Timber peeling method

A wood and peeling machine technology, applied in the field of wood processing, can solve the problems of easy accumulation of wood chips and difficulty in cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

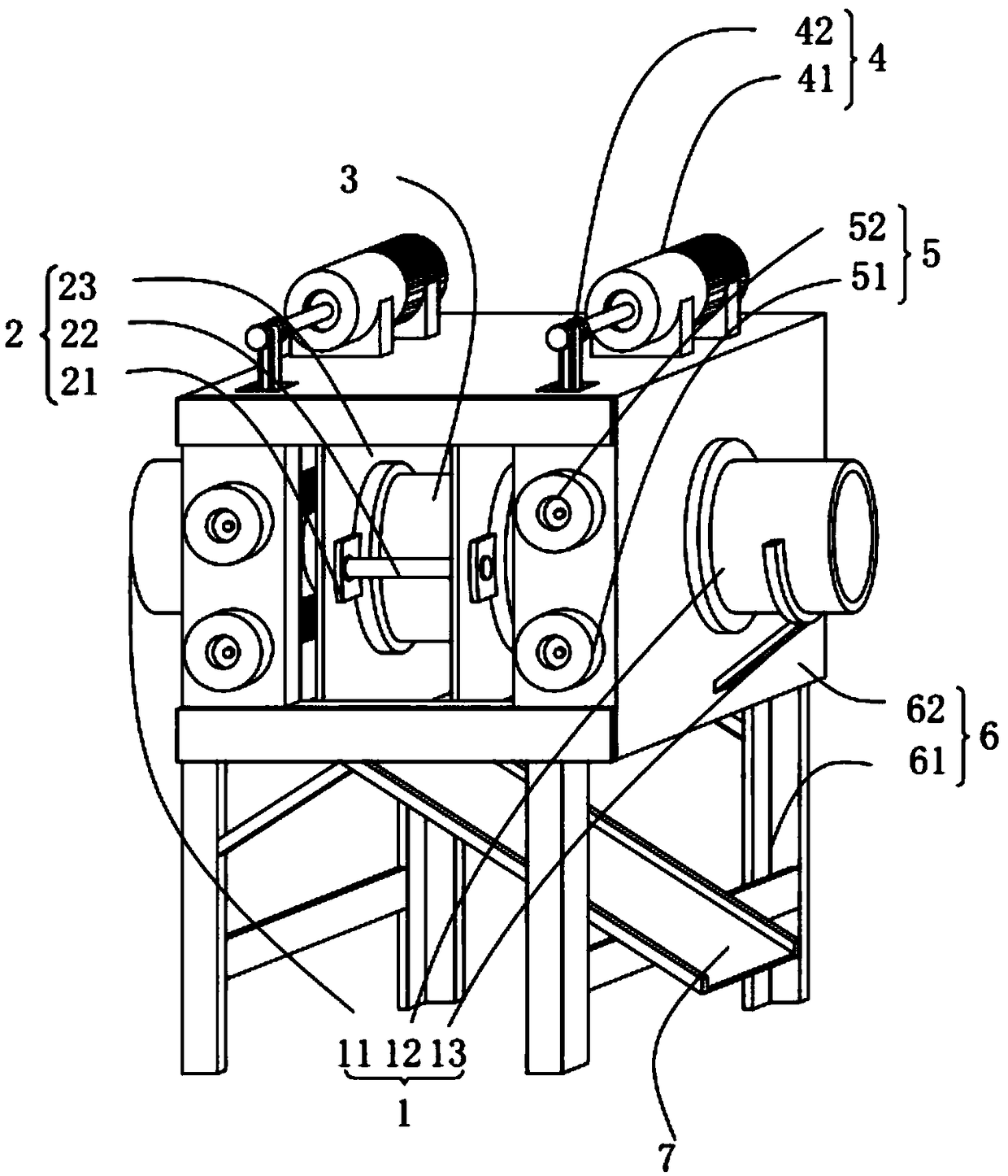

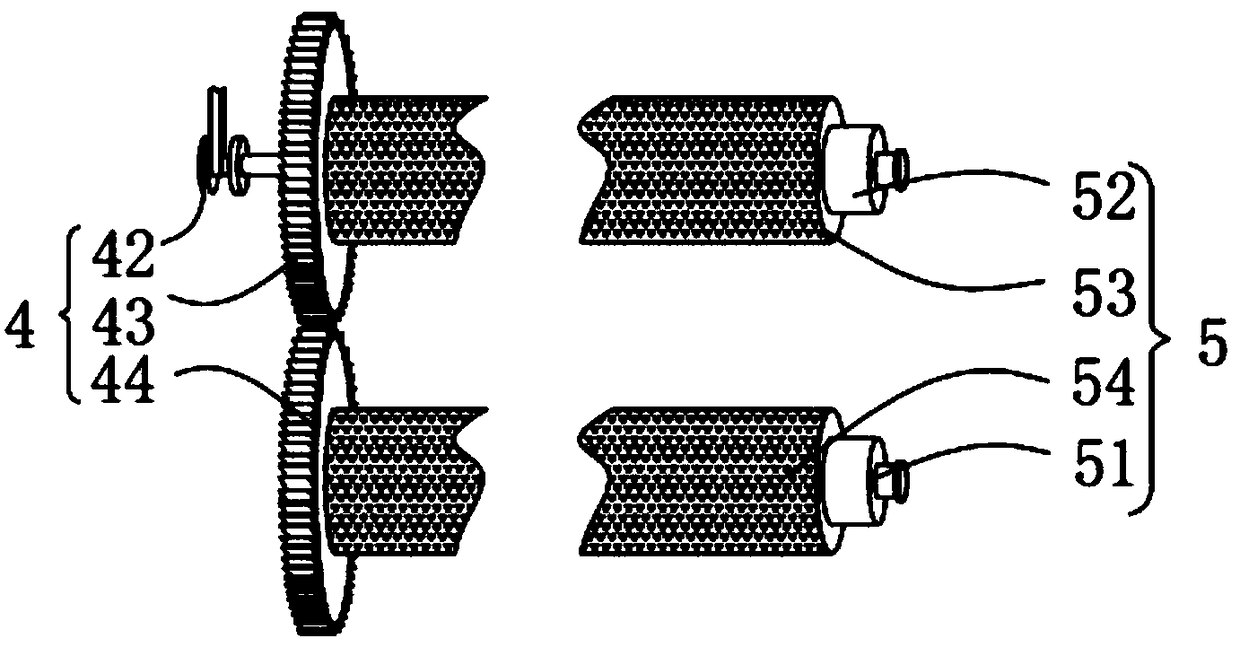

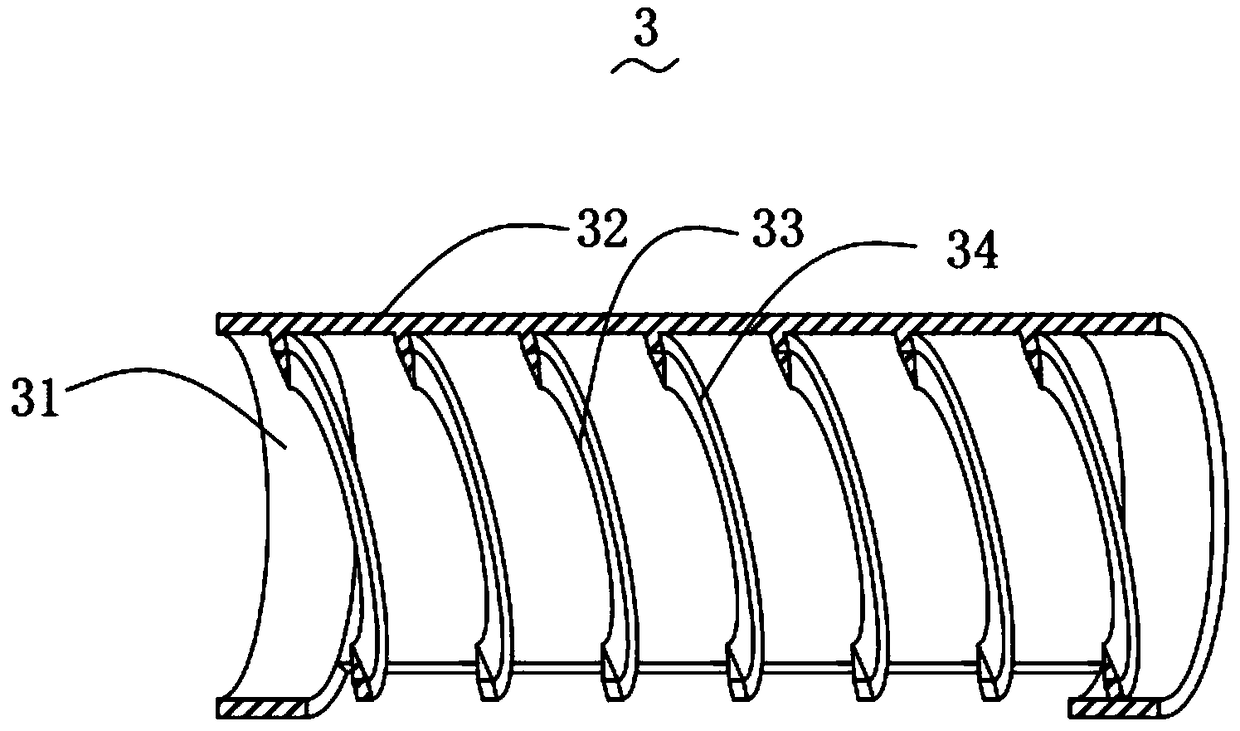

[0026] Such as figure 1 , figure 2 and image 3 Shown, a kind of timber peeling method of the present invention, this method comprises the following steps:

[0027] S1, timber is placed in the open field, aired 3-4 days, makes bark and trunk separate;

[0028] S2, then, spray water to the wood surface so that the water soaks through the bark but does not touch the trunk, and the soaking situation can be observed by peeling off the local bark;

[0029] S3, then, the timber is placed in the bark machine, and the bark machine peels off the bark;

[0030] The debarking machine adopted in this method comprises a supporting mechanism 6 for supporting the whole device, a feeding mechanism 1 for the entry of wood, a conveying mechanism 5 for entering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com