged below the slide plate, the pumping filtration adhesive tape is arranged on the slide plate, the filter cloth is arranged on the pumping filtration adhesive tape and is tightly attached to the pumping filtration adhesive tape, and the pumping filtration adhesive tape is opened with pumping filtration pockets and vent holes; the filter is characterized in that a layer of pumping filtration spacer screen is arranged between the filter cloth and the pumping filtration adhesive tape, wherein the pumping filtration spacer screen employs a spiral polyester screen with larger pore diameter and is fixed to the pumping filtration adhesive tape, and the width of the pumping filtration spacer screen is less than the width of the filter cloth. The filter has the beneficial effects that the pumping filtration spacer screen has a certain anti-compression capability and can support the filter cloth during vacuum-pumping, pumping filtration pockets of the pumping filtration adhesive tape are not blocked, the spacer screen has a certain thickness for increasing water passing volume, thickness of cloth is increased, pumping filtration effects are improved, normal operation of vacuum equipment is guaranteed, and usage life of equipment is prolonged.

Owner:TIANJIN CITY XINZE FINE CHEM

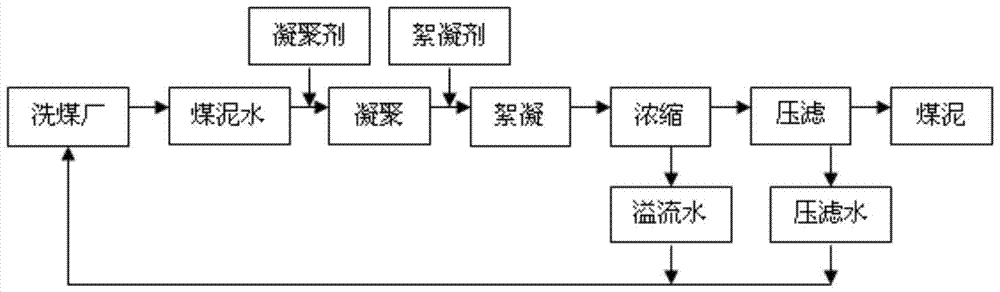

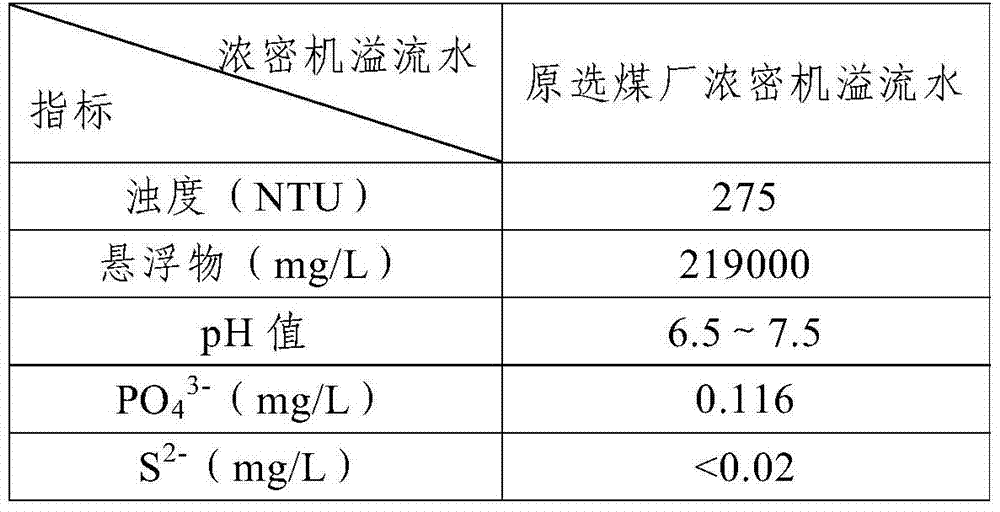

Coagulant for treating fine-grain high-viscosity soil coal slime water

ActiveCN105129943AWill not accumulateDoes not affect water qualityWater/sewage treatment by flocculation/precipitationWater qualityCalcite

The invention discloses a coagulant for treating fine-grain high-viscosity soil coal slime water, and the coagulant is prepared by evenly mixing more than two of barite powder, calcite powder, dolomite powder and medical stone powder. The coagulant is a mineral preparation, and when the coagulant is used, the coagulant can be discharged along with coal slime in usage, cannot be accumulated in water and cannot influence the water quality; the coagulant can change the electrical property of the surfaces of coal slime particles, so that high-viscosity soil mineral and the coal slime particles are easily flocculated and precipitated, the filter pressing speed of the coal slime is increased, and the cleaned coal quality and yield are improved. The coagulant can be matched with an appropriate amount of flocculating agents, the effect is good when the coagulant is used for treating the coal slime water which is complex in components and difficult to precipitate, the coagulation effect is obvious especially for the high-viscosity fine-grain soil coal slime water, and actual production requirements can be completely met; the water content of treated coal slime filter cakes is decreased below 25 percent, and the content of suspended matter in thickener overflow water is smaller than 150 mg / L.

Owner:陕西省地质矿产实验研究所有限公司

Spirulina dehydration method

InactiveCN104370431BHigh degree of dehydrationReduce weightSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPhylum CyanobacteriaCyanobacteria

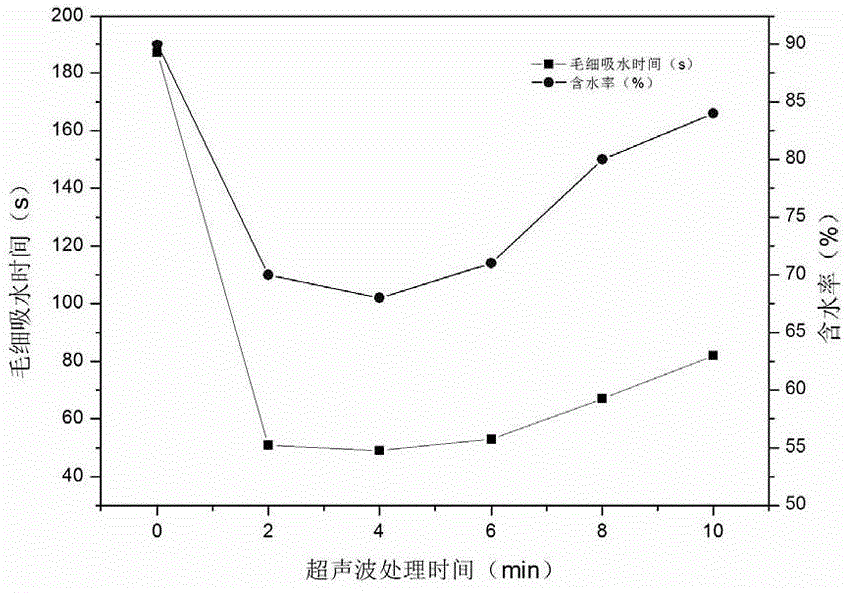

The invention discloses a blue algae dehydrating method. The method comprises the steps of performing ultrasonic processing, adding a flocculant and filter-pressing to dehydrate, wherein the specific steps are as follows: ultrasonically processing the blue algae for 2-6min; adding the flocculant in the blue algae after the ultrasonic processing, and uniformly stirring; filter-pressing the blue algae after adding the flocculant to dehydrate. Through the adoption of the method disclosed by the invention, the volume of the blue algae is greatly reduced, the heat value is not changed, and the dehydrating degree is high; the processing speed is high, the operation is simple, the large-scale production is facilitated, and the method has wide application prospect.

Owner:HUNAN UNIV

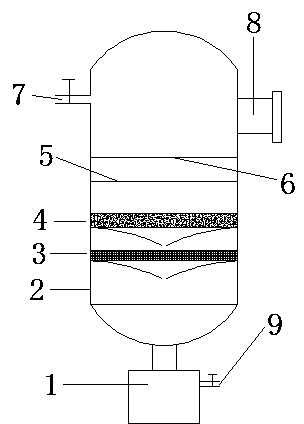

Liquid filtering device

ActiveCN103657239AGood filtering effectFast filtration speedFiltration circuitsFilter mediaMagnetic filter

The invention relates to the technical field of chemical equipment, particularly to a liquid filtering device. The device comprises a tank, wherein a feeding port and a discharging port are arranged on the tank; a magnetic filtering net, a filtering cloth, a decolorizing filtering medium and a micro-porous filtering medium are installed in the tank sequentially from top to bottom; and a receiver is connected to an outlet of the tank. With the adoption of the technical scheme, the liquid filtering device has the benefits as follows: the liquid filtering device is good in filtering effect and capable of effectively removing tiny impurities in a liquid and removing pigments in the liquid; reduced-pressure suction filtration is adopted, the suction filtration speed is high, and the efficiency is high; and a manhole is arranged on the tank, so that maintenance is facilitated.

Owner:郎溪品旭科技发展有限公司

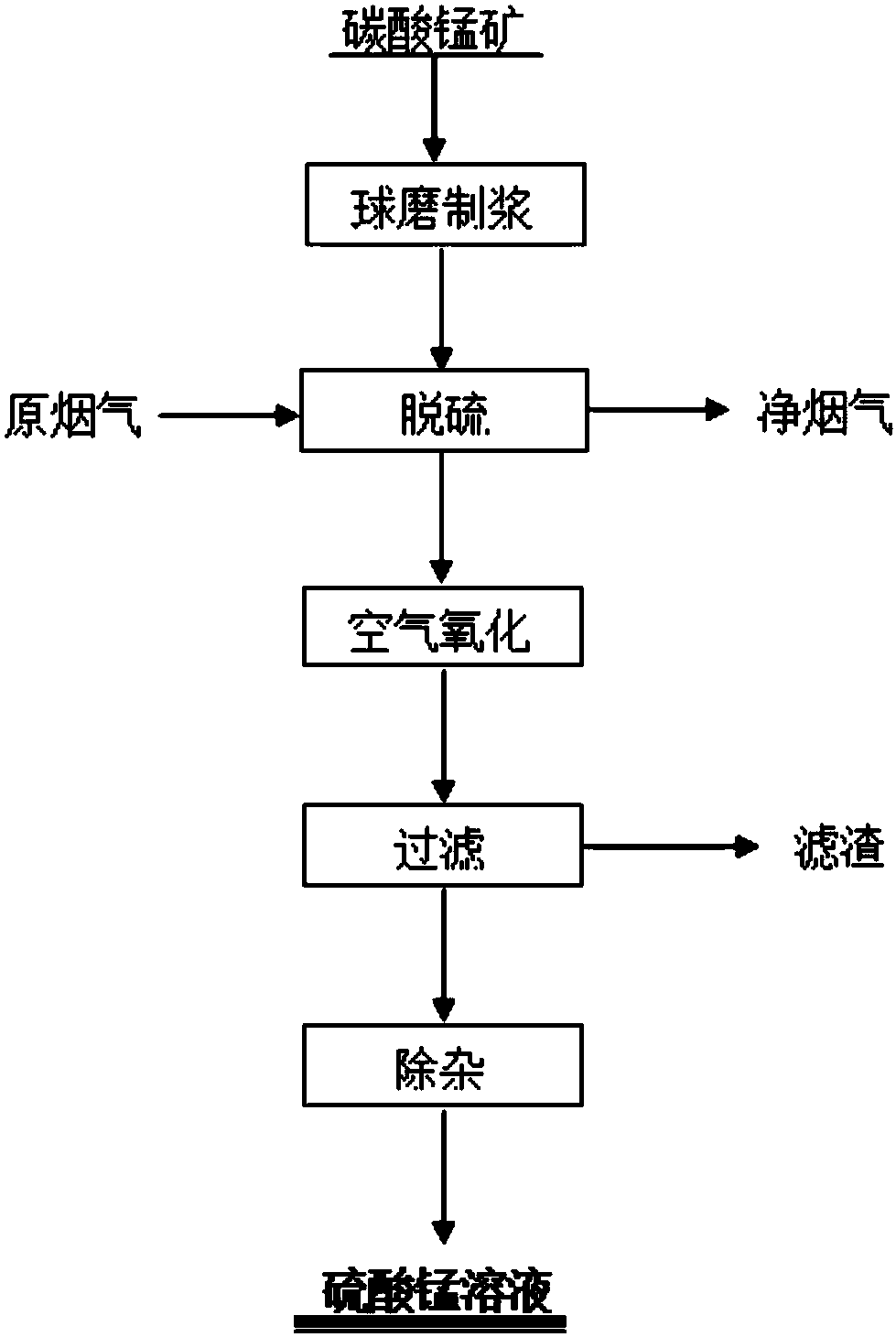

Method for removing sulfur dioxide in smoke by using manganese carbonate ore and preparing manganese sulfate solution

InactiveCN108031255AImprove desulfurization effectWide variety of sourcesGas treatmentChemical industrySulfateManganese

The invention provides a method for removing sulfur dioxide in smoke by using manganese carbonate ore and preparing a manganese sulfate solution. The method comprises the following steps: (1) introducing smoke comprising the sulfur dioxide into an absorption apparatus with manganese carbonate ore slurry, controlling a flow rate of the smoke at 1 to 4.5 m<3> / s, controlling a liquid-gas ratio of theore slurry to the smoke at 12 to 35 L / m<3>, performing the reaction, obtaining slurry and discharged smoke, wherein the concentration of sulfur dioxide in the smoke reaches the environment-friendly emission requirement; and (2) introducing oxide gas into the slurry after step (1), reacting for 1 to 4 hours, after the reaction is ended, filtering, removing the filter residue, removing impurities of the filtrate, and obtaining a manganese sulfate solution. By adopting the method of the invention, the whole reaction process is easy to control. The method has the advantages of energy conservation, environmental protection, good smoke desulphurization effect, low production cost and the like and is easy in industrialized and continuous production.

