Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Increase braking distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

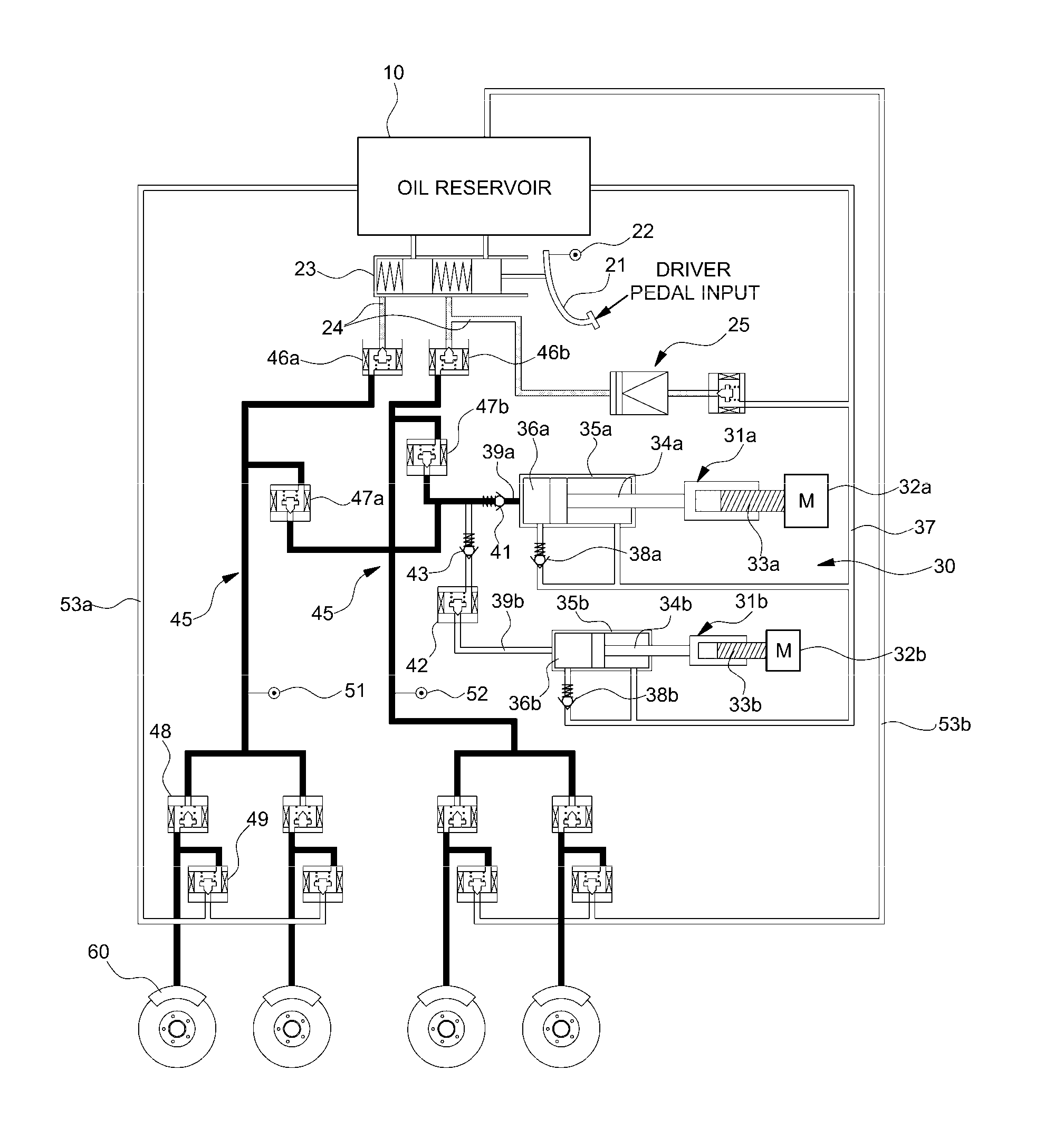

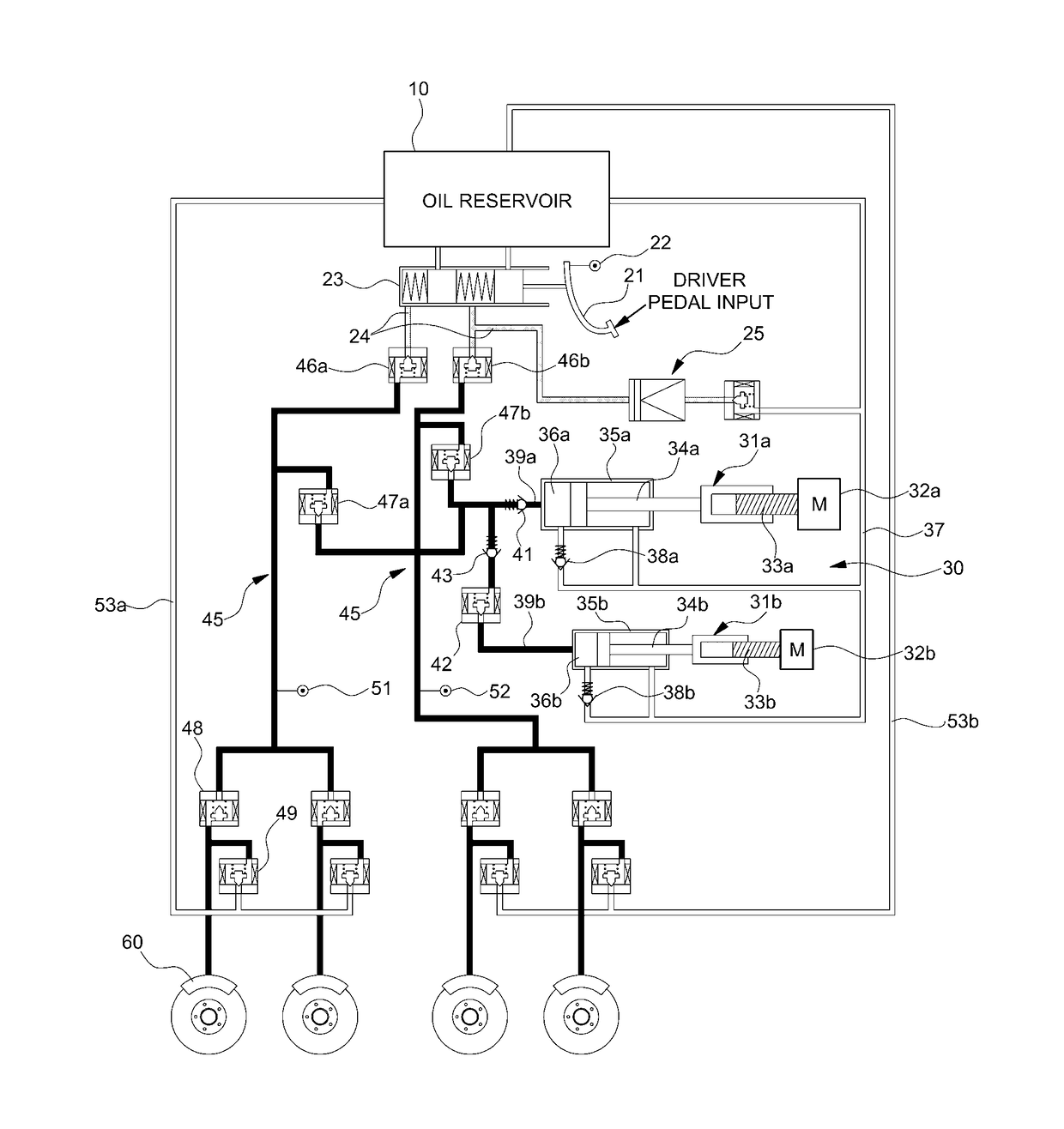

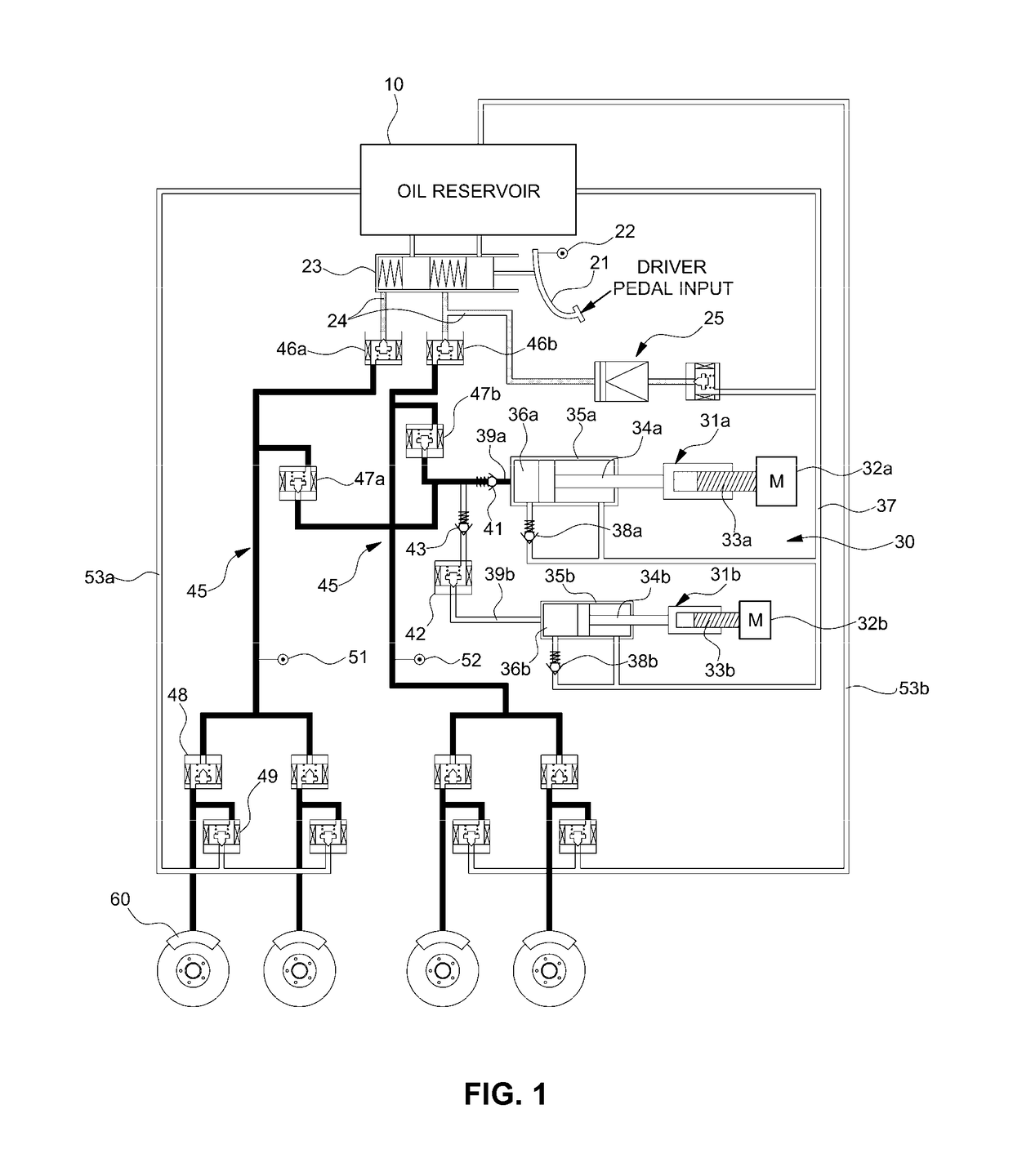

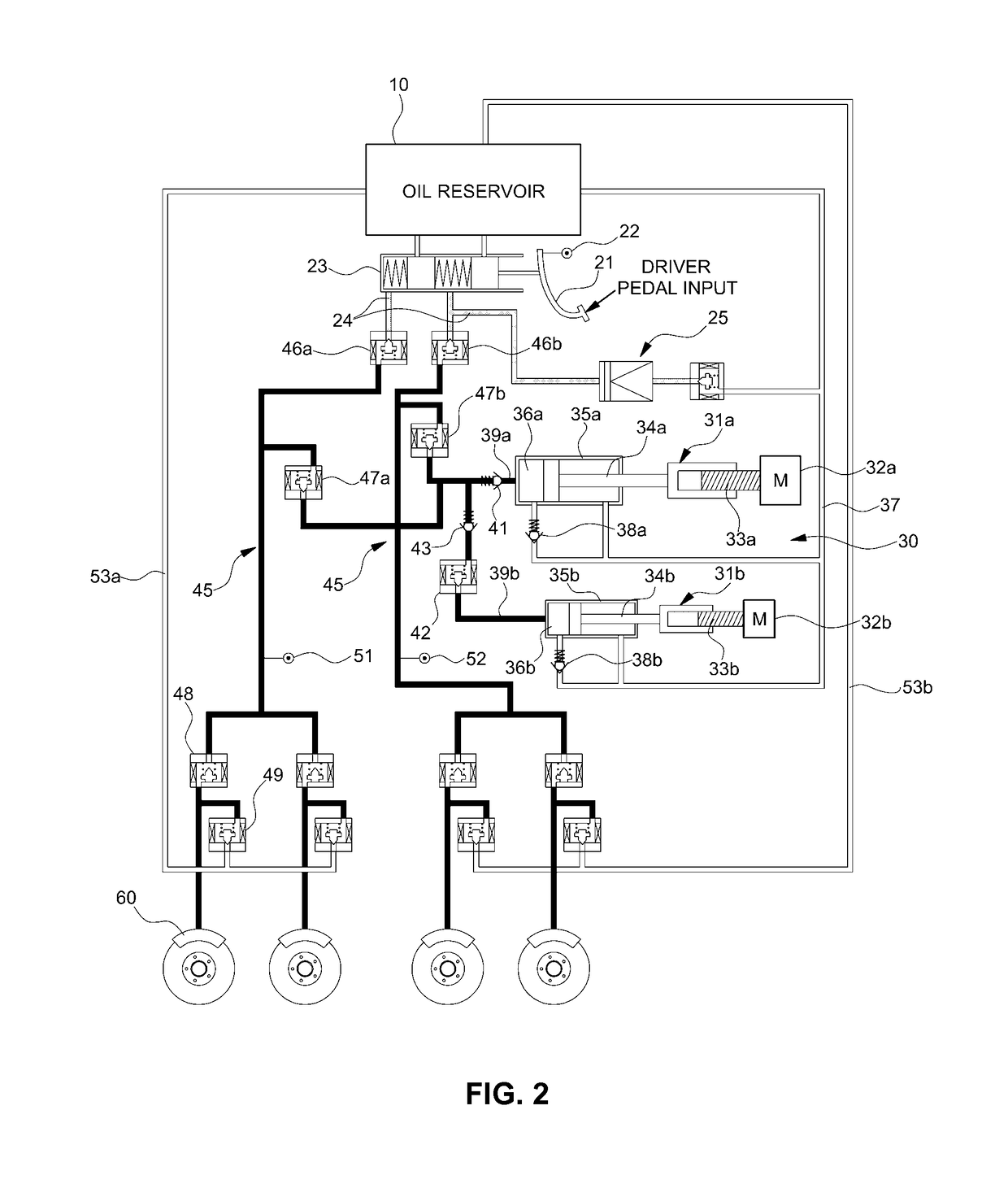

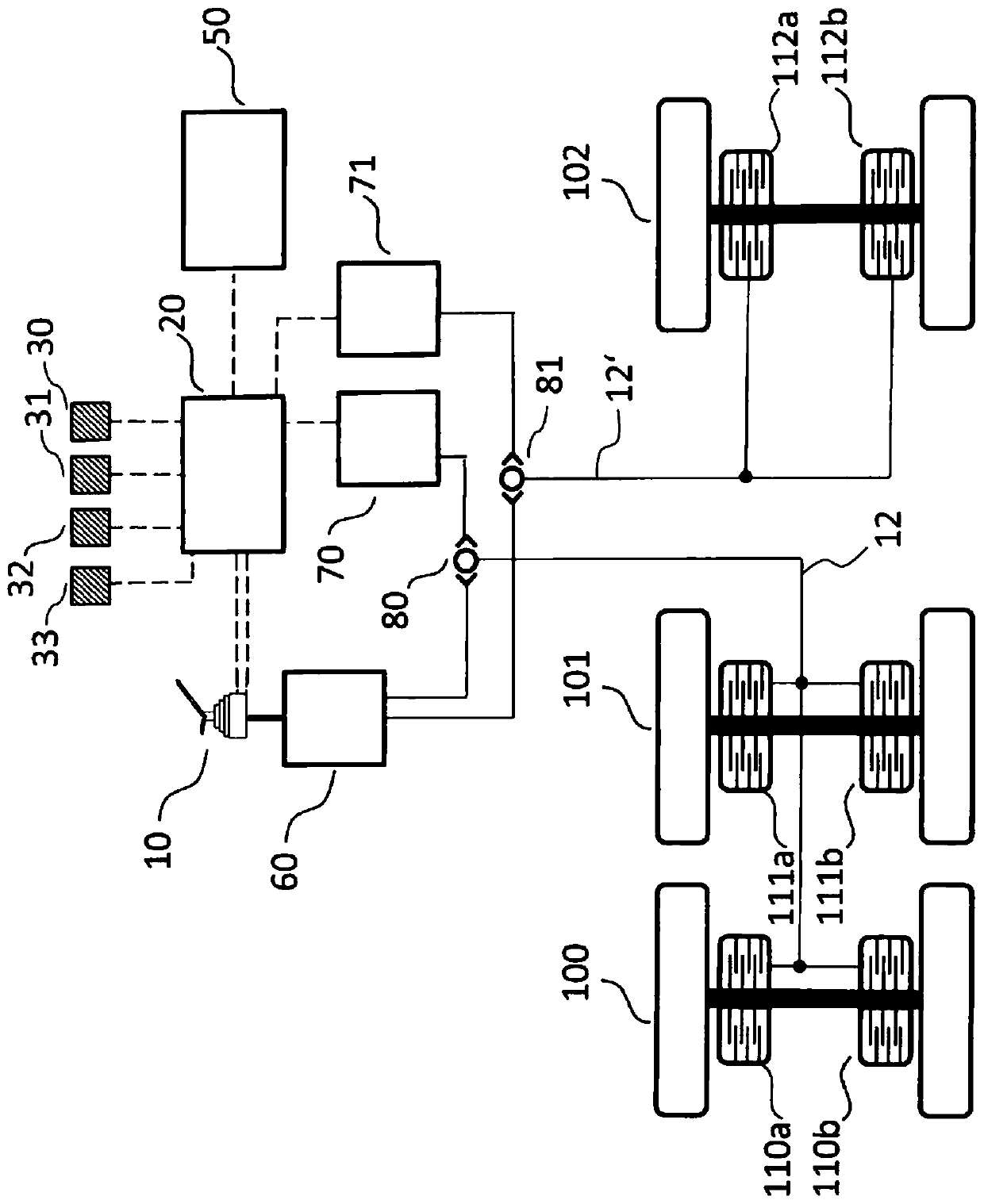

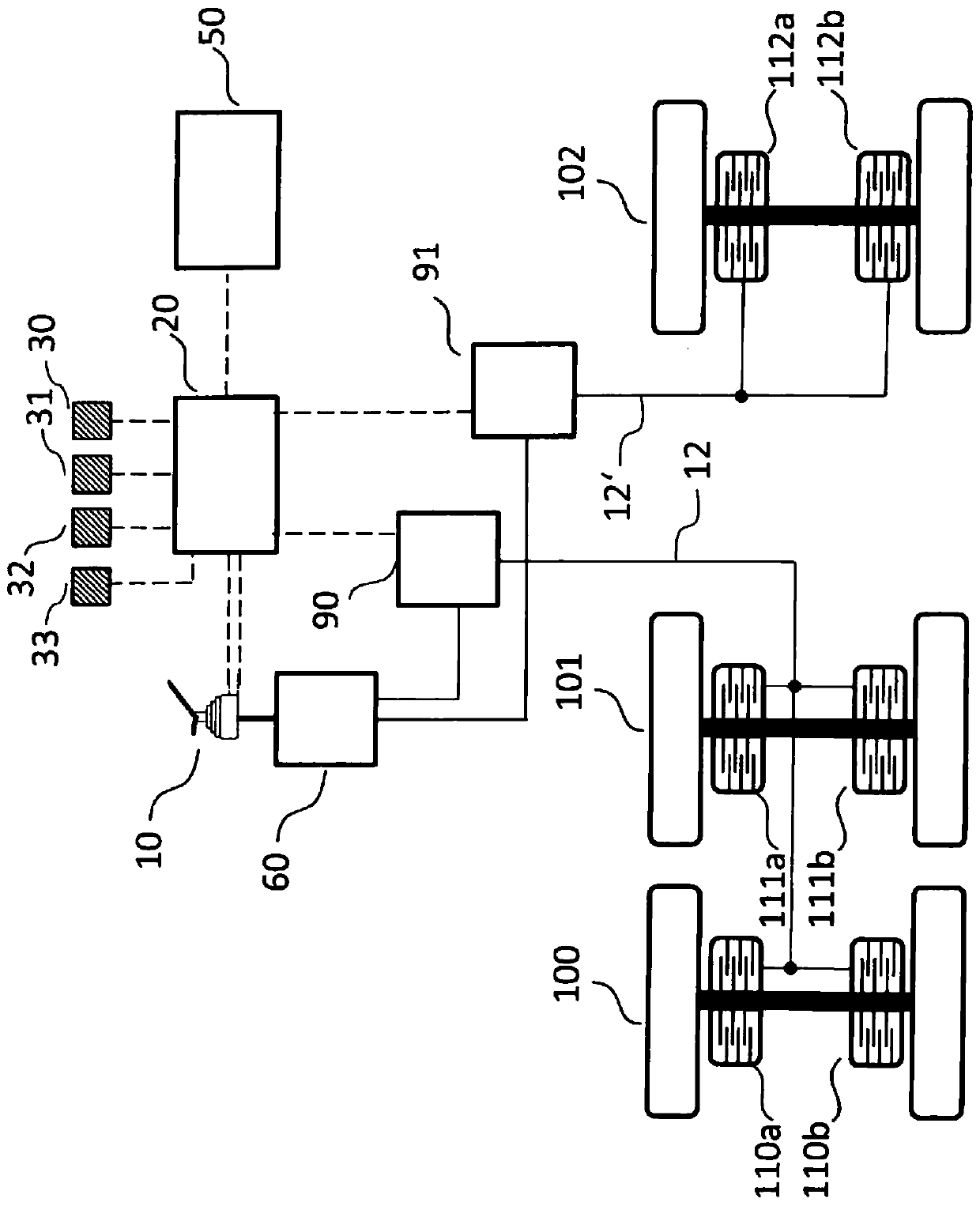

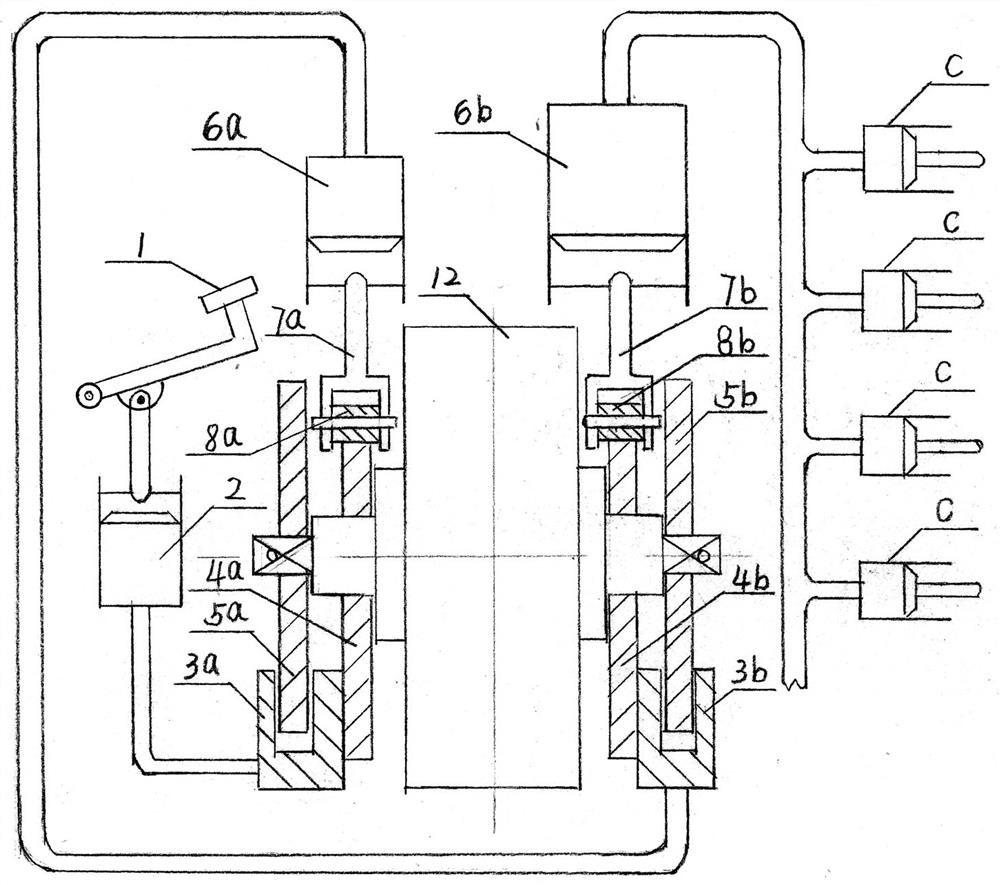

Electro-hydraulic brake system and method for controlling the same

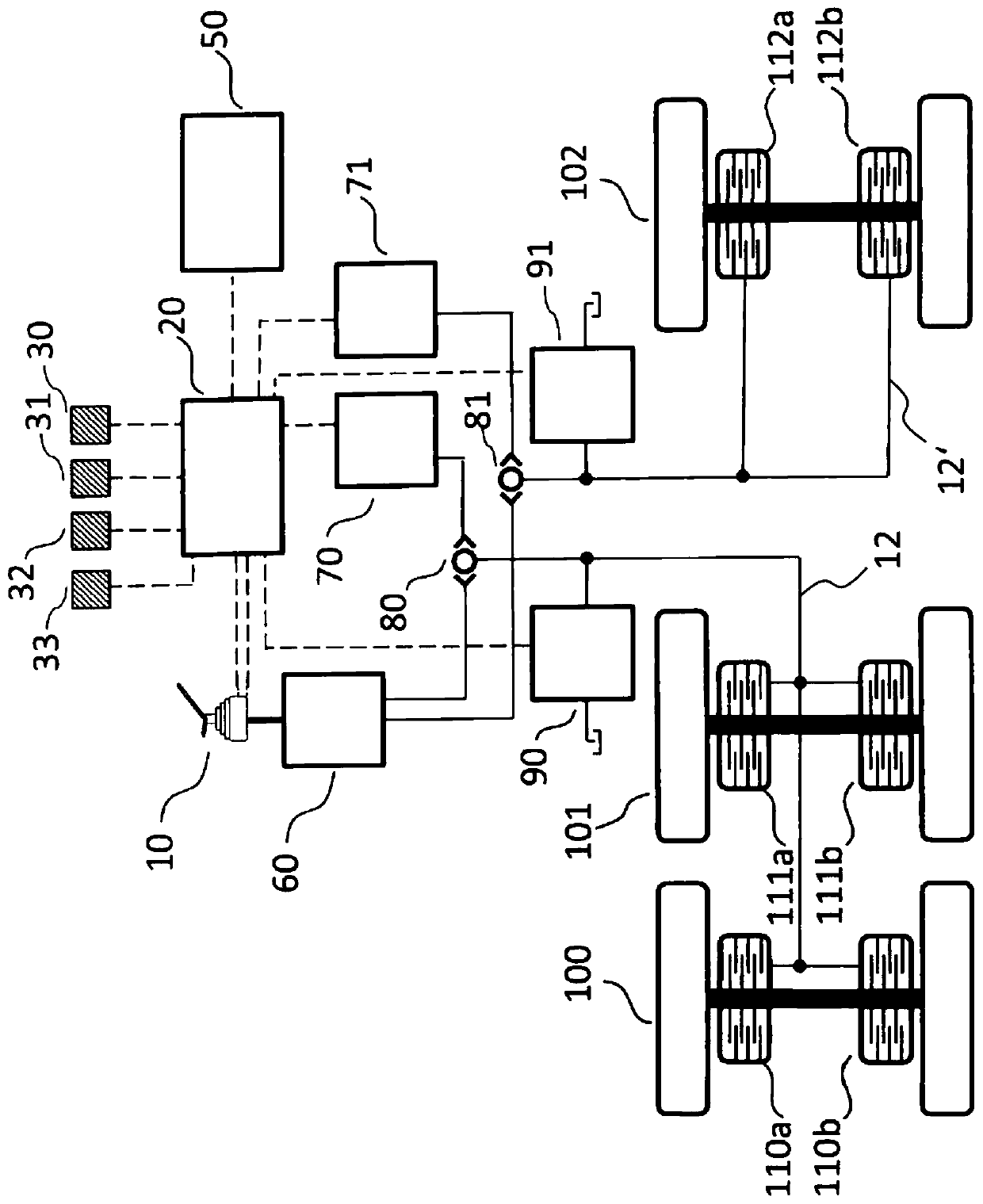

ActiveUS20160347298A1Increase manufacturing costPrevent deterioration of brake stabilityBraking action transmissionBrake action initiationsDriver/operatorControl signal

An electro-hydraulic brake system may include a brake input device manipulated by a driver to brake a vehicle, a brake input detecting sensor configured to detect a brake input value of the driver through the brake input device, a pressure generating device configured to generate a brake hydraulic pressure, a wheel cylinder configured to receive the brake hydraulic pressure generated from the pressure generating device and to generate braking power for braking rotations of each vehicle wheel, a hydraulic pressure supply line connected between the pressure generating device and the wheel cylinder to transfer the brake hydraulic pressure generated from the pressure generating device to each wheel cylinder, and a controller configured to output a control signal for controlling an operation of the pressure generating device to allow the pressure generating device to generate a target brake hydraulic pressure based on a signal of the brake input detecting sensor.

