Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve system adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

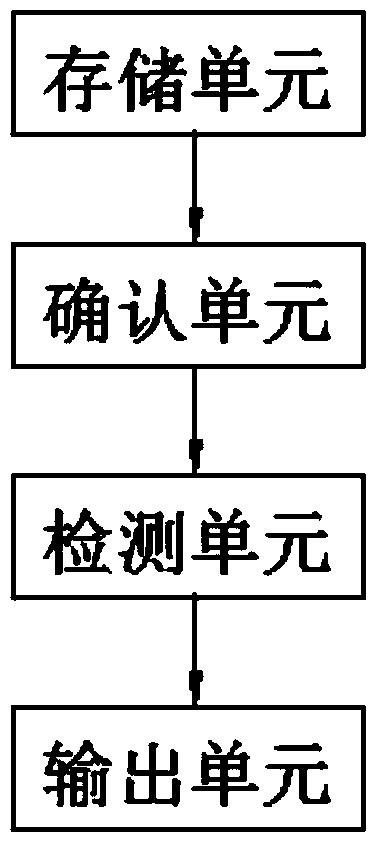

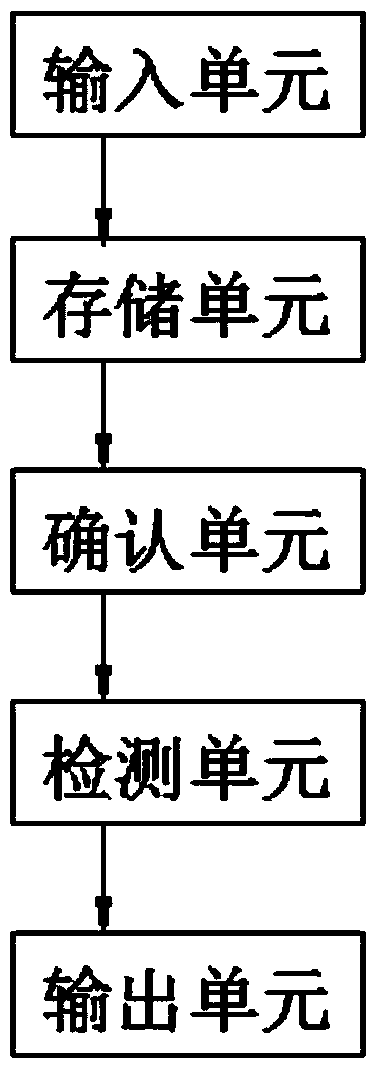

Motor encoder positioning method and system

InactiveCN103825527ASimplifies system assemblyImprove system adaptabilityMotor parameters estimation/adaptationNumerical controlComputer sciencePositioning system

The invention discloses a motor encoder positioning method and a motor encoder positioning system. The method comprises the steps of locking the position of a motor rotor according to a preset first electrical angle value and obtaining a first encoder numerical value of an absolute type encoder, wherein the first encoder numerical value is set as a first position of the motor rotor when the first electrical angle value is reached; confirming that a motor is in a normal operation state; starting the normally operating motor to obtain a fourth encoder numerical value of the absolute type encoder corresponding to the running position of the motor rotor after the motor rotor rotates; and obtaining the real-time running position of the motor rotor according to the fourth encoder numerical value and the first encoder numerical value. According to the method, by obtaining the first encoder numerical value of the absolute type encoder and then obtaining the deviation value between the obtained fourth encoder numerical value and first encoder numerical value, the running position value of the motor rotor can be confirmed, so that the effect of fixing the running position of the motor rotor is achieved; the system assembly is simplified and the dead center position of the motor rotor does not need to be adjusted manually.

Owner:DONGGUAN ROBSTEP ROBOT

Film-spraying waterproof material, and preparation and application methods thereof

InactiveCN104710849AGood inhibition effectImprove system adaptabilityCoatingsEthylenediamineEthylenediamine tetraacetate

The invention discloses a film-spraying waterproof material which is prepared from the following raw materials in parts by weight: 100 parts of magnesium acrylate monomer solution, 0.01-0.1 part of tetrasodium ethylenediamine tetraacetate, 0.01-0.1 part of copper acetate, 2-20 parts of silica white and 2-20 parts of calcium carbonate. The invention also discloses a preparation method of the film-spraying waterproof material, which comprises the following steps: adding the tetrasodium ethylenediamine tetraacetate and copper acetate into the magnesium acrylate monomer solution, uniformly stirring and mixing, adding the silica white and calcium carbonate, and stirring with a high-speed dispersion machine to obtain the film-spraying waterproof material. The invention also discloses an application method of the film-spraying waterproof material. The film-spraying waterproof material disclosed by the invention solves the problem that the original film-spraying waterproof material must be stored and transported in the refrigeratory state under high-temperature conditions, saves the cost, widens the application range, and lays solid foundation for the development of the film-spraying waterproof material.

Owner:成都市嘉洲新型防水材料有限公司

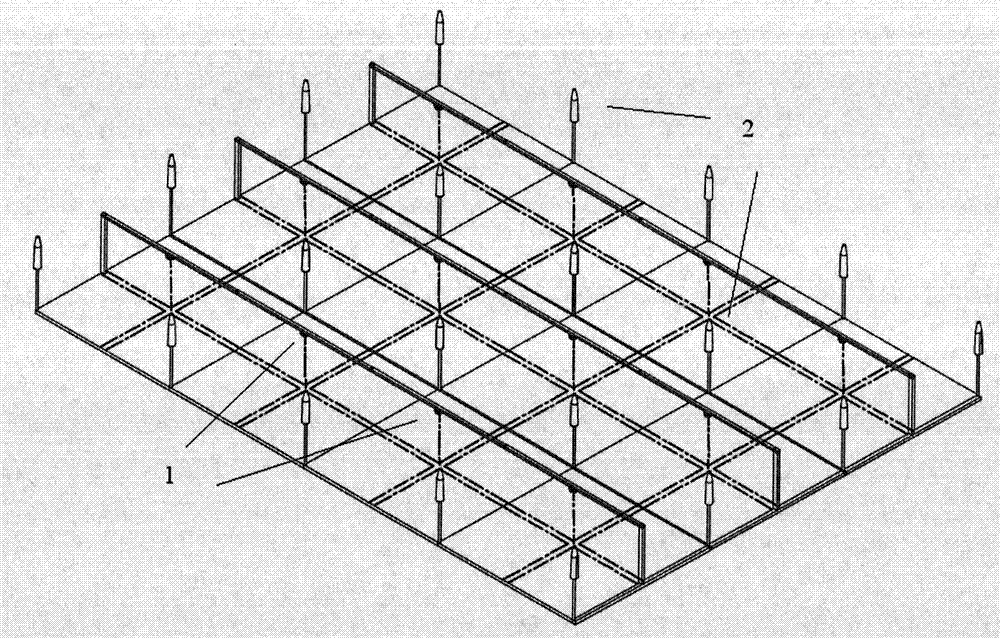

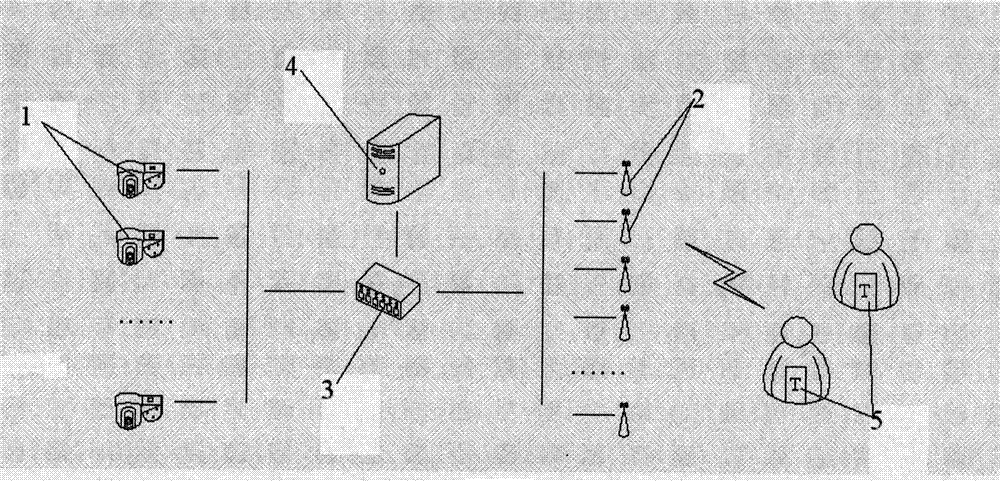

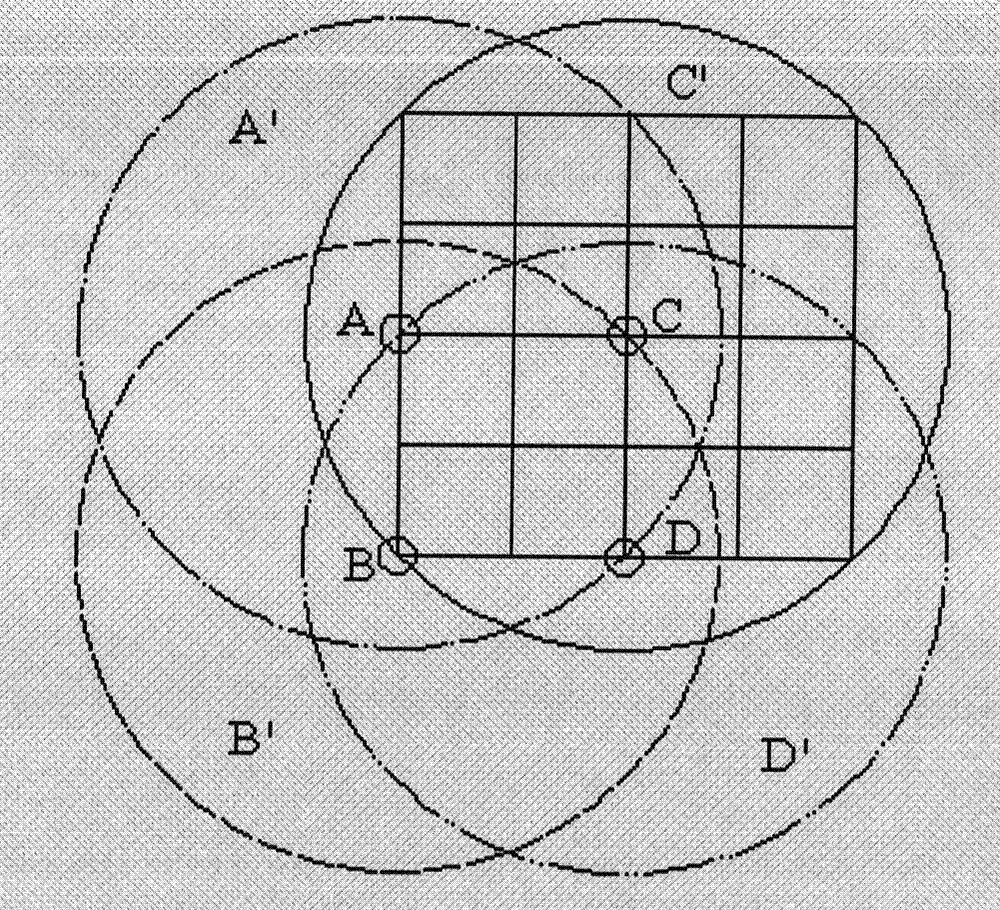

Intelligent tracking and monitoring system based on RFID label signal intensity

InactiveCN104766106AEasy to implementImprove system adaptabilityCo-operative working arrangementsClosed circuit television systemsNetwork cameraReal-time computing

The invention discloses an intelligent tracking and monitoring system based on RFID label signal intensity. The intelligent tracking and monitoring system based on RFID label signal intensity is characterized by comprising a tracking and monitoring area, an active RFID label worn by a person or an object, tracking network cameras, RFID readers, a network interchanger and a PC server, wherein the tracking network cameras and the RFID readers are distributed above the tracking and monitoring area in a grid shape, and the rectangular area defined by the four RFID readers on the outermost portion forms the tracking and monitoring area. The intelligent tracking and monitoring system based on RFID label signal intensity analyzes the movement trend by collecting the changes of the signal intensity of the 2.4GHz active RFID label worn by the person or the object and correspondingly controls a camera cloud deck, thereby accurately realizing tracking and monitoring.