Owner:贵州大龙汇成新材料有限公司

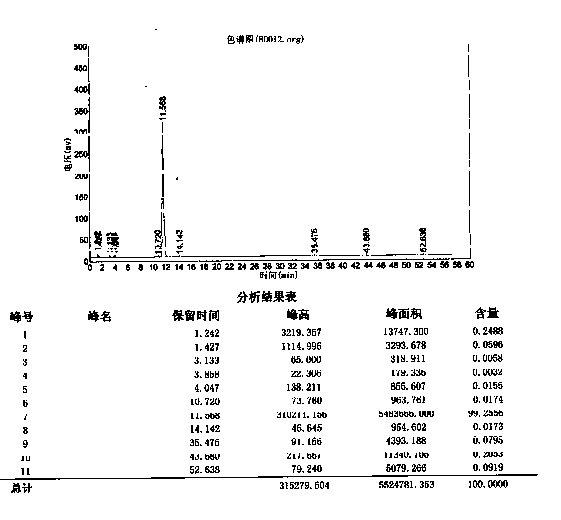

Preparation method of high-purity rebamipide

ActiveCN104230798AHigh purityEfficient removalOrganic chemistryBiochemical engineeringCombinatorial chemistry

The invention discloses a preparation method of high-purity rebamipide. During synthesis process of a rebamipide crude product, the rebamipide crude product is precipitated out, in the form of a rebamipide salt solid, directly from a reaction solution. Thus, effective separation of impurities from a product is realized. A rebamipide salt crude product has good quality and high purity. Without further refining, dissociating is carried out directly by an acid-alkali method so as to obtain a high-purity rebamipide finished product. By the above method to obtain rebamipide, operational steps and refining frequency are minimized, and production efficiency is raised remarkably. In addition, a solvent used is cheap and easily available, and it is beneficial to realize industrial production.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +2

Treatment method for acid dissolution refining mother solution of riboflavin

ActiveCN108191868AHigh extraction yieldReduce manufacturing costOrganic chemistryDialysis membranesAcid dissolution

The invention discloses a treatment method for acid dissolution refining mother solution of riboflavin, which belongs to the technical field of riboflavin extraction. The method comprises the following steps: acid dissolution refining mother solution undergoes a process of extracting concentrated hydrochloric acid by batch fractionating, so that azeotropic hydrochloric acid, the aid content of which is about 20 percent, is obtained; because the content of hydrochloric acid in the acid dissolution mother solution is reduced in the process of extracting concentrated hydrochloric acid, from 6 to8 percent to about 0.5 percent, and part of moisture is evaporated out, riboflavin is separated out from the mother solution, and riboflavin therein is then recovered by membrane separation of concentrated crystals and other steps. The step of membrane separation of concentrated crystals includes two stages of membrane treatment, i.e., tubular membrane pretreatment (microfiltration) and diffusiondialysis membrane treatment, the concentrate of a diffusion dialysis membrane returns into a pretreating tubular membrane again, and soluble riboflavin in penetrating liquid pretreated by the tubularmembrane is further recovered. After treatment by the method, the yield of extracted riboflavin in the process of preparing high-content riboflavin is increased by about 3 percent, and the discharge of high-salinity wastewater is greatly reduced.

Owner:HUBEI GUANGJI PHARMA

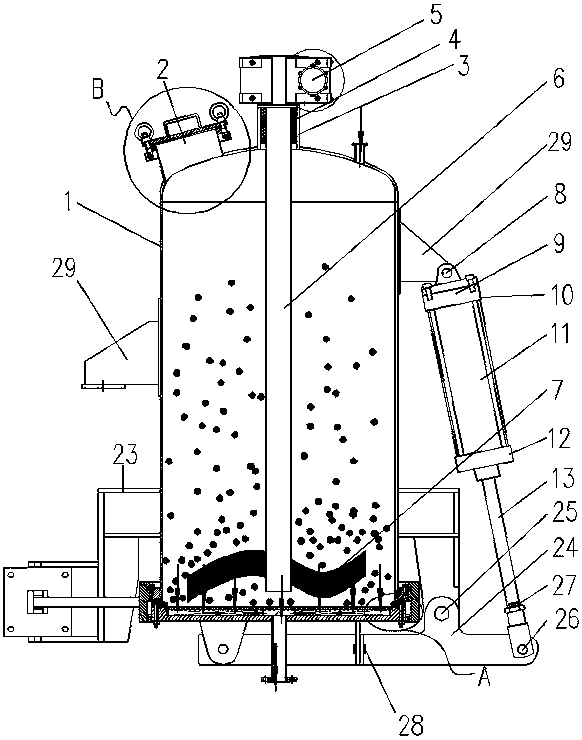

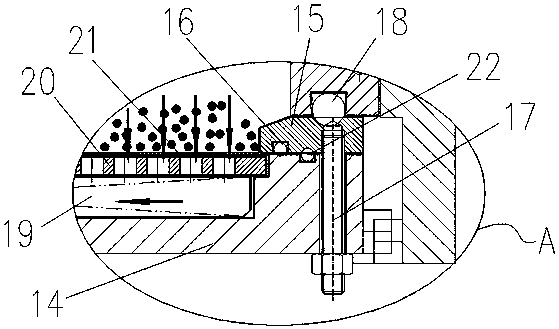

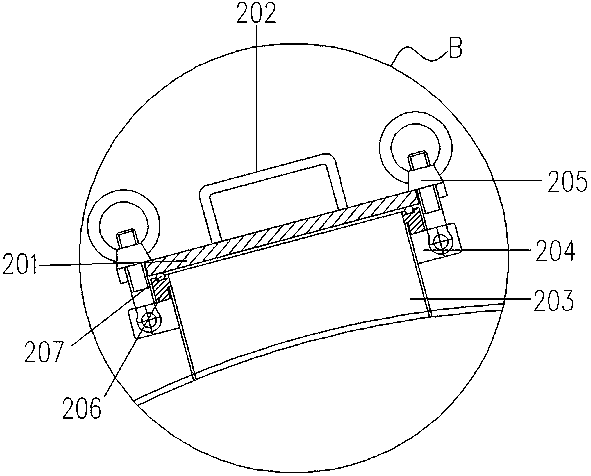

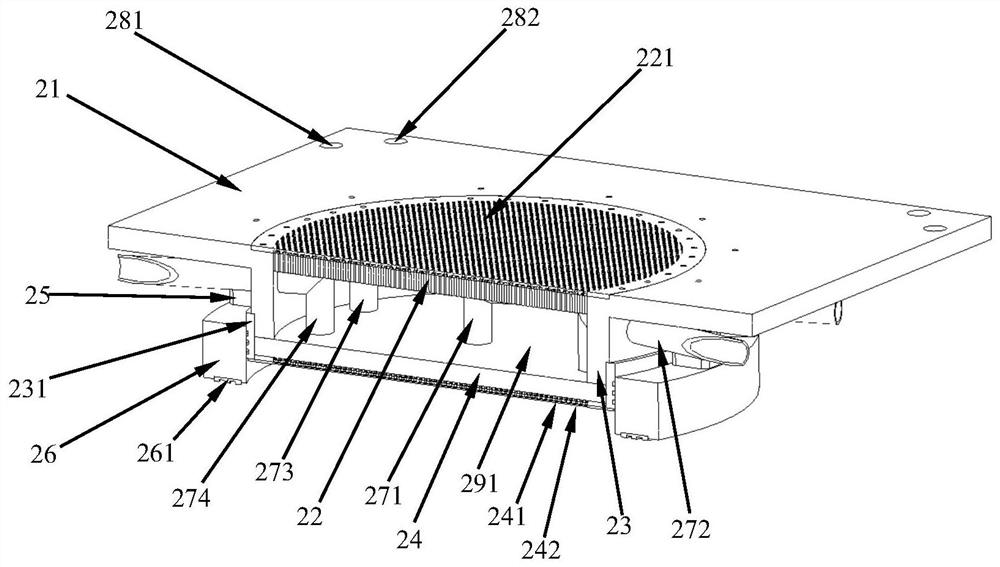

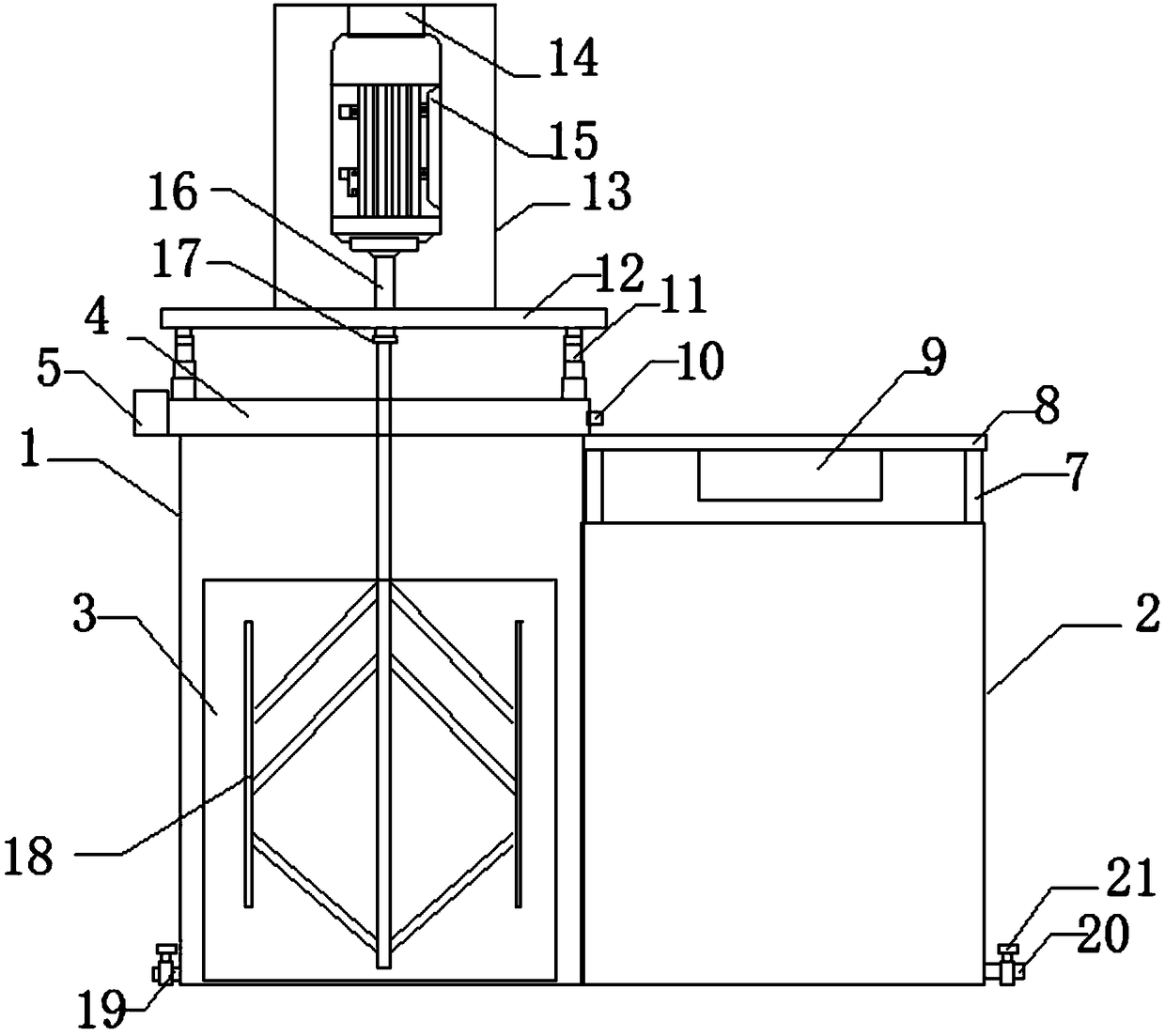

Full-automatic slagging type press filter and using method thereof

The invention discloses a full-automatic slagging type press filter and a using method thereof. The press filter comprises a cylinder. A feeding device is arranged at the left side of the top of the cylinder. A rack is fixedly connected to the center of the top of the cylinder, a shaft sealing case is arranged in an inner cavity of the rack, a driving mechanism is fixedly connected to the top of the rack, a stirring shaft is installed at the power output end of the bottom of the driving mechanism, stirring blades are installed at the lower end of the stirring shaft, a connecting block is fixedly connected to the right side wall of the cylinder, a cylinder base is rotationally connected to the lower end of the right side of the connecting block, a supporting frame is arranged at the top ofa lower cover, a porous plate is arranged at the top of the supporting frame, a filter fabric is arranged at the top of the porous plate, third sealing rings are arranged at the joints of a pressing ring and the tops of the left and right sides of the lower cover, a connecting frame is fixedly connected to the lower end of the cylinder, and supporting lugs are fixedly connected to the left side wall of the cylinder. The problems that more bolt fasteners need to be disassembled every time the cover is opened due to the design mode adopted by a conventional press filter, large operation space isneeded when the upper cover and other components are opened, residues are taken out, and replacement of the filter plate is quite inconvenient are solved.

Owner:江苏联合过滤技术有限公司

Filter pressing assembly, filter press and filter pressing method

The invention relates to a filter pressing assembly, which comprises a base plate, a through hole area in the middle of the base plate, a piston wall which surrounds the through hole area and extends downwards is arranged on the bottom face of the base plate, and a piston top plate, a channel plate and first filter cloth are sequentially arranged at the bottom end of the piston wall from top to bottom; the piston top plate is provided with a second pipe used for guiding fluid into a groove and a fourth pipe used for discharging the fluid in the groove, the outer surface surrounding the piston wall is sleeved with a piston sleeve, and the lower surface of the first filter cloth and the inner surface of the piston sleeve define a filter pressing cavity, and a first pipe for leading in slurry to be filtered is arranged in the filter pressing cavity. The invention also relates to a filter press comprising the filter pressing assembly and a filter pressing method. The product has the advantages of high operation pressure, high filter pressing speed, low liquid content of a filter cake, reliable structure, convenience in automatic operation and the like, and is particularly suitable for filter pressing of systems difficult to filter, such as activated sludge and pectin.

