Automobile hub machining process

A processing technology and technology of automobile wheel hubs, applied in the direction of wheel hubs, rims, vehicle parts, etc., can solve the problems of thin rim wall spinning, no mold sticking, etc., and achieve the effect of reducing the weight of the whole vehicle, clear steering, and increasing cruising range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The automobile wheel processing technology in the present embodiment is basically as figure 1 As shown, it specifically includes the following steps:

[0046] S1, spoke forming: spoke 15 (such as Figure 11 shown) is formed by low-temperature and low-pressure casting process. Specifically, the aluminum ingot is smelted, refined and degassed, and then formed by using a low-pressure casting mold at a temperature of 645-660 ° C. Then, solution heat treatment, aging heat treatment and lathe Composite port (this part is prior art, not repeating it here), obtains wheel spoke 15. Specifically, in this embodiment, the low-temperature and low-pressure casting method of the spoke 15 refers to a casting casting method disclosed in the Chinese invention patent application (CN110560664A).

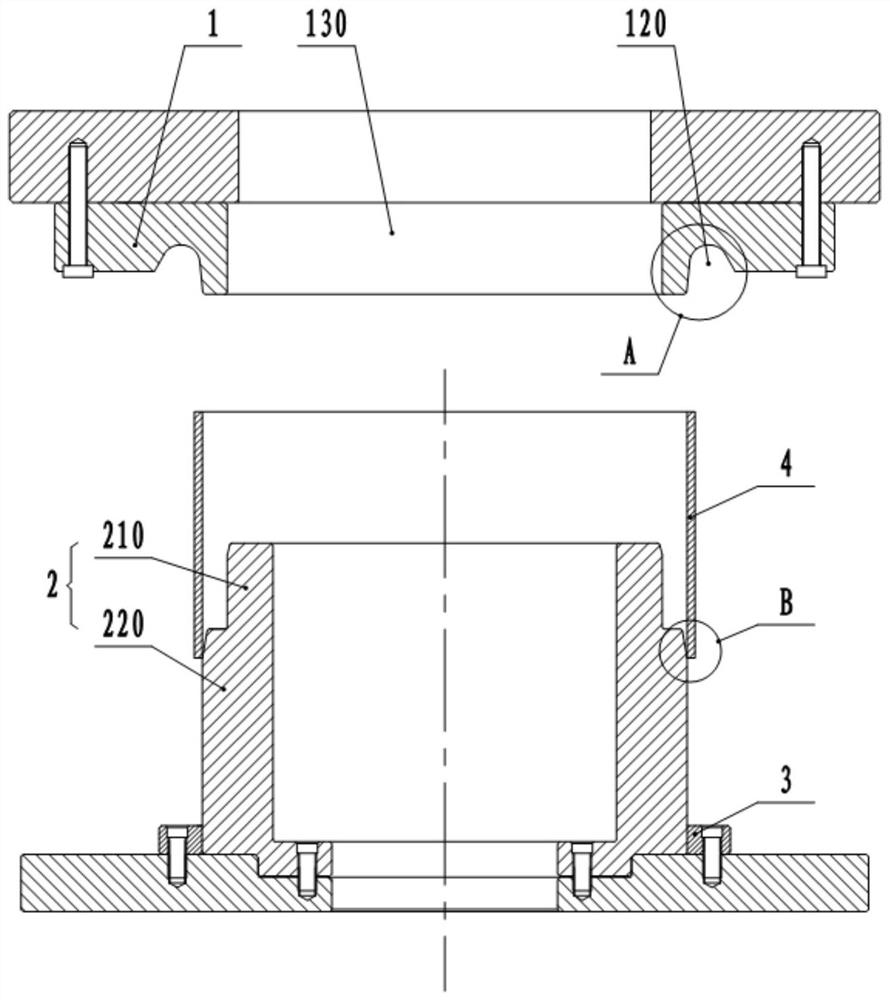

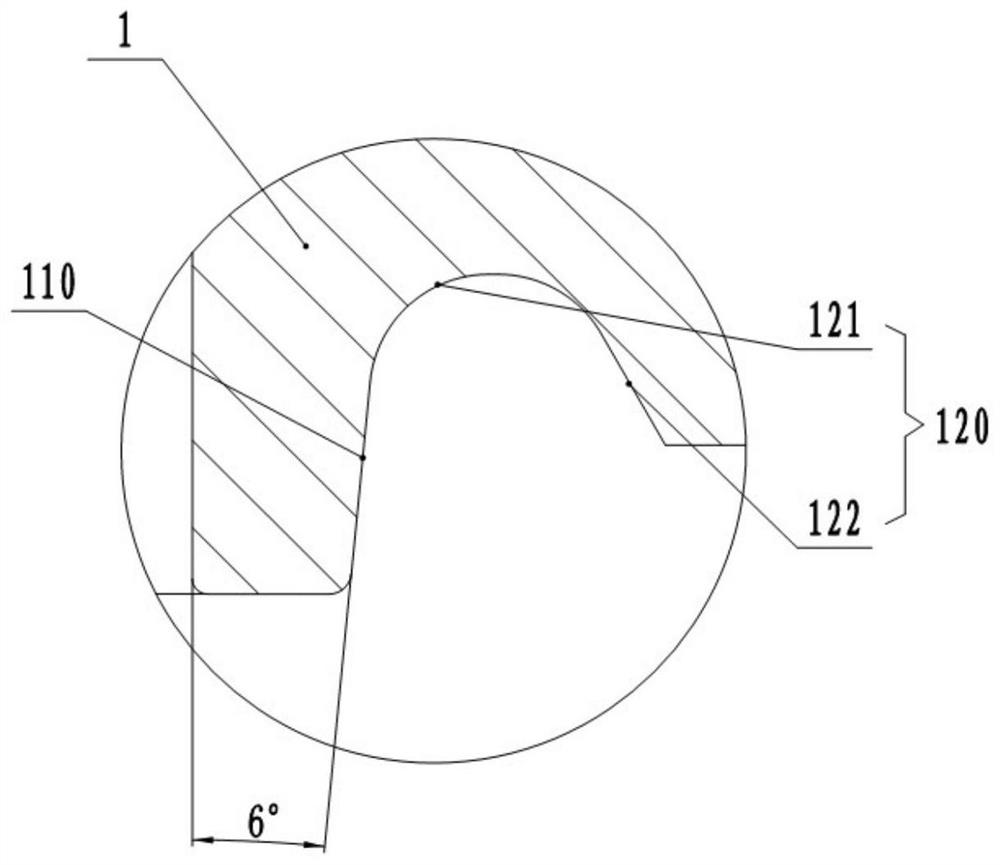

[0047] S2. Forming the rim: the aluminum plate (O-state 6061 aluminum plate, copper content 0.2-0.3%) is cut, rolled into a circle, flattened, and then welded into a cylinder 4 . In the above ...

Embodiment 2

[0070] The difference between this embodiment and Embodiment 1 is that: Figure 12 with Figure 13 As shown, in this embodiment, in step S2, in the flanging mold used in the flanging forming step, the lower end of the upper mold 1 is provided with a hanging lug 16, and the hanging lug 16 includes a vertical portion 161 and a horizontal portion 162, The vertical part 161 is connected and fixed with the upper mold 1 by bolts, and the horizontal part 162 can be offset against the curling of the cylinder 4 after flanging.

[0071] In actual use, when the cylinder 4 is flanged at the top, the crimp formed after the top flanging of the cylinder 4 is located above the horizontal portion 162 of the hanging lug 16 . When the upper mold 1 moves upwards and resets under the drive of the driving part, the curling at the top of the cylinder 4 will be hooked on the horizontal part 162 of the hanging ear 16, thereby lifting the cylinder 4 upwards, so that the cylinder 4 is disengaged. The ...

Embodiment 3

[0072] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the preload of the elastic member 10 is 300N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com