Owner:HYUNDAI MOTOR CO LTD

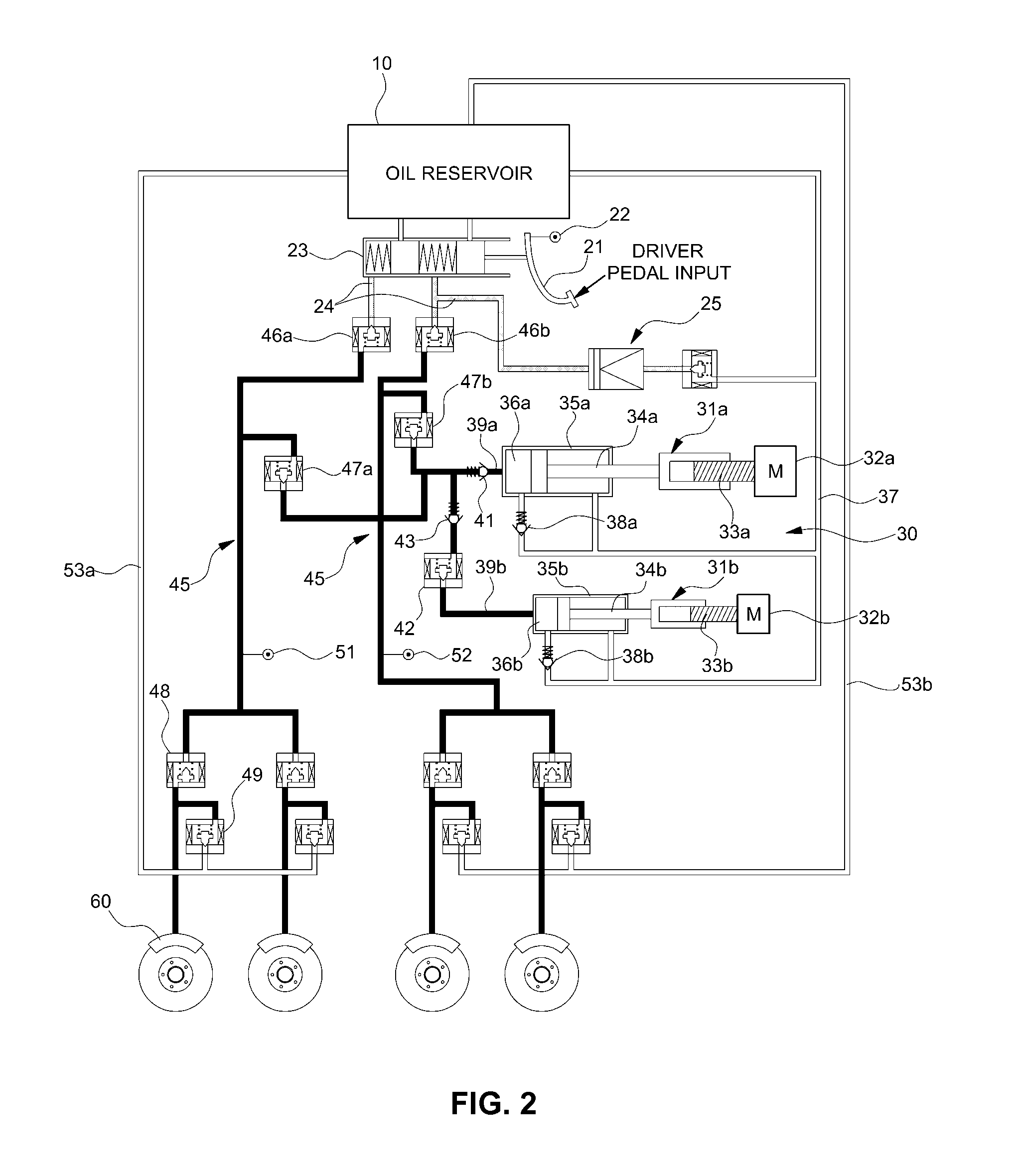

Dynamic track spike lamp under linkage control with intersection annunciator and control method of dynamic track spike lamp

ActiveCN106149584APlay a warning roleEnsure safetyRoad vehicles traffic controlTraffic signalsTraffic signalControl line

The invention discloses a dynamic track spike lamp under linkage control with an intersection annunciator and a control method of the dynamic track spike lamp. The dynamic track spike lamp comprises a column of double-face light-emitting track spike lamp bodies spaced at set intervals. Each light-emitting side face comprises red LED lamps and green LED lamps which are arranged alternately. The red LED lamps and the green LED lamps are connected with a single-chip microcomputer through control lines respectively. The track spike lamp bodies controlled by the single-chip microcomputer and the annunciator are connected with a traffic signal output port of an adjacent road. The double-face light-emitting track spike lamp bodies are laid on the two sides of a lane boundary line or zebra stripes. The dynamic track spike lamp has the beneficial effects that information of the annunciator can be displayed through the track spike lamp bodies, passing vehicles or pedestrians can judge whether to pass or not by observing track spikes on a road surface, and the situation that drivers and the pedestrians ignore observation of the lower road condition due to observation of the upper signal lamps when reaching an intersection is reduced.

Owner:SHANDONG JIAOTONG UNIV

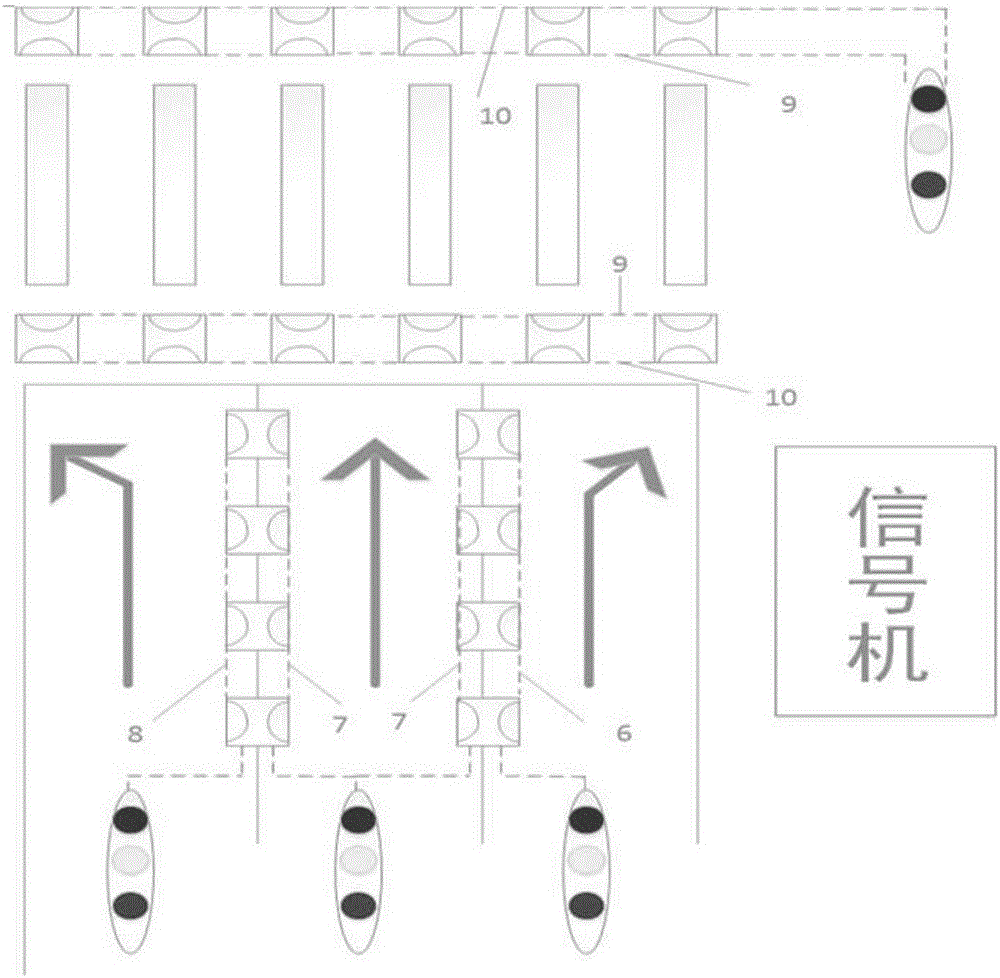

Vehicle front interior structure

InactiveUS20070164586A1Slow down decelerationReduce harmVehicle seatsPedestrian/occupant safety arrangementWindshieldAirflow

The invention concerns a vehicle front interior structure comprising an air flow distribution duct arranged essentially parallel with a windshield. The invention is characterized in that the distribution duct is divided into at least two sections connected by a flexible joint that extends in a direction essentially across the distribution duct.

Owner:VOLVO CAR CORP

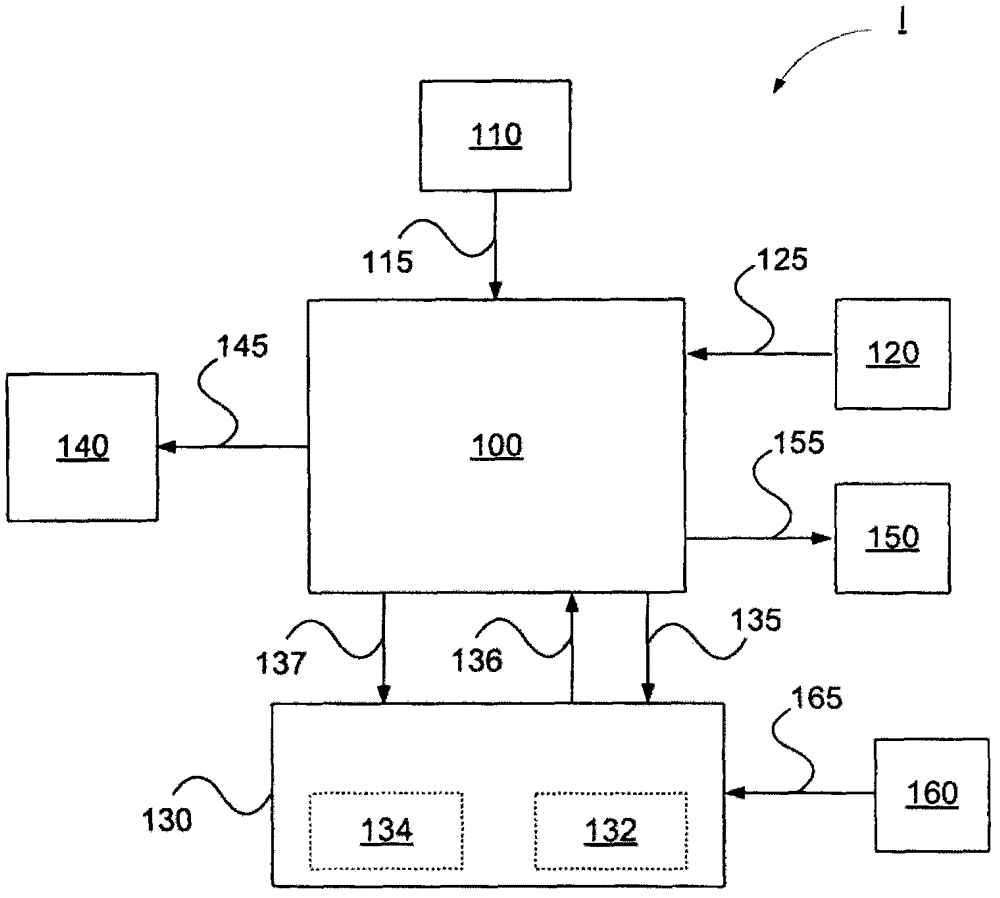

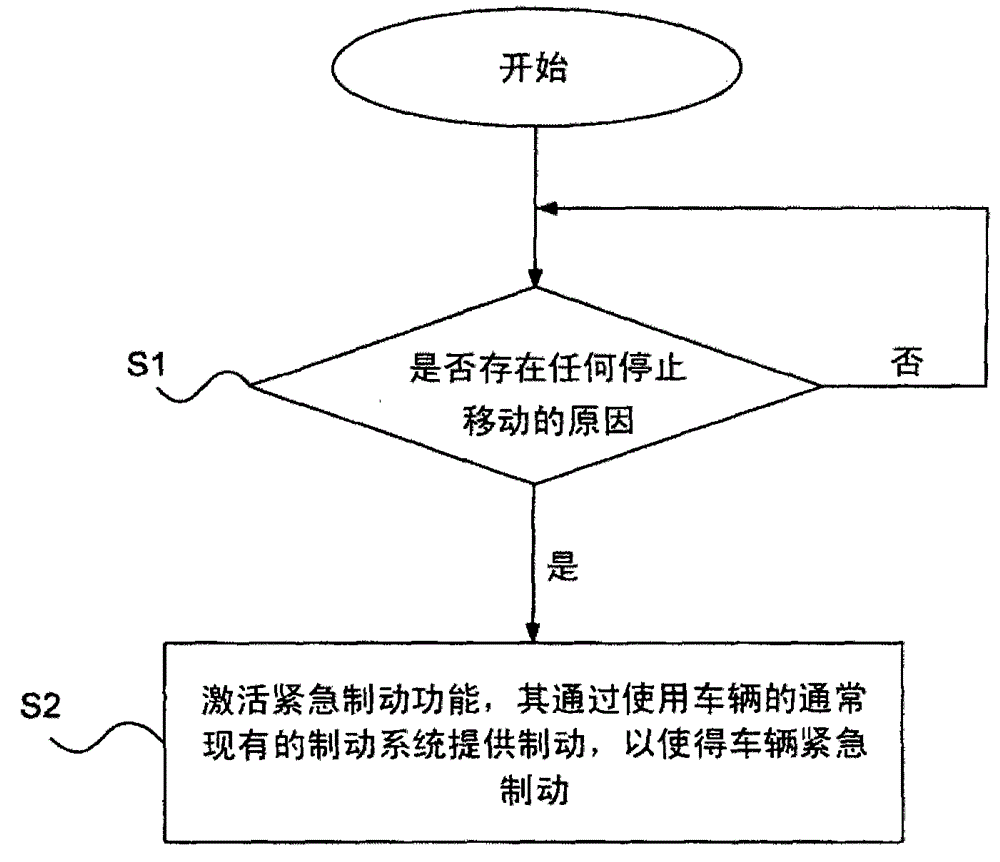

Method and system for emergency braking of motor vehicle

InactiveCN104487296ASafe and efficient brakingPrevent accelerationAutomatic initiationsTractorsMobile vehicleEngineering

The present invention relates to a method for emergency braking of a moving motor vehicle, comprising the steps of continuously monitoring whether there is any reason to prevent movement of the vehicle, and of automatically braking the vehicle if there is such reason, which step of automatically braking the vehicle comprises the step of activating an emergency brake function which caters for braking by means of the vehicle's usual existing brake system. The present invention relates also to a system for emergency braking of a motor vehicle.

Owner:SCANIA CV AB

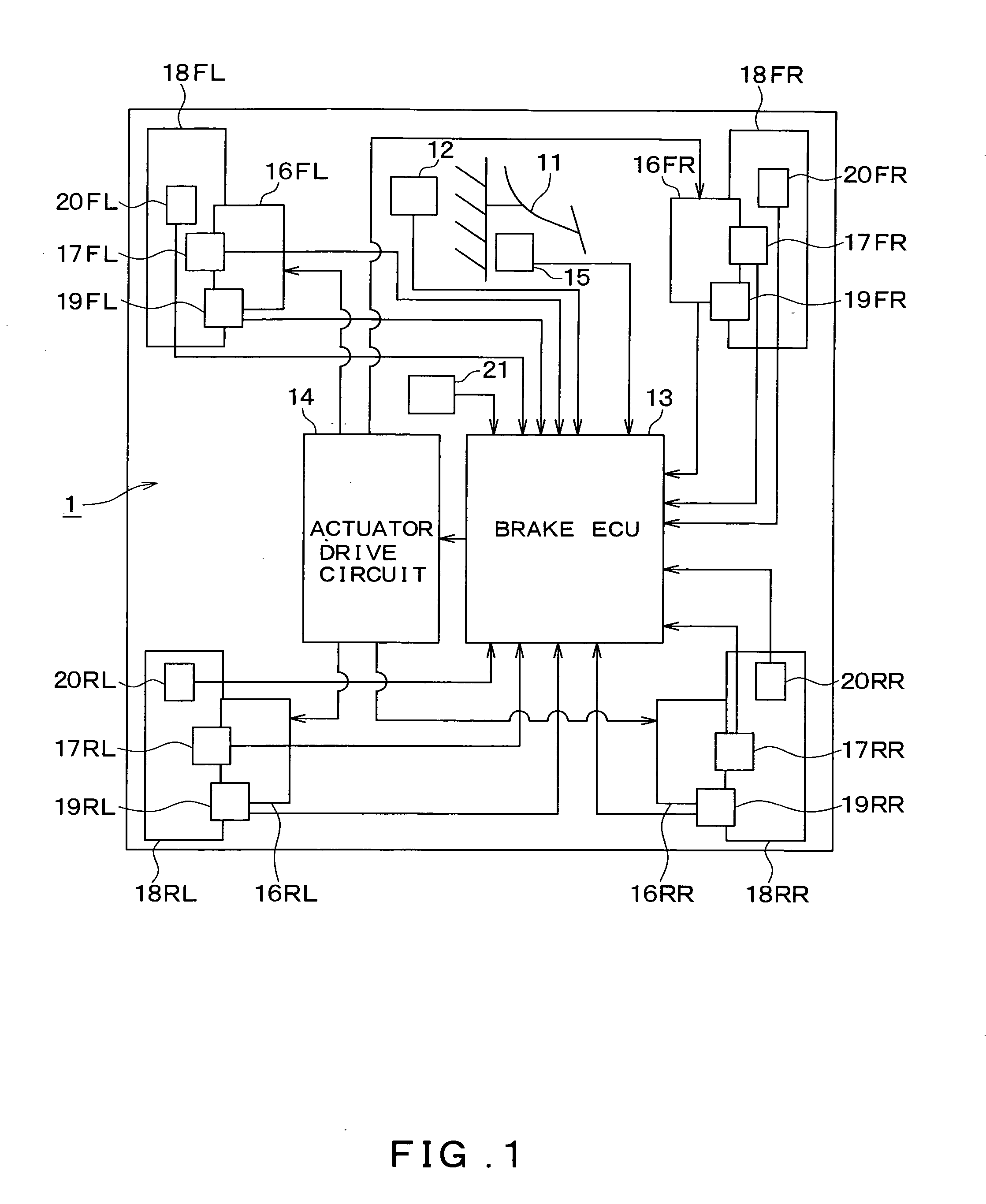

Vehicle brake control device

InactiveUS20060238020A1Shorter braking distanceReduction of forward-backward rockingApplication and release valvesVehicle brakeBrake force

Owner:ADVICS CO LTD

Electro-hydraulic brake system and method for controlling the same

ActiveUS9738263B2Weight increasePrevent deterioration of brake stabilityBraking action transmissionFoot actuated initiationsDriver/operatorControl signal

An electro-hydraulic brake system may include a brake input device manipulated by a driver to brake a vehicle, a brake input detecting sensor configured to detect a brake input value of the driver through the brake input device, a pressure generating device configured to generate a brake hydraulic pressure, a wheel cylinder configured to receive the brake hydraulic pressure generated from the pressure generating device and to generate braking power for braking rotations of each vehicle wheel, a hydraulic pressure supply line connected between the pressure generating device and the wheel cylinder to transfer the brake hydraulic pressure generated from the pressure generating device to each wheel cylinder, and a controller configured to output a control signal for controlling an operation of the pressure generating device to allow the pressure generating device to generate a target brake hydraulic pressure based on a signal of the brake input detecting sensor.

Owner:HYUNDAI MOTOR CO LTD

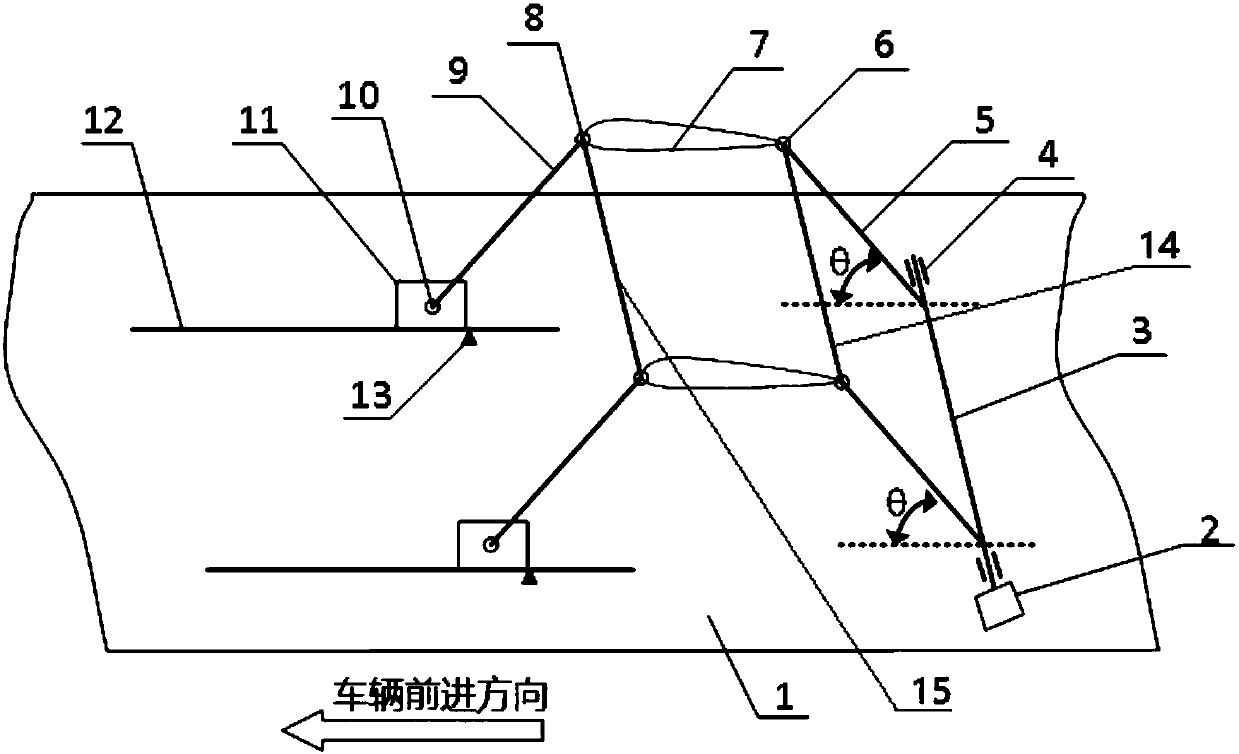

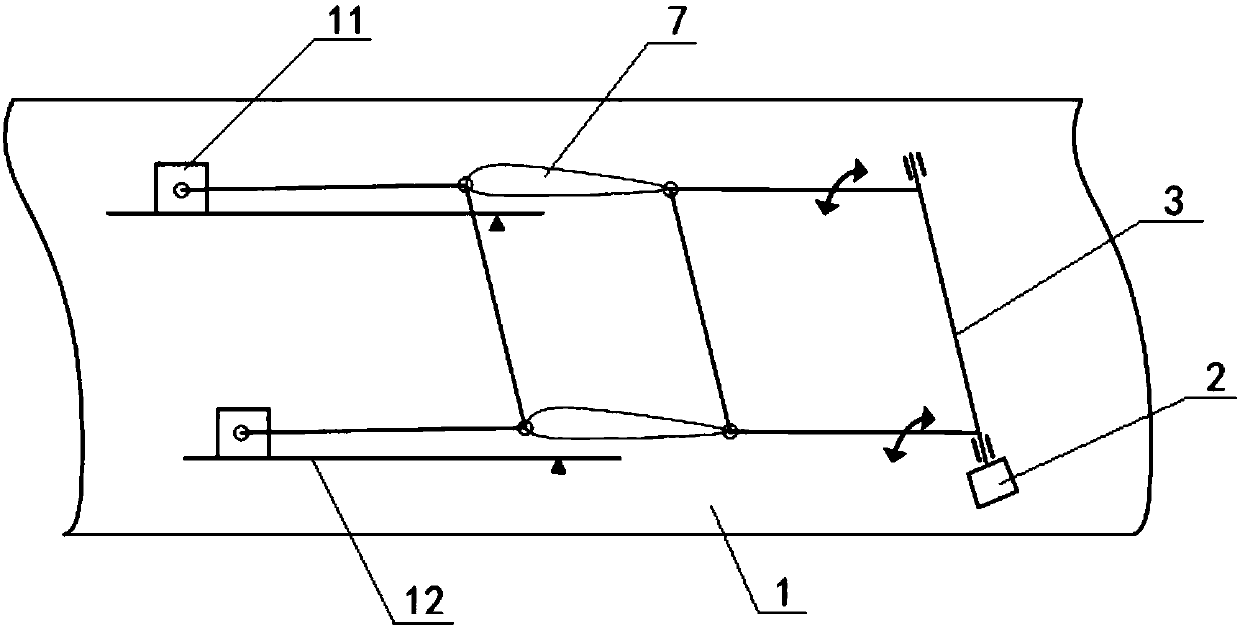

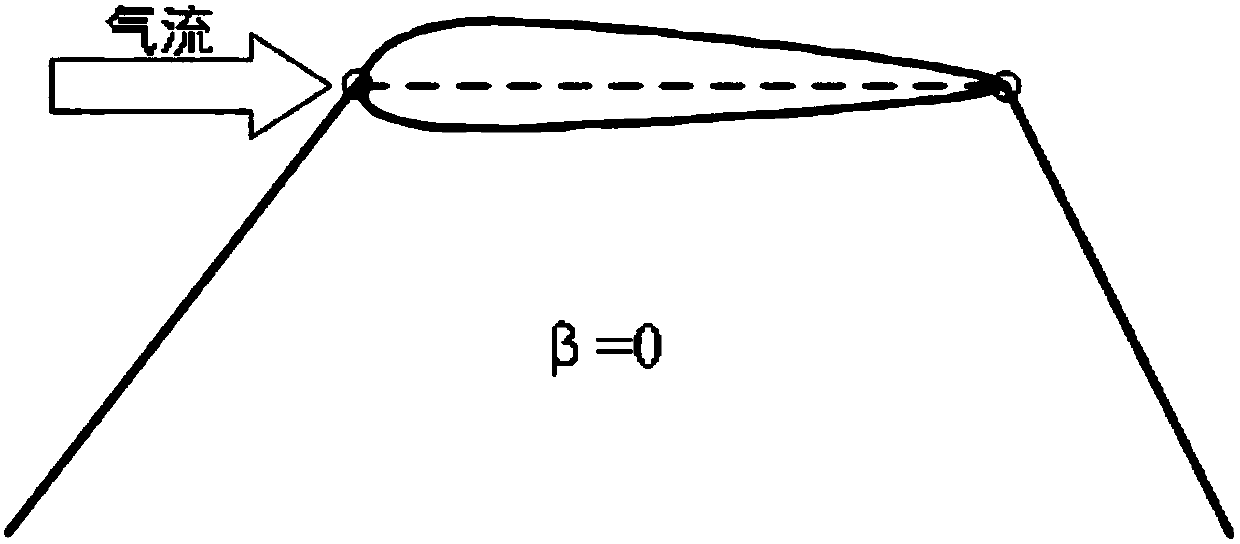

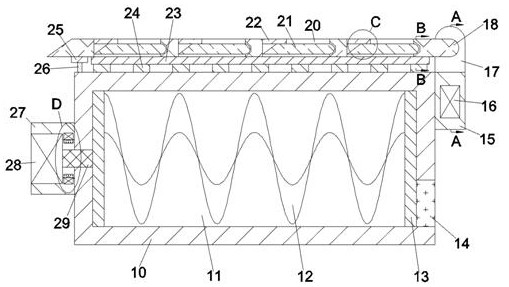

Railway vehicle roof airfoil profile board device and railway vehicle

PendingCN107901943AReduce manufacturing costImprove comfortAerodynamic brakesRailway transportDrive motorBraking distance

The invention relates to the technical field of railway vehicles, in particular to a railway vehicle roof airfoil profile board device and a railway vehicle. The provided railway vehicle roof airfoilprofile board device comprises a drive motor, a transmission assembly and an airfoil profile board. The drive motor is arranged on a vehicle roof of the railway vehicle, and an output shaft of the drive motor is arranged in the width direction of the vehicle roof. The transmission assembly comprises two rotary arms connected with the two ends of the output shaft of the drive motor, the two rotaryarms are connected with a rear beam of the airfoil profile board through rotary hinges, and the output shaft, the rear beam of the airfoil profile board and the two rotary arms jointly form a parallelogram mechanism. A front beam of the airfoil profile board is rotationally installed on the vehicle roof. The output shaft of the drive motor drives the transmission assembly to rotate around the output shaft, so that the attack angle of the airfoil profile board is controlled, aerodynamic lift is provided in the vehicle running process, and comfort and stability are improved; or aerodynamic resistance is provided in the vehicle braking process, the braking distance is shortened to improve the train braking efficiency, the structure is simple, and cost is low.