Owner:金锣水务有限公司

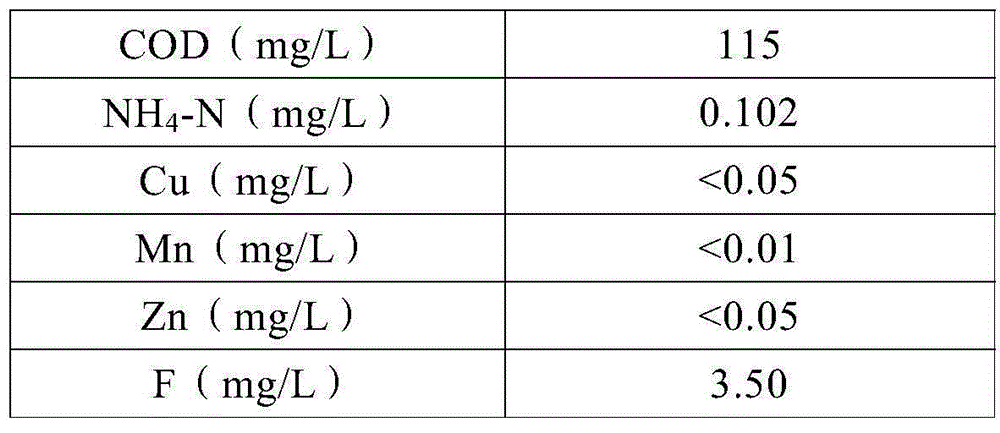

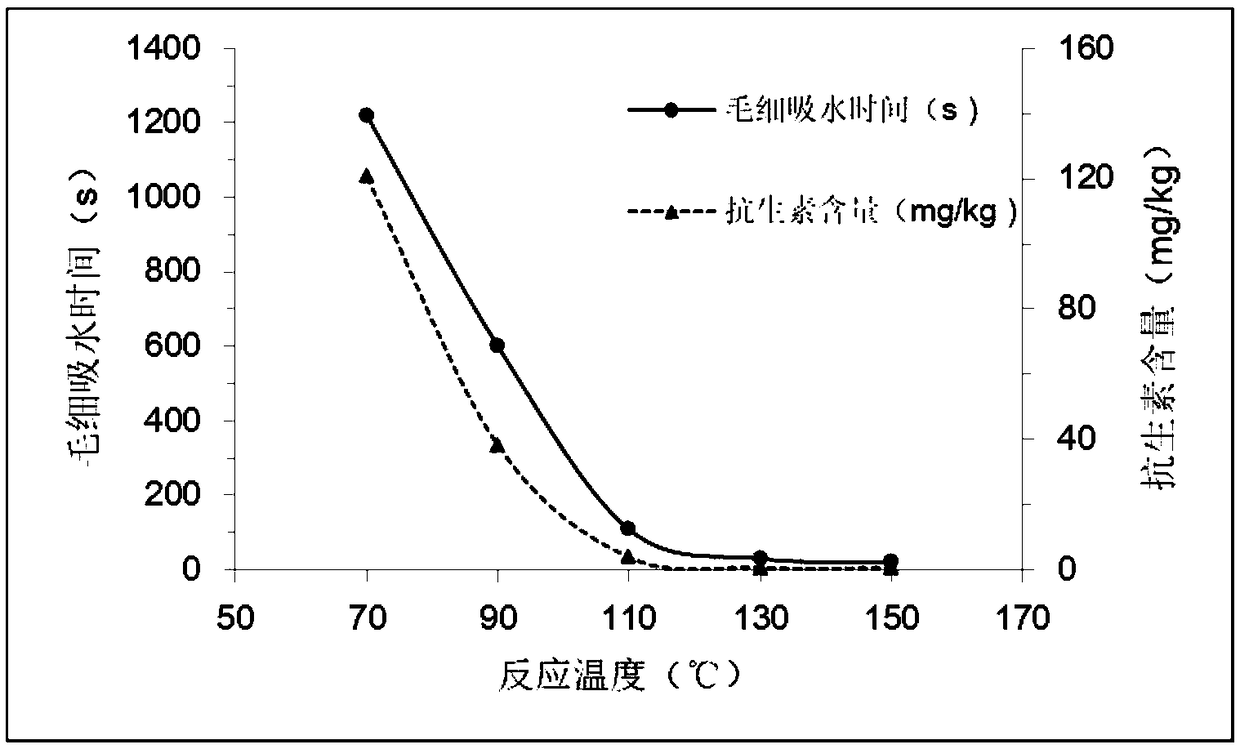

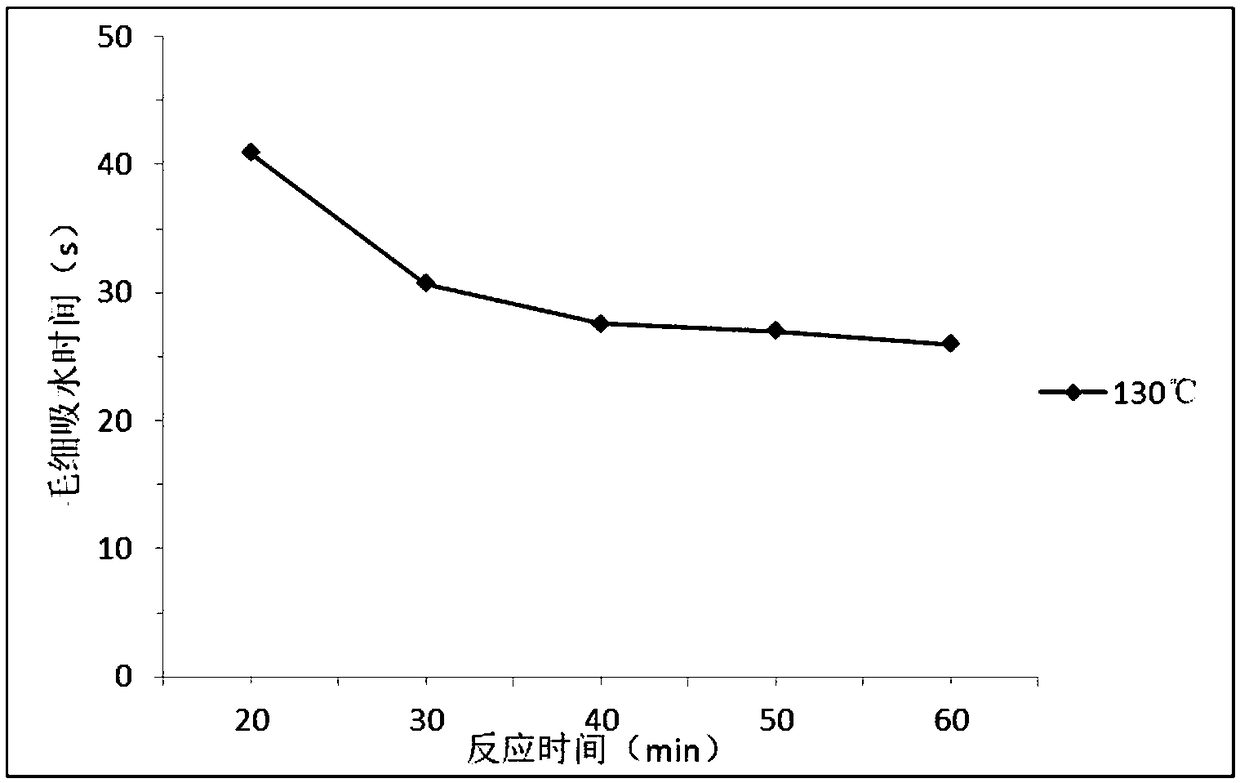

Poultry excrement hydrothermal treatment dewatering method

InactiveCN109320039AReduce capillary water absorption timeHigh degree of dehydrationSludge treatment by oxidationWater contaminantsFecesThermal treatment

The invention provides a poultry excrement hydrothermal treatment dewatering method which comprises the following steps: adding an oxidizing agent into fresh poultry excrement, mixing and performing hydrothermal reaction treatment; mixing the treated poultry excrement with a proper amount of water, then dewatering to finish the treatment on the poultry excrement. The poultry excrement hydrothermaltreatment dewatering method can perform dewatering treatment on the poultry excrement and has the advantages that equipment is simple and easy to operate, a treating speed is quick, a period is short, a dewatering degree is high, a solid recovery rate is high, energy consumption is low, cost is low, and a wide application prospect is achieved.

Owner:HUNAN AGRICULTURAL UNIV

Textile sewage press filtration device

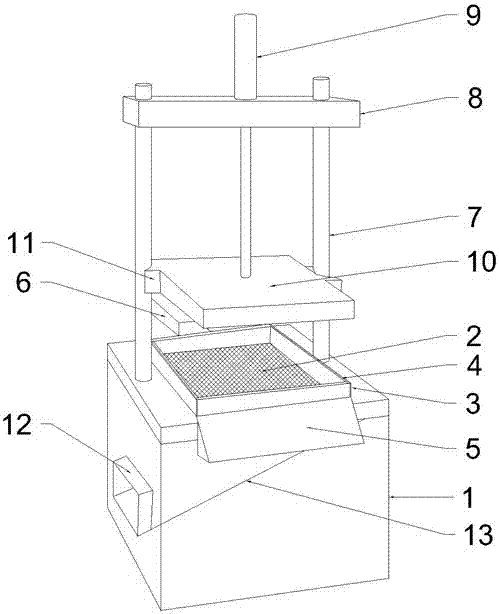

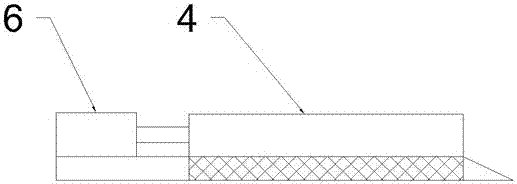

InactiveCN106943782ACompact structureImprove filtering effectStationary filtering element filtersSlagEngineering

The invention provides a textile sewage pressure filtration device. The device comprises a pressure filtration table, pressure filtration holes are arranged in the center of the top of the pressure filtration table, spacing guiding plates are arranged at two sides of the pressure filtration holes, a pressure filtration frame is movably arranged on the spacing guiding plates, the pressure filtration table at one end of the pressure filtration frame is provided with a residue guiding plate, the other end of the pressure filtration frame is connected with the piston rod of a frame pushing cylinder, the pressure filtration table outside the spacing guiding plates is provided with guiding columns, a top board is arranged at the tops of the guiding columns, a pressure filtration cylinder is fixed at the top of the top plate, the piston rod of the pressure filtration cylinder downward traverses through the top plate and is connected with the top of a pressure plate, guiding slide blocks are arranged at two sides of the pressure plate, a filtered water outlet is arranged at one side of the lower portion of the pressure filtration table, and a water guiding groove is arranged in the pressure filtration table below the pressure filtration holes. The device has the advantages of compact structure, good pressure filtration effect, fast pressure filtration speed and high efficiency.

Owner:湖州市星智造服饰有限公司

Method for crushing fine powders of whole rice for fuel ethanol production

InactiveCN108160206AMeet the production process requirementsAvoid cloggingGrain treatmentsMetallurgySlurry

The invention discloses a method for crushing fine powders of whole rice for fuel ethanol production. The method is characterized in that rice (1) is fed into a pulverizer (3) through a conveying system (2), the crushed fine powder is conveyed and separated by a negative pressure conveying system (4), the fine powder enters a fine powder drum screen (5) for screening, undersize products are qualified fine powders (6) and enter a stirring system (7) for stirring and mixing, the slurry is sent to a next procedure (8), the fine powders enter the fine powder drum screen (5) to be sieved, the oversize products are flaky rice hulls, and the flaky rice hulls (9) are re-crushed by the pulverizer (3). The method has the beneficial effects that the problems that the rice with hulls is crushed and the fine powders are mixed with strip rice hulls are solved, the crushed rice fine powder reaches the control range of qualified particle size, the production process requirements are met, the method isapplied to the fuel ethanol in rice production and the effect is good.