Owner:桑田智能技术(上海)有限公司

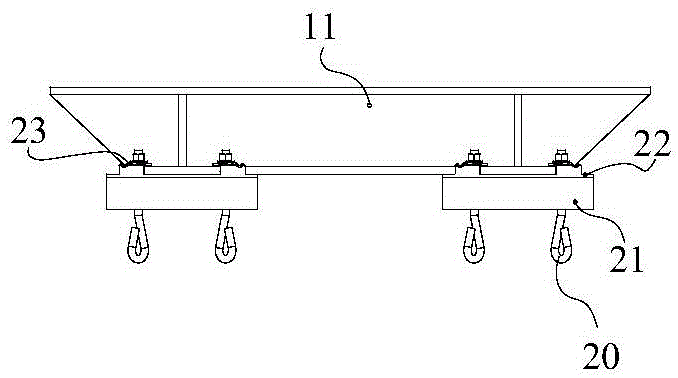

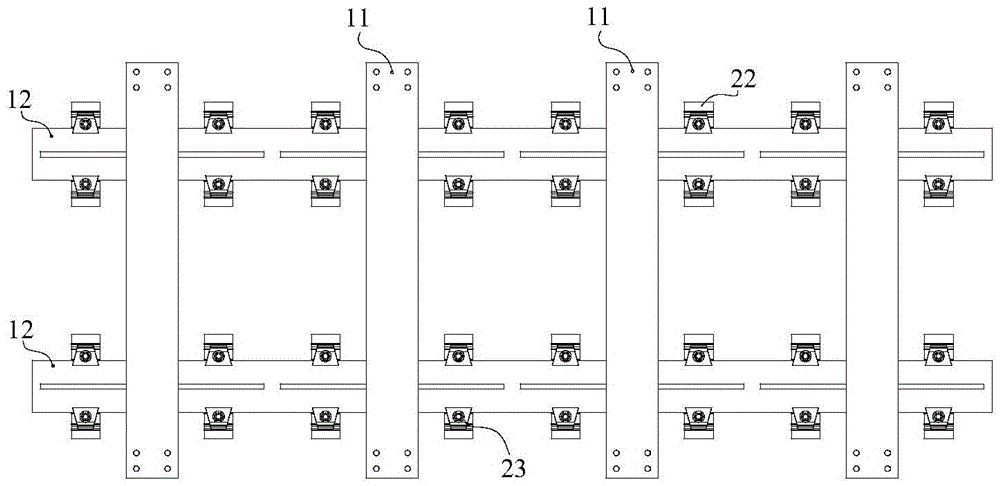

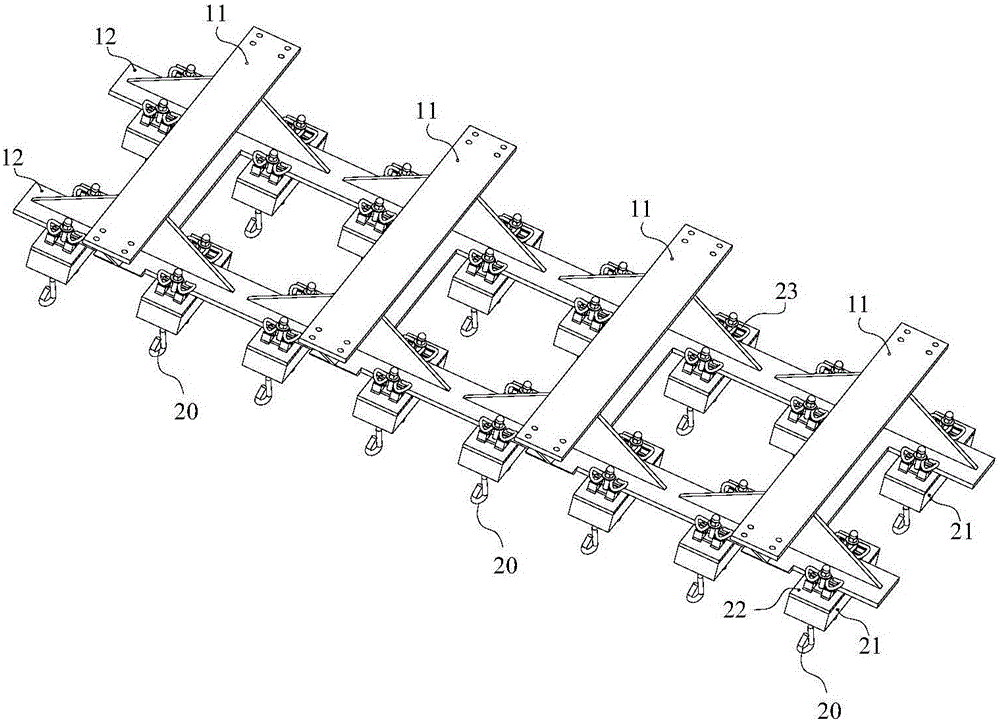

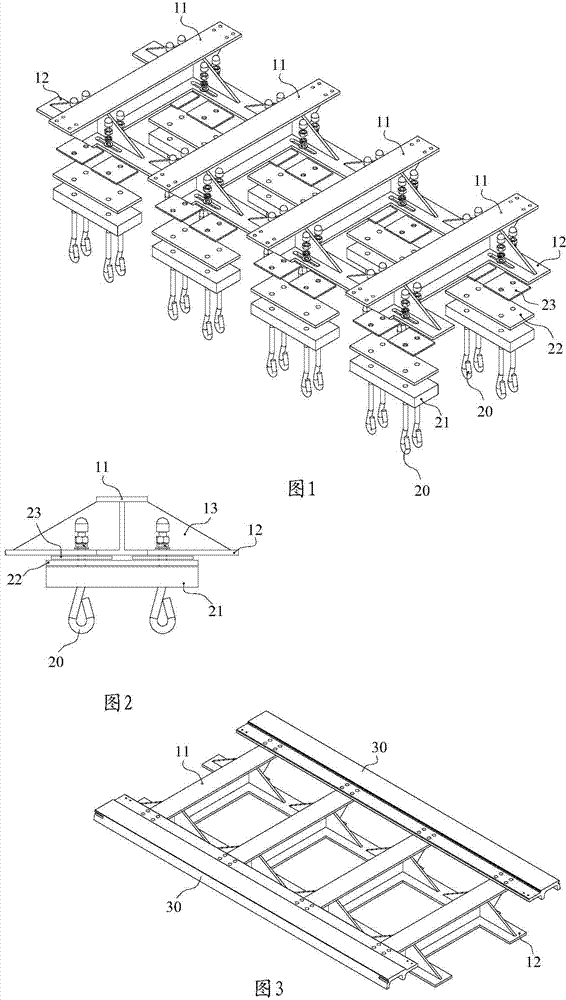

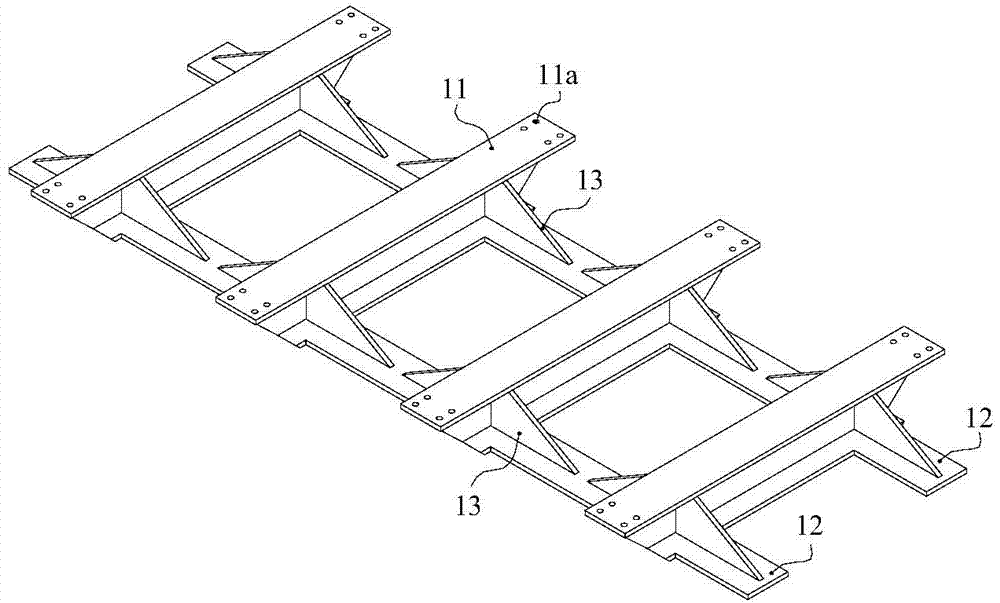

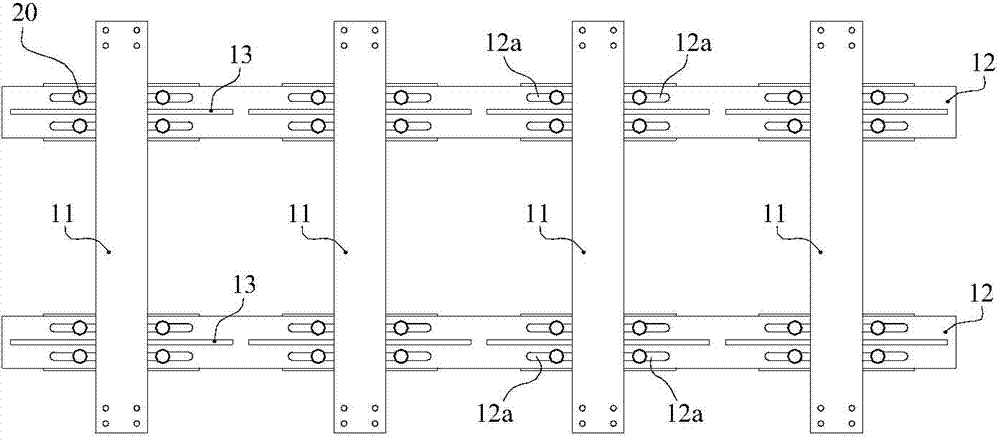

Track telescopic adjustment structure for medium and low speed magnetic suspension transportation system

ActiveCN103938544AImprove laying efficiencyImprove the state of stressBridge structural detailsLow speedTemperature difference

A track telescopic adjustment structure for a medium and low speed magnetic suspension transportation system effectively solves the driving problem caused by temperature difference telescopic deformation of a long-span bridge. The track telescopic adjustment structure comprises a rib plate type track skeleton, under-rail supporting vibration reduction bodies, and foundation bolt assemblies. The body of the rib plate track skeleton is composed of sleeper units and two longitudinal connecting plates, wherein the sleeper units are arranged in the longitudinal direction at intervals and are fixedly connected into a whole through the two longitudinal connecting plates which are transversely arranged in a spaced mode, rib plates are welded between all the sleeper units and the longitudinal connecting plates, and long groove holes extending in the longitudinal direction are formed in the longitudinal connecting plates at intervals in the longitudinal direction and the transverse direction. The under-track supporting vibration reduction bodies are arranged between the bottom face of the rib plate type skeleton and the surface of a bridge body of the bridge. The lower portions of the foundation bolt assemblies are embedded in the bridge body of the bridge, and the upper portions of the foundation bolt assemblies penetrate through the under-track supporting vibration reduction bodies and the long groove holes.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

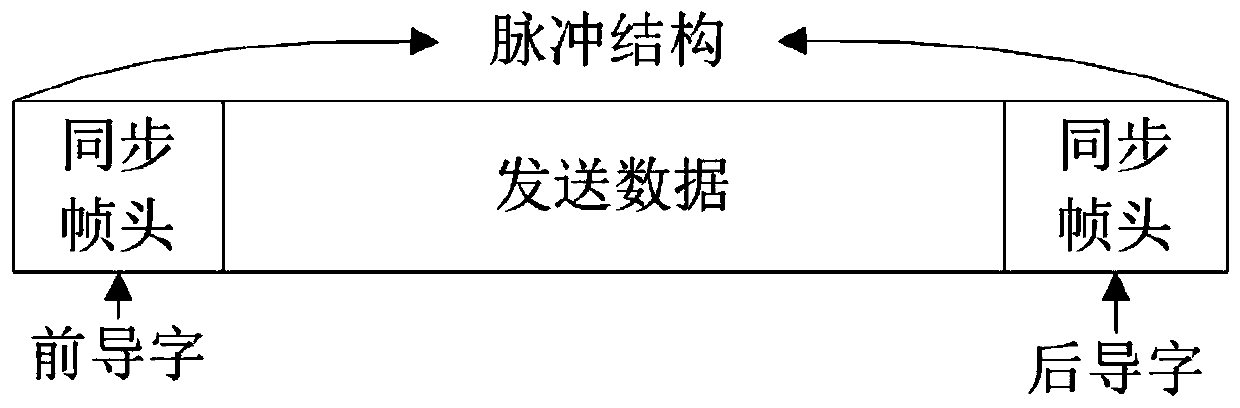

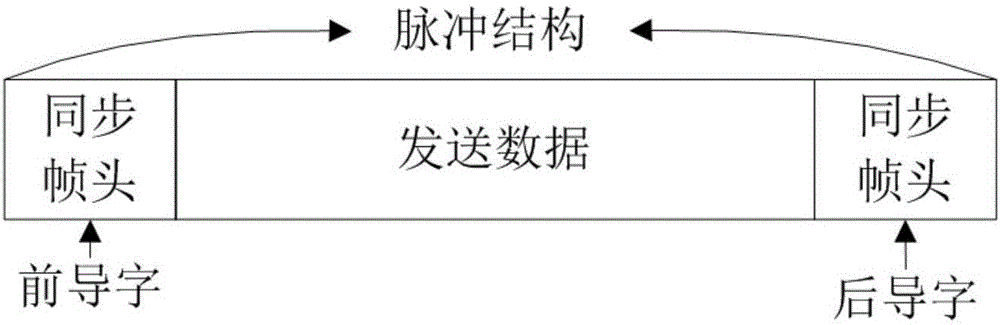

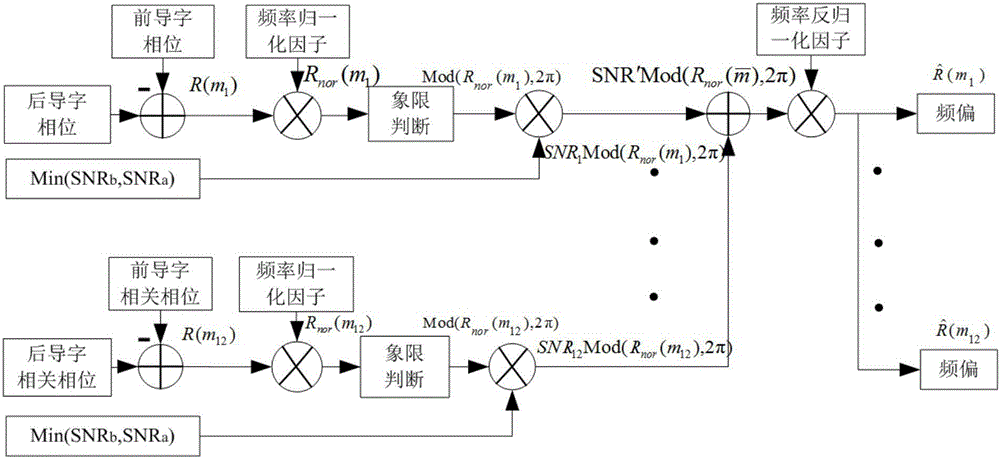

Frequency offset estimation and compensation method based on broadband frequency hopping system

ActiveCN106656454AFlexible designStrong system adaptabilityModulated-carrier systemsSynchronisation signal speed/phase controlSignal-to-noise ratio (imaging)Broadband

The invention provides a frequency offset estimation and compensation method based on broadband frequency hopping system. The method comprises the following steps: dividing each to-be-transmitted message into a plurality of pulses with the two ends of each pulse added by a synchronous frame header consisting of known pseudo-random sequences; correlating the front end and the back end of the received synchronous frame header with the local PN codes respectively to obtain the frequency offset estimation values; normalizing the frequency offset estimation values of different frequency points; utilizing the signal-to-noise ratio estimation information as weighted values for weighted sums so as to obtain relatively accurate frequency offset estimation values; then, conducting anti-normalization followed by the compensation for the different frequency points so as to obtain the phase offset estimation value of each pulse; conducting phase offset compensation; and finally restoring the received data and conducting coherent demodulation. The method proposed in the invention can estimate and compensate the frequency offset in a high speed wide frequency hopping system, and can provide good performances especially in a complex electromagnetic environment.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

Method of detecting apovincamine acid and vincamine acid in vinpocetine simultaneously

InactiveCN110455944AEasy detectionEasy to separateComponent separationChromatographic separationPhosphate

The invention provides a method of detecting apovincamine acid and vincamine acid in vinpocetine simultaneously. The method comprises steps of (1) preparing a test solution by using a vinpocetine rawmaterial or vinpocetine injection; (2) diluting the test solution by 1000 times to be used as a control solution; (3) performing chromatographic separation on the test solution and the control solution by using high-performance liquid chromatography, and recording a chromatograph, wherein chromatographic conditions are as follows: detection wavelength is 262nm-266nm, column temperature is 25DEG C-35DEG C, a mobile phase A is a phosphate buffer solution, a mobile phase B is methanol, and eluting flow rate is 0.8-1.5ml / min; and (4) calculating contents of apovincamine acid and vincamine acid inthe test solution according to a self-control method of a principle component with a calibration factor. Peaks of the vincamine acid and apovincamine acid and the peak of vinpocetine can be well separated. The method can highly adapt to a system, and has low detection limit and high precision.

Owner:武汉华龙生物制药有限公司

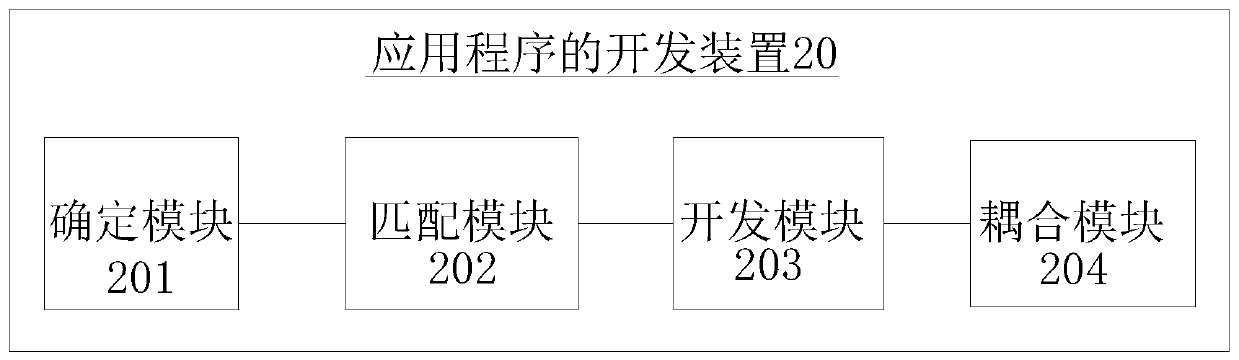

Application program development method and device and electronic equipment

ActiveCN111290737AImprove system adaptabilityReduce development difficultySoftware designSoftware engineeringApplication procedure

Embodiments of the invention provide an application program development method and device, and electronic equipment, and belong to the technical field of computer applications. The method comprises the steps of determining an application type of each to-be-developed service module in an application program; matching a development scheme corresponding to the application type for each service module, and the development scheme being any one of a native development scheme, a WebView development scheme and a Flutter development scheme; developing each service module by utilizing the development scheme matched with each service module; and coupling all the service modules to obtain the application program. Through the processing scheme disclosed by the invention, a hybrid development scheme fordifferent service modules in the application program is provided, the system adaptability of the service modules is improved, the development difficulty and time consumption are reduced, and the development and maintenance process of the application program is optimized.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

A kind of spray film waterproof material and its preparation and application method

InactiveCN104710849BGood inhibition effectImprove system adaptabilityCoatingsEthylenediamineEthylenediamine tetraacetate

The invention discloses a film-spraying waterproof material which is prepared from the following raw materials in parts by weight: 100 parts of magnesium acrylate monomer solution, 0.01-0.1 part of tetrasodium ethylenediamine tetraacetate, 0.01-0.1 part of copper acetate, 2-20 parts of silica white and 2-20 parts of calcium carbonate. The invention also discloses a preparation method of the film-spraying waterproof material, which comprises the following steps: adding the tetrasodium ethylenediamine tetraacetate and copper acetate into the magnesium acrylate monomer solution, uniformly stirring and mixing, adding the silica white and calcium carbonate, and stirring with a high-speed dispersion machine to obtain the film-spraying waterproof material. The invention also discloses an application method of the film-spraying waterproof material. The film-spraying waterproof material disclosed by the invention solves the problem that the original film-spraying waterproof material must be stored and transported in the refrigeratory state under high-temperature conditions, saves the cost, widens the application range, and lays solid foundation for the development of the film-spraying waterproof material.

Owner:成都市嘉洲新型防水材料有限公司

Method for detecting sorafenib-tosylate-related substances

The invention relates to the field of analytical chemistry, and particularly discloses a method for detecting sorafenib-tosylate-related substances. The detecting method includes the steps that a to-be-tested sorafenib-tosylate product is taken to prepare a test solution, and the test solution is diluted by one hundred times to serve as a contrast solution; then a pH3.0 phosphate buffer solution (1.36 g of monopotassium phosphate is taken, dissolved with water and diluted to 1000 ml, and the pH value is adjusted to be 3.0 with phosphoric acid) serves as a mobile phase A, acetonitrile-ethanol (60:40) serves as a mobile phase B, and gradient eluting is carried out according to the following table, wherein the detection wavelength is 250 nm, and the column temperature is 35 DEG C; HPLC detection is carried out, and the content of the related substances is measured according to the correction-factor-added main-constituent self-contrast method. According to the method, the acetonitrile-ethanol phosphate-buffer-solution gradient elution system is adopted, the chromatographic peak of sorafenib tosylate can have the higher separation degree than that of other related substances and high peak-pattern symmetry, the related substances can be detected, and high system suitability is achieved; meanwhile, incomparable advantages are shown in the specificity, the quantitation limit, the detection limit, the linear range and the repeatability, and high precise is achieved.

