Poultry excrement hydrothermal treatment dewatering method

A technology for hydrothermal treatment and manure, applied in water/sludge/sewage treatment, sludge treatment, oxidation treatment of sludge, etc., can solve the problems of high moisture content of fresh poultry manure, unfavorable transportation and final disposal, etc., to achieve large-scale convenience The effect of chemical industry production, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a. add hydrogen peroxide solution in fresh chicken manure (initial moisture content is 83%), the amount that adds described hydrogen peroxide is 0.15mol in the dry basis of every kilogram of described chicken manure, stirs, and adds to In the hydrothermal reaction device, the temperature was adjusted to 110°C, and the reaction was fully performed for 30 minutes.

[0033] b. Add water to the reacted chicken manure in step a, adjust the water content to 90%, mix and stir evenly.

[0034] c. Dehydrating the chicken manure obtained after step b through a plate and frame filter press to complete the treatment of fresh chicken manure. The filter cloth of the plate and frame filter press has a pore size of 30 μm.

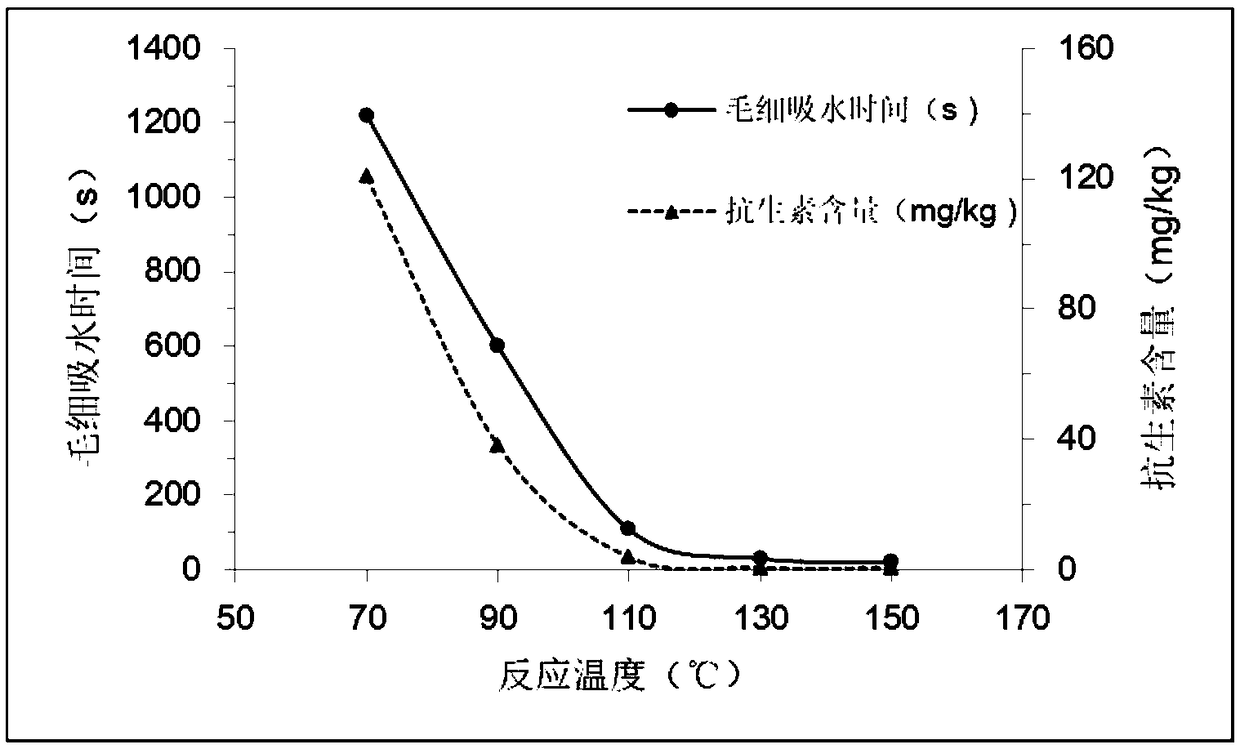

[0035] The capillary water absorption time of the fresh chicken manure before the treatment in this embodiment was 1536.3s, and the antibiotic content was 152.33mg / kg. The capillary water absorption time of the chicken manure treated in step a is 96.3s, the moistur...