Owner:GUANGXI COFCO BIO ENERGY

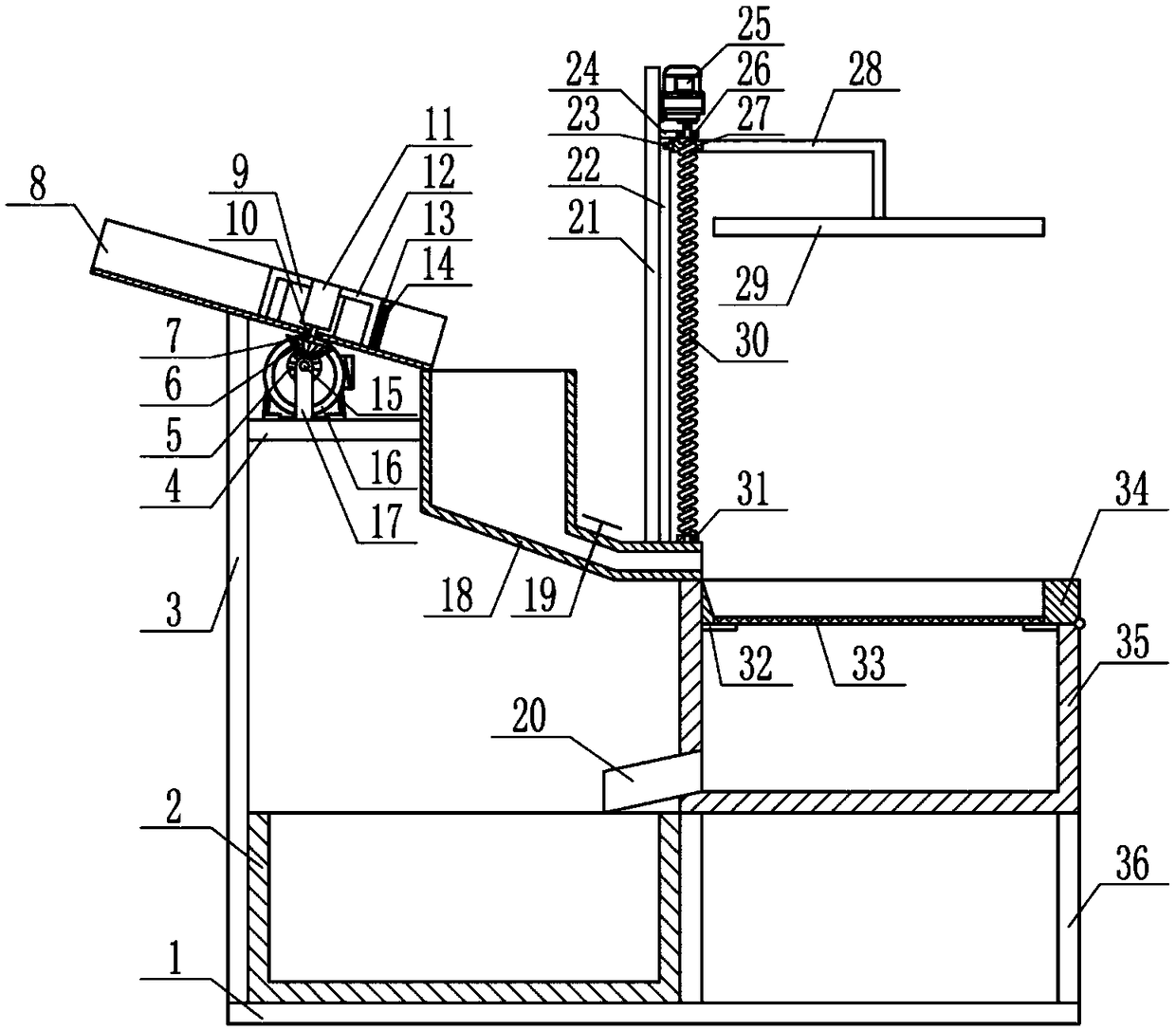

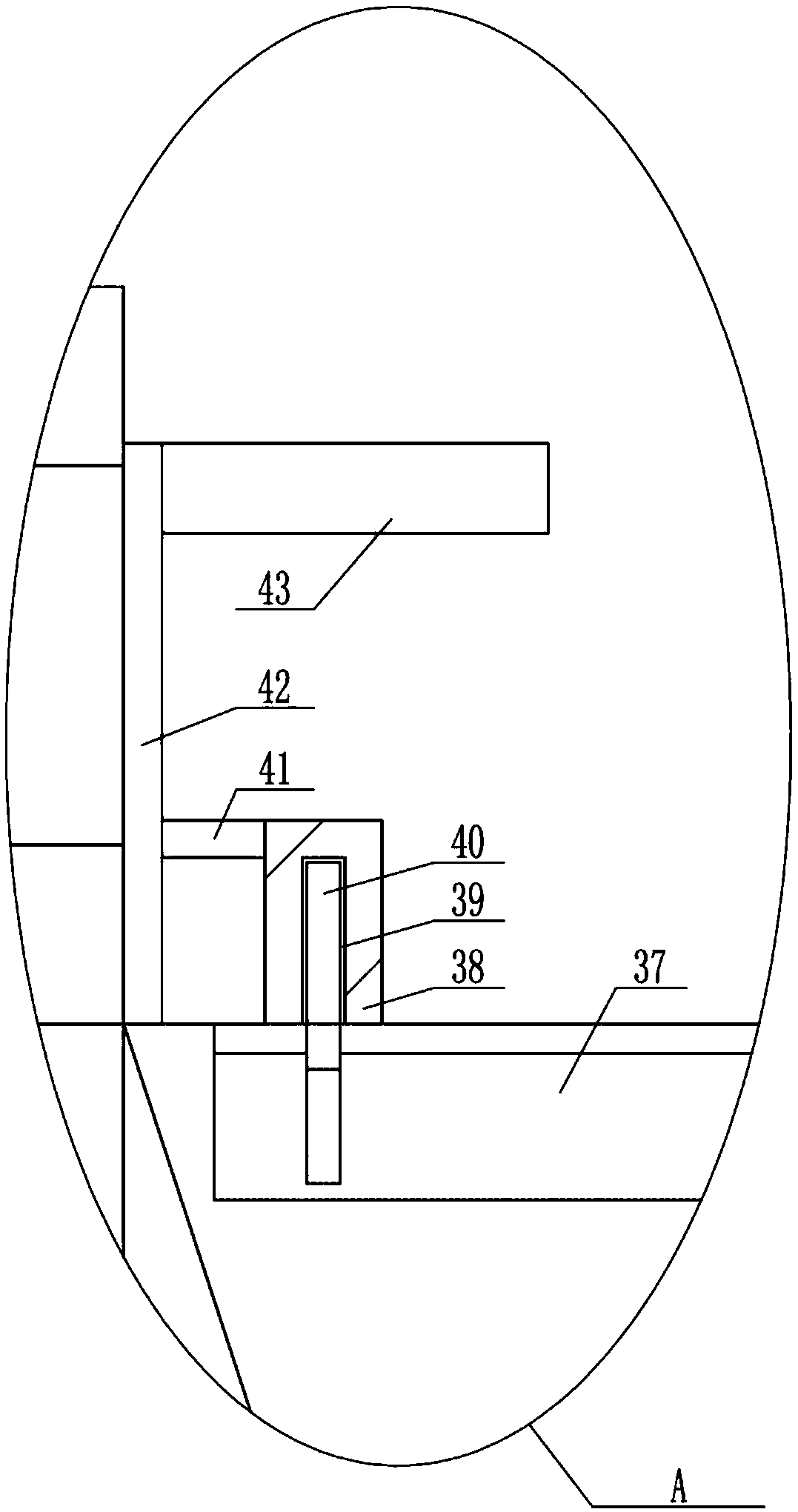

Press filter device for treatment of textile wastewater

InactiveCN108889014AEasy to driveEasy to scrape offStationary filtering element filtersWater storageWastewater

The invention belongs to the field of wastewater treatment and particularly relates to a press filter device for treatment of textile wastewater. The technical problem to be solved herein is to provide a press filter device for treatment of textile wastewater, which can conveniently separate the impurities, such as large chopped cloth and cloth strips, and can provide press filtering for small chopped cloth. The press filter device for treatment of textile wastewater comprises a first mounting plate, a collection frame, a second mounting plate, a third mounting plate, a first bevel gear, a second bevel gear, a first spindle, a water delivery channel, a first bearing block, a roller, a first L-shaped plate, an arc plate, a first filter mesh, a second spindle, a first motor, a first fixing plate, a feed bucket, an electric valve, an outflow pipe and the like; a water storage frame is fixedly connected to the top of the first mounting plate through two support rods. The press filter device for treatment of textile wastewater can conveniently separate the impurities, such as large chopped cloth and cloth strips and can provide press filtering for small chopped cloth.

Owner:高俊生

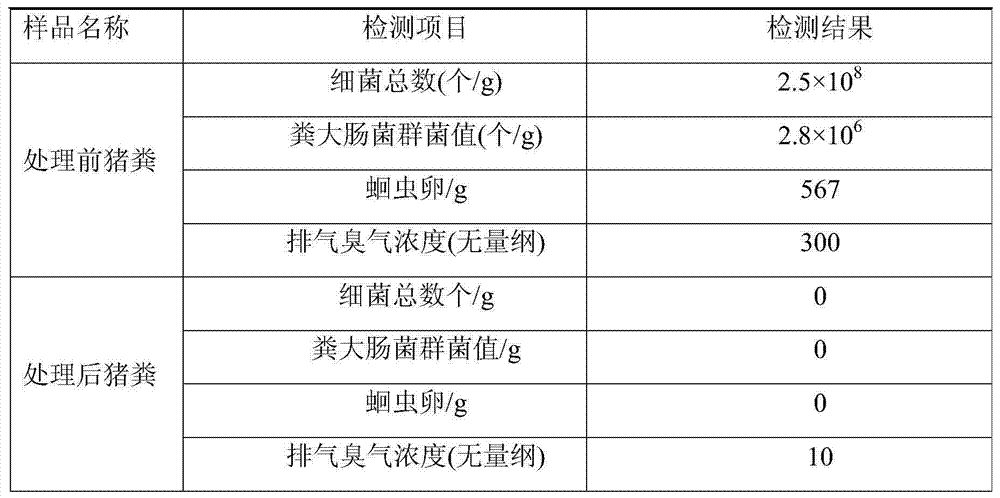

Sterilization, deodorization and deep-dehydration method for livestock excrements

ActiveCN103708689BWide range of processingHigh degree of dehydrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFecesMicrowave

The invention relates to the field of treatment of livestock excrements, and in particular relates to a sterilization, deodorization and deep-dehydration method for livestock excrements. The method comprises the steps of acidification, namely adjusting the pH of the livestock excrements to be 3 to 6 by using acid; oxidization, namely adding an oxidizing agent into the acidified livestock excrements at the ratio that 0.5 to 1.2 moles of oxidizing agent is added into every kilogram of dry livestock excrements, and performing uniform stirring; microwave heating treatment, namely heating the oxidized livestock excrements to 95 to 120 DEG C by using microwaves, and continuing performing microwave treatment while stirring for 5 to 12 minutes at the temperature; pressure filtration dehydration, namely performing pressure filtration dehydration on the microwave-treated livestock excrements by using a pressure filter. The method is low in using cost, easy to operate and high in treatment speed, and the treated livestock excrements are high in solid recovery rate, low in heat value reduction and high in dehydration degree.

