Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Improve dynamic responsiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

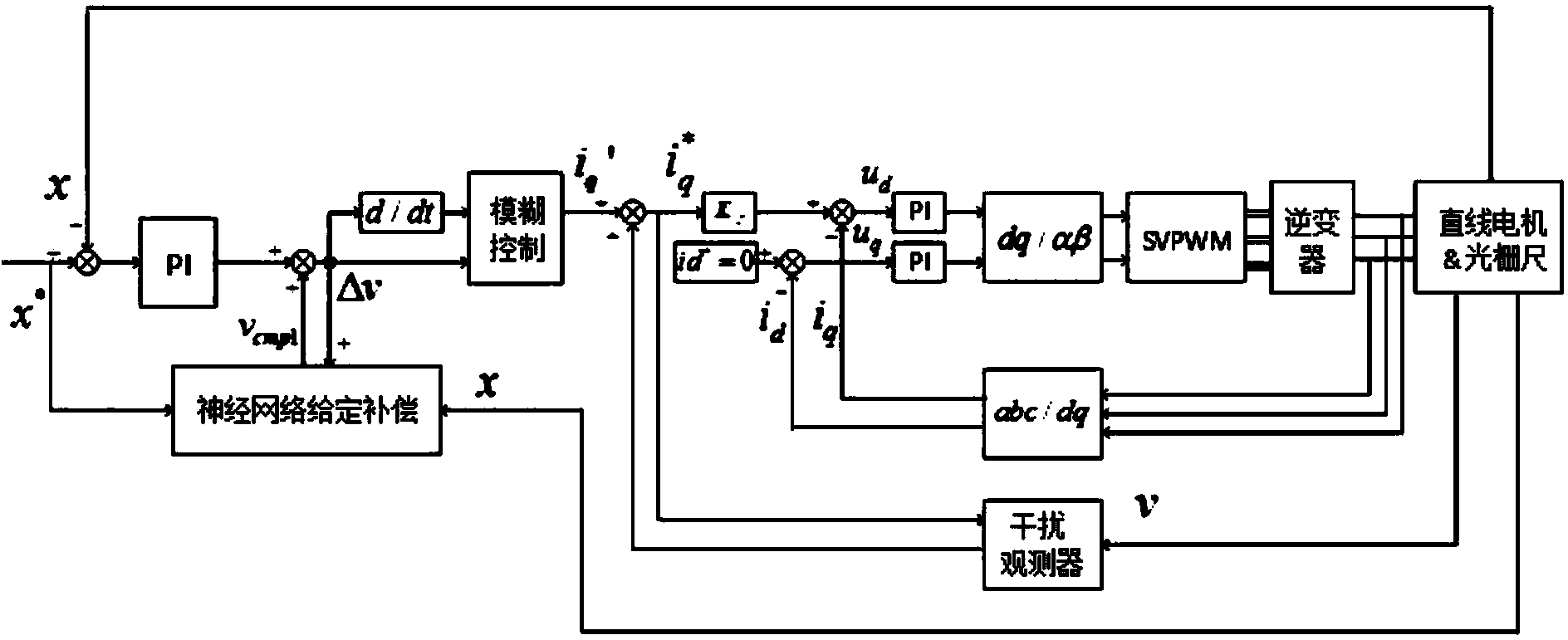

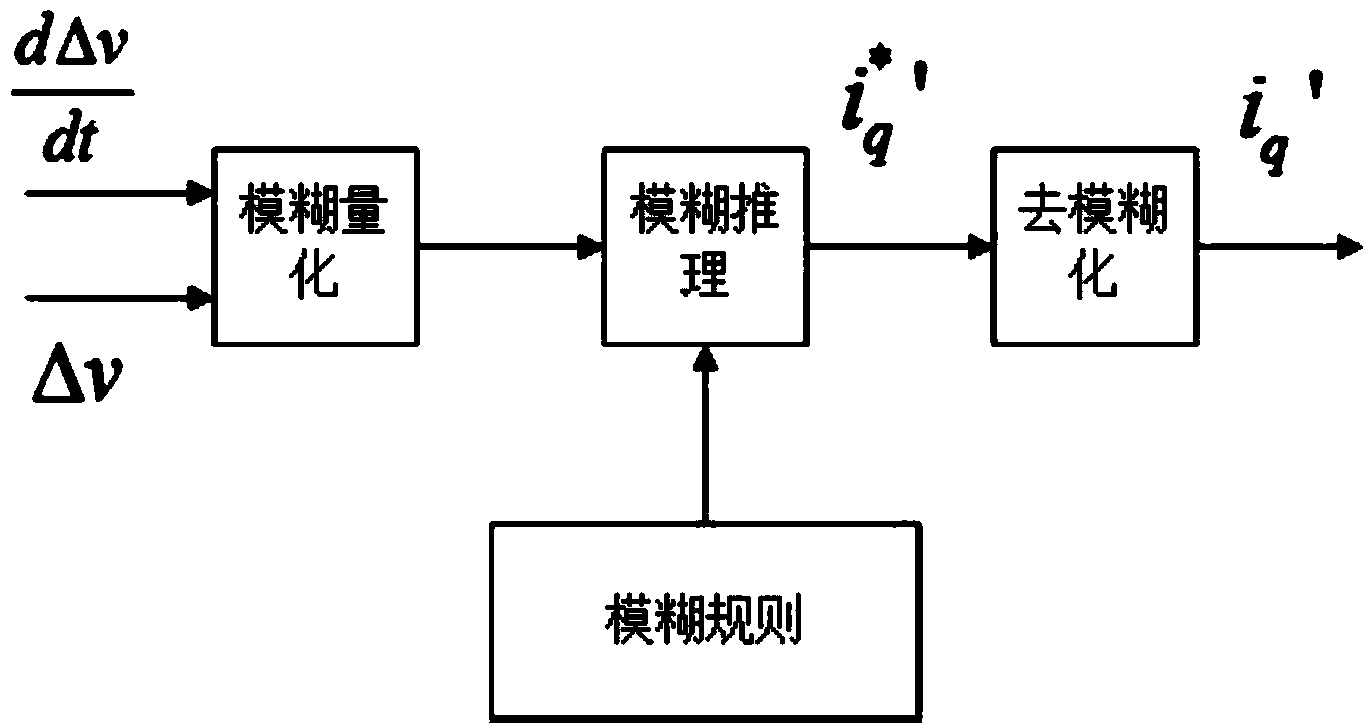

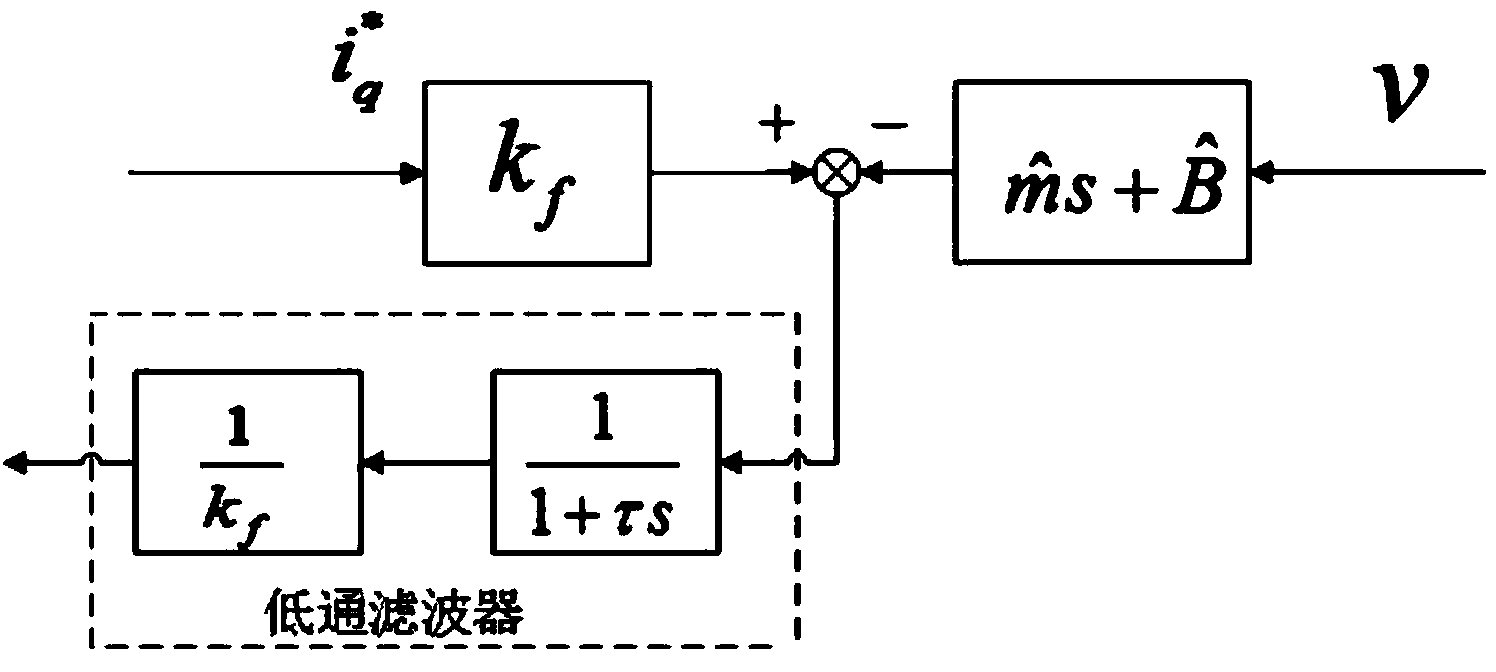

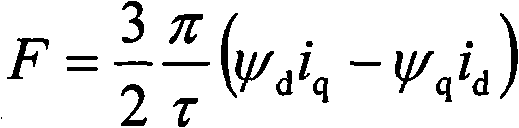

Linear servo motor control method for numerically-controlled machine tool driving

InactiveCN103532459AReduce switching lossesImprove dynamic responsivenessElectronic commutation motor controlAC motor controlAnti jammingControl vector

The invention discloses a linear servo motor control method for numerically-controlled machine tool driving. According to the method, a sine wave linear motor is controlled through a feedback signal detection module, a position control ring, a speed control ring and a current control ring, and the feedback signal detection module comprises a position detection module, a speed detection module and a current detection module, wherein the position control ring adopts a composite control method combining PI (proportional-integral) feedback control and neural network given compensation control, the speed control ring adopts a fuzzy controller with a disturbance observer, and the current control ring adopts a space vector PWM (pulse-width modulation) technology with a PI regulator. The linear servo motor control method has the advantages that the neural network compensation PI control technology, the fuzzy control and the alternating current motor vector control are combined, and the anti-jamming capability, the dynamic response capability and the system stable state precision of a linear servo motor are improved.

Owner:SOUTHEAST UNIV

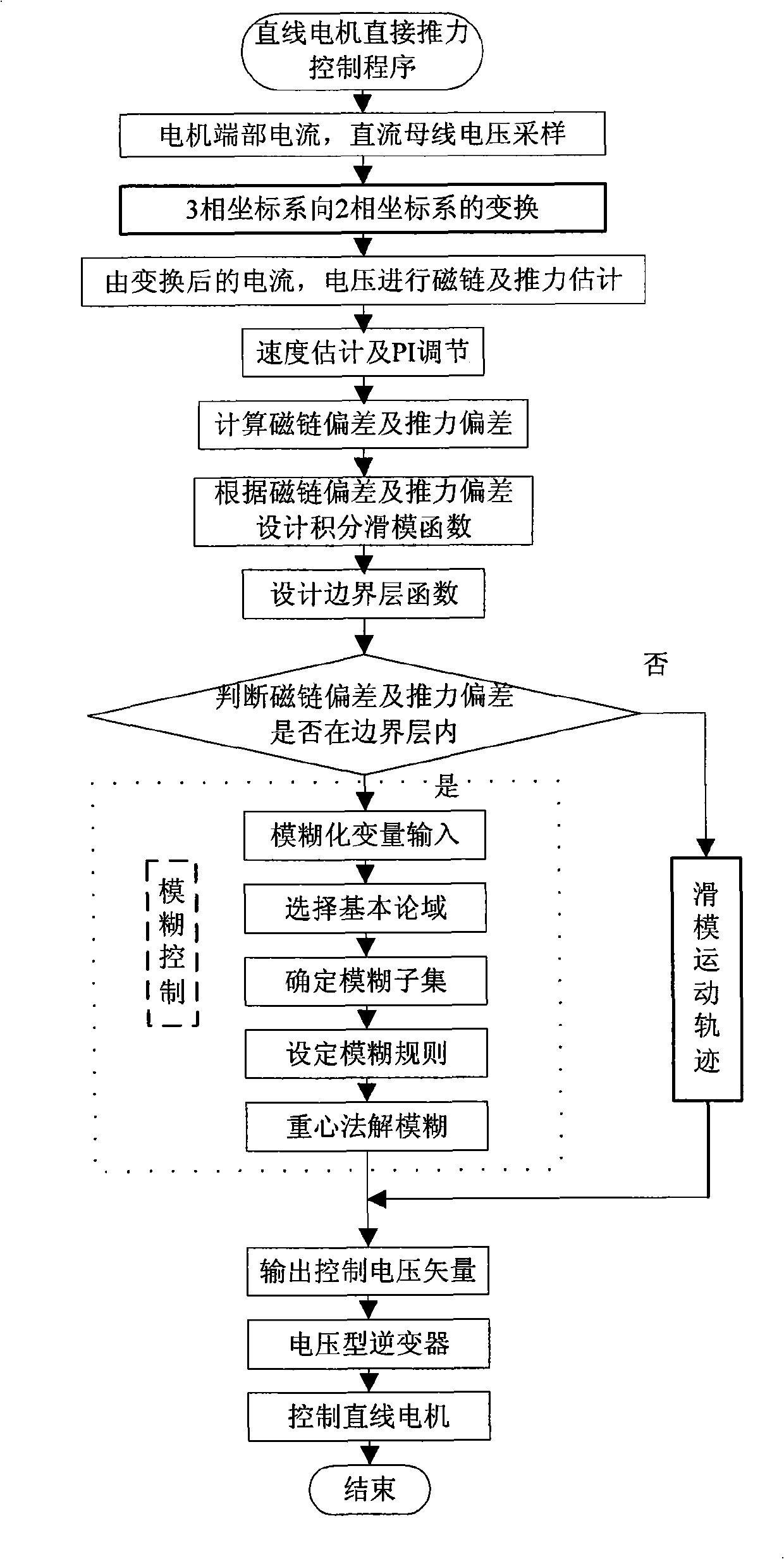

Method for suppressing pulse of linear motor pushing force system

InactiveCN101340173ANon-linearWith multivariateElectronic commutation motor controlAC motor controlData informationControl system

The invention relates to the field of linear motor control, in particular to a method for restraining the pulsation of a thrust system of a linear motor; the method adopts a sliding mode thrust controller and a magnetic flux controller, the thrust deviation and the magnetic flux deviation are selected as controlled variables, an integral sliding mode surface which is composed of the thrust deviation and the magnetic flux deviation design the sliding mode motion trajectory, thereby a system can move according to the sliding mode trajectory and the output thrust and the magnetic flux can better track specified value, wherein, a fuzzy controller utilizes the fuzzy control method which uses language information and data information to approach any specified continuous function to solve the jitter problem of a sliding mode control system. The method has the advantages that: a direct drive control system of the linear motor has strong coupling property, nonlinear property, multiple variables and unique end effect, the use of the direct thrust control method of the fuzzy sliding mode linear motor with high robust performance can solve the impacts of various factors on the control performance, thereby achieving the purposes of restraining the thrust pulsation of the linear motor and obtaining great dynamic response performance.