Owner:CRRC IND INST CO LTD

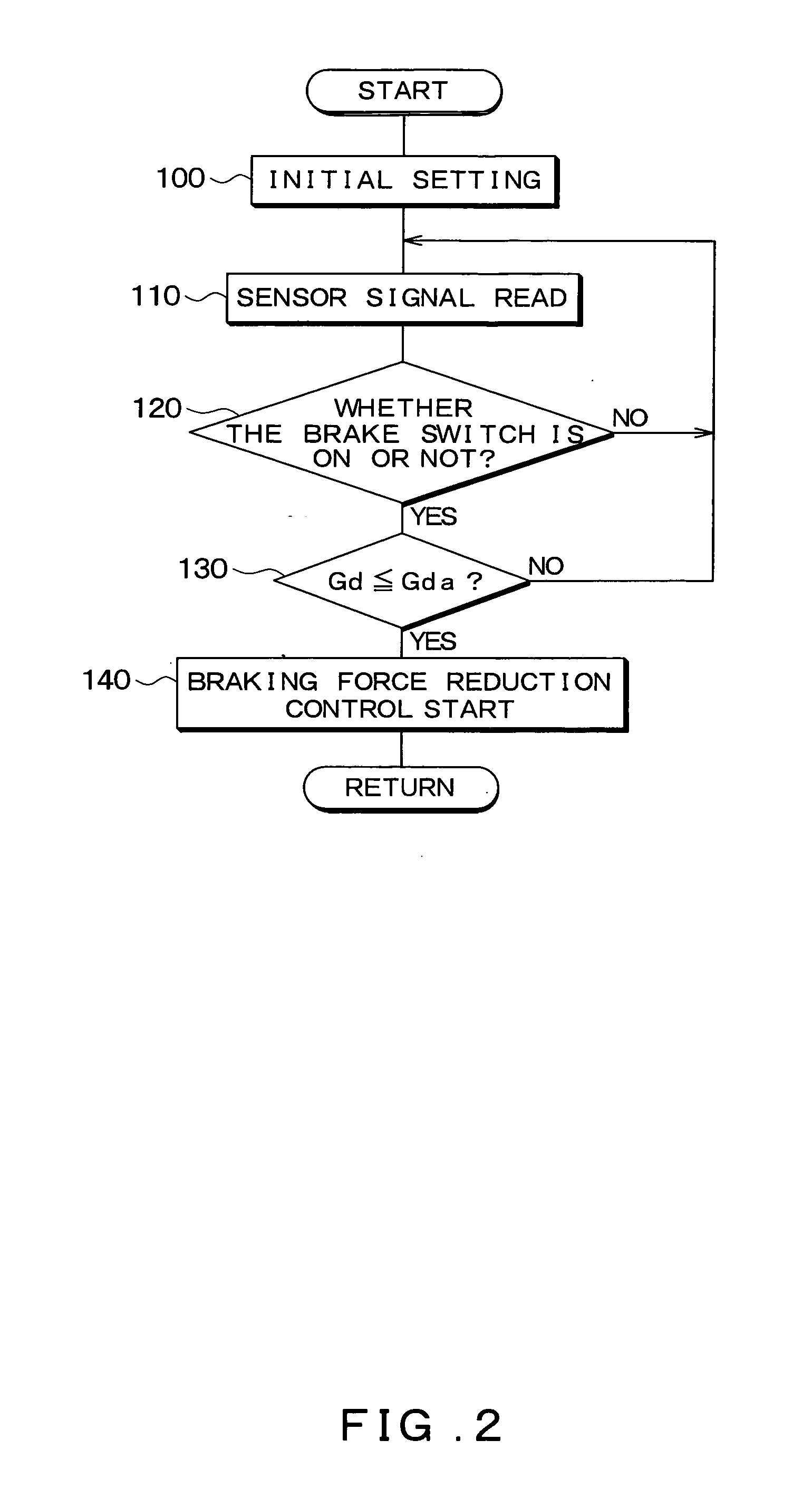

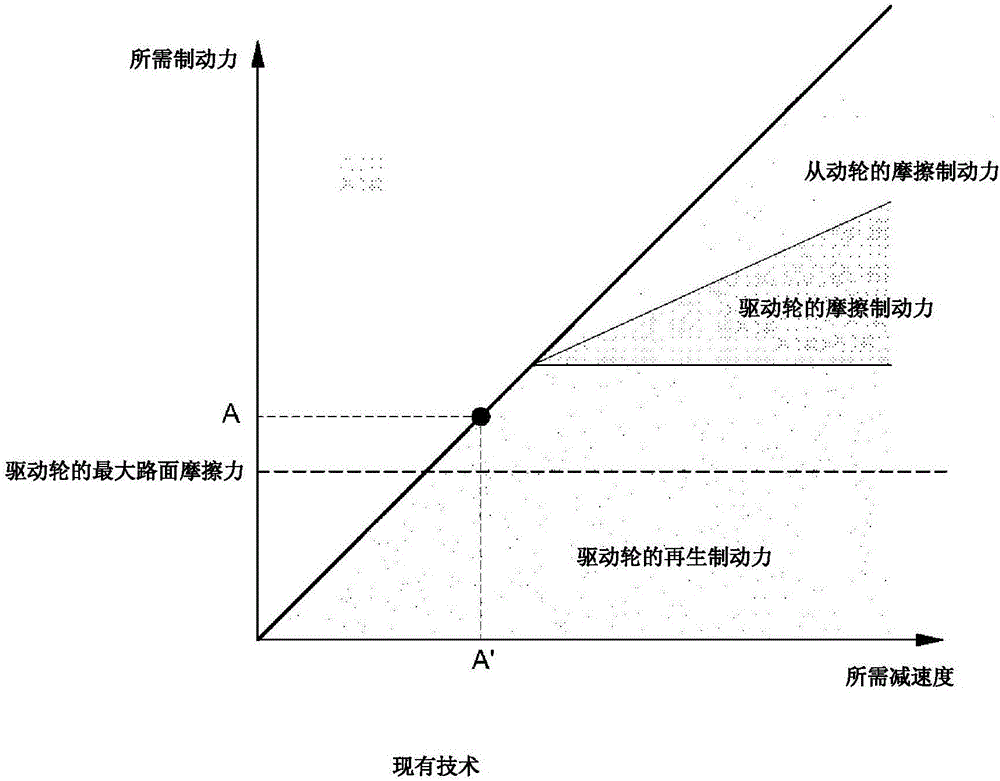

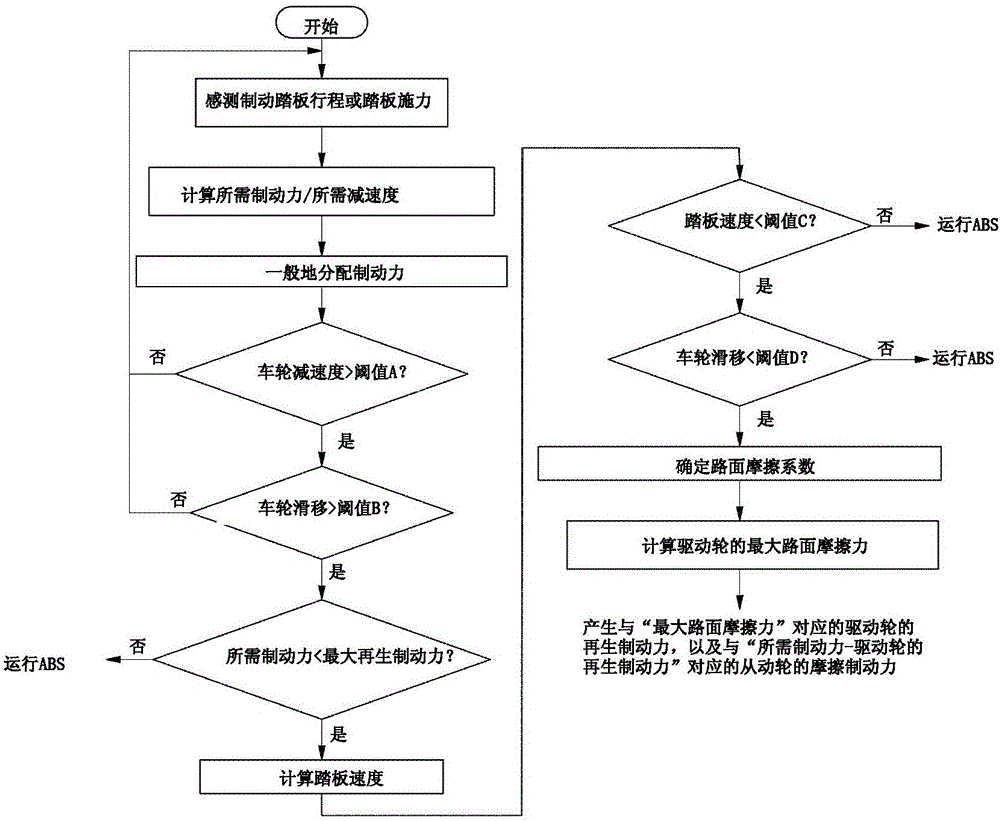

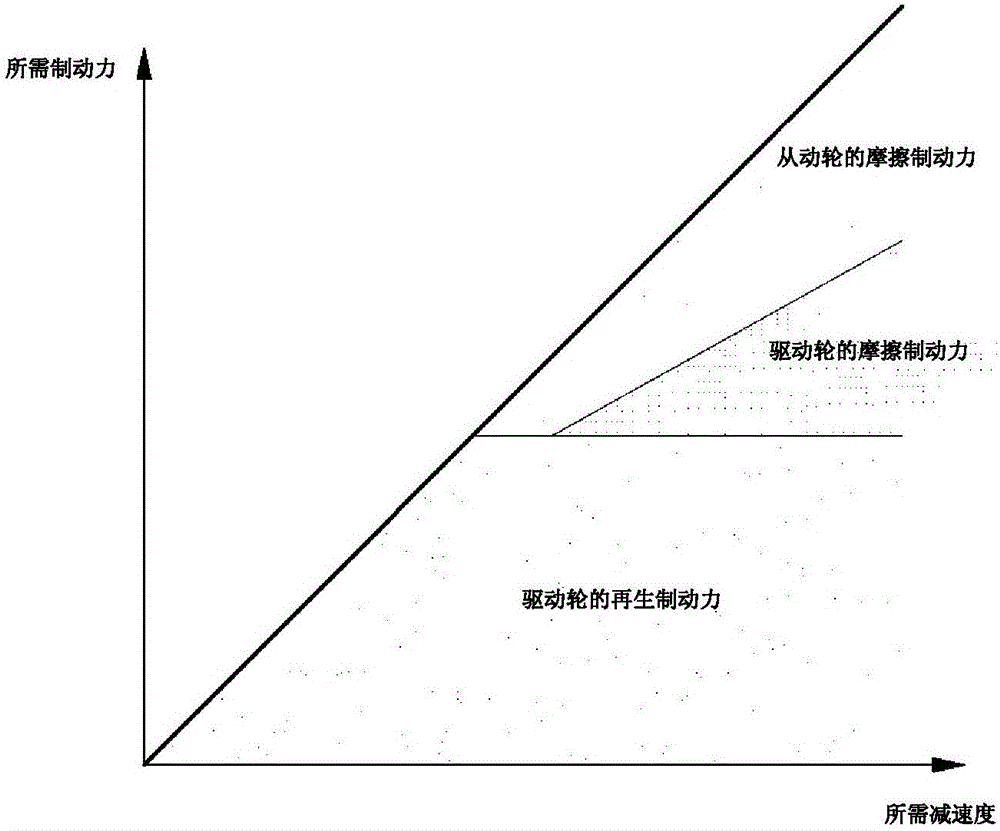

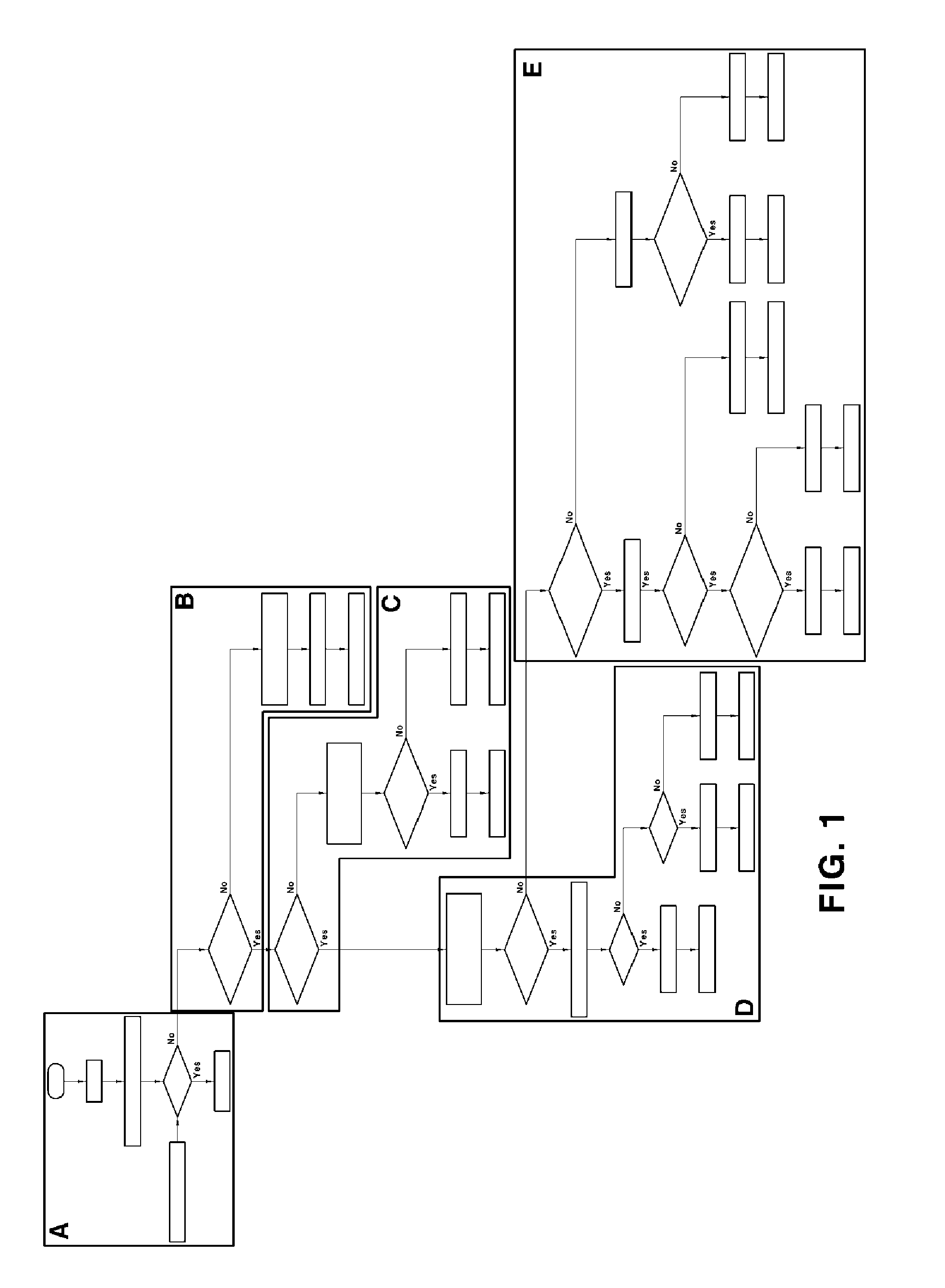

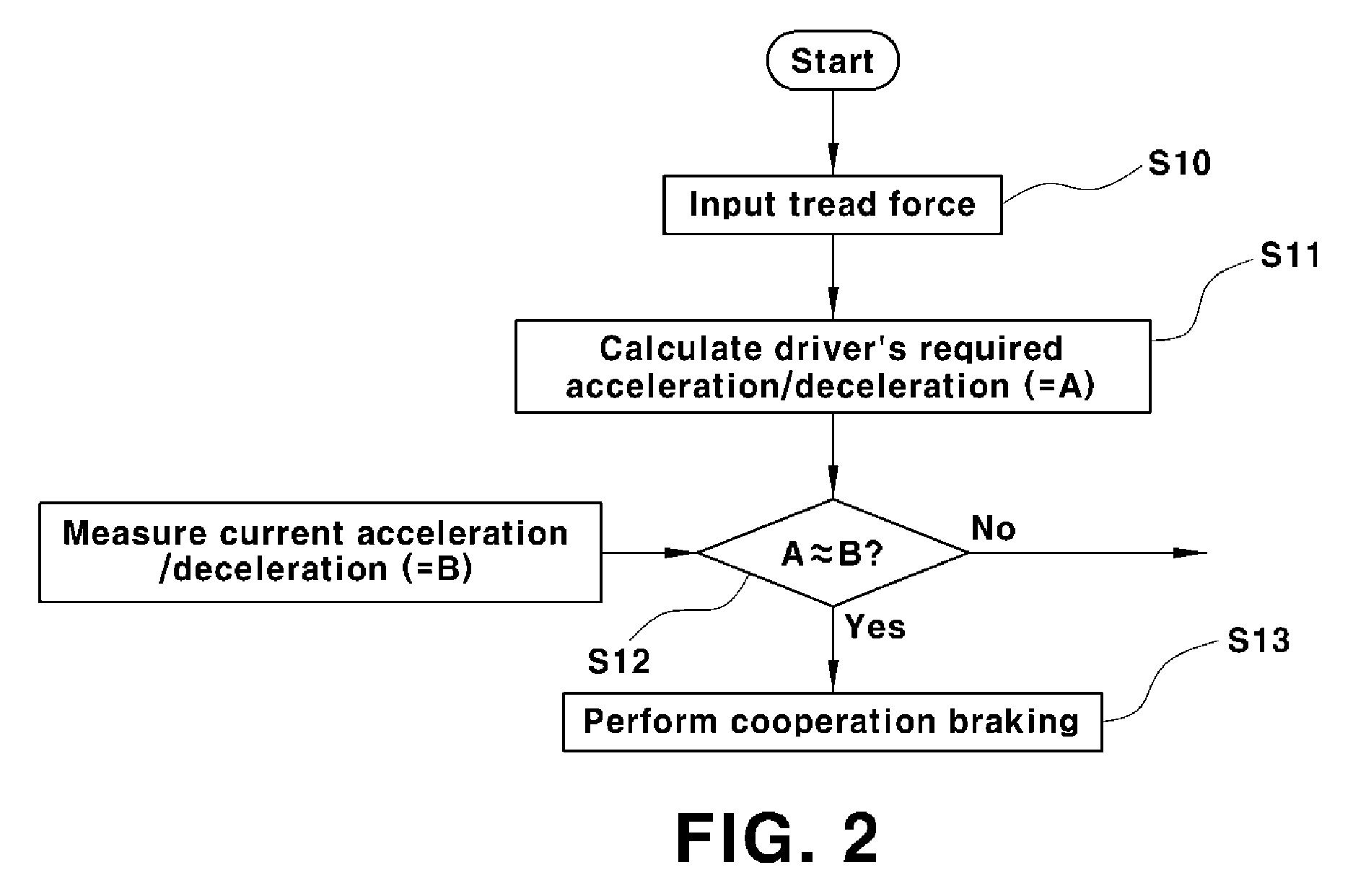

Method For Controlling Braking Of Regenerative Braking Co-operative Control System For Vehicle

InactiveCN106560359AImprove fuel efficiencyPrevent regenerative brakingSpeed controllerElectric devicesDrive wheelRegenerative brake

A method for controlling braking of a regenerative braking co-operative control system for a vehicle may include detecting, by a controller, whether a brake pedal is manipulated, determining, by the controller, a driver demand braking force, a wheel deceleration, and wheel slip when the brake pedal is manipulated, comparing, by the controller, the determined wheel deceleration value and the wheel slip value with a predetermined threshold deceleration value and a predetermined first threshold slip value, respectively, and determining, by the controller, a maximum road frictional force when the wheel deceleration value is larger than the threshold deceleration value and the wheel slip value is larger than the first threshold slip value and determining a regenerative braking force of driving wheels in accordance with the determined maximum road frictional force.

Owner:HYUNDAI MOTOR CO LTD

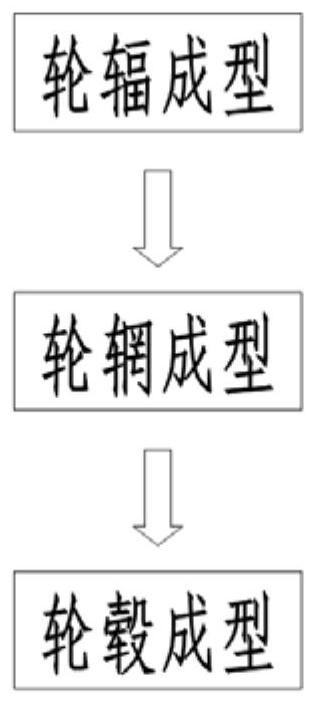

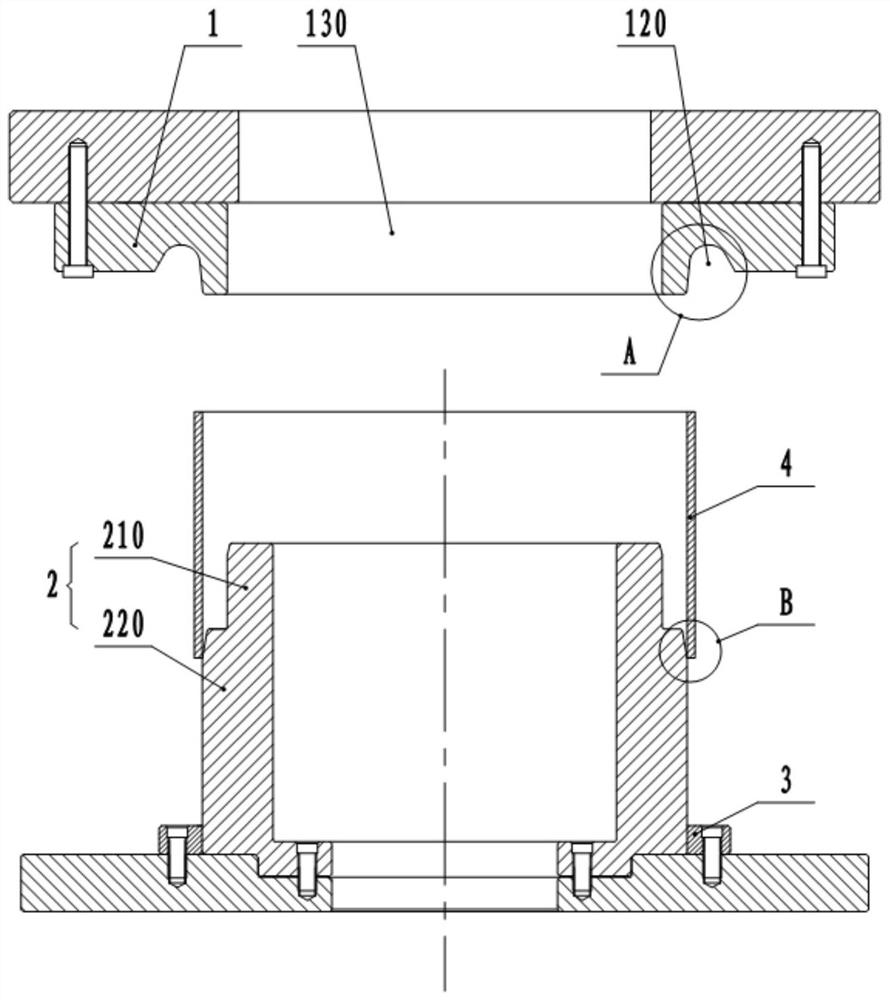

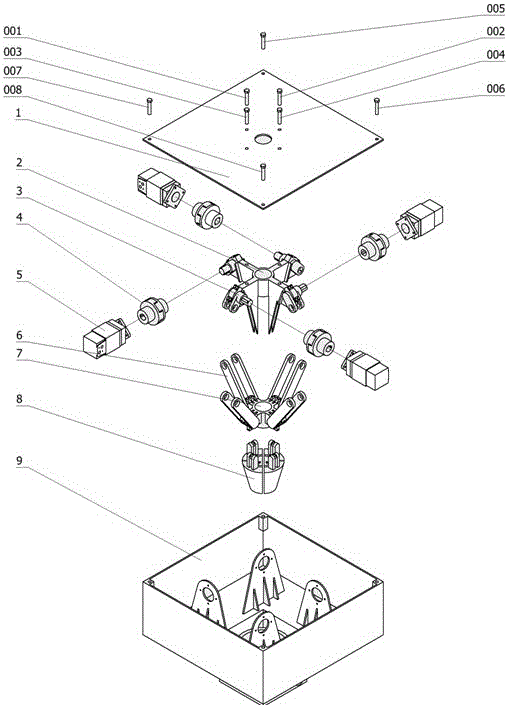

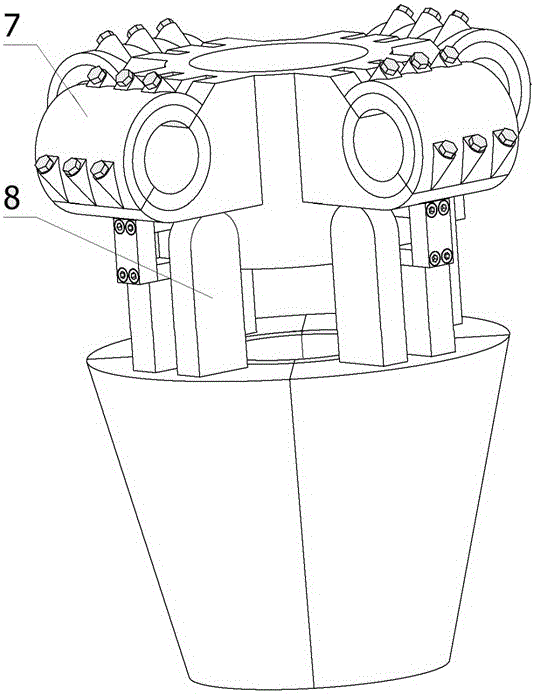

Automobile hub machining process

The invention relates to the field of hub machining, and discloses an automobile hub machining process. The process comprises the following steps: (1) spoke forming; (2) rim forming, specifically, a rim is manufactured by conducting flanging forming and spinning forming on a cylinder, and in the spinning forming step, a spinning cutter assembly is used for conducting spinning on the cylinder subjected to flanging forming; and the spinning cutter assembly comprises a first spinning cutter for primarily spinning the outer wall of the cylinder, a second spinning cutter for spinning the end part of the cylinder and a third spinning cutter for finely spinning the outer wall of the cylinder; and (3) hub forming, specifically, a spoke obtained in the step (1) and the rim obtained in the step (2) are composited to obtain a composite area, the composite area is welded, and a hub is obtained. In the process, the spoke and the rim are separately molded and manufactured, so that the modular line production of hub production is realized, the yield of the hub is greatly improved, the lightweight design of the hub is realized, and the driving performance of an automobile is improved. In addition, the problems that in the rim forming process, die attaching is not achieved, and the rim wall is spun too thin can be solved.

