Hollow double-tempered glass with water scraping function

A tempered glass, functional technology, applied in the direction of cleaning methods and appliances, cleaning flexible objects, lighting and heating equipment, etc., can solve the problems of poor wiping effect, no drainage, and insufficient functions on the glass surface, and achieve improved wiping performance. Effect, good cleaning effect, effect of improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

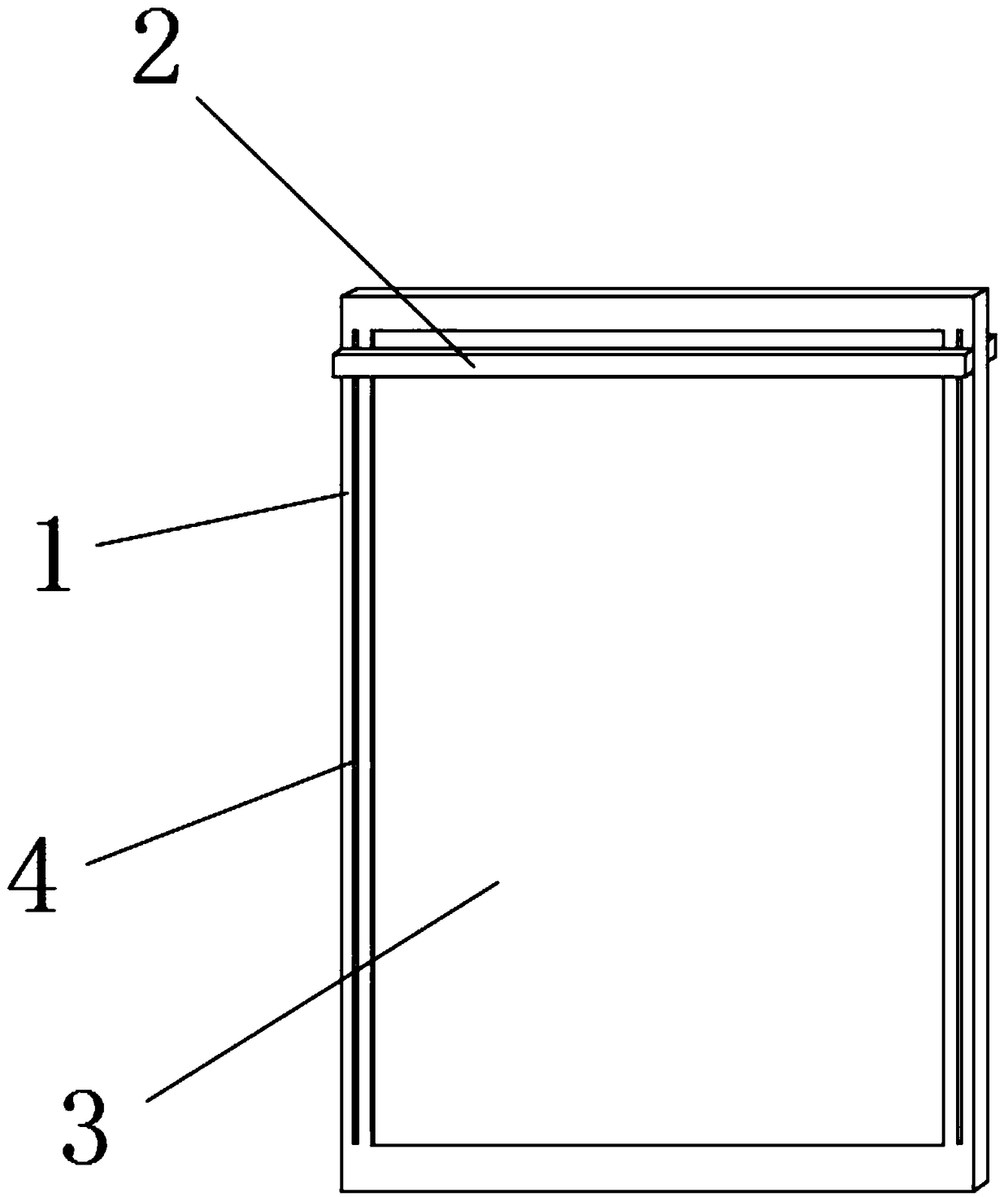

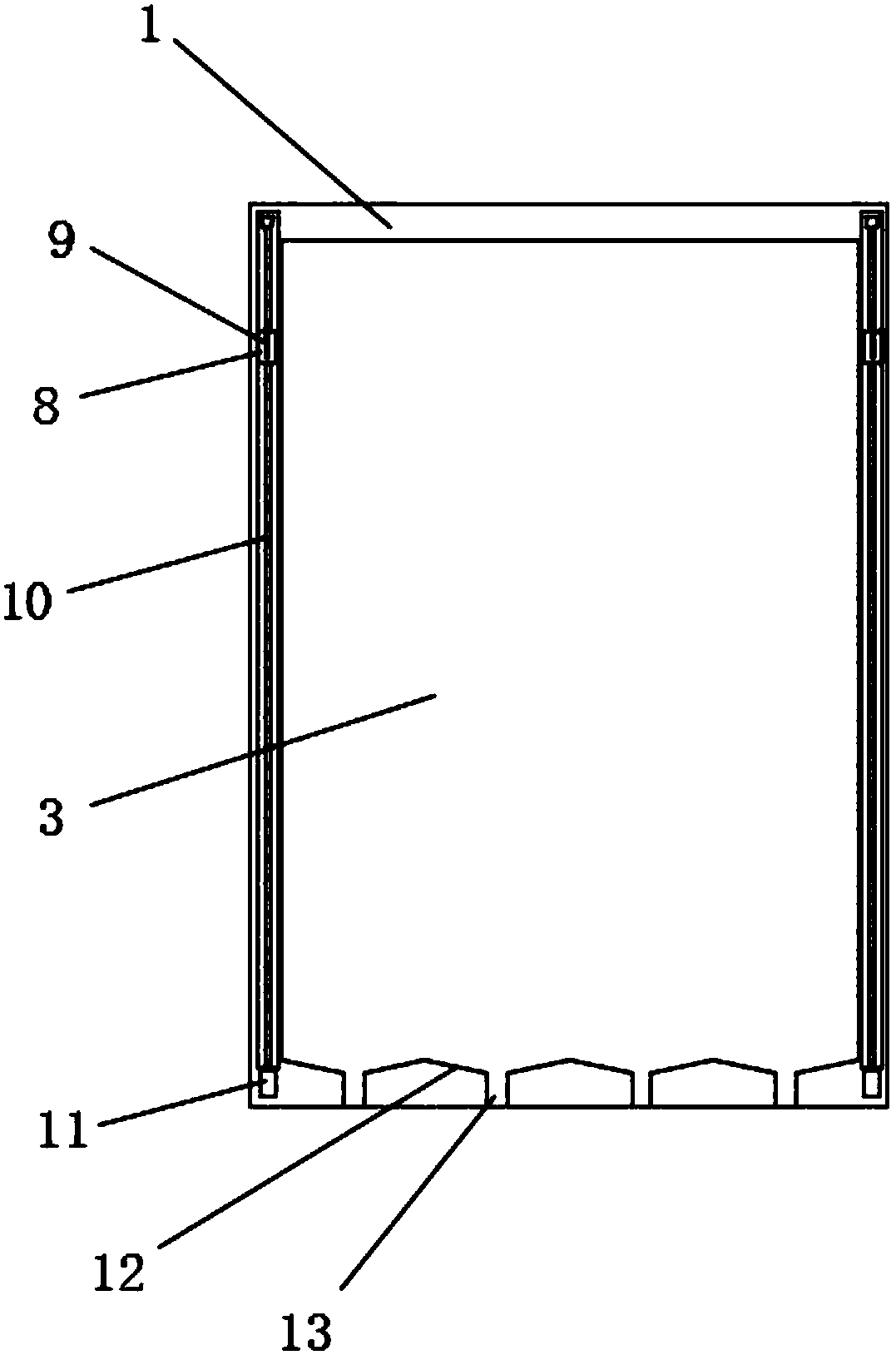

[0028] Embodiment 1: as Figure 1-3 As shown, a hollow double-steel glass with a wiper function includes an outer frame 1, two sets of guide grooves 4 are opened on both sides of the outer frame 1, and two sets of tempered glass are fixed on the inner wall of the outer frame 1. 3. A motor 11 is fixedly installed at the bottom of the left and right inner cavity of the outer frame 1, the top of the motor 11 is fixedly connected with a screw 10, and the middle part of the screw 10 is movably connected with a threaded sleeve 8, and the thread The front side of the sleeve 8 is fixedly connected with a connecting key 9, and the connecting key 9 penetrates the guide groove 4 and is fixedly connected with the scraper frame 2, and the inner cavity of the scraper frame 2 is movably connected with a fixed frame 6. The right side of the frame 6 is fixedly connected with a rubber scraper 5, the rubber scraper 5 is closely attached to the outer surface of the tempered glass 3, the bottom of...

Embodiment 2

[0037] Embodiment 2: as figure 1 As shown, a hollow double-steel glass with a wiper function includes an outer frame 1, two sets of guide grooves 4 are opened on both sides of the outer frame 1, and two sets of tempered glass are fixed on the inner wall of the outer frame 1. 3. A motor 11 is fixedly installed at the bottom of the left and right inner cavity of the outer frame 1, the top of the motor 11 is fixedly connected with a screw 10, and the middle part of the screw 10 is movably connected with a threaded sleeve 8, and the thread The front side of the sleeve 8 is fixedly connected with a connecting key 9, and the connecting key 9 penetrates the guide groove 4 and is fixedly connected with a scraper frame 2, and the inner cavity of the scraper frame 2 is movably connected with a fixed frame 6, and the fixed The right side of the frame 6 is fixedly connected with a rubber scraper 5, the rubber scraper 5 is closely attached to the outer surface of the tempered glass 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com