Owner:SHENYANG POLYTECHNIC UNIV

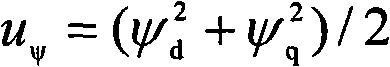

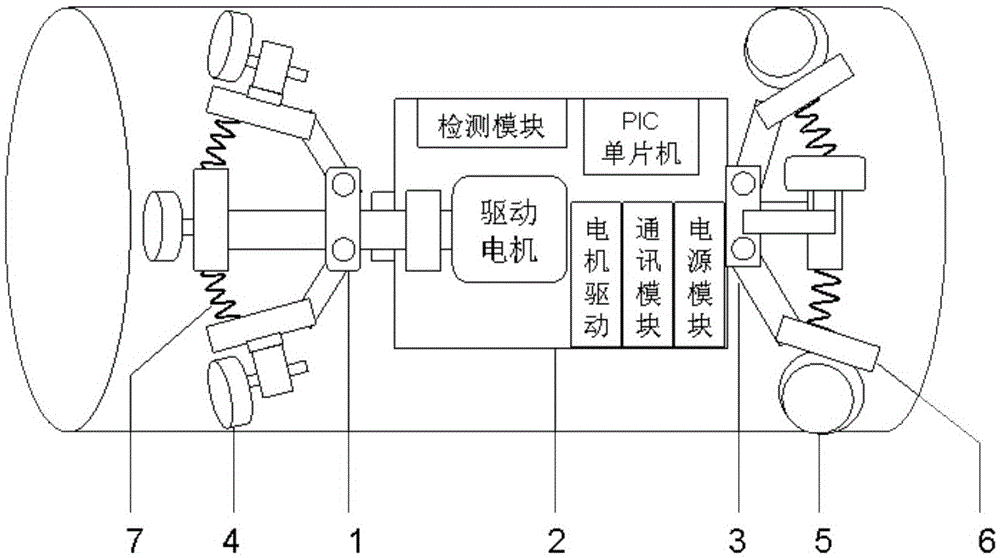

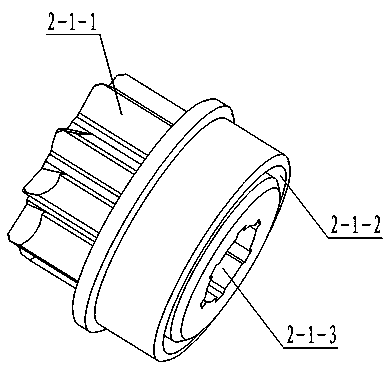

Worm wheel type driving pipeline robot system based on high-strength spring wall press apparatus

InactiveCN105487545AHigh precisionSmall overshootPosition/course control in two dimensionsVehiclesRobotic systemsPid control algorithm

A worm wheel type driving pipeline robot system based on a high-strength spring wall press apparatus is characterized by comprising a body mechanical structure and a control system; the body mechanical structure comprises a spiral head, a body and a holding frame; the body is a main body of the robot; the working method is that the robot system is a fully-closed loop servo control system taking wheel linear speed as a feedback quantity through a fuzzy adaptive PID control algorithm. The advantages of the robot system are: (1) the robot system can steadily and flexibly move within a tilted and vertical pipeline with a minimal variable diameter; (2) the robot system exhibits good dynamic responsiveness, robustness and stability; (3) signal transmission is convenient; and (4) the robot system is highly controllable and is high in accuracy.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

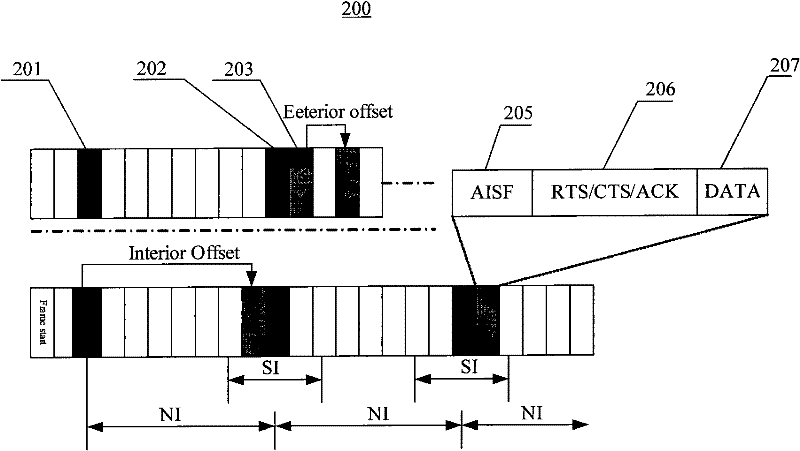

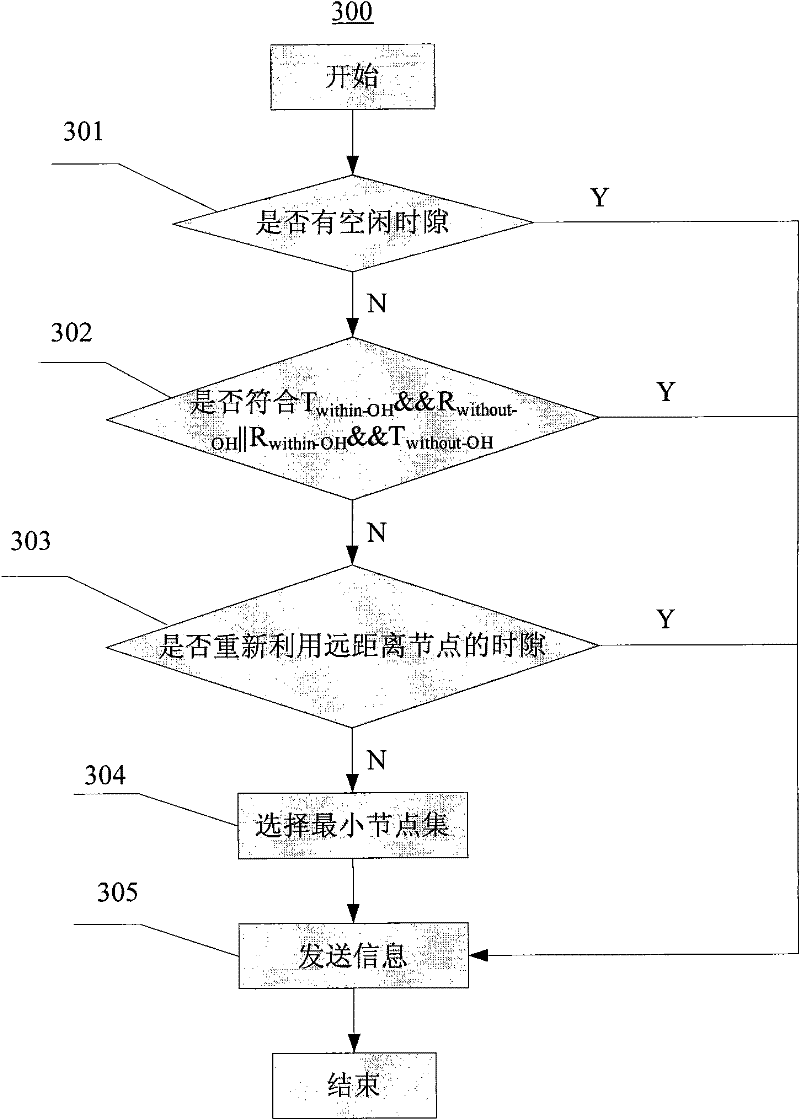

Channel access method for ship-mounted wireless mobile Ad-hoc network based on self-organization time division multiple access

InactiveCN102547584AImprove communication performanceReduce network access timeError prevention/detection by using return channelSynchronisation arrangementBroadcast channelsThree level

The invention relates to a channel access method for a ship-mounted wireless mobile Ad-hoc network based on self-organization time division multiple access, which is characterized in that a unicast channel is compatible with a broadcast channel, and channel is accessed in by means of the mode of a self-organization synchronous time division multiple access; two movement parameters of distance and speed are considered according to actual conditions of a ship, and an emergency signal is ensured to be preferentially accessed into the channel by means of risk factor levels; strategies of solving a constraint set of a minimum node and a three-level node withdraw scheme are adopted. Furthermore, if a broadcast signal is not obtained, a protocol degrades to an ordinary IEEE802.11 DCF to guarantee robustness of a system. Geographic information is fully utilized to solve the problem of exposure and concealing of a terminal and the scheme of selecting the constraint set of the minimum node (SMC) is solved. The channel access method is one of key technologies for constructing the ship-mounted mobile Ad-hoc network (MANET), and provides strong reference value for other mobile device organization networks.

Owner:ZHEJIANG OCEAN UNIV

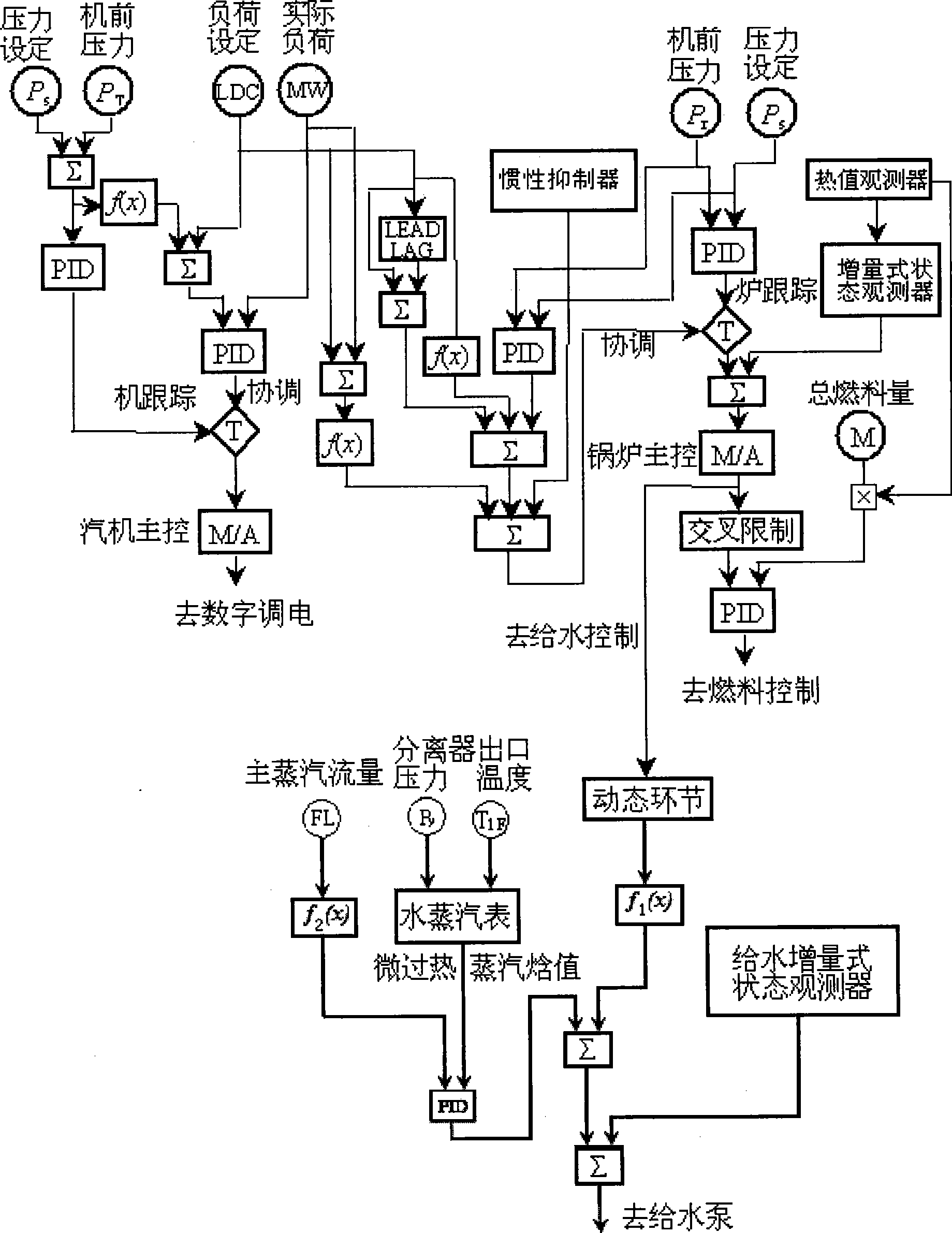

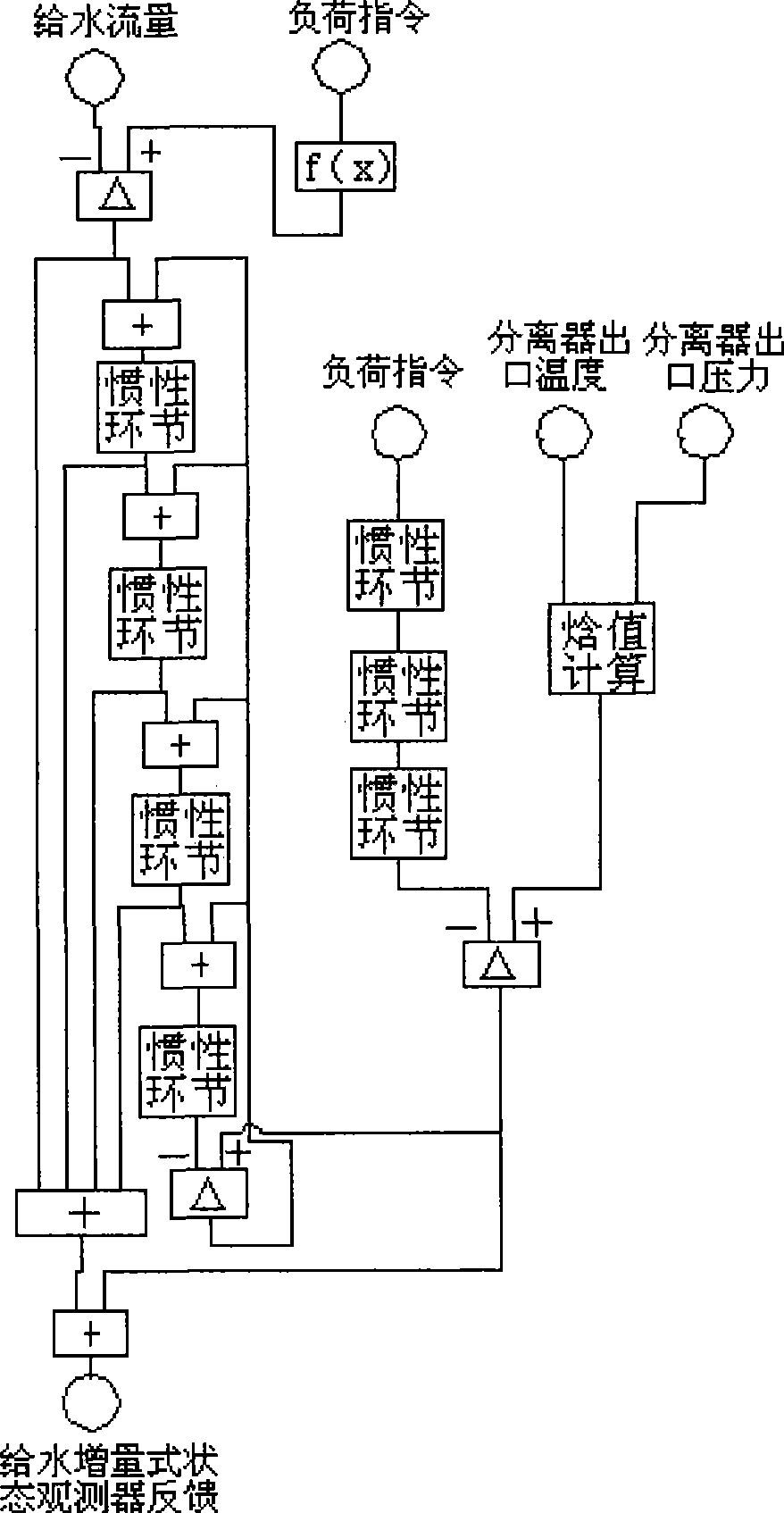

Supercritical DC furnace synthesis type coordinating control method

ActiveCN101509656AOvercome steam pressure overshoot or oscillationImprove dynamic responsivenessBoiler controlCoalCoordinate control

The invention relates to a comprehensive method for harmonizing and controlling a supercritical monotube boiler, comprising the steps as follows: 1) logic configuration of a traditional harmonizing and controlling system is carried out, the differential signal of the practical load given value is added in main control circuit of the boiler of the traditional harmonizing and controlling system, and interfaces are preserved for an increment-typed state observer, an inertia suppressor and a heat value observer; 2) the logic configuration of the increment-typed state observer is carried out and the output thereof is led into the traditional harmonizing and controlling system so as to be used as a feedforward signal for controlling the combustion rate; 3) the logic configuration of the inertia suppressor is carried out and the output thereof is led into the traditional harmonizing and controlling system so as to be used as the feedforward signal for controlling the combustion rate; 4) the logic configuration of the water-supply increment-typed state observer is carried out and the output thereof is led into the traditional harmonizing and controlling system so as to be used as a feedforward signal for controlling the water-supply; 5) the heat value observer is added in the heat value calculation circuit of the traditional harmonizing and controlling system, thus leading the heating-value signal of the quantity of the coal entering the boiler to be corrected. The method obtains excellent control effect during the controlling to the supercritical monotube boiler.