Owner:HUNAN UNIV

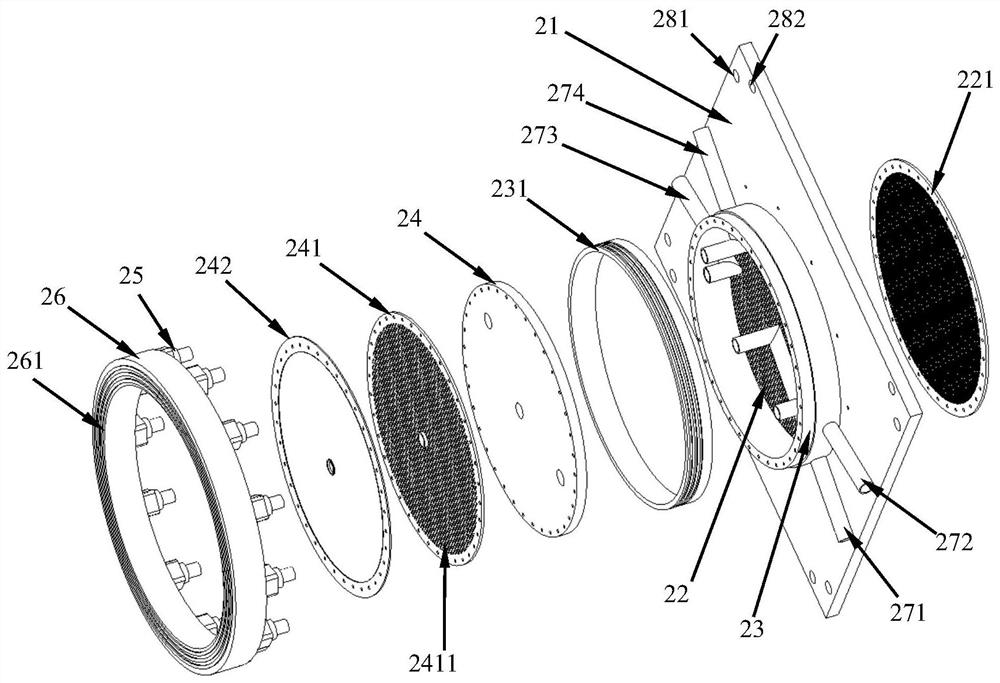

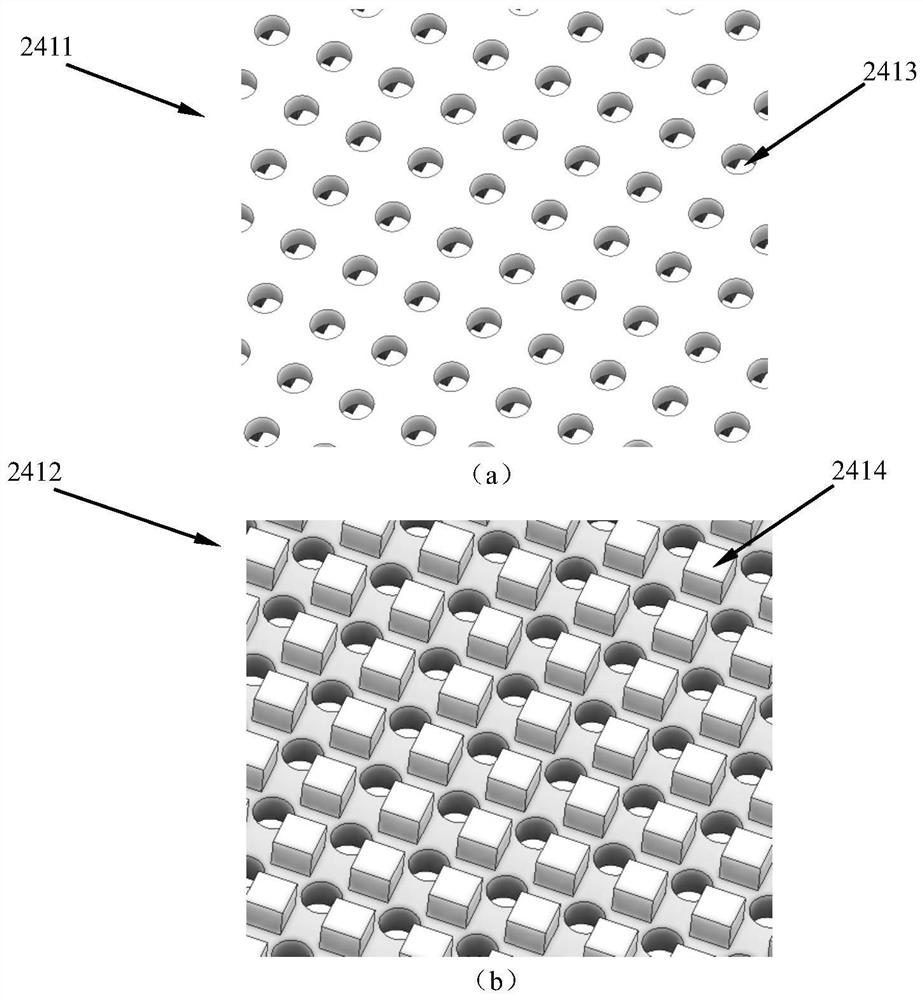

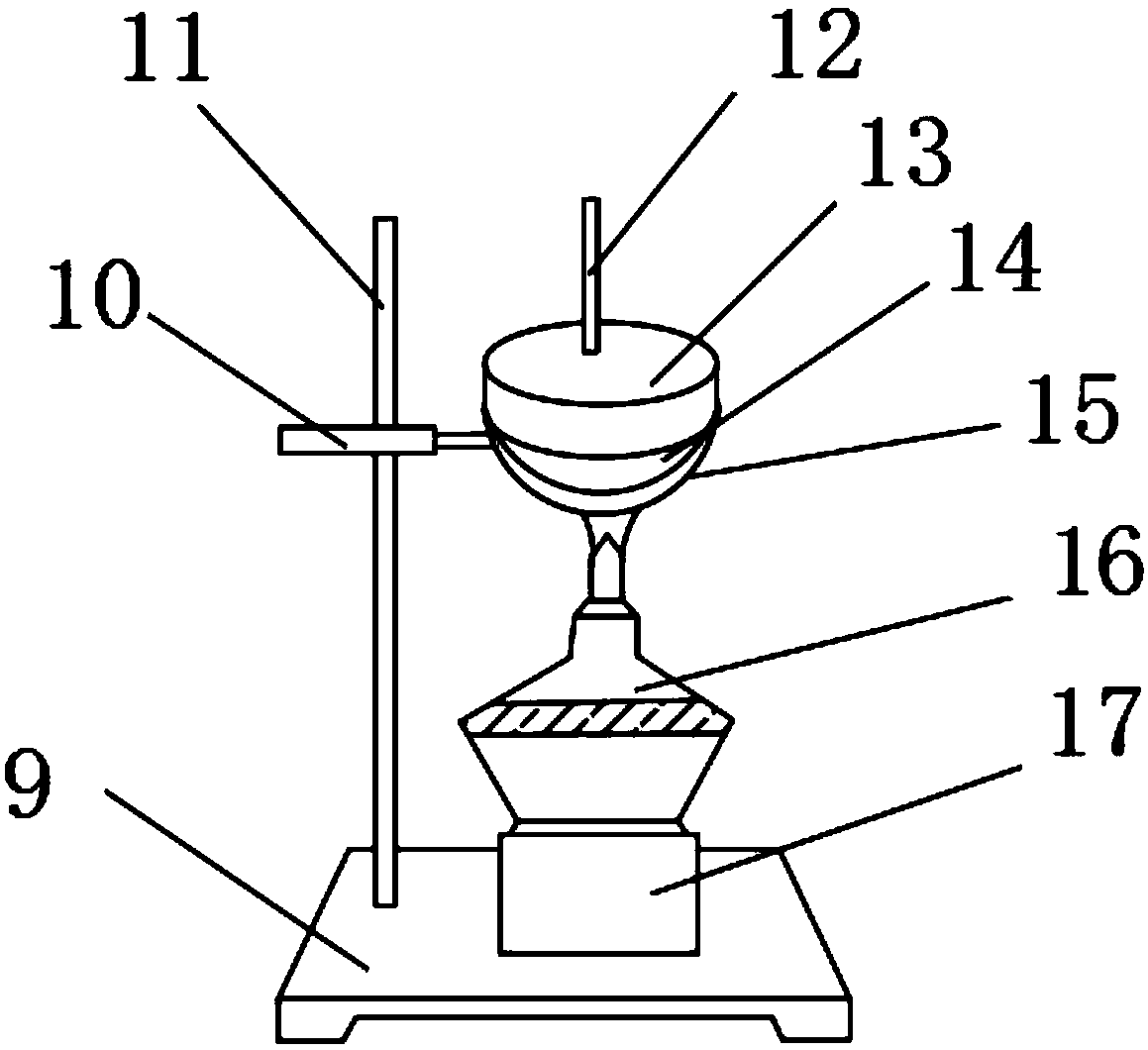

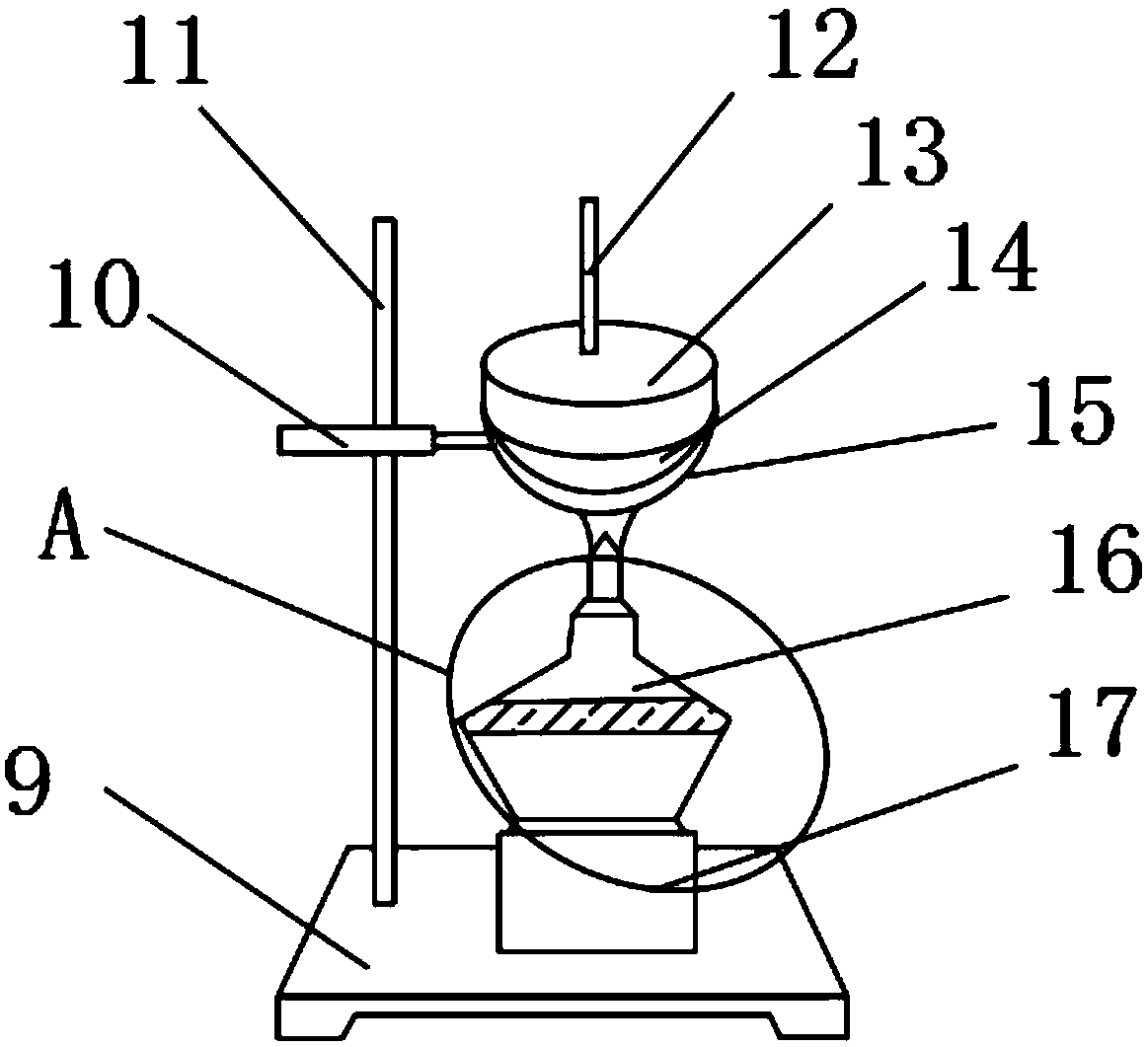

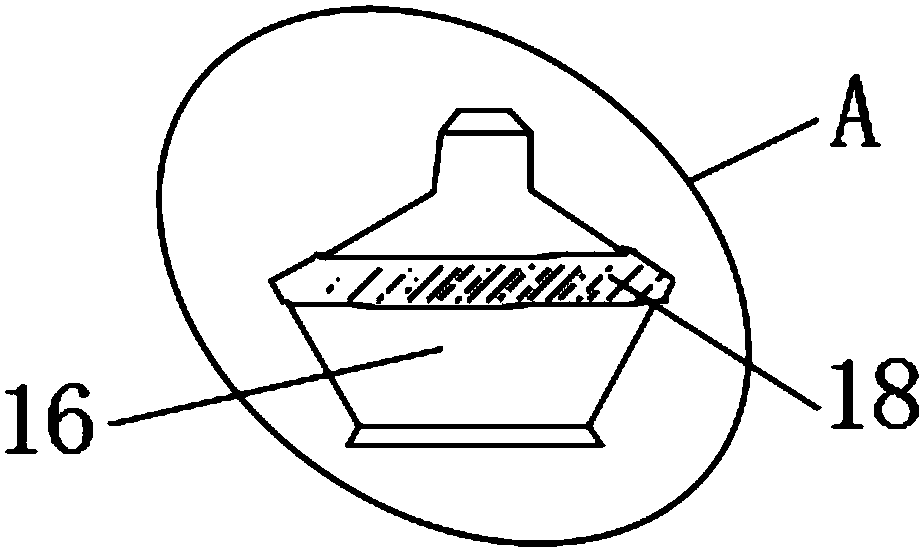

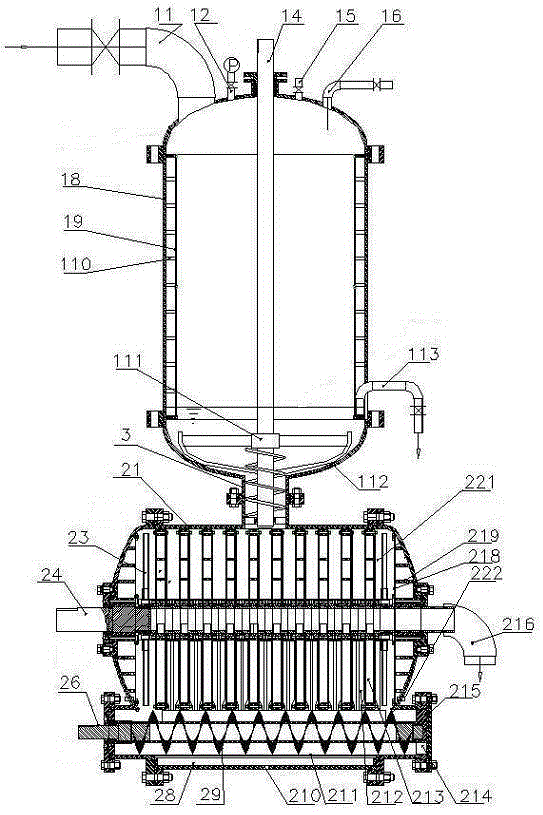

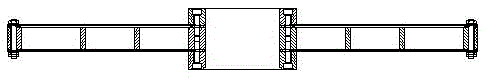

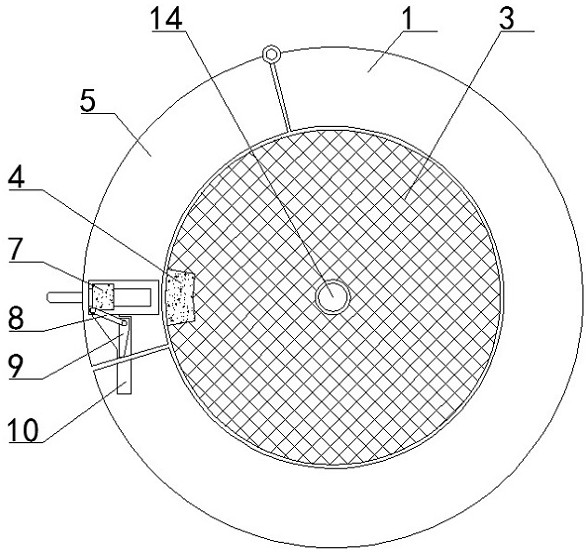

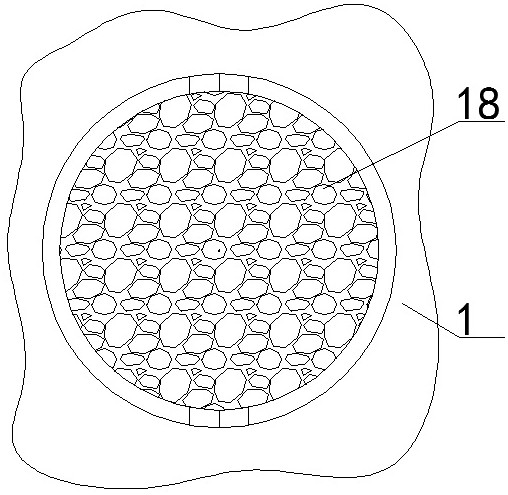

Disk type filter pressing device

ActiveCN104785002ASolve the problem that cannot be uninstalledSave pipesStationary filtering element filtersBiochemical engineeringFilter press

The invention discloses a disk type filter pressing device, which is composed of a grouting tank and a filter press, wherein the bottom end of a grouting tank shell is communicated with the top end of a filter press shell, a stirrer extending towards the filter press is arranged in the inner cavity of the grouting tank shell; a slewing shaft of the filter press horizontally penetrates through the filter press shell and is of a hollow structure; one end of the slewing shaft is communicated with a filtrate connector of the filter press; multiple disk type filter cores communicated with the inner cavity of the slewing shaft are coaxially arranged on the slewing shaft and in the inner cavity of the filter press shell; a fixed scraping plate fixed relative to the filter press shell is arranged between each two adjacent disk type filter cores; a filter press auger is arranged at the lower part of the inner cavity of the filter press shell. According to the disk type filter pressing device, the filter press auger is arranged at the lower part of the filter press, and a certain space is cleared out through the filter press auger when filter cakes are discharged; the grouting tank is directly arranged on the filter press, and thus pipelines are shortened; the stirrer is used for crushing the filter cakes in the grouting tank, so that the cakes fall into the filter press and the problem that filter cakes of an existing disk type filter pressing device cannot be discharged is solved.

