Friction brake based on cylinder locking

A friction type, brake technology, applied in hydraulic drum brakes, brake parts, brake actuators, etc., can solve the problems of limited braking distance, poor braking effect, safety, etc., and achieve axial braking. Good dynamic performance, compact structure, small mass and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

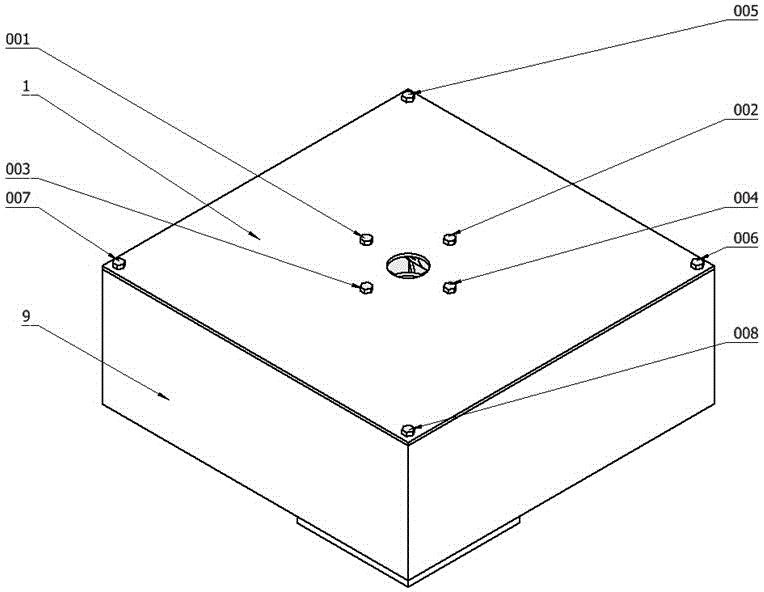

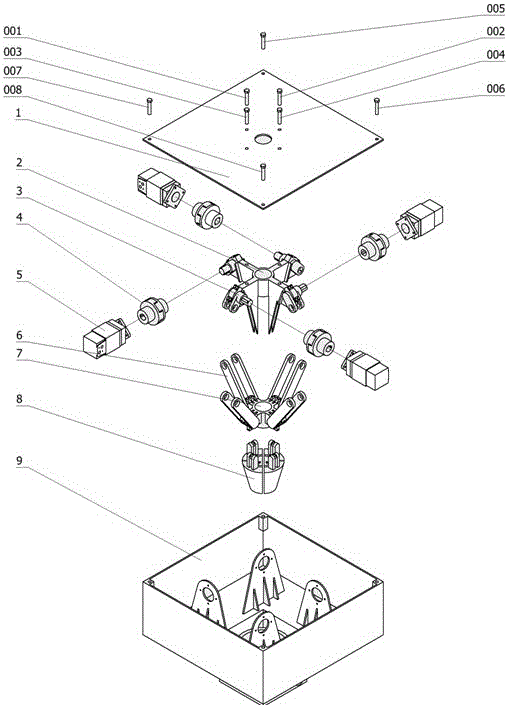

[0029] As shown in the figure, the friction brake based on cylindrical locking includes top cover 1, wedge mechanism 2, active rod 3, coupling 4, hydraulic motor 5, driven rod 6, slideway mechanism 7, and stop block 8 and base 9.

[0030] The base 9 is a cuboid structure, and the frame is formed by welding. There is an inverted conical groove in its center, and the stop block moves in the inverted conical groove to clamp or loosen the brake lever.

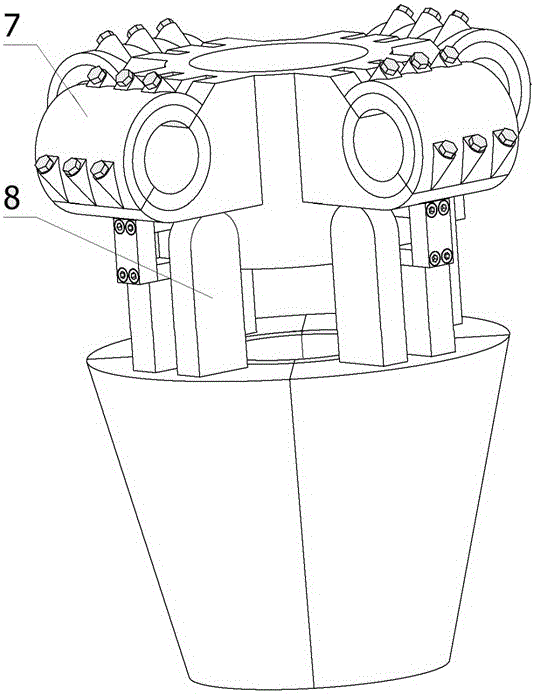

[0031] The structure of the stop block 8 is shown in FIG. 6 , six M10 socket head cap screws 803 are divided into two rows to fix the friction plate 802 on the stop block main body 801 .

[0032] Base 9 is fixed on the frame, and four stop blocks 8 are as image 3 As shown, it is assembled into the slideway of the slideway mechanism 7, and the upper and lower surfaces of the square connecting body on the upper part of the stopper body 801 are respectively in contact with the upper and lower inner surfaces of the slideway, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com