Fresh zanthoxylum oil resin separation and purification process

A technology for separation of fresh pepper oil and resin, which is applied in separation methods, natural resin refining, food processing, etc. It can solve the problems of unrealistic processing operations and low equipment compatibility, so as to improve extraction efficiency and yield, and prolong contact time , Improve the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

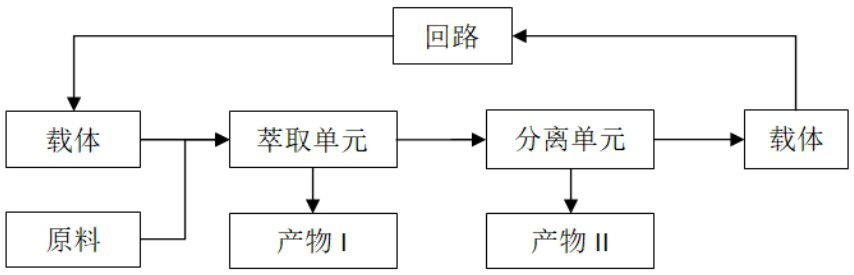

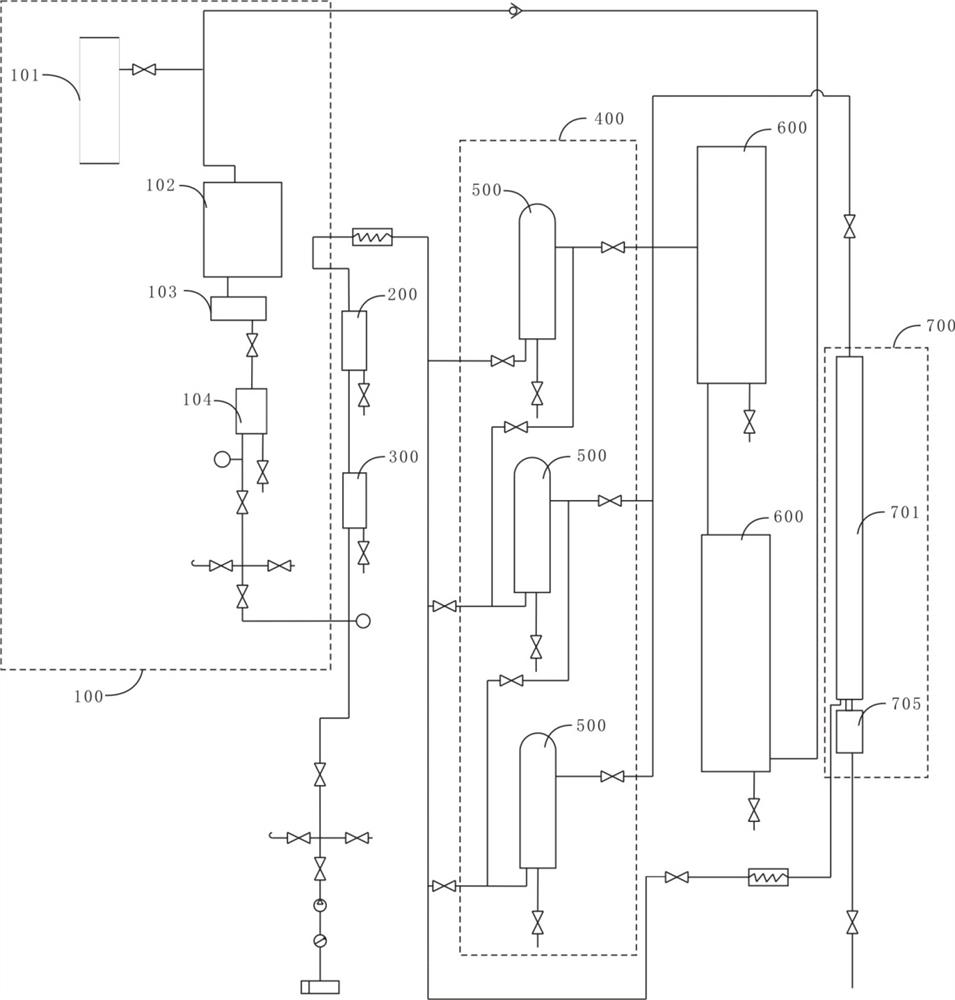

[0037] A separation and purification process of fresh pepper oleoresin, that is, the fresh pepper oleoresin is subjected to supercritical CO 2 The fluid dynamic countercurrent extraction and separation system performs dynamic countercurrent extraction and separation.

[0038] Among them, supercritical CO 2 Fluid dynamic countercurrent extraction separation system, including:

[0039] CO 2 Air source unit (100),

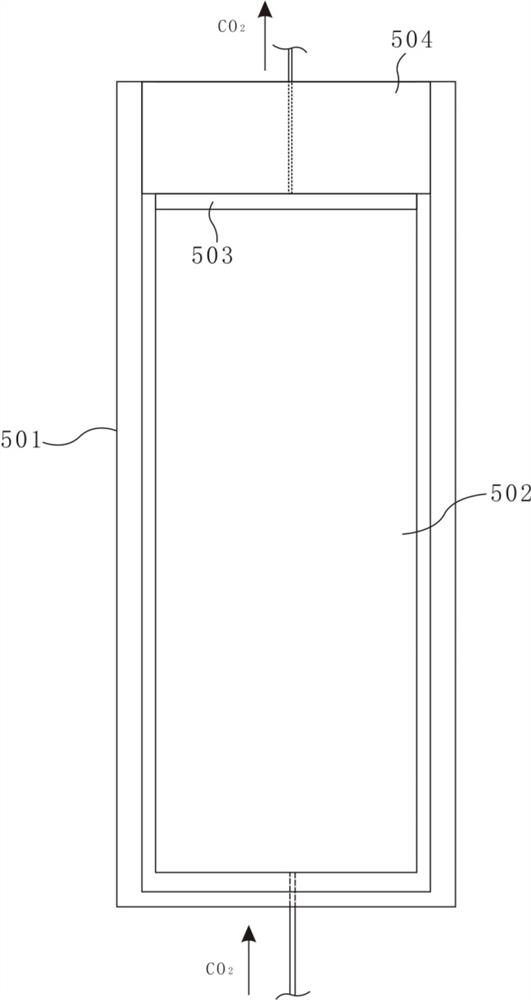

[0040] Solid matter extraction unit (400), through pipeline with CO 2 The gas source unit (100) is connected, and the supercritical CO 2 Reverse transport to the solid matter extraction unit (400);

[0041] Liquid substance extraction unit (700), through pipeline with CO 2 The gas source unit (100) is connected, and the supercritical CO 2 reverse delivery to the liquid substance extraction unit (700); and

[0042] The separation unit is respectively connected to the solid substance extraction unit (400) and the liquid substance extraction unit (700), and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com