Owner:CHINA ELECTRIC POWER RES INST +2

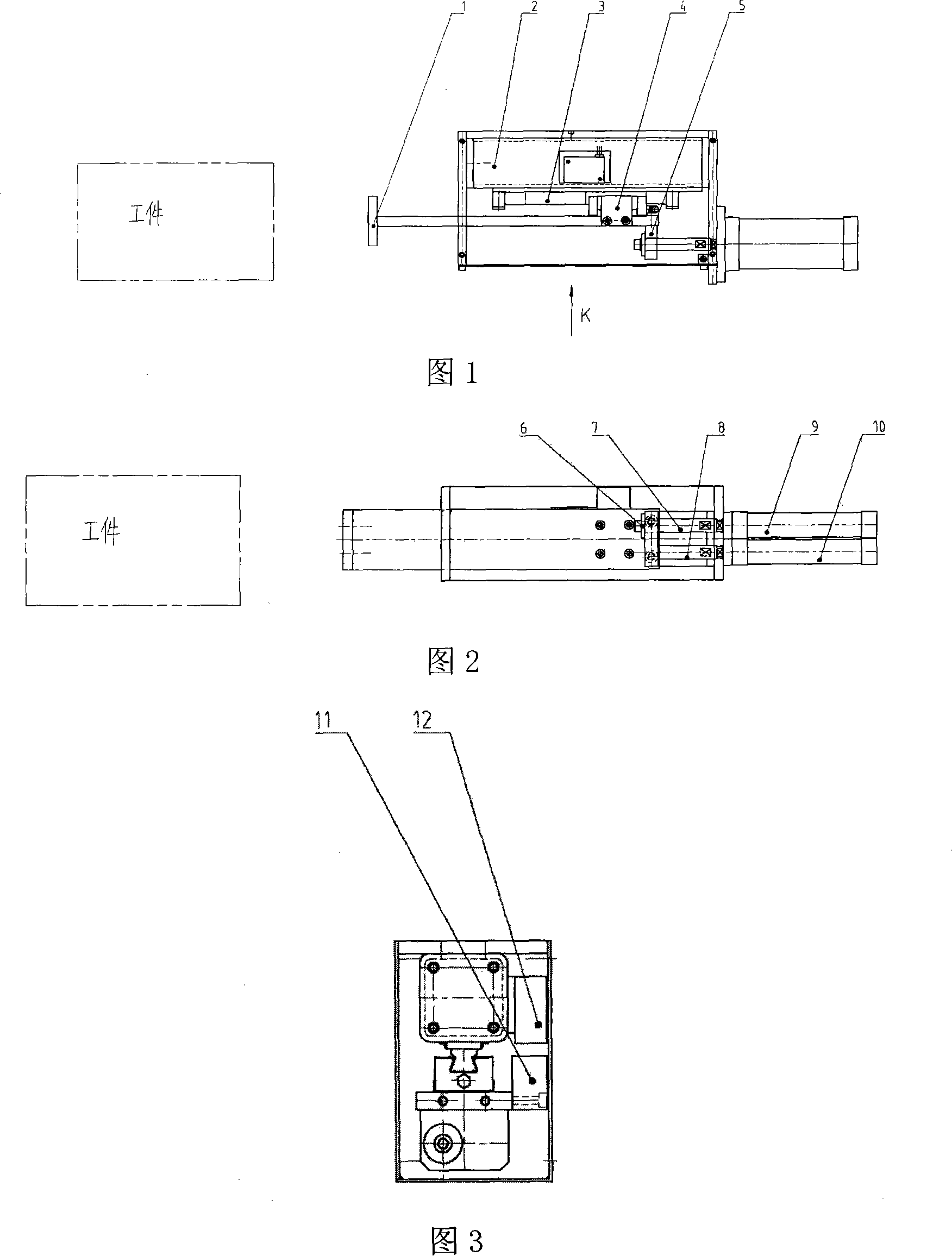

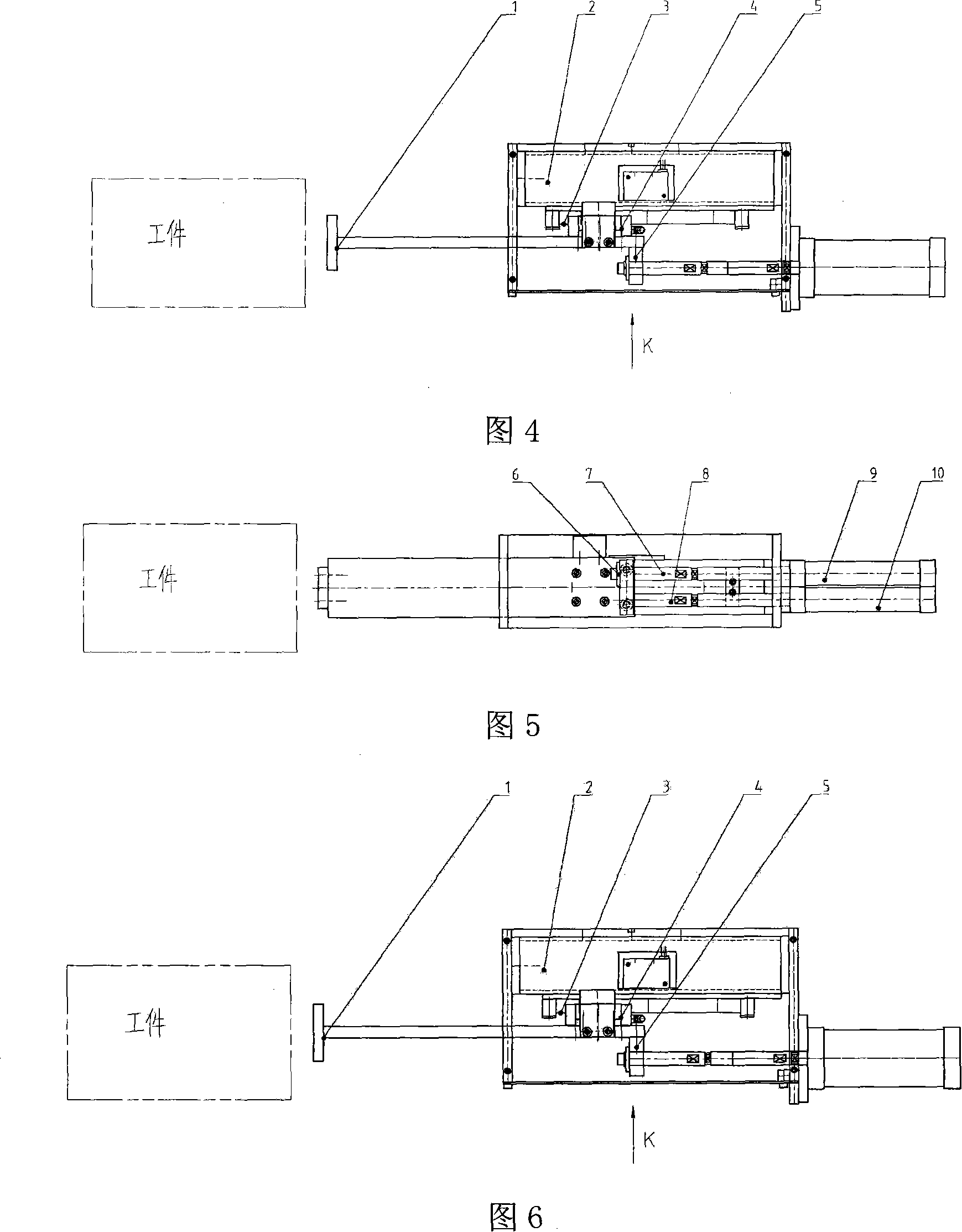

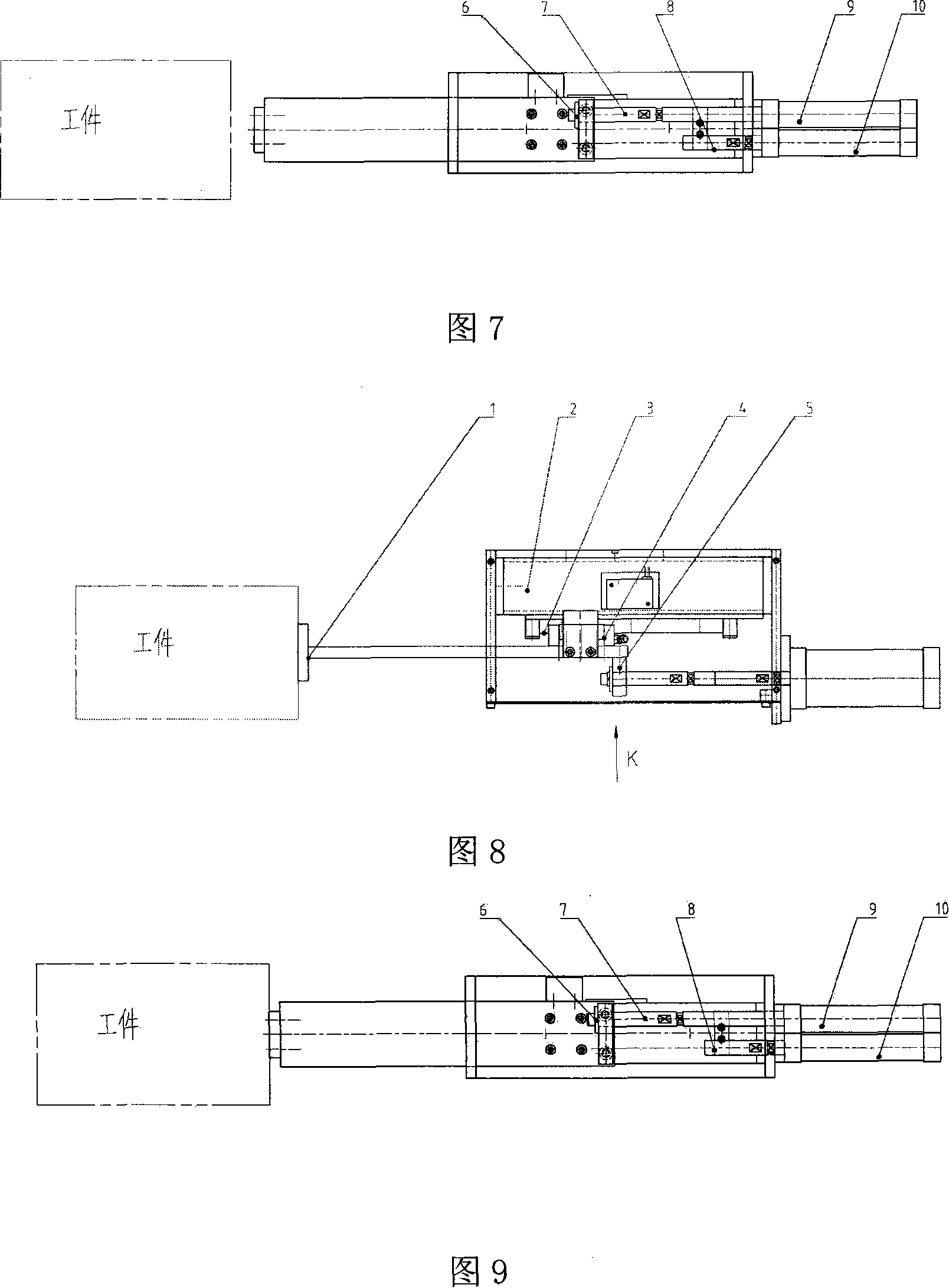

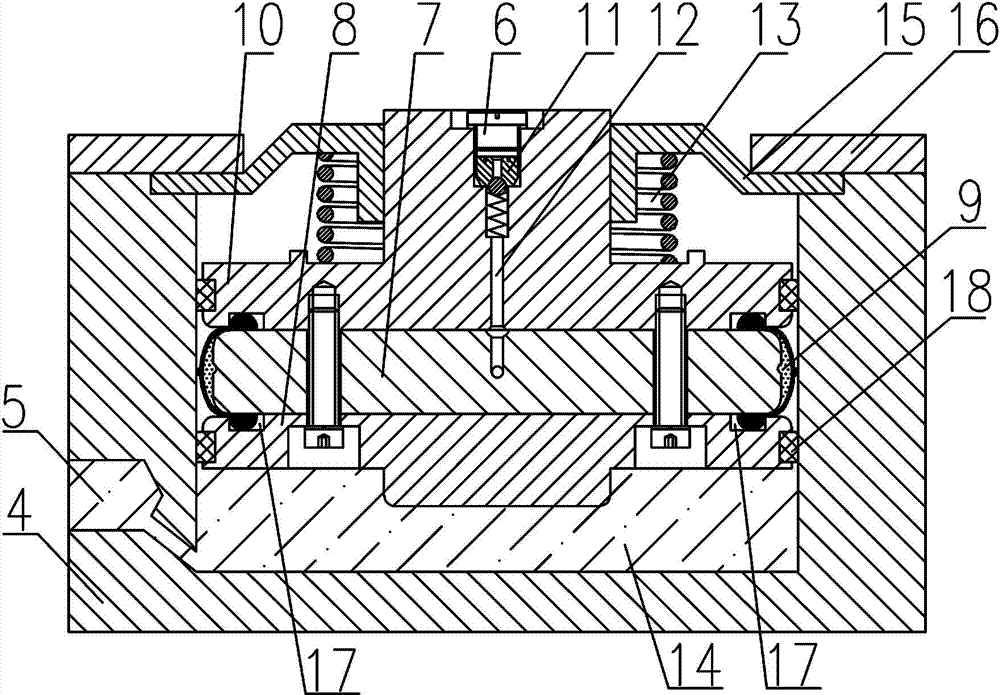

Detecting device

InactiveCN101100036AHigh speed recordingEfficient recordingMeasurement/indication equipmentsSoftware engineeringPosition sensor

The present invention relates to one kind of detection device for detecting position deviation or contour deviation of workpiece. The detection device includes one test rod, test rod driving cylinders, one track for the test rod to move linearly, one pedestal for the track to be fixed on, one position sensor fixed on the pedestal, and one sensing block on the test rod. Two cylinders include one connected to the test rod through one push rod and one other connected to the test rod through one pull rod. The present invention may be applied in detecting sections, plates, pipes, etc by using different test rods designed based on the shapes of the workpieces to be detected, and has wide application range, easy manufacture and high practicability.