Owner:重庆市超群工业股份有限公司

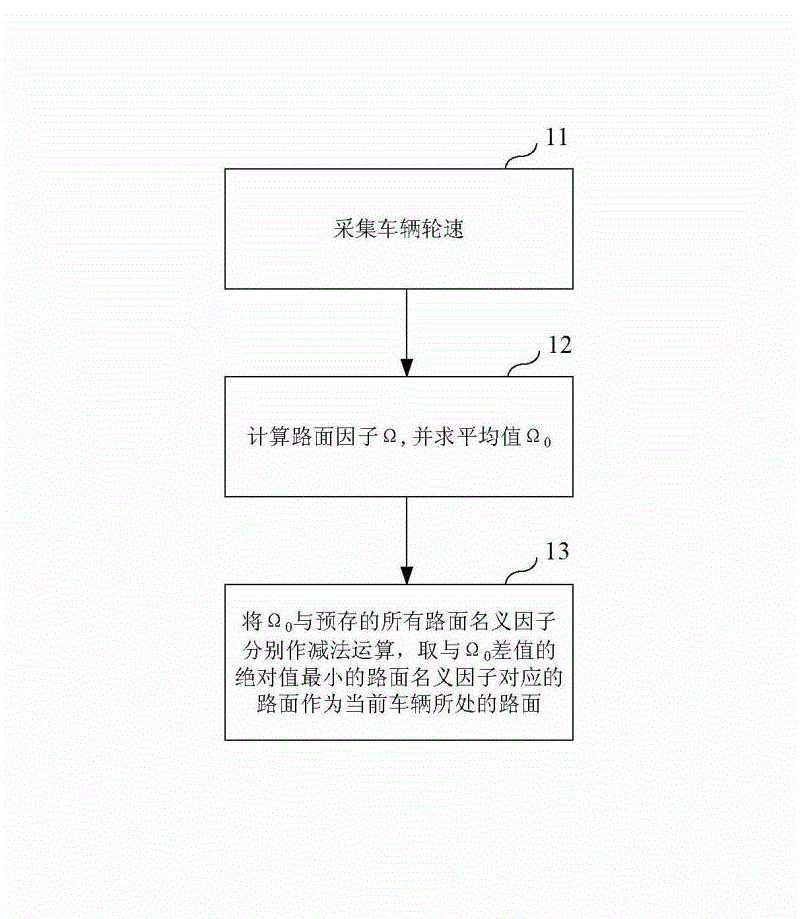

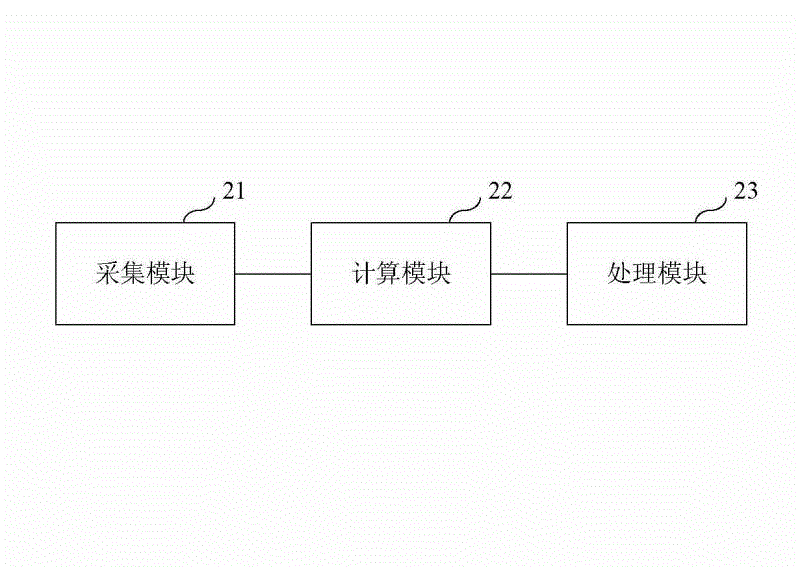

Pavement identification method and system as well as vehicle anti-lock brake method and system

ActiveCN102616222AAvoiding Antilock Braking MethodsAffect accuracyBraking systemsEngineeringRoad surface

The invention relates to a pavement identification method. The pavement identification method comprises the following steps: firstly collecting the speed of a vehicle wheel in real time during braking time quantum T of a vehicle provided with an ABS (Anti-lock Brake System); calculating a slip rate lambda, a change rate d lambda / dt of the slip rate, a deceleration a and a change rate da / dt of the deceleration, and calculating a pavement factor omega according to the speed of the vehicle wheel, and carrying out an average calculation on the obtained omega at each time coefficient delta T to obtain omega 0; and finally respectively carrying out one subtraction operation on the omega 0 and pre-stored all pavement nominal factors to take pavement corresponding to the minimum pavement nominal factor of an absolute value of the omega 0 difference value as pavement on which a vehicle is located at current time. According to the pavement identification method disclosed by the invention, defect that the existing pavement identification method is lower in identification accuracy by utilizing a single parameter are prevented, not only can the identification precision be improved, but also the braking time of the vehicle is fully utilized.

Owner:BYD CO LTD

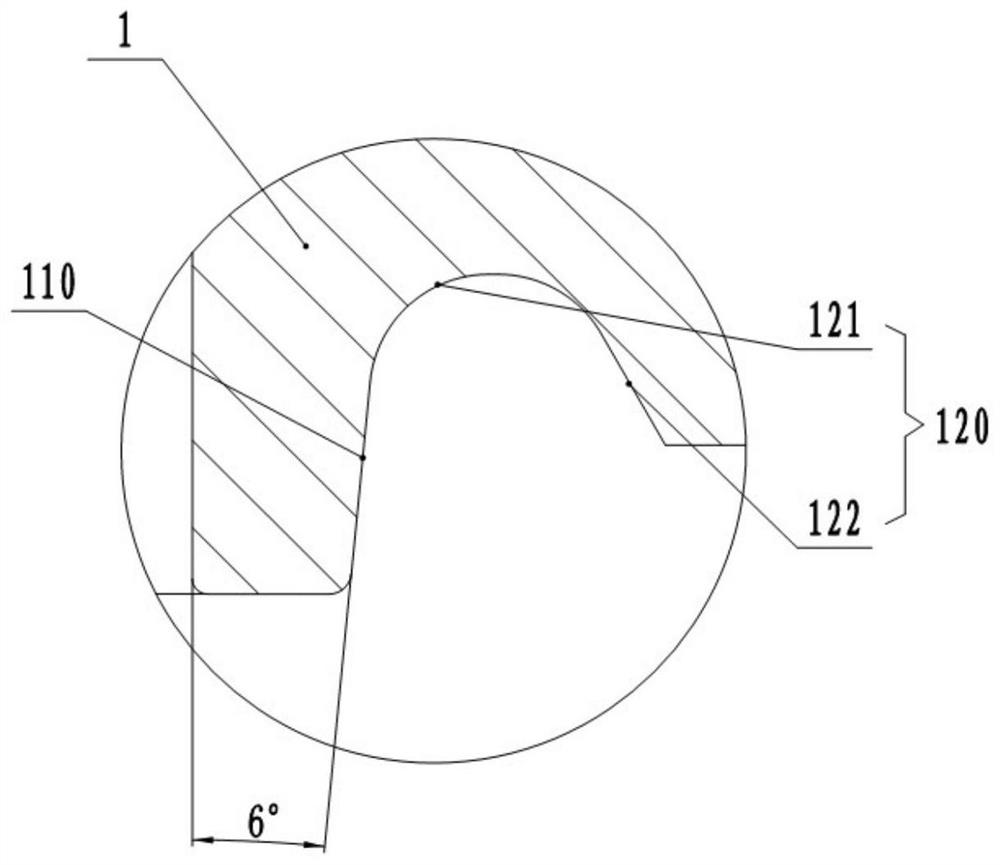

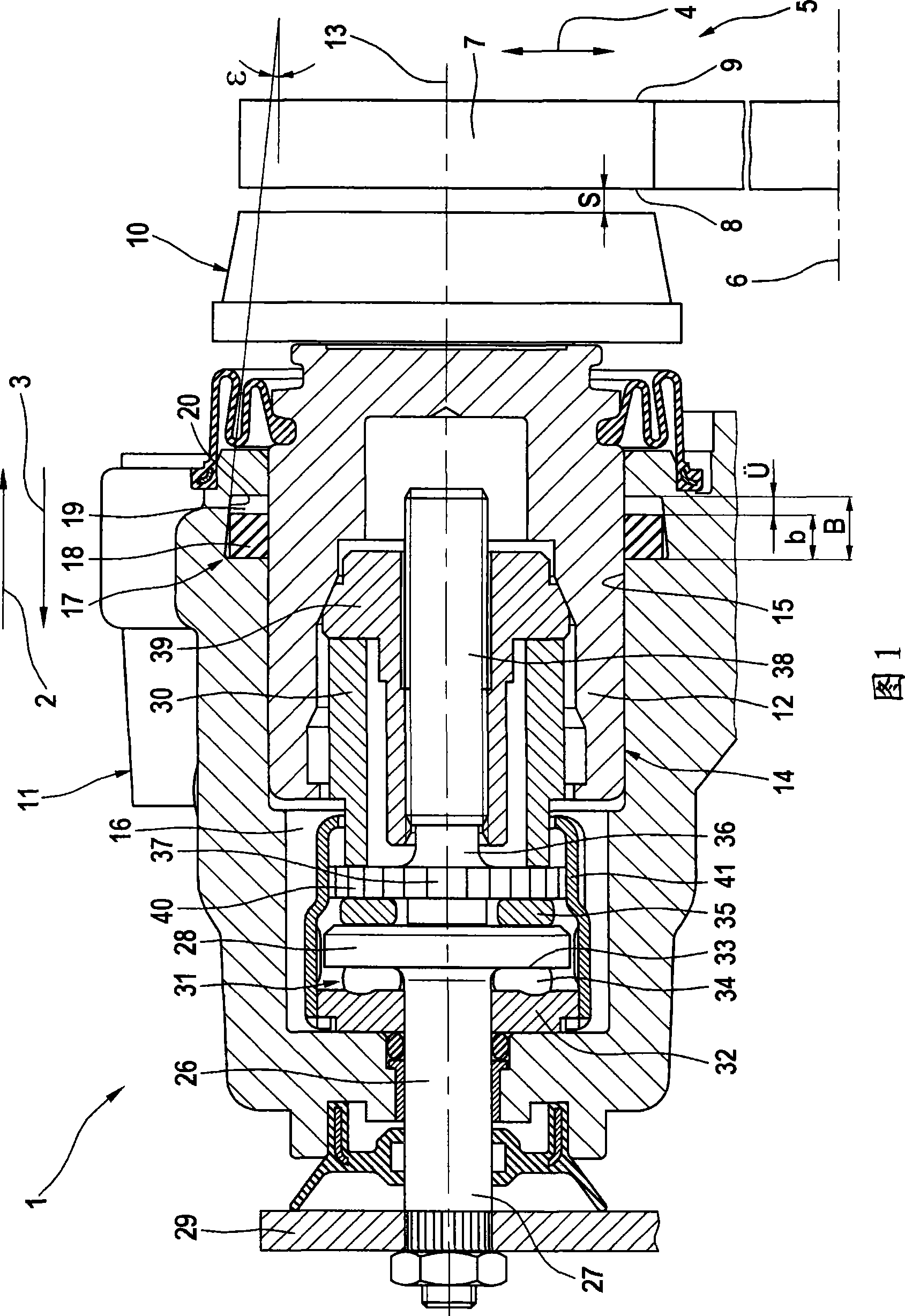

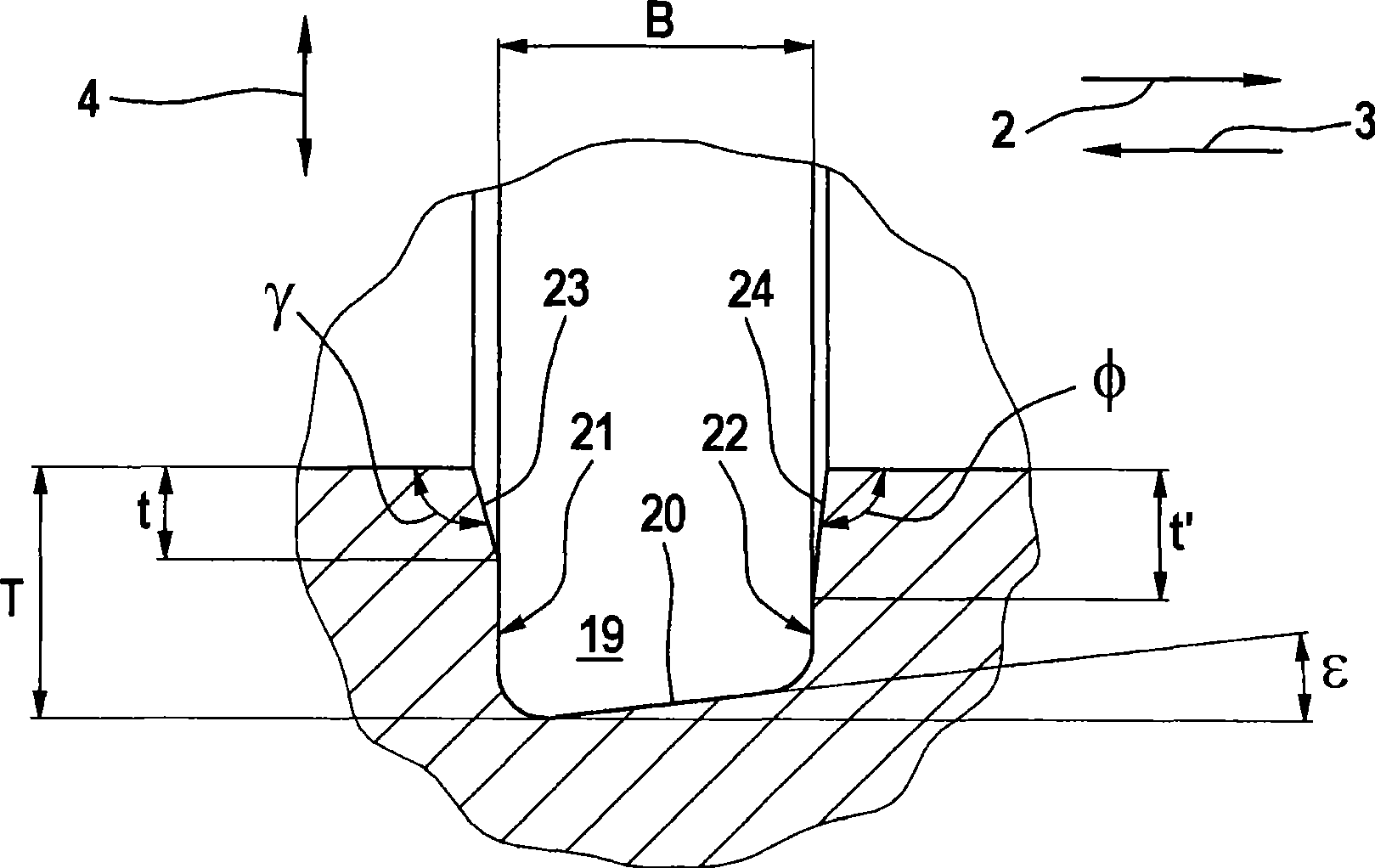

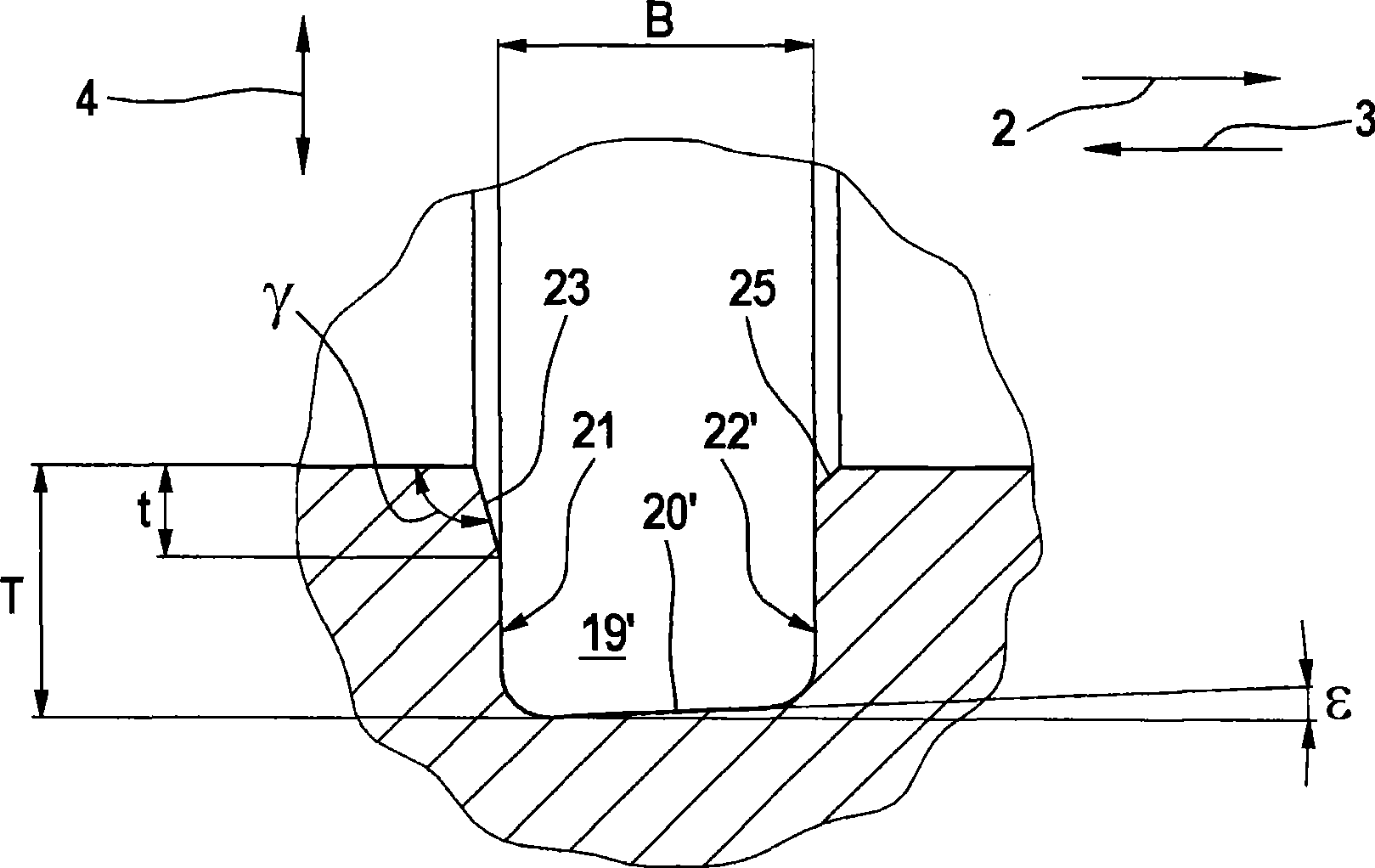

Brake caliper

ActiveCN101438076AImprove exercise effectGood deformabilityEngine sealsBrake actuating mechanismsEngineeringCalipers

The invention relates to a brake caliper (1) for a disk brake with a caliper housing, in which there is an actuating device with a piston (12) in a bore (14). This piston (12) is movable in the bore (14) along a bore axis (13), wherein motion is possible in both an actuation direction and in a release direction. There is a seal system (17) between the piston (12) and the bore (14), with a gasket ring (18) in a radial groove (19). A problem addressed by the invention is to provide a brake caliper for a disk brake with an actuating device that avoids the drawbacks of the prior art and especially achieves effective resetting of the piston after actuation of the brake. According to the invention the problem is solved with the features of the characterizing part of claim 1, wherein a groove bottom (20,20') of the groove (19) is arranged in the direction of the bore axis (13) and anti-parallel to the bore axis (13) so that in the brake actuation direction the groove bottom (20,20') approaches the bore axis (13).

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

Failure diagnosis method for brake system of vehicle

InactiveUS9272696B2Stable generationPrevented from feelingHybrid vehiclesBraking element arrangementsMaximum torqueRegenerative brake

