Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "Easy to scrape off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

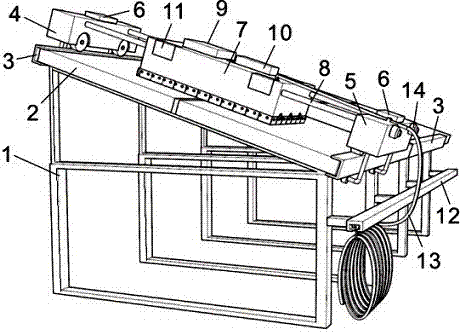

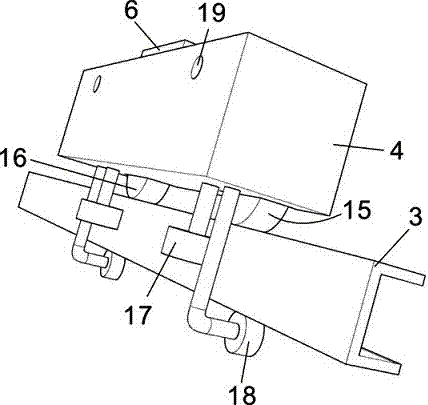

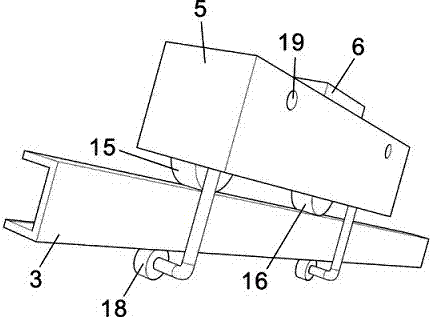

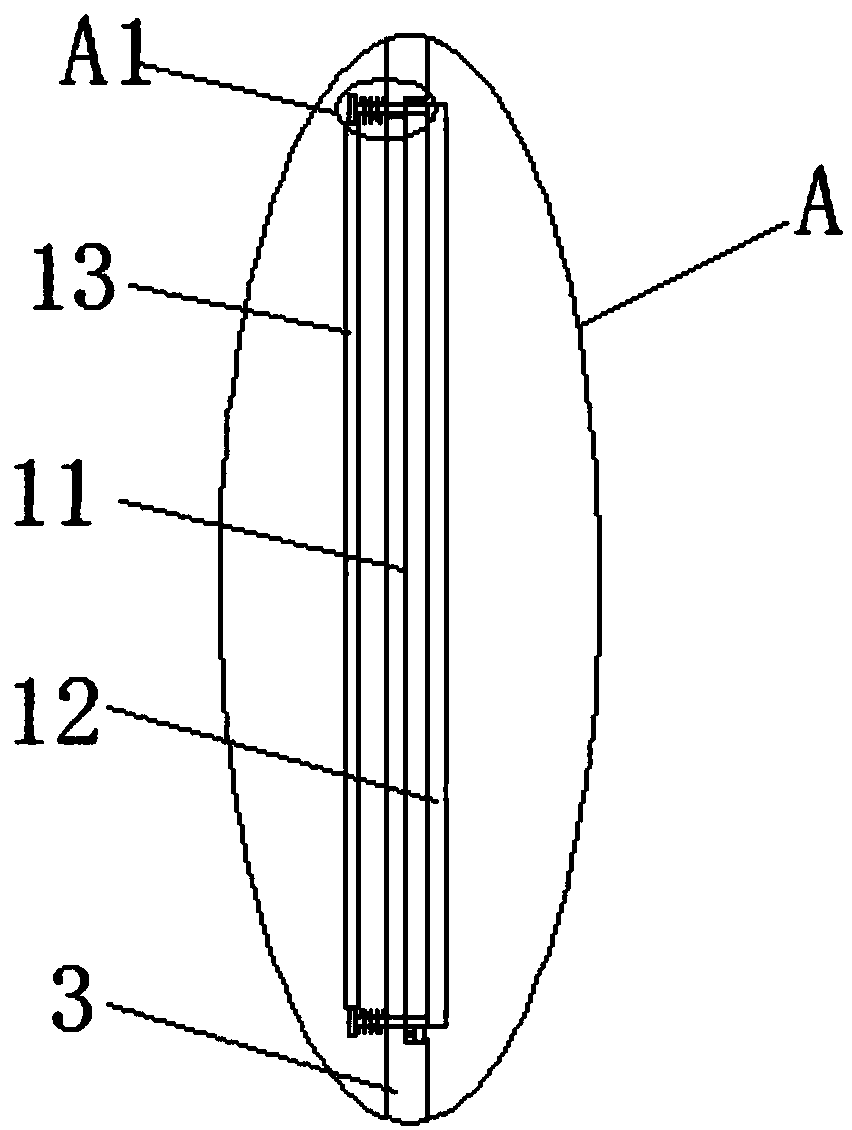

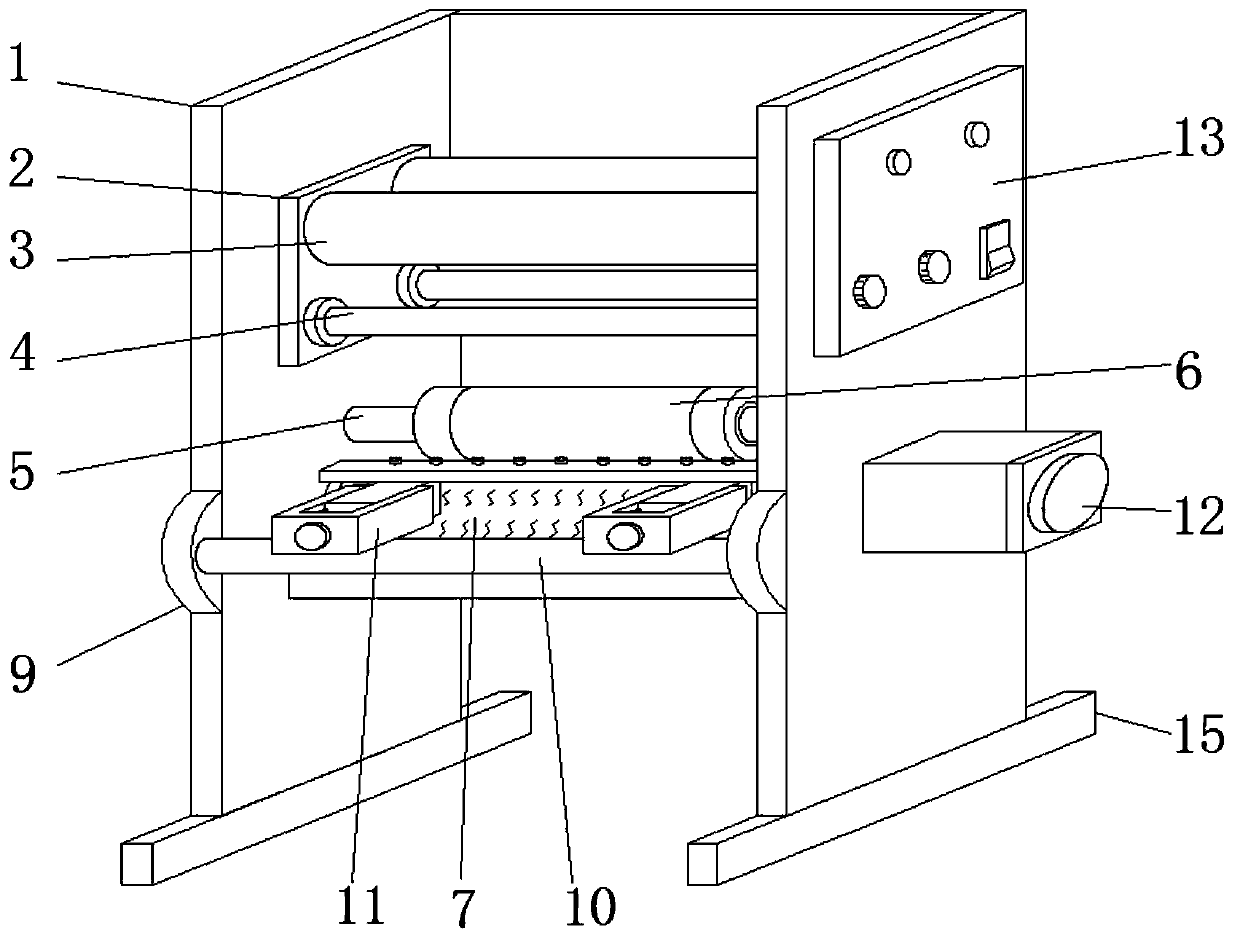

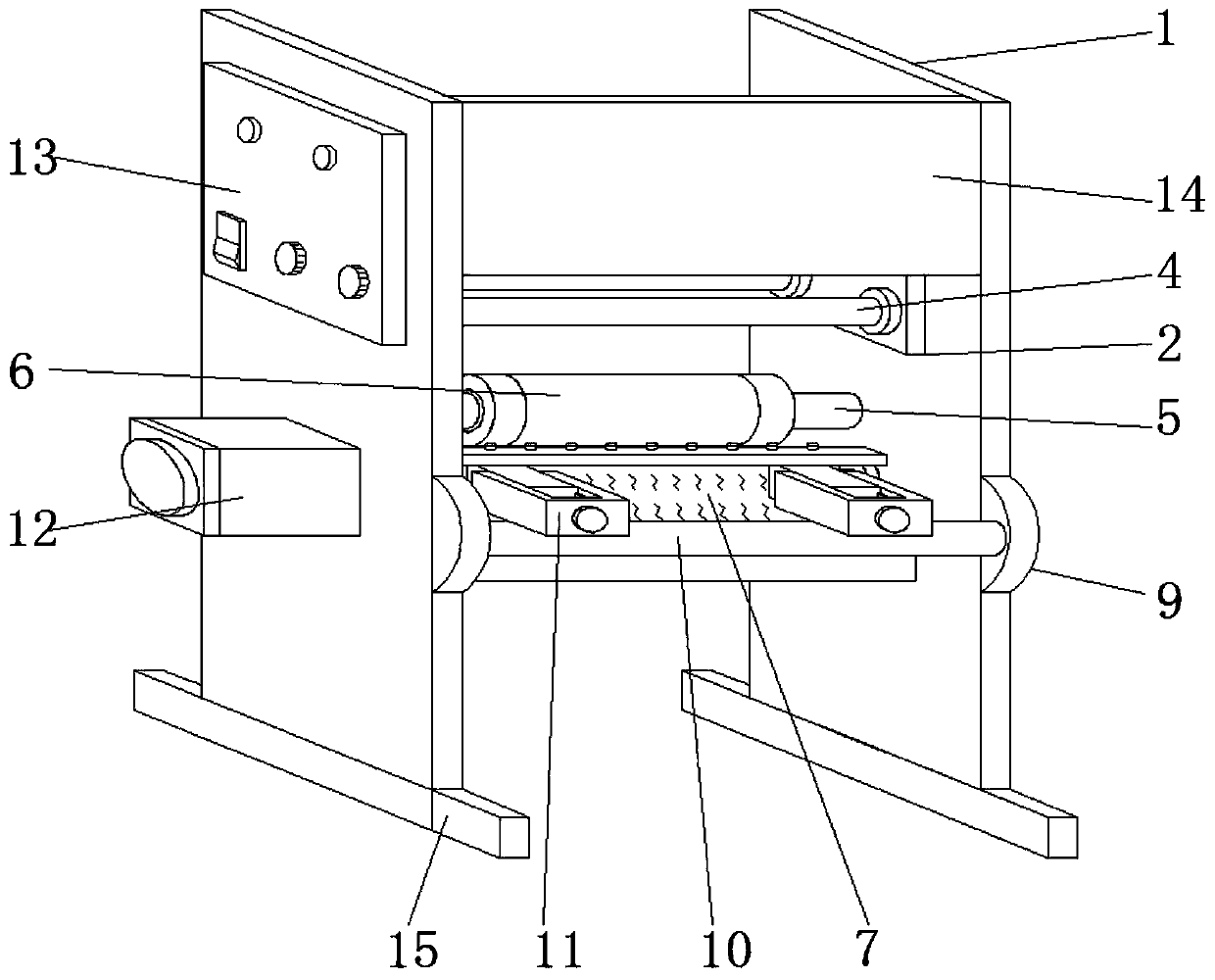

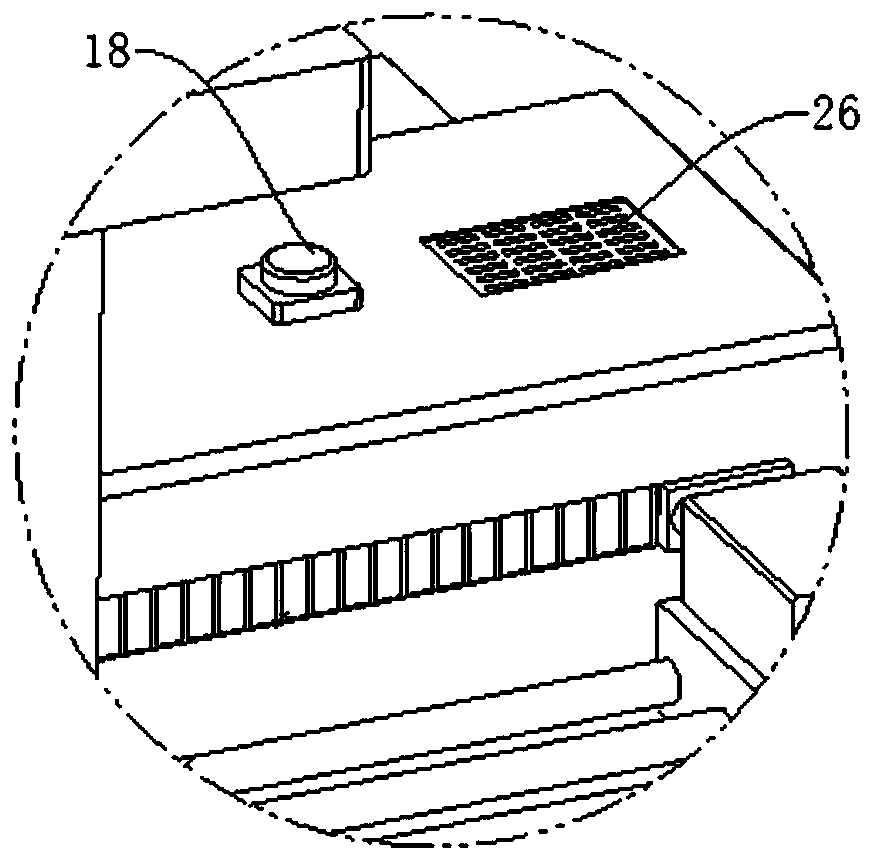

Novel solar photovoltaic panel cleaning device

InactiveCN107052009AEasy to cleanEasy to transportPhotovoltaicsFlexible article cleaningDrive wheelFixed frame

The invention relates to a novel solar photovoltaic panel cleaning device and belongs to the field of solar photovoltaic panel cleaning devices. The novel solar photovoltaic panel cleaning device is characterized in that a photovoltaic panel is obliquely fixed to a photovoltaic fixing frame, and a sliding rail is fixedly arranged on the front side of the fixing frame; rails are mounted on the upper side and the lower side of the photovoltaic panel, the upper rail is provided with an upper sports car, and the lower rail is provided with a lower sports car; each of the upper sports car and the lower sports car is provided with a driving wheel and a driven wheel which are pressed on the top face of the corresponding rail, the driving wheels are controlled by motors in remote electromechanical boxes on the corresponding sports cars, and the lower portions of the two sports cars are further provided with rail lower clamping wheels through L-shaped shafts; shaft holes are formed in a brush roller fixing box, the brush roller fixing box is mounted on a fixed connecting shaft between the upper sports car and the lower sports car, and the position of the brush roller fixing box is adjusted by self-locking nuts in adjusting grooves; the adjusting grooves are correspondingly located in the front edge and the rear edge of the top of the brush roller fixing box; and a brush roller power distribution signal box is mounted on the top of the brush roller fixing box, a scraper is mounted on the lower edge of the brush roller fixing box, and a sliding rod is transversely fixed to the front side face of the brush roller fixing box.

Owner:李琦

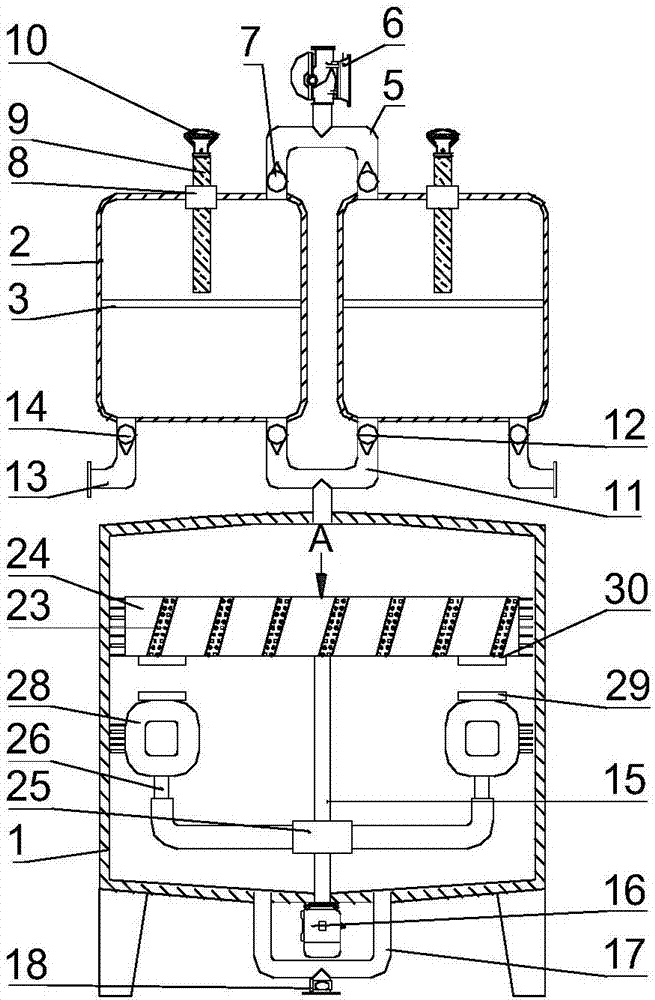

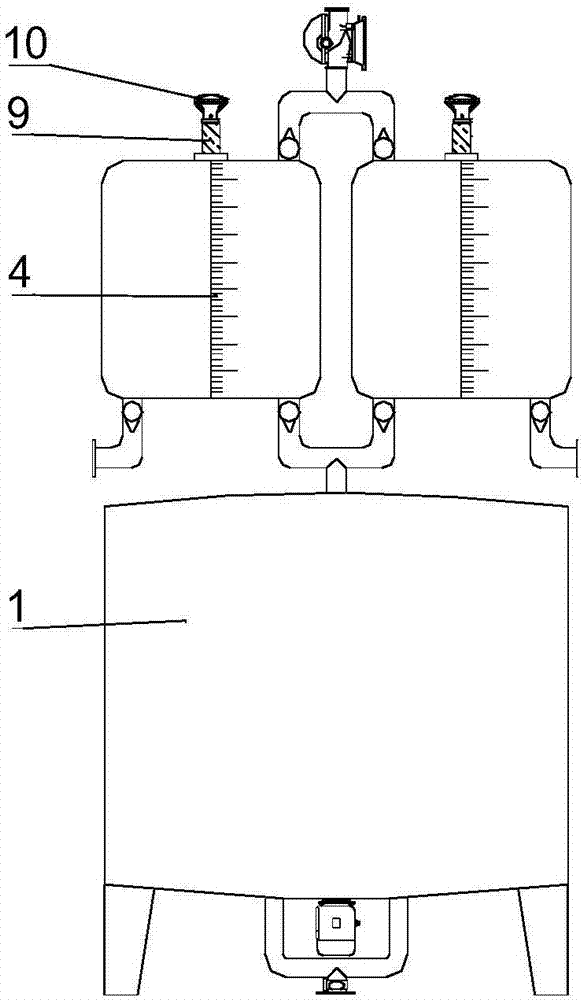

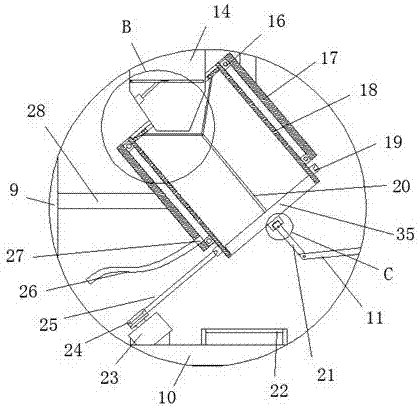

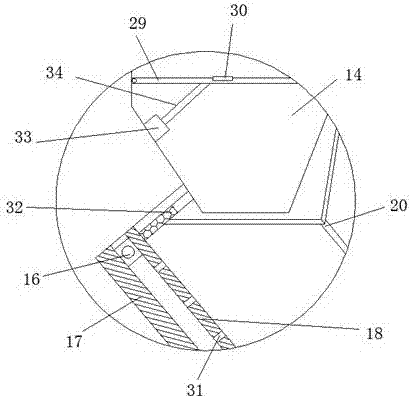

Mixed paint fast proportioning device for building construction

InactiveCN107398216AEasy to scrape offIncrease the mixing areaRotary stirring mixersTransportation and packagingBristleReciprocating motion

The invention discloses a mixed paint fast proportioning device for building construction. The device consists of: proportioning tanks, a mixing tank, piston plates, threaded columns, threaded sleeves, a negative pressure pump, movable sleeves, L-shaped columns and a rotating ring. Stock solutions of different types are injected into the proportioning tanks according to needed capacity, the stock solutions in the proportioning tanks enter the mixing tank to enable proportioning of the stock solution according to a needed ratio, the centrifugal force makes stirring plates stretch outward to increase the stirring area and improve the mixing quality, first bristle and second bristle scrape off the mixed slurry adhered to the mixing tank inner wall to improve the mixing quality, when the mixed slurry adhered to the mixing tank inner wall is difficultly scraped off, the magnetic-south poles and magnetic-north poles of second magnets under a rotational state and first magnets under a stationary state are the same or opposite alternately, a frame body drives the second bristle to do reciprocating motion up and down, thus achieving easy scraping of the adhered mixed slurry, and further improving the mixing quality.

Owner:林红英

Lining band type filter press with press rolls for fixing mud

InactiveCN101376073ARestore elasticityImprove working conditionsPressesMoving filtering element filtersPulp and paper industryFilter press

The invention discloses a lining belt type pressure filter with a solid mud press roller. The press filter comprises a stander, a driving device, a feeding device, a press area and an auxiliary device, and has the structure that the press area comprises the solid mud press roll, a carrier roller, a guide roller, a filtering stripe and a compression lining belt; the solid mud press roller is a press roller with a solid mud layer covering the surface of the roller, and the solid mud layer adopts the material which has high elasticity, high recoverability, and high fraction coefficient, and is easy to separate from dehydrate material; the solid mud press roller is provided with a maintenance device, which is arranged behind the press position of the solid mud press roller, and the elasticity and the fraction coefficient of the solid mud layer can be recovered in time through the maintenance to the solid mud press roller by the maintenance device; the filtering stripe wraps the solid mud press roller, the carrier roller and the guide roller in sequence; the compression lining belt and the filtering stripe are stacked in parallel in the press segment of the press area; the driving device drives filtering stripe and the compression lining belt; and the feeding device and the auxiliary device are arranged in the corresponding positions of the filtering stripe. The pressure filter of the invention has solid mud structure, thereby effectively solving the problem of mud leaking and achieving better press filter effect.