Owner:SHANDONG FIN CNC MACHINE

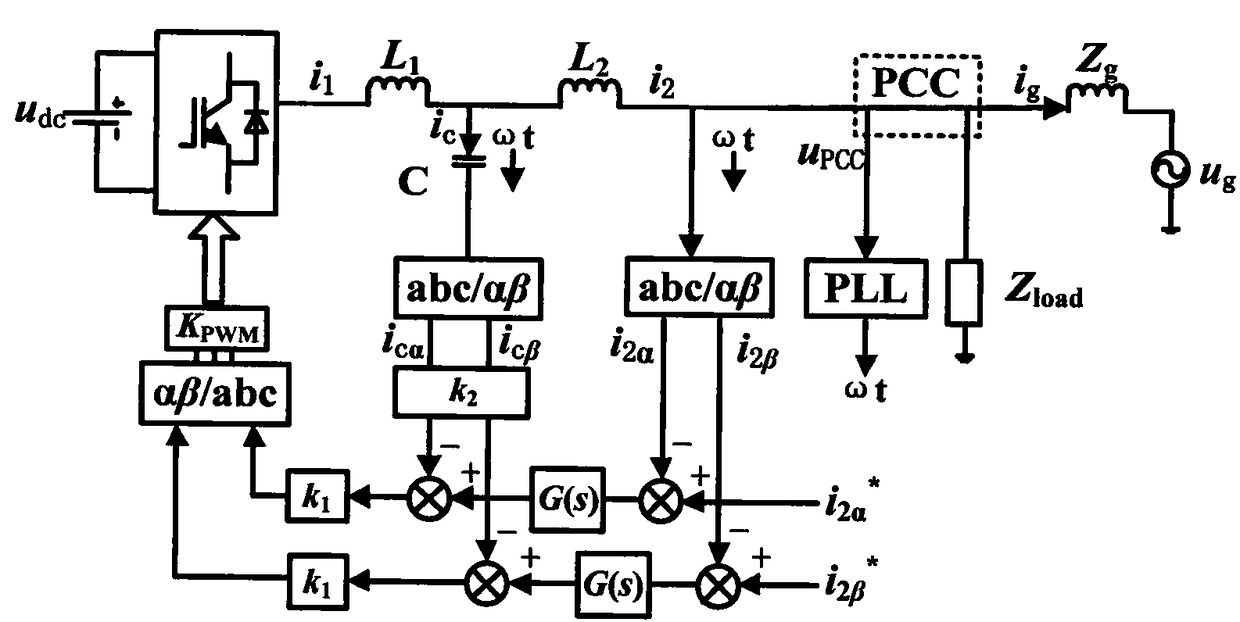

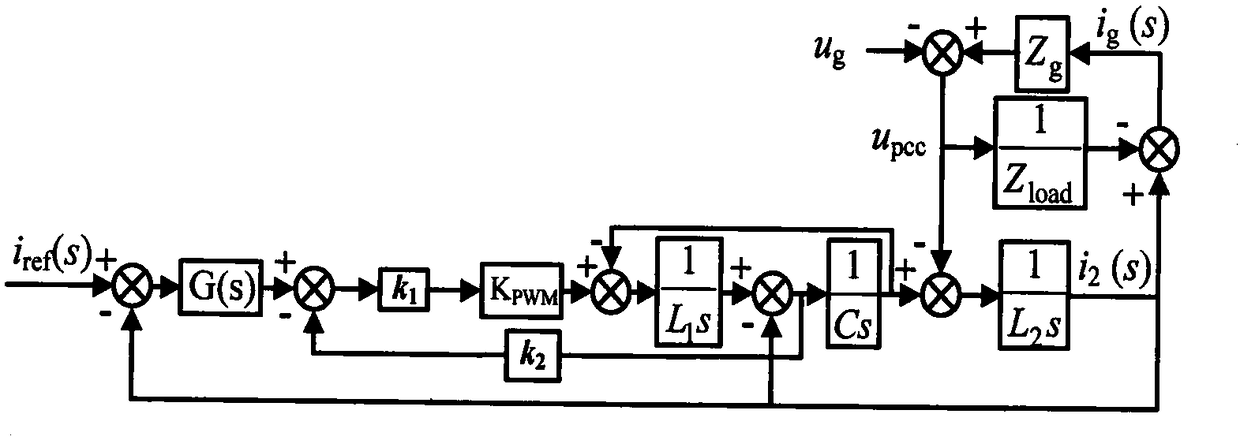

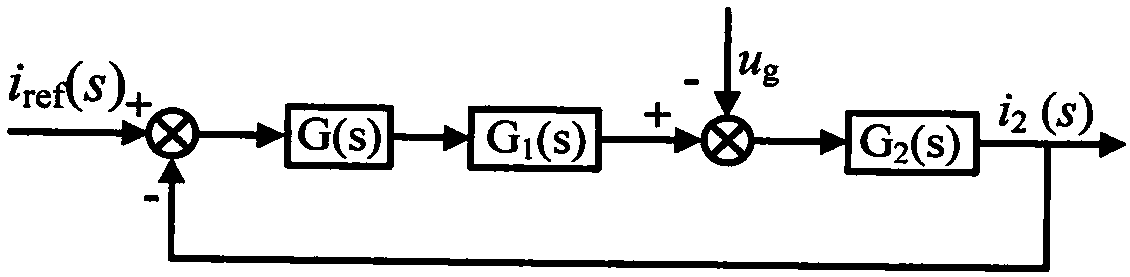

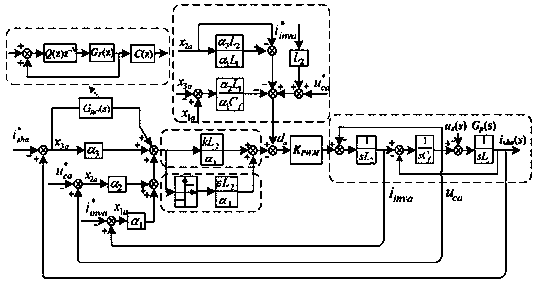

LCL-type grid-connected inverter parallel connection virtual impedance control method

ActiveCN108429281AHarmonic reductionStable jobSingle network parallel feeding arrangementsHarmonic reduction arrangementResponse processPower inverter

The invention relates to an LCL-type grid-connected inverter parallel connection virtual impedance control method. Under weak grid conditions, a parallel connection virtual impedance control method isprovided, difference is solved between grid-connected current ig and grid-connected instruction current parameters iref to obtain a signal ei, then difference is solved between the signal ei and a current signal fed back by an inverter side virtual impedance Zp(s), a and after double-current feedback control, a PWM modulating wave signal is generated to be transmitted into a PWM generator to generate a switch signal. After parallel connection virtual impedance, a system phase margin is increased, a harmonic is obviously lowered, the robustness and the interference resisting capability of thesystem are effectively improved, it is guaranteed that grid-inlet current is not greatly influenced by grid resistance, a parallel connection inverter can still normally work under the change of gridresistance wide ranges, the harmonic is small, and the applicability is good; in the dynamic response process of transforming a half load to a full load of the grid-connected virtual impedance, compared with a traditional method, the transition time is shorter, the overshooting amount is reduced, and stable running of a grid-connected inverter system is not influenced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

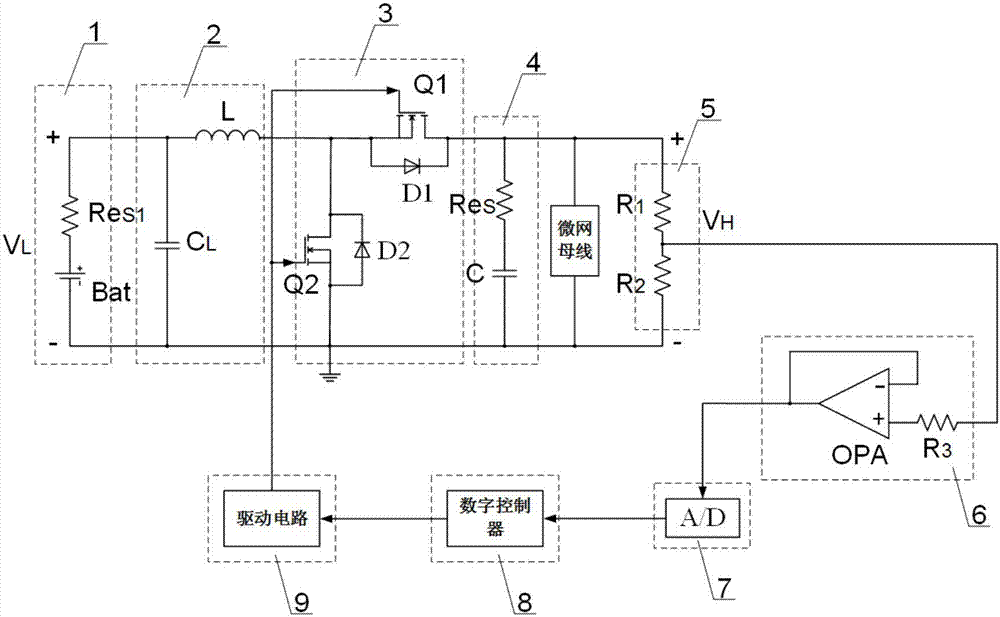

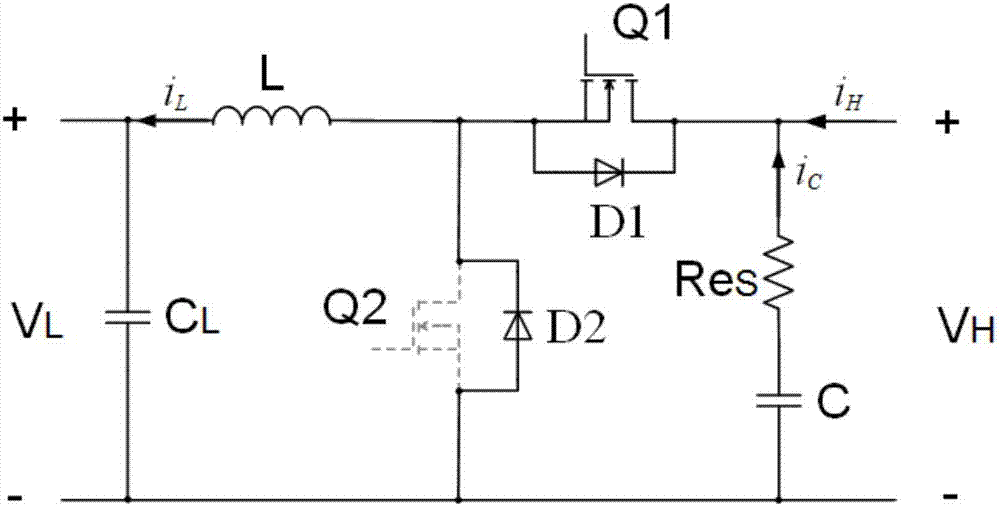

Control circuit of two-way DC/DC (Direct Current/Direct Current) power converter and control method of control circuit

PendingCN107070222AShort adjustment timeImprove dynamic responsivenessDc-dc conversionAc network load balancingResponse processHigh pressure

The invention discloses a control circuit of a two-way DC / DC (Direct Current / Direct Current) power converter and a control method of the control circuit, and belongs to the field of control circuits of power converters. The control circuit comprises a voltage division detection circuit, a voltage follower, an A / D (Analog to Digital) conversion circuit, a digital controller and a driving circuit. The control method takes control of voltage of a high voltage side as an example, and comprises the steps of stabilizing the voltage of the high voltage side by the digital controller in a PID (Proportion Integration Differentiation) control mode when the power converter operates in a steady state, and switching to capacitor charge balance control in a corresponding Buck or Boost mode from the PID control mode when the voltage division detection circuit detects that a fluctuation of the voltage of the high voltage side exceeds a set threshold. For the problem of poor dynamic property of the two-way DC / DC power converter in the prior art, the control circuit ensures an optimal transient state response process, has high steady state output accuracy, and is applicable to any non-isolated two-way DC / DC power converter.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

