Coating modification method of ncm622 cathode material

A positive electrode material and coating technology, which is applied in the field of NCM622 positive electrode material coating modification, can solve the problems of small production capacity, expansion of production capacity and performance cannot be taken into account, and achieve the effect of protecting the environment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

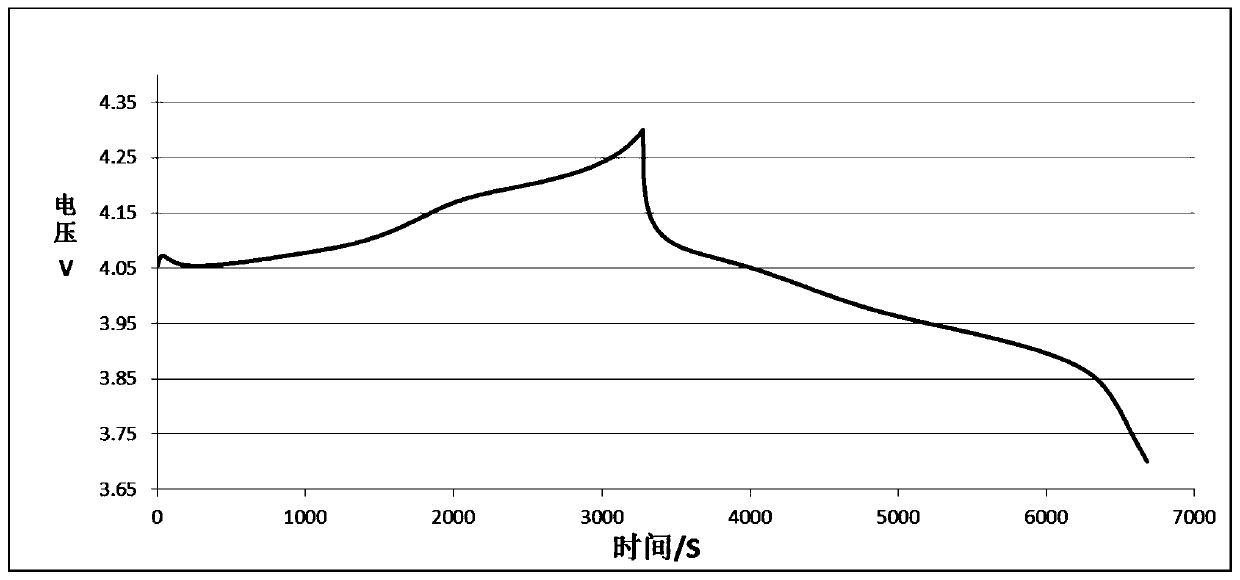

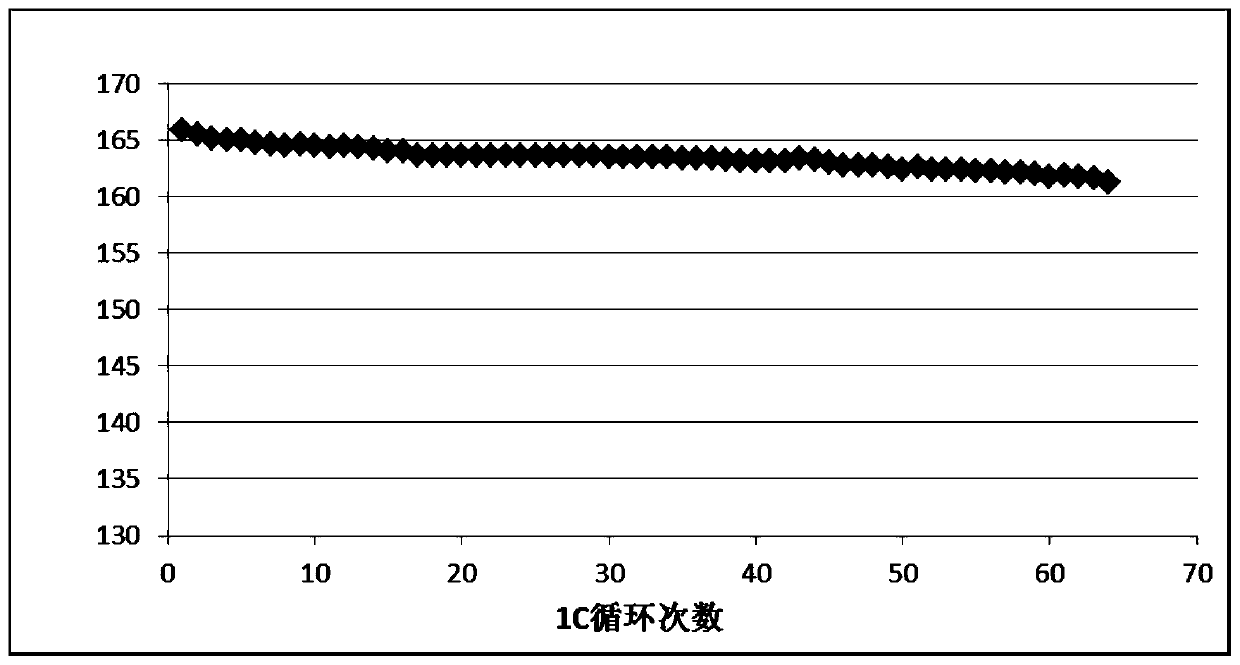

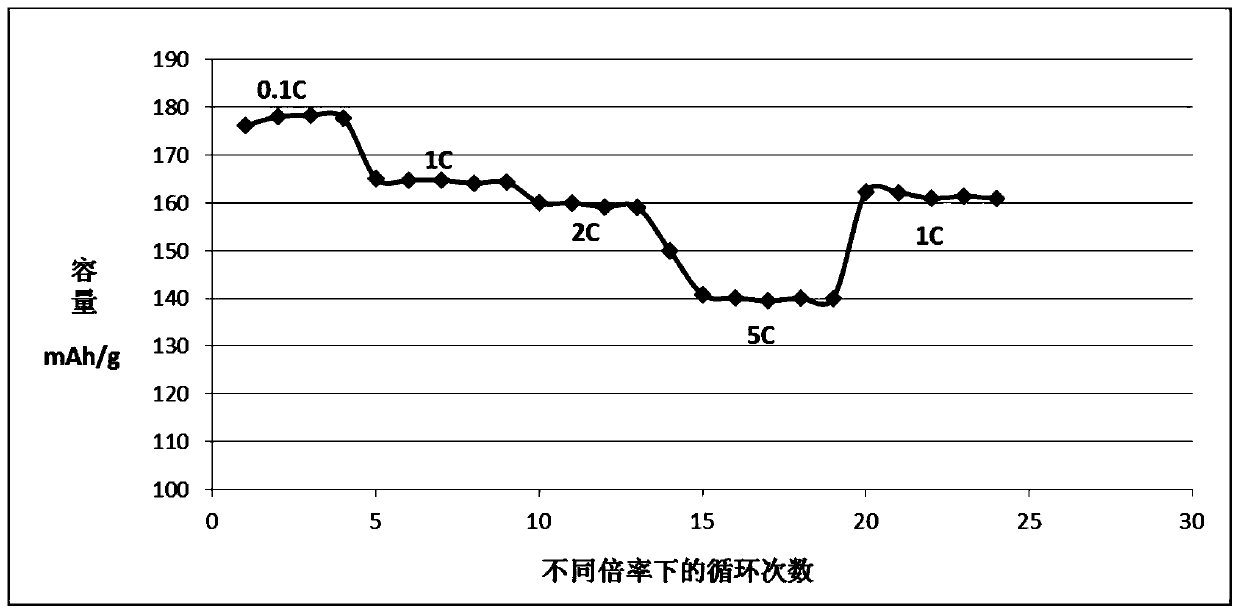

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] The invention relates to a 622 power type NCM622 cathode material coating modification method, comprising the following steps:

[0032] 1) Coating: Mix nickel-cobalt-manganese ternary cathode material powder with deionized water at a mass ratio of 1:1, add aluminum sol (manufacturer: Dalian Snow), and react at a constant temperature of 35°C.

[0033] 2) Water washing: Add tap water with the same weight as the material into the mixing tank (the upper edge of the scale corresponds to the water level line of 450Kg material), start stirring, then add the material for water washing and stirring for 20 minutes. The amount of each washing material is controlled at 500-1000Kg.

[0034] After stirring, turn on the air pump, put the slurry into the suction filter tank, then use 10Kg tap water to clean the mixing tank, and put the cleaning slurry into the suction filter tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com