Owner:ZHEJIANG HUAZHANG TECH

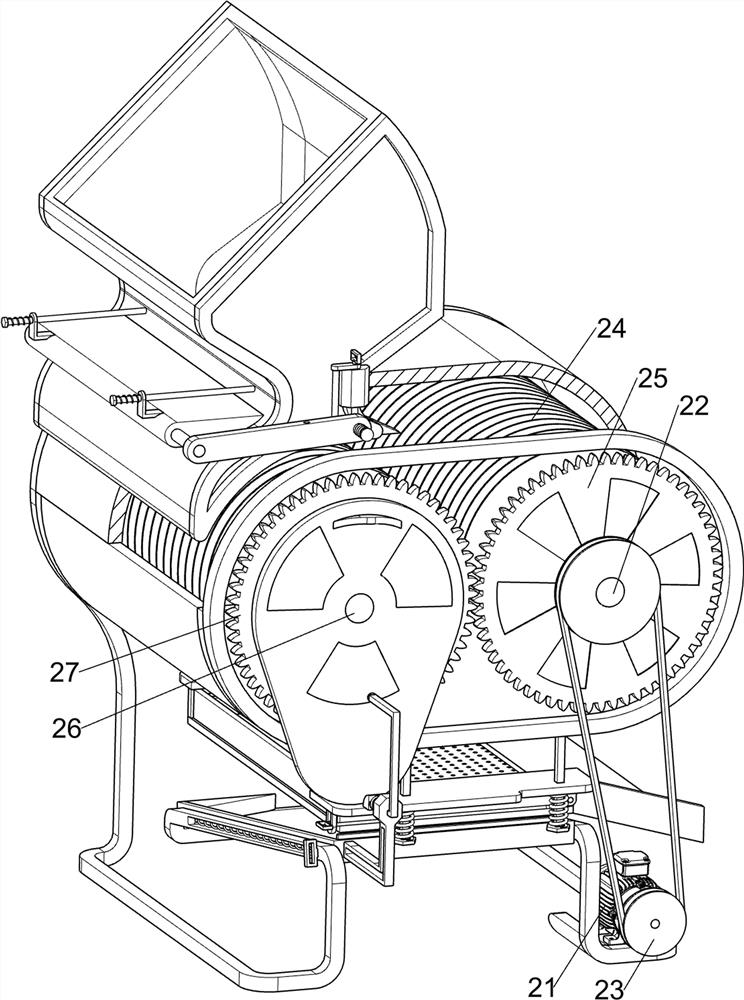

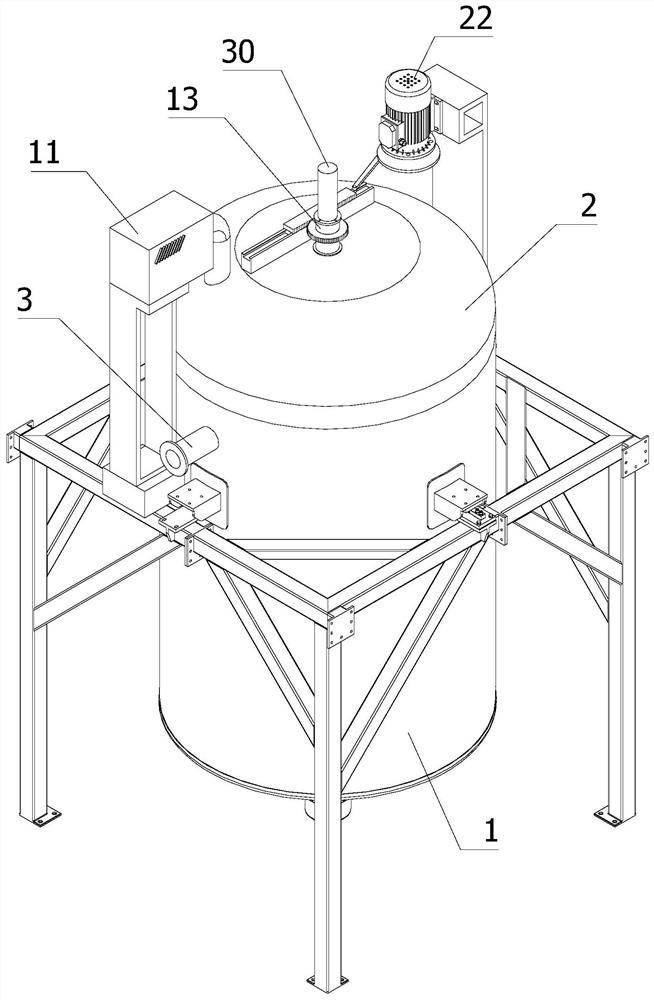

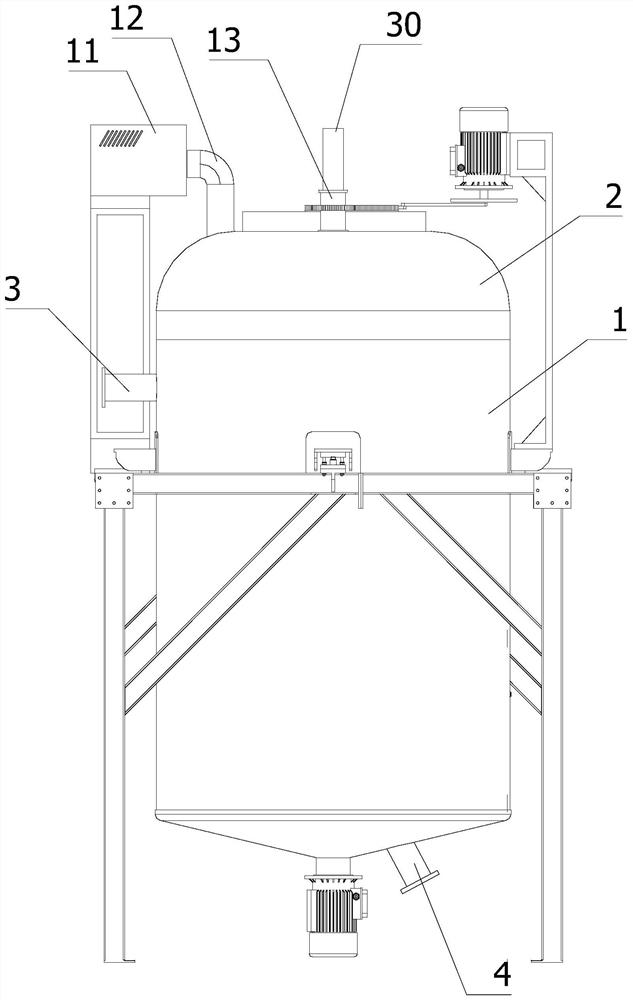

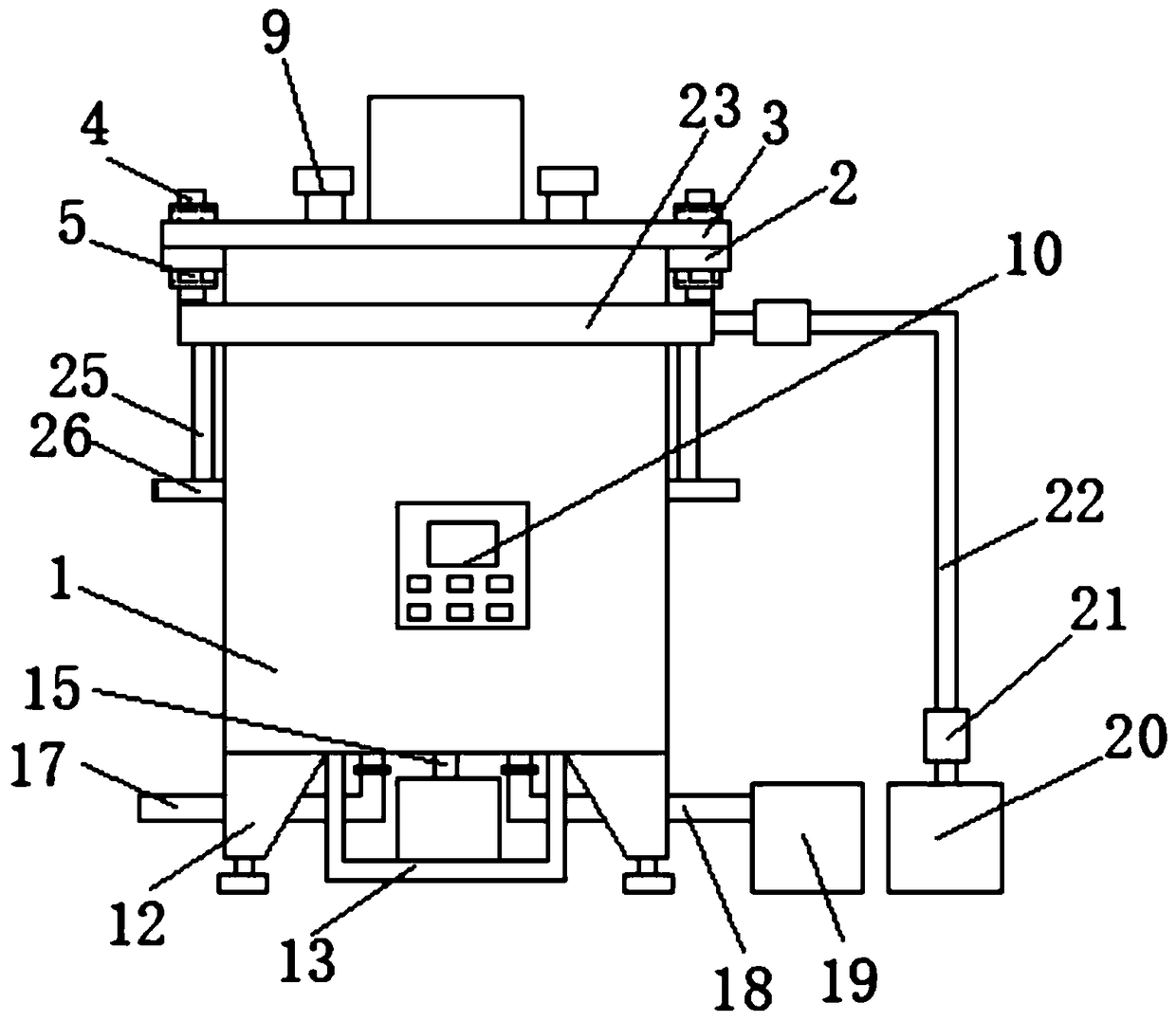

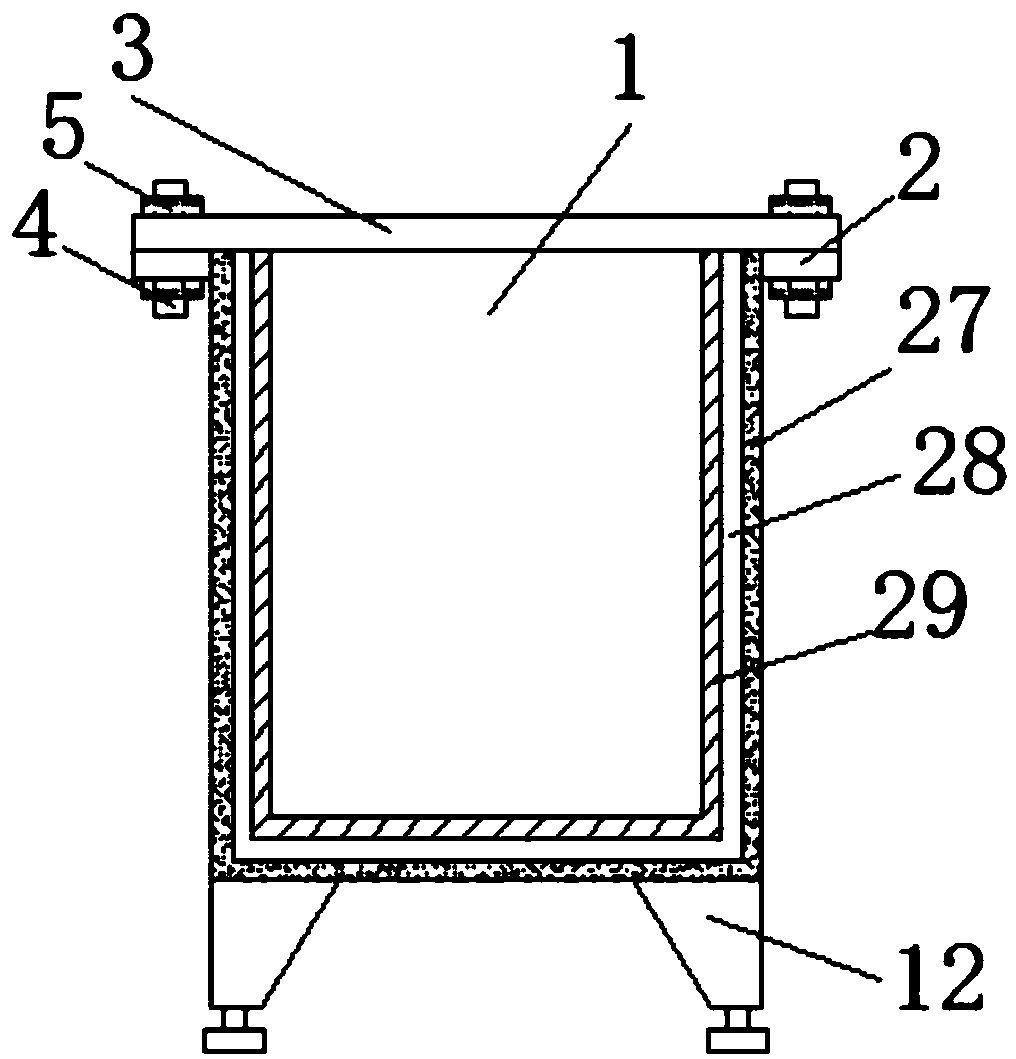

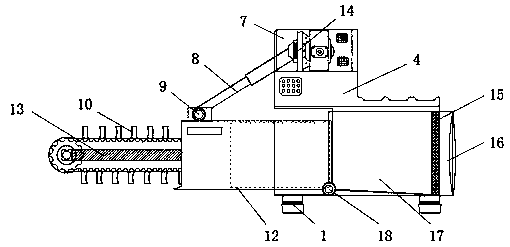

Novel livestock manure processor

InactiveCN106927660AReduce moisture contentEasy to scrape offSludge treatment by de-watering/drying/thickeningLivestock manureWastewater

The invention discloses a novel livestock manure processor and belongs to the field of manure processors. A novel livestock manure processor comprises a conveyer pipe, which is connected to a feed hopper. A screw shaft is rotatably connected inside the conveyer pipe. Screw blades are connected onto the screw shaft. The conveyer pipe is fixedly connected to a support, on which a first driving motor is installed. A driving end of the first driving motor is connected to the screw shaft. The bottom of the conveyer pipe is provided with a wastewater opening and a discharge port. First dehydration treatment of manure can be realized through the conveyer pipe. The discharge port of the conveyer pipe is connected to a discharge buffer. When manure inside the discharge buffer reaches a certain weight, the manure enters a centrifugal rolling cylinder. The centrifugal rolling cylinder rotates at high speed for secondary dehydration treatment of manure. By dual dehydration through screw extrusion dehydration and high-speed rotation dehydration of the centrifugal rolling cylinder, water content of filtered manure is low, and the manure can directly undergo fermentation treatment.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

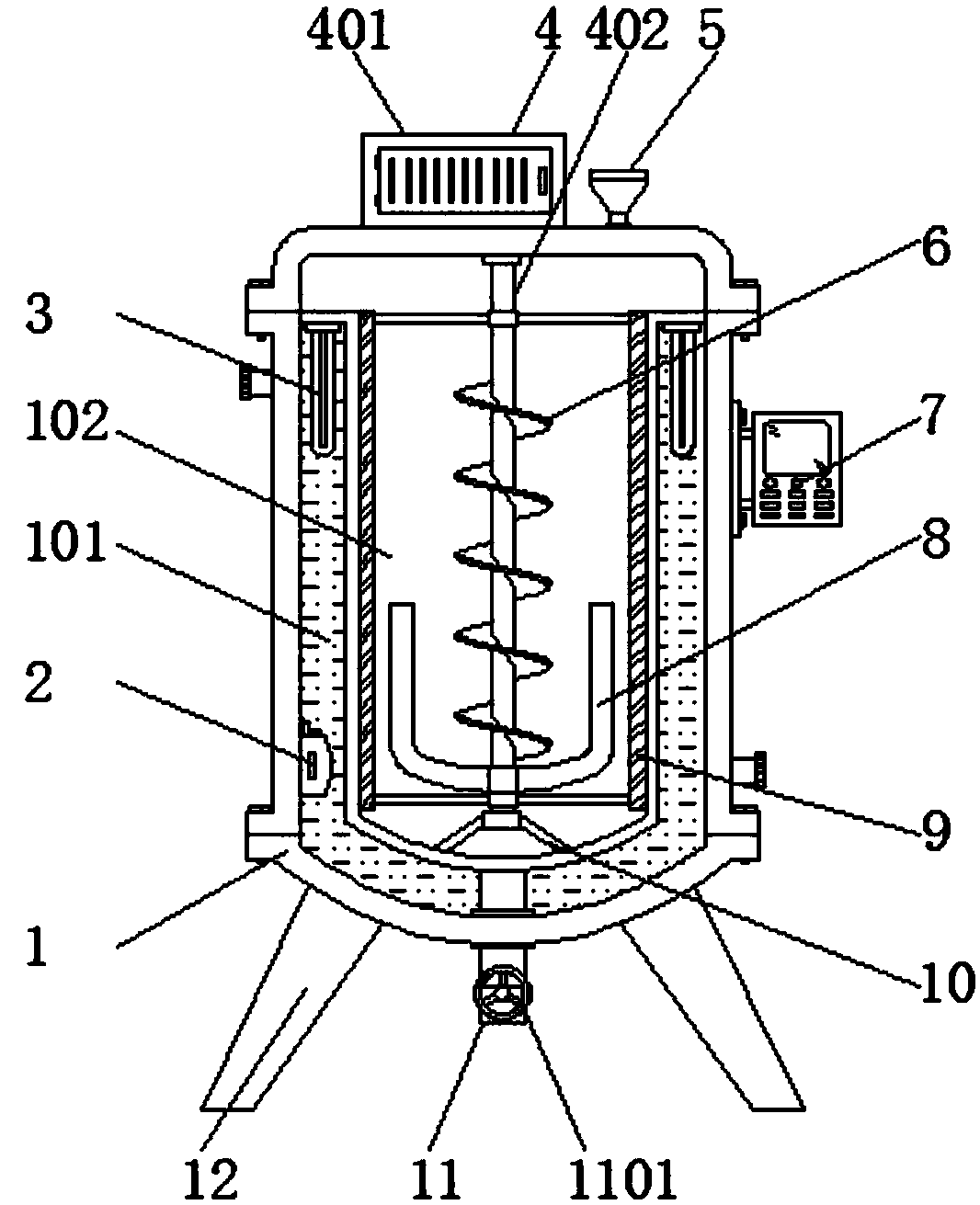

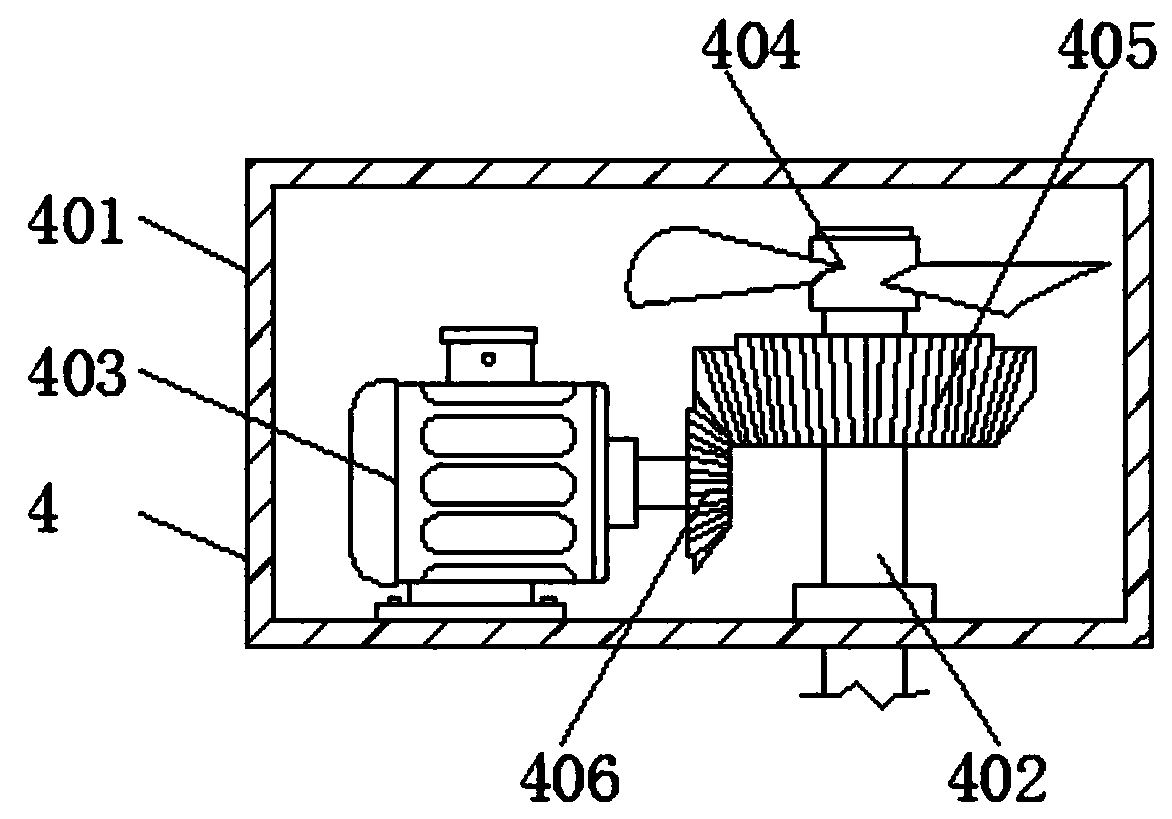

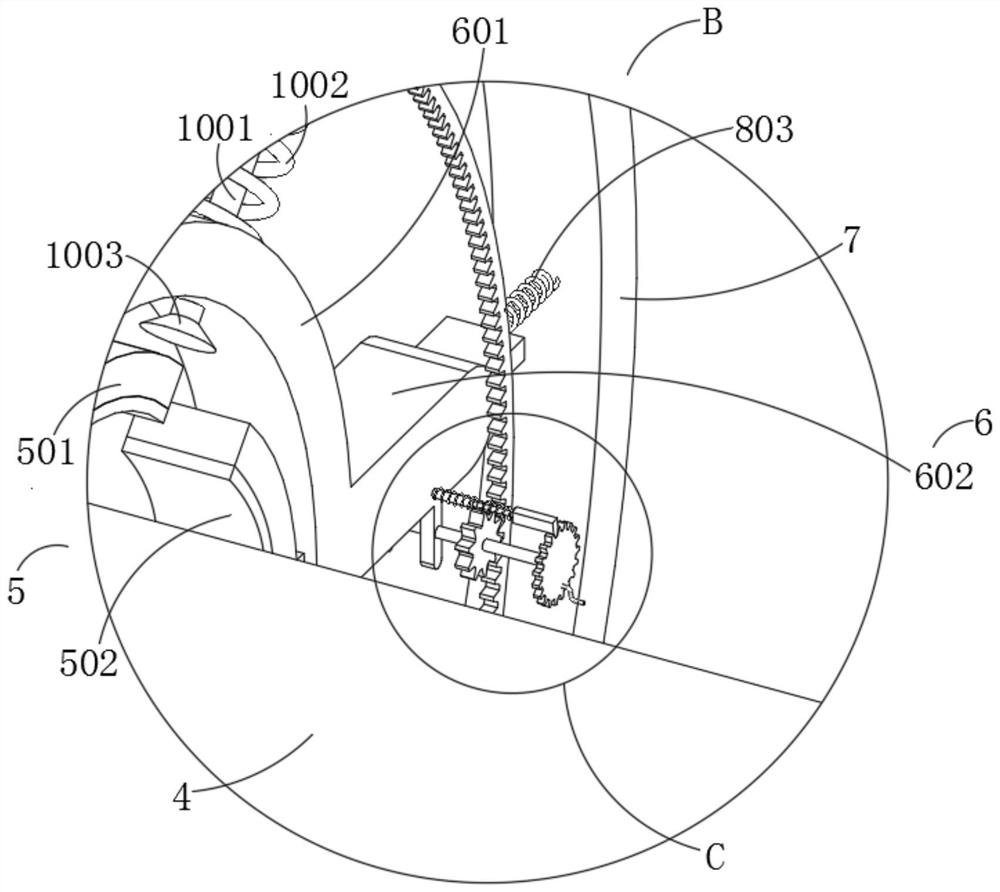

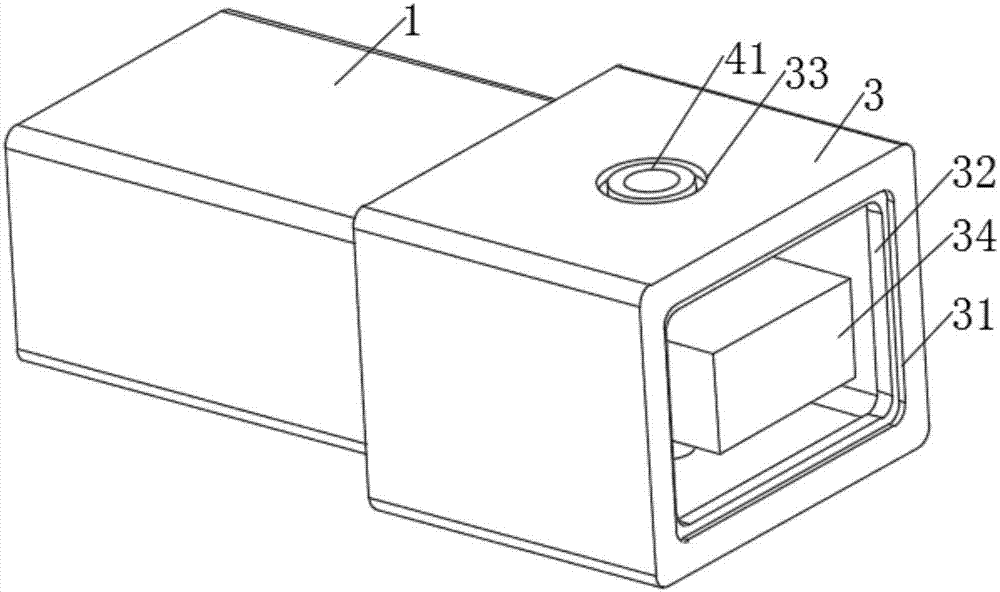

Special mixing tool for preparing composite nanometer fiber porous membrane

InactiveCN110201586AImprove cooling effectWell mixedRotary stirring mixersTransportation and packagingFiberWater baths

The invention discloses a special mixing tool for preparing a composite nanometer fiber porous membrane. The special mixing tool comprises a device main body, a transmission mechanism and a controller, wherein the device main body comprises a water bath chamber and a stirring chamber, both sides of the inner top end of the water bath chamber are respectively provided with an electric heating pipe,the bottom end of one side inside the water bath chamber is provided with a temperature sensor, one side of the top end of the device main body is provided with a material inlet, one side of the material inlet is provided with the transmission mechanism, the transmission mechanism comprises an outer shell, a stirring shaft, a motor, fan blades, a first bevel gear and a second bevel gear, the bottom end of the stirring shaft extends to the interior of the device main body, and is provided with a spiral blade and a stirring blade, both sides of the stirring shaft are respectively provided witha scraping plate through support rods, the bottom end of the stirring chamber is provided with a material outlet, and one side of the device main body is provided with the controller. According to thepresent invention, the special mixing tool can achieve uniform stirring, can uniformly heat a solution, can avoid a solution from being adhered to the inner side wall of the device, and has a long service life.