Owner:江苏银鼎生物质科技有限公司

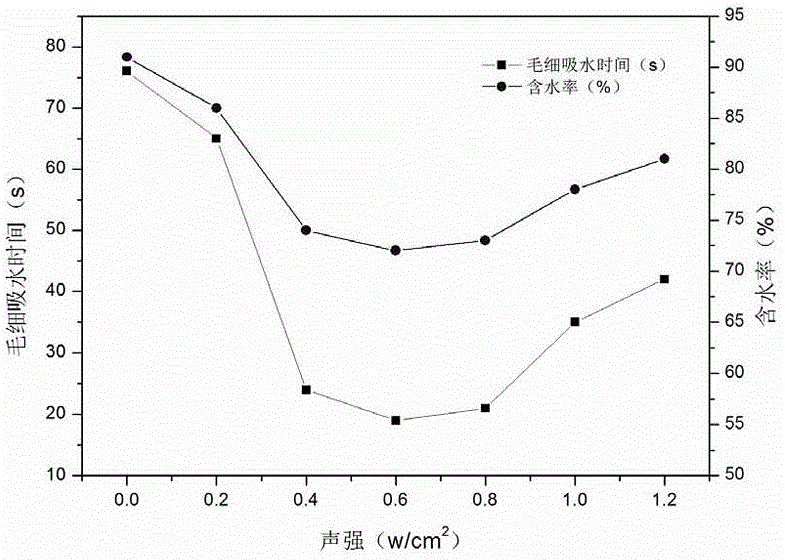

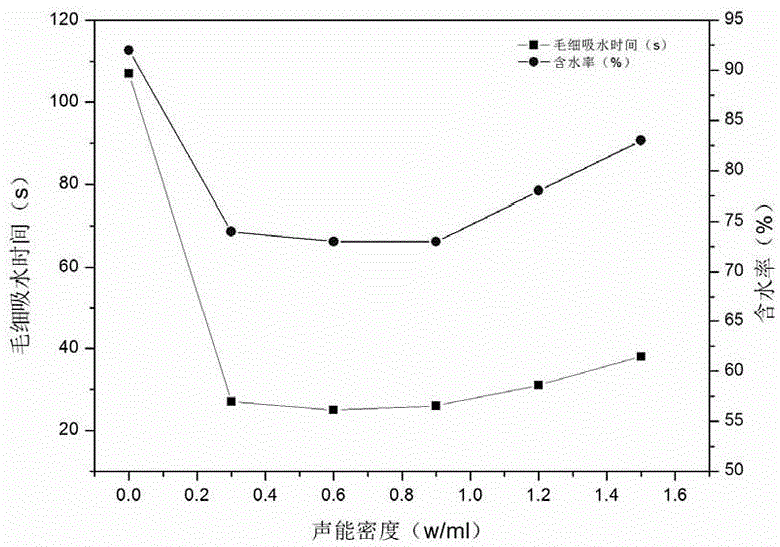

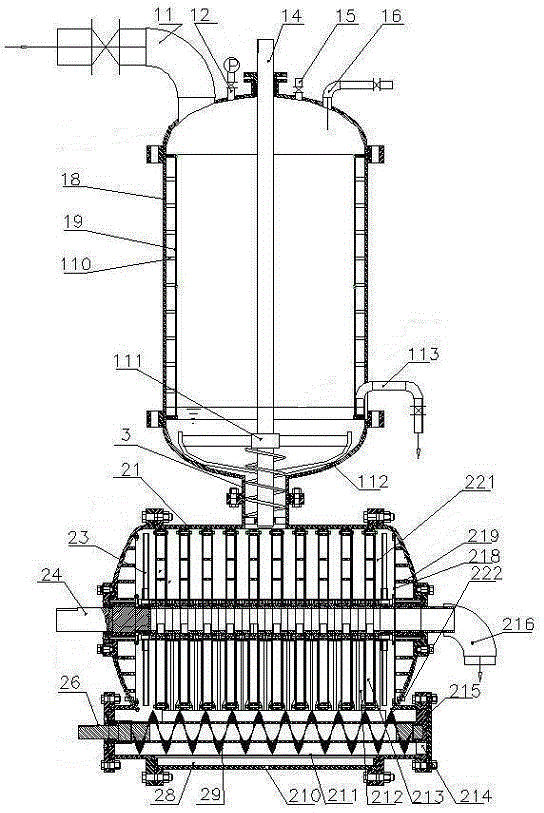

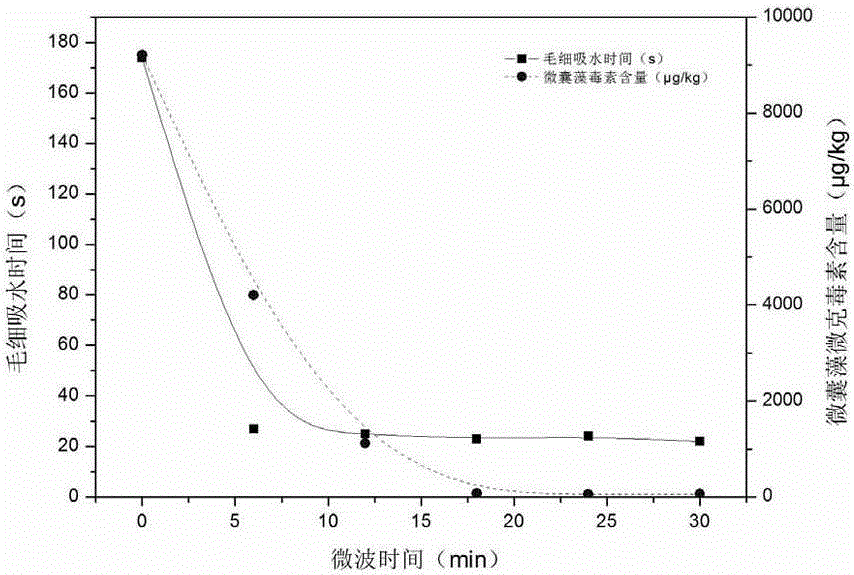

A method for simultaneously detoxifying and dehydrating cyanobacteria

InactiveCN104399315BEfficient dehydrationReduce capillary water absorption timeFiltration separationEnergy based chemical/physical/physico-chemical processesMicrobiologyCyanobacteria

The invention discloses a method for simultaneously detoxifying and dehydrating blue-green algae, which specifically comprises the following steps: adjusting the pH of blue-green algae to be acidic; adding an oxidant to the acidic blue-green algae, and then performing microwave radiation treatment; Carry out pressure filtration and dehydration to complete the treatment of cyanobacteria. The invention can carry out detoxification and rapid dehydration treatment on large quantities of salvaged cyanobacteria, with simple equipment, low use cost, convenient operation and maintenance, high degree of dehydration, greatly reduced volume of cyanobacteria, thorough detoxification, no secondary pollution, and broad application potential. Application prospects.

Owner:HUNAN UNIV

Recrystallization device for chemical product

InactiveCN108888984APrevent wasted product and safety risksGood high temperature resistanceSolution crystallizationCrystallization by component evaporationAsbestosEngineering

The invention discloses a recrystallization device for a chemical product. The device comprises a suction flask, a hose, a base and a base plate. A soft wood plug is arranged above the suction flask,a funnel port and a Buchner funnel are arranged at one end of the soft wood plug, a rubber plug is arranged at one end of the hose, the other end of the hose is connected to the suction flask, a glasstube and a safety bottle are arranged at one end of the rubber plug, a bracket and an iron bracket are arranged above the base, an asbestos wire gauze is fixedly mounted at one end of the bracket, and an evaporation hood and an evaporation vessel are arranged above the asbestos wire gauze. The recrystallization device for the chemical product is provided with a rubber anti-skid sleeve, the safetybottle and the evaporation hood, can prevent slip when sweated hands are in contact with an alcohol lamp, also can prevent a suck-back phenomenon caused by operating errors to pollute a sample, can reduce evaporation of the sample, saves resources and suitable for different working conditions, and brings a better application prospect.

Owner:沈家洛

a liquid filter

ActiveCN103657239BImprove filtering effectEfficient removalFiltration circuitsFilter mediaFilter effect

The invention relates to the technical field of chemical equipment, particularly to a liquid filtering device. The device comprises a tank, wherein a feeding port and a discharging port are arranged on the tank; a magnetic filtering net, a filtering cloth, a decolorizing filtering medium and a micro-porous filtering medium are installed in the tank sequentially from top to bottom; and a receiver is connected to an outlet of the tank. With the adoption of the technical scheme, the liquid filtering device has the benefits as follows: the liquid filtering device is good in filtering effect and capable of effectively removing tiny impurities in a liquid and removing pigments in the liquid; reduced-pressure suction filtration is adopted, the suction filtration speed is high, and the efficiency is high; and a manhole is arranged on the tank, so that maintenance is facilitated.

Owner:郎溪品旭科技发展有限公司

A disc filter press device

ActiveCN104785002BSolve the problem that cannot be uninstalledSave pipesStationary filtering element filtersBiochemical engineeringFilter press

The invention discloses a disk type filter pressing device, which is composed of a grouting tank and a filter press, wherein the bottom end of a grouting tank shell is communicated with the top end of a filter press shell, a stirrer extending towards the filter press is arranged in the inner cavity of the grouting tank shell; a slewing shaft of the filter press horizontally penetrates through the filter press shell and is of a hollow structure; one end of the slewing shaft is communicated with a filtrate connector of the filter press; multiple disk type filter cores communicated with the inner cavity of the slewing shaft are coaxially arranged on the slewing shaft and in the inner cavity of the filter press shell; a fixed scraping plate fixed relative to the filter press shell is arranged between each two adjacent disk type filter cores; a filter press auger is arranged at the lower part of the inner cavity of the filter press shell. According to the disk type filter pressing device, the filter press auger is arranged at the lower part of the filter press, and a certain space is cleared out through the filter press auger when filter cakes are discharged; the grouting tank is directly arranged on the filter press, and thus pipelines are shortened; the stirrer is used for crushing the filter cakes in the grouting tank, so that the cakes fall into the filter press and the problem that filter cakes of an existing disk type filter pressing device cannot be discharged is solved.

Owner:江苏银鼎生物质科技有限公司

Simple carbon removing device for silicon carbide micropowder

ActiveCN108249441ASimple structureEasy to manufactureSilicon carbideWet separationFiltrationInvestment material

The invention discloses a simple carbon removing device for silicon carbide micropowder. The simple carbon removing device for silicon carbide micropowder comprises a first water tank, wherein a second water tank is fixedly connected to one side of the outer surface of the first water tank; a material loading box is placed at a middle position of the bottom of the inner cavity of the first water tank; a sliding top cover is transversely connected to the top of the first water tank in a sliding manner; a scraping device is arranged on the surface of one side, away from the second water tank, ofthe sliding top cover; fixing piles are fixedly connected to the surface of the top of the second water tank and at 90-degree included angle positions; a first supporting plate is fixedly connected to the tops of the fixing piles. The invention relates to the technical field of auxiliary materials for electricians. The simple carbon removing device for the silicon carbide micropowder achieves thepurpose of improving the carbon removing efficiency; the whole simple carbon removing device is simple in structure, convenient to manufacture and relatively low in production cost; a carbon removingtechnology is simple and convenient in technological operation; through combination of vacuum suction filtration and the scraping device, the improvement on the overall carbon removing efficiency andthe enhancement on the carbon removing effect are facilitated.