Owner:HYUNDAI MOTOR CO LTD +1

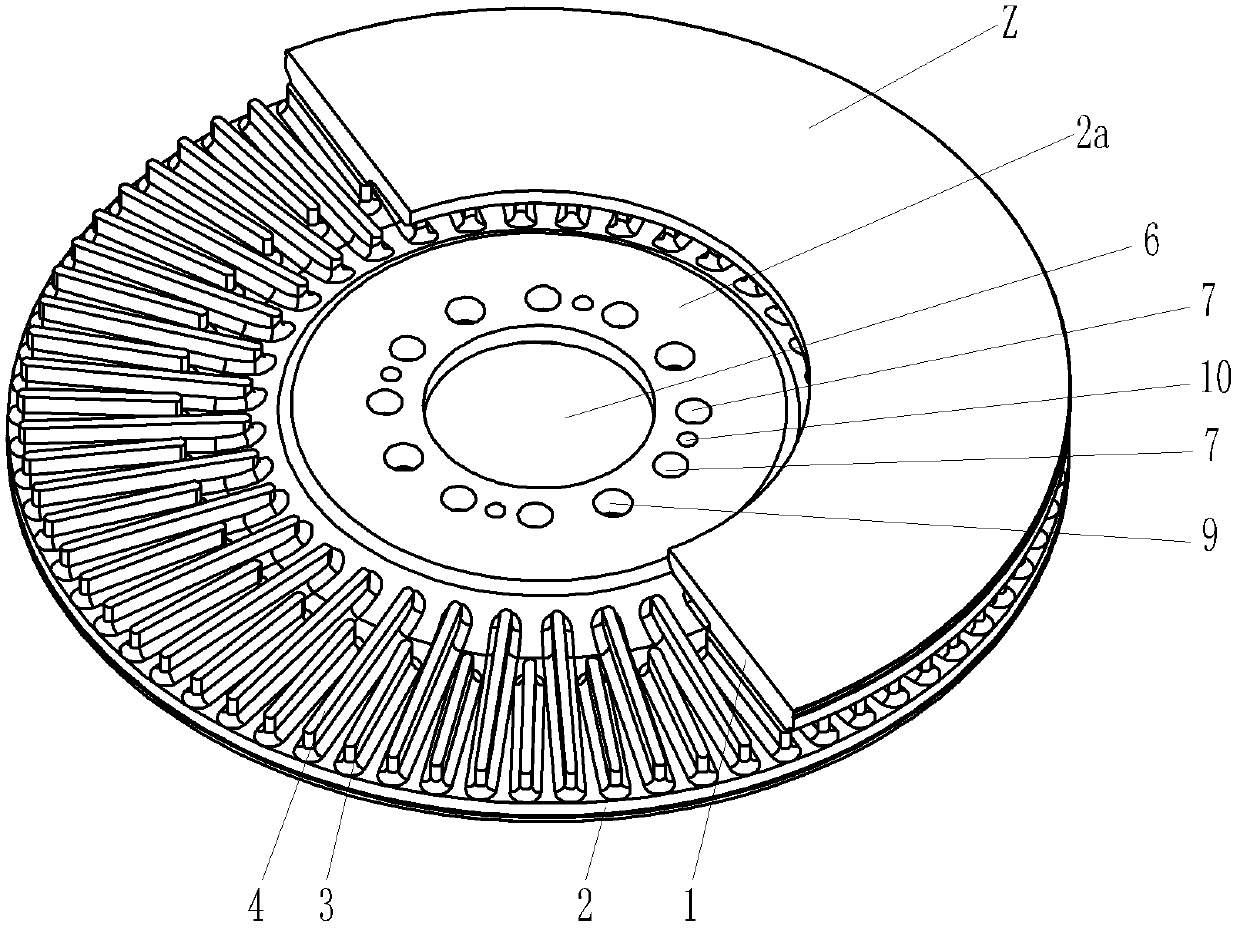

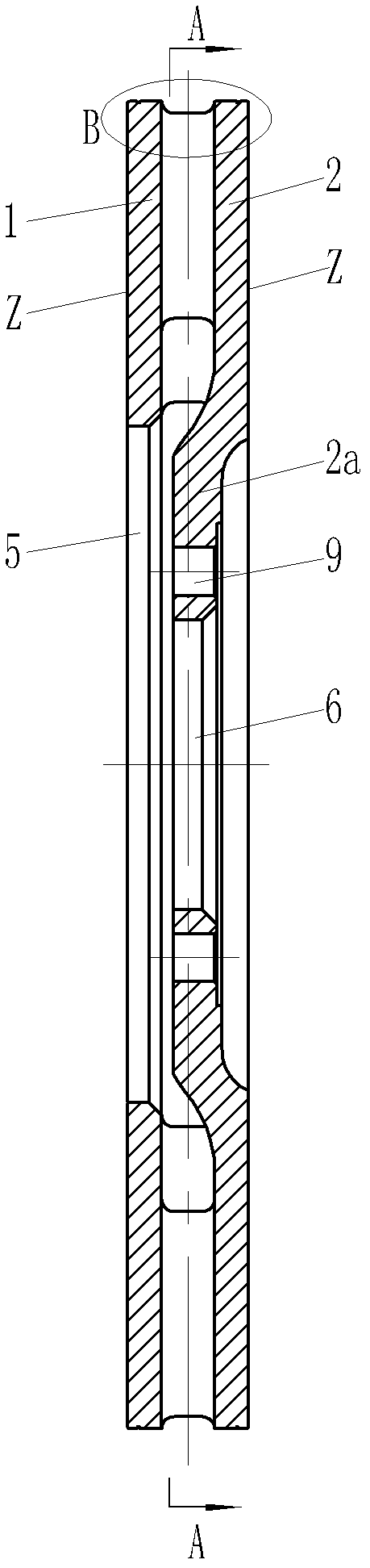

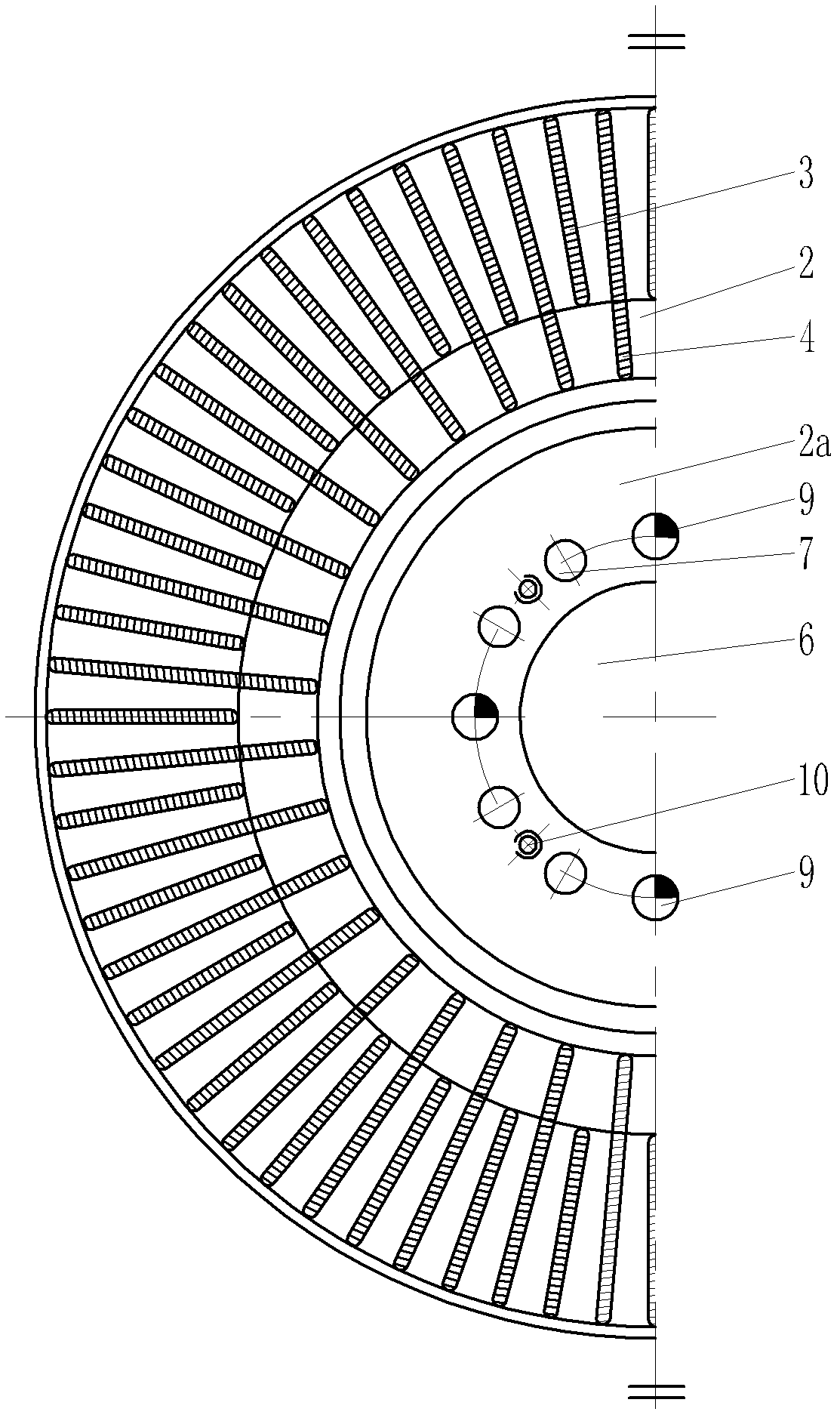

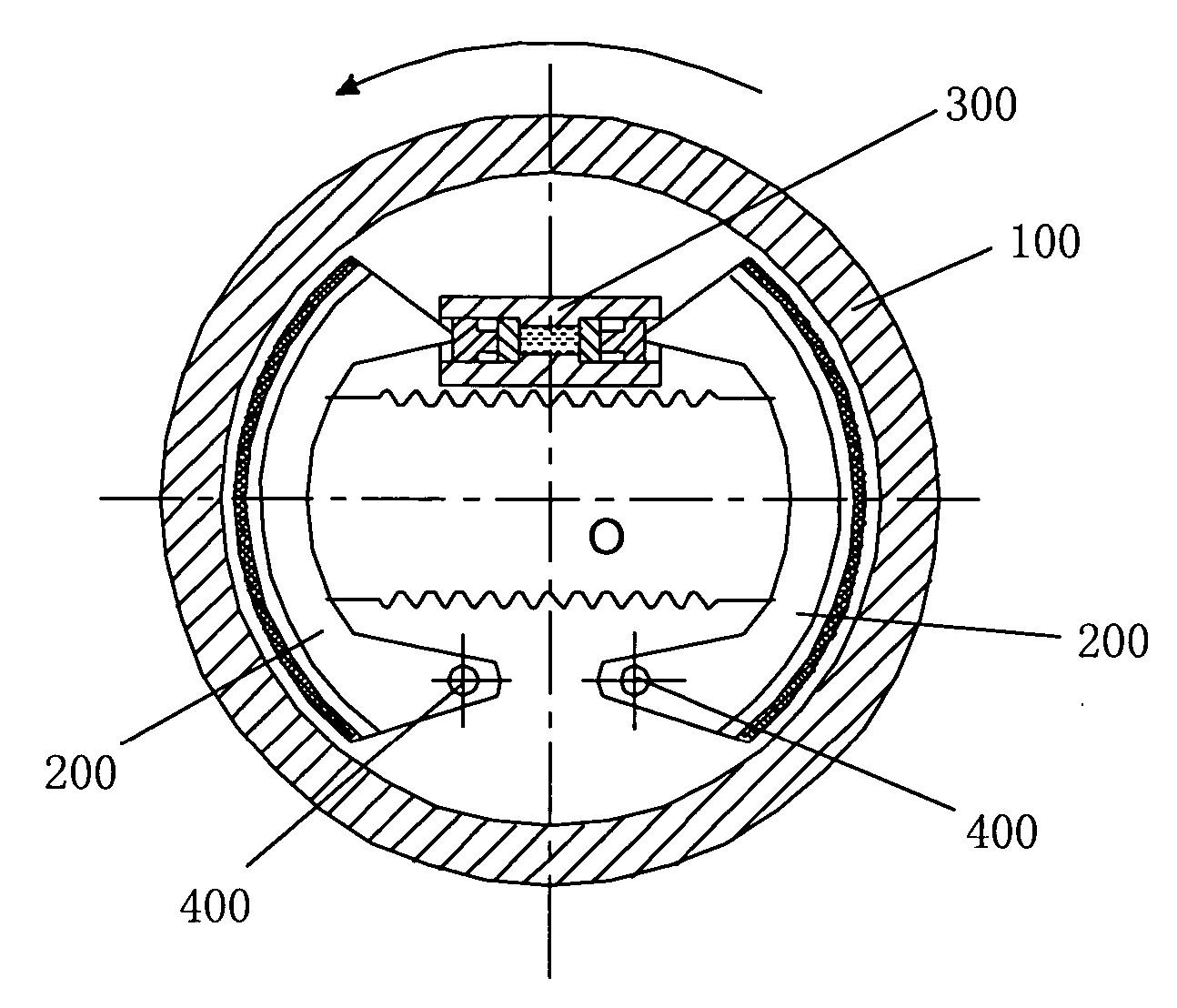

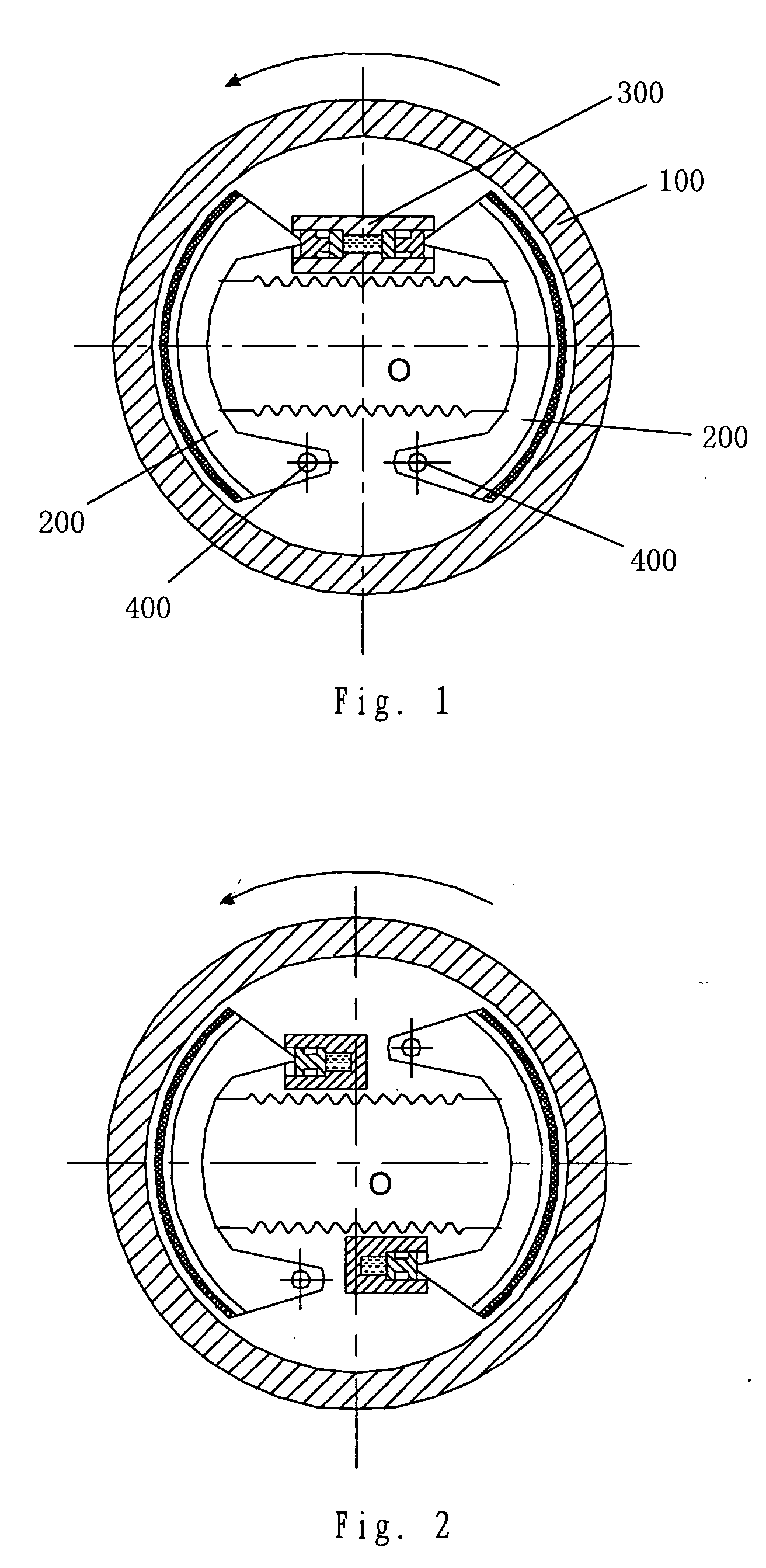

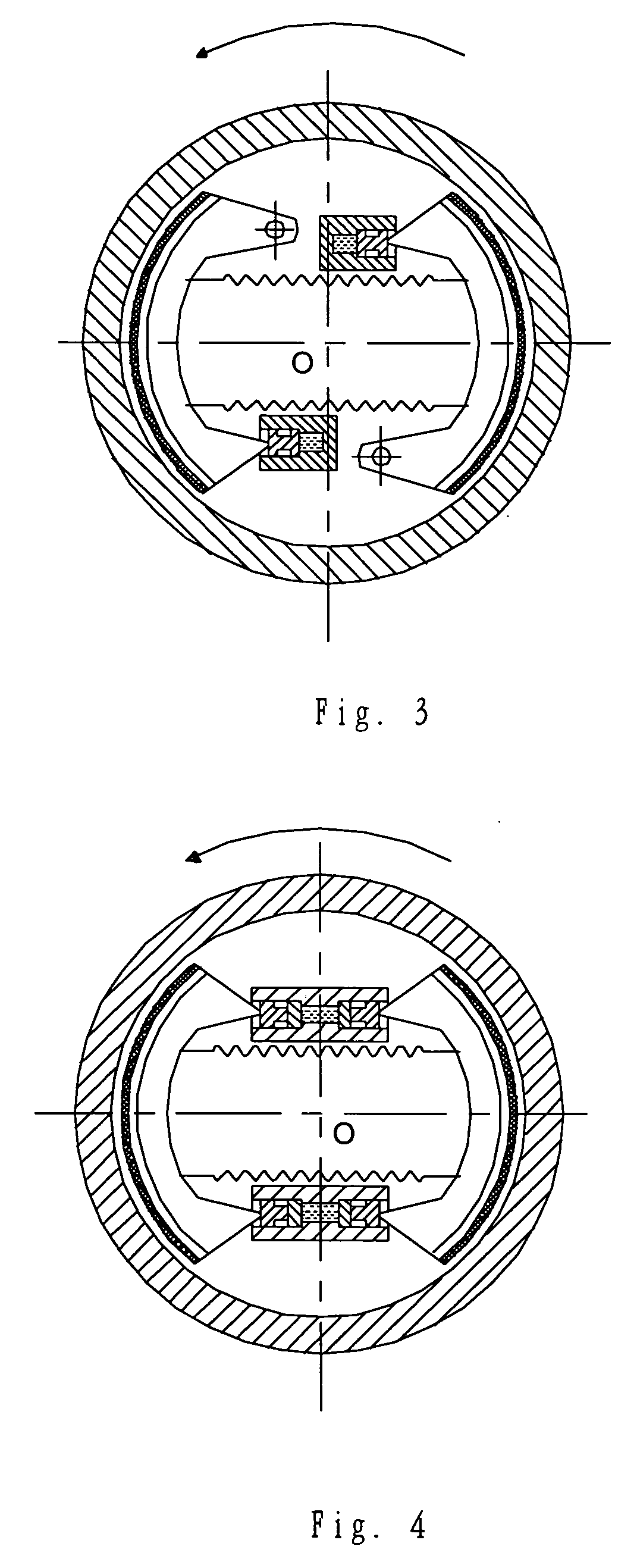

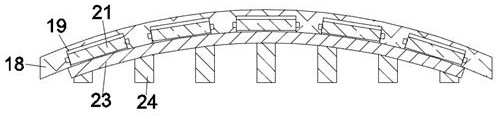

Braking disc for railway vehicles

The invention discloses a braking disc for railway vehicles, which is made of vermicular graphite cast iron. The chemical composition by weight is: 3.45%-3.77% of carbon, 1.86%-2.25% of silicon, 0.5%-0.8% of manganese, less than or equal to 0.02% of sulfur and less than or equal to 0.05% of phosphorus, and the balance is iron, wherein vermicular rate of the vermicular graphite cast iron is larger than or equal to 60%. The braking disc is formed by a left disc body, a right disc body, a first radial connection rib and a second radial connection rib, the diameter of the left disc body is identical to that of the right disc body, the left surface of the left disc body and the right surface of the right disc body are braking work surfaces, and roughness of the two braking work surfaces is respectively 1.6mm-3.2mm. The braking disc for railway vehicles prevents cracks from generating through material replacement and structure adjustment and further avoids safety accidents. The braking distance of the braking disc is moderate, and the braking disc is simple in structure, easy to manufacture, has good economic and technological value and is suitable for large-scale popularization and application.

Owner:重庆海通机械制造有限公司

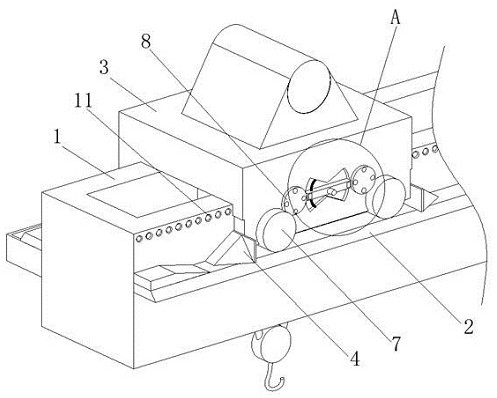

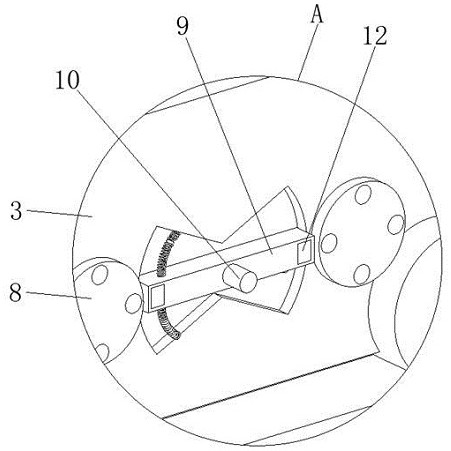

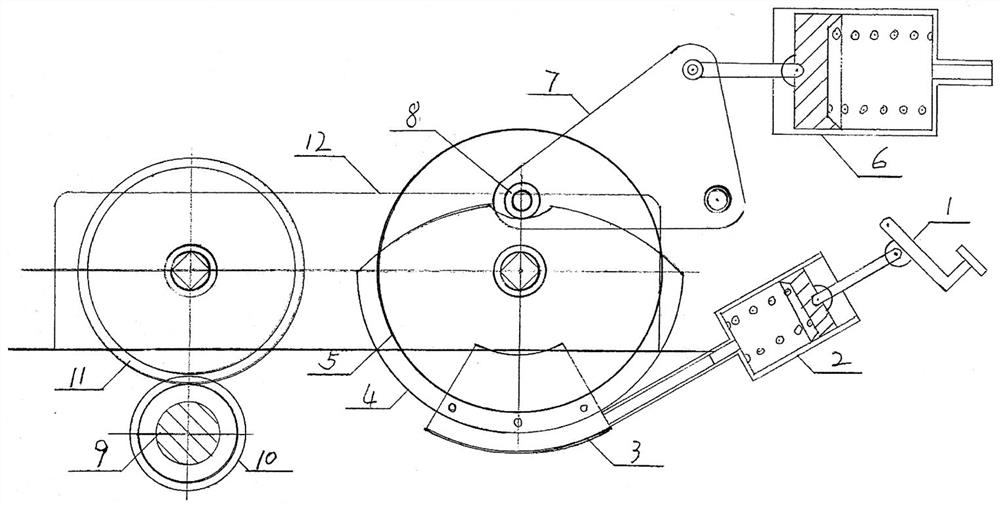

Friction brake based on cylinder locking

InactiveCN106812831ACompact structureOverall small sizeBraking membersFluid actuated drum brakesHydraulic motorCoupling

The invention relates to a friction brake for locking cylindrical parts by four stop blocks. The friction brake comprises such parts as a base, stop block parts, a slide way mechanism, a wedge block mechanism, a driving rod and a driven rod. The driving rod, the driven rod and the slide way mechanism form an altered crank slide block mechanism; a hydraulic motor drives the driving rod to rotate through a coupling; and the driven rod is enabled to push the slide way mechanism to move in the vertical direction so as to drive the stop blocks to move up and down. Meanwhile, the stop blocks respectively finish the actions of braking and releasing under the effects of a conical surface of the base and a wedged part under the wedge block mechanism. When the stop blocks lock a brake rod in a lowest point, a pressure angle on the driven rod is 90 degrees, and the slide way mechanism and the stop blocks are self-locked. The friction brake is compact in structure, smaller in weight and size and easy to arrange, can realize mechanical self-locking in the locking position, is high in braking reliability, can perform braking on whole cylindrical parts, is long in braking distance, and enables the axial braking performances of the cylindrical parts to become better.