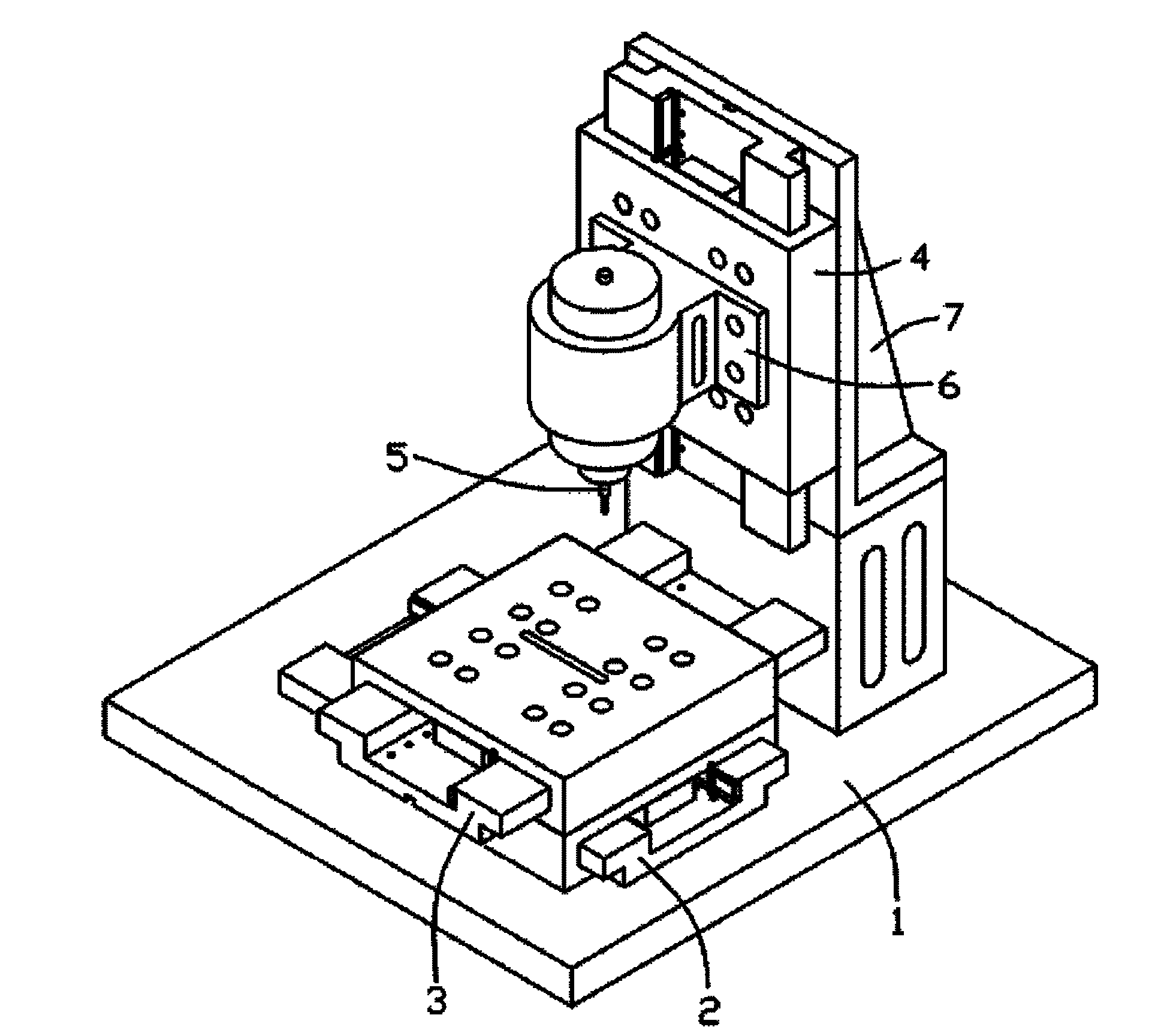

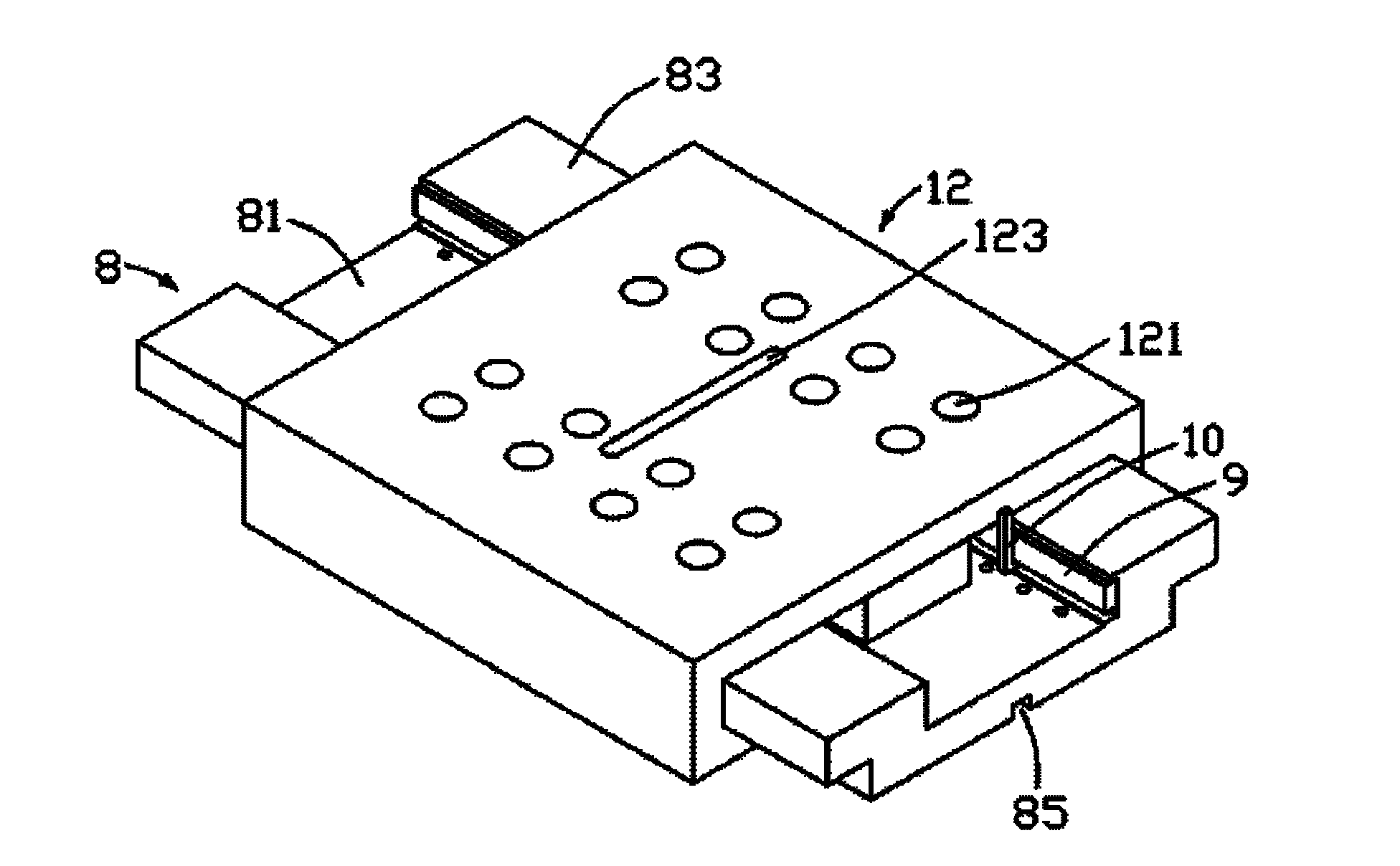

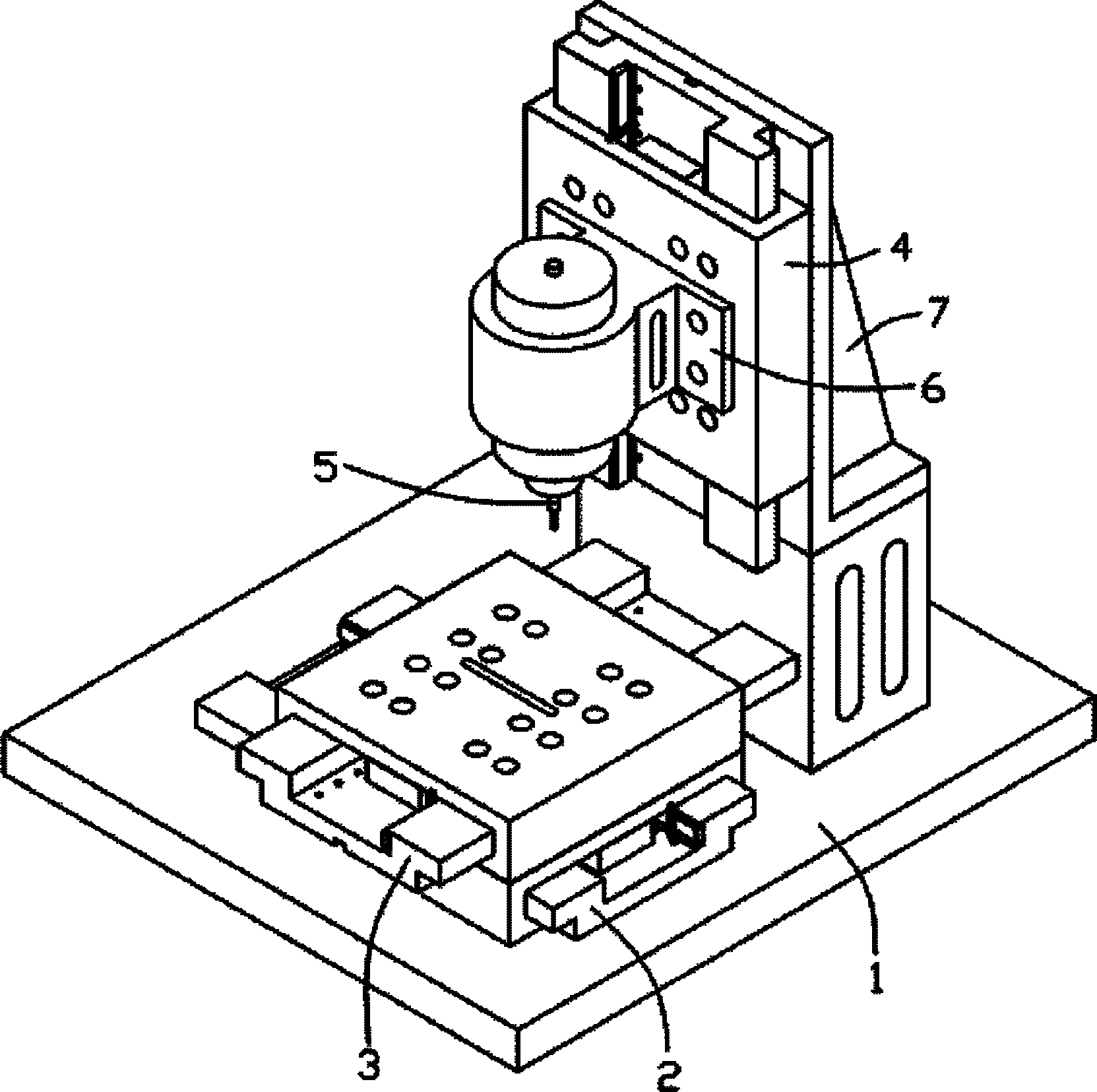

Tabletop milling machine, gantry tabletop milling machine and combined motion platform

ActiveCN102145456AReduce frictional resistanceReduce volumeLarge fixed membersEngineeringLinear motor

The invention discloses a tabletop milling machine, a gantry tabletop milling machine and a combined motion platform. The tabletop milling machine comprises an X-axis motion platform, a Y-axis motion platform and a Z-axis motion platform, wherein both the X-axis motion platform and the Y-axis motion platform respectively comprise a sliding platform and a sliding base; the sliding base of the Y-axis motion platform is fixed above the sliding platform of the X-axis motion platform; each sliding base comprises air floatation guide rails formed at both sides of the sliding base and a first grooveformed at the middle part of the sliding base; both the X-axis motion platform and the Y-axis motion platform respectively comprise a linear motor; each linear motor comprises a stator and a rotor; each stator is fixed at the bottom of the corresponding first groove; and each rotor is fixed on the bottom surface of the corresponding sliding platform and is arranged relative to the corresponding stator. By the mode, the feeding motion in the X-axis, Y-axis and Z-axis directions can be realized and the utilization rate of the space is improved.

Owner:BEIJING A&E TECH

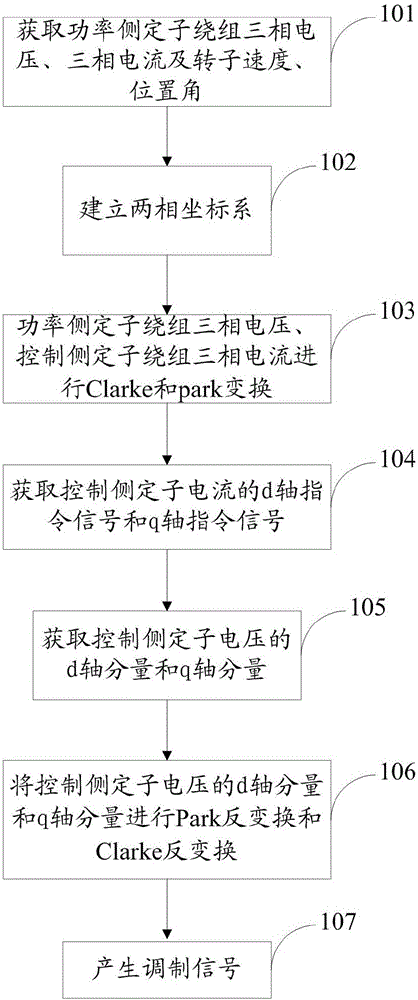

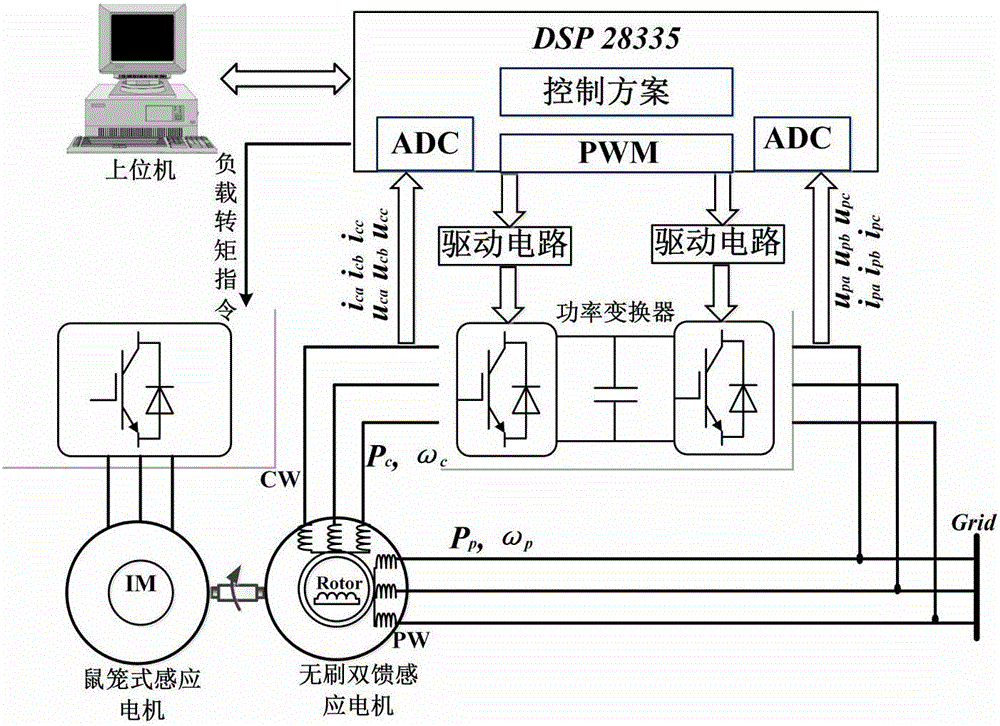

Motor speed regulation control method and system

ActiveCN106505921AHelps Advance Industrial ApplicationsPromote the process of industrial applicationElectronic commutation motor controlVector control systemsInner loopDoubly fed induction machine

The invention discloses a motor speed regulation control method and system. According to the method, based on power side stator flux orientation, a dual-closed-loop cascading structure of a rotary speed, a reactive power outer ring and a control side stator current inner loop is established by simplifying a mathematical model; influence from a current cross coupling item is counteracted through feedforward control; and decoupling control on the speed and reactive power of a brushless doubly-fed induction motor is realized; meanwhile, by adopting a phase-locked loop design thought, a power side stator flux observer is configured to obtain information of amplitude value, frequency, phase angle and the like of the stator flux so as to complete coordinate transformation of related electric quantity; by adoption of the method, dependency on parameter is low; the decoupling control on electromagnetic torque and reactive power can be realized; the static performance of a speed regulation system of the brushless doubly-fed induction motor can be ensured while high dynamic response performance also can be ensured under sudden change conditions of load and speed; and in addition, the technical scheme is simple to realize, low in calculated quantity and low in parameter dependency.