Owner:HEFEI HUAFANG PHARMA SCI & TECH

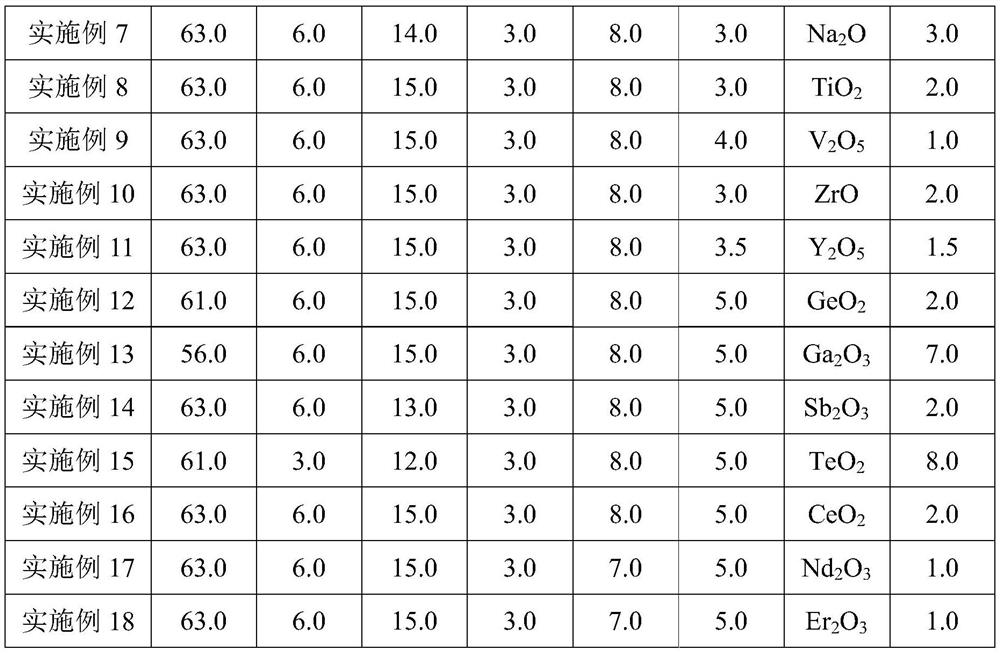

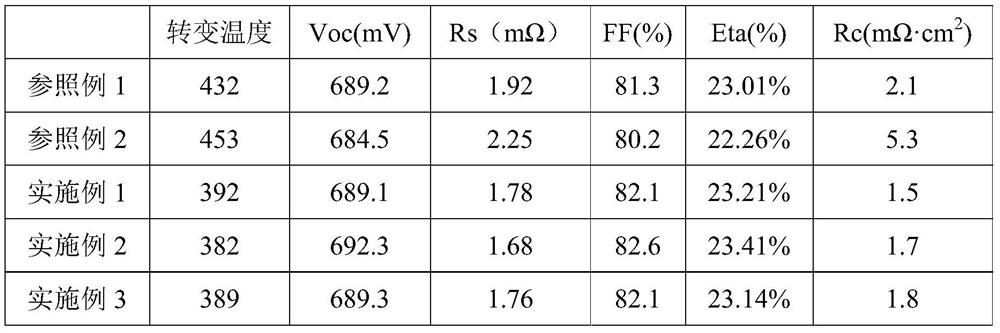

Glass powder suitable for crystalline silicon p + layer contact and used for thick film silver paste and preparation method of glass powder

PendingCN114380507AReduce contact resistanceShorten speedSemiconductor devicesCrystallographySilver paste

The invention relates to C03C, in particular to glass powder suitable for crystalline silicon p + layer contact and used for thick film silver paste and a preparation method of the glass powder. The preparation raw materials of the glass powder comprise a metal oxide and a non-metal oxide. According to the glass powder for the thick film silver paste suitable for crystalline silicon p + layer contact, the glass powder is introduced into the thick film silver paste, so that the metal-semiconductor contact resistance and the metal induced recombination speed can be reduced. By controlling the particle size and the use amount of the glass powder, rapid formation of silver microcrystals in silver paste sintering can be promoted, corrosion to a doping layer and formation of aluminum pinning are reduced, and the open-circuit voltage and the filling factor of the cell are improved. The glass powder provided by the invention can be used in TOPCon cell silver-aluminum paste, optimizes the metal-semiconductor contact performance of the silver-aluminum paste and a p + layer of a crystalline silicon solar cell, reduces metal induced recombination, improves the open-circuit voltage of the solar cell, and improves the photoelectric conversion efficiency of an N-type or P-type TOPCon crystalline silicon solar cell.

Owner:GUANGDONG NANHAI ETETB TECH CO LTD +1

Method for detecting residual solvents in pantoprazole sodium sesquihydrate

PendingCN111812234AStrong specificityImprove system adaptabilityComponent separationDichloromethaneChloromethane

The invention provides a method for detecting residual solvents in pantoprazole sodium sesquihydrate. The method comprises the following steps: (1) preparing a test solution which comprises pantoprazole sodium sesquihydrate and a solvent, wherein the solvent comprises dimethyl sulfoxide and / or water; (2) preparing a reference substance solution, wherein the reference substance solution comprises methanol, dichloromethane, ethanol, acetonitrile and benzene, wherein a solvent is the same as the solvent in step (1); and (3) performing headspace gas chromatography test by using a medium-polarity capillary column and adopting temperature programming, wherein the sequence of the step (1) and step (2) is not sequential. The method can be used for simultaneously detecting the residual quantity ofmethanol, dichloromethane, ethanol, acetonitrile and benzene in the pantoprazole sodium sesquihydrate. The method has good specificity, system adaptability, extremely low detection limit and quantification limit, good linearity, good accuracy and durability.