Owner:江苏南京国家农业高新技术产业示范区发展集团有限公司

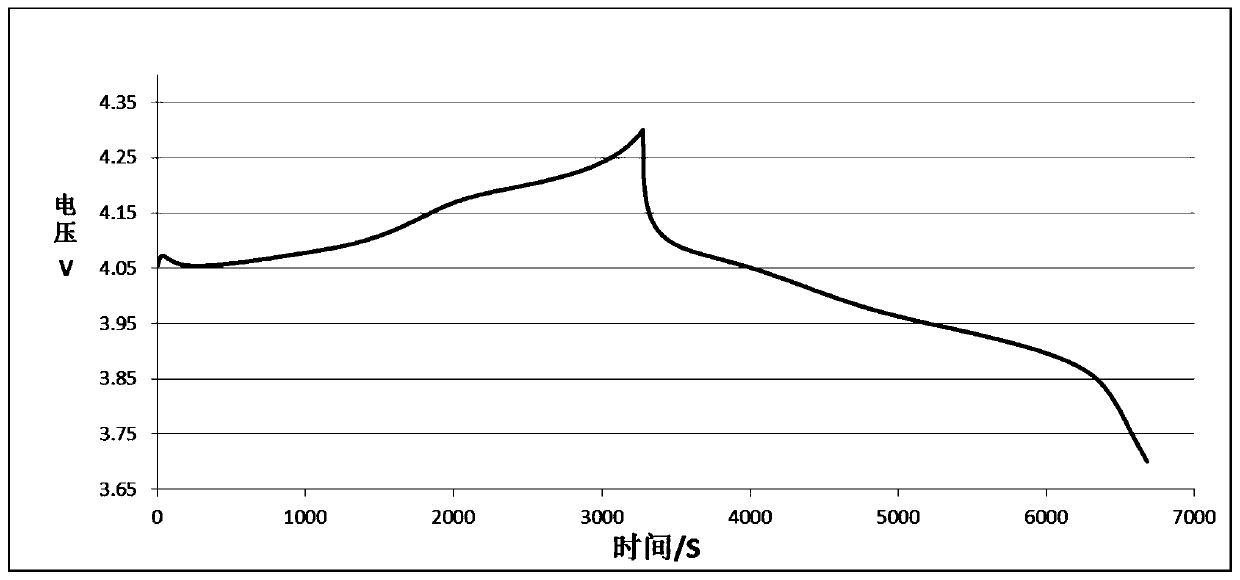

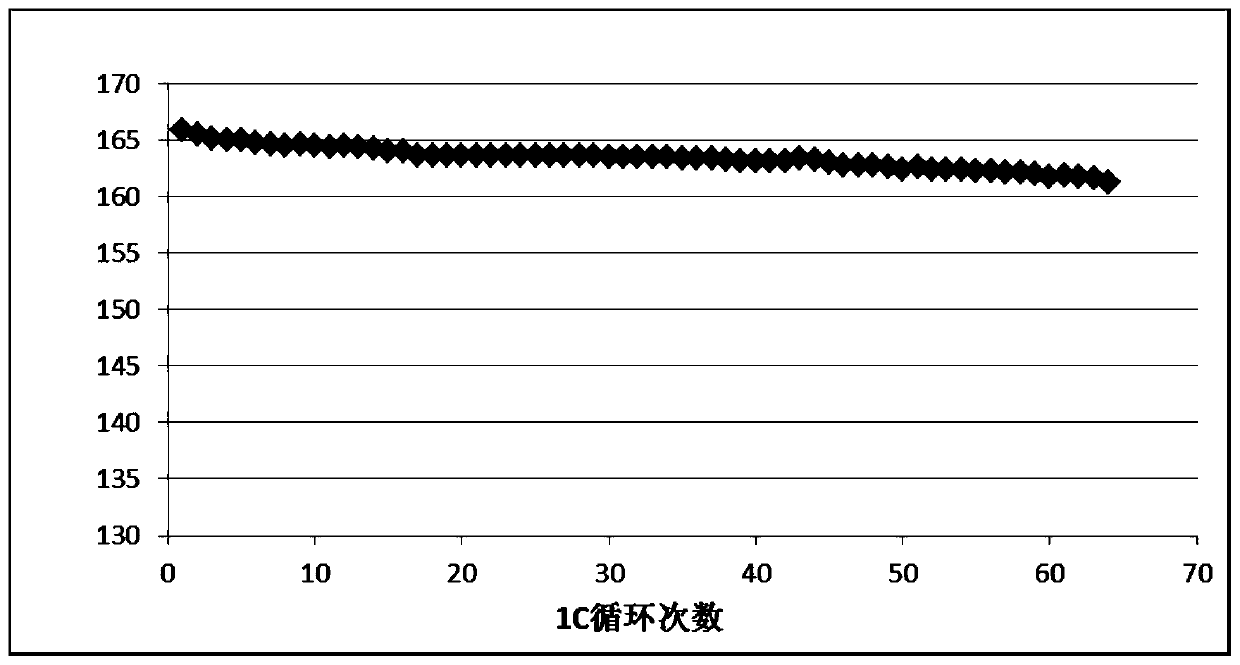

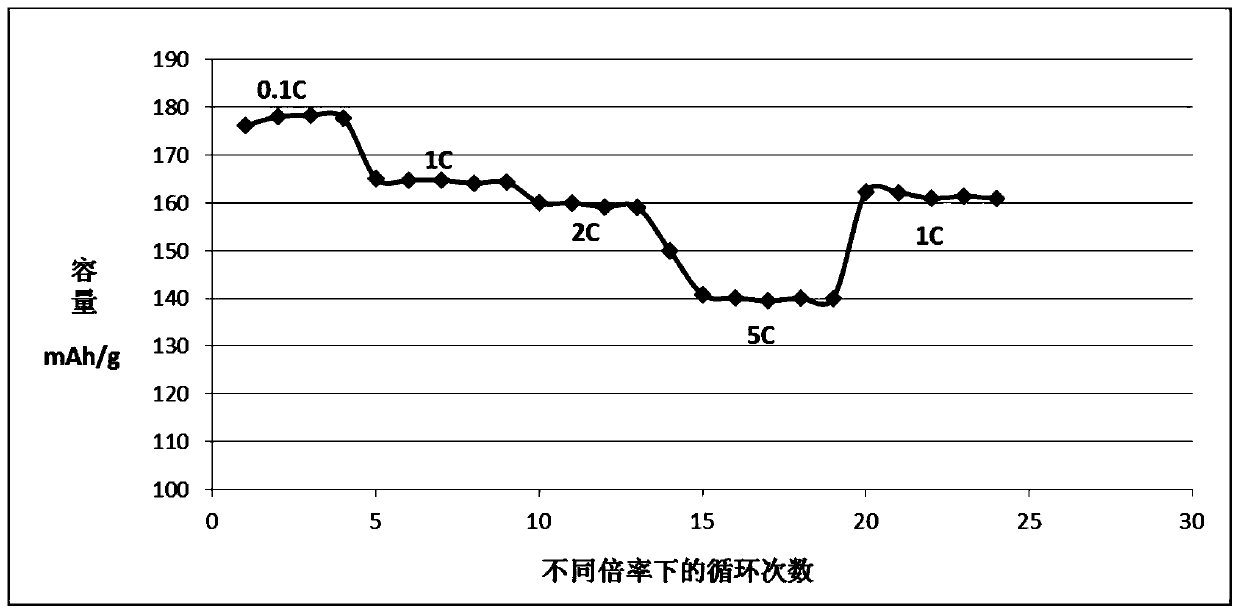

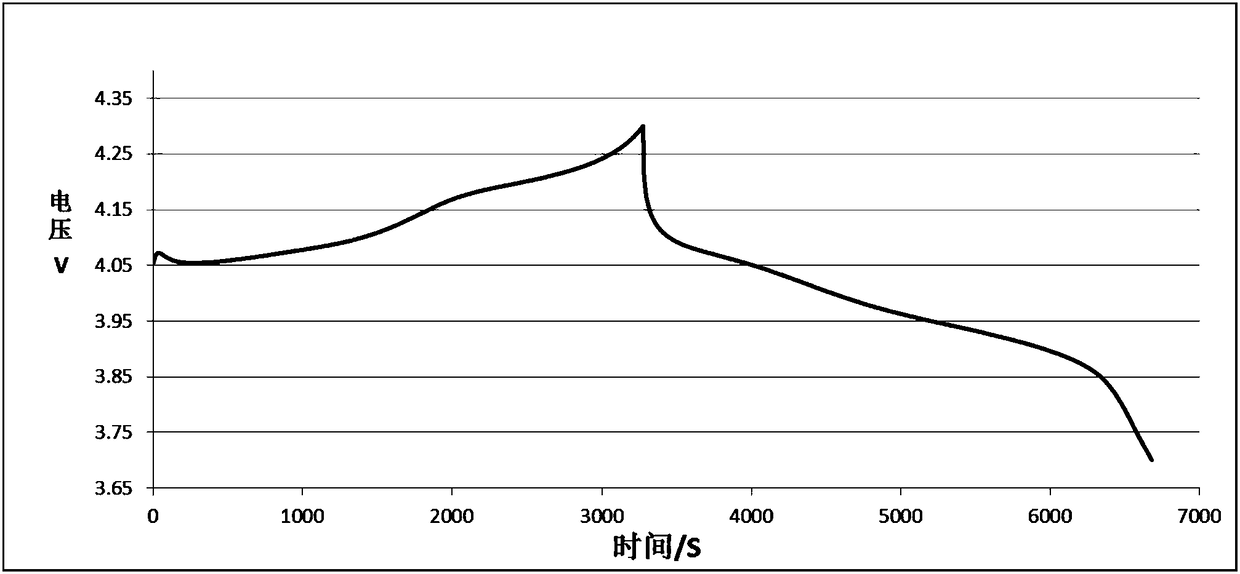

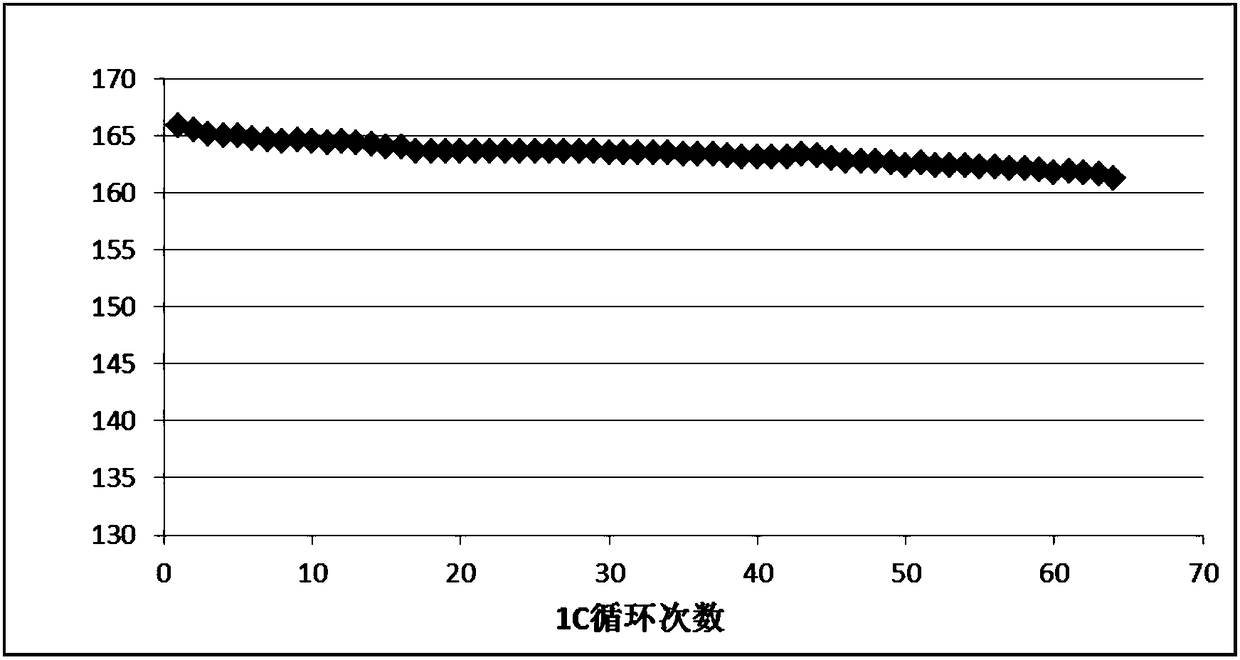

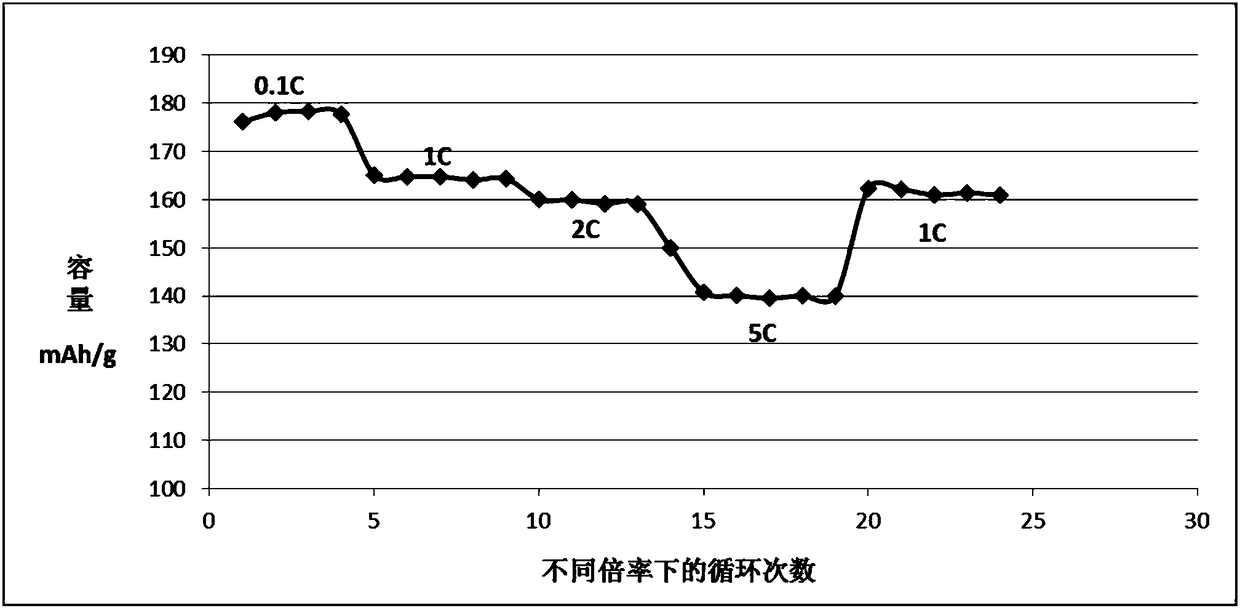

Coating modification method of ncm622 cathode material

ActiveCN108123122BImprove cycle performanceGood coating effectCell electrodesSecondary cellsManganeseSlurry

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

NCM622 anode material coating modification method

The invention relates to an NCM622 anode material coating modification method and belongs to the technical field of preparation of electrode materials. The method comprises the following steps: (1) coating: mixing nickel-cobalt-manganese ternary anode material powder with a dispersing agent, adding an alumina sol, and performing thermostatic reaction; (2) water washing: adding stirred material andequal weight of water into a stirring tank, and stirring to obtain a slurry; (3) suction filtration: pumping the sufficiently stirred slurry into a suction filtration tank for suction filtration; and(4) drying: putting the material after suction filtration into a double-cone drying tank for drying, so as to obtain the aluminum coated ternary anode material. According to the invention, the waterwashing cost is lowered based on the procedures of water washing and drying, and therefore, water washing is simpler, suction filtration speed is higher, efficiency is higher, productivity is promotedby more than two times, the production efficiency of a dynamical type ternary anode material is increased, and influence to the performances is avoided.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

A simple carbon removal device for silicon carbide micropowder

ActiveCN108249441BSimple structureEasy to manufactureSilicon carbideWet separationFiltrationInvestment material

The invention discloses a simple carbon removing device for silicon carbide micropowder. The simple carbon removing device for silicon carbide micropowder comprises a first water tank, wherein a second water tank is fixedly connected to one side of the outer surface of the first water tank; a material loading box is placed at a middle position of the bottom of the inner cavity of the first water tank; a sliding top cover is transversely connected to the top of the first water tank in a sliding manner; a scraping device is arranged on the surface of one side, away from the second water tank, ofthe sliding top cover; fixing piles are fixedly connected to the surface of the top of the second water tank and at 90-degree included angle positions; a first supporting plate is fixedly connected to the tops of the fixing piles. The invention relates to the technical field of auxiliary materials for electricians. The simple carbon removing device for the silicon carbide micropowder achieves thepurpose of improving the carbon removing efficiency; the whole simple carbon removing device is simple in structure, convenient to manufacture and relatively low in production cost; a carbon removingtechnology is simple and convenient in technological operation; through combination of vacuum suction filtration and the scraping device, the improvement on the overall carbon removing efficiency andthe enhancement on the carbon removing effect are facilitated.

