Method for continuous gradient acidification of DSD acid

A gradient, acidification kettle technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfonic acid, etc., can solve the problems of inability to meet mass production, small DSD acid crystals, low production efficiency, etc. The effect of fast filtration and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

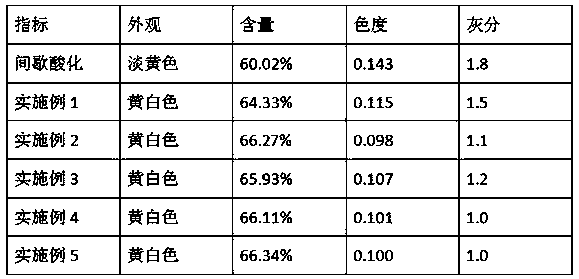

Examples

Embodiment 1

[0029] Example 1, using two-stage acidification, that is, using a two-stage acidification kettle, first preheating the DSD acid sodium salt solution to 80 ° C, and protecting it with nitrogen; prepare sulfuric acid, and calibrate the flow meter and pH meter;

[0030] The first-stage acidification kettle, the pH value is set to 5.5: inject 6000LDSD acid sodium salt solution into the 8000L jacketed enamel reaction kettle, turn on stirring and steam, and maintain the temperature at 90±3℃; slowly turn on the sulfuric acid dropwise Valve, adjust the pH value in the kettle to 5.5±0.2; close the sulfuric acid valve, continue to stir for 2 hours, take a sample to observe whether there is agglomeration; if there is, continue to stir until there is no agglomeration; after no agglomeration, open DSD sodium acid at the same time Salt solution and sulfuric acid dripping valve, stabilize the flow of DSD sodium salt solution, and use the pH meter to control the opening of the sulfuric acid dr...

Embodiment 2

[0032] Example 2, using three-stage acidification, that is, using a three-stage acidification kettle, first preheating the DSD acid sodium salt solution to 80 ° C, and protecting it with nitrogen; prepare sulfuric acid, and calibrate the flow meter and pH meter;

[0033] The first-stage acidification kettle, the pH value is set to 5.0: inject 6000LDSD acid sodium salt solution into the 8000L jacketed enamel reaction kettle, turn on stirring and steam, and maintain the temperature at 90±3°C; slowly turn on the sulfuric acid dropwise Valve, adjust the pH value in the kettle to 5.0±0.2; close the sulfuric acid valve, continue to stir for 2 hours, take a sample to observe whether there is agglomeration; if there is, continue to stir until there is no agglomeration; after no agglomeration, open DSD sodium acid at the same time Salt solution and sulfuric acid dripping valve, stabilize the flow of DSD sodium salt solution, and use the pH meter to control the opening of the sulfuric ac...

Embodiment 3

[0036] Example 3, using three-stage acidification, that is, using a three-stage acidification kettle, first preheating the DSD acid sodium salt solution to 70 ° C, and protecting it with nitrogen; prepare sulfuric acid, and calibrate the flow meter and pH meter;

[0037] The first-stage acidification kettle, the pH value is set to 5.0: put 6000LDSD acid sodium salt solution into the 8000L jacketed enamel reaction kettle, turn on stirring and steam, and maintain the temperature at 80±3℃; slowly turn on the sulfuric acid dropwise Valve, adjust the pH value in the kettle to 5.0±0.2; close the sulfuric acid valve, continue to stir for 2 hours, take a sample to observe whether there is agglomeration; if there is, continue to stir until there is no agglomeration; after no agglomeration, open DSD sodium acid at the same time Salt solution and sulfuric acid dripping valve, stabilize the flow of DSD sodium salt solution, and use the pH meter to control the opening of the sulfuric acid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com