Permanent magnet eddy current linear braking system for elevator testing

A permanent magnet eddy current and braking system technology, applied in elevators, hoisting devices, transportation and packaging, etc., can solve problems such as unsuitable long-distance braking, complex structure, and braking force that cannot be changed in time, so as to prolong the service life , reduce wear and save braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

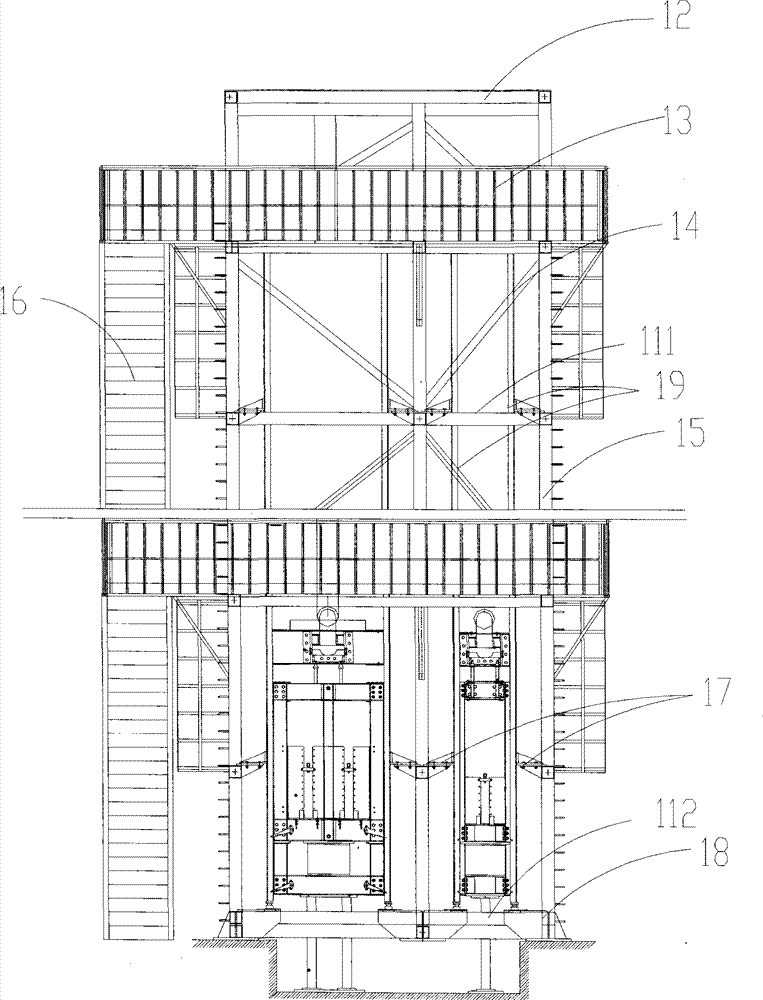

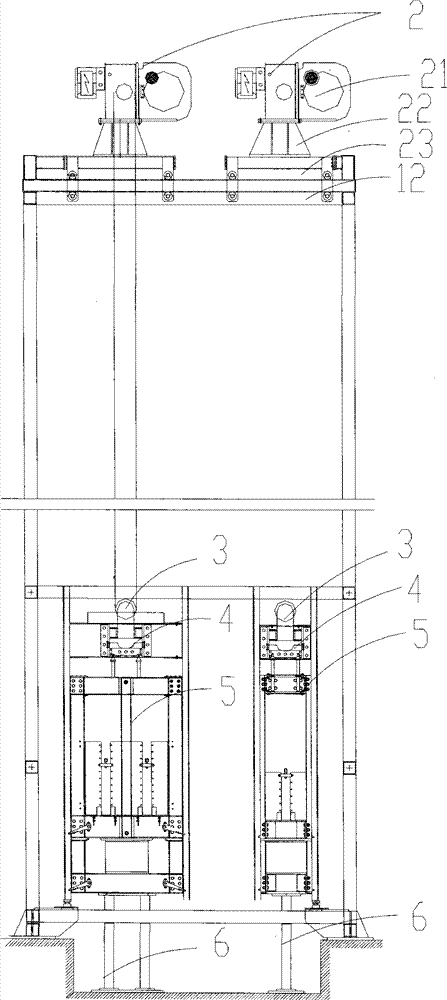

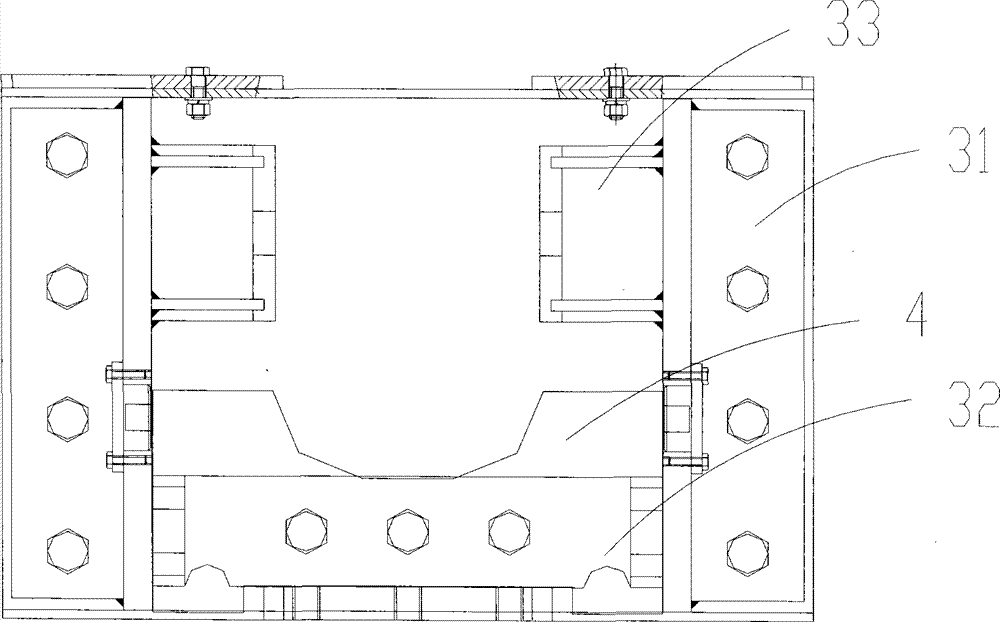

[0048] The elevator safety test system of the present invention has an uplink tower and a downlink tower frame, wherein the downlink tower frame tests the elevator downlink safety device, the uplink tower frame tests the elevator uplink overspeed protection device and speed limiter, and tests various devices A measurement and control system is shared; the downward safety device includes a downward safety gear and a buffer device, and the upward overspeed protection device includes a traction machine, a rope clamp and an upward safety gear. The tests of each elevator safety device are now described separately.

[0049]The basic component of the descending test system of the present invention is a descending tower, please refer to figure 1 As shown, it is a schematic diagram of the main structure of the down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com