Owner:武汉九州钰民医药科技有限公司

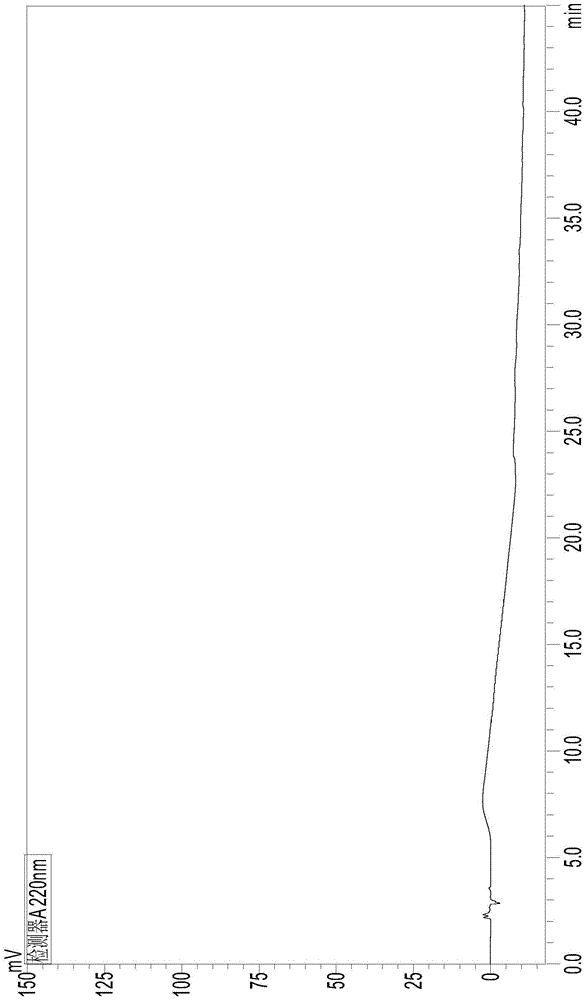

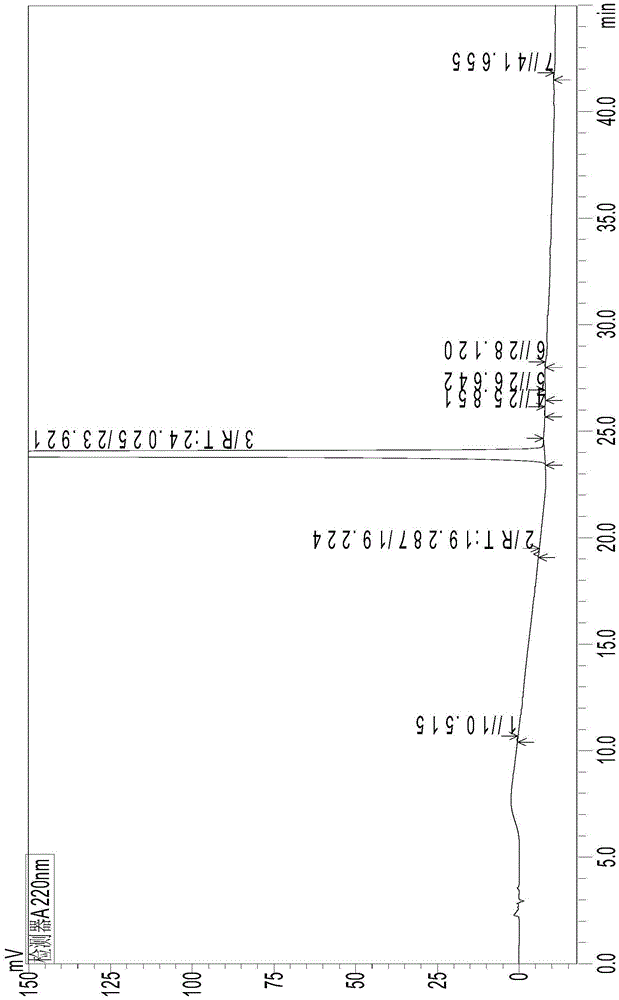

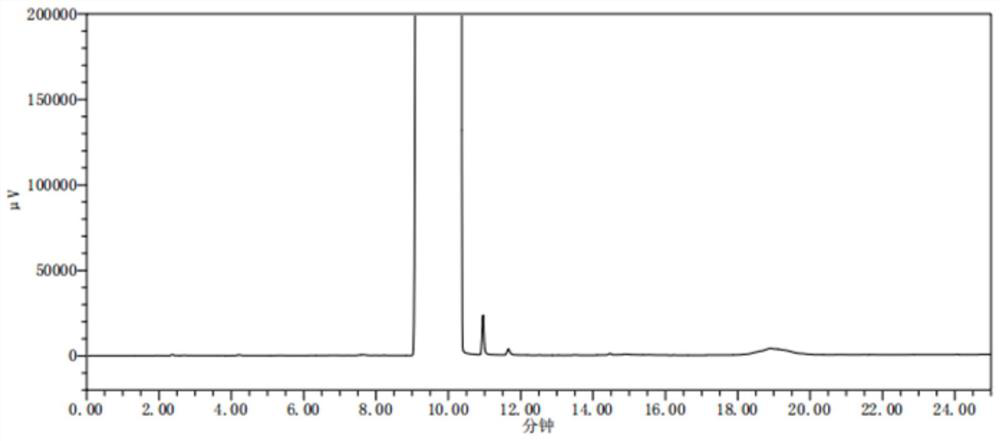

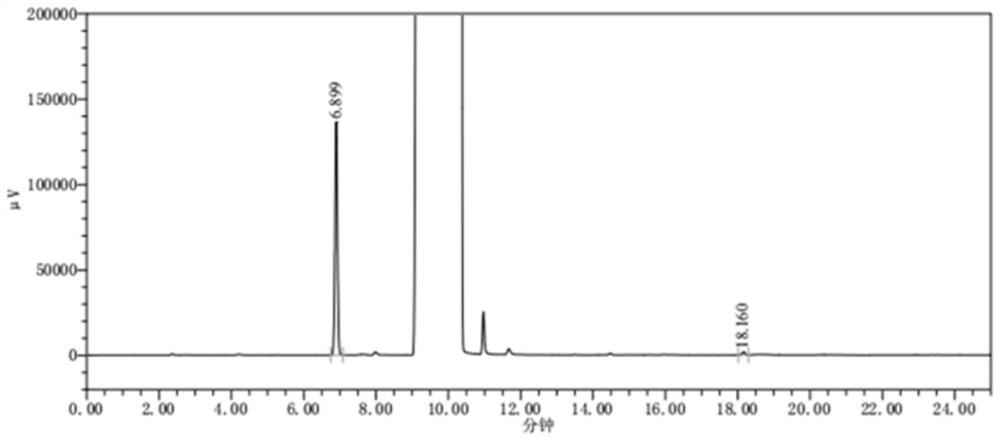

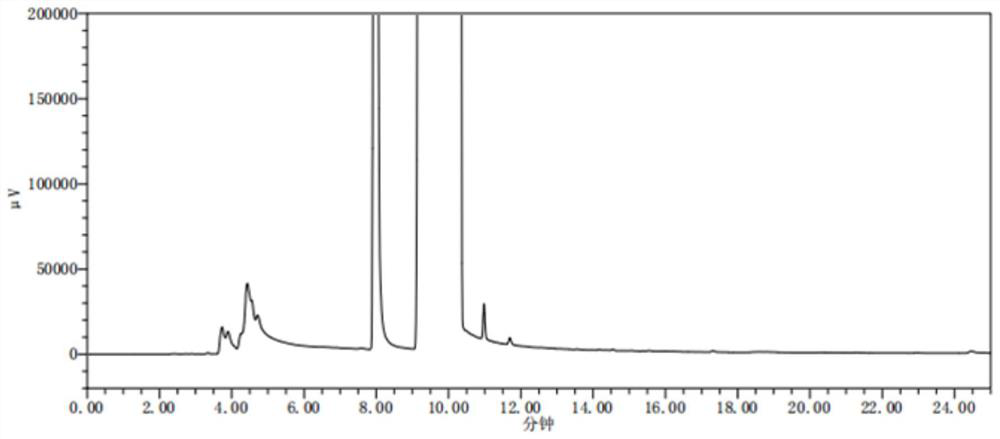

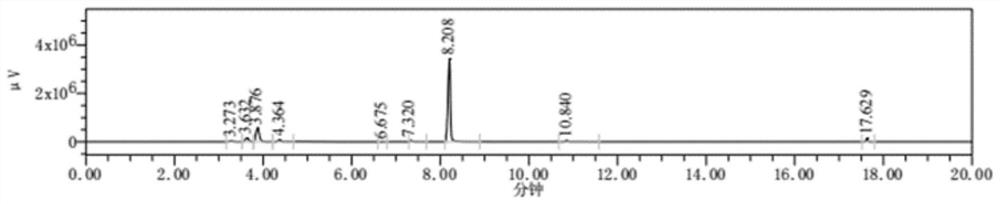

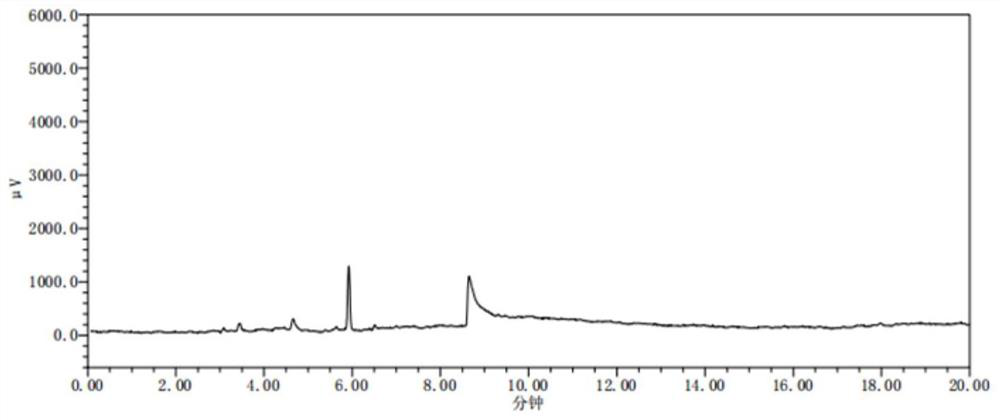

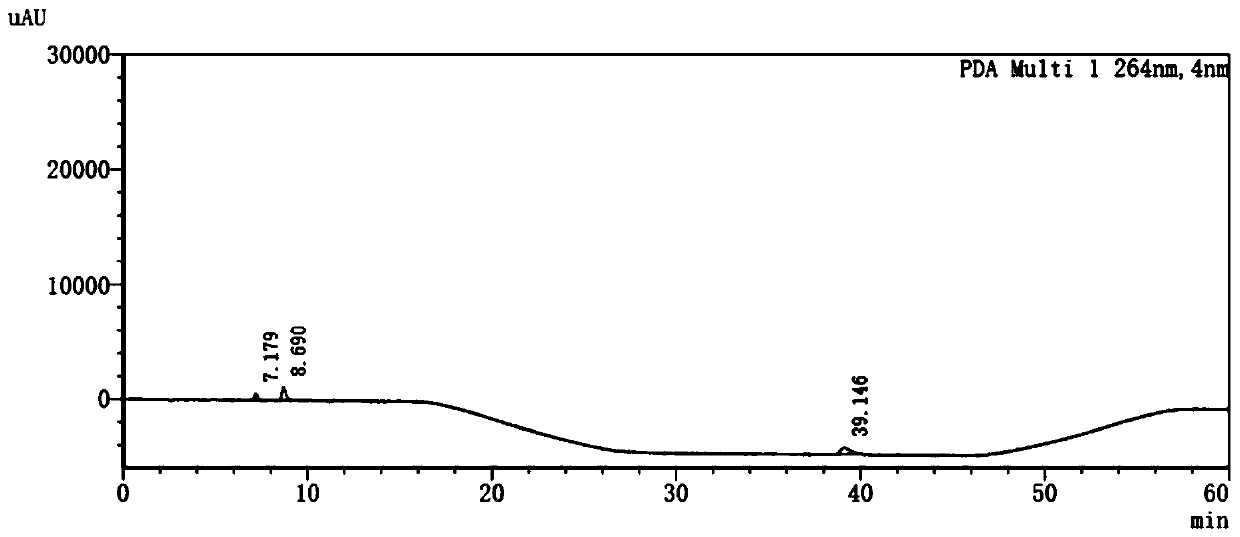

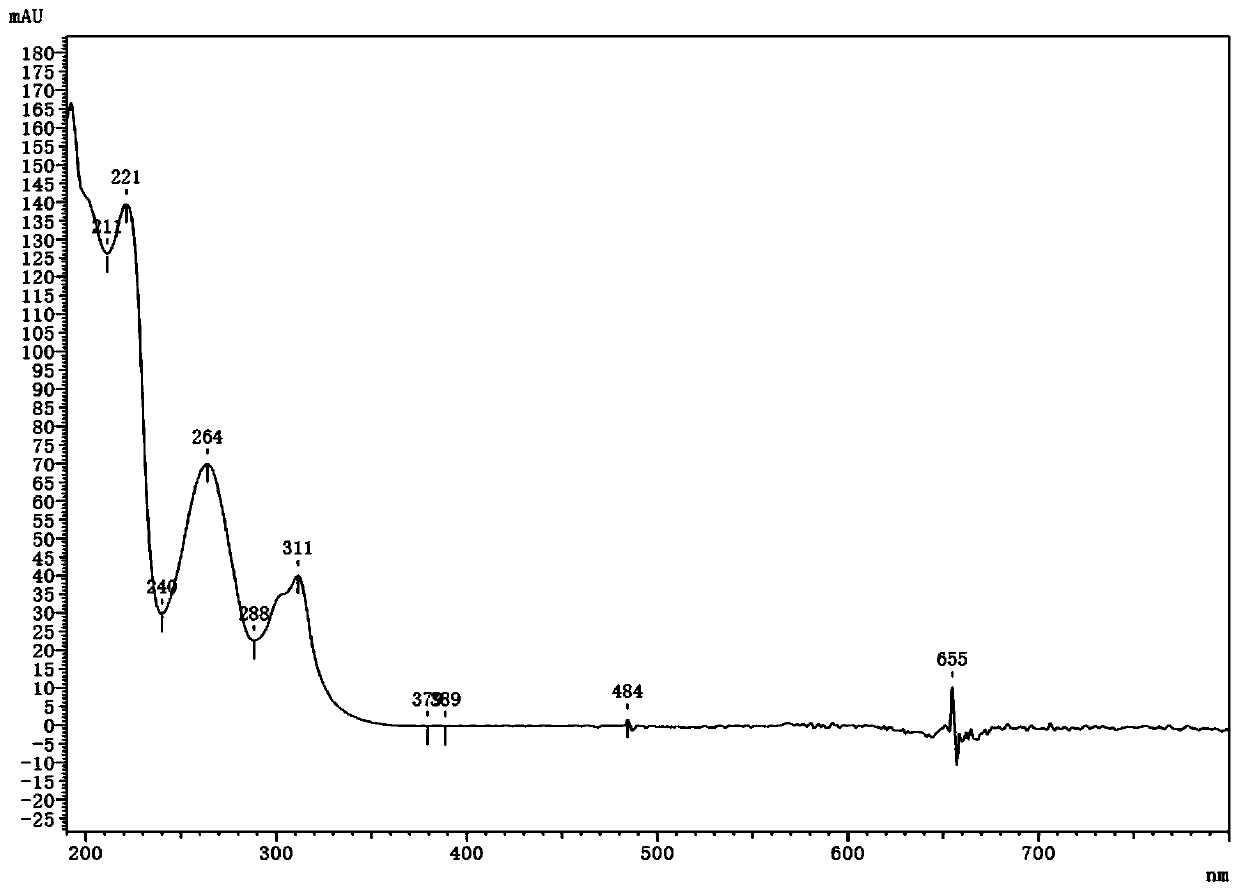

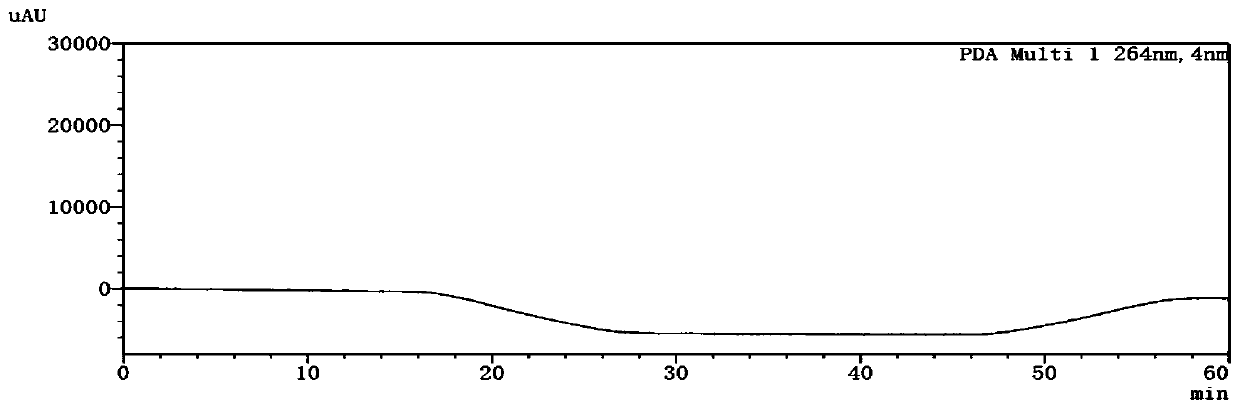

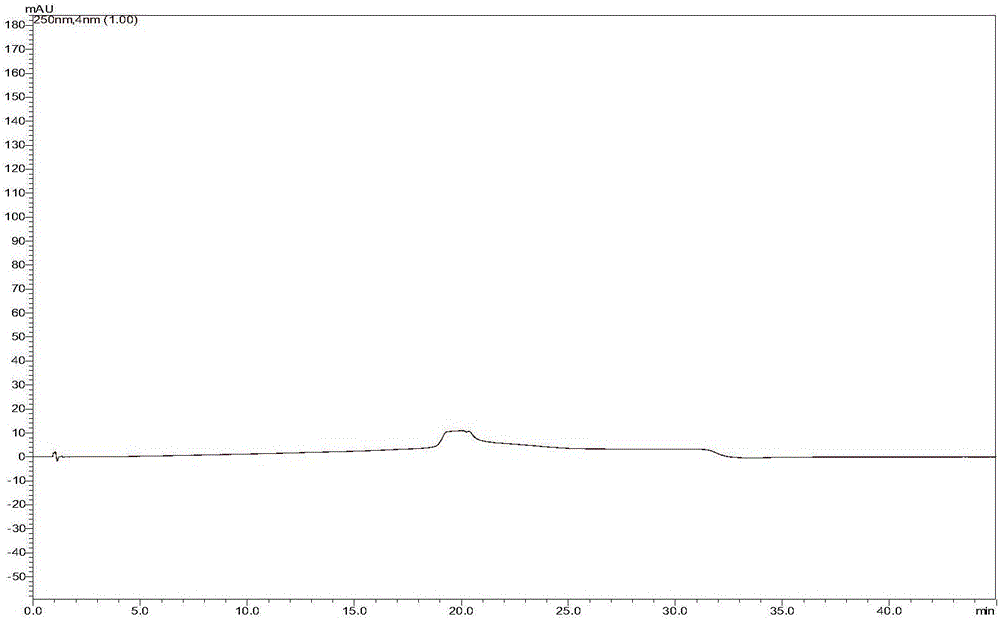

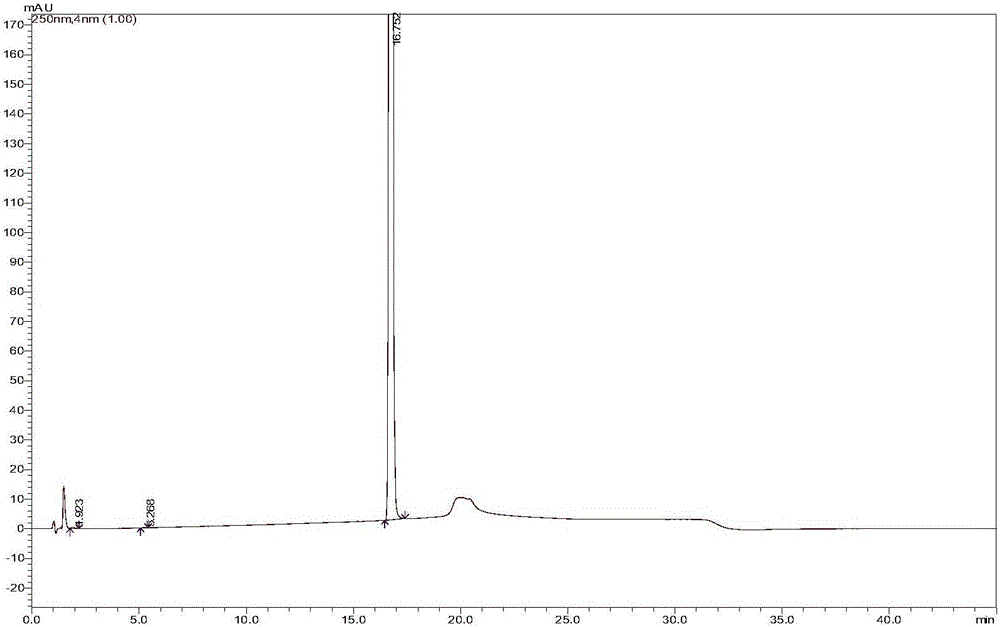

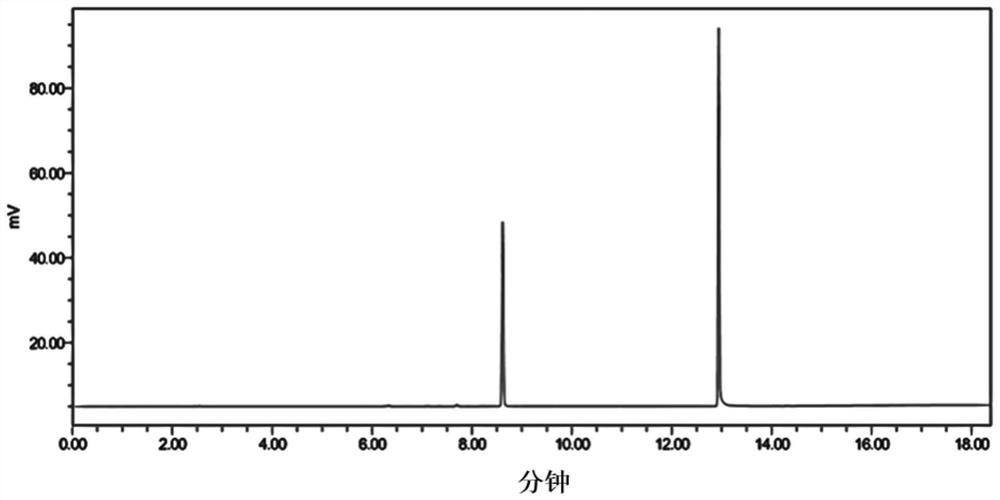

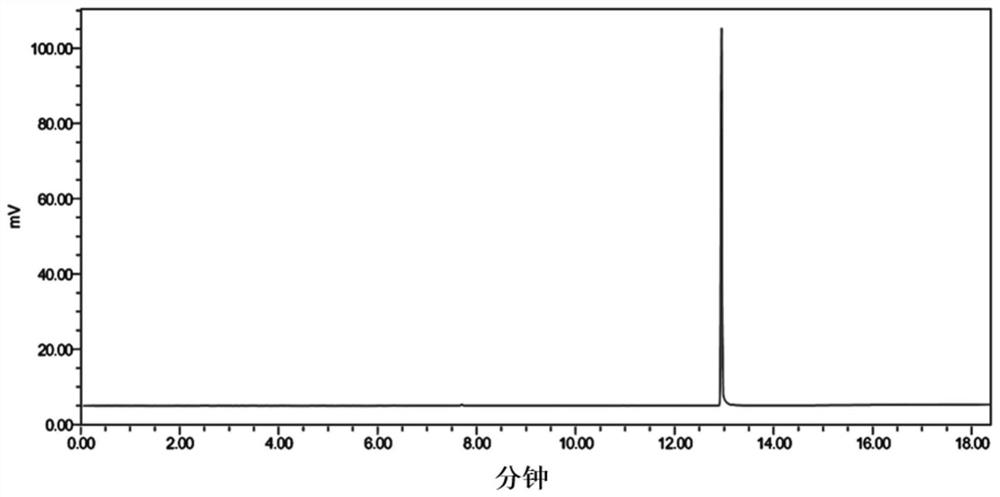

Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea

The invention belongs to the field of chemical analysis, and particularly relates to a method for detecting melamine and cyanuric acid in carbon [<13>C]-urea. The method comprises the following steps:a) mixing a carbon [<13>C]-urea sample with a diluent to obtain a test solution, wherein the diluent is a phosphate buffer solution; b) performing liquid chromatographic detection on the test solution to obtain a chromatogram of the test solution, wherein in the process of chromatographic detection, a filler in an adopted chromatographic column is hydrophilic siloxane-bonded silica gel, an adopted mobile phase is composed of a phosphate buffer solution and methanol, and an adopted elution mode is gradient elution; and c) acquiring the detection results of melamine and cyanuric acid in the sample according to the appearance conditions of characteristic peaks corresponding to melamine and cyanuric acid in the chromatogram. The method provided by the invention is suitable for qualitative andquantitative detection and analysis of melamine and cyanuric acid in the carbon [<13>C]-urea product, and is high in accuracy and good in repeatability.

Owner:JIANGSU HUAGEN TAILAI BIOTECH +1

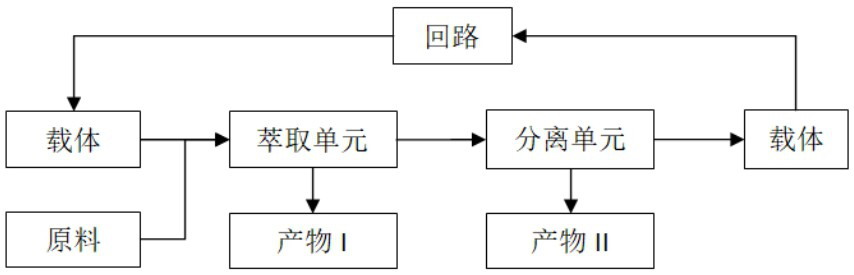

Modularized treatment system and method for black odor river water and lake water

InactiveCN109422365AMiniaturizationSingle performance solutionWater treatment parameter controlSpecific water treatment objectivesWater filterWater quality

The invention relates to the technical field of water purification, and particularly relates to a modularized integrated device and method for treatment of black odor water. The device comprises a conveying component, a filtering water purifier, an on-line monitoring component and a programmable logic controller (PLC) control component; the filtering water purifier, the on-line monitoring component and the PLC control part are connected to form a normal operation loop and a filter water purification module regeneration loop through the conveying component; and a separation assembly composed ofa plurality of modules is arranged in the filter water purifier. According to the invention, through the functional design and combination of the system units, different functional units can be flexibly selected in the system according to technological requirements, and a process purpose is achieved, so that system adaptability is high. Meanwhile, the filter material modules with different filterwater purification characteristics are combined into the filter water purifier, so that miniaturization of various filtering water purification functions is realized, and the problems that a single filter water purification material is single in performance, insufficient in water quality adaptability, frequent in replacement of filter water purification material and inconvenient in replacement are solved.