Owner:北京英鸿光大科技有限公司

Rotary rotary electrolytic mechanical composite polishing machine

InactiveCN110820037ALow mechanical scraping forceNo deformation stressElectrolysis componentsPolishingNonwoven fabric

The invention discloses a rotary body electrolytic mechanical composite polishing machine. The polishing machine comprises an electrolytic mechanical polishing device, an electrolytic grinding liquidcooling device, an electrolytic grinding liquid circulating device and a machine base, wherein the electrolytic mechanical polishing device comprises an electric spindle, a cathode polishing disc, a connecting rod, a non-woven fabric and a clamp, the electric spindle is arranged on a bracket on a sliding block, the sliding block is in sliding fit with a sliding groove on the machine base, the clamp is arranged in the moving direction of the sliding block, the connecting rod is connected with the cathode polishing disc and the electric spindle, the polishing surface of the cathode polishing disc is clung to the non-woven fabric, and a splash-proof box is further arranged outside the clamp and the electric spindle. According to the polishing machine, the machining range is wide, the polishing machine is suitable for machining of various materials, the machining precision is high, the surface quality is good, a grinding tool is small in abrasion, the procedures are few, the machining efficiency is high, and the cost is low.

Owner:成都进禄永建材有限公司

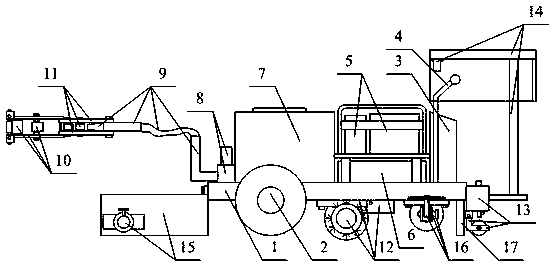

Intelligent equipment for filling cracks of bituminous paving

ActiveCN107724219AEasy to scrape offAvoid the problem of overconvexityRoads maintainenceLine drawingsEngineering

The invention provides a piece of intelligent equipment for filling cracks of bituminous paving. The equipment comprises the following components: a vehicle body, wheels, a control cabinet, a pushinghand, a generator, a combustion engine, a material storing tank, a discharging pump, a material guiding pipe, a scraper plate structure, an asphalt pressing wheel structure, a foreign material cleaning disc structure, a line drawing cylinder structure, a sun shading protective cover structure, a protection plate structure, a cutting wheel structure, and a support column, wherein the wheels are installed at the left lower part of the vehicle body; the control cabinet is welded at the back side of the right upper part of the vehicle body, and the pushing hand is welded at the front side of the right upper part of the vehicle body; the generator is installed at the left side of the control cabinet; the combustion engine is installed at the bottom of the generator. The product has the beneficial effects that the asphalt pressing wheel structure and the foreign material cleaning disc structure are arranged, in order to avoid the problem of appearance of unevenness on asphalt pavement; the sun shading protective cover structure is arranged in order to increase the heat radiation effects of the sun shading protective cover structure, and at the same time working personnel can carry out work with cool environment.

Owner:广东明鑫建设工程有限公司

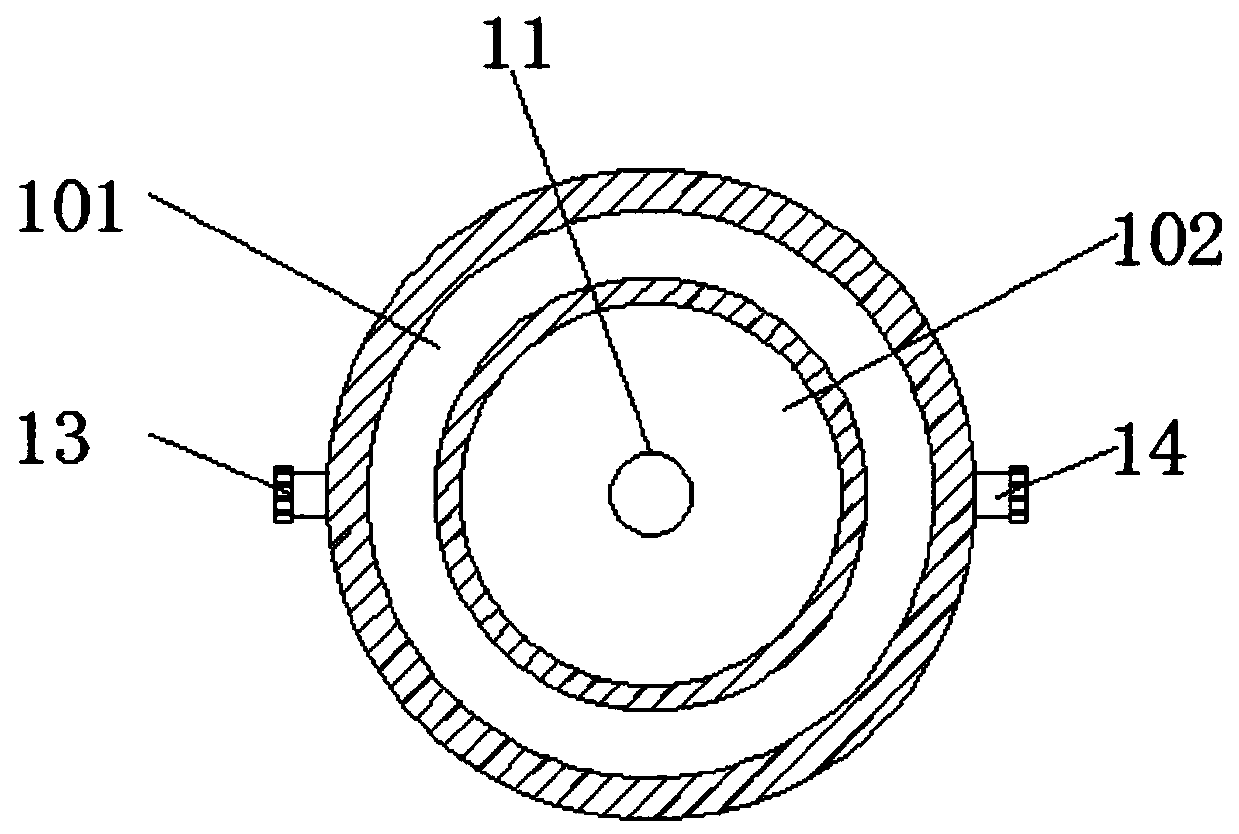

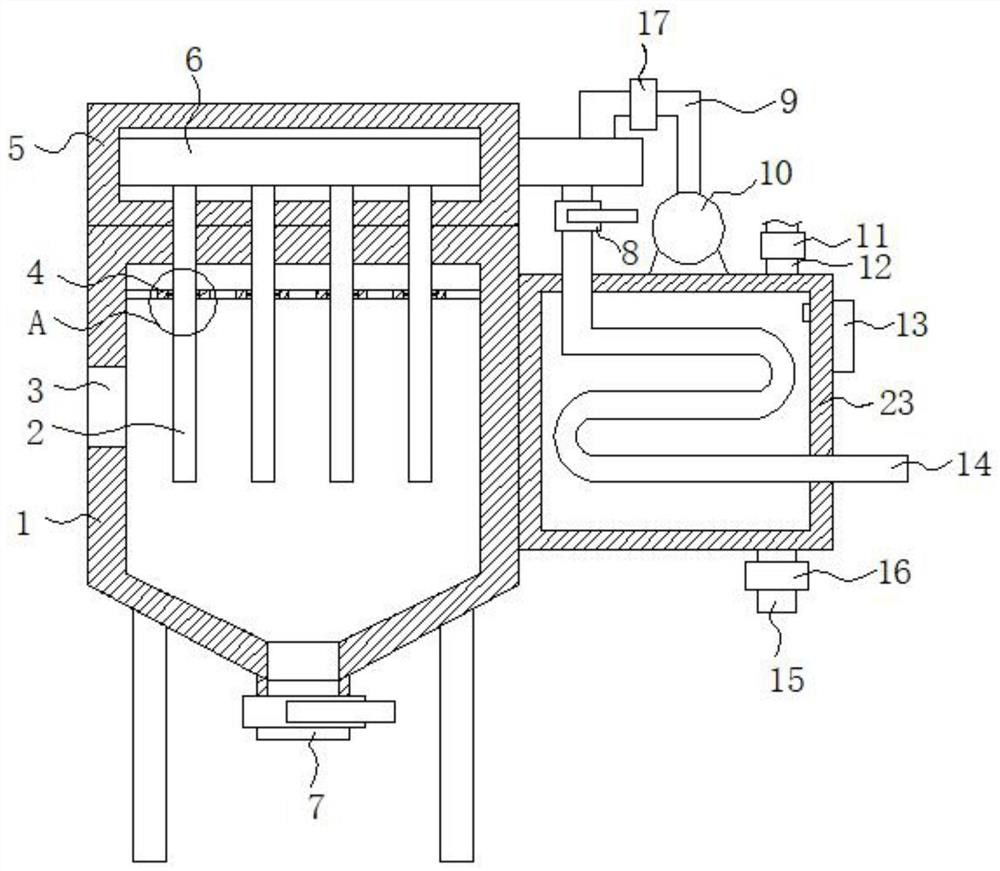

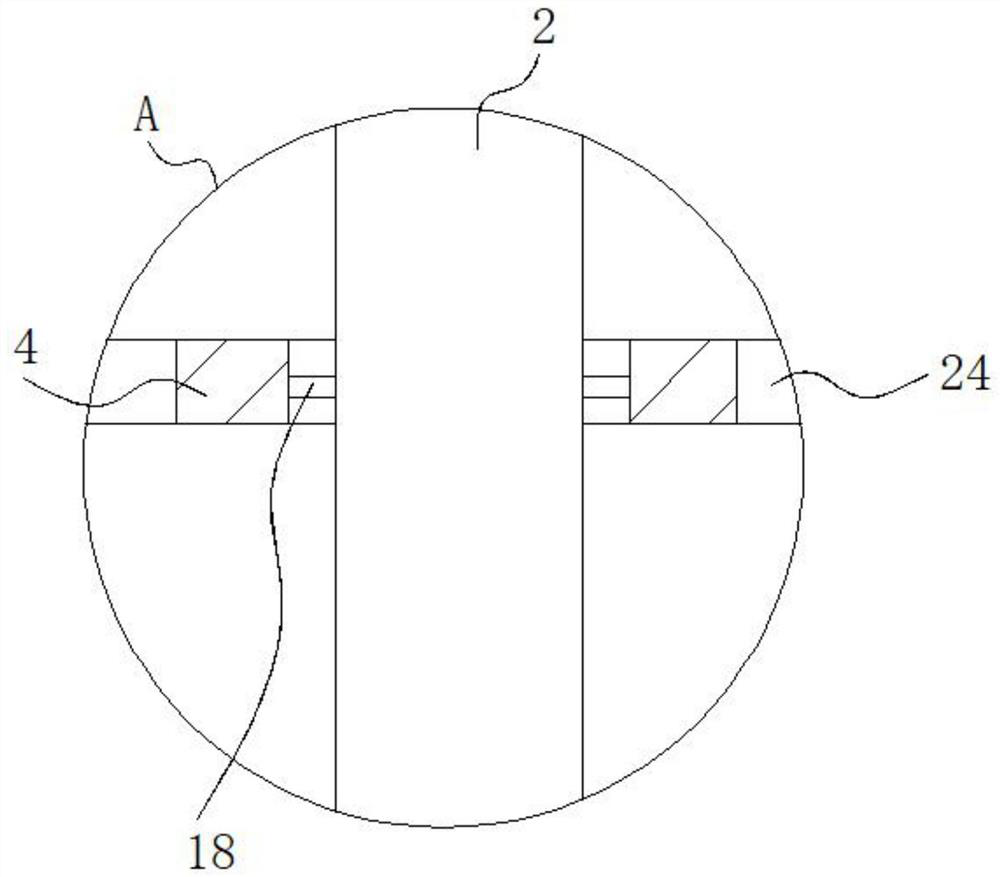

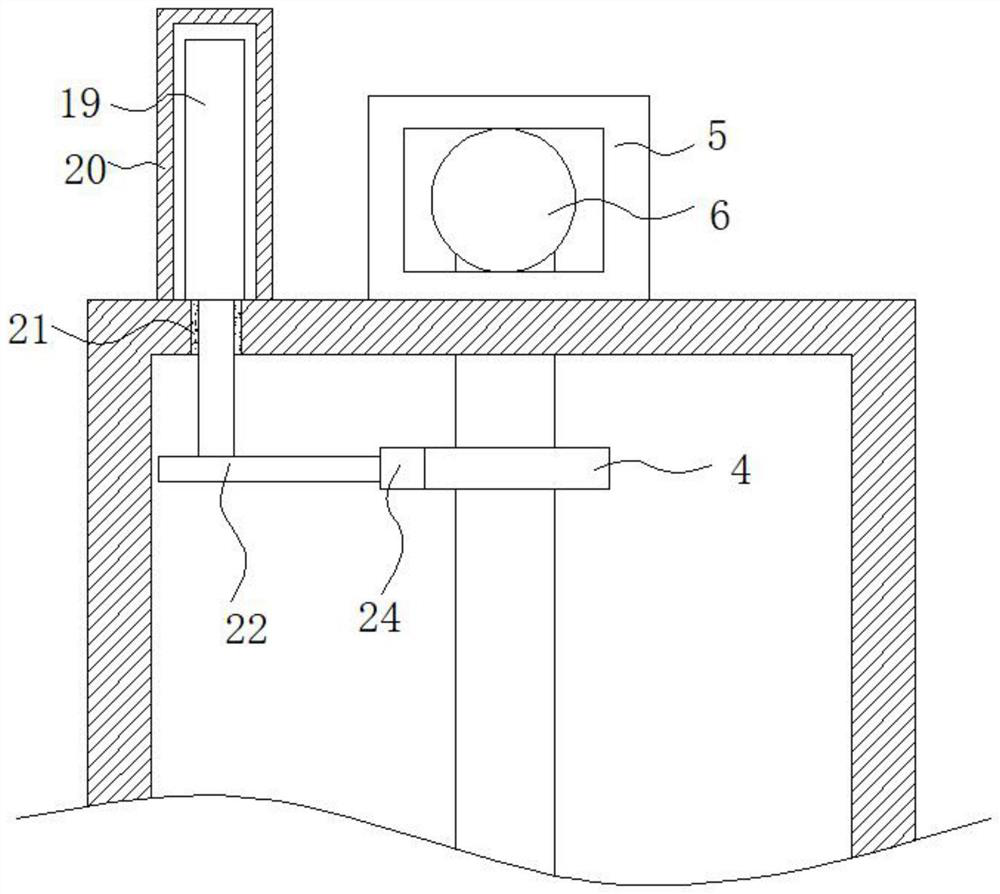

Waste water treatment device beneficial to cleaning

PendingCN108404463AEliminate manual scrapingLow running costFiltration circuitsSedimentation settling tanksSewageWater treatment

The invention discloses a waste water treatment device beneficial to cleaning, wherein the waste water treatment device comprises a sedimentation chamber and a filter chamber communicating with the sedimentation chamber. The sedimentation chamber comprises a tank body, a cylindrical sedimentation chamber arranged in the tank body, a conical sewage draining outlet communicating with the sedimentation chamber, and a sludge scraping mechanism. By arrangement of the sludge scraping mechanism in the tank body, sludge attached to the inner wall of the sedimentation chamber and the inner wall of thesewage draining outlet is conveniently scraped after long-term use, not only is the cleaning of the sedimentation chamber facilitated but also the labor cost is saved, and the operation cost is reduced.