Owner:湖南仰高数控设备有限公司

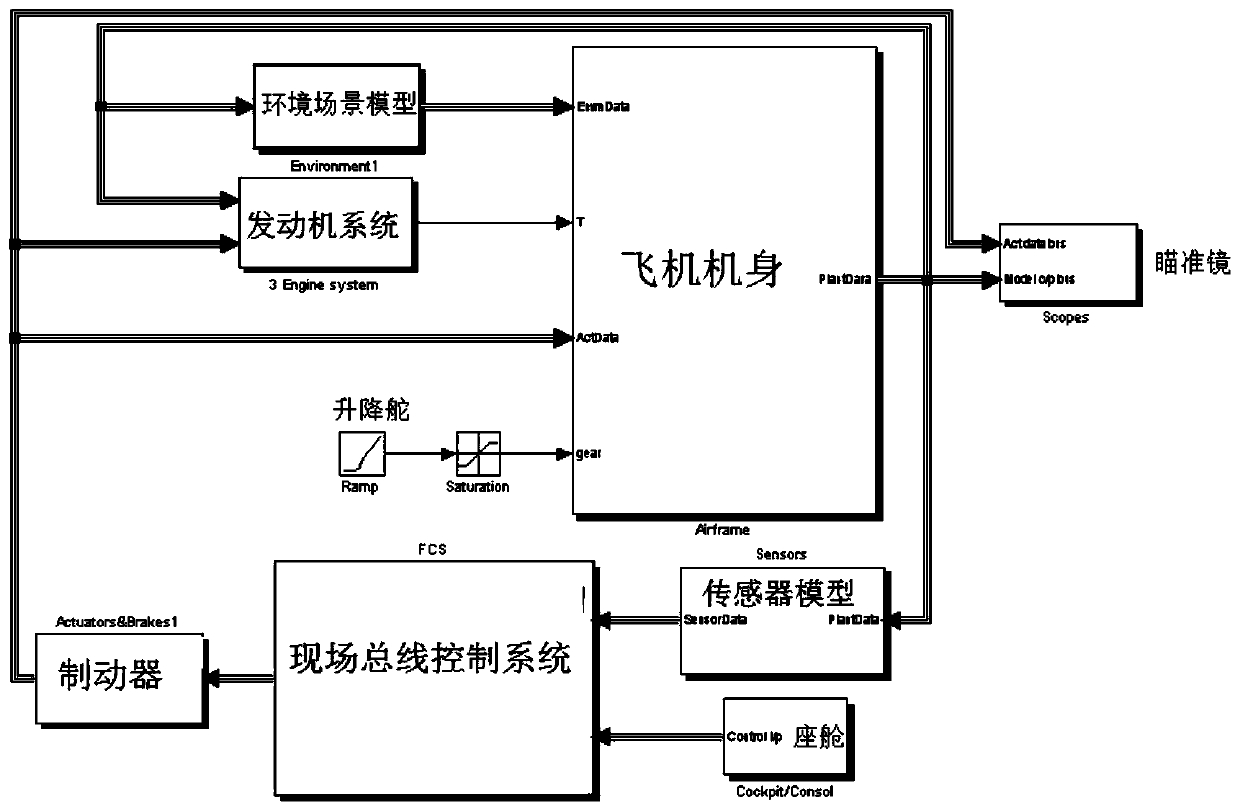

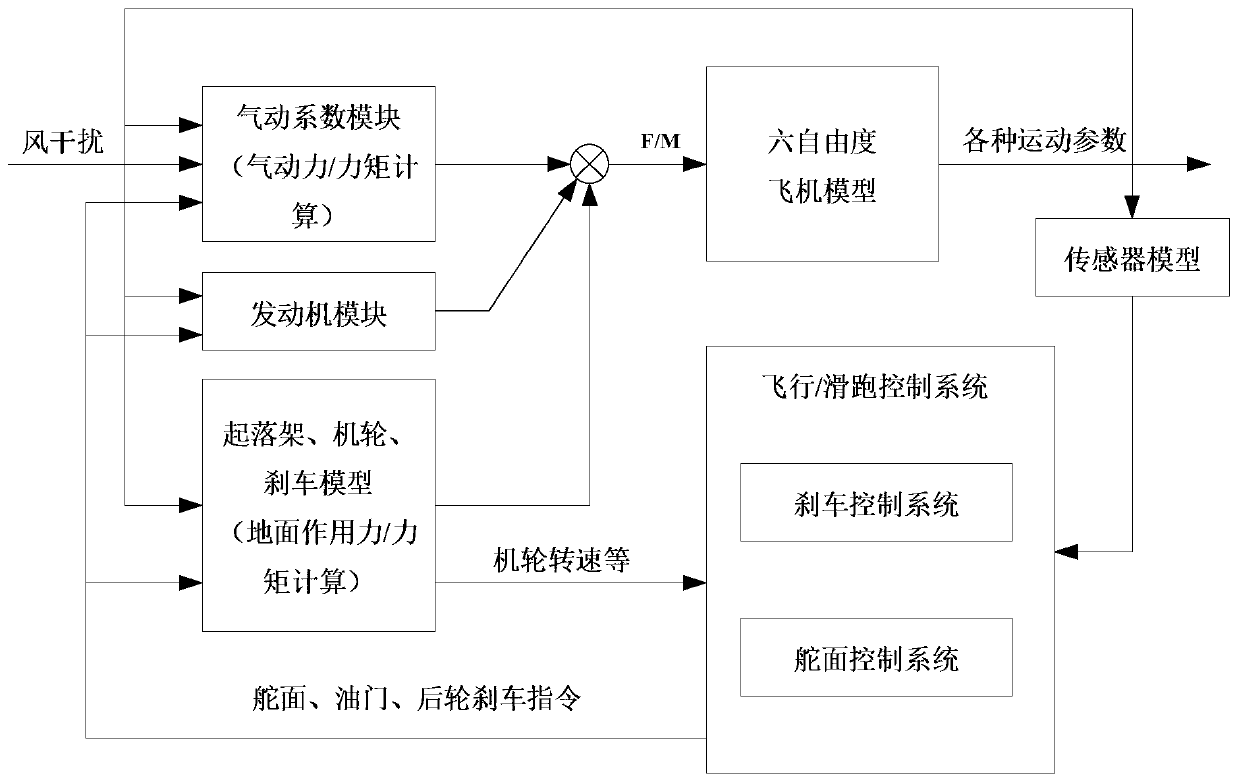

Unmanned aerial vehicle UAV control law parameter adjusting method

InactiveCN110032797AAvoid huge workloadImprove dynamic responsivenessDesign optimisation/simulationSpecial data processing applicationsJet aeroplaneAcquired characteristic

The invention discloses an unmanned aerial vehicle UAV control law parameter adjusting method, and aims at providing a parameter adjusting method which is large in parameter adjusting freedom degree,capable of effectively improving system design efficiency and capable of saving cost. According to the technical scheme, the method comprises the steps that a Matlab is used as a tool, and a general control console, a pneumatic coefficient module, an engine module, an undercarriage, airplane wheels, a brake model, a pitch angle local controller at the balance point of the unmanned aerial vehicle,a six-degree-of-freedom airplane model and a general module library of a sensor model for building the control law of the unmanned aerial vehicle are generated; a field bus control system FCS selectsa set control mode to calculate a control law, an accelerator position instruction and a rudder deviation instruction according to a control instruction given by the general console, ,,sends the flight state parameters of the unmanned aerial vehicle, and directly fits the obtained controller parameters at the characteristic points to obtain a function of the controller parameters about the heightH and the Mach number M and a parameter adjustment control law of a continuous change law of the controller parameters along with the parameter variables in the whole situation.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

LCLCL type active power filter control method based on repeated sliding-mode control

ActiveCN108899907ASolve the robustness problemFast dynamic responseActive power filteringAc network to reduce harmonics/ripplesMode controlResonance

The invention relates to an LCLCL type active power filter control method based on repeated sliding-mode control, and belongs to the field of an active power wave filter control. A slide mode switching function is built by a linear combination of three error variables of the current error, wave filtering capacitance voltage error and grid-connected harmonic current error output by an inverter; thesliding mode control effect is solved through index reaching law; by aiming at the sliding mode surface drift problem due to system modeling incompleteness and system parameter uncertainty, the repeated control is used for replacing multi-proportional resonance control to be added into a sliding mode surface; the harmonic current error item x3a is compensated; a repeated sliding mode composite control strategy is provided; the whole harmonic compensation is realized; the steady state error is further reduced; the frequency adaptivity is enhanced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

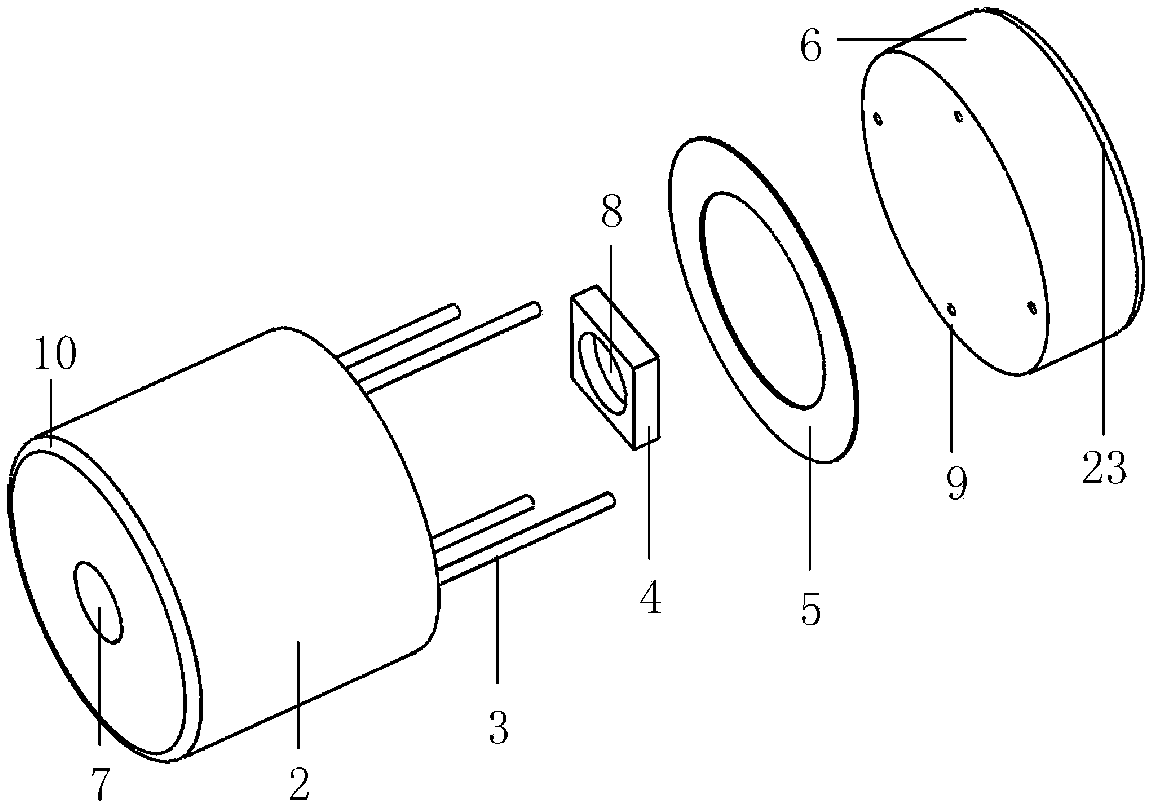

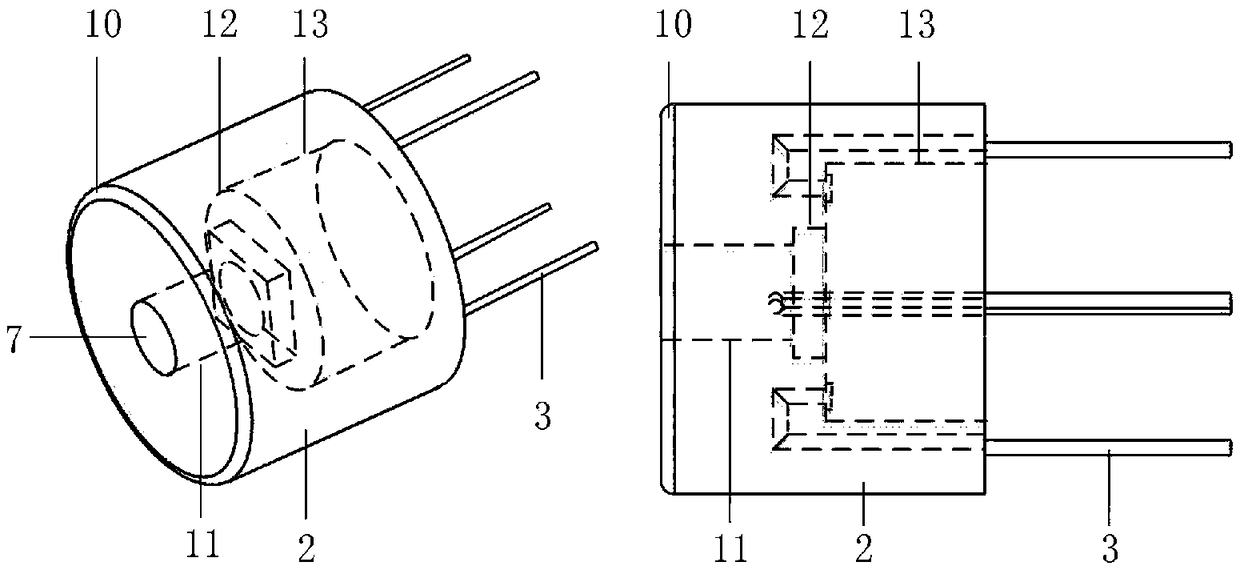

Miniaturized heat-resistant and high-dynamic pressure sensor

ActiveCN108871652ASolve the problem of high temperature failureImprove high temperature stabilityFluid pressure measurement by electric/magnetic elementsAdhesiveEngineering

A miniaturized heat-resistant and high-dynamic pressure sensor comprises a sensor probe which is internally provided with a sensor chip, the sensor chip is fixed through a heat-resistant ceramic adhesive, the sensor probe is connected with a metal tungsten filament which passes through a seal plate, and the seal plate is connected with the sensor probe; the front end face of the sensor probe is provided with a pressure guidance hole which communicates with a pressure channel and a square sensor chip in the sensor probe, the rear end of the sensor chip installation groove is provided with a sensor vacuum chamber, and the side wall of the sensor probe is internally provided with a the metal tungsten filament taken as a lead terminal of the pressure sensor; the sensor chip is square-shaped, four sensitive resistors are arranged at the front surface of the sensor chip in the same direction, the back surface of the sensor chip is a square cavity corresponding to a square sensitive film, andthe pressure is applied to the square sensitive film through the pressure guidance hole. The miniaturized heat-resistant and high-dynamic pressure sensor is small in volume, resistant to heat and fast in response, and can be used for measurement of the total pressure and the static pressure.