Embodiment 2

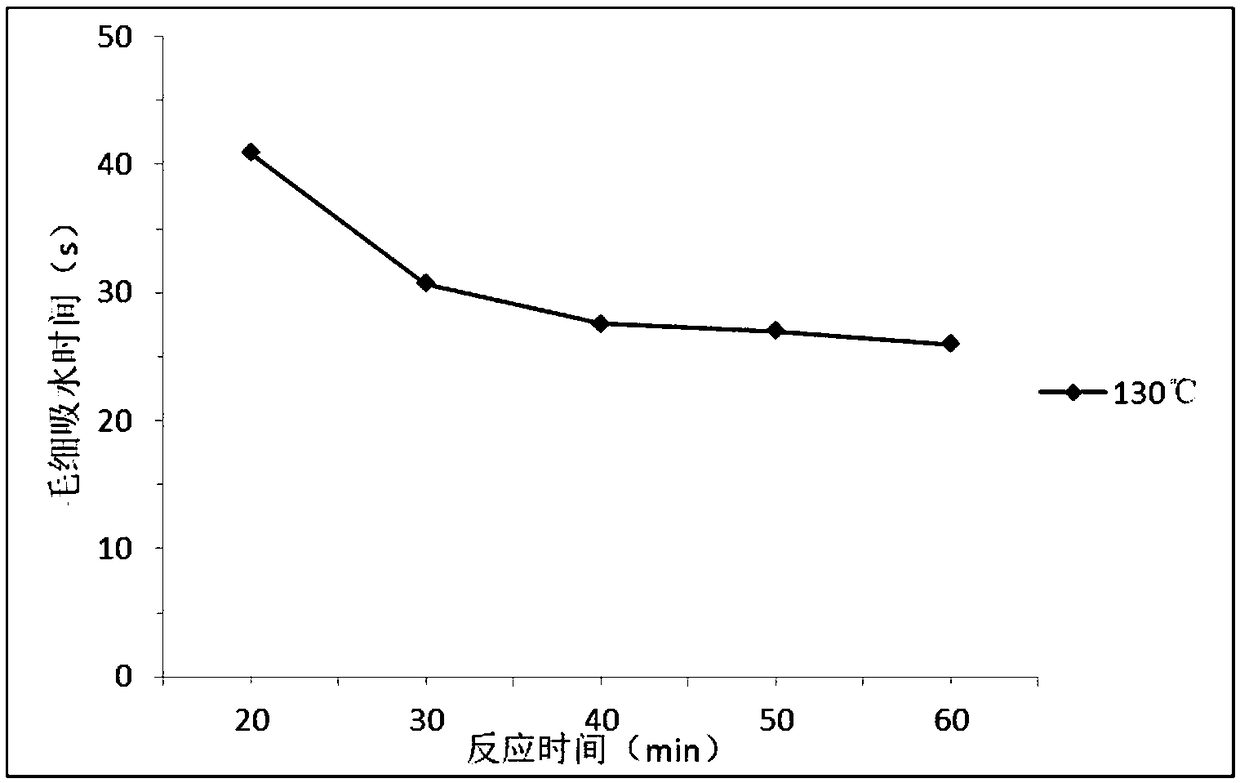

[0037]a. add potassium persulfate solution in fresh duck manure (initial moisture content is 81%), the amount that adds described potassium persulfate in every kilogram of described duck manure dry basis is 0.20mol, stirs then, and adds to In the hydrothermal reaction device, adjust the temperature to 130°C and fully react for 50 minutes.

[0038] b. Add water to the reacted duck manure in step a, adjust the water content to 92%, mix and stir evenly.

[0039] c. Dehydrating the duck manure obtained after step b through a plate and frame filter press to complete the treatment of fresh duck manure. The pore diameter of the filter cloth of the plate and frame filter press is 30 μm.

[0040] The tested capillary water absorption time of the fresh duck manure before the treatment in this embodiment is 1245.6s, and the antibiotic content is 183.66mg / kg. The capillary water absorption time of the duck manure treated in step a is 26.2s, the moisture content of the treated duck manure...

Embodiment 3

[0042] a. add sodium persulfate solution in fresh goose droppings (initial moisture content is 84%), the amount that adds described sodium persulfate in every kilogram of described goose droppings dry basis is 0.3mol, stirs then, and joins in In the hydrothermal reaction device, the temperature was adjusted to 150°C, and the reaction was fully performed for 60 minutes.

[0043] b. Add water to the reacted goose manure in step a, adjust the water content to 95%, mix and stir evenly.

[0044] c. The goose manure obtained after step b is dehydrated through a plate and frame filter press to complete the treatment of fresh goose manure. The pore diameter of the filter cloth of the plate and frame filter press is 40 μm.

[0045] The tested capillary water absorption time of the fresh goose droppings before the treatment in this example was 1358.1s, and the antibiotic content was 132.87mg / kg. The capillary water absorption time of the goose manure treated in step a is 14.1s. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com