Owner:毛渊

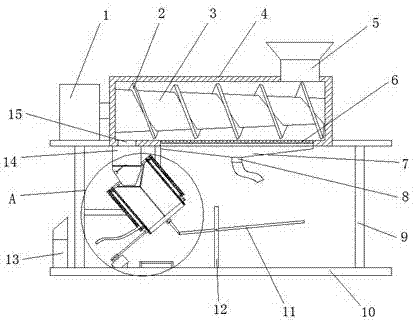

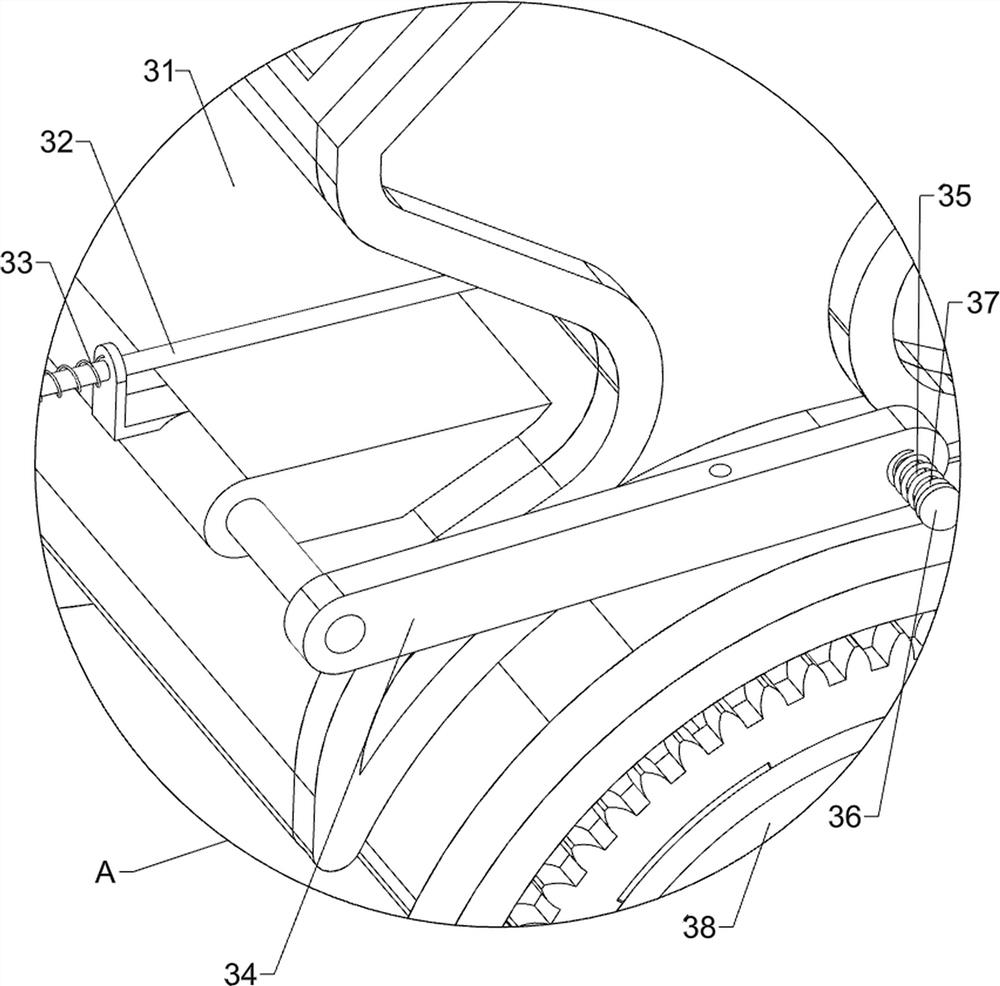

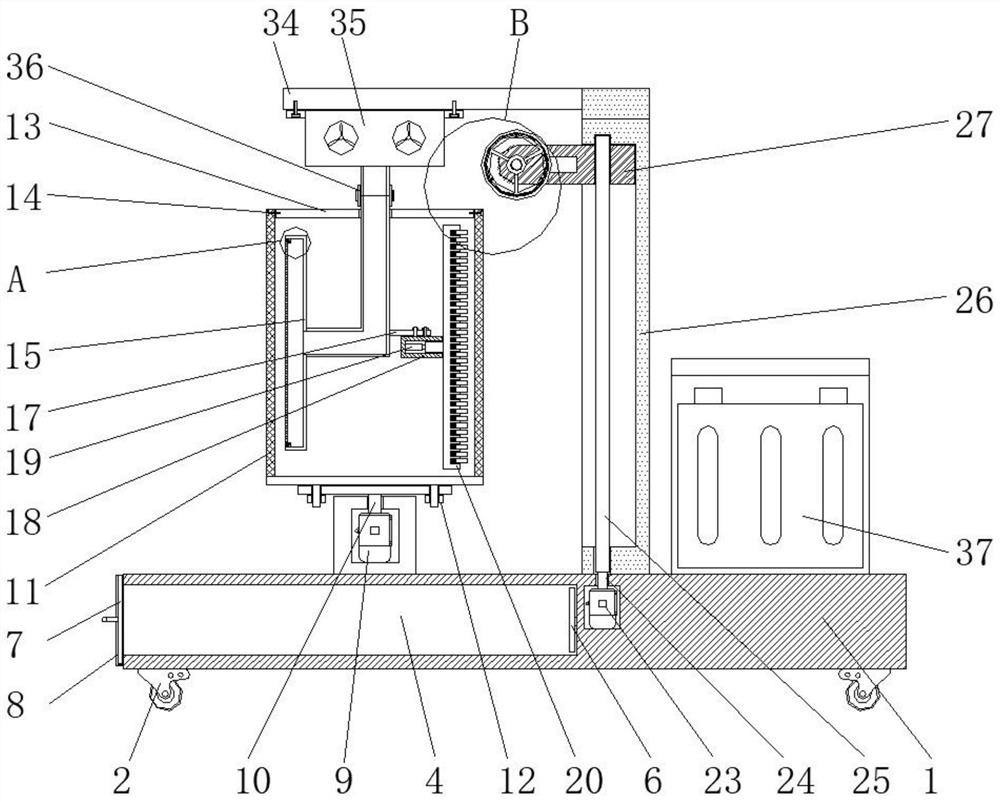

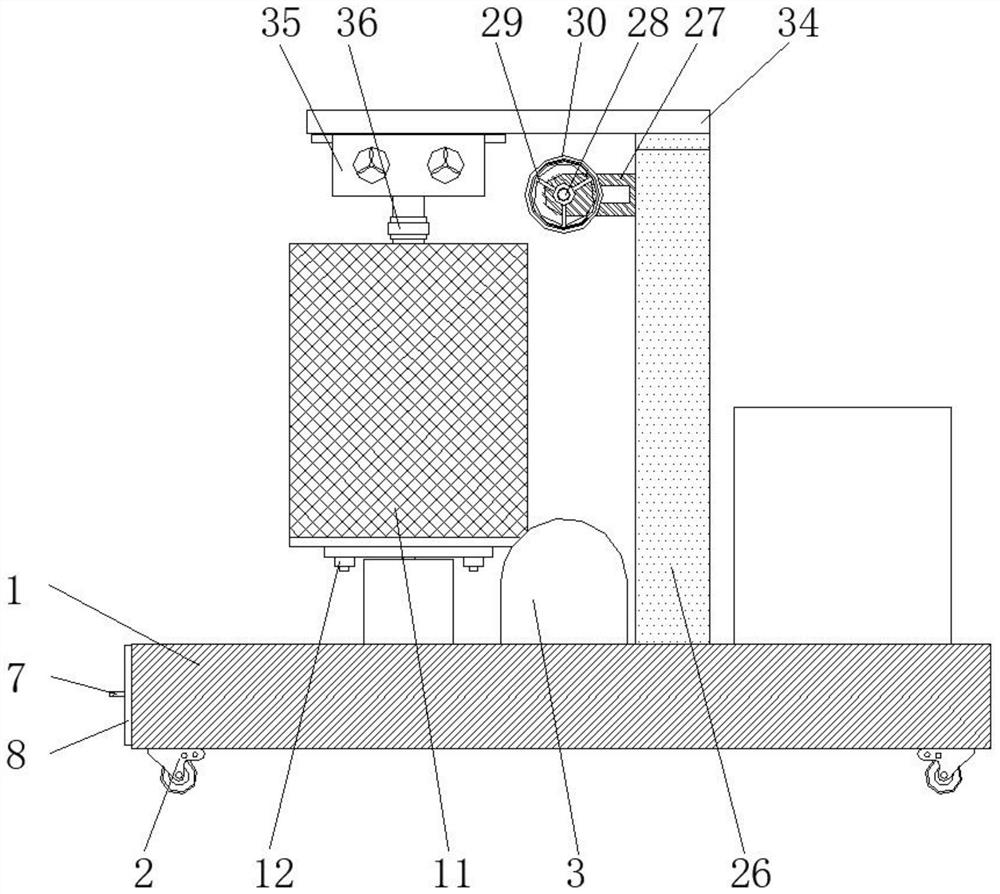

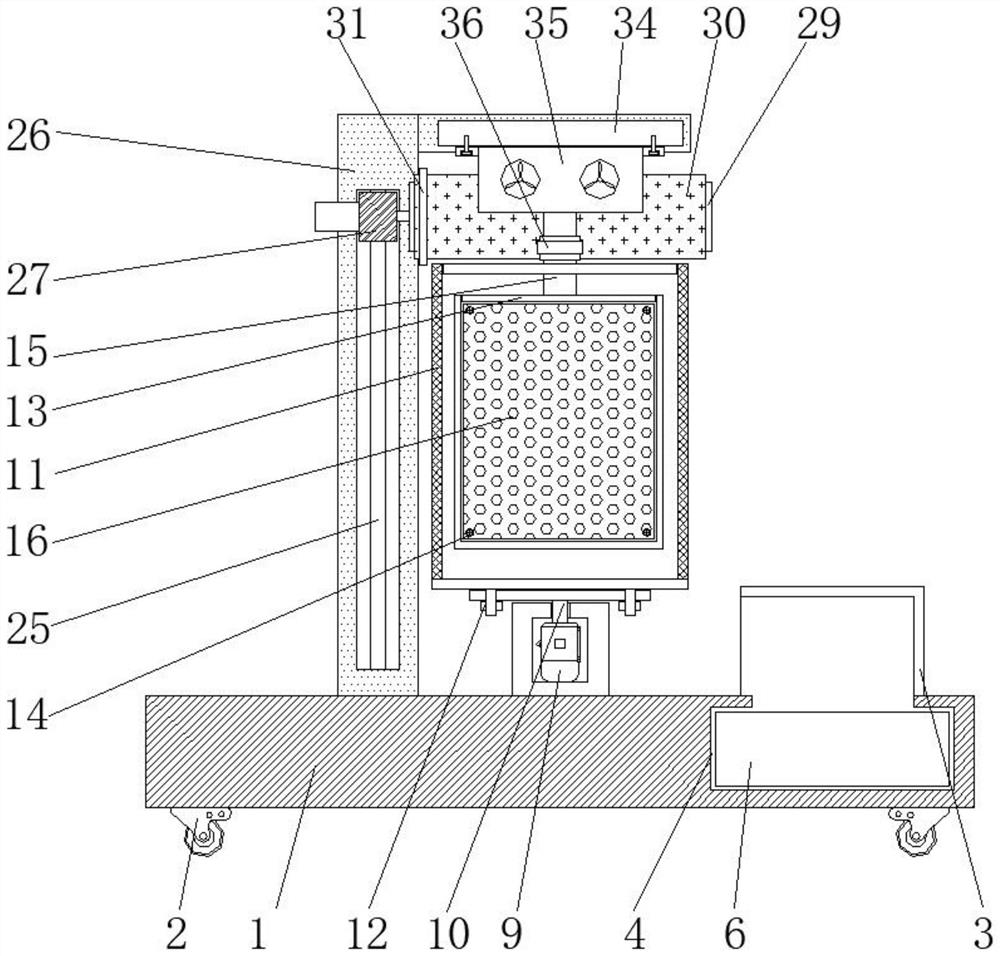

Automatic crushing device for blocky rare earth

ActiveCN112871296AScreen finelyEasy to scrape offProcess efficiency improvementGrain treatmentsClassical mechanicsEngineering

The invention relates to a crushing device, in particular to an automatic crushing device for blocky rare earth. According to the automatic crushing device for the blocky rare earth, automatic intermittent discharging is achieved, the rare earth is automatically crushed, the rare earth is further screened, qualified rare earth and large rare earth blocks are conveniently collected, and crushing of the rare earth can be stopped immediately. The automatic crushing device for the blocky rare earth comprises a supporting frame, wherein a discharging groove frame is connected to one side of the upper portion of the supporting frame; a material receiving plate, wherein the material receiving plate is connected between the two sides of the middle of the lower side of the supporting frame; a crushing mechanism, wherein the crushing mechanism is arranged on the supporting frame; and a feeding mechanism, wherein the feeding mechanism is arranged between the lower portion of the discharging groove frame and the crushing mechanism. According to the device, a first handle is pulled to move leftwards, a second push plate is pulled to move rightwards through a pull rope, large rare earth blocks on a screen groove plate is pushed out of the screen groove plate, and the effects of conveniently scraping off the large rare earth blocks and collecting the large rare earth blocks in a unified mode are achieved.

Owner:赣州华京稀土新材料有限公司

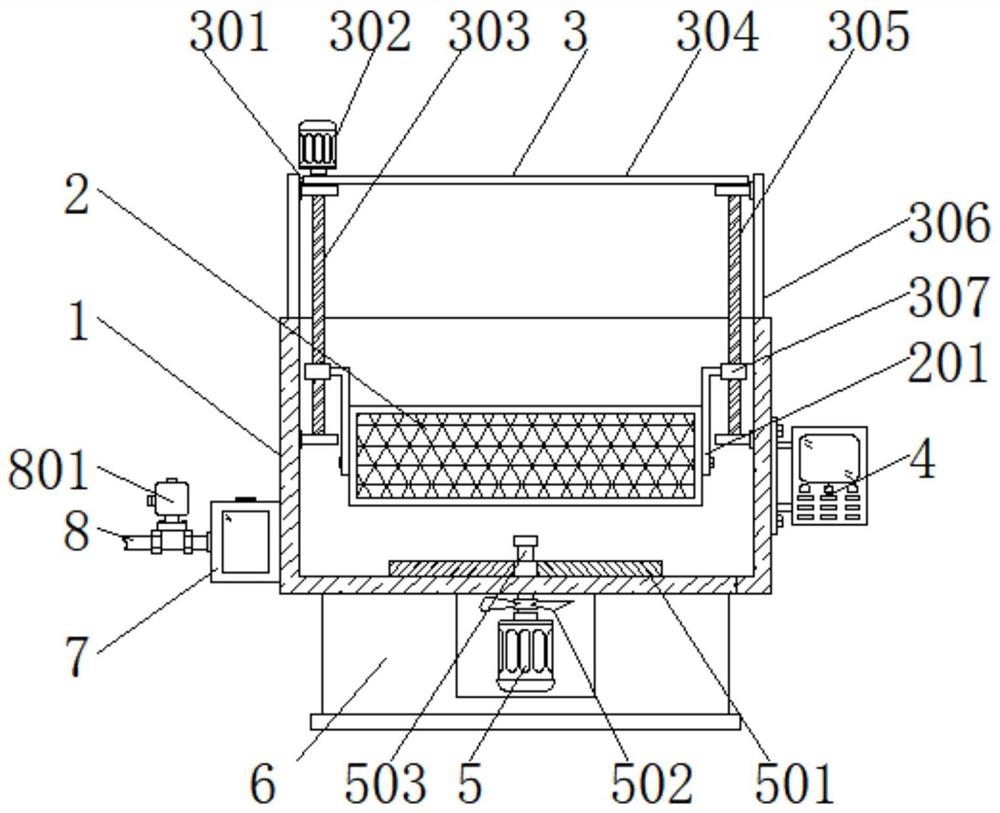

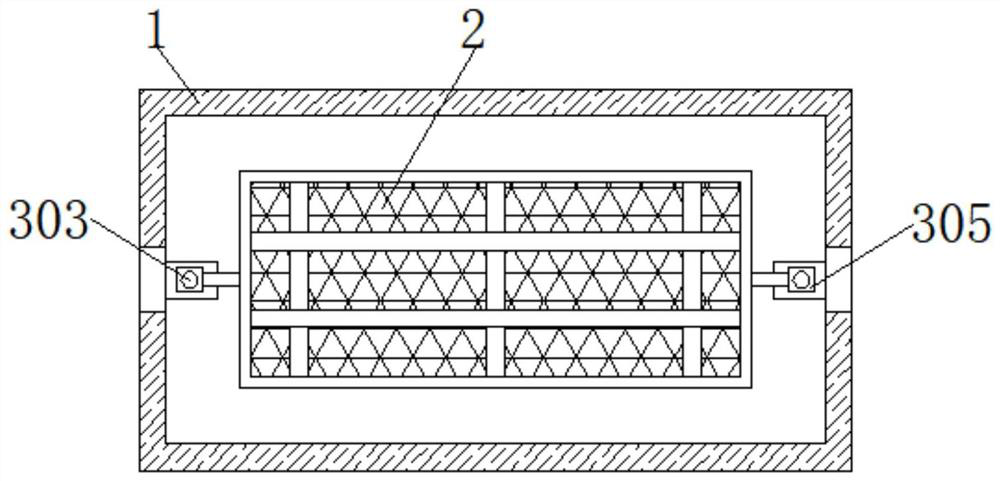

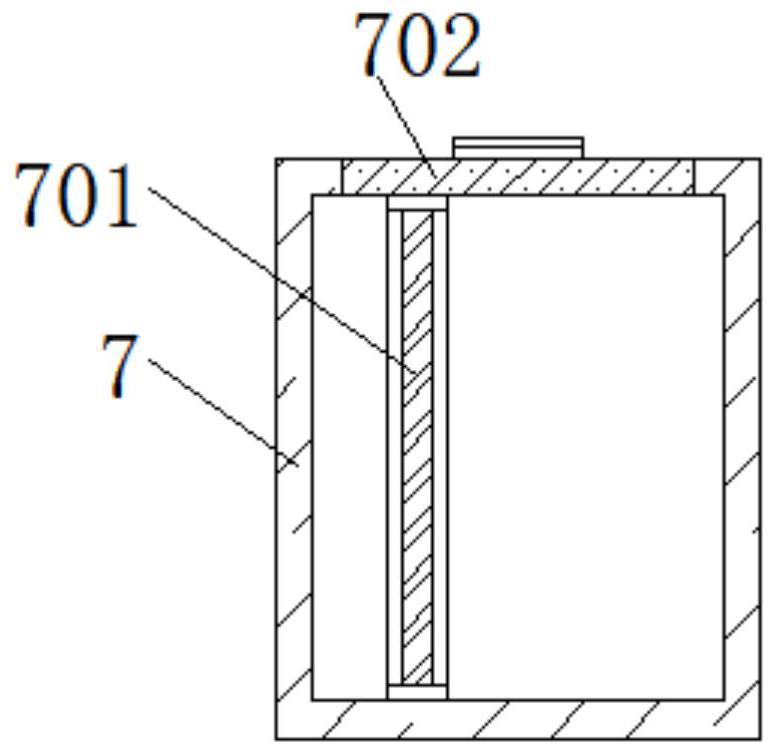

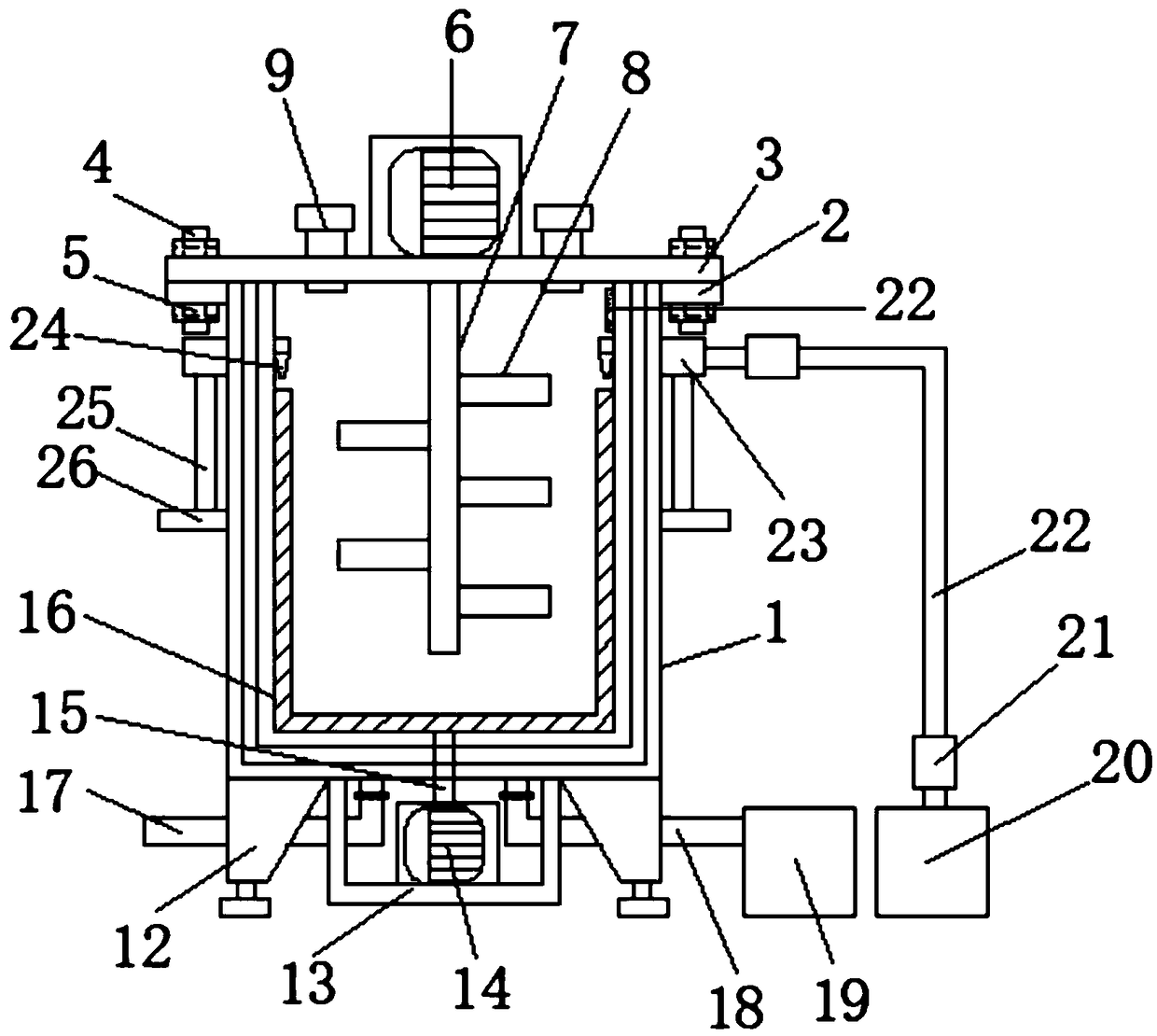

Bearing quenching equipment

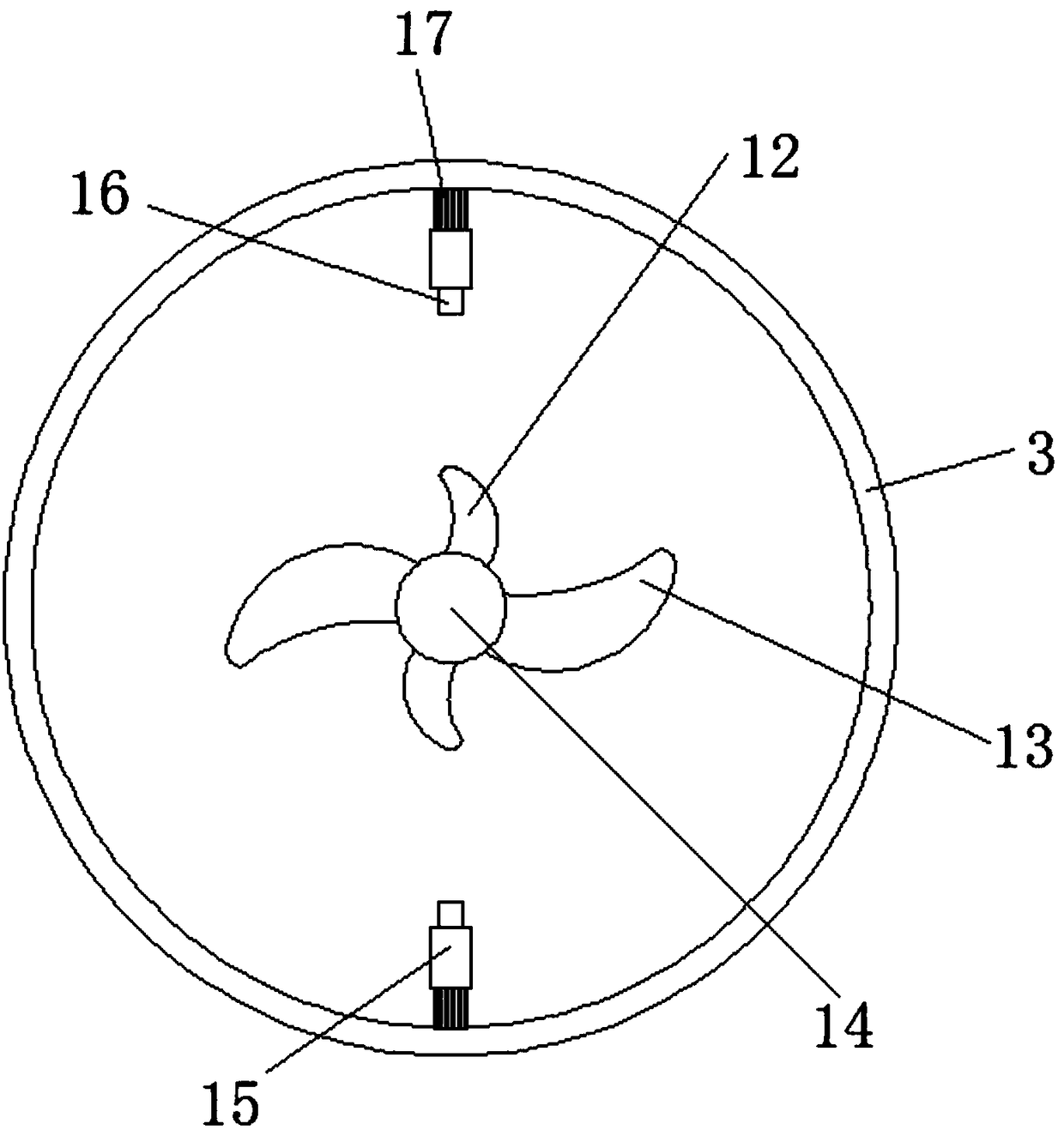

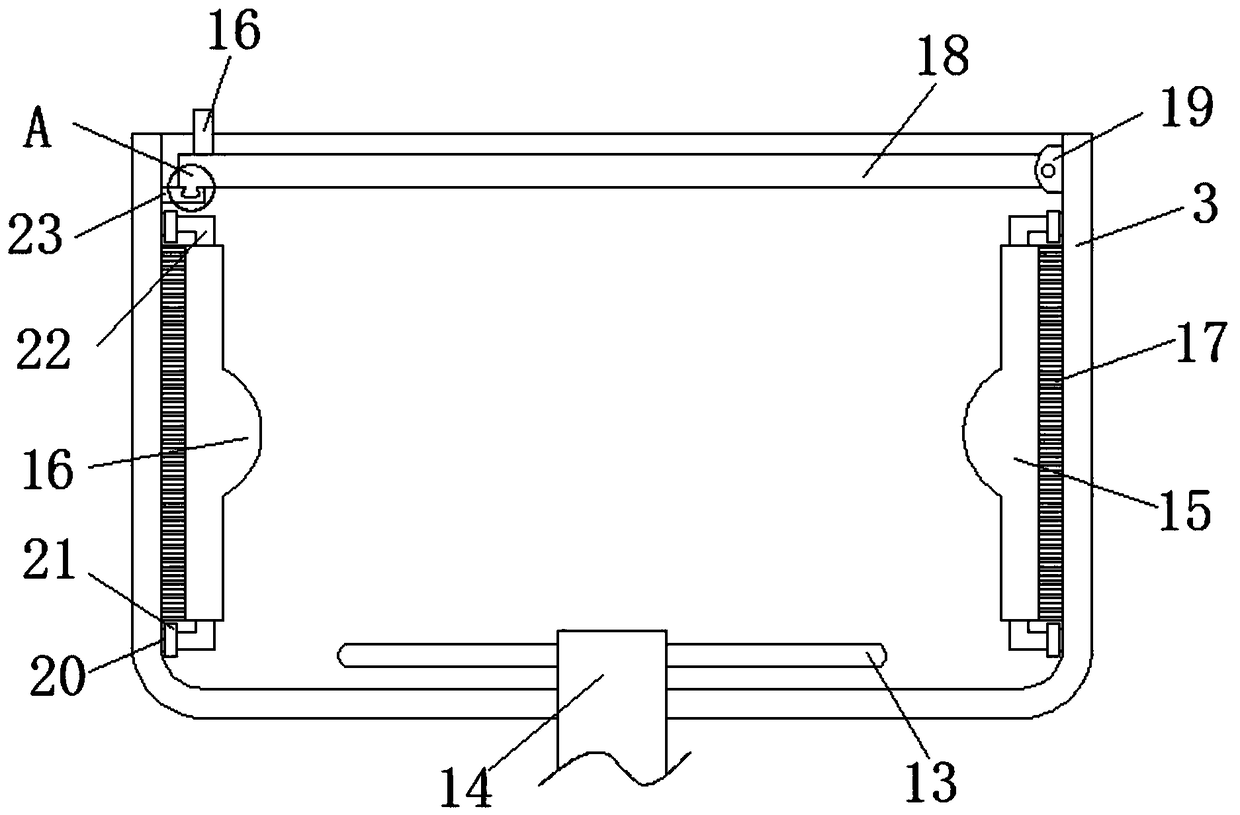

PendingCN112981085AEasy to take outSimple and fast operationFurnace typesHeat treatment furnacesElectric machineFan blade

The invention relates to the technical field of bearing heat treatment devices, in particular to bearing quenching equipment. The defects that in the prior art, operation is troublesome, a liquid discharging pipe is prone to being blocked, and the temperature of all positions in a quenching tank is uneven are overcome. The bearing quenching equipment comprises the quenching tank, a controller and a base, and a containing basket is movably arranged in the quenching tank through a transmission mechanism. The transmission mechanism comprises a first roller, a first motor, a first lead screw, a belt, a second lead screw, supporting vertical plates and sliding blocks, the first lead screw and the second lead screw are installed on the two sides of the quenching tank correspondingly, the first roller is connected to the top end of the first lead screw and the top end of the second lead screw in a sleeving mode correspondingly, and the sliding blocks are connected to the first lead screw and the second lead screw in a sleeving mode correspondingly. Discharging is convenient, and the work efficiency is high. A filtering cavity is formed in the bottom end of one side of the quenching tank, a second motor is arranged in the middle of the bottom end of the quenching tank, and a rotating shaft, a scraping plate and fan blades are arranged at the output end of the second motor, so that scrap iron is prevented from being deposited in the quenching tank.