Owner:TONGJI UNIV

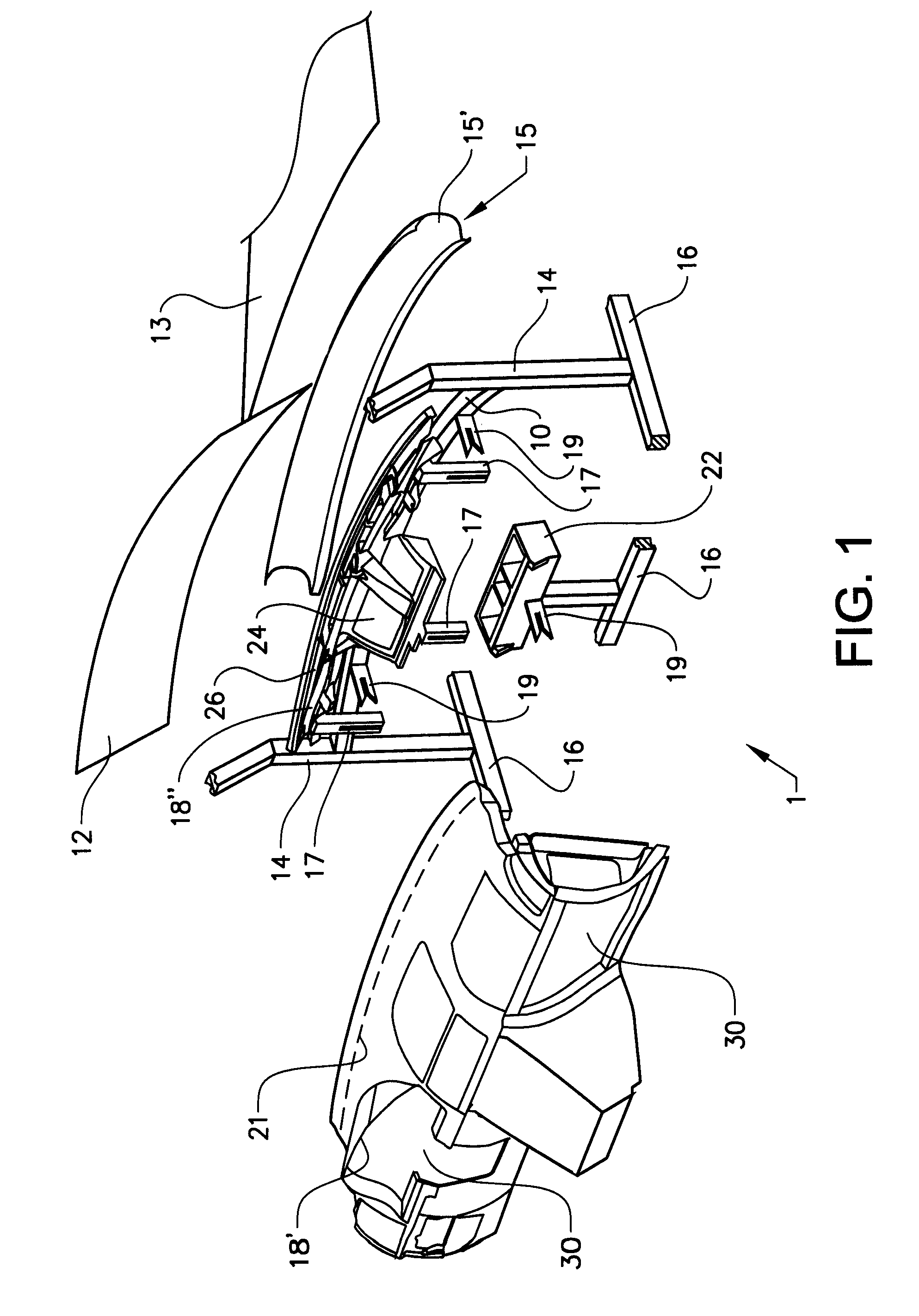

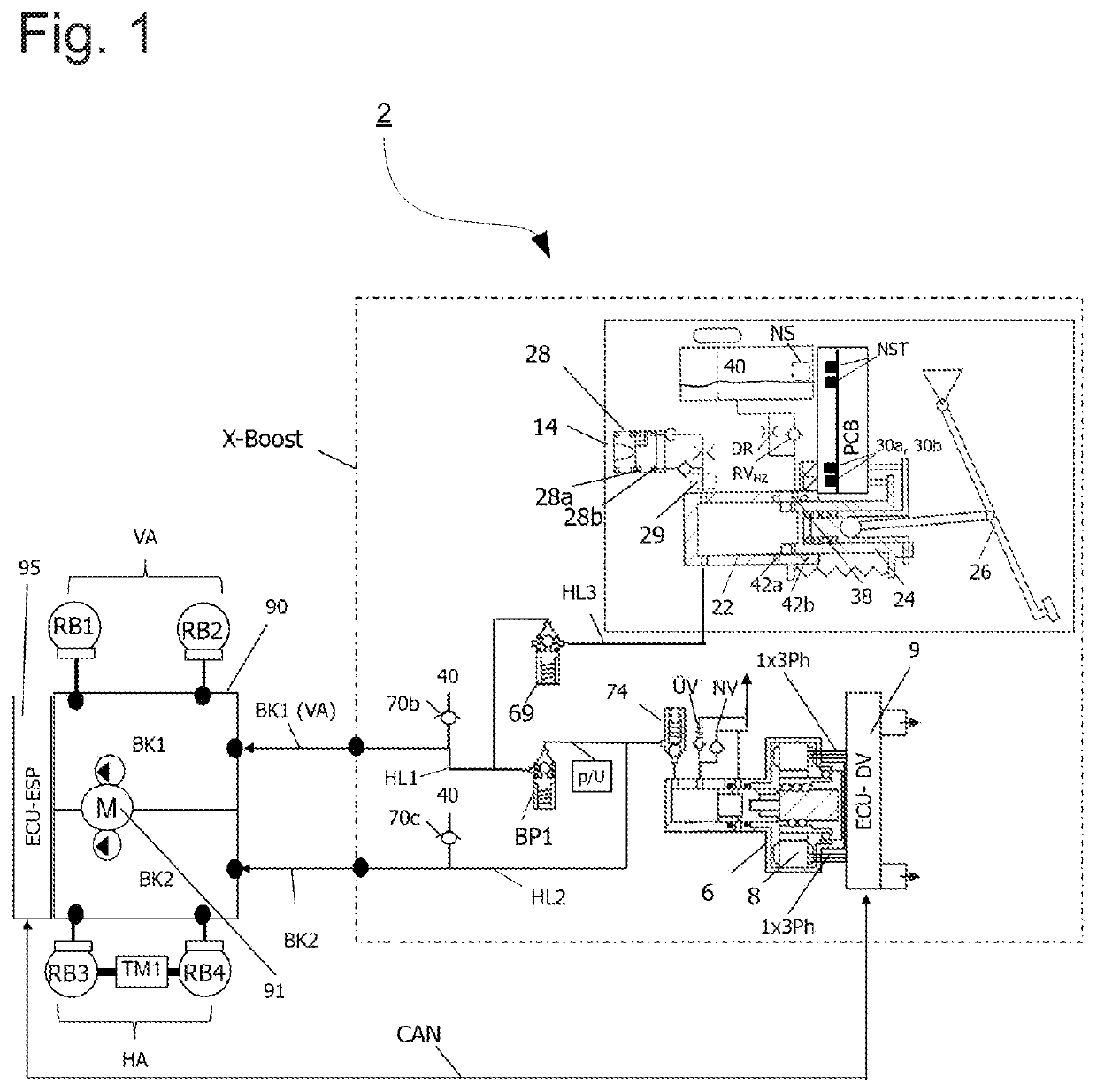

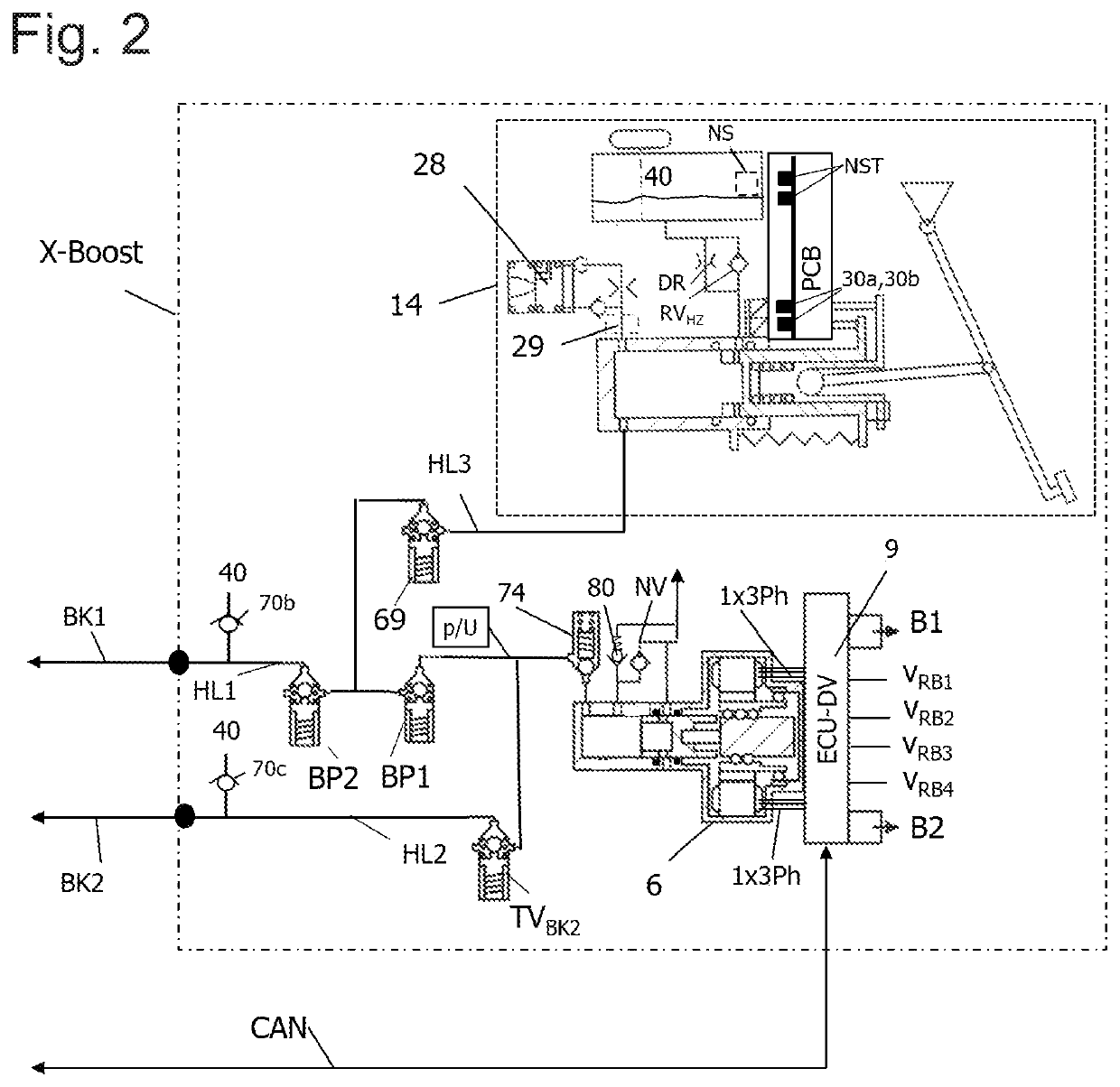

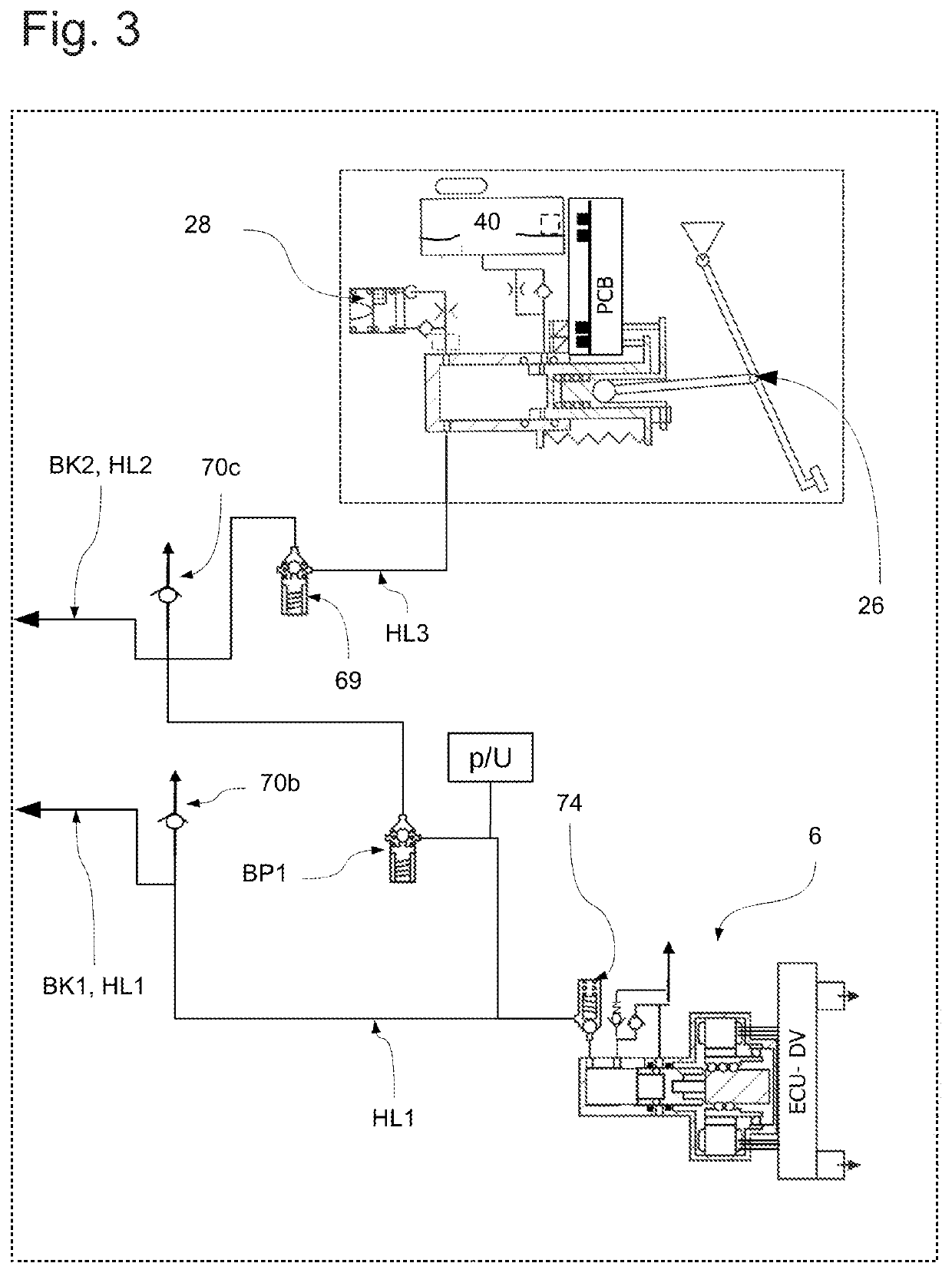

Brake system and method for controlling a brake system

PendingUS20220250600A1PowerfulReduce weightBraking action transmissionApplication and release valvesIsolation valveControl theory

A brake system may include a first pressure supply unit having an electromotive drive and arranged to supply pressure medium to first and second brake circuits; a motor-pump unit to supply pressure medium to at least one of the brake circuits; a second pressure supply unit, connected to the motor-pump unit via first and second hydraulic lines and arranged to supply pressure medium to at least one of the brake circuits; and a valve unit. The second pressure supply unit may be connected via a third hydraulic line to at least one of the brake circuits. The valve unit may include at least one feed valve via which the third hydraulic line may be at least partially reversibly shut off. An isolating valve may be disposed in at least one of the hydraulic lines to at least partially reversibly shut off the at least one hydraulic line.

Owner:IPGATE

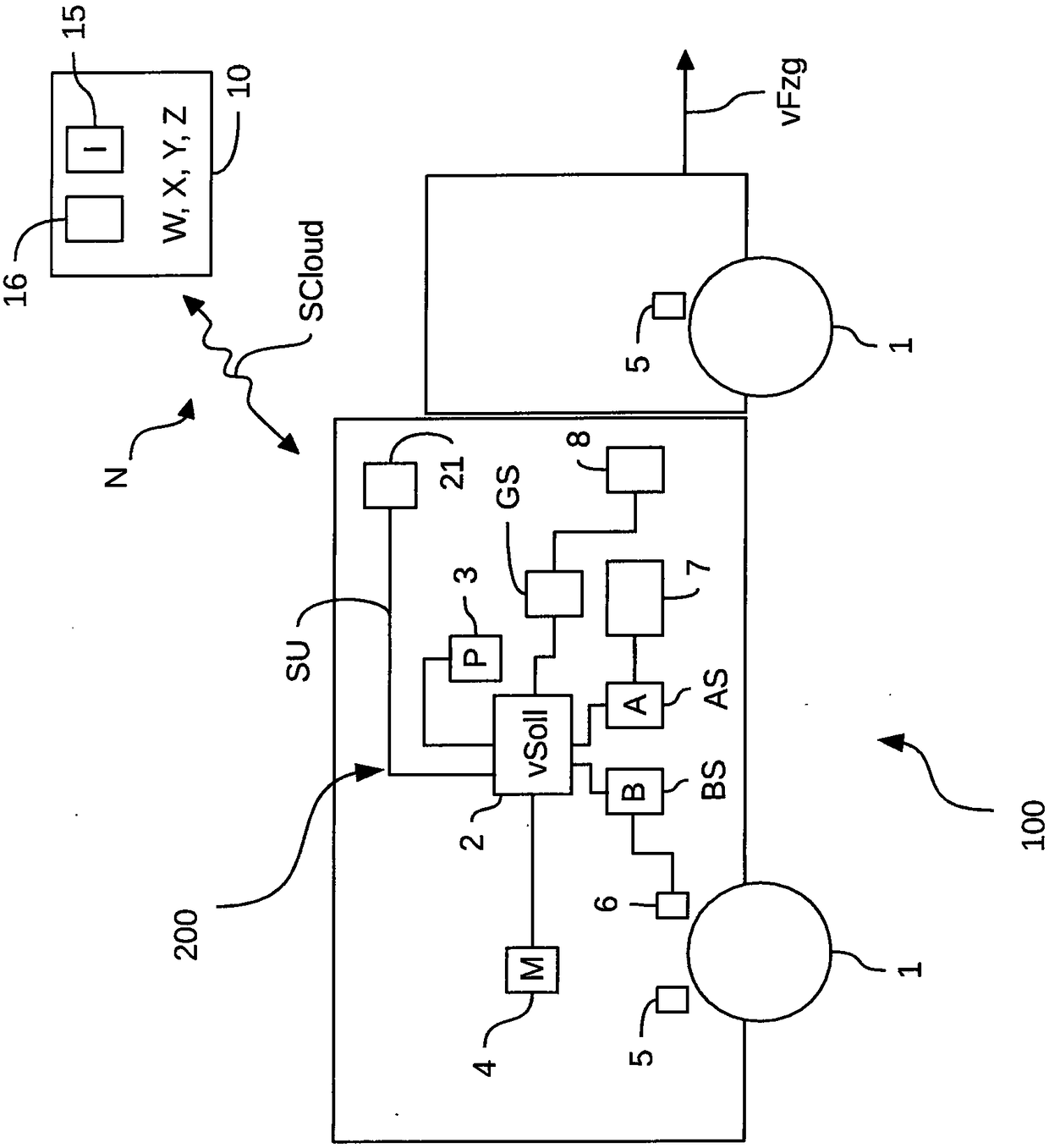

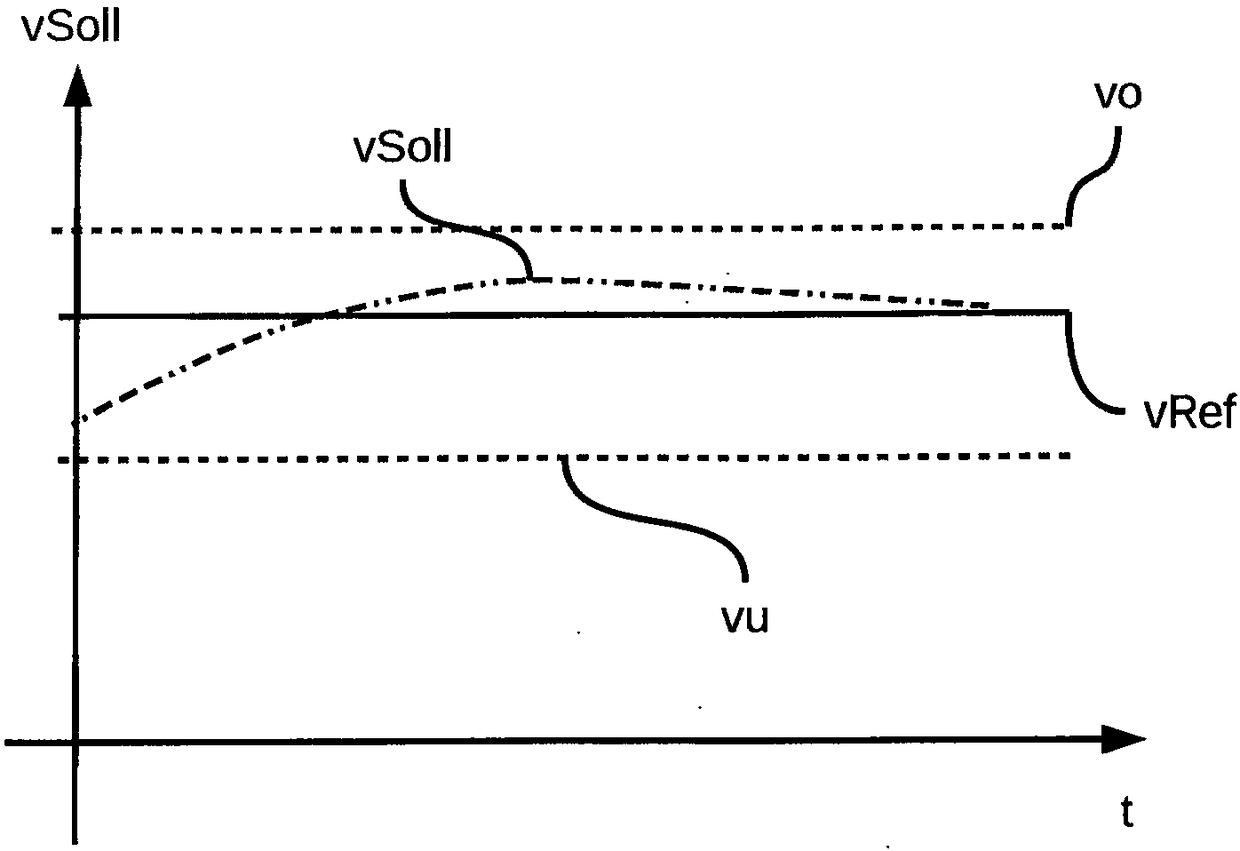

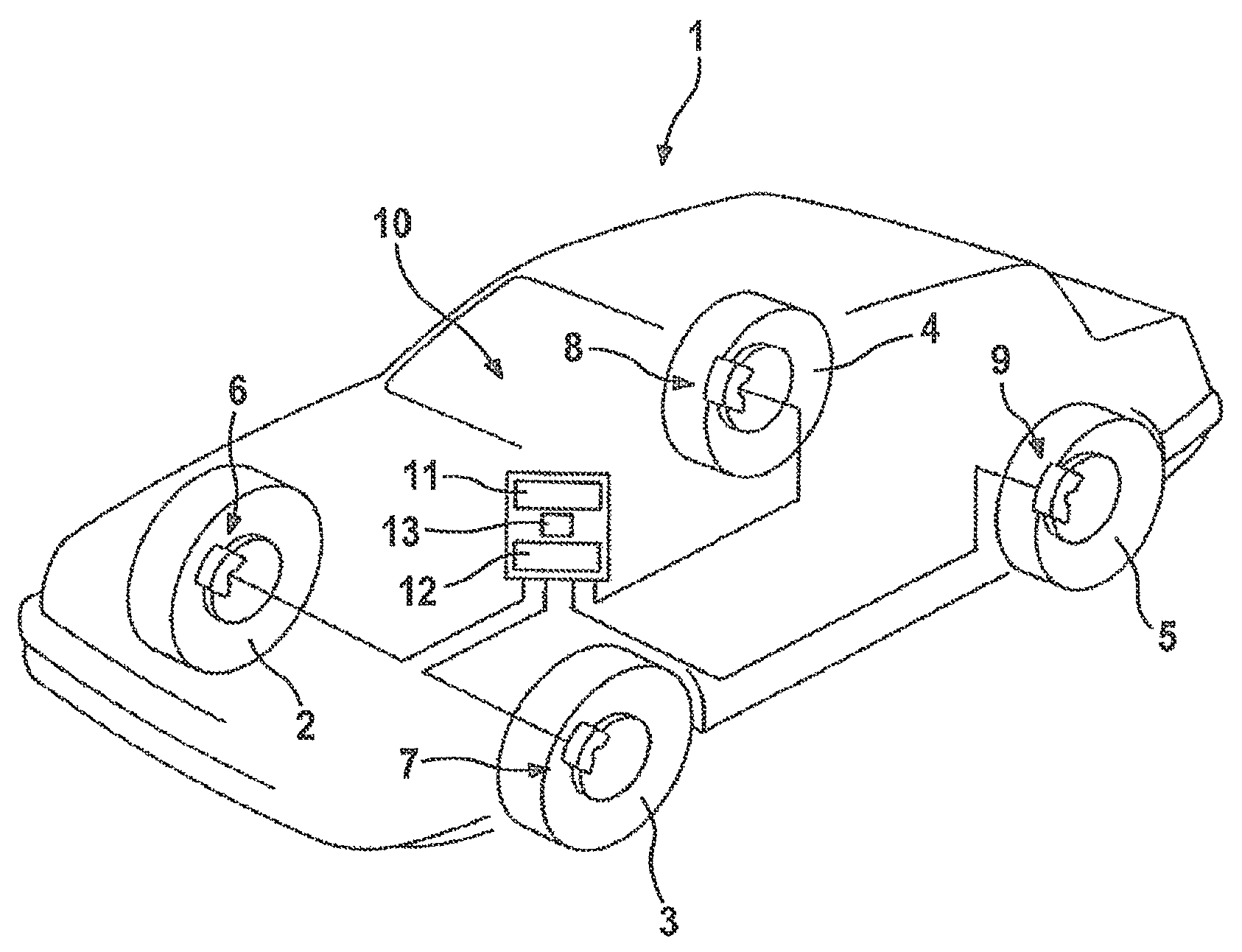

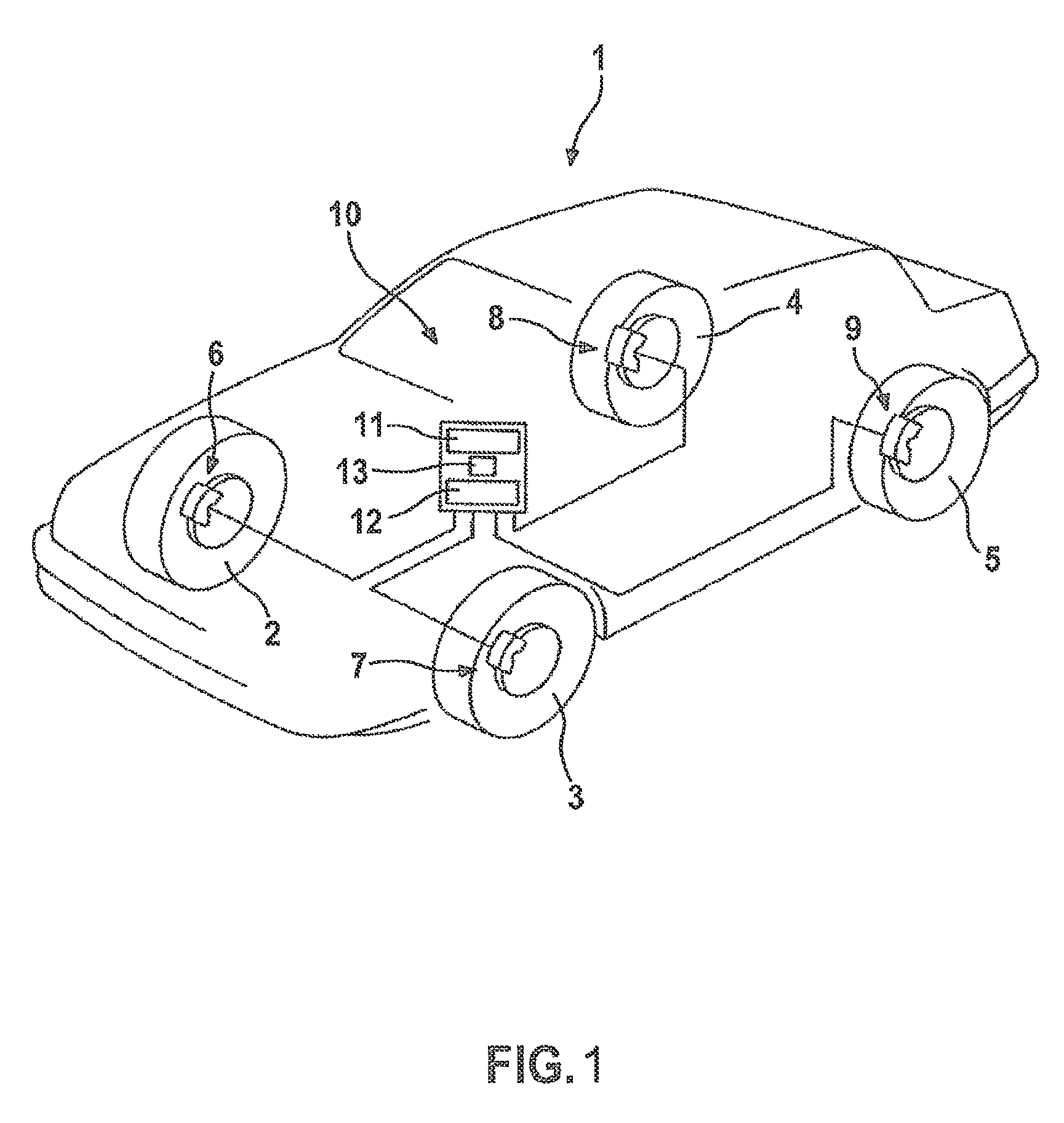

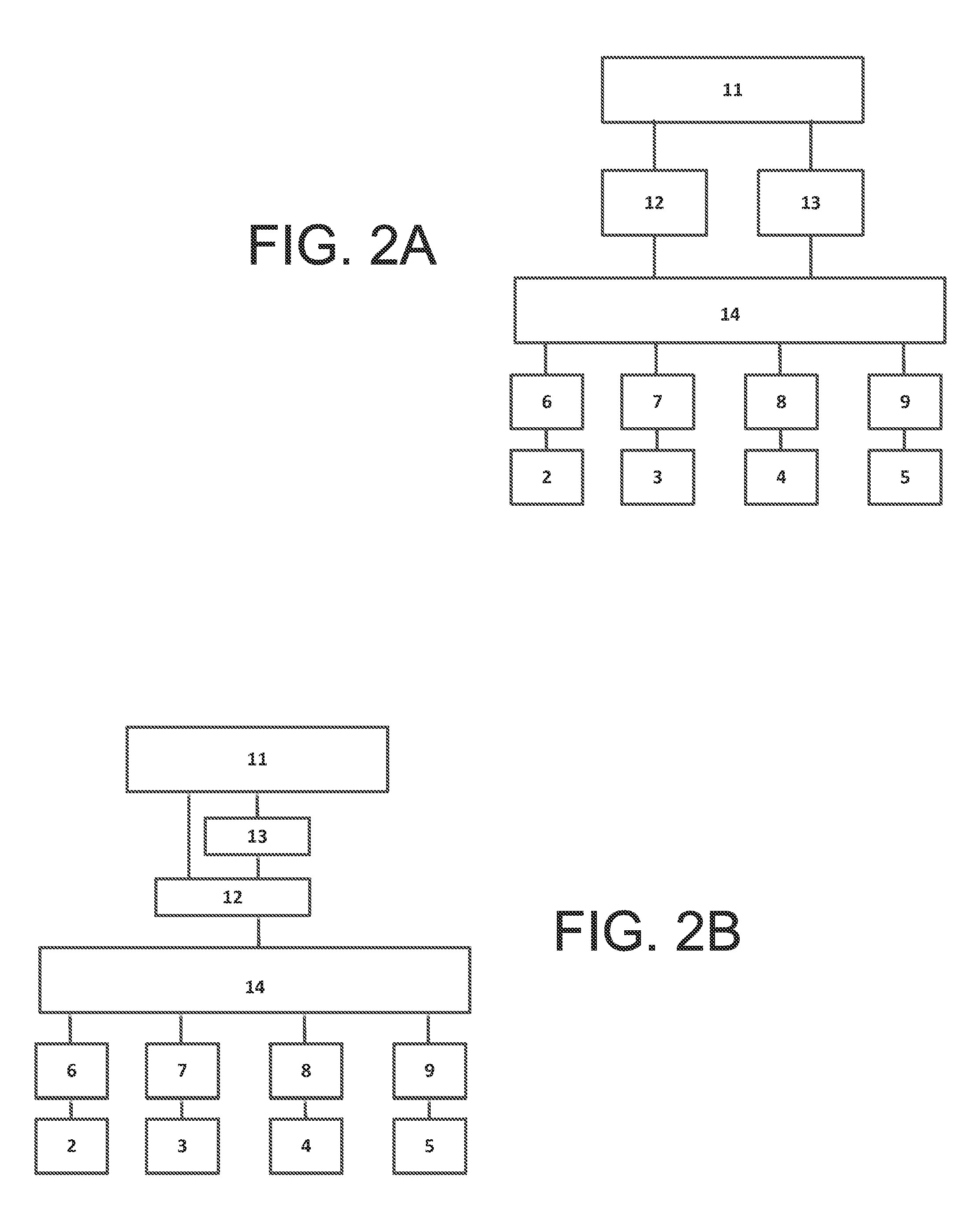

Method for adaptively controlling a vehicle speed in a vehicle, and speed control system for carrying out the method

ActiveCN108349485AIncrease speedReduce speedHybrid vehiclesBrake system interactionsSpeed control systemDynamic vehicle

The invention relates to a method for adaptively controlling a vehicle speed (vFzg) in a vehicle (100), in particular a utility vehicle having a speed control system (200), comprising at least the following steps: determining a reference speed (vRef); actuating an engine (7) and / or brakes (6) and / or a transmission (8) of the vehicle (100) via the speed control system (200) in accordance with a target vehicle speed and / or a target vehicle deceleration in order to adapt the current vehicle speed (vFzg) to the reference speed in a fuel-efficient manner. According to the invention, the target vehicle speed and / or the target vehicle deceleration is determined for a current driving dynamic situation of the vehicle (100), defined by driving dynamic vehicle parameters (vFzg, M, A, B, P), in accordance with at least one calculation coefficient (W, X, Y, Z), wherein the at least one calculation coefficient (W, X, Y, Z) is provided by an external processor (10) outside of the vehicle (100) in accordance with the current driving dynamic vehicle parameters (vFzg, M, A, B, P), and in accordance with current route information (I) for a route section ahead, wherein the route section ahead is established on the basis of the current driving dynamic vehicle parameters (vFzg, M, A, B, P).