Owner:南京恒嘉坤科技有限公司

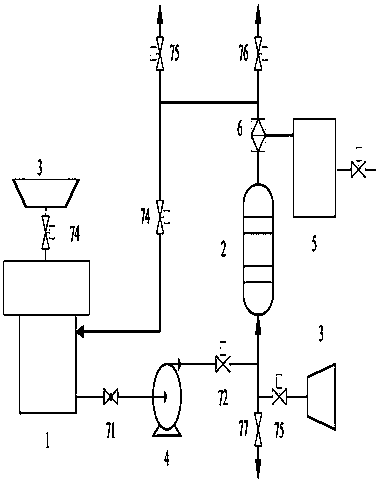

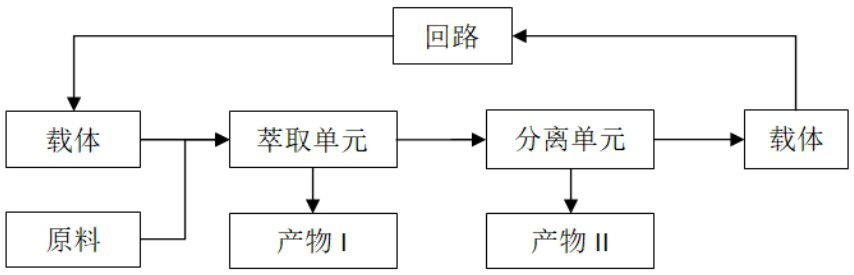

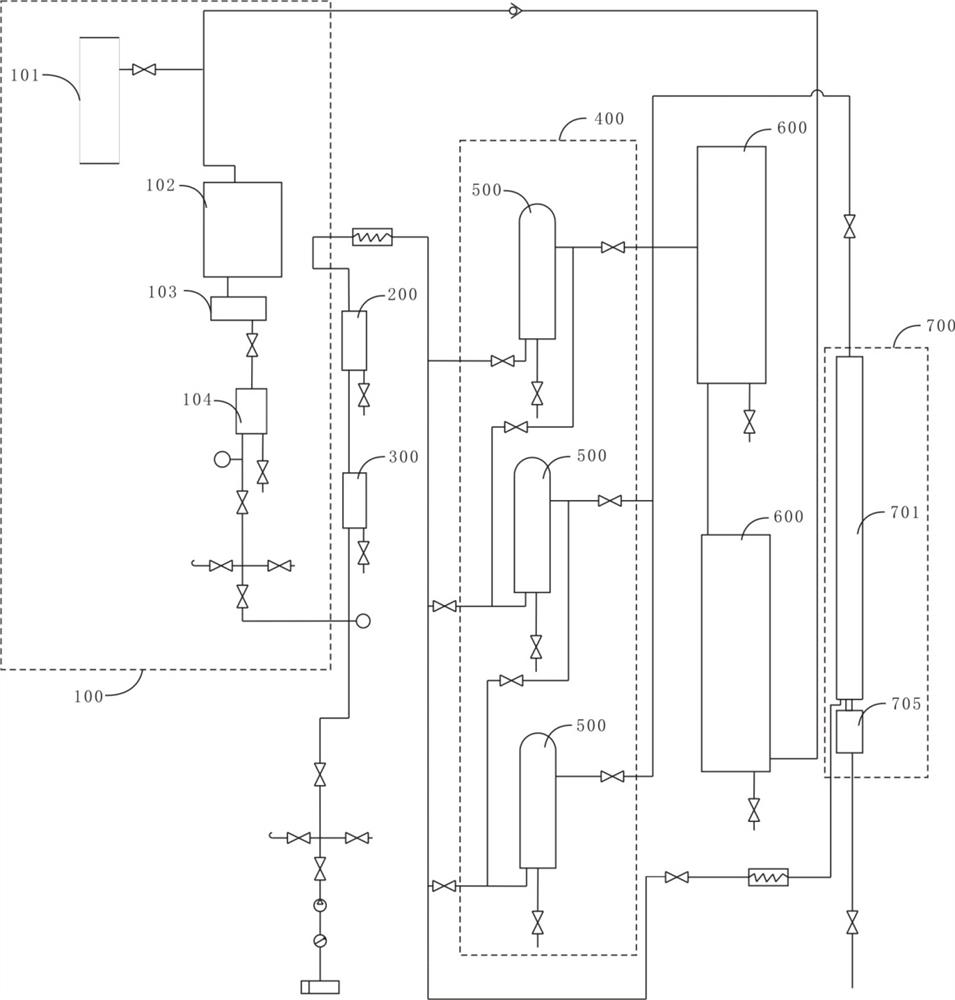

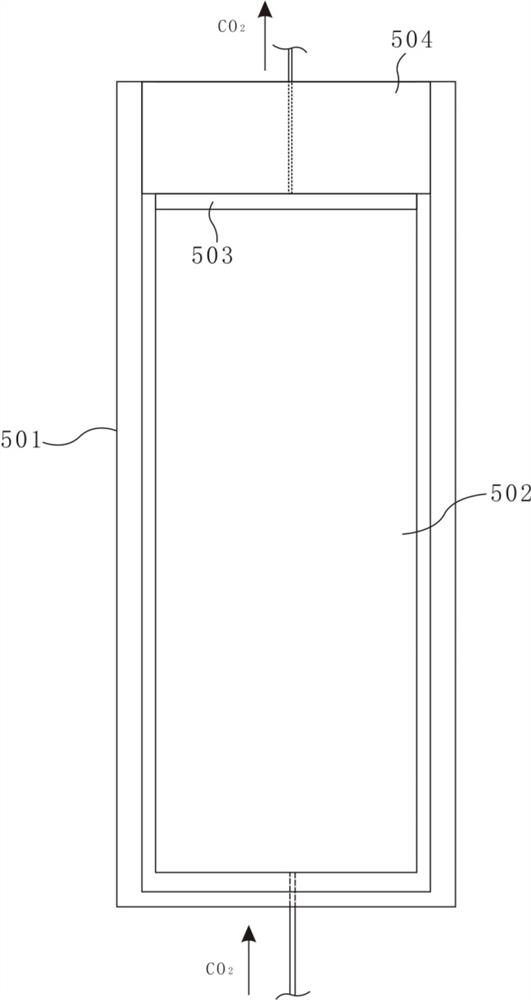

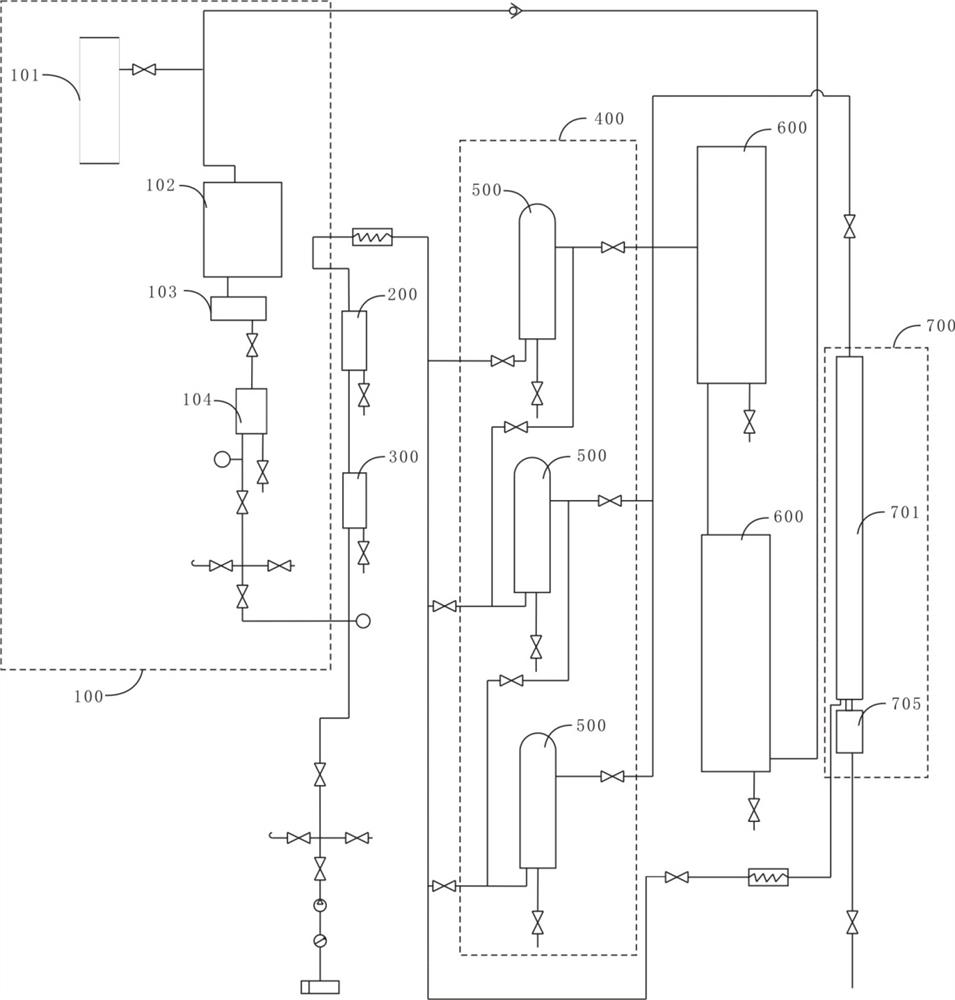

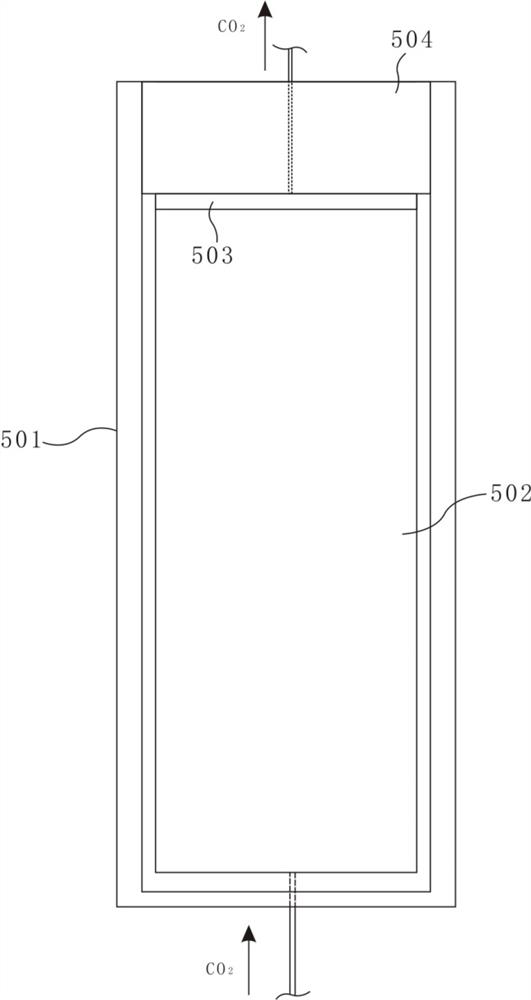

Fresh zanthoxylum oil resin separation and purification process

InactiveCN113430053AExtraction achievedAchieve independenceCounter-current extractionEssential-oils/perfumesZanthoxylum bungeanumPhysical chemistry

The invention discloses a fresh zanthoxylum oleoresin separation and purification process which comprises the following steps: after harvesting fresh zanthoxylum, carrying out cold pressing within two hours to obtain fresh zanthoxylum oleoresin, carrying out countercurrent extraction separation on the fresh zanthoxylum oleoresin through a liquid substance extraction and separation unit of a supercritical CO2 fluid dynamic countercurrent extraction and separation system, and after the countercurrent extraction separation is completed, obtaining fresh zanthoxylum resin from an extraction unit, and obtaining the fresh pepper essential oil through the separation unit. The extraction separation process is as follows: the feeding rate is 40kg / h, the CO2 flow rate is 600L / h, the extraction temperature is 45 DEG C, and the extraction pressure is 20MPa; the separation temperature I is 40 DEG C, the separation pressure I is 7.5 MPa, the separation temperature is 55 DEG C, and the separation pressure II is 4-6 MPa; the total yield of the fresh zanthoxylum oil resin product reaches 98.74%-99.19%, and the separation efficiency reaches 94.00%-99.24%; the volatile oil content of the obtained fresh zanthoxylum bungeanum essential oil can reach 101.94-128.93 ml / 100g, and the numb degree is lower than 5 mg / g; and the content of volatile oil in the obtained fresh zanthoxylum bungeanum maxim resin is smaller than 5 ml / 100 g, the hemp degree can reach 141.12 mg / g to 182.56 mg / g, and the hemp degree is increased to 42.59% to 53.17%. According to the process disclosed by the invention, the fresh Chinese prickly ash essential oil with high volatile oil content and the fresh Chinese prickly ash resin with high numb degree can be obtained, and the purification effect of the two products is remarkable.

Owner:四川丁点儿食品开发股份有限公司

Fresh pericarpium zanthoxyli oleoresin separation and purification process

PendingCN113563975AExtraction achievedAchieve independenceCounter-current extractionEssential-oils/perfumesPhysical chemistryOleoresin

The invention discloses a fresh pericarpium zanthoxyli oleoresin separation and purification process which comprises the following steps: after harvesting fresh pericarpium zanthoxyli, carrying out cold pressing within two hours to obtain fresh pericarpium zanthoxyli oleoresin, carrying out countercurrent extraction separation on the fresh pericarpium zanthoxyli oleoresin through a liquid substance extraction and separation unit of a supercritical CO2 fluid dynamic countercurrent extraction and separation system, and after the countercurrent extraction separation is completed, obtaining fresh pericarpium zanthoxyli resin from the extraction unit, and obtaining fresh pericarpium zanthoxyli essential oil through a separation unit. The extraction separation process is as follows: the feeding rate is 40kg / h, the CO2 flow rate is 600L / h, the extraction temperature is 45 DEG C, and the extraction pressure is 20MPa; the separation I temperature is 40 DEG C, the separation I pressure is 7.5 MPa, the separation II temperature is 55 DEG C, and the separation II pressure is 4-6 MPa; the total yield of the oleoresin product reaches 98.74%-99.17%, and the separation efficiency of volatile oil reaches 94.00%-99.24%; the volatile oil content of the obtained essential oil can reach 101.94-128.93 ml / 100g; the content of amide substances in the obtained resin can reach 575.22 mg / g to 645.99 mg / g, and the content of the amide substances is increased to 79.08% to 98.25%. According to the process disclosed by the invention, the fresh pericarpium zanthoxyli essential oil with high volatile oil content and the fresh pericarpium zanthoxyli resin with a high amide substance content can be obtained, and the purification effect of the two products is remarkable.