Owner:常州高度新能源科技有限公司

Novel small oil shale pulverizer

InactiveCN108212381AEasy to pourEasy to scrape offHollow article cleaningGrain treatmentsLocking mechanismDrive shaft

The invention discloses a novel small oil shale pulverizer including a pulverizing barrel and a driving motor. The driving motor is fixed at the bottom end of the pulverizing barrel, an output shaft of the driving motor is connected with a driving shaft, the driving shaft is placed on the bottom end of the interior of the pulverizing barrel, and the upper end of the driving shaft is provided witha group of main pulverizing blades; a U-shaped base is arranged below the driving motor, and one side of the U-shaped base is provided with a control box; the control box is provided with a control switch; the control switch is connected with the driving motor through a wire; two ends of the driving motor are fixedly provided with pins; two ends of each pin are rotatingly connected on the U-shapedbase, and the end part of the pin at one end is provided with a locking mechanism; the upper end of the pulverizing barrel is also connected with a seal top cover in a screw manner, and two sides ofthe inner wall of the pulverizing barrel are each slidingly connected with a scraping plate; the scraping plates are arranged in the height direction of the pulverizing barrel, and are fixedly provided with hair brushes. The problems that a conventional oil shale pulverizer does not easily pour oil shale powder and wall sticking easily happens are solved.

Owner:安徽龙谷商贸有限公司

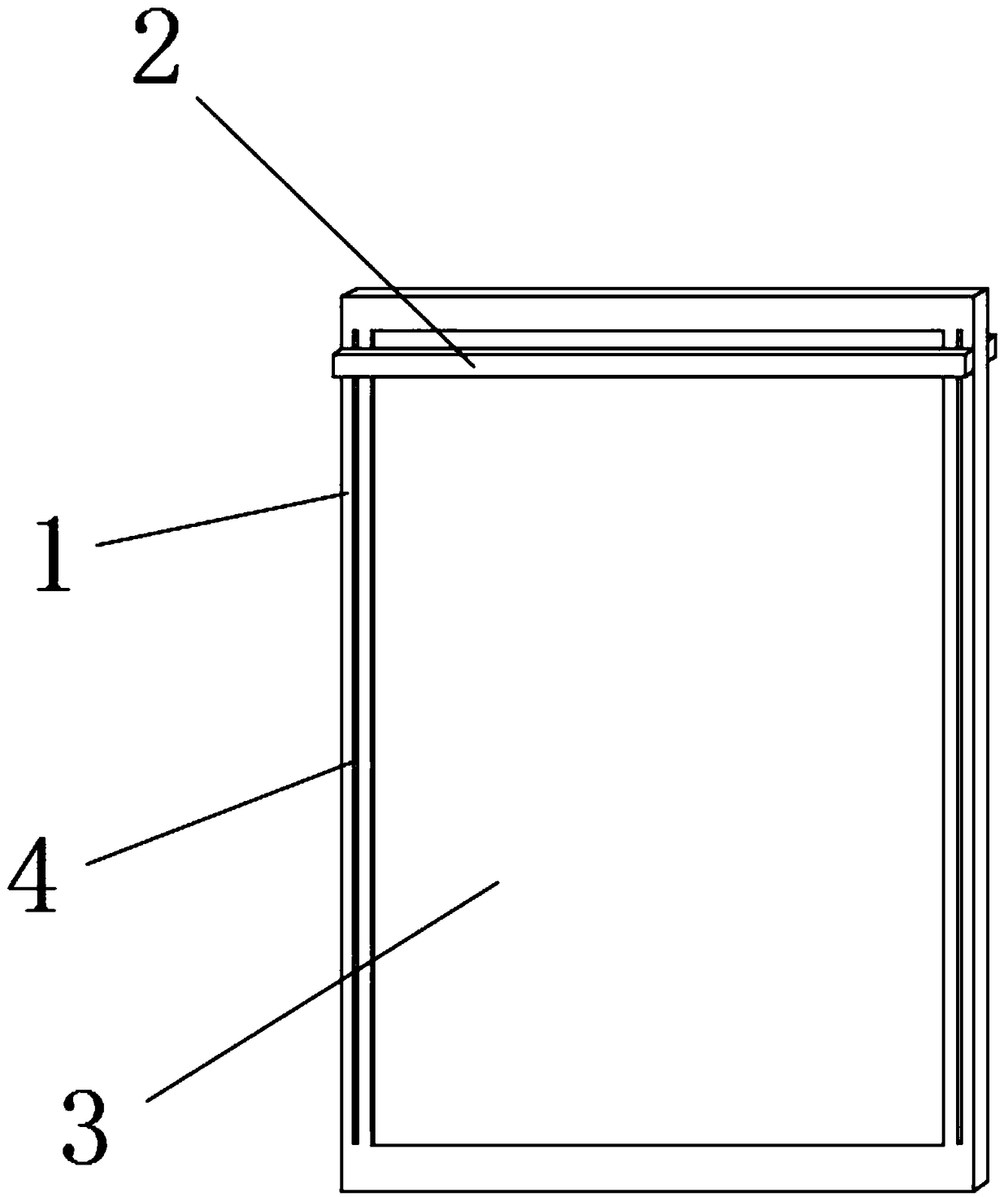

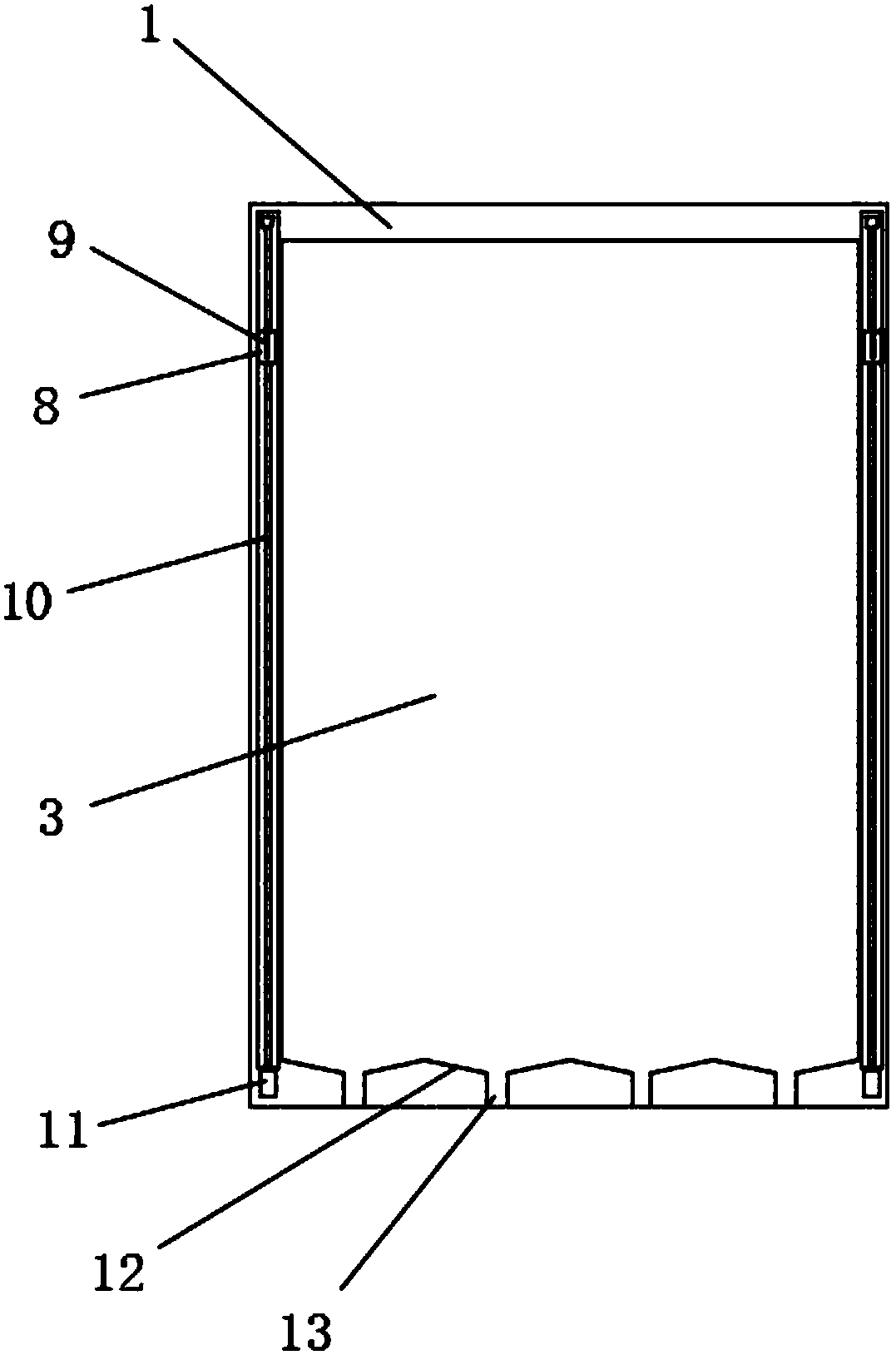

Hollow double-tempered glass with water scraping function

InactiveCN108489202AEasy to scrape offAvoid damageDrying solid materials without heatFlexible article cleaningAgricultural engineeringToughened glass

Owner:安徽荣春智能科技有限公司

Excessive glue scraping equipment for protective film laminating rubber roller and using method of excessive glue scraping equipment

ActiveCN112756184AAchieve softeningEasy to scrape offLiquid surface applicatorsCoatingsAdhesive glueEngineering

Owner:河源昆腾电子科技有限公司

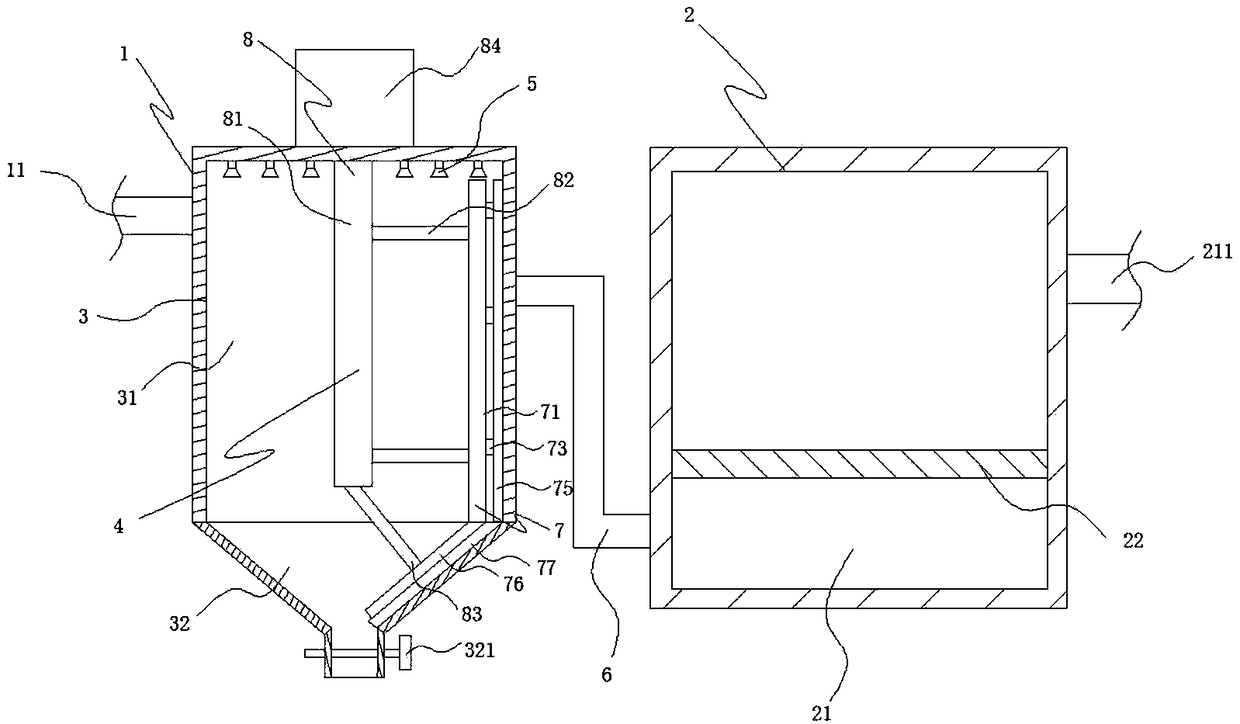

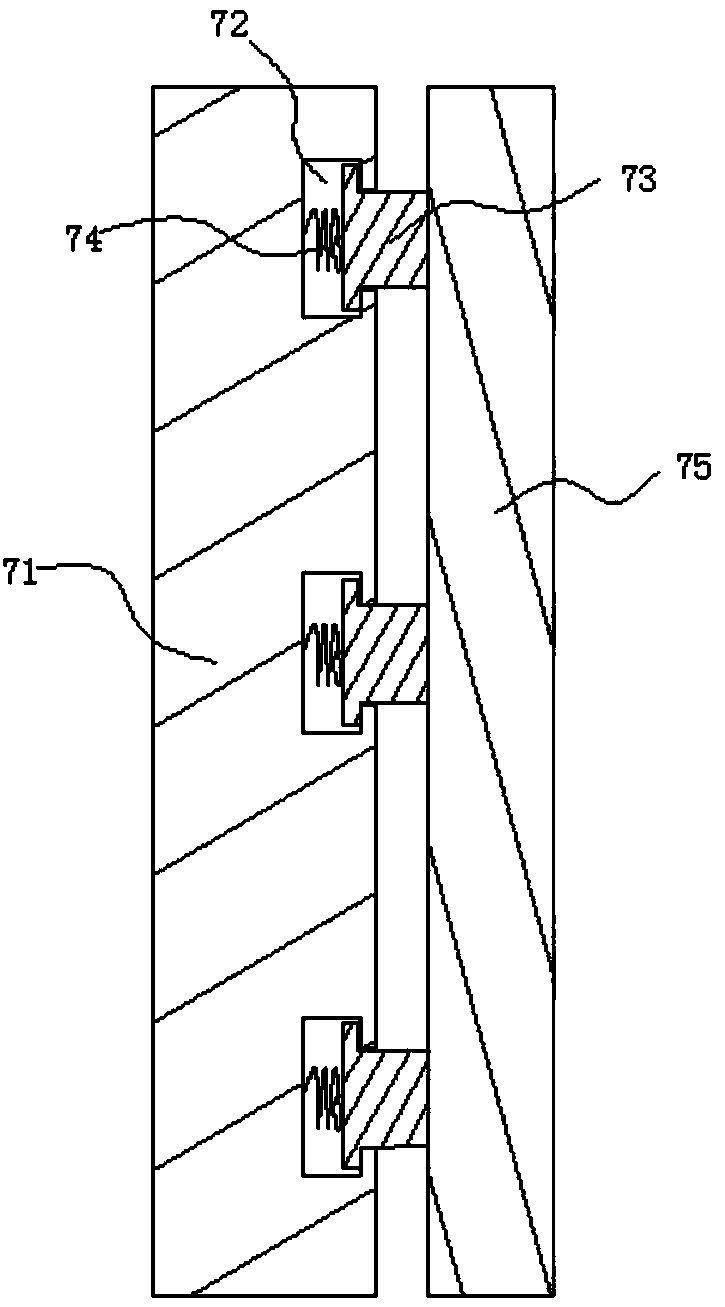

Reaction kettle cleaning and drying device

PendingCN113522201ASpray evenlyFully distributedHollow article cleaningDrying gas arrangementsTube cleaningMechanical engineering

The invention relates to the technical field of reaction kettles, in particular to a reaction kettle cleaning and drying device. The reaction kettle cleaning and drying device comprises a reaction kettle body, wherein a top cover is arranged at the top of the reaction kettle body, a feeding pipe is arranged on one side of the upper end of the reaction kettle body, and a discharging pipe is arranged on one side of the bottom of the reaction kettle body; a cleaning mechanism, which is arranged in the reaction kettle body; a drying mechanism, which is arranged in the reaction kettle body, wherein the cleaning mechanism comprises a first rotating disc which is horizontally and rotatably arranged at the center of the upper end of the interior of the top cover; four spray heads; a stirring shaft, which is vertically arranged in the center of the interior of the reaction kettle body; and a pair of vertical side rods, wherein a plurality of swing rods which are distributed at equal intervals in the vertical direction are arranged between the vertical side rods and the stirring shaft, and a scraping plate is arranged on the face, close to the inner wall of the reaction kettle body, of each vertical side rod. The drying mechanism comprises a heating machine, which can efficiently and uniformly clean and dry the reaction kettle, and improve the cleaning and drying efficiency.

Owner:JIUJIANG ZHONGTIAN PHARMA

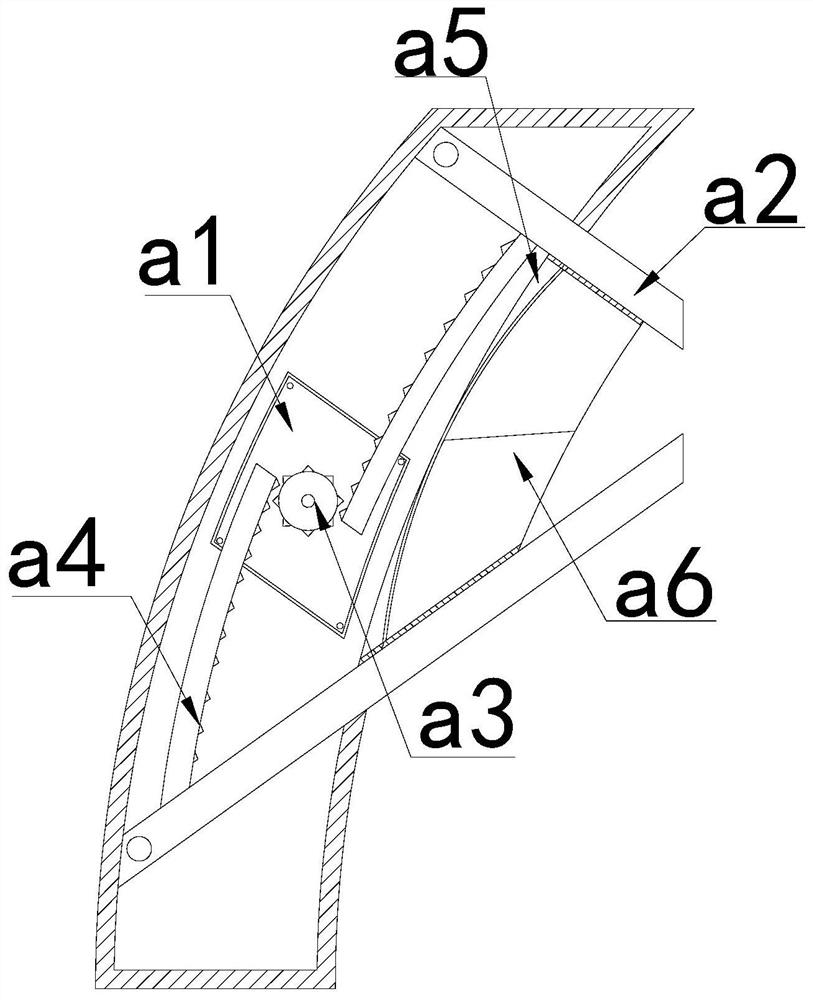

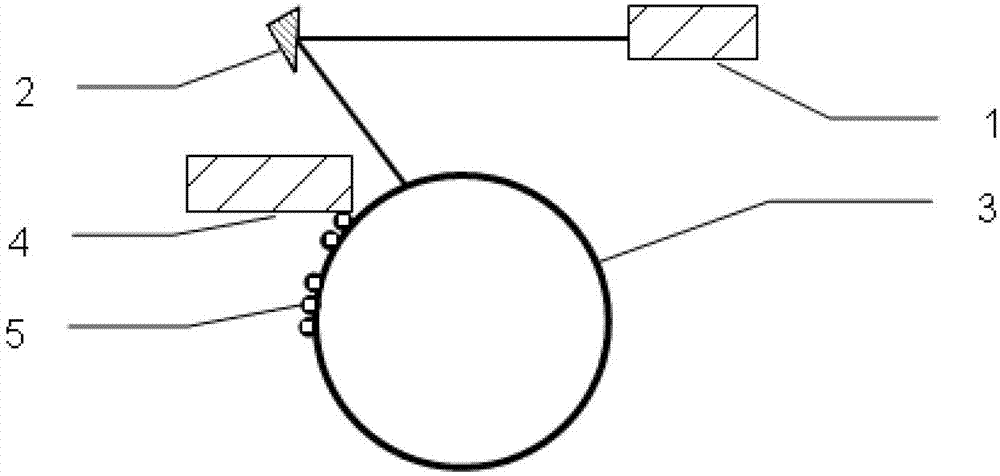

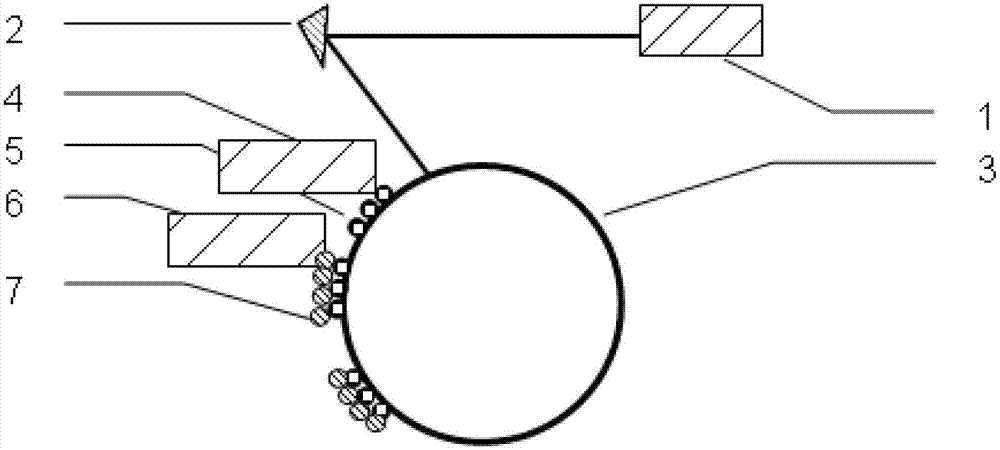

Wood peeling machine

InactiveCN108995001AEasy to collectEasy to scrape offTree debarkingBark-zones/chip/dust/waste removalKnife bladesWood processing

The invention relates to the field of wood processing, in particular to a wood peeling machine. The wood peeling machine comprises a support mechanism, feeding mechanisms, conveying mechanisms, driving mechanisms, fixing mechanisms, a peeling mechanism and a discharging plate. The feeding mechanisms are mounted on the side walls of the support mechanism. The two conveying mechanisms are mounted inside the support mechanism. Each driving mechanism is connected with the corresponding conveying mechanism in a rotary manner. The two fixing mechanisms are mounted between the two conveying mechanisms. The peeling mechanism is fixedly connected with the fixing mechanisms and comprises a fixing sleeve, a mounting plate, blades and fixing rings. The fixing sleeve is fixedly connected to the side walls of the fixing mechanisms. One end of the fixing sleeve is fixedly connected with the arc-shaped mounting plate with the side wall being in an arc shape. The fixing rings are mounted inside the fixing sleeve and the mounting plate in an inclined manner. The blades are mounted inside the fixing rings. The support mechanism is fixedly connected to the top end of the discharging plate. By means ofthe wood peeling machine, veneer can be cleared conveniently, and wood chips can be collected conveniently.