Owner:XI AN JIAOTONG UNIV

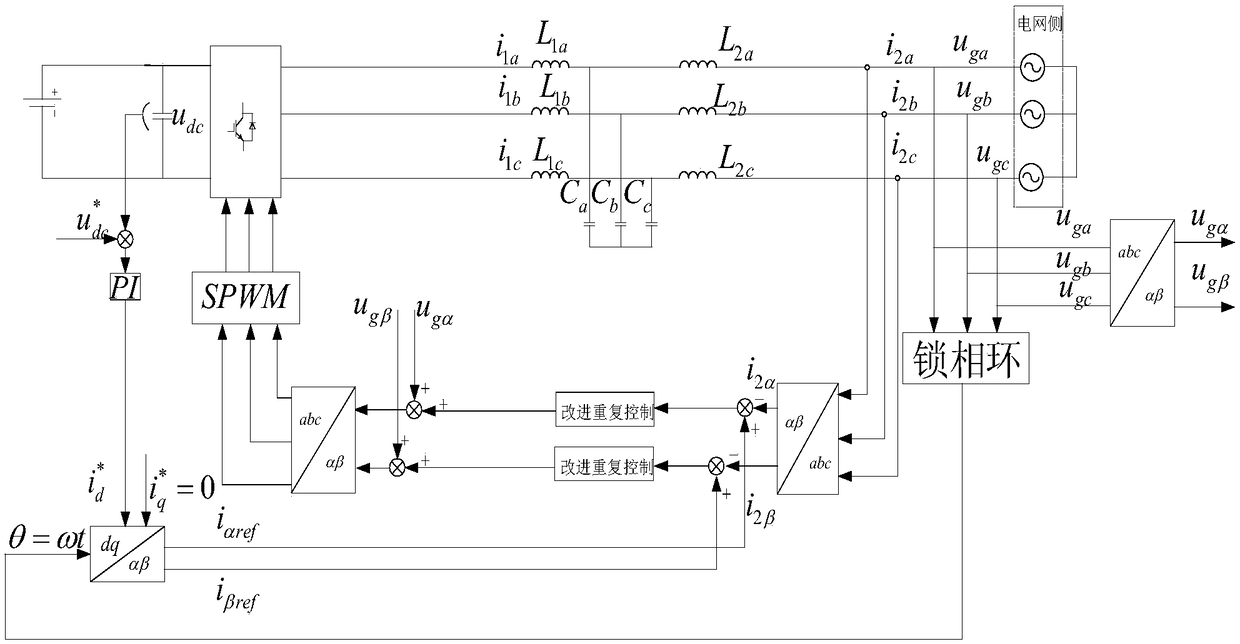

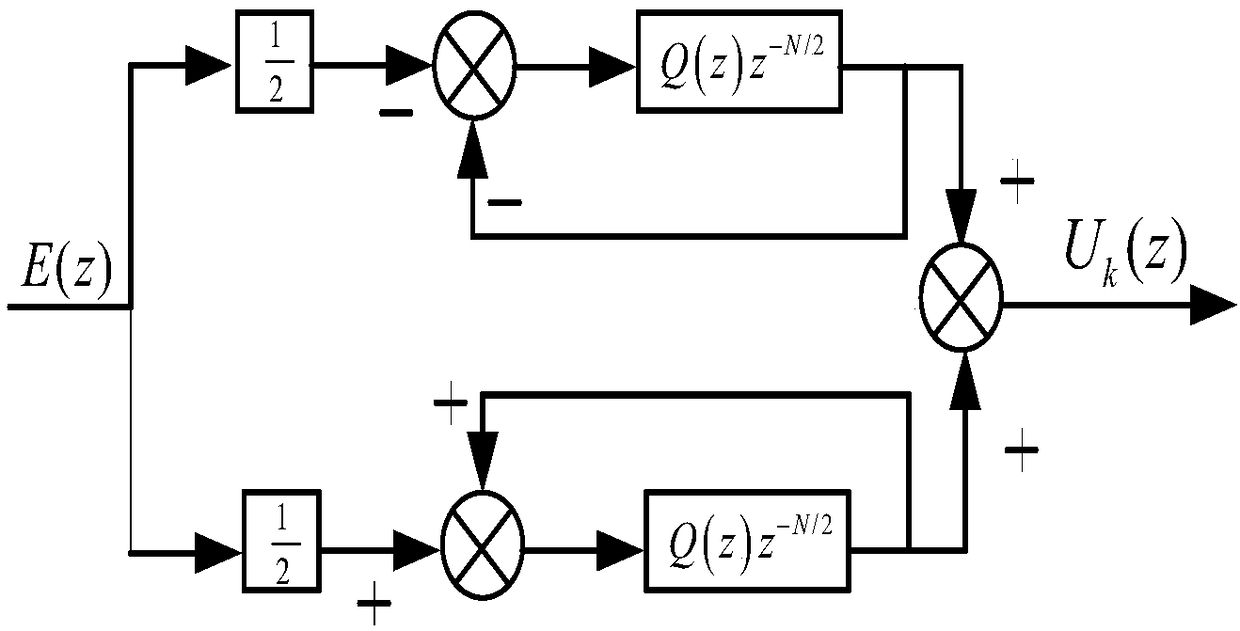

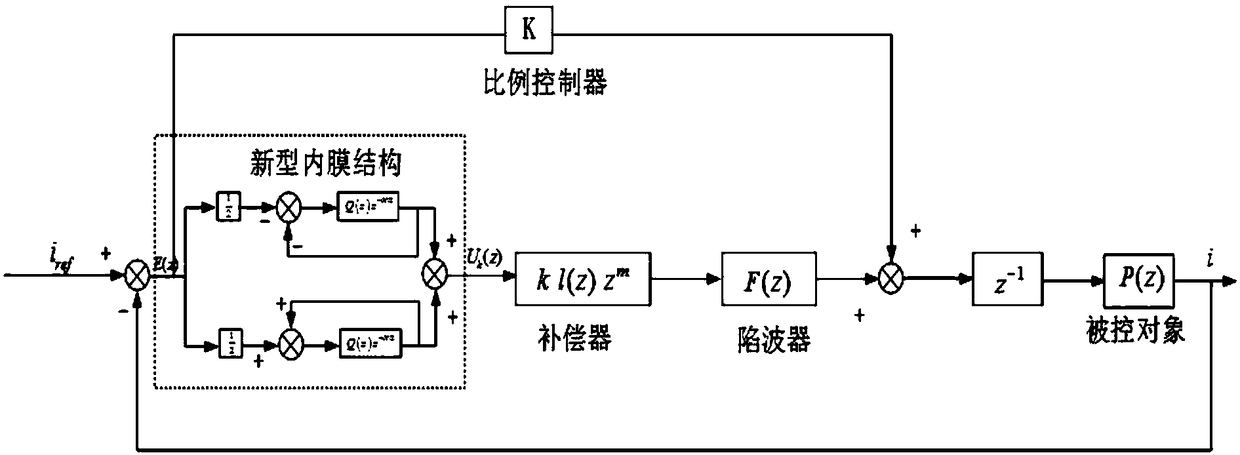

Grid-connected inverter current control method based on improved repetitive controller

InactiveCN109378862AImprove dynamic responsivenessSuppress grid voltage disturbanceAc-dc conversionSingle network parallel feeding arrangementsPower inverterPower grid

The present invention relates to a three-phase grid-connected inverter grid-connected current control method, and relates to a three-phase LCL-type grid-connected inverter grid-connected current control method based on an improved repetitive controller, especially to a grid-connected inverter current control method based on an improved repetitive controller. The voltage of a direct current side ofthe inverter is controlled by a voltage regulation outer ring, the output of a direct current IP regulator is taken as a given electric current as shown in the description of a d axis in a two-phaserotating coordinate system; currents as shown in the description are subjected to inverse park transformation to obtain current set values i[Alpha]ref and i[Beta]ref in an [Alpha][Beta] coordinate system; an inner film structure with repetitive control is improved to shorten the delay time to half of the original delay time; the improvement of the repetitive control is that a proportional controller and a repetition controller are connected in parallel to improve the dynamic response capacity of the repetitive control; and a voltage of a power grid is subjected to clark transformation and thenis output after processing through a feed-forward function as output of a feed-forward link of the voltage of the power grid. The grid-connected inverter current control method based on the improvedrepetitive controller shortens the inherent delay time of the repetitive control to achieve rapid and accurate tracking of the set reference current by employing the inverter grid-connected current soas to have better steady accuracy, response speed and robustness.

Owner:NORTHEASTERN UNIV

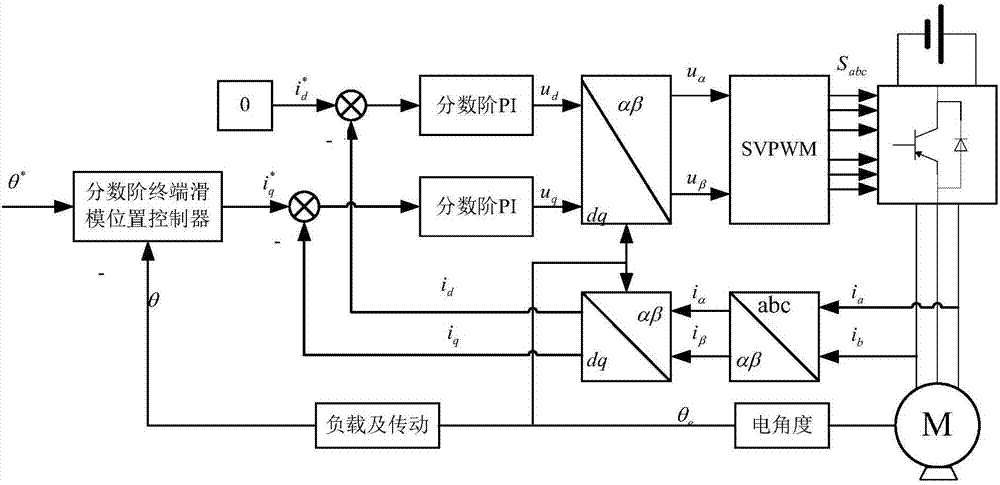

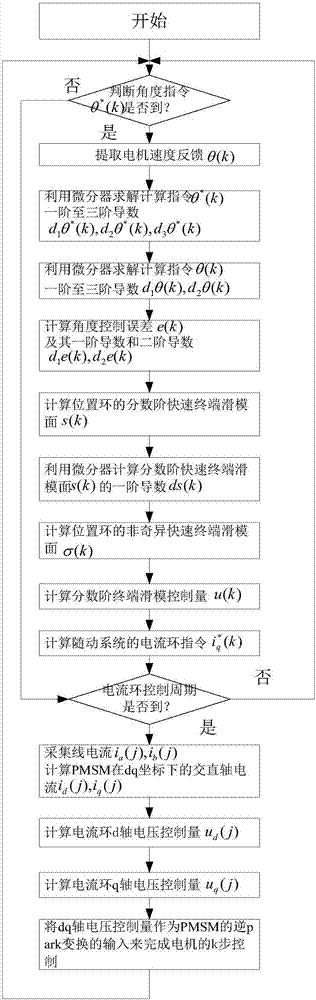

Follow-up control method by means of fractional-order quick terminal sliding mode control

InactiveCN107577149AImprove response bandwidthEliminate chatterAdaptive controlTerminal sliding modeShaft voltage

The invention provides a follow-up control method by means of fractional-order quick terminal sliding mode control. The follow-up control method includes receiving angle instructions, extracting follow-up angle feedback, computing first-order derivatives, second-order derivatives and third-order derivatives of the instructions and computing first-order derivatives and second order-derivatives of the angle feedback; computing angle control errors and first-order derivatives and second-order derivatives of the angle control errors; computing first-order derivatives of fractional-order quick terminal sliding mode surfaces and non-singular quick terminal sliding mode surfaces of position loops; computing fractional-order terminal sliding mode control quantities and current loop instructions offollow-up systems; acquiring line currents, computing alternating and direct shaft currents of PMSM (permanent magnet synchronous motors) in dq coordinates and inputting dq shaft voltage control quantities for inverse park transformation on the PMSM to control the motors. The follow-up control method has the advantages that the systems are excellent in dynamic response capacity, and static positioning and dynamic tracking precision requirements can be met.

Owner:西北机电工程研究所

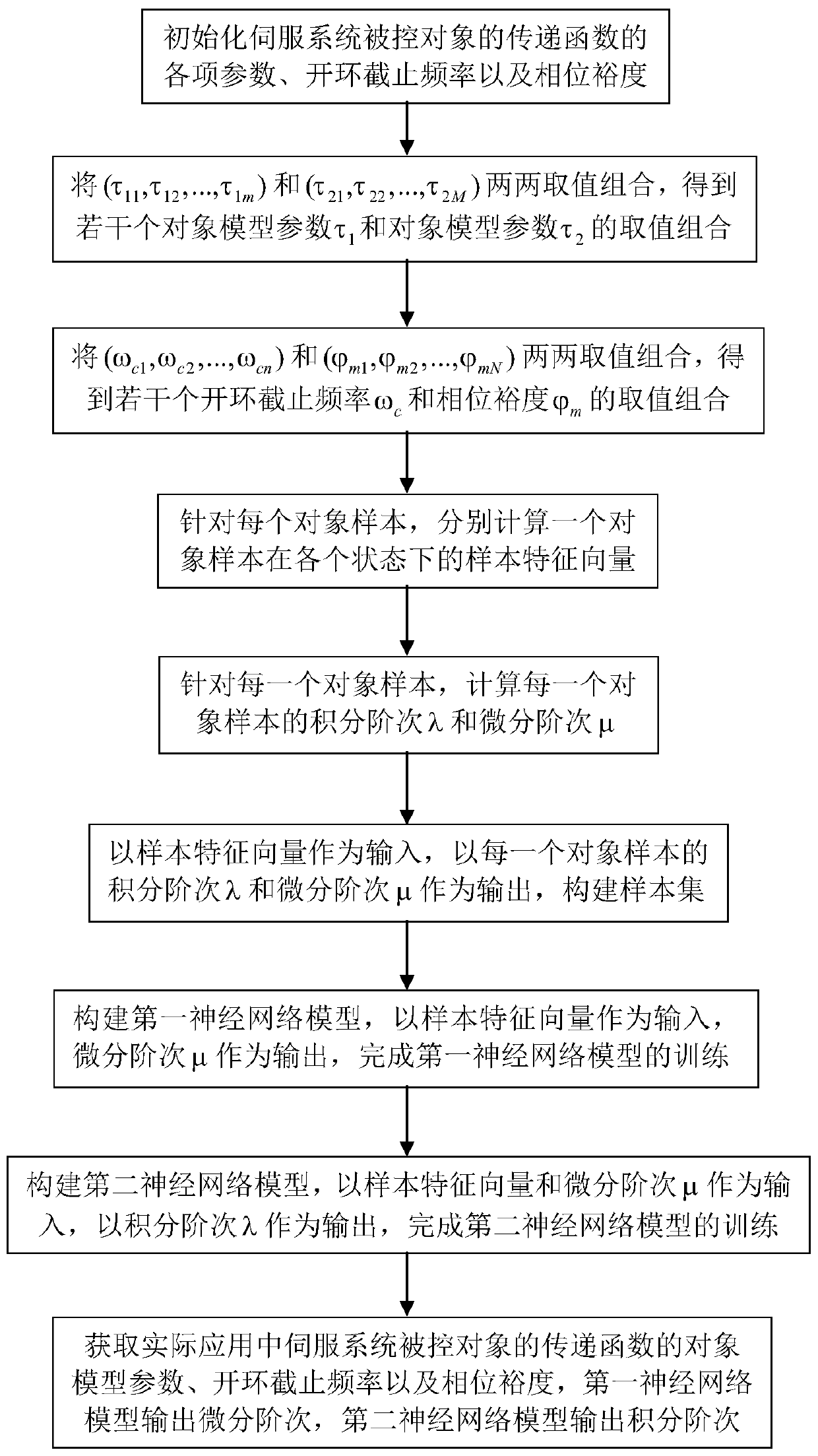

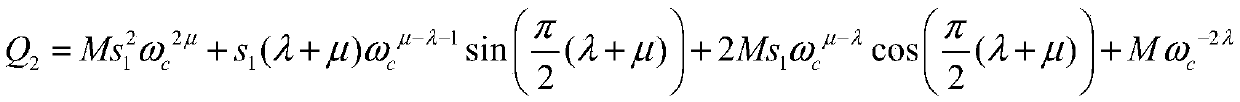

Parameter tuning method for fractional-order PID controller

ActiveCN110531612ARobustImprove dynamic responsivenessControllers with particular characteristicsFractional-order controlNetwork model

The invention discloses a parameter tuning method for a fractional-order PID controller, and the method comprises the following steps of calculating an integration order lambda and a differential order mu of a model of the fractional-order PID controller based on a neural network model; and calculating a proportional gain Kp, an integral gain Ki and a differential gain Kd of the model of the fractional-order PID controller by using a horizontal phase criterion based on the obtained integration order lambda and the differential order mu of the model of the fractional-order PID controller. The method provided by the invention first calculates the integration order lambda and the differential order mu of the fractional-order PID controller based on the neural network model, and then calculates the proportional gain Kp, the integral gain Ki and the differential gain Kd of the model of the fractional-order PID controller by using the horizontal phase criterion based on the integration orderlambda and the differential order mu obtained based on the neural network model, which can achieve the best dynamic response performance while ensuring good robustness of the PID controller, and simplify the entire calculation process.