Owner:江苏南京国家农业高新技术产业示范区发展集团有限公司

A coagulant for treating fine-grained high-clay slime water

ActiveCN105129943BWill not accumulateDoes not affect water qualityWater/sewage treatment by flocculation/precipitationWater qualityCalcite

The invention discloses a coagulant for treating fine-grained high-clay coal slime water, which is prepared by uniformly mixing two or more of barite powder, calcite powder, dolomite powder and medical stone powder. The coagulant of the present invention is a mineral preparation, which is discharged together with the coal slime during use, does not accumulate in water, and does not affect water quality. The particles are easy to flocculate and settle, which speeds up the pressure filtration speed of coal slime and improves the quality and output of clean coal. The coagulant of the present invention, combined with a suitable flocculant, has a good effect when used to treat coal slime water with complex components and is difficult to settle, especially for high-clay, fine-grained coal slime water, the coagulation effect is obvious, and it can fully meet the actual production needs. The water content of the final coal slime filter cake is reduced to below 25%, and the content of suspended solids in the overflow water of the thickener is less than 150mg / L.

Owner:陕西省地质矿产实验研究所有限公司

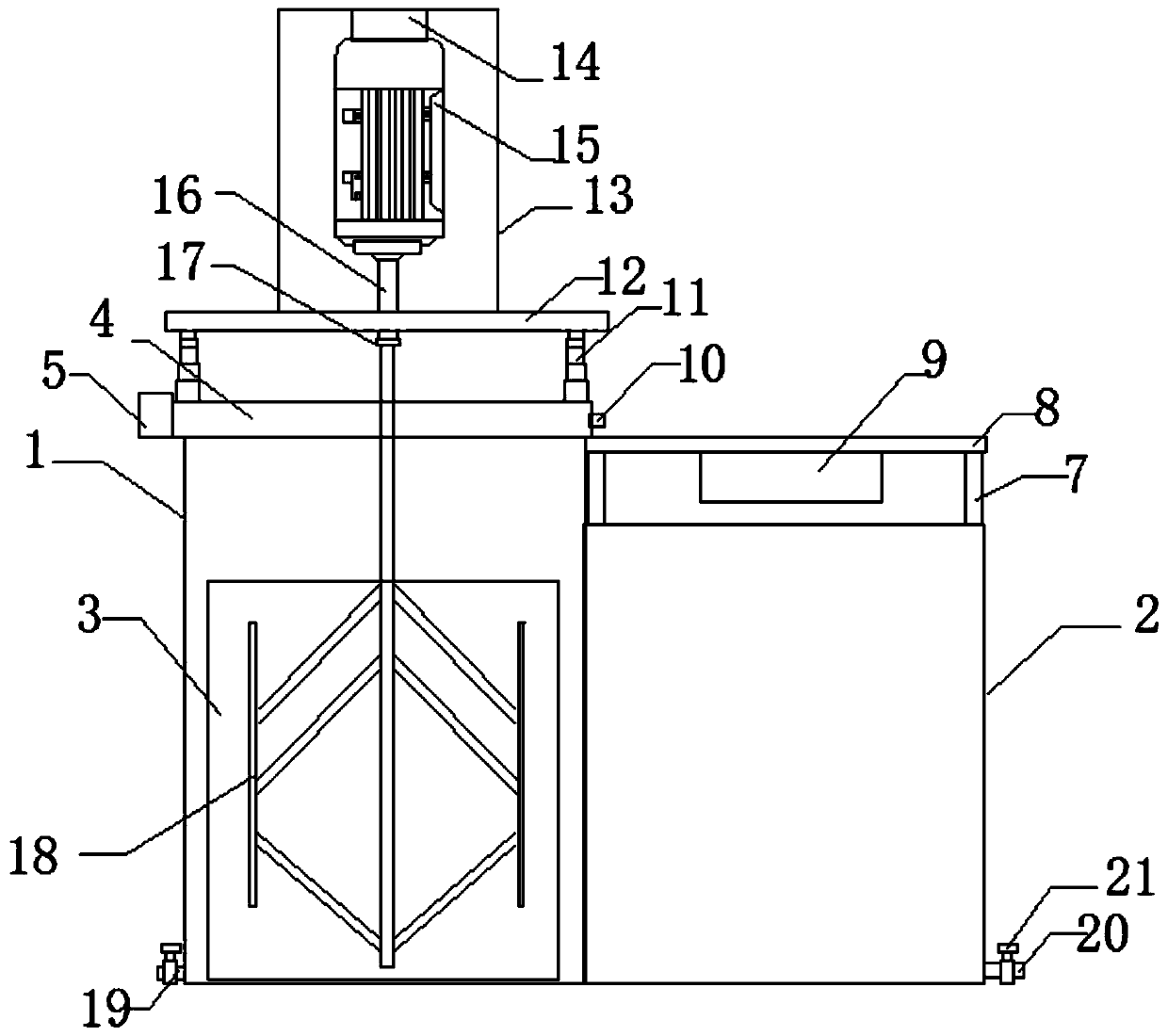

Fermentation device for preparing straw organic fertilizer

PendingCN114685207AIncrease fermentation speedImprove dispersion efficiencyBio-organic fraction processingOrganic fertiliser apparatusChemistryAgricultural engineering

The invention discloses a fermentation device for preparing straw organic fertilizer, which comprises a tank body, the tank body is a main shell structure of the fermentation device, and a fermentation cavity is arranged in the tank body; the bearing plate is located in the fermentation cavity, supporting springs are fixedly connected to the bottom surface of the bearing plate, and the bearing plate and the fermentation cavity form an elastic structure through the supporting springs; the cover plate is mounted on the outer surface of the tank body, and the tank body and the cover plate form a rotating structure. According to the fermentation device for preparing the straw organic fertilizer, in the fermentation process, part of the mass in the fermentation device can become CO2 to be volatilized, so that the weight of a material is reduced, at the moment, a supporting spring can gradually jack up a bearing plate to ascend, a first magnetic block on the bearing plate can repel a second magnetic block, and the second magnetic block can repel the second magnetic block; and at the moment, the second magnetic block stretches the blocking block through the top cover and is not clamped with the groove any more, so that the cover plate can be pushed away through pressure.

Owner:ANHUI SCI & TECH UNIV

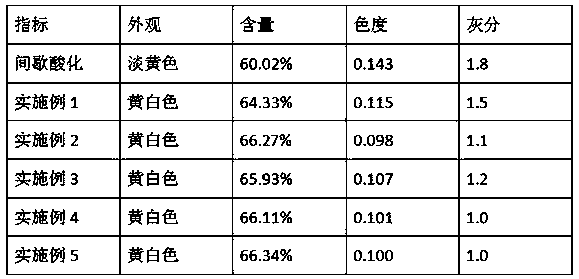

A method for continuous gradient acidification of DSD acid

ActiveCN110317154BLess impuritiesIncrease fermentation speedOrganic compound preparationSulfonic acid preparationBiochemistrySalt solution

A method for continuous gradient acidification of DSD acid, the method uses 2-6 acidification tanks, the feed port of the latter acidification tank is connected to the discharge port of the previous acidification tank, and the pH value of the first-level acidification tank is The set value of the pH value of the final acidification tank is not less than 5.0, the set value of the pH value of the last stage acidification tank is not greater than 3.5, and the set value of the pH value of the latter stage acidification tank is not greater than the set value of the pH value of the previous stage acidification tank; the process is as follows : First, stabilize the temperature of each stage of acidification kettle at 60°C-110°C, and start stirring, then add DSD acid sodium salt solution and inorganic acid to the first stage acidification kettle, and then add additional inorganic acid to the subsequent acidification kettle, so that each stage The pH value of the acidification tank is stable at the set value of the pH value of the acidification tank of this stage, and the solid-liquid mixture flowing out of the last stage of acidification tank is the acidified DSD acid. This method utilizes the method of decreasing the pH value by gradient, not only uses a small amount of DSD acid crystals precipitated in the early stage as seeds, but also provides necessary conditions for the subsequent growth of DSD acid crystals.

Owner:ZHEJIANG HONGDA CHEM

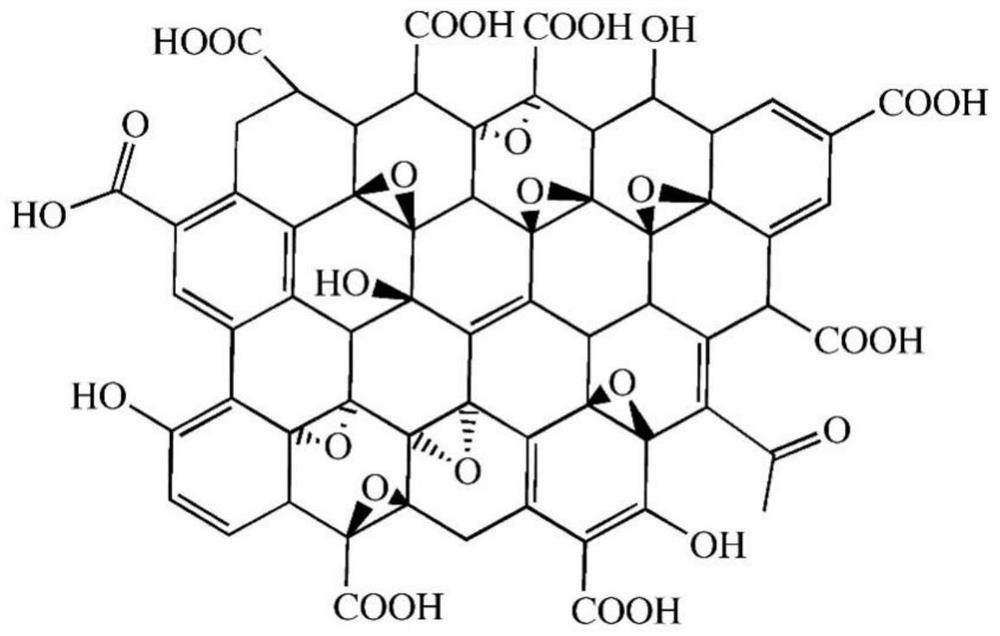

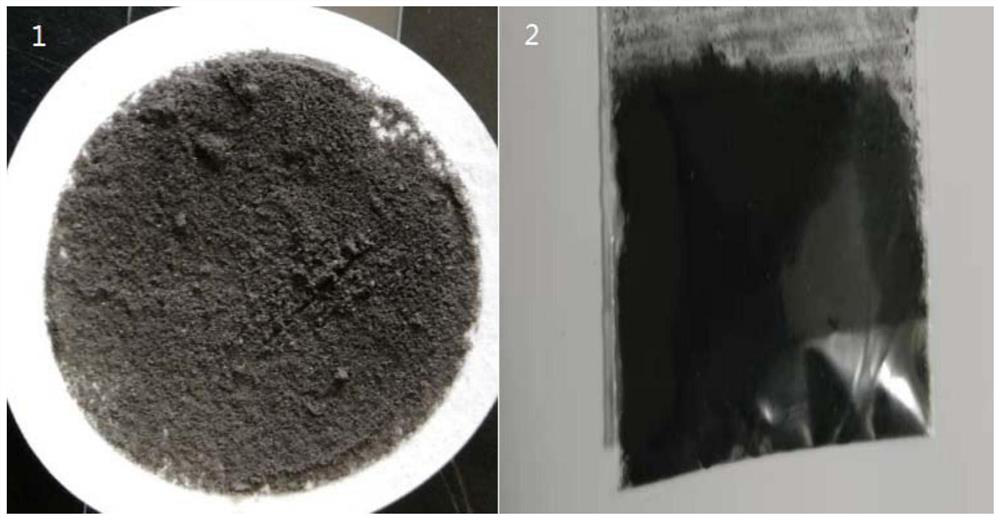

Preparation method of high-efficiency and environment-friendly graphene-paraffin phase change microcapsule material

PendingCN114029009ASimple processImprove hydrophobicityHeat-exchange elementsMicroballoon preparationParaffin waxGraphite

The invention discloses a preparation method of a high-efficiency and environment-friendly graphene-paraffin phase change microcapsule material, and relates to a preparation method of a graphene-paraffin phase change microcapsule material. The problems of low yield, high pollution and low production efficiency in the existing graphene-paraffin phase change microcapsule material production process are solved. The preparation method comprises the following steps: 1, preparing a graphene oxide dispersion liquid; 2, adjusting the pH value; 3, adding solid paraffin; 4, adding L-ascorbic acid; 5, cooling; and 6, carrying out suction filtration, washing and drying in the shade. The method is used for preparing the high-efficiency and environment-friendly graphene-paraffin phase change microcapsule material.

Owner:HARBIN INST OF TECH

Method for continuous gradient acidification of DSD acid

ActiveCN110317154ALess impuritiesIncrease fermentation speedOrganic compound preparationSulfonic acid preparationFiltrationCrystal growth

Provided is a method for continuous gradient acidification of DSD acid. The method uses 2-6-stage acidification kettles, a feed port of the later-stage acidification kettle is communicated with a discharge port of the former-stage acidification kettle, the set value of the pH value of the first-stage acidification kettle is not smaller than 5.0, the set value of the pH value of the last-stage acidification kettle is not larger than 3.5, and the set value of the pH value of the later-stage acidification kettle is not larger than the set value of the pH value of the former-stage acidification kettle. The process includes the following steps of stabilizing the temperature of each stage of acidification kettle at 60-110 DEG C, starting to conduct stirring, adding a DSD sodium sulfate solutionand inorganic acid into the first-stage acidification kettle, and only adding inorganic acid into the subsequent acidification kettles so that the pH value of each stage of acidification kettle can bestabilized at the set value of the pH value of the stage of acidification kettle to obtain a solid-liquid mixture (the acidified DSD acid) flowing out of the first-stage acidification kettle. By means of the gradient pH value reducing method, a small number of DSD acid crystals separated out in the former period serve as the crystal seeds, necessary conditions are provided for the subsequent DSDacid crystal growth, and the obtained DSD acid is high in press-filtration speed and high in content and contains few impurities.

Owner:ZHEJIANG HONGDA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com