Owner:ZF CV SYST EURO BV

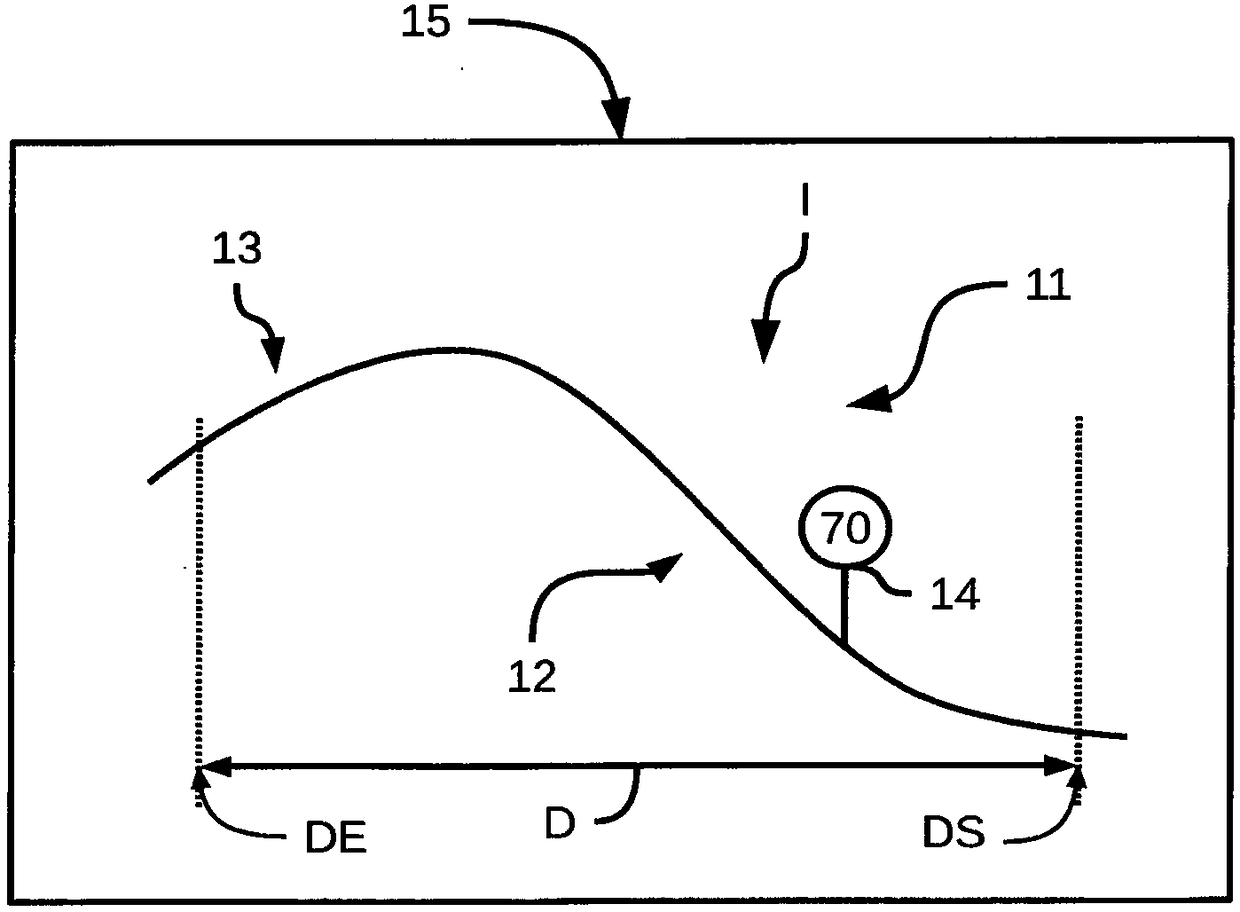

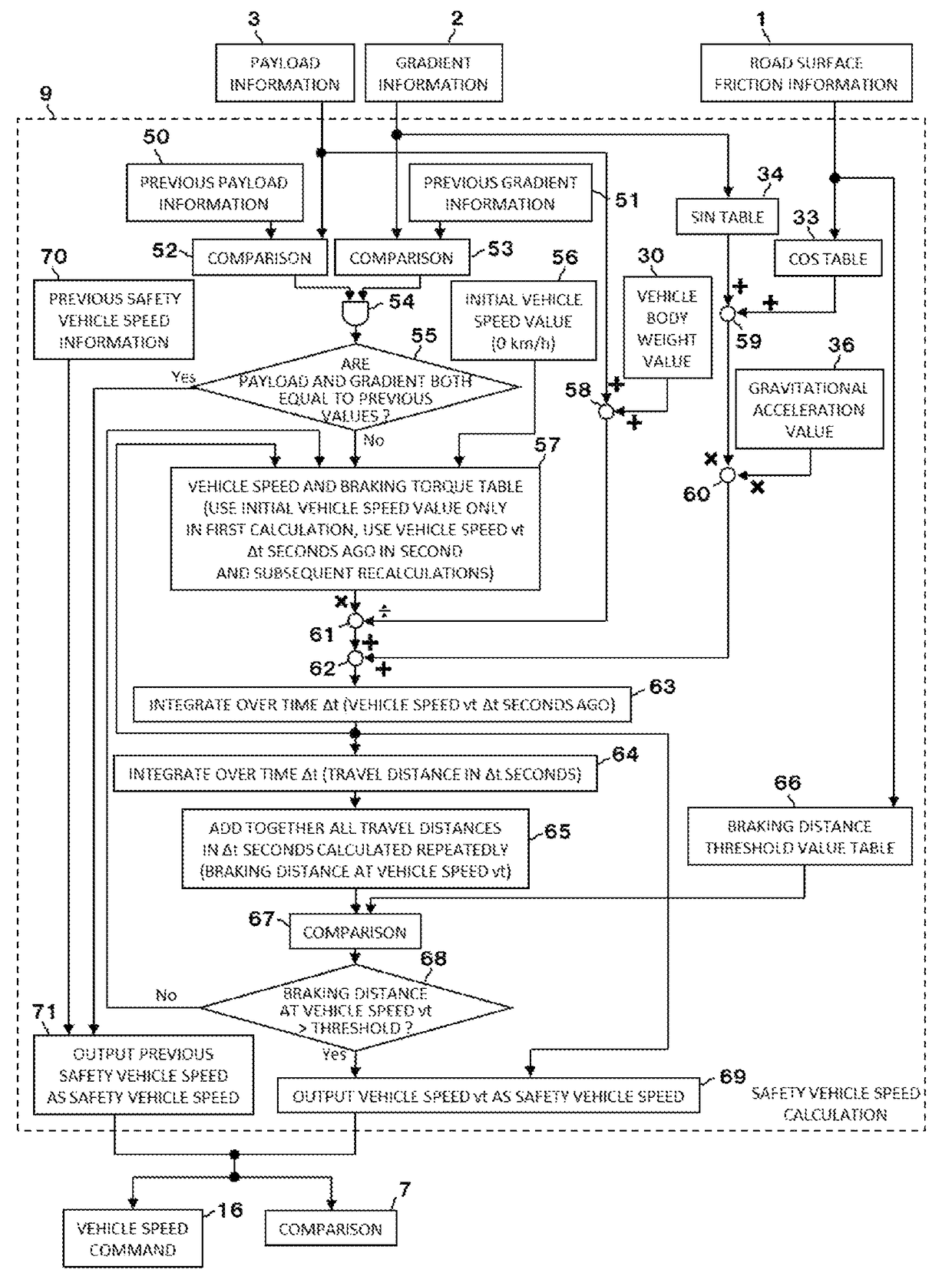

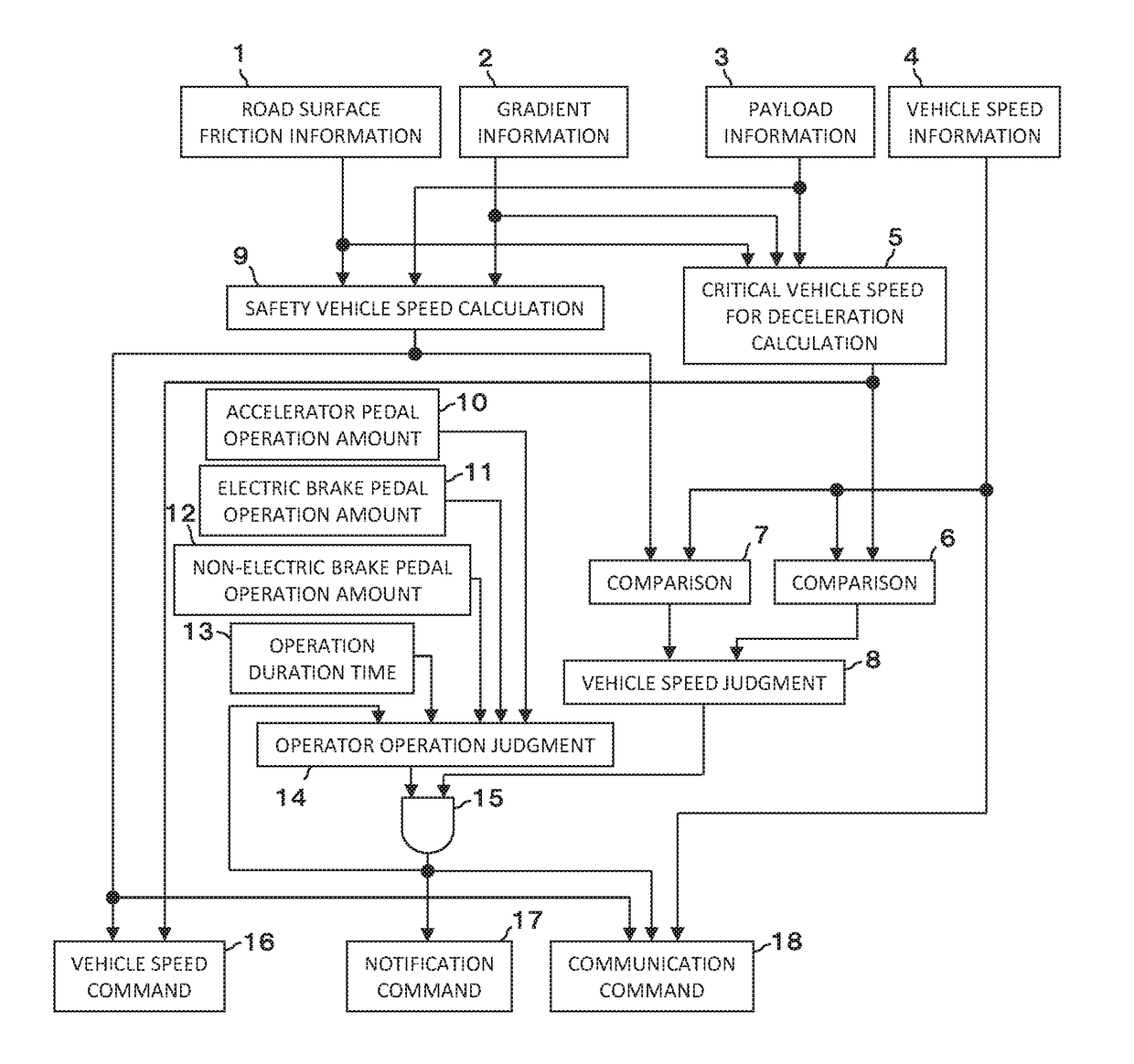

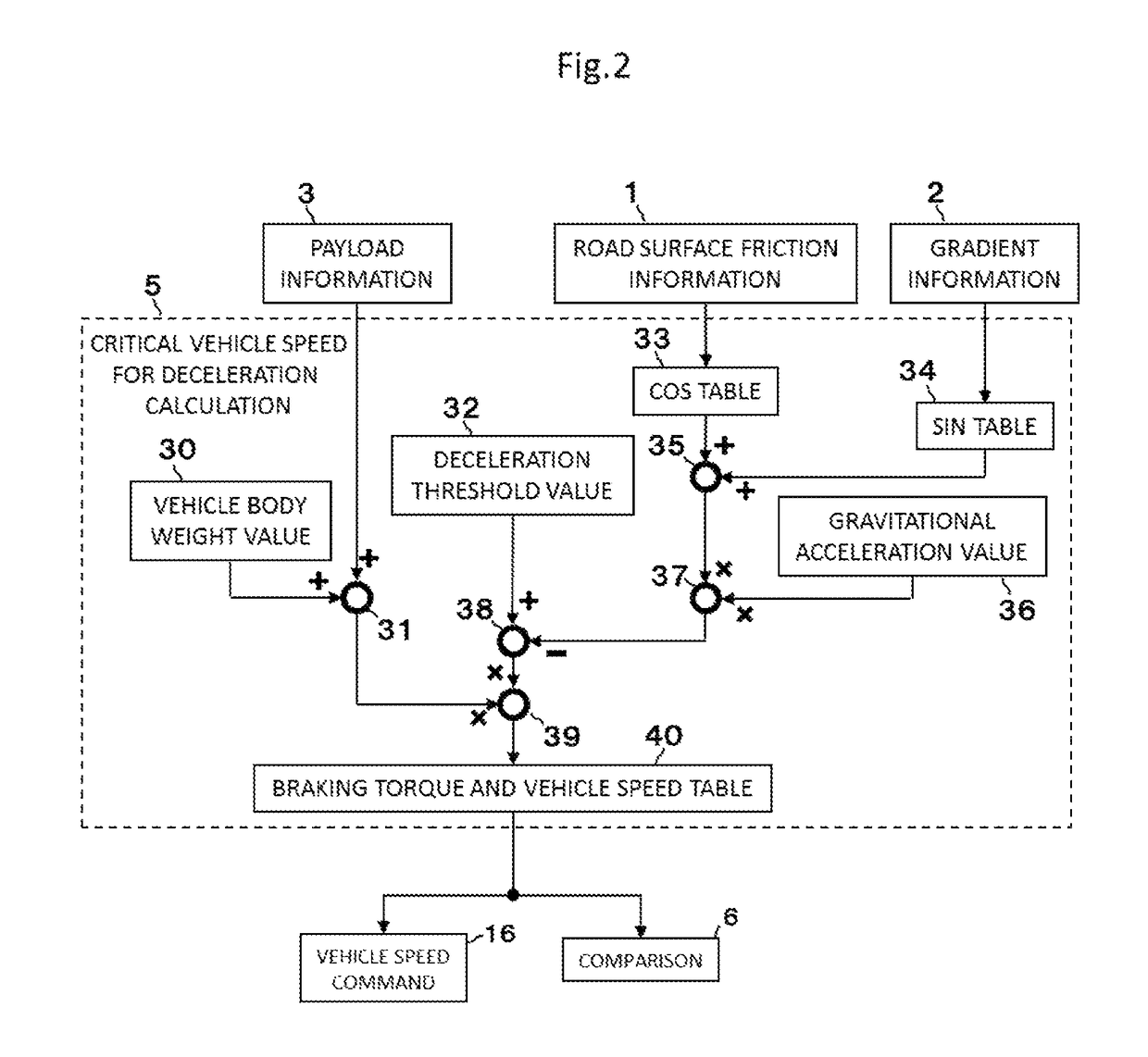

Braking distance control device

ActiveUS9914441B2Increase braking distanceElectrodynamic brake systemsPropulsion using engine-driven generatorsBrake torqueRoad surface

A braking distance control device employed for an electrically driven work vehicle includes a safety vehicle speed calculation unit that calculates a safety vehicle speed at which a braking distance provided by use of an electric brake device becomes less than or equal to a threshold value, based on gradient information, payload information, road surface friction information, vehicle speed information, and a braking torque characteristic of electric motors: a critical vehicle speed for deceleration calculation unit that calculates a critical vehicle speed for deceleration at which deceleration provided by use of the electric brake device becomes less than or equal to a threshold value; and an operation judgment unit 14 that judges a setting of notification, based on pedal operation amounts.

Owner:NIHON KENKI CO LTD

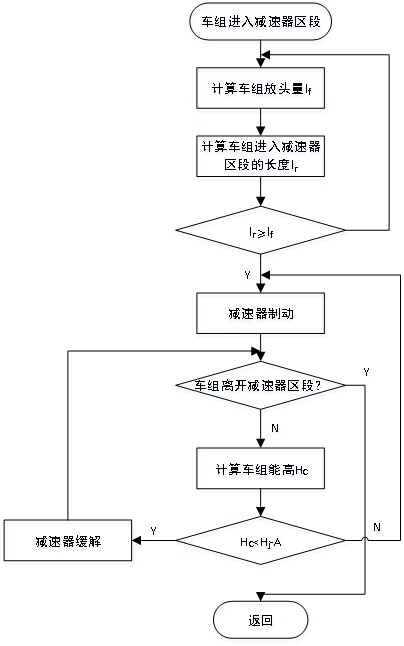

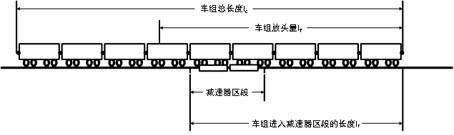

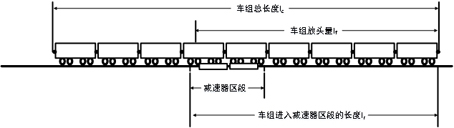

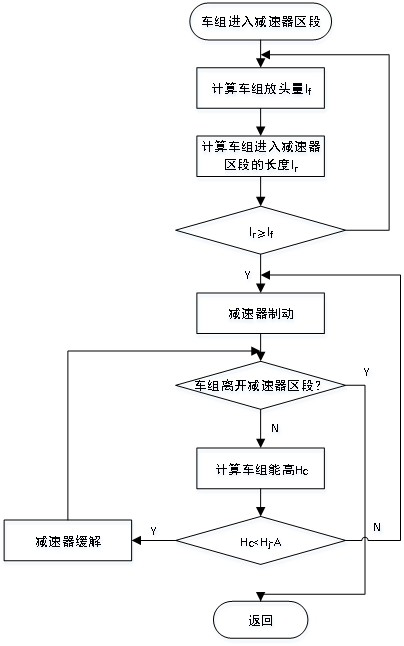

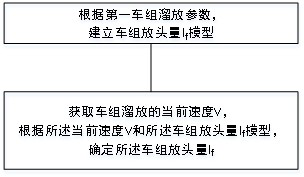

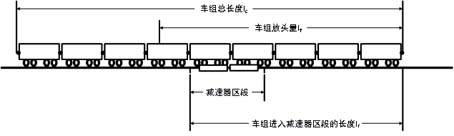

Speed control method and system for hump humping vehicles

PendingCN112046554AIncrease braking distanceReduce speedRailway signalling and safetyPositive railway stopsReduction driveControl theory

The invention provides a speed control method and system for hump humping vehicles. The speed control method comprises the steps that whether a vehicle set enters a speed reducer section or not is detected; after the vehicle set enters the speed reducer section, the head releasing amount lf of the vehicle set and the length lr of the portion, entering the speed reducer section, of the vehicle setare dynamically calculated, and the lf with the lr are compared; whether the speed reducer starts braking or not is judged according to a comparison result of lf and lr; and if the speed reducer starts braking, whether the vehicle set leaves the speed reducer section or not is detected. According to the speed control method and system, in the humping process of the vehicle set, the speed reducer is braked in advance, the braking distance is increased, the probability of overspeed can be effectively reduced for special vehicles, the energy height of the vehicle set is dynamically calculated andcompared with the braking energy height of the speed reducer to dynamically regulate and control the action of the speed reducer, the average speed of the vehicle set passing through the speed reducer section is effectively increased, and the hump operation efficiency is improved.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

Brake device for a working machine

InactiveCN111434543AImproved braking behaviorFeature increase or decreaseBraking action transmissionBrake action initiationsBrake torqueLoop control

The invention relates to a braking device for a work machine comprising a pressure supply, a brake circuit, at least one brake actuable via the brake circuit, a manually controllable brake valve by means of which the brake circuit is actuable, a control unit, and at least one control valve that is controllable by the control unit and by means of which the brake circuit is actuable. In accordance with the invention, the total brake torque exerted by the at least one brake is adjustable by means of a corresponding control or regulation of the at least one control valve in dependence on at leasttwo input signals detectable by the control unit, with a first input signal relating to a current state of the manual actuation of the brake valve and a second input signal relating to a current driving state of the work machine.

Owner:LEIBHERR HYDRAULIKBAGGER GMBH

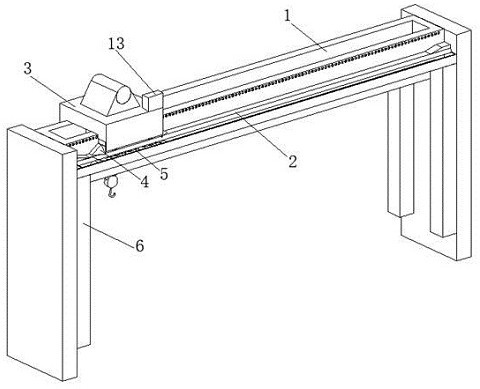

Crane with slide rail anti-slip function

ActiveCN113620183AIncrease braking distanceAvoid collisionTrolley cranesRunwaysStructural engineeringControl theory

The invention relates to the technical field of cranes, and discloses a crane with a slide rail anti-slip function. The crane comprises a frame body, wherein slide rails are fixedly connected to two sides of the frame body; a slide block is slidably connected to the top of the frame body; push blocks are slidably connected to the front part and the rear part of the slide block; a collecting device is arranged at the bottoms of the slide rails; a discharging device is arranged at the inner wall of the frame body; the inside of the slide block is hollowed out, and the inside of the slide block is rotationally connected with rolling wheels; the bottoms of the rolling wheels extend out of the slide block and are in contact with the surface of a rotating disc; the inside of the slide block is rotationally connected with a rotating rod; in addition, springs are arranged between the slide block and one end of the rotating rod; and a clamp block is fixed to the inner wall of the rotating rod. According to the crane with the slide rail anti-slip function, when the rolling wheel slips, the rotating rod can reset and can drive a slide rod to move leftwards and to be inserted into a clamping groove, the slide block can be further limited, the crane can be monitored at any time, and a slipping accident is prevented.

Owner:XINXIANG UNIV

Drum brake apparatuses

ActiveUS20070034460A1Improve braking distanceIncrease braking distanceFluid actuated brakesMechanically actuated brakesDrum brakeAutomotive engineering

This invention discloses a type of drum brake that can be used for automobiles, comprising a brake drum, one or more brake shoes, and one ore more brake cylinders. Its special characteristics are: the drum brake further comprises an ordinary gear train which comprises an annulus, one or more planetary gears and a sun gear. Here, the annulus is attached to the brake drum. The sun gear and a mounting shell of the brake shoes are attached to each other. The planetary gears are located between the annulus and the sun gear, and one ore more planetary gear axles of the respective planetary gears are affixed with one or more planetary carriers. By adopting the drum brake of this invention and the ordinary gear train, when the brake is applied, the brake shoes rotate in the opposite direction relative to the moving direction of the brake drum, thereby greatly reduce the braking distance and braking time.

Owner:SHANGHAI BYD

A crane with slide rail anti-skid function

ActiveCN113620183BIncrease braking distanceAvoid collisionTrolley cranesRunwaysClassical mechanicsControl theory

The invention relates to the technical field of cranes, and discloses a crane with a slide rail anti-skid function, comprising a frame body, slide rails are fixedly connected to both sides of the frame body, and sliders are slidably connected to the top of the frame body, Both the front and the rear of the slider are slidably connected with push blocks, the bottom of the slide rail is provided with a collection device, the inner wall of the frame is provided with a discharge device, and the inside of the slider is hollowed out. , and the inner rotation of the slider is connected with a roller, the bottom of the roller protrudes from the outside of the slider and contacts with the surface of the turntable, the inner rotation of the slider is connected with a rotating rod, and there is a Spring, the inner wall of the rotating rod is fixed with a block. When the roller slips in the present invention, the rotating rod will reset and drive the sliding rod to move to the left and be inserted into the card slot, so that the sliding block can be limited and can Monitor the crane at all times to prevent slipping accidents.