Owner:王桂英

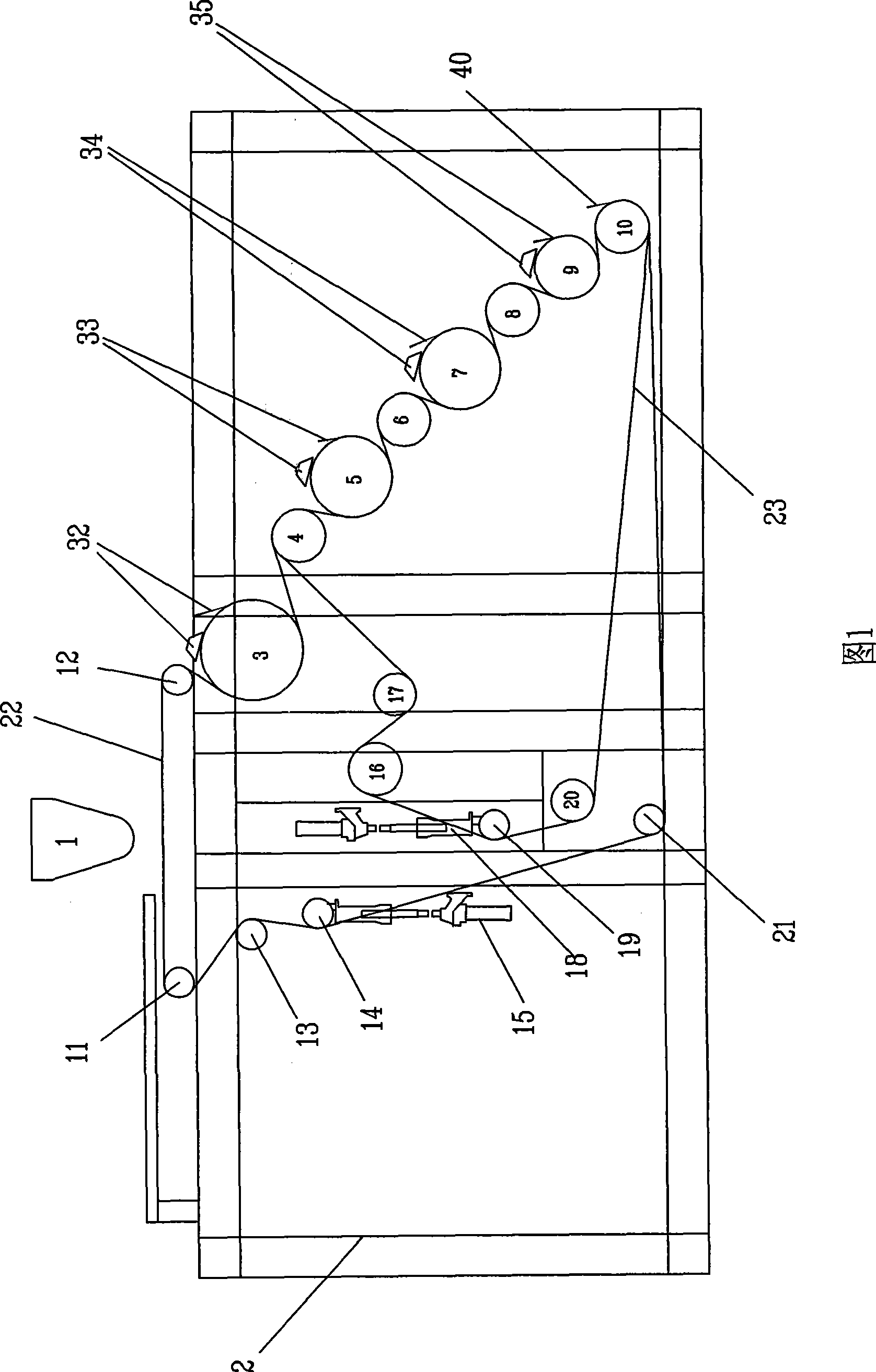

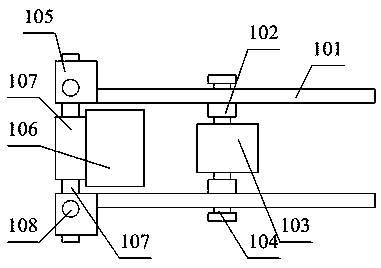

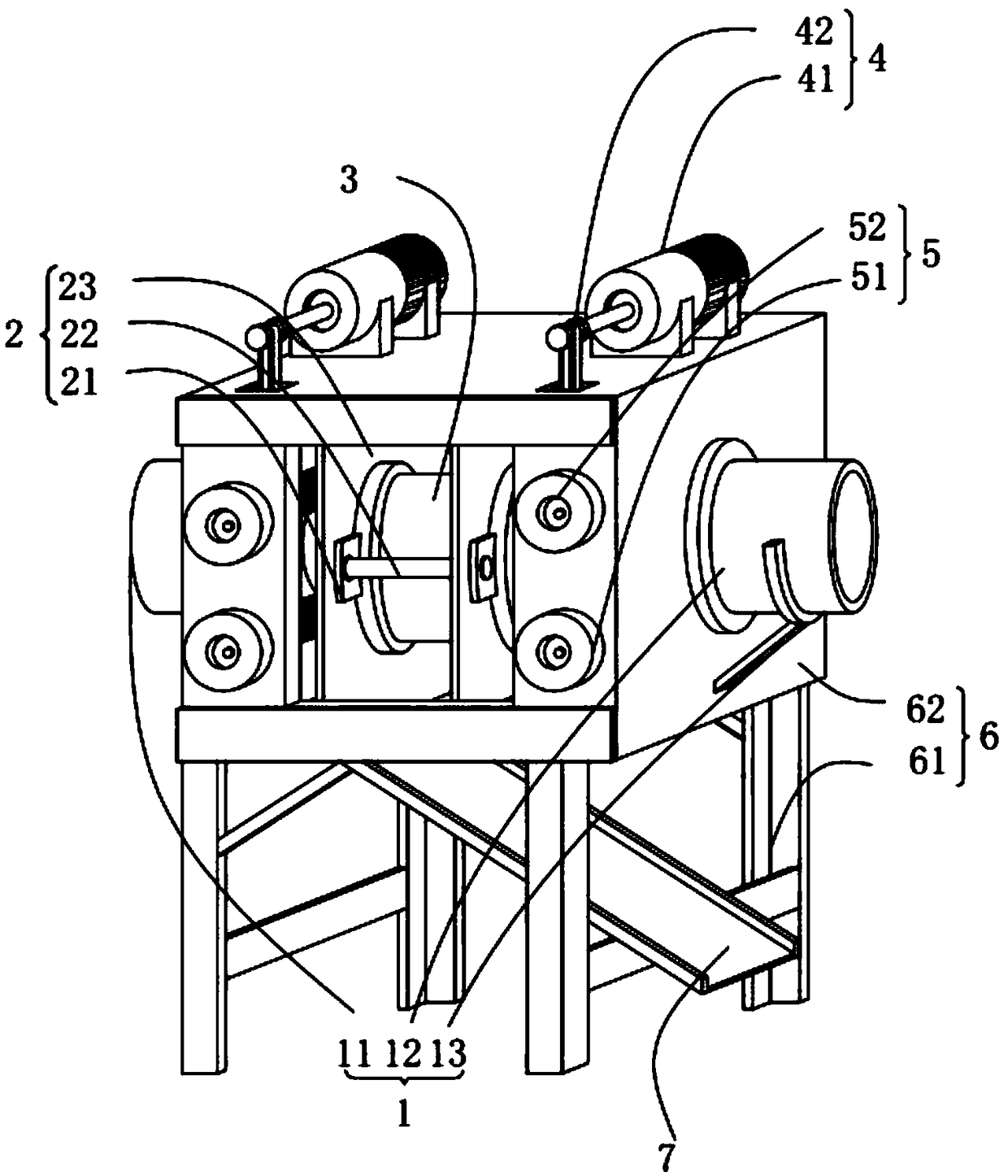

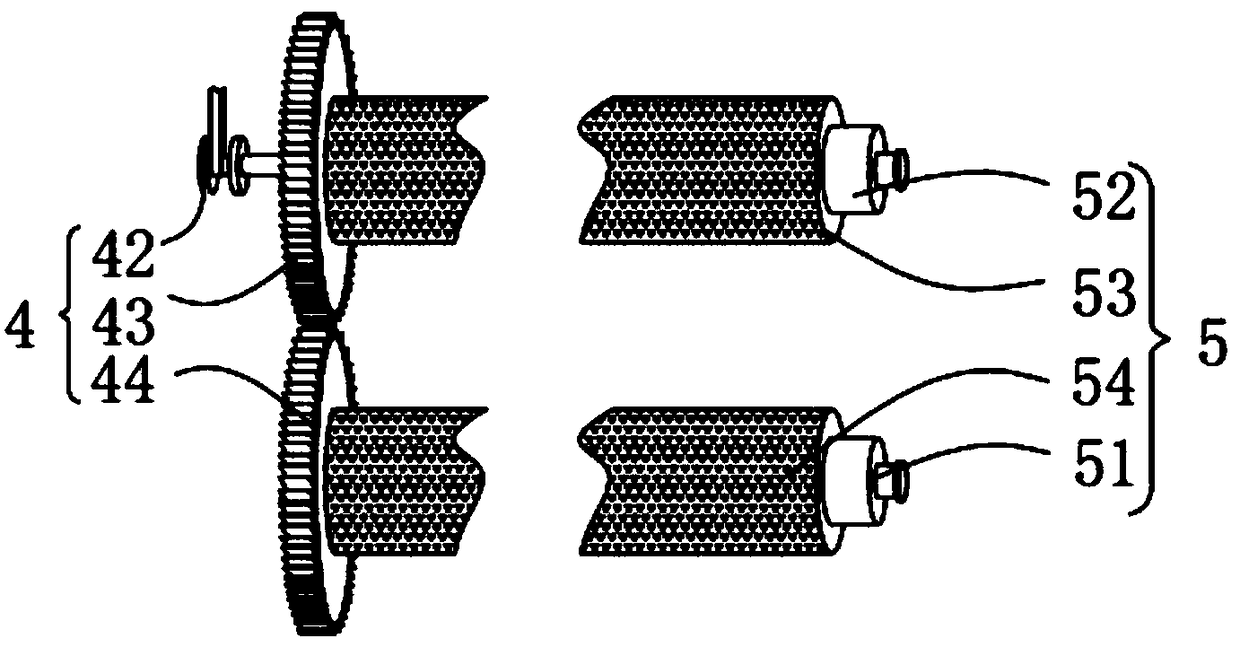

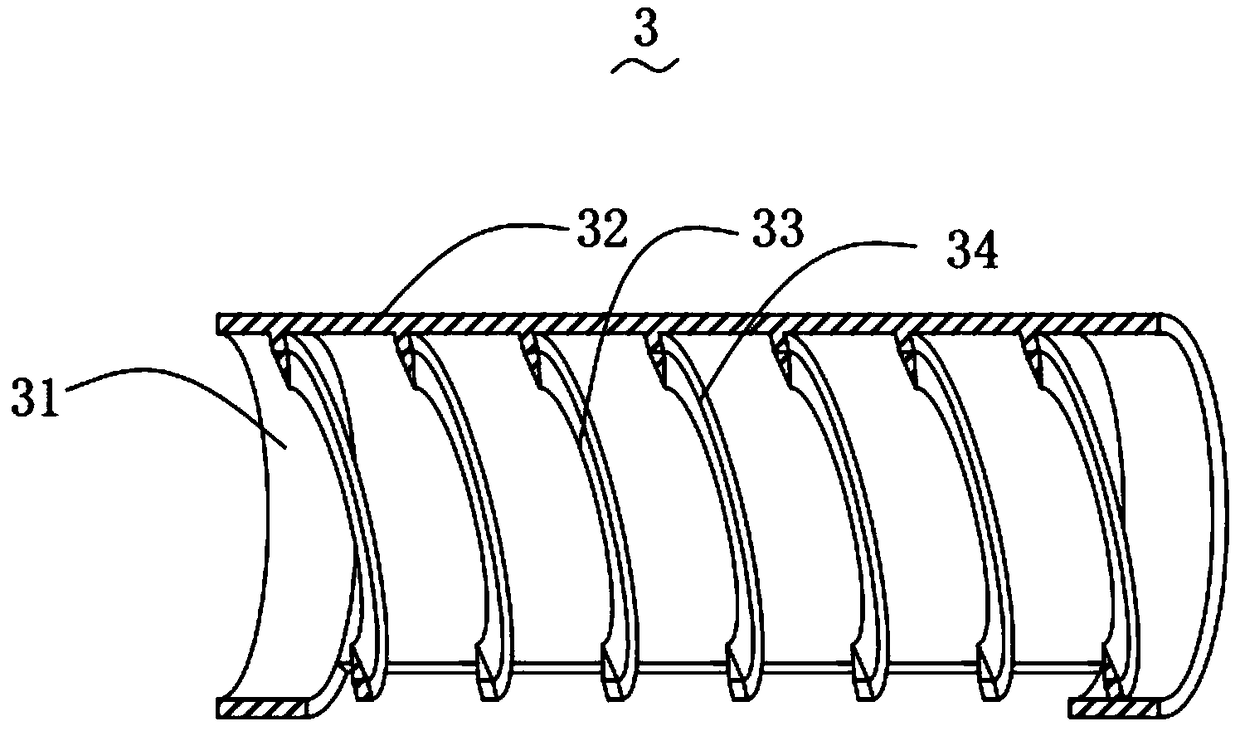

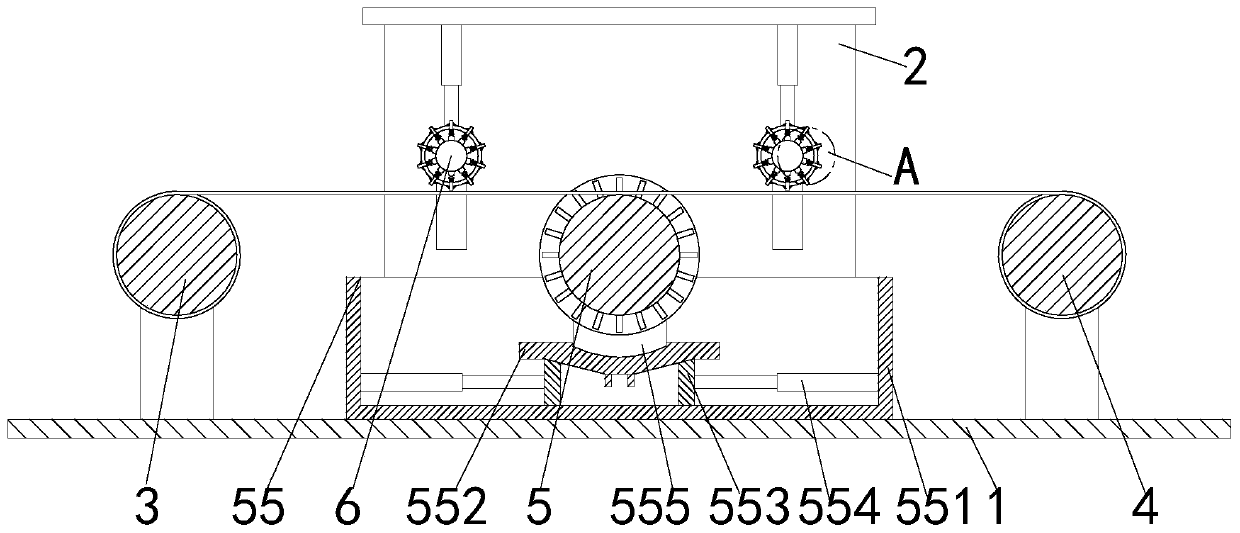

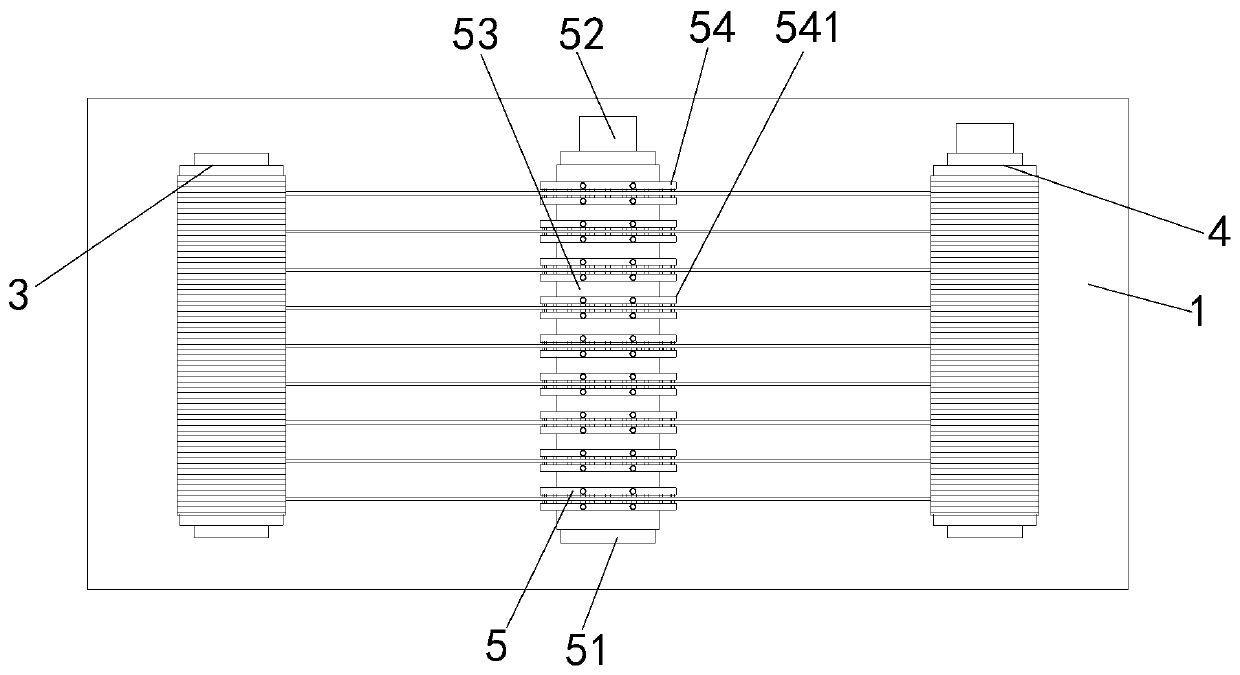

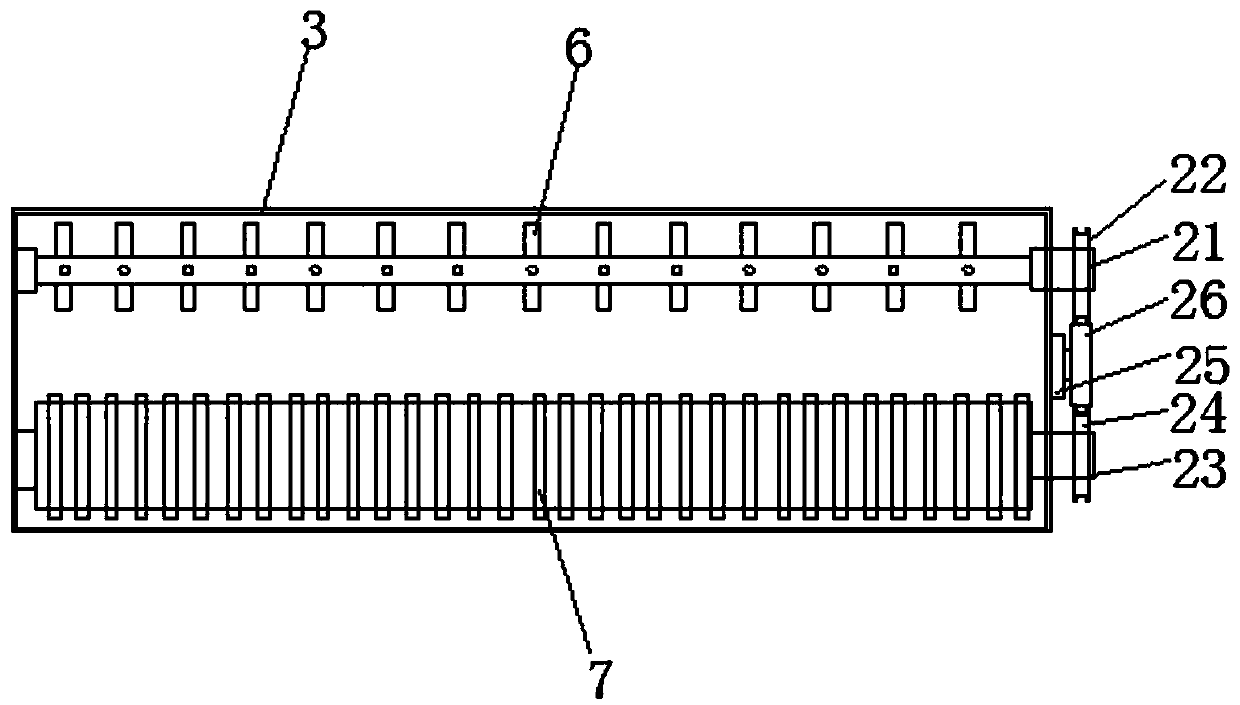

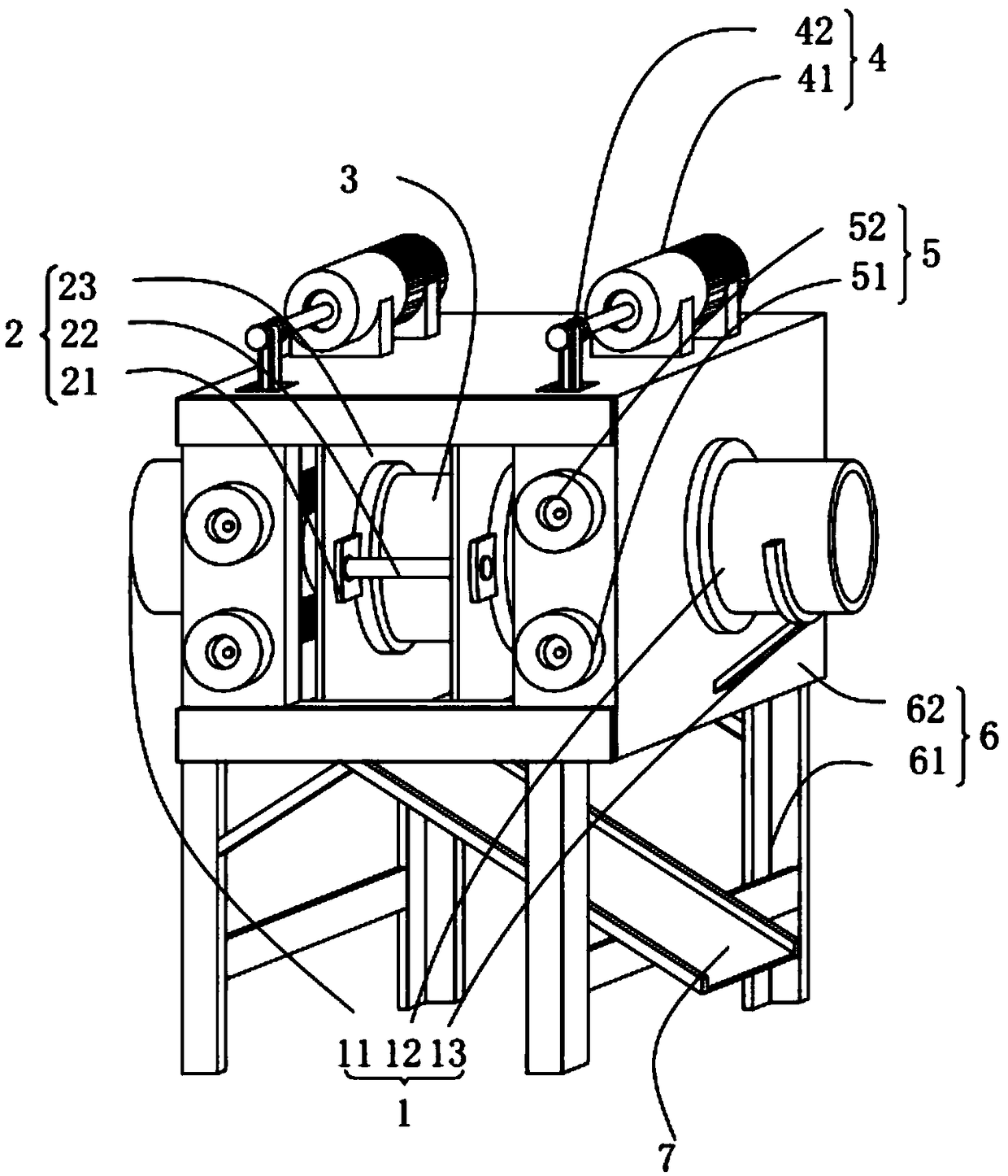

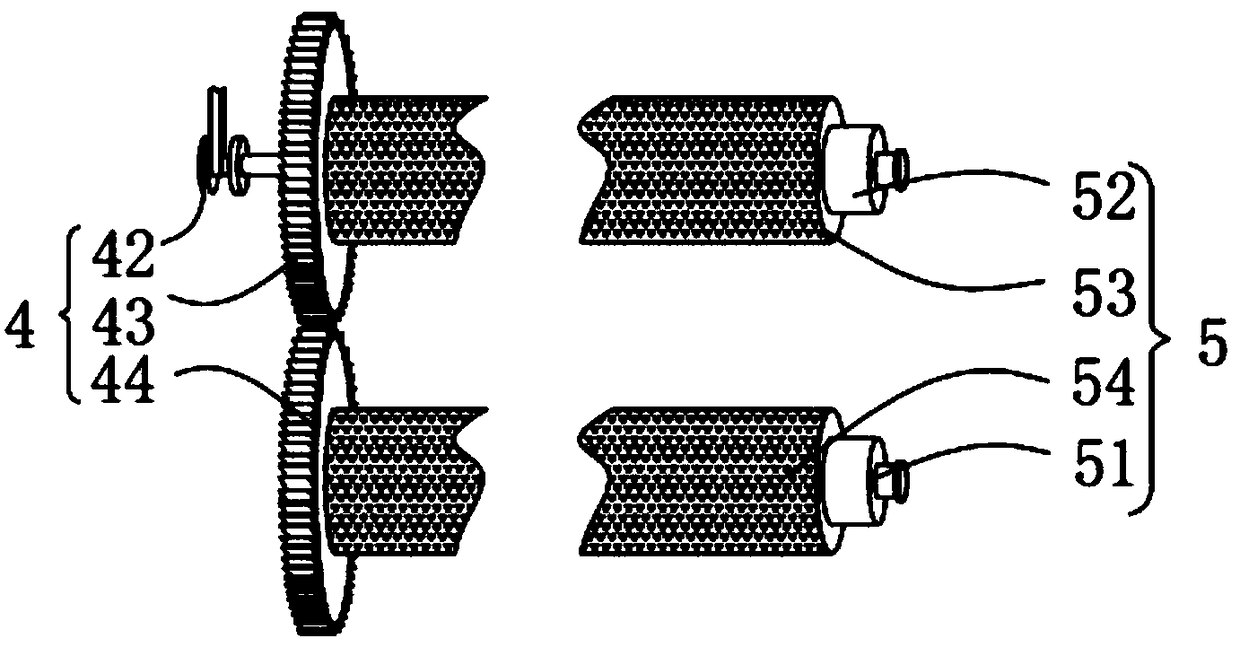

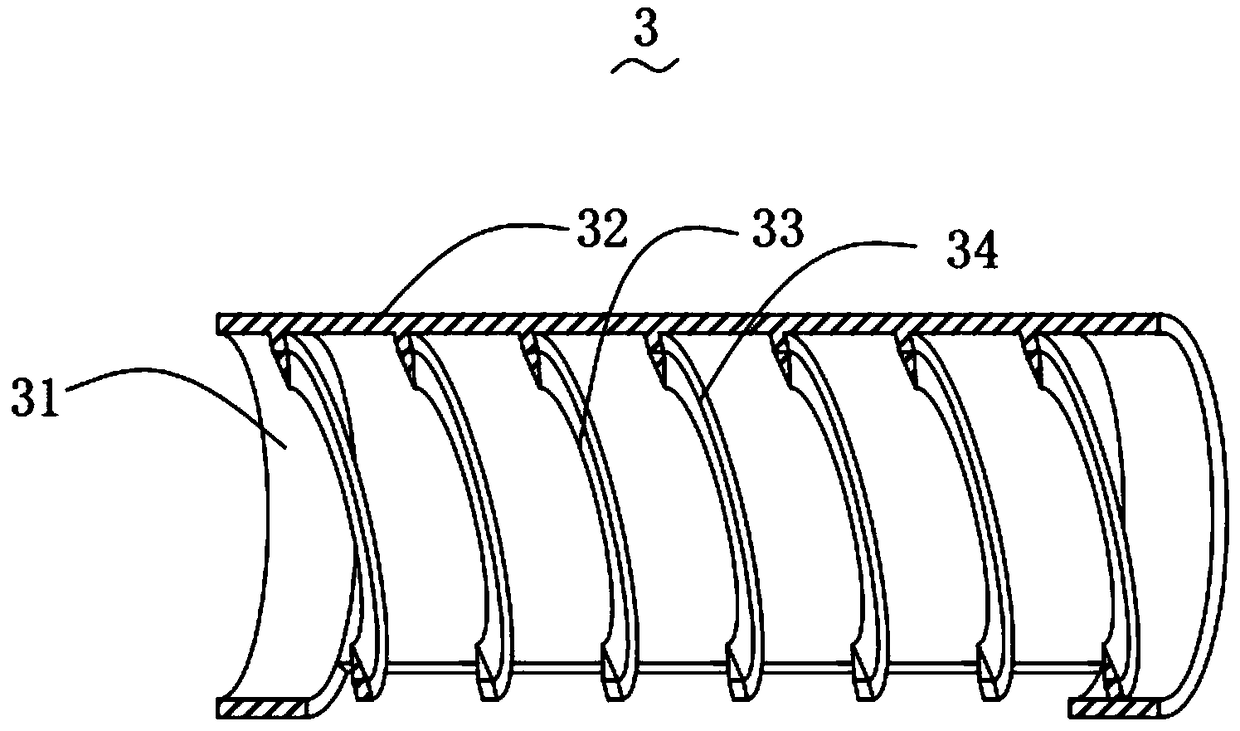

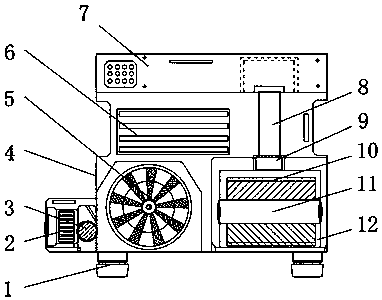

Textile yarn carding processing system

ActiveCN111304798ATo achieve the effect of yarn clearingEasy to operateFibre cleaning/openingCardingTextile yarn

The invention relates to a textile yarn carding processing system. The textile yarn carding processing system comprises a bottom plate, a mounting frame, an upper winding roller, a lower winding roller, a main carding mechanism and an auxiliary carding mechanism, wherein the mounting frame is mounted at the rear end of the bottom plate; the upper winding roller is mounted at the left end of the bottom plate; the lower winding roller is mounted at the right end of the bottom plate; the main carding mechanism is mounted in the middle of the bottom plate; and the auxiliary carding mechanism is arranged at the upper end of the main carding mechanism and installed on the side wall of the mounting frame. Yarn cleaning work is completed through cooperation of the main cleaning mechanism and the auxiliary cleaning mechanism, the main cleaning mechanism and the auxiliary cleaning mechanism only need to rotate and do not need to do reciprocating linear motion in the cleaning process, and the defect that the surface of the yarn is fluffed and broken due to friction on yarn in different directions generated in the reciprocating linear motion process is avoided.

Owner:福建荣耀纺织有限公司

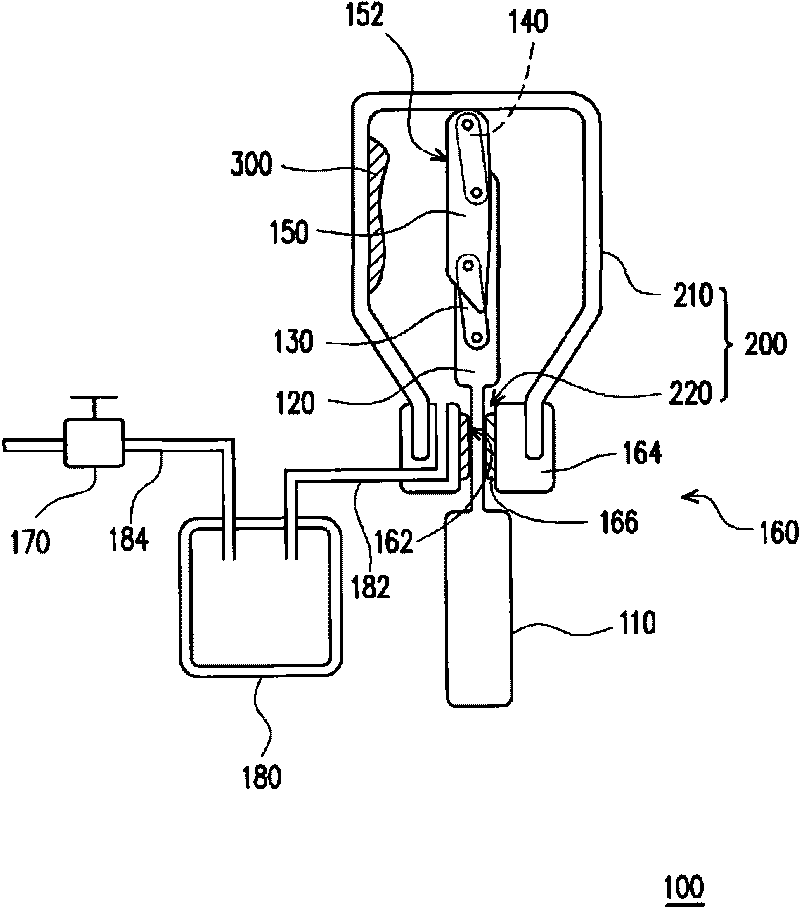

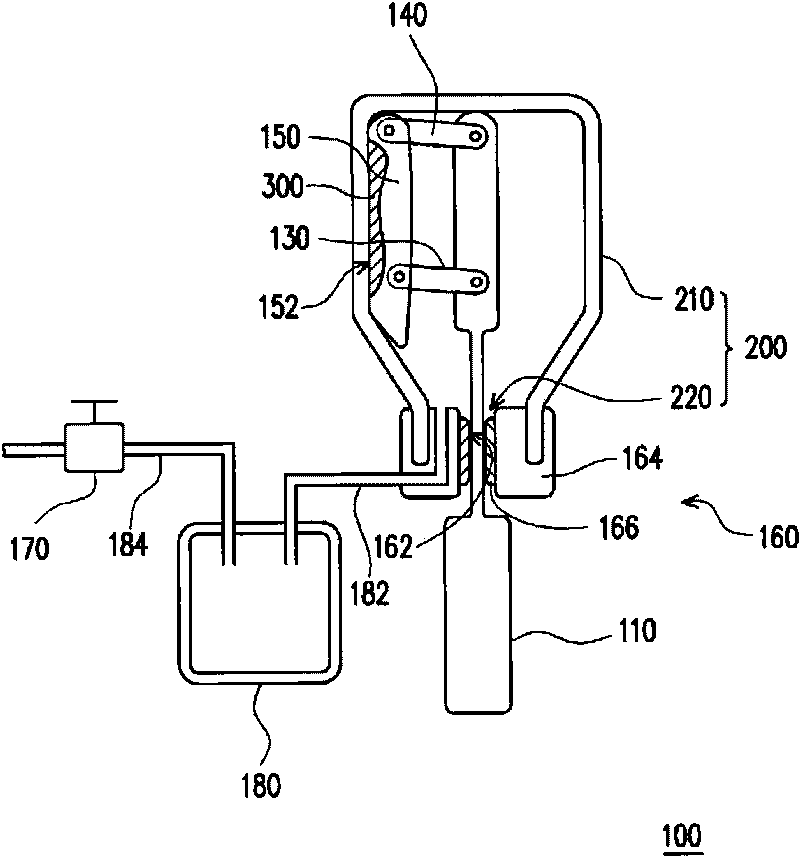

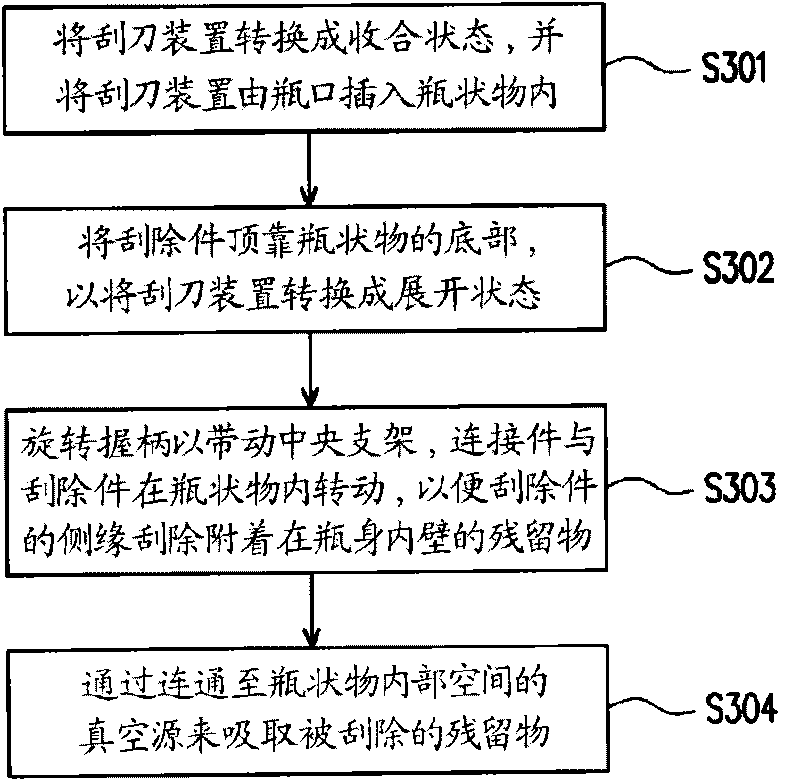

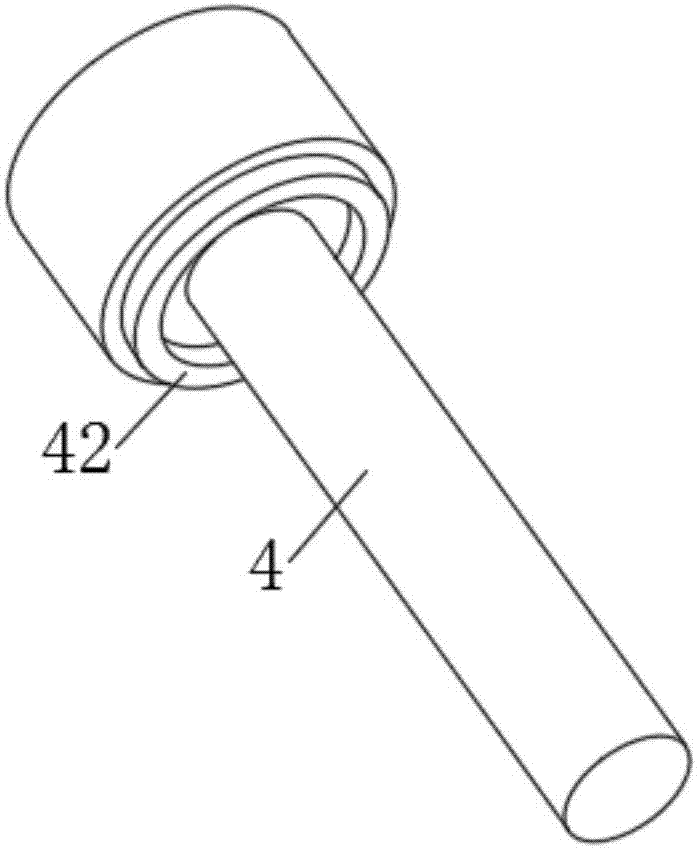

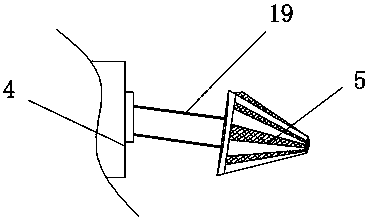

Scraper device and method for removing residue attached to bottle shaped objects

The invention discloses a scraper device and a method for removing residue attached to bottle shaped objects; wherein the scraper device is suitable for removing the residue attached to the inner wall of the bottle body of bottle shaped objects; the bottle shaped object is provided with a bottle opening, and the caliber of the bottle opening is less than the inner diameter of the bottle body of bottle shaped object; the scraper device comprises a grab handle, a central bracket, two connecting pieces and a scraping piece; the central bracket is connected with the grab handle, and the shape of the central bracket is designed that the bracket can enter in the bottle shaped object through the bottle opening; the connecting pieces are arranged in parallel, one end of each connecting piece is pivoted with the central bracket, the scraping piece is provided with a side edge and the profile of the scraping piece is consistent to the inner wall of the bottle body of the bottle shaped object; the other end of each connecting piece is pivoted with the scraping piece, so as to lead the central bracket, the connecting pieces and the scraping piece to form a four-connecting-rod mechanism, and cause the scraper device to switch from the folding state that the scraping piece is drawn closely to the central bracket to the unfolding state that the scraping piece is far away from the central bracket.

Owner:AU OPTRONICS CORP

Wadding removing device for non-woven fabric processing

ActiveCN111874633AConvenient for centralized processingSo as not to damageBulk conveyorsConveyor partsElectric machineryWoven fabric

