High power diesel vehicle hydraulic brake inertia booster

A diesel vehicle, hydraulic braking technology, applied in the direction of brakes, brake transmission devices, control devices, etc., can solve problems such as waste of fuel, and achieve the effect of reducing the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it should not be understood as a limitation on the technical solution, and equivalent improvements on this basis all belong to the protection scope of the present invention.

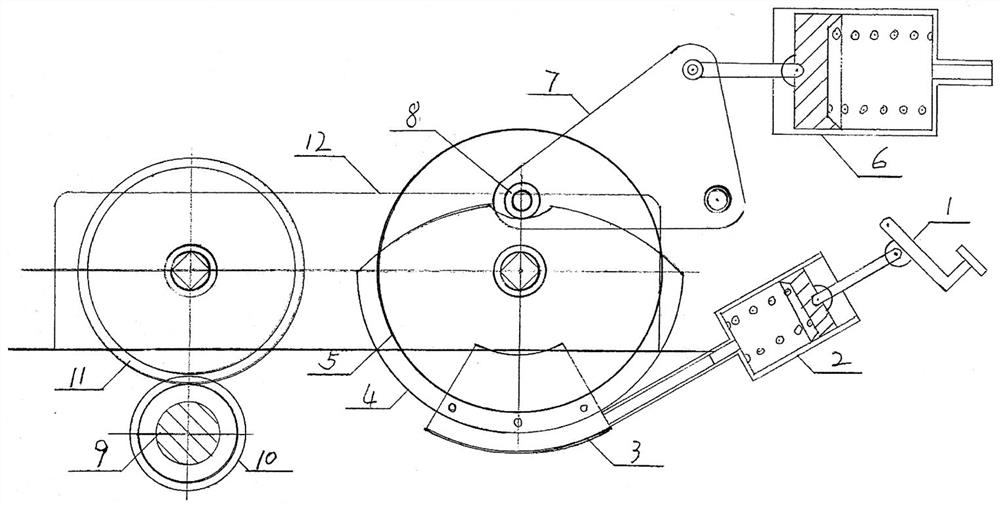

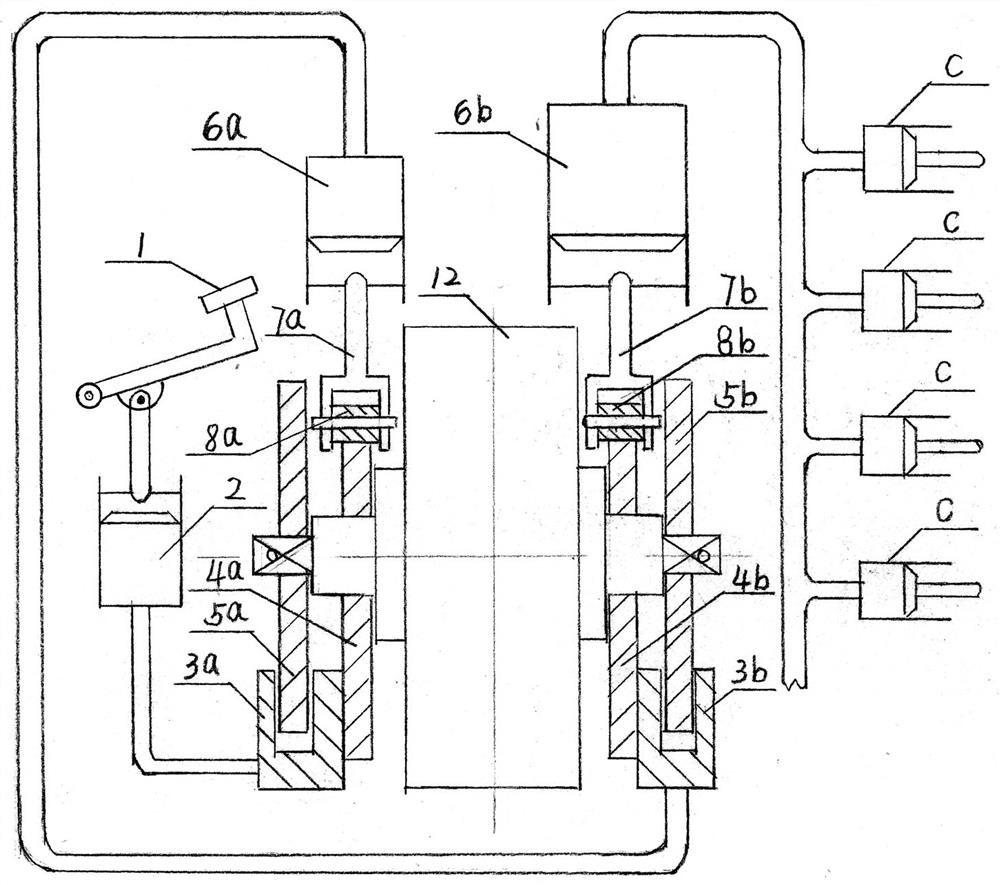

[0028] Such as figure 1 As shown, the high-power diesel vehicle hydraulic brake inertia booster includes a brake pedal 1, a brake master cylinder 2, a brake caliper 3, a cam disc 4, an inertia disc 5, a booster pump 6, a triangular plate lever 7, a roller 8, Automobile transmission shaft 9, transmission shaft gear 10 and speed reducer 12, fix a bracket to install speed reducer 12 on the upper part of the automobile rear axle, and fix a transmission shaft gear 10 in series in the universal joint that automobile transmission shaft 9 and rear axle are connected, speed reducer The reducer input gear 11 of 12 meshes with the transmission shaft gear 10 on the automobile driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com