Owner:XINXIANG UNIV

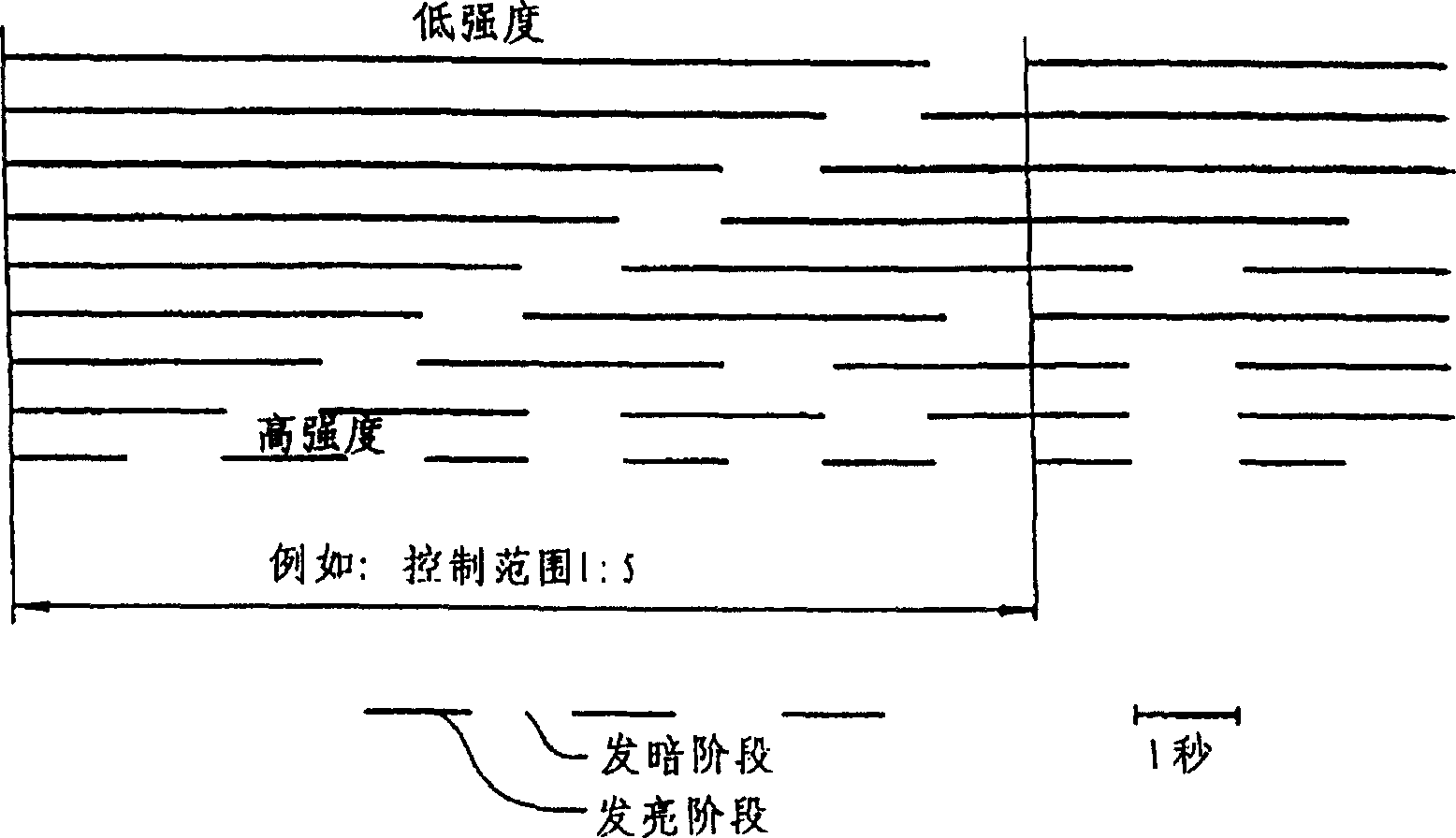

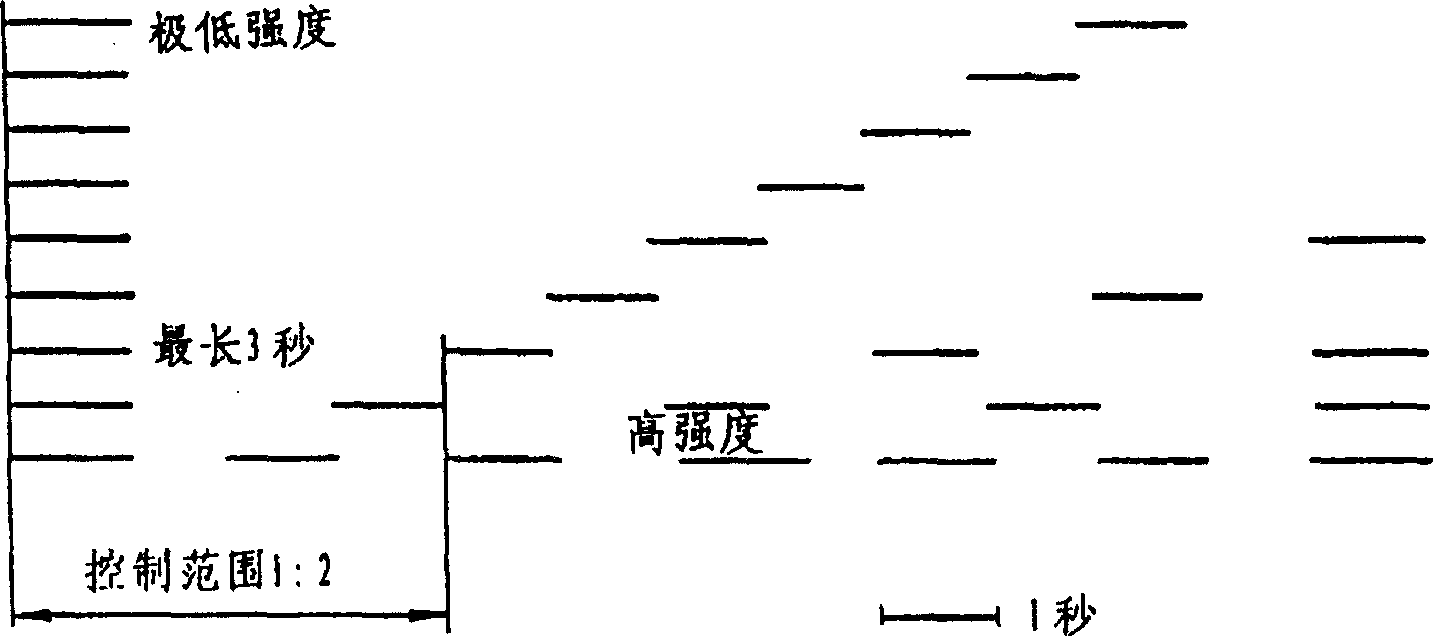

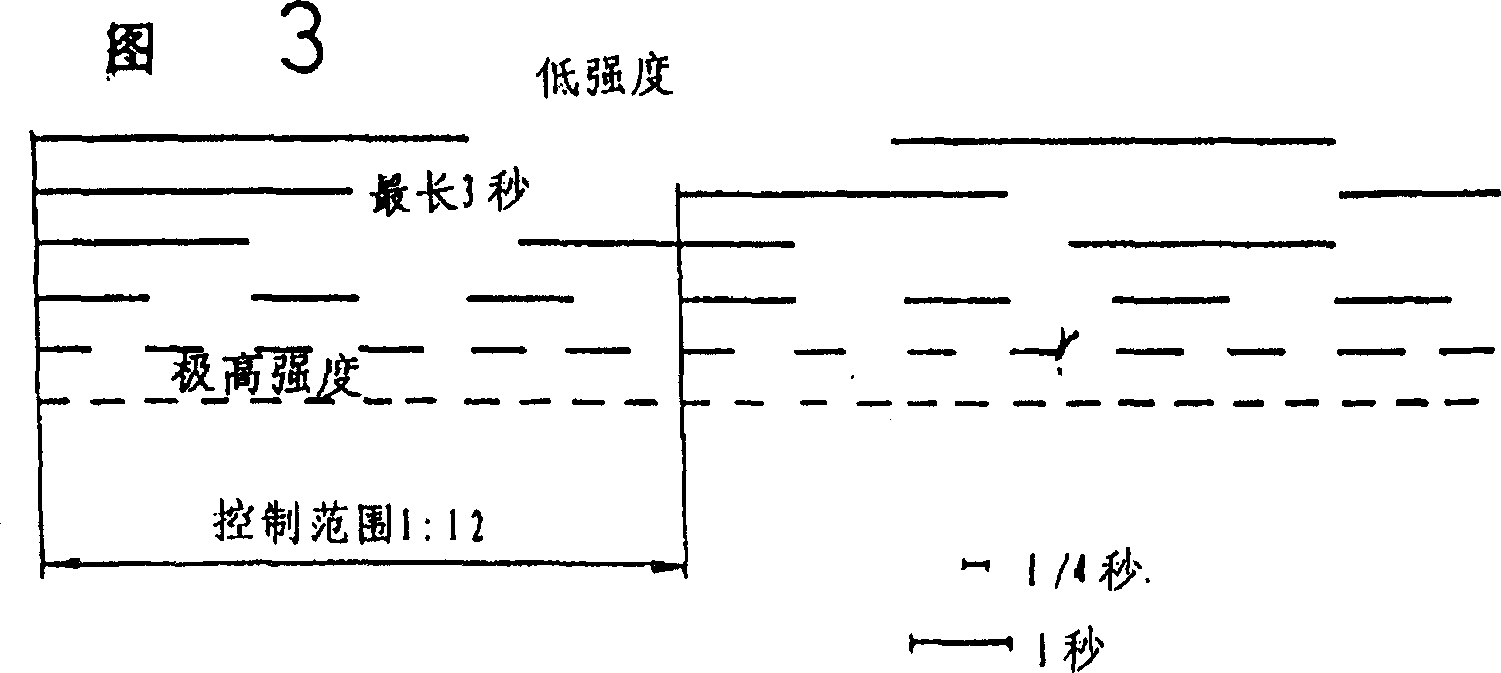

A declaration warning system

InactiveCN1145132CIncrease braking distanceNo rear-end collisionVehicle headlampsArrangements for variable traffic instructionsRear-end collisionEngineering

A deceleration warning device and a method for its control serve to reduce the risk of rear-end collisions in road traffic or in other movement processes. In order to avoid or to reduce the disadvantages of conventional brake lights and flashing hazard warning systems, the intensity of warning given by the deceleration warning device of a vehicle travelling ahead is dependent on the size of the risk value G which originates from this vehicle and can be effective for subsequent vehicles.

Owner:BAYERISCHE MOTOREN WERKE AG

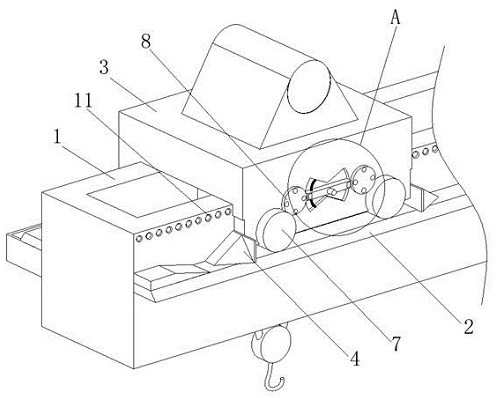

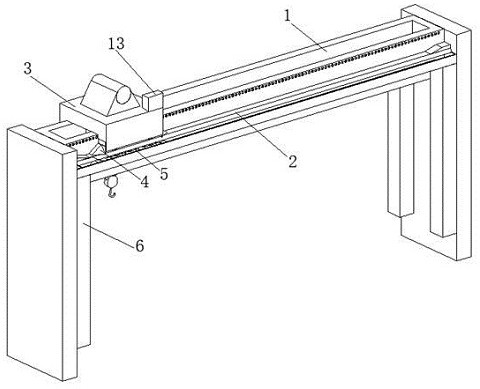

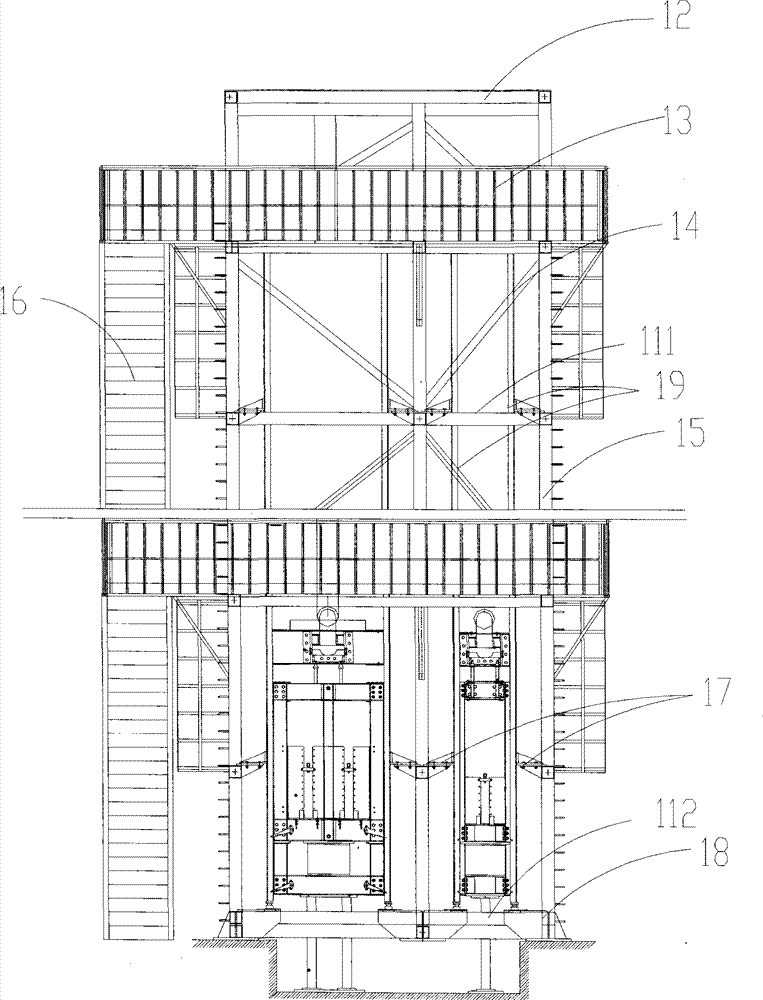

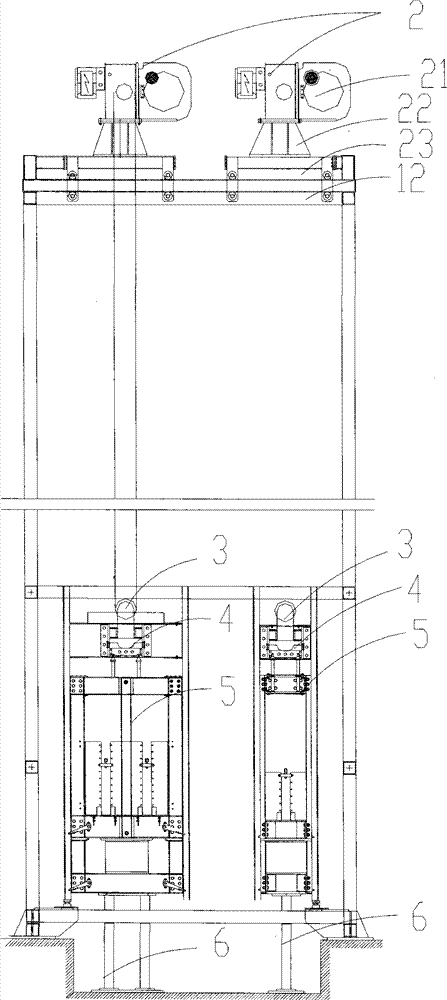

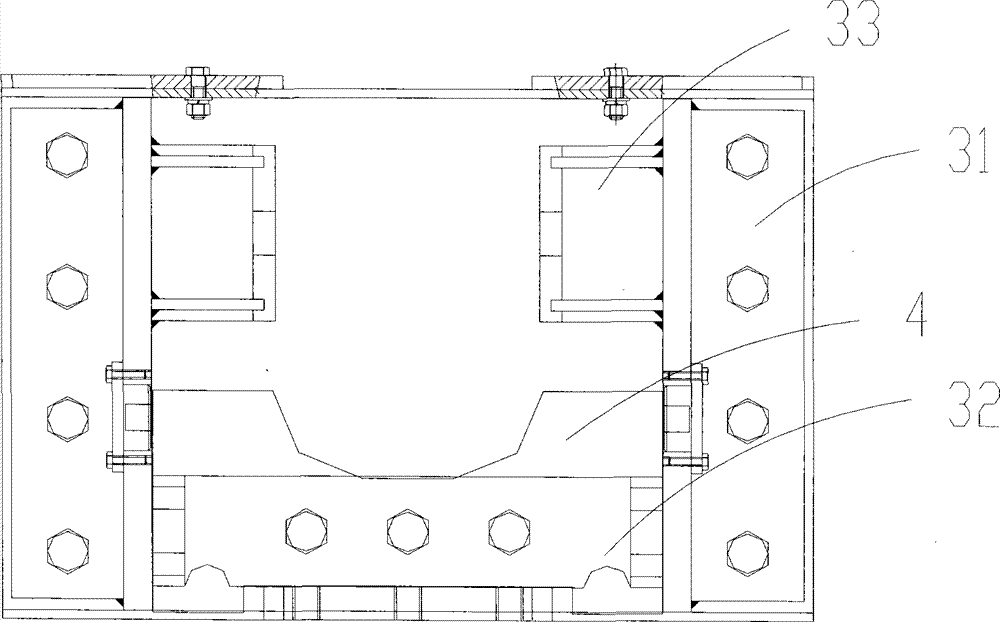

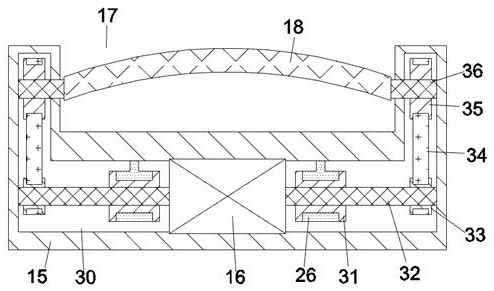

Permanent magnet eddy current linear braking system for elevator testing

InactiveCN103231959BAvoid deformationReduce wearElevatorsHoisting equipmentsEddy currentHigh intensity

The invention relates to a permanent magnet eddy current linear braking system for elevator testing. The permanent magnet eddy current linear braking system for elevator testing is applied to a safety tongs testing experiment in an elevator testing system and is used for braking a testing stand loaded with safety tongs when the safety tongs fail. The permanent magnet eddy current linear braking system for elevator testing comprises a magnetic steel group, a braking guide rail and a transverse movement mechanism. The magnetic steel group is arranged on opposite corners on two sides of the testing stand and generates a high-intensity magnetic field in the power-up state. Two ends of the braking guide rail are fixed on a beam of a testing tower through a guide rail installation support, one end of the braking guide rail extends into a gap between the N pole and the S pole, and the braking guide rail and the magnetic steel group have relative movement. The transverse movement mechanism is arranged on the beam of the testing tower, is aligned at the end of the braking guide rail and connected with the braking guide rail, and drives the braking guide rail to move transversely to change the contact area between the braking guide rail and the magnetic steel group. The permanent magnet eddy current linear braking system achieves permanent magnet braking of the testing stand and reduces mechanical friction in a conventional braking system.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Color function road surface

ActiveCN100362166CGood water permeabilityNot easy to fall off and fadeIn situ pavingsCalcium silicateFiber

The color functional road surface features that it is porous polymer concrete layer comprising white cement 200-500 weight portions, stone material 500-2000 weight portions, vinyl acetate copolymer 10-200 weight portions, inorganic pigment 0.5-20 weight portions, dibutyl phthalate 0.5-90 weight portions, aluminum silicate or fine silica powder 10-100 weight portions, antiageing fiber 0.5-10 weight portions and water 70-200 weight portions. The color functional road surface has good water permeability and is color fast.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

Method for operating a brake system of a vehicle, and brake system

InactiveUS9132816B2Complete functioning performanceImpairing functioning performanceBraking action transmissionApplication and release valvesBrake fluidBraking system

Owner:ROBERT BOSCH GMBH

Method, device and system for determining head setting amount of vehicle set and computer readable storage medium

InactiveCN111923954AHigh braking energyReduce speedTrain hauling devicesTrack brakesReduction driveControl theory

The invention provides a method, device and system for determining the head setting amount of a vehicle set and a computer readable storage medium. The method comprises the steps of building a head setting amount lf model of the vehicle set according to a first vehicle set humping parameter, and acquiring the current speed V of vehicle set humping, and determining the vehicle set head setting amount lf according to the current speed V and the vehicle set head setting amount lf model. In the model of the head setting amount lf, the braking energy height Hj of the speed reducer is multiplied bythe braking energy height use coefficient R of the speed reducer; the braking energy height use coefficient R of the speed reducer is smaller than 1, so that the calculated head setting amount can becorrespondingly reduced, the speed reducer can be braked in advance, the braking distance is increased, and the probability of overspeed of special vehicles can be effectively reduced.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

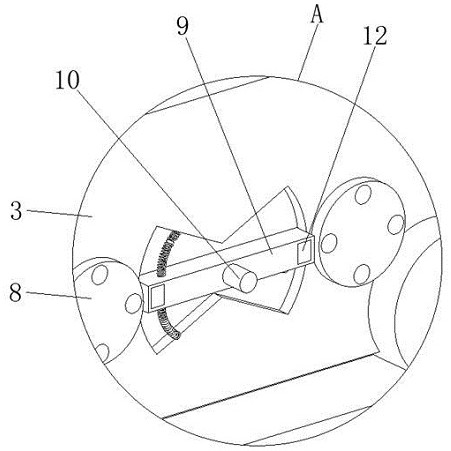

Anti-falling safety device with automatic grease injection function for elevator

PendingCN114590671APrevent disengagementAvoid losing fitBearing componentsElevatorsPull forceControl engineering

The invention relates to the technical field of anti-falling safety devices for elevators, in particular to an anti-falling safety device with an automatic grease injection function for an elevator. The technical problem to be solved is that a tension spring connected with a centrifugal block fails or tension is weakened after a long time, so that the centrifugal block is easy to trigger a braking effect. According to the technical scheme, the anti-falling safety device with the automatic grease injection function for the elevator comprises an outer cone, an automatic grease injection mechanism and a centrifugal mechanism, the automatic grease injection mechanism is arranged on the front portion of the outer cone, and the centrifugal mechanism is located in the middle of the outer cone. By arranging the centrifugal mechanism, the situation that when the device works normally, a centrifugal block is thrown out to make contact with a second fixing block, an elevator is braked when descending, and normal use of the elevator is affected is avoided; the situation that an operator does not inject grease into the sealed bearing in time, and consequently a bearing bush in the sealed bearing is abraded is avoided.

Owner:SYNEY ELECTRIC HANGZHOU CO LTD

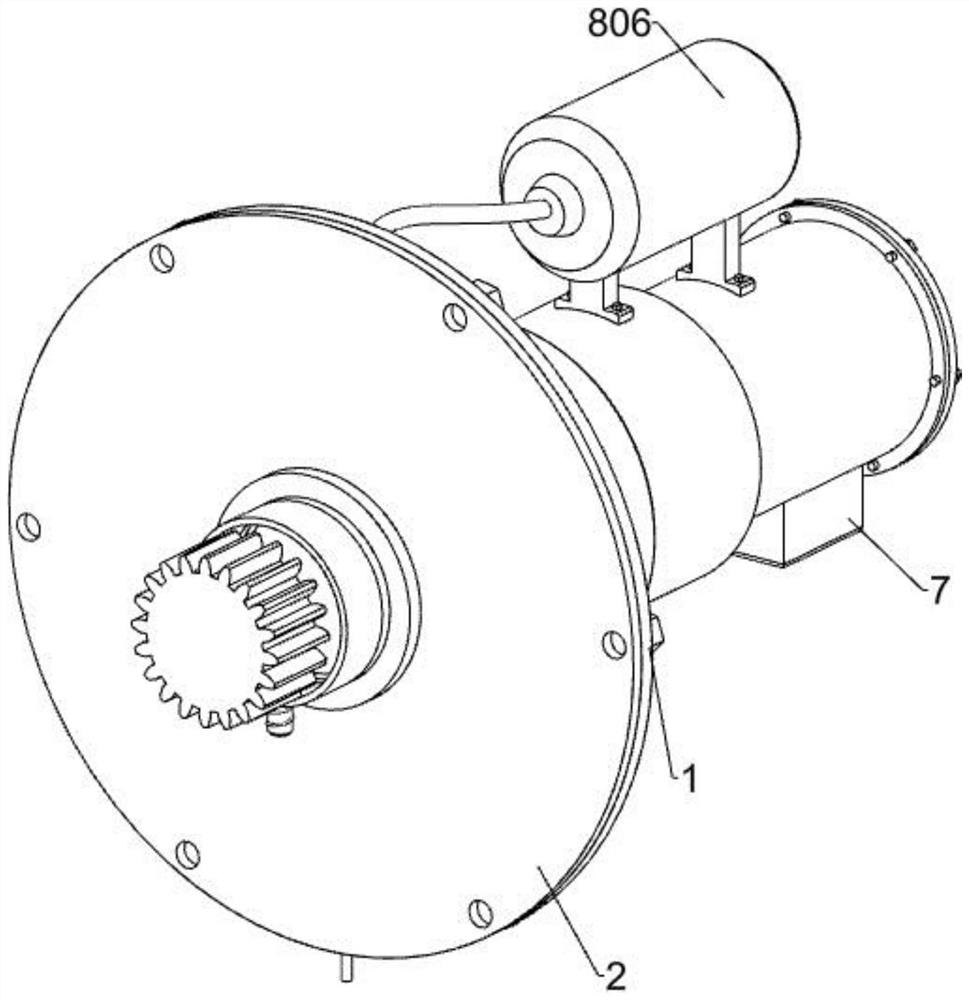

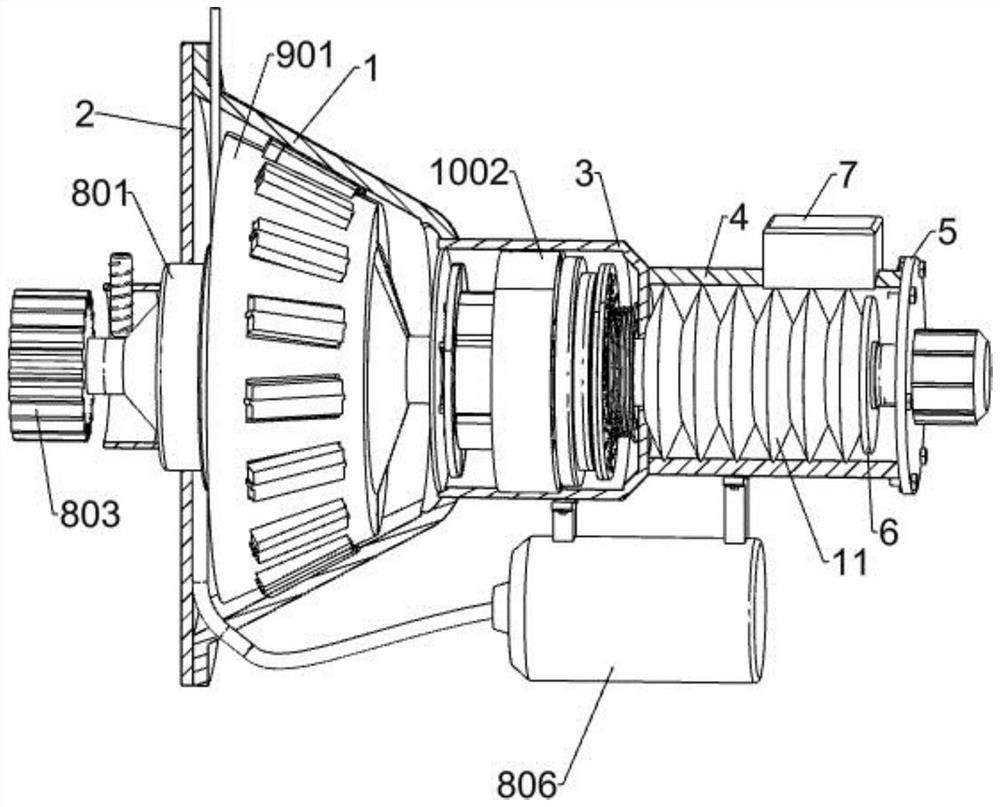

High power diesel vehicle hydraulic brake inertia booster

ActiveCN109515416BShort duration of actionThe forward and backward braking effect is the sameAuxillary drivesBraking action transmissionReduction driveGear wheel

The invention discloses a high-power diesel automobile hydraulic braking inertia booster, a fixed reducer (12) on the rear axle of the automobile, an automobile drive shaft (9) connected in series with the drive shaft gear (10), and the reducer input gear (11) meshing with the drive shaft Gear (10), the inertia disc (5) is installed on the output shaft of the reducer and the cam disc (4) is suspended, the brake caliper (3) is fixed on the lower part of the cam disc (4), and the inertia disc (5) is put into the brake caliper ( 3) In the mouth, the brake caliper (3) is connected to the piston of the master cylinder (2), the connecting rod of the piston of the master cylinder (2) is connected to the brake pedal (1), and the roller is installed in the groove of the cam disc (4) ( 8), the top corner of the triangular plate lever (7) is fixed on the roller (8), the bottom corner of the triangular plate lever (7) is connected to the booster pump (6) piston ejector rod, and the piston of the triangular plate lever (6) is connected to the brake cylinder. The invention has sufficient power source to provide brake braking, flexible forward and backward braking, no fuel consumption for braking, and good braking efficiency and safety factor.

Owner:翟正环

Oil tank truck capable of reducing vehicle braking distance

InactiveCN113085705AReduce lossEmission reductionBraking element arrangementsTank vehiclesRoad traffic safetyVehicle brake

The invention discloses an oil tank truck capable of reducing a vehicle braking distance. The oil tank truck comprises an oil tank; an energy conversion mechanism used for collecting energy in the running process is arranged on the left side of the oil tank, and a threaded plate mechanism matched with the energy conversion mechanism and used for transmitting mechanical energy and reducing liquid shaking during emergency braking of the oil tank truck is arranged in the oil tank; the right side of the oil tank is provided with a speed reduction mechanism used for assisting the oil tank truck in forced speed reduction during emergency braking of the oil tank truck, the end face of the top of the oil tank is fixedly provided with sixty three supporting rods, and the supporting rods are provided with a bearing plate matched with the speed reduction mechanism to support the speed reduction mechanism. According to the oil tank truck capable of reducing the vehicle braking distance in the technical schemes, operation of the oil tank truck is assisted, loss of chemical raw materials in the operation process of the oil tank truck is reduced, emission of waste gas is reduced, meanwhile, the braking distance of the oil tank truck is reduced, and traffic safety is effectively guaranteed.

Owner:深圳市佳英运输有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com