The invention discloses a wadding removing device for non-woven fabric processing. The device comprises a base, a baffle, a first motor, an air draft pipeline, a bearing cylinder and a battery pack, agroove is formed in the left end face of the base, a first electric telescopic rod is fixed to the right side wall of the groove, and a rotating box is rotatably connected to the top of the base; andthe air draft pipeline penetrates through a top cover to be connected with a filter net, the top of the bearing cylinder penetrates through the bottom of a support and is in threaded connection witha fastener, a sliding rail is fixed to the upper end face of the base, a roller is rotatably connected to the front side of a sliding block, a hydraulic cylinder is fixed to the right side of the front end face of the sliding block, and a top plate is fixed to the left side of the top of the sliding rail. According to the wadding removing device for non-woven fabric processing, after broken wadding in a side face hole of the rotating box is ejected out, the roller and a wadding sticking barrel can move downwards along with the sliding block, meanwhile, the wadding sticking barrel can rotate along with the roller, the wadding sticking barrel and the outer side wall of the rotating box are attached together, and the ejected broken wadding can be conveniently stuck down.

Owner:昆山洁宏无纺布制品有限公司

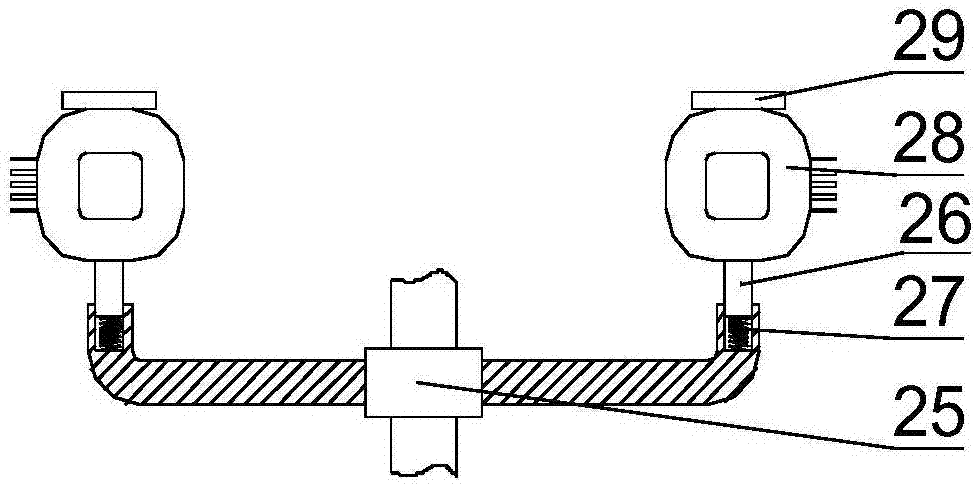

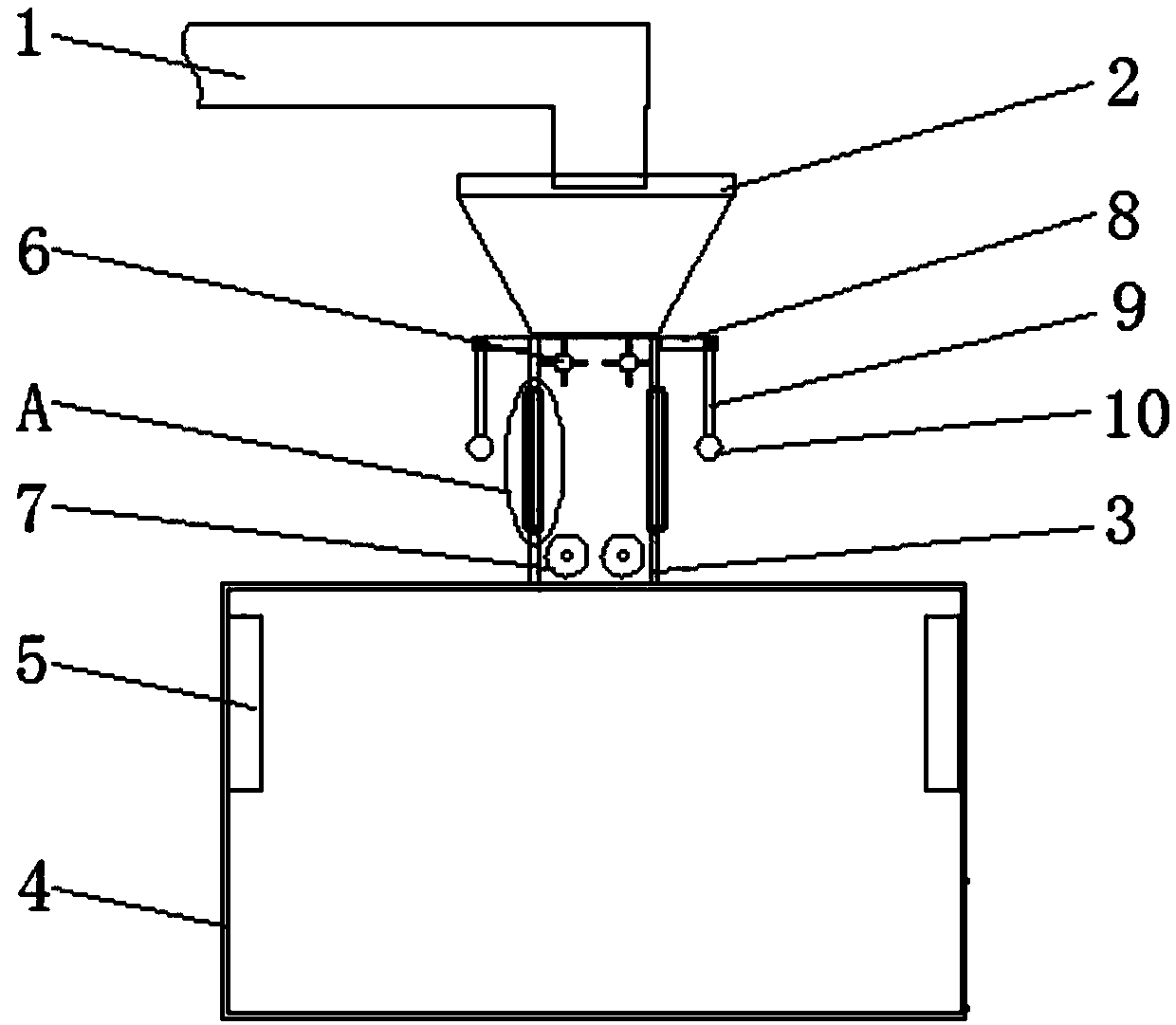

Printing and dyeing mill sludge treatment equipment with mud scraper

PendingCN107651819AEasy to removeReduce clearanceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeEngineering

The invention discloses printing and dyeing mill sludge treatment equipment with a mud scraper. The printing and dyeing mill sludge treatment equipment with the mud scraper comprises a sludge conveying pipe, wherein a feeding hopper is communicated to one end of the sludge conveying pipe; a mud scraping mechanism for cleaning an inner wall of the feeding hopper is arranged in the feeding hopper; afeeding pipe is communicated to the bottom end of the feeding hopper; a heating tank is fixedly arranged at the bottom end of the feeding pipe; the feeding pipe is communicated with the heating tank;a heating pipe is fixedly arranged on an inner wall of the heating tank; a mud smashing roller is rotatably arranged in the feeding pipe; one end of the mud smashing roller is rotatably arranged on an inner wall at one side of the feeding pipe; the other end of the mud smashing roller is rotatably connected with a first rotary rod; one end, far away from the mud smashing roller, of the first rotary rod extends to the outside of the feeding pipe and is fixedly connected with a first gear in a sleeving way. According to the printing and dyeing mill sludge treatment equipment with the mud scraper provided by the invention, dust pollution caused by transportation and storage can be conveniently reduced, meanwhile, sludges on inner walls of the feeding pipe and the feeding hopper can be conveniently cleaned, and the equipment is simple in structure and convenient to use.

Owner:JIANGSU SHUANGYING TEXTILE TECH

Automatic ash removing device for monitoring

ActiveCN108080312AAvoid inconvenienceEasy to scrape offTelevision system detailsColor television detailsSurveillance cameraMonitor equipment

The invention belongs to the technical field of monitoring equipment, and in particular, discloses an automatic ash removing device for monitoring. The automatic ash removing device for monitoring comprises an ash removing shell; a cleaning mechanism and a dirt loosening mechanism are arranged in the ash removing shell; the cleaning mechanism comprises a first rotating shaft; the first rotating shaft is coaxially and fixedly connected with a ratchet; a cleaning scraper is bonded on the end surface of the ratchet; the ratchet is filled with a cleaning agent; the ratchet is provided with a cleaning agent outlet; a rope is fixed and wound on the first rotating shaft; a free end of the rope is connected with a gravity block; the dirt loosening mechanism comprises a second rotating shaft; the second rotating shaft is positioned above the first rotating shaft; the second rotating shaft is fixedly connected with a clamping jaw clamped with the ratchet; the ash removing shell is provided witha loosening driving mechanism for driving reciprocating rotation of the second rotating shaft; the second rotating shaft is fixedly connected with a swing rod; a swing hammer is fixed at a free end ofthe swing rod; and a gravity block return mechanism is arranged on the ash removing shell. The automatic ash removing device for monitoring can solve the problem of difficult cleaning of monitoring cameras.

