Crane with slide rail anti-slip function

An anti-skid and crane technology, which is applied in the direction of trolley cranes, cranes, track systems, etc., can solve problems such as slide rails slipping, cranes not being able to stop immediately, and affecting the normal use of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

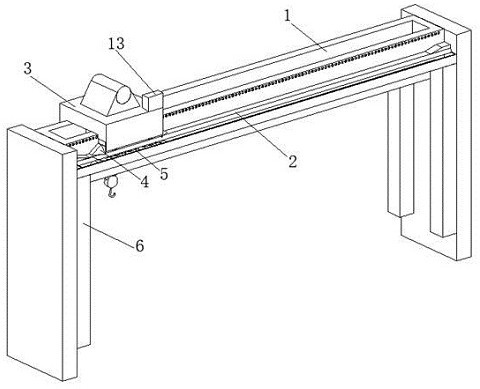

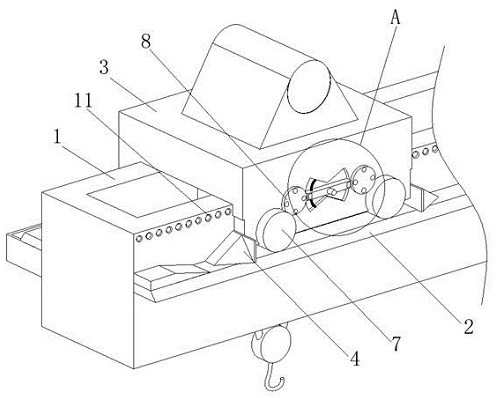

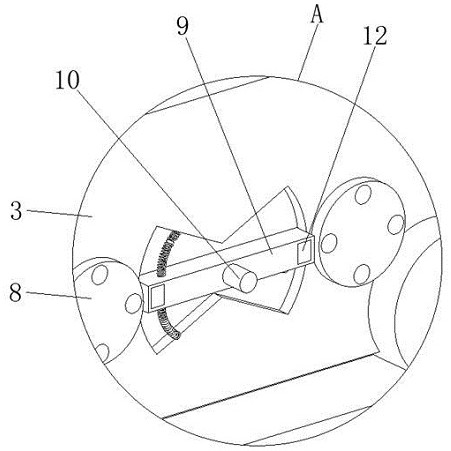

[0031] A crane with slide rail anti-skid function, such as Figure 1-Figure 8 As shown, it includes a frame body 1, the two sides of the frame body 1 are fixedly connected with slide rails 2, the top of the frame body 1 is slidably connected with a slider 3, and the front and rear parts of the slider 3 are slidably connected with a push block 4, The bottom of the slide rail 2 is provided with a collection device 5, the inner wall of the frame body 1 is provided with a discharge device 6, the inside of the slider 3 is hollowed out, and the inside of the slider 3 is connected with a roller 7, and the bottom of the roller 7 protrudes The outside of the slider 3 is in contact with the surface of the turntable 8, the inside of the slider 3 is connected with a rotating rod 9 for rotation, and a spring is arranged between the slider 3 and one end of the rotating rod 9, and the inner wall of the rotating rod 9 is fixed with a block 91, The block 91 is slidingly connected with the spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com