Owner:四川丁点儿食品开发股份有限公司

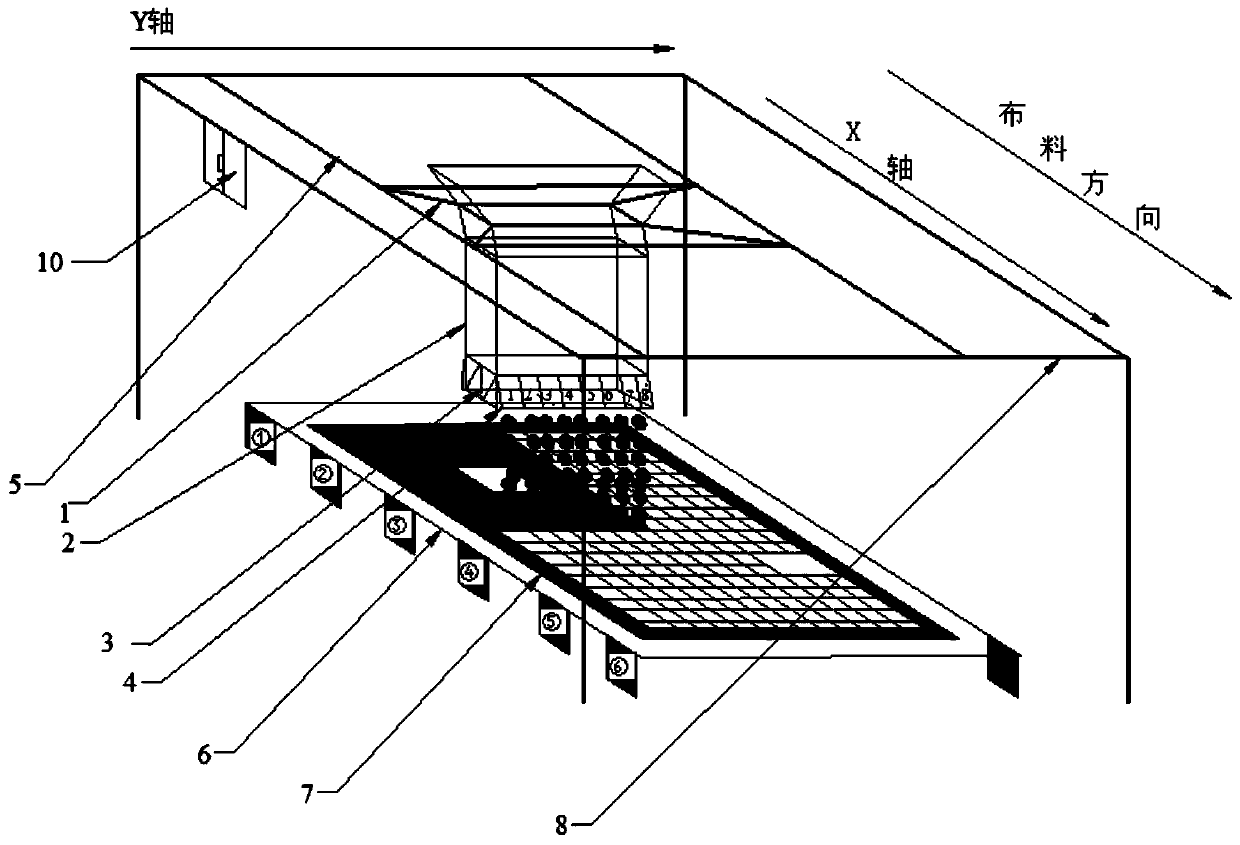

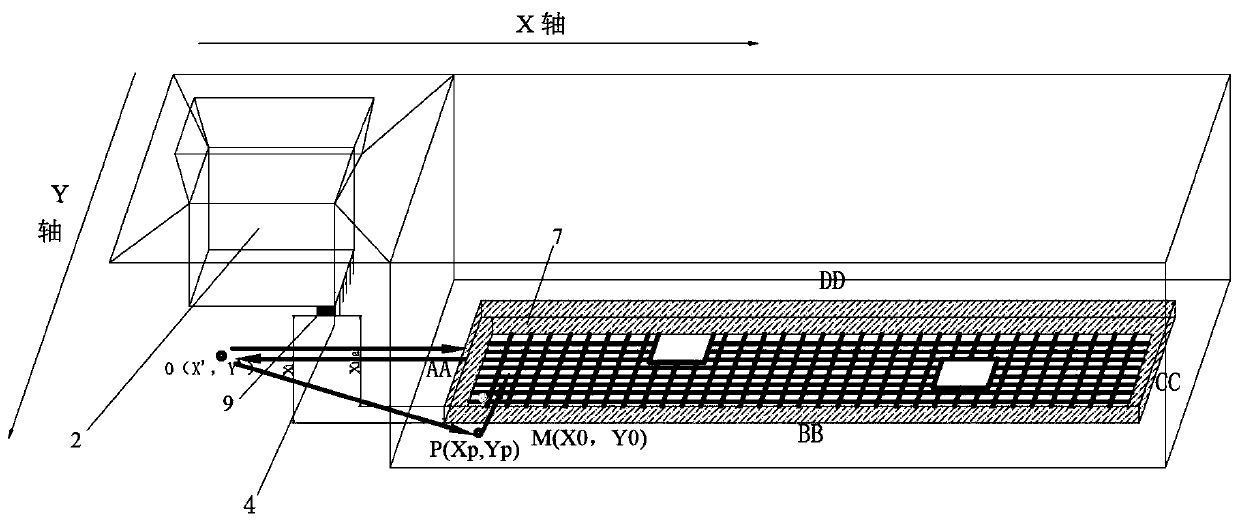

An automatic pre-calibration method for concrete placing machine based on laser ranging

ActiveCN109291231BMinor changesLow retrofit costFeeding arrangmentsAuxillary shaping apparatusLaser rangingAutomatic control

The invention provides a concrete distributor automatic pre-calibration method based on laser ranging, and relates to the field of automatic control of prefabricated component concrete distributors inbuilding industrialization. The method comprises the steps that a laser distance sensor is mounted, and meanwhile the axis X and the axis Y are determined; the distance between the laser distance sensor and a bottom mold tray and the distance between the laser distance sensor and a magnetic side mold are measured, and the permissible error range is set; the initial position that a distributor arrives at the position outside a distribution area is controlled, and a controller is utilized for recording the pre-calibration point of the laser distance sensor of the distributor; the pre-calibration point of the distributor is calculated by the controller; and the relative position of the distributor is calculated, the distributor is controlled by the controller to move to the pre-calibration point, and distribution production is prepared. According to the method, modification to existing equipment and detection systems is small, the modification cost is low, compatibility with existing distribution systems is good, and operation is easy to implement; and meanwhile, pre-calibration of the distributor can be completed automatically, and the accuracy that the concrete distributor determines the pre-calibration point and the pre-calibration efficiency can be improved.

Owner:SHENYANG JIANZHU UNIVERSITY

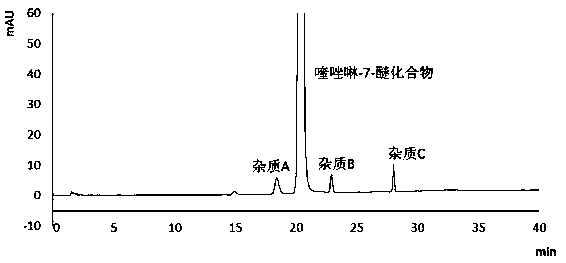

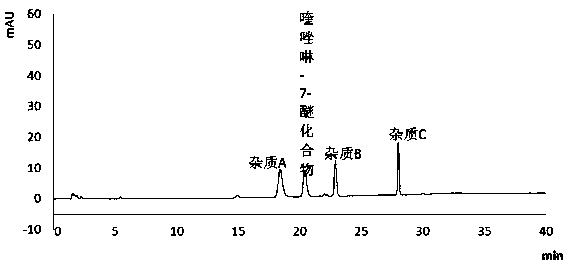

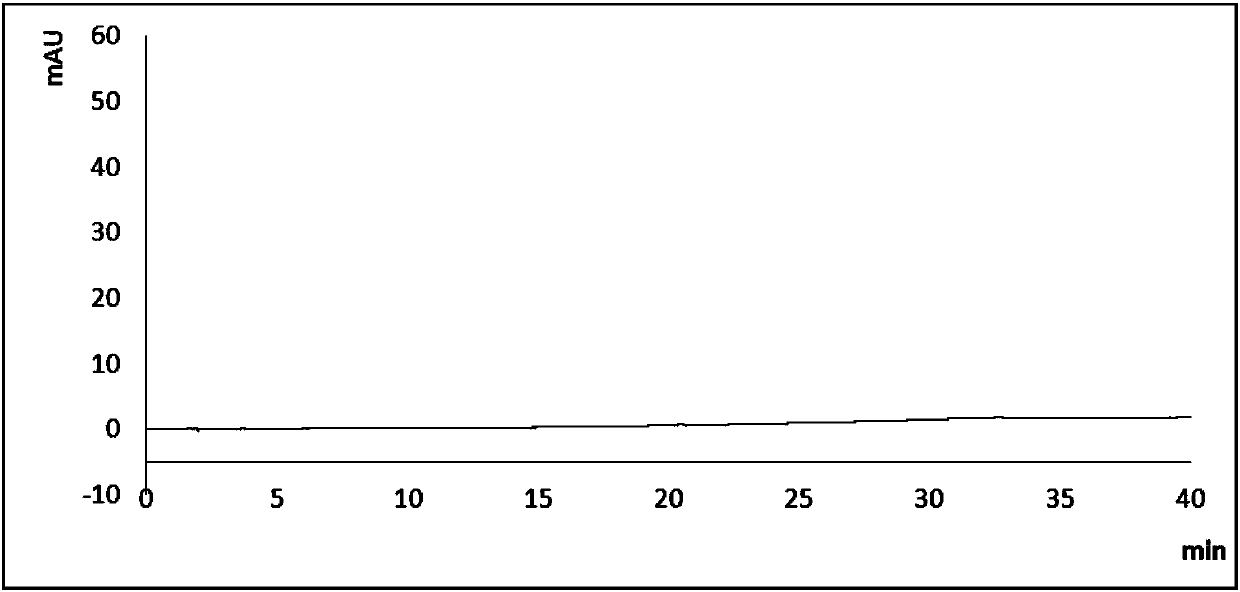

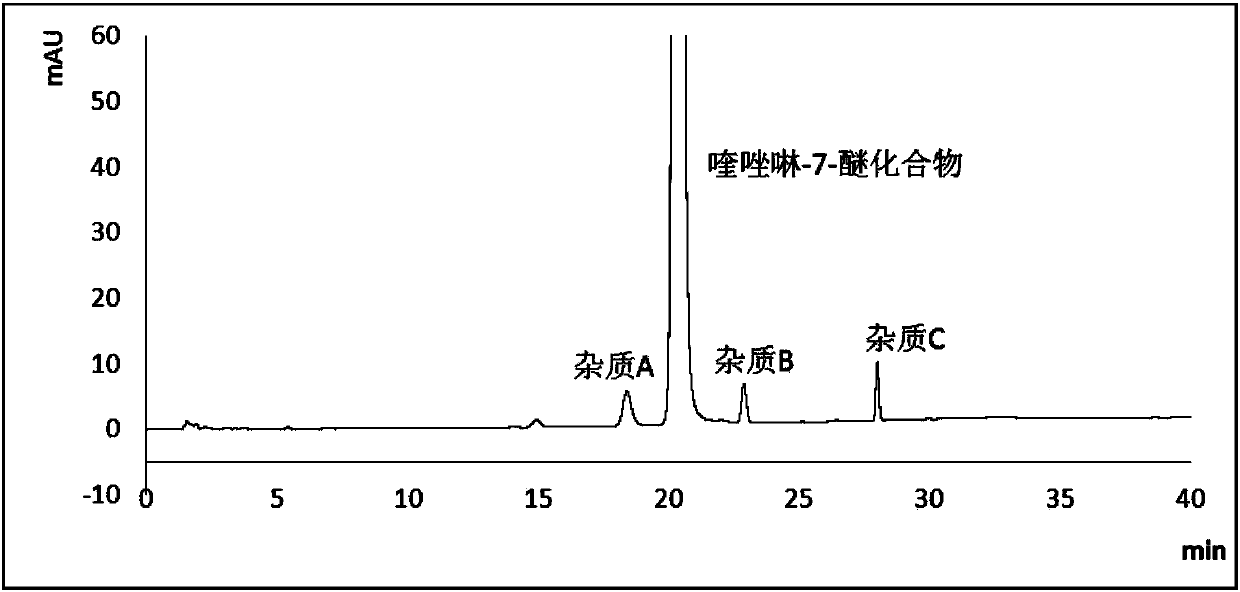

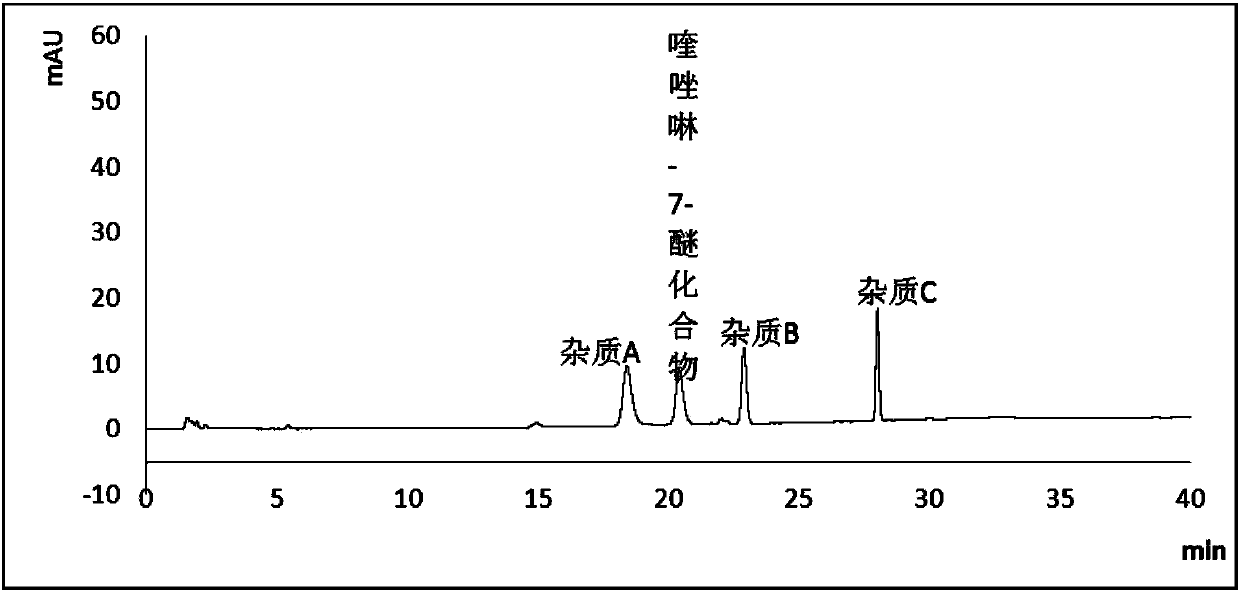

A kind of detection method of quinazoline-7-ether compound and its related substances

The invention relates to the field of chemical analysis, in particular to a detection method for a quinazoline-7-ether compound and related substances thereof. The detection method comprises the following step: detecting the content of a to-be-tested sample with the synthetic quinazoline-7-ether compound by using high performance liquid chromatography to respectively obtain the contents of the quinazoline-7-ether compound and the related substances thereof in the to-be-tested sample, wherein the quinazoline-7-ether compound has a structure shown in the formula I; the related substances of thequinazoline-7-ether compound comprise one or more of structural compounds shown in the formulas (II) to (IV); and a mobile phase used in the high performance liquid chromatography detection process isan ammonium acetate-phosphate buffer solution, methanol and acetonitrile. According to the detection method of the quinazoline-7-ether compound, disclosed by the invention, an ammonium acetate-phosphate buffer solution-methanol-acetonitrile elution system is adopted, so that the detection of the quinazoline-7-ether compound and other related substances is benefited. (The formula is shown in the description).

Owner:JIANGSU KANION PHARMA CO LTD

A method for detecting related substances of ambrisentan

The invention relates to the field of analytical chemistry, and in particular relates to a detection method of ambrisentan related substances. The detection method comprises the following steps: preparing a solution for test products by using a to-be-detected ambrisentan product, diluting the solution for the test products for 100 times to be used as a reference solution, then respectively performing HPLC (High Performance Liquid Chromatography) detection by using a trifluoroacetic acid aqueous solution as a mobile phase A and a trifluoroacetic acid acetonitrile solution as a mobile phase B, and measuring the content of the related substances according to a self-contrasted method of main components added with correction factors. The detection method disclosed by the invention adopts an acetonitrile-water-trifluoroacetic acid gradient elution system, and ensures that a chromatographic peak of ambrisentan has higher separation degree with other related substance peaks, and the chromatographic peak of ambrisentan is relatively high in peak type symmetry, so that the detection method is beneficial to detection on the related substances, has relatively high system suitability, also shows incomparable advantages in specificity, quantitation limit, detection limit, linear range and repeatability, and has relatively high precision degree.

Owner:JIANGSU KANION PHARMA CO LTD

Method for detecting triethylamine and N, N-diethylaniline in ceftazidime and application

PendingCN114414716AEasy to detectQuick checkComponent separationGas liquid chromatographicEthyl group

The invention discloses a method for detecting triethylamine and N, N-diethylaniline in ceftazidime and application of the method. The detection method disclosed by the invention comprises the following steps: injecting a test solution containing ceftazidime into a gas chromatograph in a direct sample injection manner, recording a chromatogram, and calculating the content according to an external standard method; wherein the detection conditions of the chromatography are as follows: a chromatographic column is a capillary column taking modified dimethyl polysiloxane as a stationary liquid or a capillary chromatographic column with equivalent efficiency; the initial temperature is 95-105 DEG C, the temperature is maintained for 3 minutes, the temperature is raised to 220 DEG C at the rate of 10 DEG C per minute, and the temperature is maintained for 10 minutes. The method has good specificity and system adaptability, extremely low detection limit and quantitation limit, good linearity and good accuracy.

Owner:武汉九州钰民医药科技有限公司

Method for detecting benzene in ceftazidime residual solvent and application

PendingCN114414715AEasy to detectQuick checkComponent separationAgainst vector-borne diseasesCapillary TubingColumn temperature

The invention discloses a method for detecting benzene in a ceftazidime residual solvent and application. The detection method disclosed by the invention comprises the following steps: respectively injecting a test solution and a reference solution into a gas chromatograph by adopting headspace sampling, recording a chromatogram, and carrying out quantitative analysis on the chromatogram by adopting an external standard method, wherein the detection conditions of the chromatography are as follows: a chromatographic column is a capillary column taking 100% dimethyl polysiloxane as a stationary liquid or a capillary chromatographic column with equivalent efficiency; the column temperature is programmed temperature rise: the initial temperature is 45-55 DEG C, the temperature is maintained for 3 minutes, and the temperature is raised to 200 DEG C at the rate of 10 DEG C per minute, and the temperature is maintained for 2 minutes; the balance temperature of the headspace bottle is 90 DEG C, and the balance time is 30 minutes. The method has good specificity and system adaptability, extremely low detection limit and quantitation limit, good linearity and good accuracy.