Owner:重庆轩腾科技有限公司

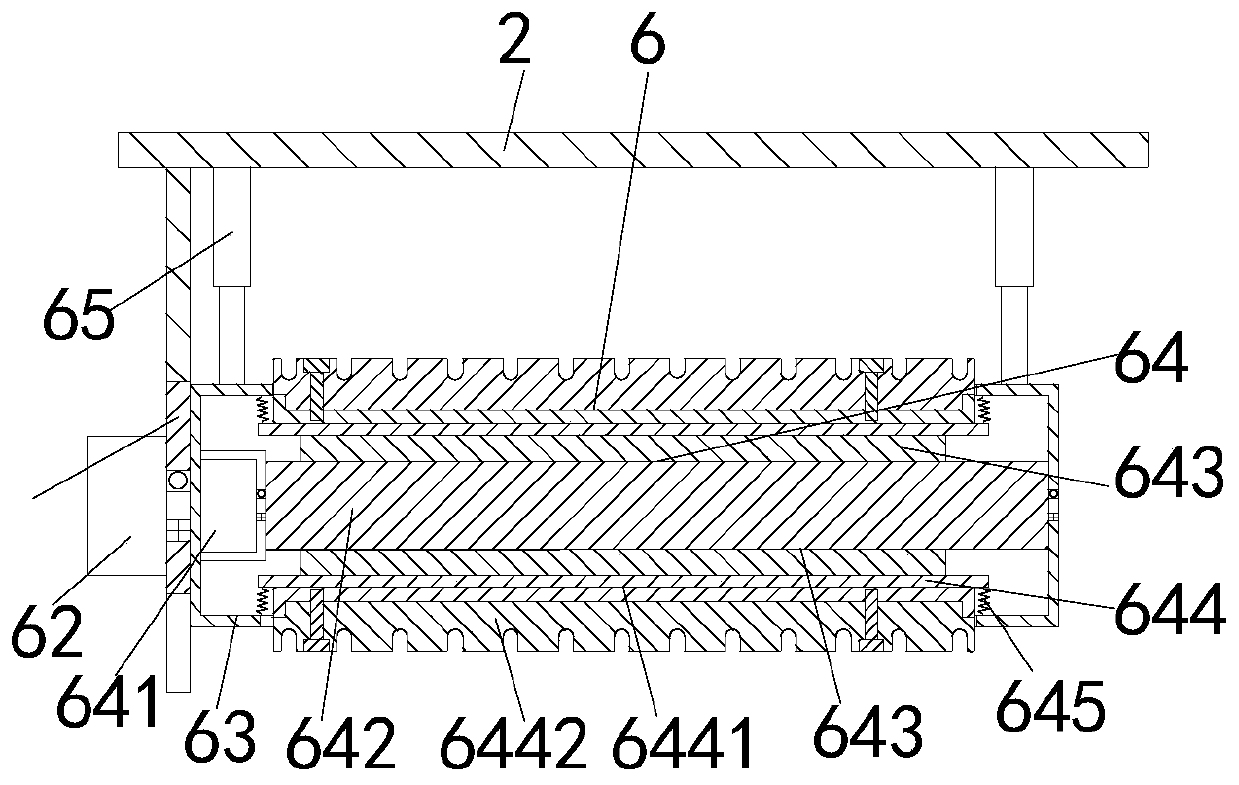

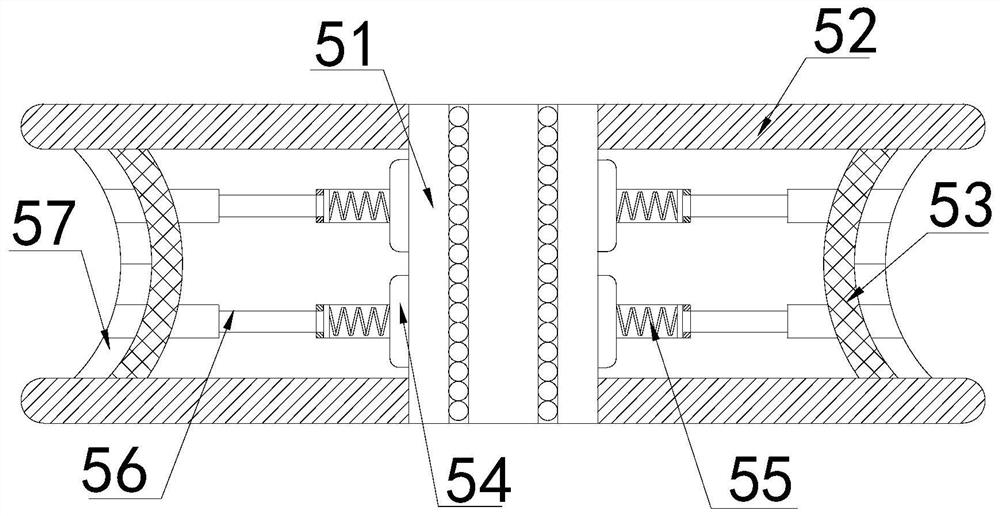

Double-sided scraper equipment for aluminum foil coloring

PendingCN109910428AChange the scrape effectUniform colorRotary pressesPrinting press partsPulp and paper industryAluminum foil

The invention discloses double-sided scraper equipment for aluminum foil coloring. The double-sided scraper equipment comprises two baffles, mounting plates are arranged on the upper parts of the inner sides of the two baffles correspondingly, first guiding rollers are rotationally mounted at the two ends of the upper part between the two mounting plates through bearings correspondingly, second guiding rollers are rotationally mounted at the two ends of the lower part between the two mounting plates through bearings correspondingly, a fixing shaft is fixedly mounted in the middle between the two baffles, a pressing roller is rotationally arranged on the fixing shaft through a bearing in a sleeving mode, mounting rods are mounted on the lower parts of the two ends between the two baffles through protruding blocks correspondingly, and scraper assemblies are arranged on the two mounting rods correspondingly. According to the double-sided scraper equipment for aluminum foil coloring, the scraper assemblies are arranged at the front end and the rear end between the baffles correspondingly, when aluminum foil paper is colored, bubbles can be removed through the two scraper assemblies correspondingly, thus coloring is more uniform, the effect is better, redundant dye without a pattern part is scraped conveniently, and thus the pattern on the aluminum foil paper is colored more clearly.

Owner:ZHUOZHOU HAOYUAN FOIL IND

Filtering device for calcium carbide furnace gas treatment

InactiveCN113198260AValid conversionAvoid excessive wasteDispersed particle filtrationTransportation and packagingFlue gasProcess engineering

The invention relates to the technical field of calcium carbide furnace gas, in particular to a filtering device for calcium carbide furnace gas treatment, and aims to solve the problems that a calcium carbide furnace gas treatment device in the prior art is inconvenient for cleaning dust on the surface of a filtering pipe and waste heat in flue gas cannot be recycled. According to the technical scheme, the filtering device comprises a filter tank, a water tank mounted on the outer wall of one side of the filter tank, a mounting box mounted at the top of the filter tank, and a plurality of ceramic fiber filter pipes mounted on the inner wall of the top of the filter tank, an air inlet is formed in one side of the filter tank, a dust discharge pipe is mounted at the bottom of the filter tank, and a dust discharge valve is mounted on the dust discharge pipe. An air outlet pipe is mounted in the mounting box, and the two ends of the air outlet pipe are each of a closed structure. The device is reasonable in structure and easy to operate, smoke dust attached to the ceramic fiber filter pipe can be conveniently removed, waste heat in furnace gas can be effectively utilized, excessive waste of energy is avoided, and the device is easy to popularize and use.

Owner:HWASU

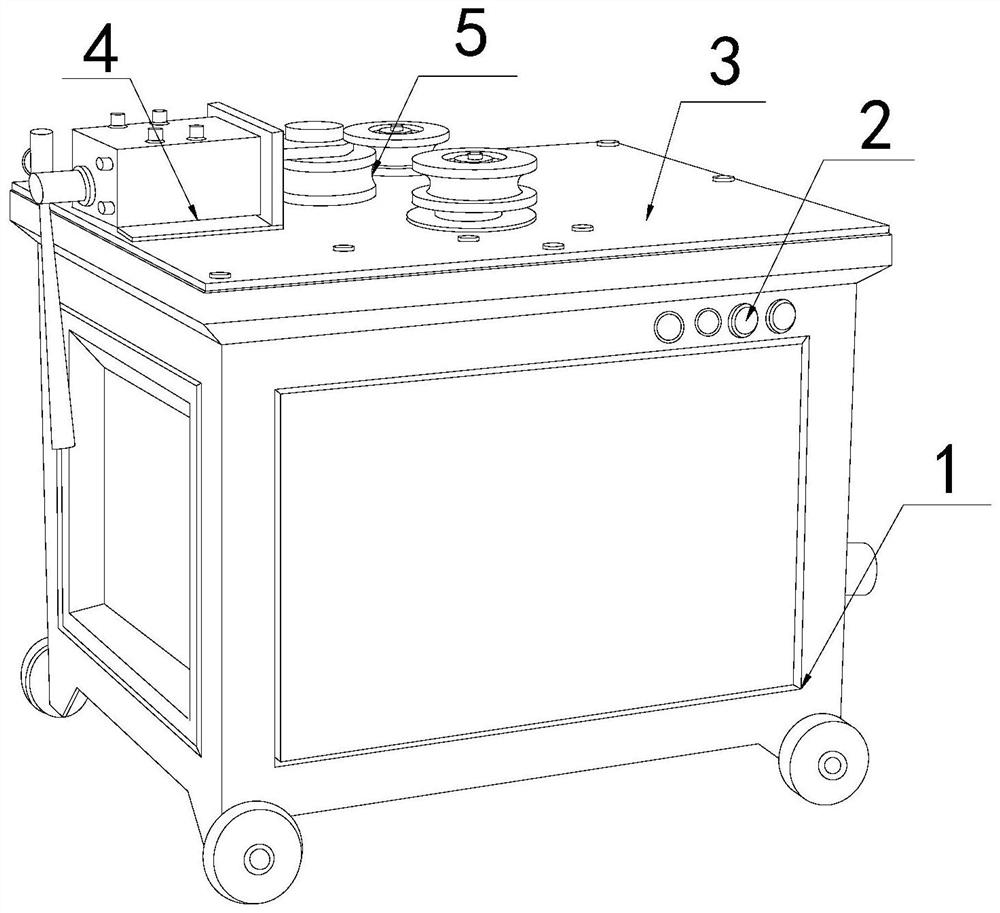

Motorized construction machine

The invention discloses a motorized construction machine. The motorized construction machine structurally comprises a machine body, a button, a workbench, a telescopic table and an arc bending roller,wherein the button is installed on the front face of the machine body, the workbench is fixed to the top of the machine body, the arc bending roller is movably clamped to the top of the workbench, the telescopic table is in bolted connection with the top of the workbench and movably matched with the arc bending roller, a reinforcing steel bar arc bending machine is used for carrying out arc bending on a reinforcing steel bar, the reinforcing steel bar is limited by a buffer block during arc bending, so that the problems that the position of the sharp-corner-shaped notch is changed during arcbending, the sharp-corner-shaped notch extrudes the roller surface, the roller surface is damaged, when the damaged part of the roller surface is in contact with the reinforcing steel bar, a purification film on the surface is easily scraped to cause rusting of the scraped part, the rusting speed of the reinforcing steel bar is increased, and use is influenced are solved; and a brush block of a rotating rod is used for brushing away and collecting cuttings of the notch, and the situation that the notch of the steel bar contains filamentous cuttings, the cuttings fall off and are accumulated onthe surfaces of the limiting plates during arc bending, the reset block between the limiting plates is clamped, and limiting and buffering are affected during steel bar arc bending is avoided.

Owner:福州凯辉铭机械设备有限公司

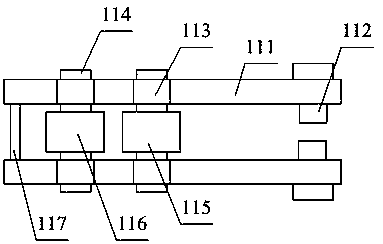

Automatic cable stripping and separating device and stripping and separating method

ActiveCN111384687AAvoid meltingFast peeling speedBasic electric elementsApparatus for removing/armouring cablesStructural engineeringElectric cables

The invention relates to the technical field of cables, and particularly relates to an automatic cable stripping and separating device and a stripping and separating method. The device comprises a base, and also comprises a controller, a continuous feeding mechanism, a peeling mechanism and a discharging mechanism. The continuous feeding mechanism comprises a straightening machine, a container anda positioning assembly. The peeling mechanism comprises a workbench, a heating assembly and two sets of scraping assemblies. The discharging mechanism comprises a hanging plate and a clamping assembly, wherein four supporting rods are symmetrically arranged at the top of the base; the hanging plate is fixedly arranged at the tops of the four supporting rods; the clamping assembly is arranged at the bottom of the hanging plate in a sliding mode. The automatic cable peeling and separating device is high in peeling speed and high in efficiency; meanwhile, peeled skin layers can be separated frominternal wires of cables and can be effectively collected, and recycling and secondary utilization are facilitated.

Owner:日照市睿翅电子商务产业有限公司

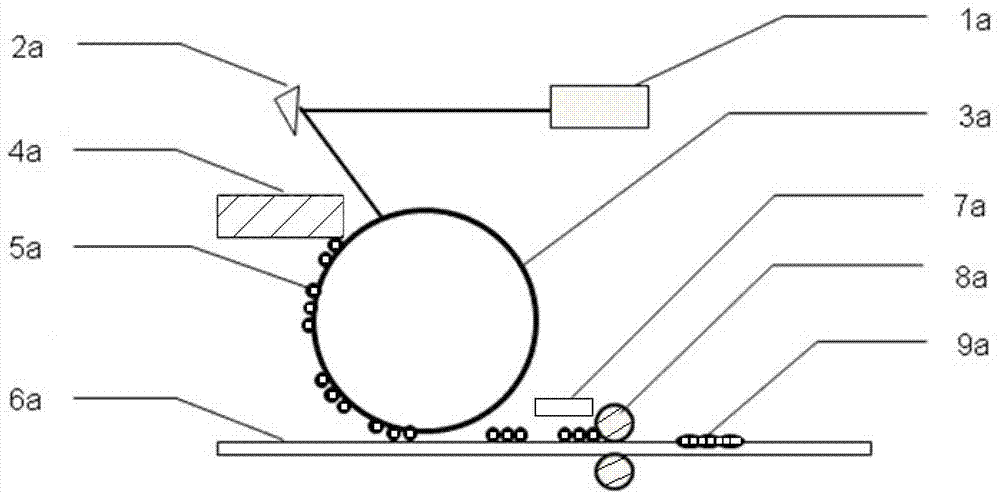

Printing/copying method and equipment

InactiveCN103092038AEasy to scrape offEasy to separateElectrographic process apparatusFiberSurface layer

The invention relates to the printing technical field, in particular to a printing / copying method and equipment, wherein the printing / copying method comprises the following steps of: step 1, drawing an electrostatic image in the form of a charge pattern by using laser; and step 2, attracting colorless powdered ink and colored powdered ink to the position of the electrostatic image under the electrostatic action of charges, respectively; and then transferring the colorless powdered ink and the colored powdered ink on paper, wherein the colored powdered ink covers one side of the colorless powdered ink far away from paper, the colorless powdered ink is located in the fibers of the paper, and the colored powdered ink floats on the surface layer of the paper. The printing / copying method and equipment provided by the invention are capable of clearing away character or image ink marks caused by printing or copying on the paper surface so that the paper can be used for repeated printing or copying of new characters or images.

Owner:吴涛

Reaction kettle capable of being conveniently washed, having temperature control function and used for chemical production

InactiveCN108745236AEasy to cleanEasy to scrape offProcess control/regulationHollow article cleaningTemperature controlCoupling

The invention discloses a reaction kettle capable of being conveniently washed, having temperature control function and used for chemical production. The reaction kettle comprises a kettle body, wherein the top portion of the kettle body is provided with an upper cover, the upper cover is provided with a rotation motor, the left side and the right side of the rotation motor are respectively provided with a material inlet pipe, the surface of the kettle body is provided with a DSP controller, the bottom portion of the kettle body is provided with supporting legs, the bottom portion, positionedon the inner sides of the supporting legs, of the kettle body is provided with an installation frame, the installation frame is provided with a forward and reverse motor, the output shaft of the forward and reverse motor is fixedly connected to a rotation rod through a coupling, the output end of the rotation rod is connected to a scraping plate, a water inlet box is communicated to the water inlet of a water sucking pump through a pipeline, the water outlet of the water sucking pump is connected to a water inlet pipeline, the water outlet of the water inlet pipeline is connected to a water spraying pipe, and the water spraying pipe is horizontally provided with high pressure spraying nozzles. According to the present invention, the reaction kettle can improve the reaction efficiency, canconveniently wash the kettle body, can maintain the cleanliness of the reaction kettle in an effective, environmentally-friendly and low-cost manner, has the prolonged service life, and further has characteristics of simple structure and low production cost.

Owner:杨季维

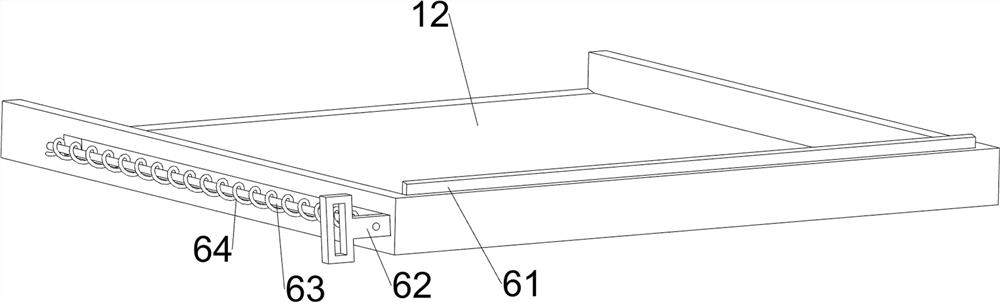

Semi-automatic envelope machine

InactiveCN110271311AGuaranteed to be smoothAvoid bumpingCasing-inBookbinding adhesiveMelting tankSemi automatic

The invention discloses a semi-automatic envelope machine which structurally comprises a clamping switch, a first clamping plate, a second clamping plate, a separating plate, a heat dissipation opening, a hot melting tank, a glue removal structure and a machine body. The hot melting tank is formed at one end of the machine body, the heat dissipation opening is formed in one side of the hot melting tank, the clamping switch is arranged on the other side, opposite to the heat dissipation opening, of the hot melting tank, the first clamping plate and the second clamping plate which are parallel to each other are arranged inside the hot melting tank, the second clamping plate is vertically fixed to the bottom surface, close to the heat dissipation opening, of the hot melting tank, the first clamping plate and the clamping switch are horizontally fixed, and the separating plate is vertically fixed on the machine body. By means of joint cooperation of the glue removal structure and a sliding port, glue overflowing condensation caused in the enveloping process is scraped through reciprocating movement in the hot melting tank, smoothness of the bottom face of the hot melting tank is ensured, the problem that pages are uneven when placed into the hot melting tank for the second time is avoided, a rotating shaft is rotated, the knife point is in a zigzag shape to apply pressure, and therefore hot melt glue can be more easily scraped away.

Owner:袁田

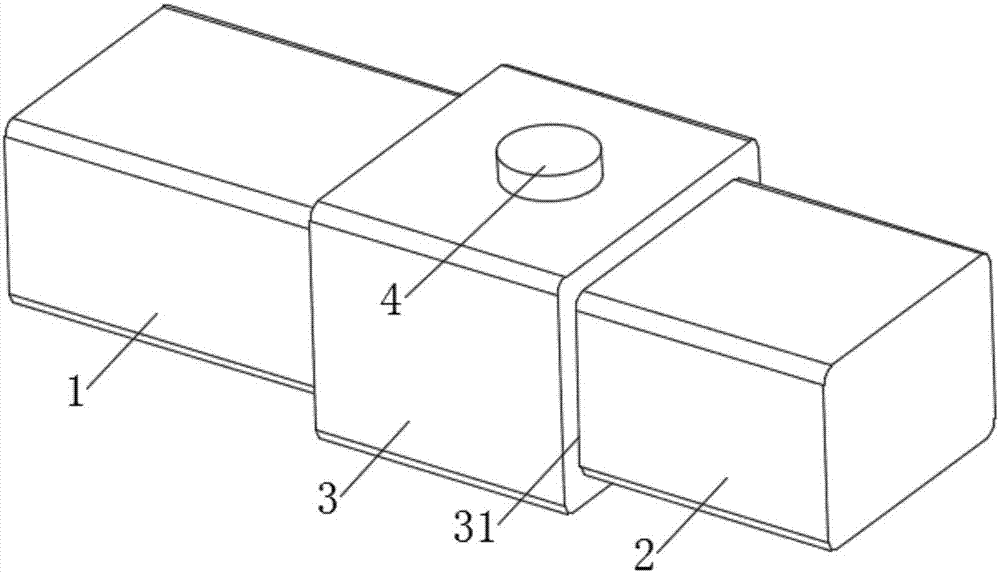

Difficult-to-corrode steel structure

PendingCN107975145AReasonable structureFunctionalBuilding insulationsUltimate tensile strengthMoisture

The invention discloses a difficult-to-corrode steel structure, which comprises a left side steel plate, a right side steel plate, a stainless steel sleeve and a fixing screw, wherein the left side steel plate, the stainless steel sleeve and the right steel plate are in sequential arrangement from the left side to the right side; each of the left side steel plate and the right side steel plate isof a rectangular plate-shaped structure; and round chamfers are arranged in the edge positions of the left side steel plate and the right side steel plate. The round chamfers are arranged in the edgepositions of the left side steel plate and the right side steel plate in the device, so that the abrasion is small; paint in the edge positions cannot be easily scraped away, so that building steel cannot be corroded by moisture in the air and rainwater; the building steel cannot easily rust; high structure intensity can be maintained; the safety is high; a corresponding sealing device is arrangedin the stainless steel sleeve; a sealing ring is also arranged in a screw cap position of the fixing screw; the sealing performance in a connecting position of the screw connecting position and the building steel is good; the abrasion cannot easily occur; the paint protection is good; the building steel cannot easily rust; the connecting intensity between the building steel can also be correspondingly improved; the service life is long; and the difficult-to-corrode steel structure is suitable for being popularized.

Owner:重庆大安渝南重型钢结构工程有限公司

Timber peeling method

The invention relates to the field of timber processing, in particular to a timber peeling method. The timber peeling method comprises the following steps: S1, placing timbers on an open area, and air-drying the timbers for 3-4 days to separate barks from trunks; S2, then spraying water to the surface of the timbers, wherein the water soaks the barks but is not in contact with the trunks, and thesoakage condition of a bark can be observed by peeling a local part; and S3, placing the timbers in a peeling machine, and peeling off the barks by the peeling machine. According to the method, the barks are separated from the trunks by air-drying the timbers at first, then the barks are wetted with water, chippings raised by the barks during peeling are avoided, and the generated chippings are greatly reduced.

Owner:王桂英

Environmentally-friendly sludge cleaning device with filtering and dewatering functions

InactiveCN109083221AEasy to cleanEasy to scrape offSoil-shifting machines/dredgersEnvironmentally friendlyWater pipe

The invention discloses an environmentally-friendly sludge cleaning device with filtering and dewatering functions. The environmentally-friendly sludge cleaning device comprises supporting legs and athird rotating shaft, wherein a machine body is mounted at the upper ends of the supporting legs; the machine body is connected with the supporting legs in a welding manner; a water pump is arranged at the lower end of the left side of the machine body; the water pump is fixedly connected with the machine body; the front end of the water pump is connected with a water pipe; the third rotating shaft is located at the front end below the left side of the machine body; and a stirrer is mounted at the front end of the third rotating shaft. The environmentally-friendly sludge cleaning device with the filtering and dewatering functions is provided with scraper blades and a conveying belt; and the conveying belt is connected with the device through a connection rod. When sludge is required to becleaned, the conveying belt rotates anticlockwise to drive the scraper blades connected to the upper end and the lower end of the conveying belt to operate, so as to scrape off the sludge towards therear end, and then the sludge enters a sludge box for next cleaning; and furthermore, due to the characteristic of an arc-shaped structure of the outer wall of each of the scraper blades, scraping ofthe sludge is facilitated.

Owner:海数(青岛)医学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com