Owner:武汉九州钰民医药科技有限公司

Frequency Offset Estimation and Compensation Method Based on Broadband Frequency Hopping System

ActiveCN106656454BFlexible designImprove system adaptabilityModulated-carrier systemsSynchronisation signal speed/phase controlSignal-to-noise ratio (imaging)Engineering

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

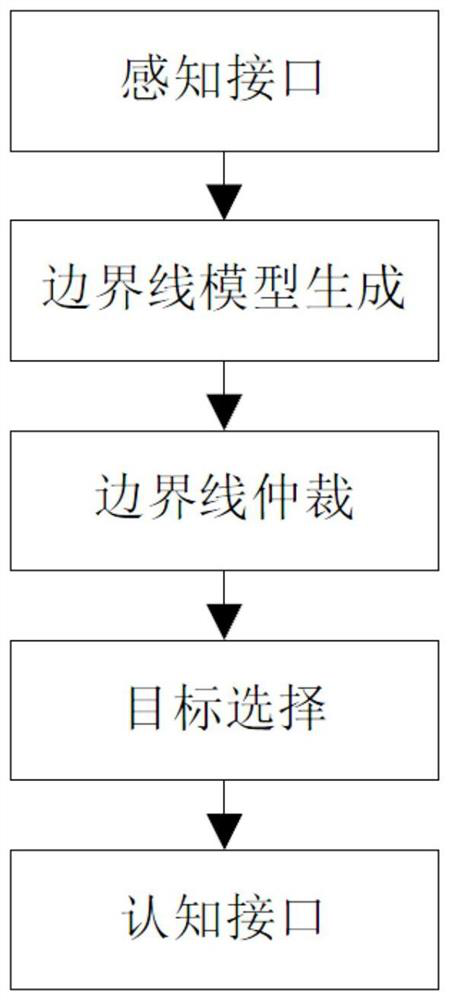

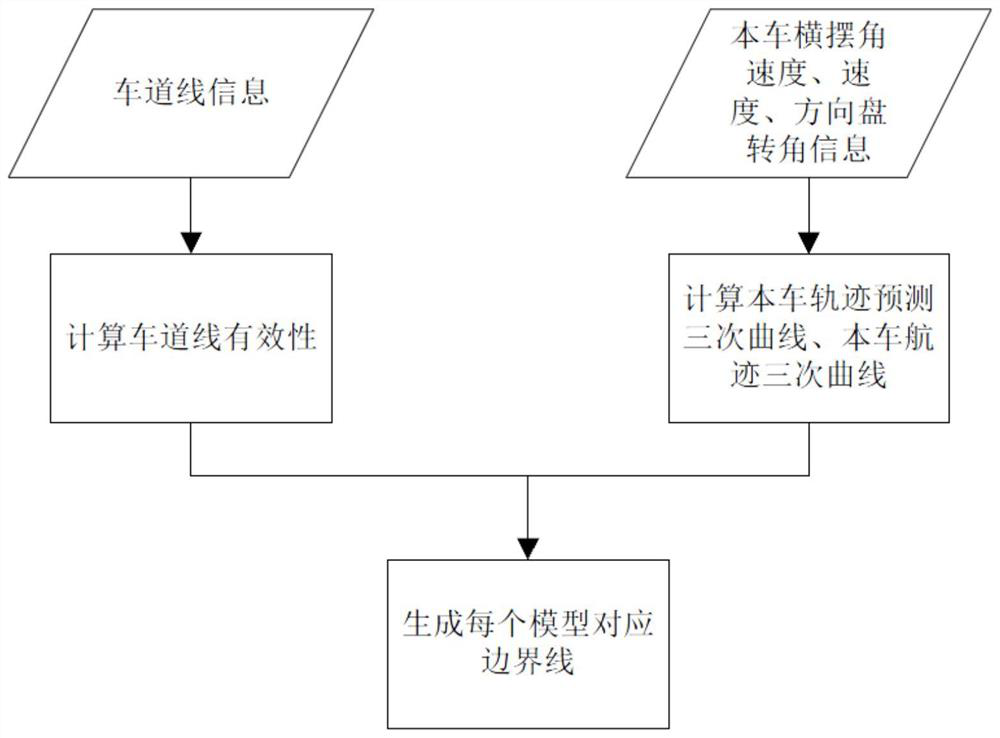

Autonomous vehicle driving environment cognitive target selection method and device and storage medium

ActiveCN112706785AAccurate informationImprove system adaptabilityControl devicesInternal combustion piston enginesReal-time computingTrajectory planning

The invention discloses an autonomous vehicle driving environment cognitive target selection method and device and a machine readable storage medium. The method comprises the steps: 1, acquiring perception information and vehicle information from a vehicle perception interface; 2, establishing a boundary line model for the driving environment according to the perception information and the vehicle information; 3, establishing a boundary line arbitration module, and selecting an optimal boundary line model of the current scene; and 4, according to the optimal boundary line model, putting the targets into the corresponding lanes in sequence, and filtering the targets exceeding the boundary line. According to the method, a plurality of models are established for the driving environment of the automatic driving vehicle by collecting the information data of the sensor and the vehicle, the target in the driving road is selected, accurate and effective information is provided for automatic driving vehicle trajectory planning, and the problems of target selection robustness, adaptability and the like in the prior art are partially solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

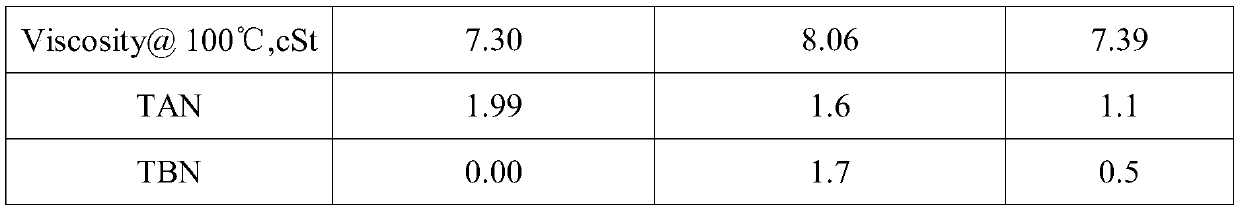

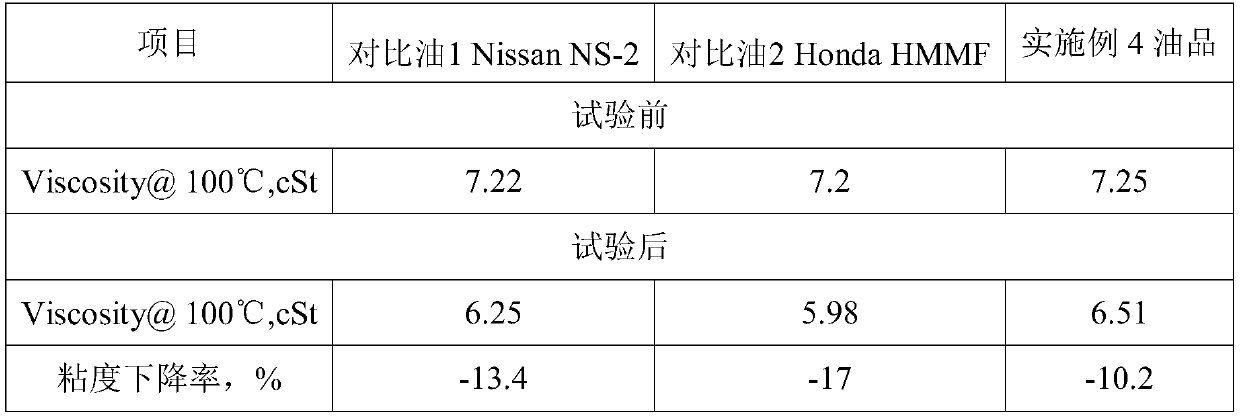

Multi-vehicle-type general progressive transmission oil and preparation method thereof

ActiveCN110305724AExtended service lifeLittle impact on shear resistanceAdditivesAntioxidantGlycol diacrylate

The invention discloses multi-vehicle-type general progressive transmission oil and a preparation method thereof. The multi-vehicle-type general progressive transmission oil is prepared from the following raw materials in parts by weight: 42-47 parts of synthesized base oil, 31-35 parts of deeply and finely processed III-class base oil, 0.02-0.04 part of a coloring agent, and 20-23 parts of a functional agent; and the functional agent is prepared from the following raw materials in parts by weight: 67-72 parts of an acrylamide-pentamethylene glycol diacrylate copolymer, 7-12 parts of tricresylphosphate, 12-16 parts of didecyl phenyl phosphate, 6-10 parts of high-base-number calcium alkylbenzene sulfonate, 3-6 parts of an antioxidant, 0.9-1.5 parts of a defoaming agent, and 0.5-0.8 part ofan antirust agent. The multi-vehicle-type general progressive transmission oil has good comprehensive properties such as the anti-shearing property, the oxidation-resistant property, the anti-foamingproperty and the abrasion-resistant property, the oil can be generally used for multiple vehicle types, and in the using process, the anti-shearing property, the oxidation-resistant property, the anti-foaming property, the abrasion-resistant property and the like can keep stable and permanent.

Owner:QUANZHOU CITY OUMEI LUBRICANT PRODS

Buckle plate type medium and low speed maglev transportation system track telescopic adjustment structure

ActiveCN104389265BImprove laying efficiencyImprove the state of stressBridge structural detailsLow speedTemperature difference

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Spring buckle type medium and low speed maglev transportation system track telescopic adjustment structure

ActiveCN103966951BImprove laying efficiencyImprove the state of stressBridge structural detailsLow speedTemperature difference

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

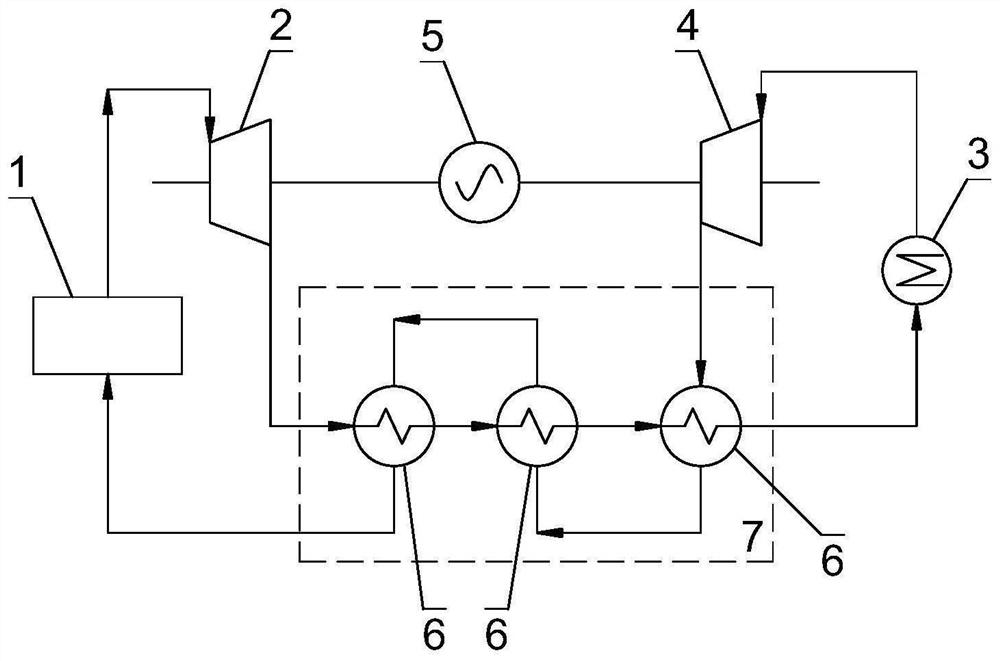

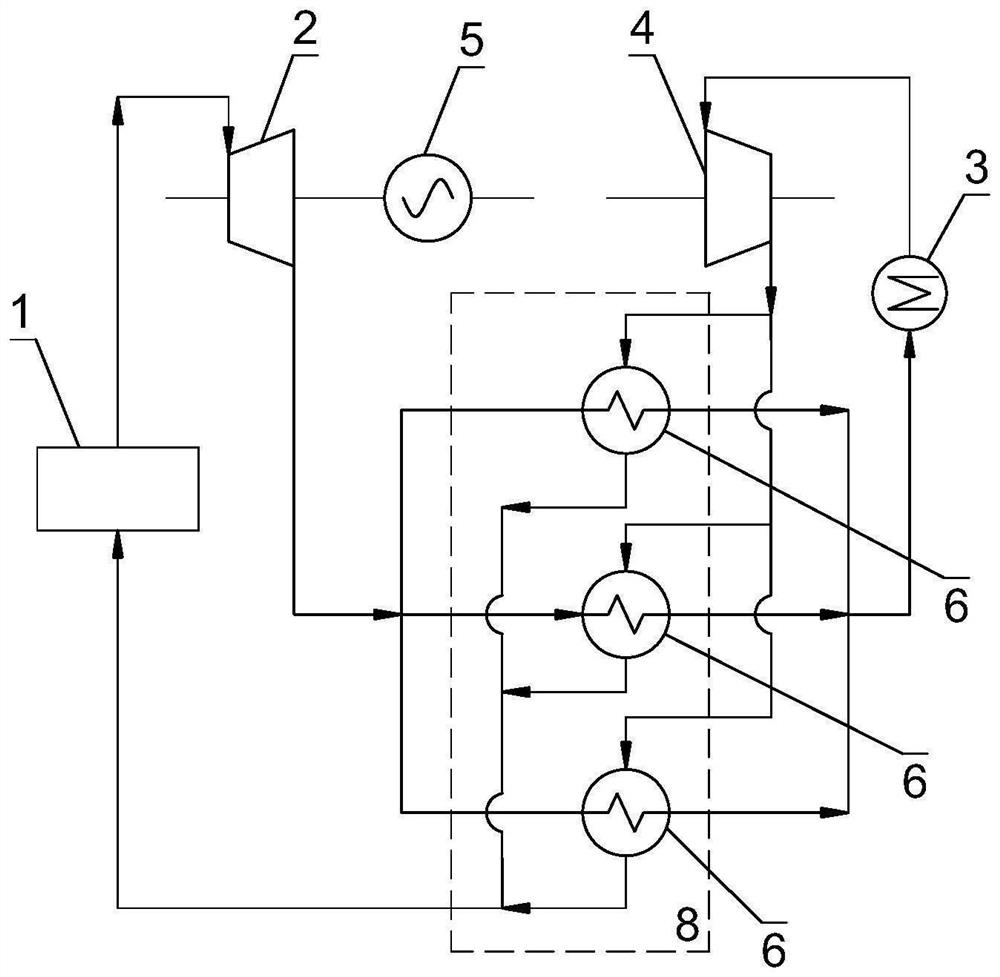

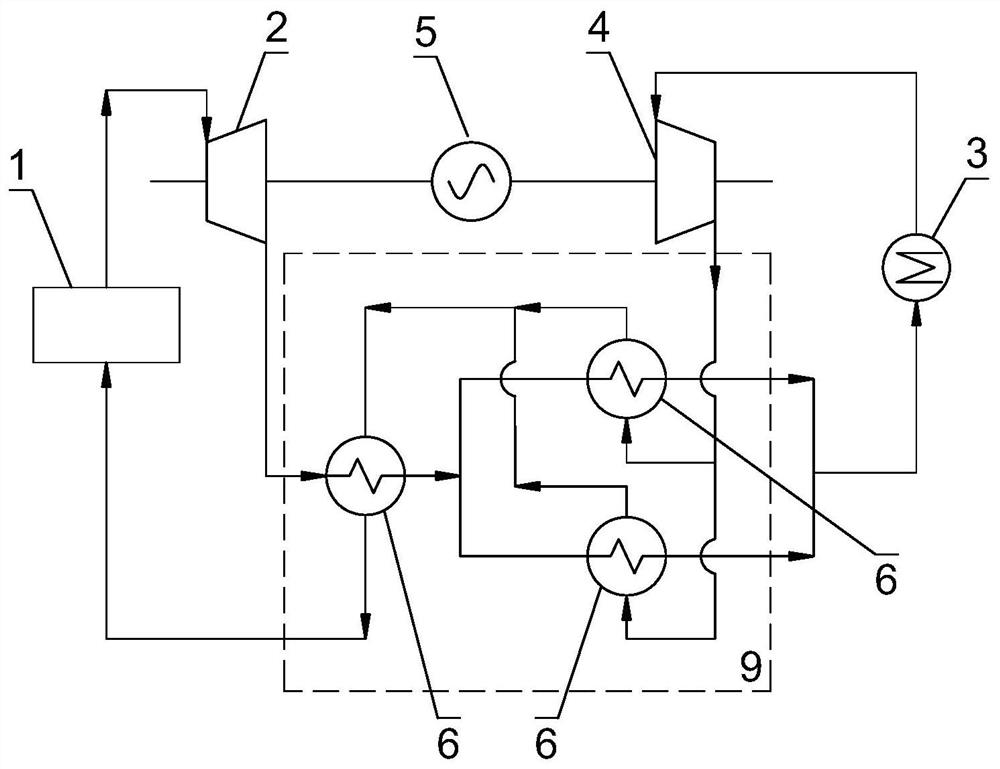

Supercritical carbon dioxide Brayton cycle system

PendingCN113586186ASolve the problem of limited heat exchangeMeet heating needsSteam engine plantsBrayton cycleCold side

The invention relates to the technical field of heat exchange equipment, and discloses a supercritical carbon dioxide Brayton cycle system. The supercritical carbon dioxide Brayton cycle system comprises a generator, a heat source heat exchanger, a turbine, a cooler and a compressor, the heat source heat exchanger, the turbine, the cooler and the compressor are sequentially and circularly connected, the generator is connected with the output end of the turbine, and a plurality of heat regenerators are further arranged between the turbine and the cooler. The number of the heat regenerators is not less than three, a hot side inlet and a hot side outlet of each heat regenerator are connected with the turbine and the cooler, and a cold side inlet and a cold side outlet of each heat regenerator are connected with the compressor and the heat source heat exchanger. Compared with the structure of an existing circulating system, the multiple heat regenerators can form multiple connection modes, so that the heat regeneration requirements of large Brayton cycle systems of different magnitudes can be met, a system regulation and control strategy based on heat regenerator equipment can be conveniently formed, the regulation and control modes of a closed Brayton cycle system are increased. The flexibility of the supercritical carbon dioxide Brayton cycle system is improved.

Owner:ZHEJIANG UNIV

Detection method for quinazoline-7-ether compound and related substances thereof

The invention relates to the field of chemical analysis, in particular to a detection method for a quinazoline-7-ether compound and related substances thereof. The detection method comprises the following step: detecting the content of a to-be-tested sample with the synthetic quinazoline-7-ether compound by using high performance liquid chromatography to respectively obtain the contents of the quinazoline-7-ether compound and the related substances thereof in the to-be-tested sample, wherein the quinazoline-7-ether compound has a structure shown in the formula I; the related substances of thequinazoline-7-ether compound comprise one or more of structural compounds shown in the formulas (II) to (IV); and a mobile phase used in the high performance liquid chromatography detection process isan ammonium acetate-phosphate buffer solution, methanol and acetonitrile. According to the detection method of the quinazoline-7-ether compound, disclosed by the invention, an ammonium acetate-phosphate buffer solution-methanol-acetonitrile elution system is adopted, so that the detection of the quinazoline-7-ether compound and other related substances is benefited. (The formula is shown in the description).

Owner:JIANGSU KANION PHARMA CO LTD

A kind of multi-model universal stepless transmission oil and preparation method thereof

ActiveCN110305724BExtended service lifeLittle impact on shear resistanceAdditivesPhosphoric Acid EstersPhosphoric acid

The invention discloses a multi-vehicle universal stepless transmission oil and a preparation method thereof. The multi-vehicle universal stepless transmission oil is made of raw materials including the following parts by weight: synthetic base oil: 42-47 parts, deeply refined Type III base oil: 31-35 parts, colorant: 0.02-0.04 parts, functional agent: 20-23 parts; the functional agent includes the following raw materials in parts by weight: acrylamide-pentanediol diacrylate copolymer: 67 ~72 parts, tricresyl phosphate: 7~12 parts, didecylphenyl phosphite: 12~16 parts, high alkali value synthetic calcium sulfonate T106: 6~10 parts, antioxidant 3~6 parts, 0.9-1.5 parts of defoaming agent, 0.5-0.8 parts of rust inhibitor. The multi-vehicle general-purpose continuously variable transmission oil of the present invention has comprehensive properties such as good shear resistance, oxidation resistance, good anti-foam performance, and good anti-wear performance, and can be used for multiple vehicle types, and the shear resistance performance is improved during use. , anti-oxidation performance, good anti-foam performance and good anti-wear performance can maintain stability and durability.

Owner:QUANZHOU CITY OUMEI LUBRICANT PRODS

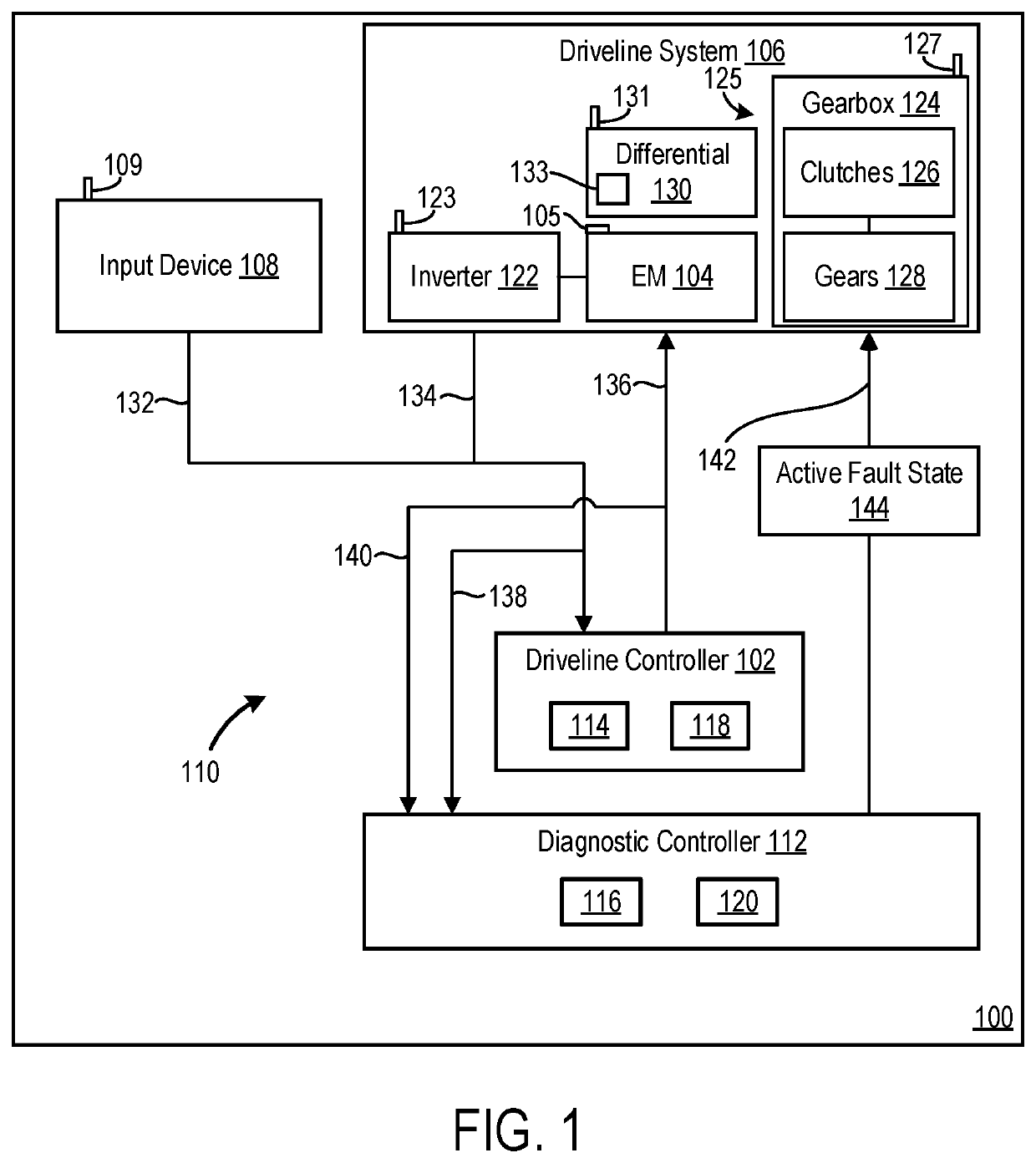

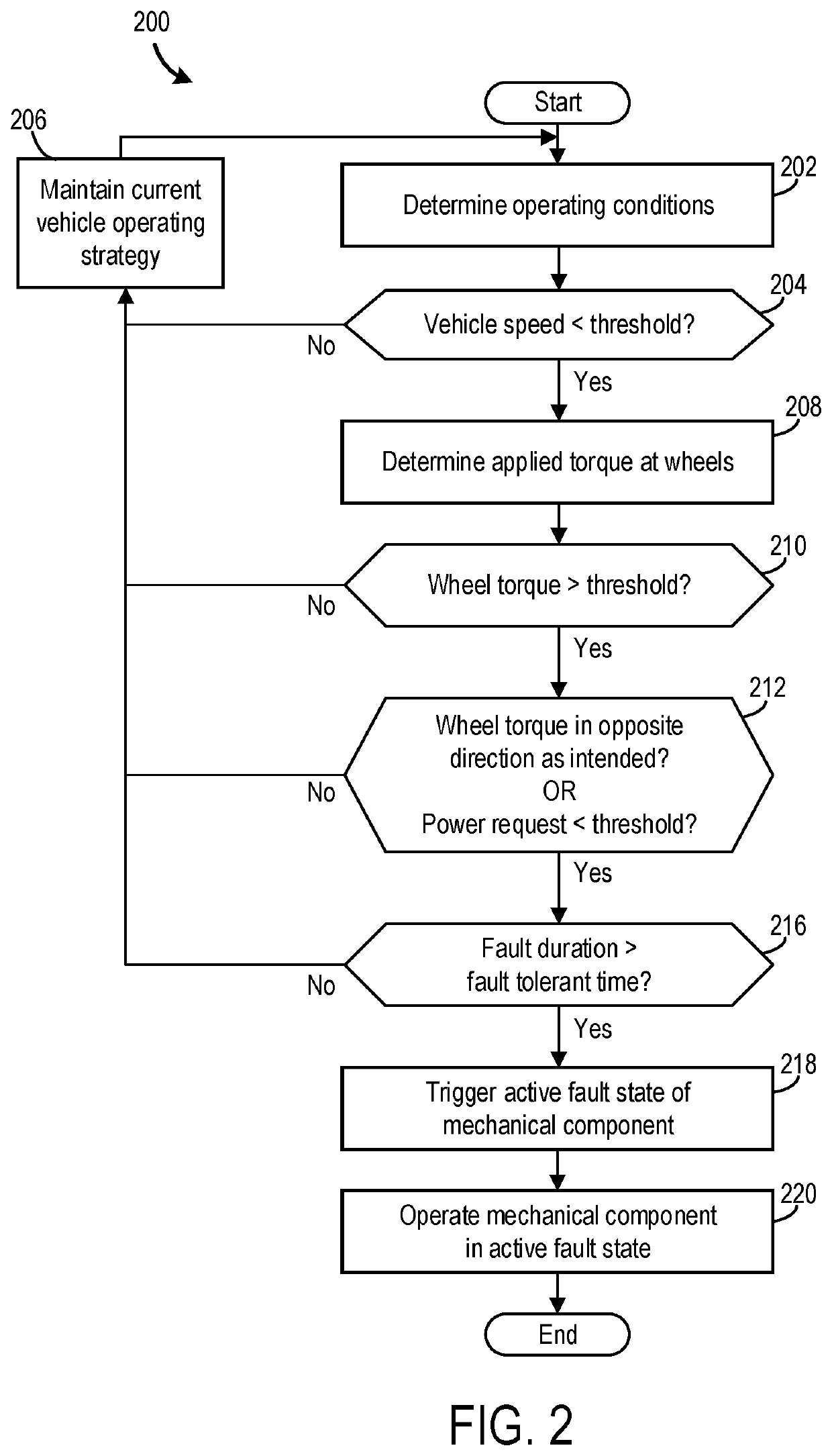

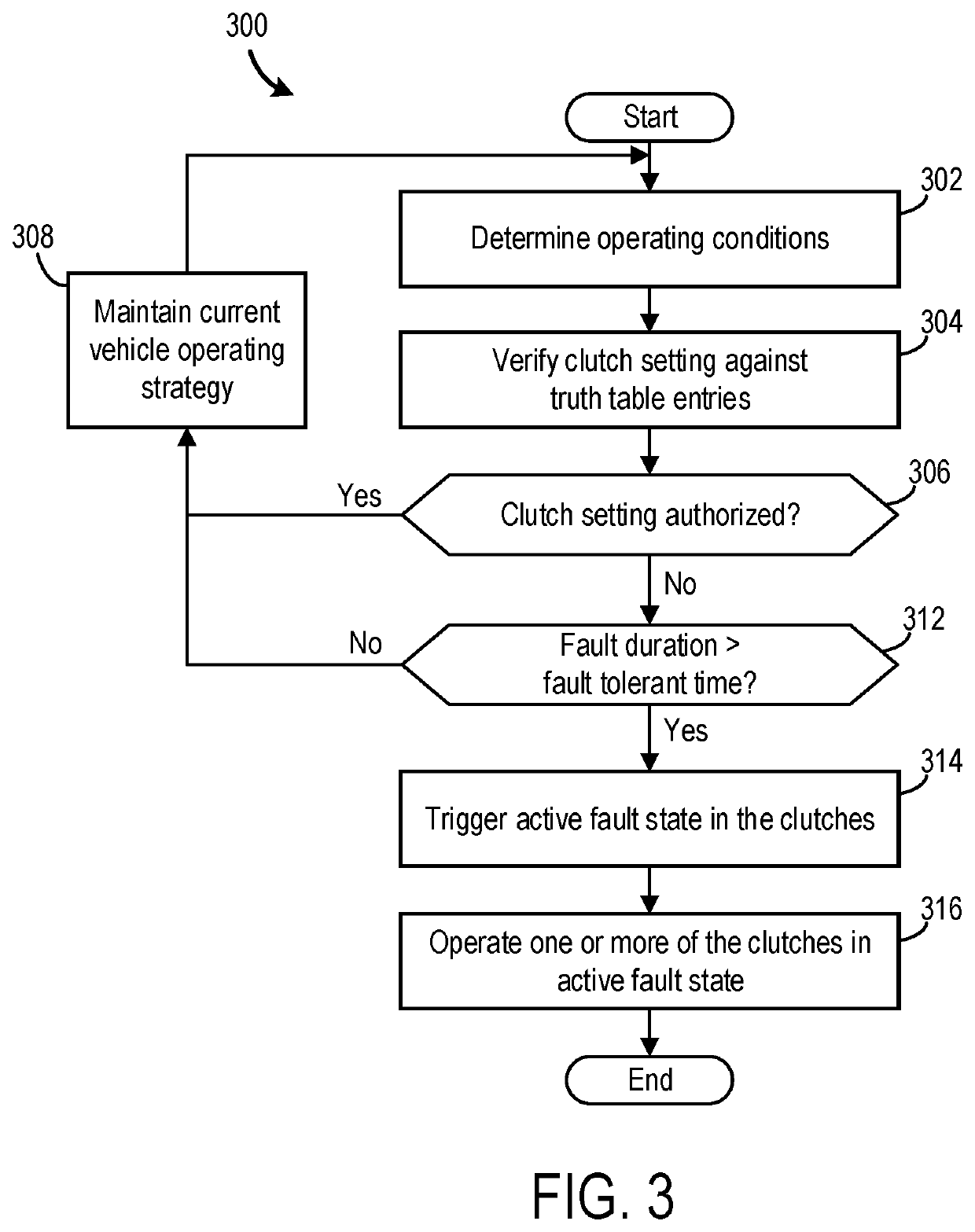

Diagnostic and control method for a vehicle system

ActiveUS20220363242A1Reduce chanceImprove system adaptabilityProgramme controlHybrid vehiclesIn vehicleControl engineering

Methods and systems are provided for controlling and diagnosing a mechanical vehicle component. In one example, a method may include determining a vehicle speed and a plurality of clutch position settings at a diagnostic controller, and identifying unauthorized conditions based on these determinations. Further, the diagnostic controller may trigger an active fault state of the mechanical vehicle component in order to avoid unauthorized conditions that may lead to unwanted or unanticipated changes in vehicle motion.

Owner:DANA BELGIUM

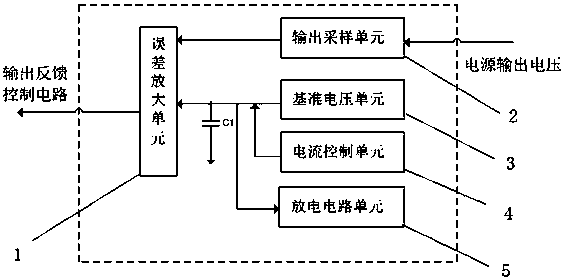

A switching power supply output voltage linear start control circuit

The invention relates to a starting control circuit for the output linear voltage of a switching power supply. The circuit comprises an error amplifier unit, an output sampling unit, a reference voltage unit, a current control unit, a discharging circuit unit and a first capacitor C1. One end of the first capacitor C1 is connected with the input end of the error amplifier unit, and the other end of the first capacitor C1 is grounded. The input end of the output sampling unit is connected with the output voltage of a power supply, and the output end of the output sampling unit is connected with the input end of the error amplifier unit. The output end of the reference voltage unit is connected with the input end of the error amplifier unit. The output end of the current control unit is connected with the input end of the error amplifier unit. The input end of the discharging circuit unit is connected with the output end of the reference voltage unit. According to the technical scheme of the invention, during the starting process of the switching power supply, the waveform of the output voltage of the switching power supply can be controlled to have the linear rising characteristic. Therefore, the circuit security and the circuit adaptivity are improved. Meanwhile, the safety of a load system can be ensured.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f02ddc9a-04ce-4c7e-b63b-b8af5f6c043f/HDA0002787049210000011.png)

![Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f02ddc9a-04ce-4c7e-b63b-b8af5f6c043f/HDA0002787049210000012.png)

![Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea Method for detecting melamine and cyanuric acid in carbon [<13>C]-urea](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f02ddc9a-04ce-4c7e-b63b-b8af5f6c043f/HDA0002787049210000013.png)