Owner:FOSHAN UNIVERSITY

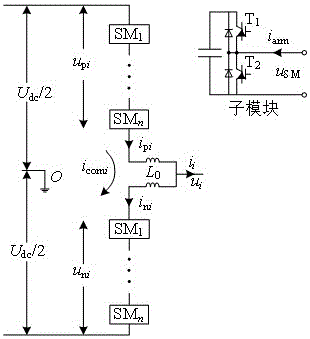

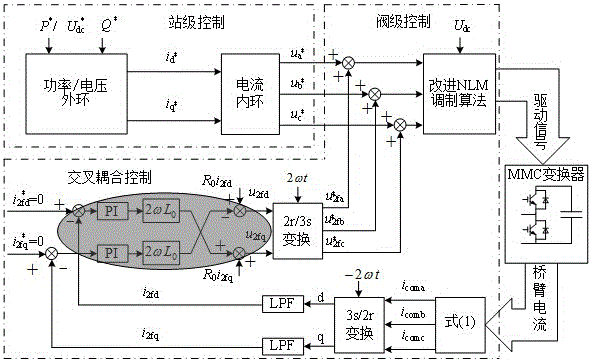

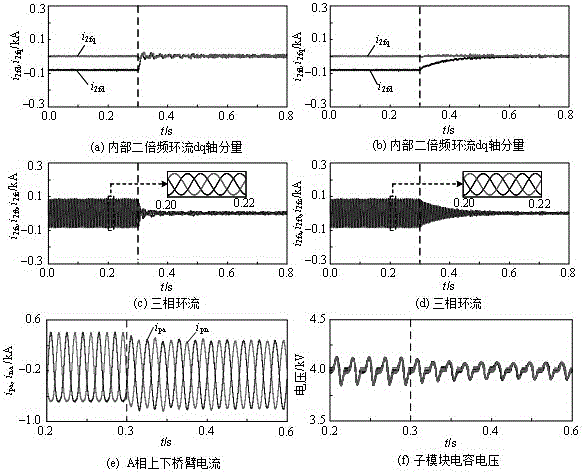

Loop current inhibition method suitable for modular multilevel converter

The invention discloses a loop current inhibition method suitable for a modular multilevel converter. The loop current inhibition method includes that loop current inside the modular multilevel converter (MMC) is separated from detected bridge arm current through frequency-doubled negative sequence rotation coordinate conversion, and a cross coupling novel control mode is adopted to realize quick inhibition of frequency-doubled loop current inside the MMC, so that capacitor voltage fluctuation of an MMC submodule can be effectively reduced, and stability and overall running performance of an MMC system can be improved.

Owner:CHONGQING UNIV

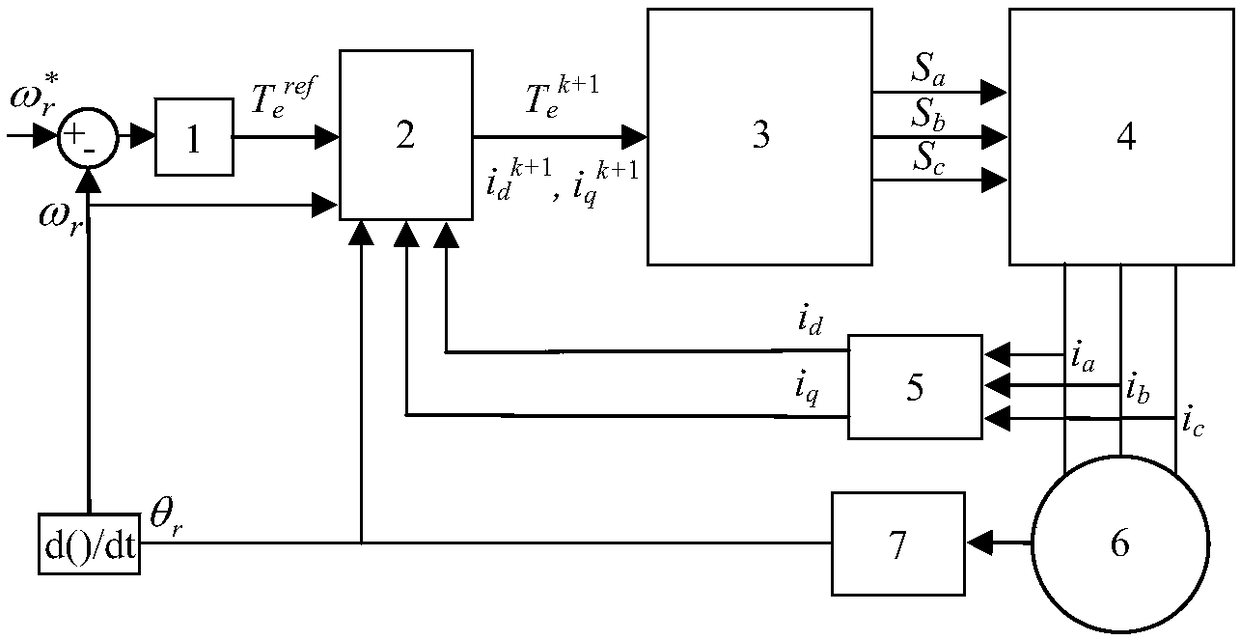

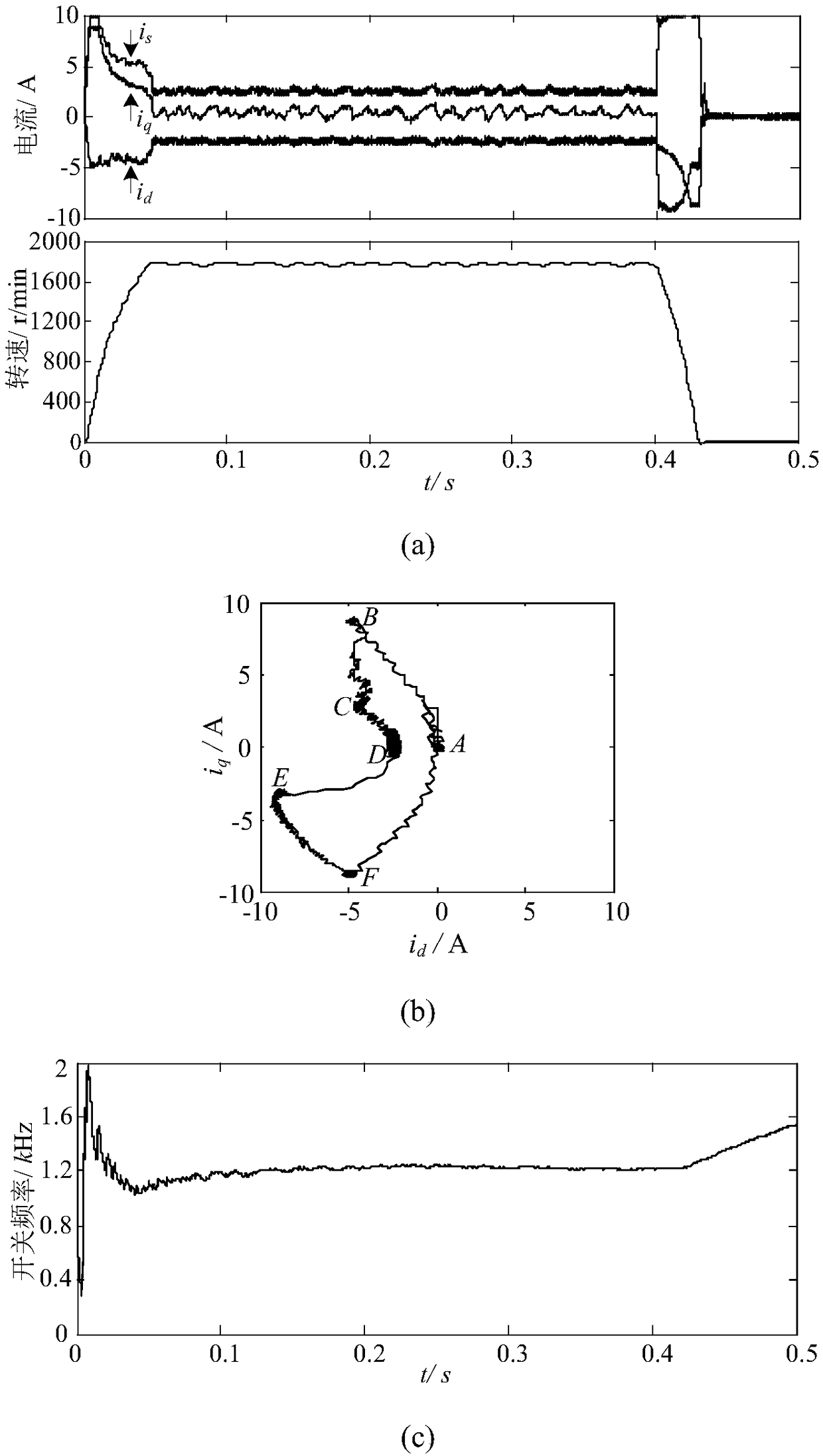

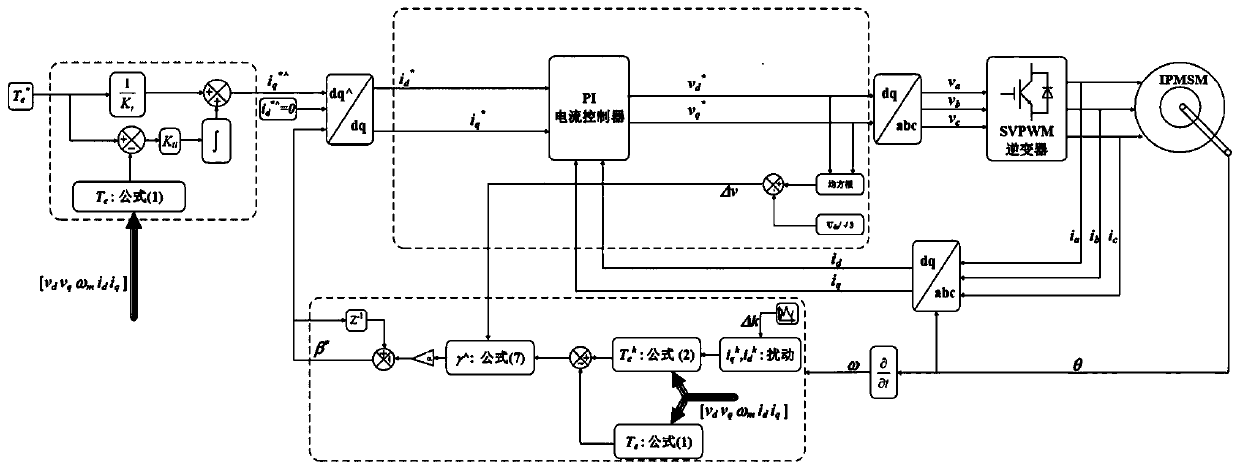

Permanent magnet synchronous motor model predictive torque control method considering switching frequency optimization

ActiveCN108448961AReduce switching frequencyImprove dynamic responsivenessAC motor controlVector control systemsPower inverterNegative feedback

Owner:江苏富浩电子科技有限公司

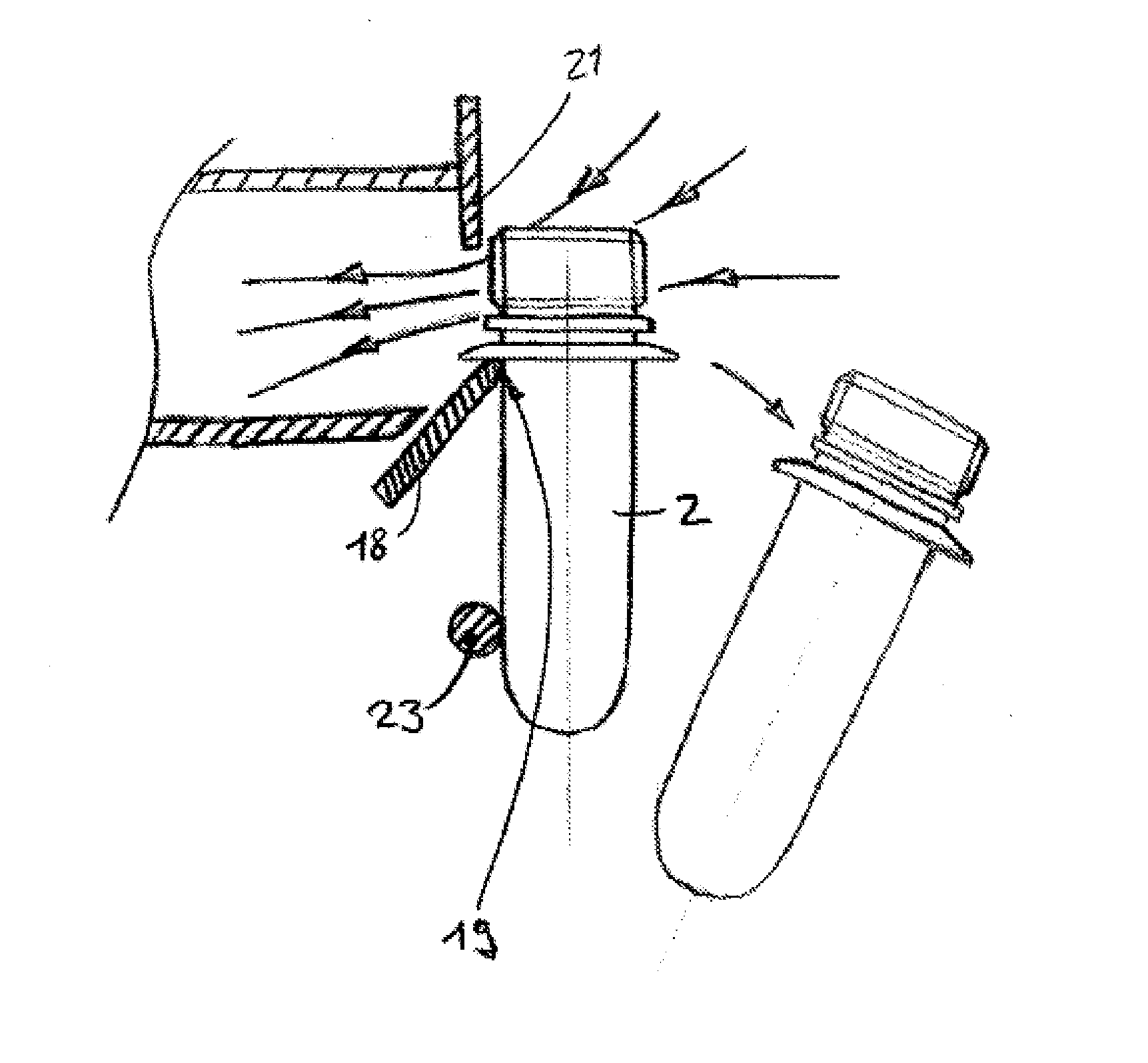

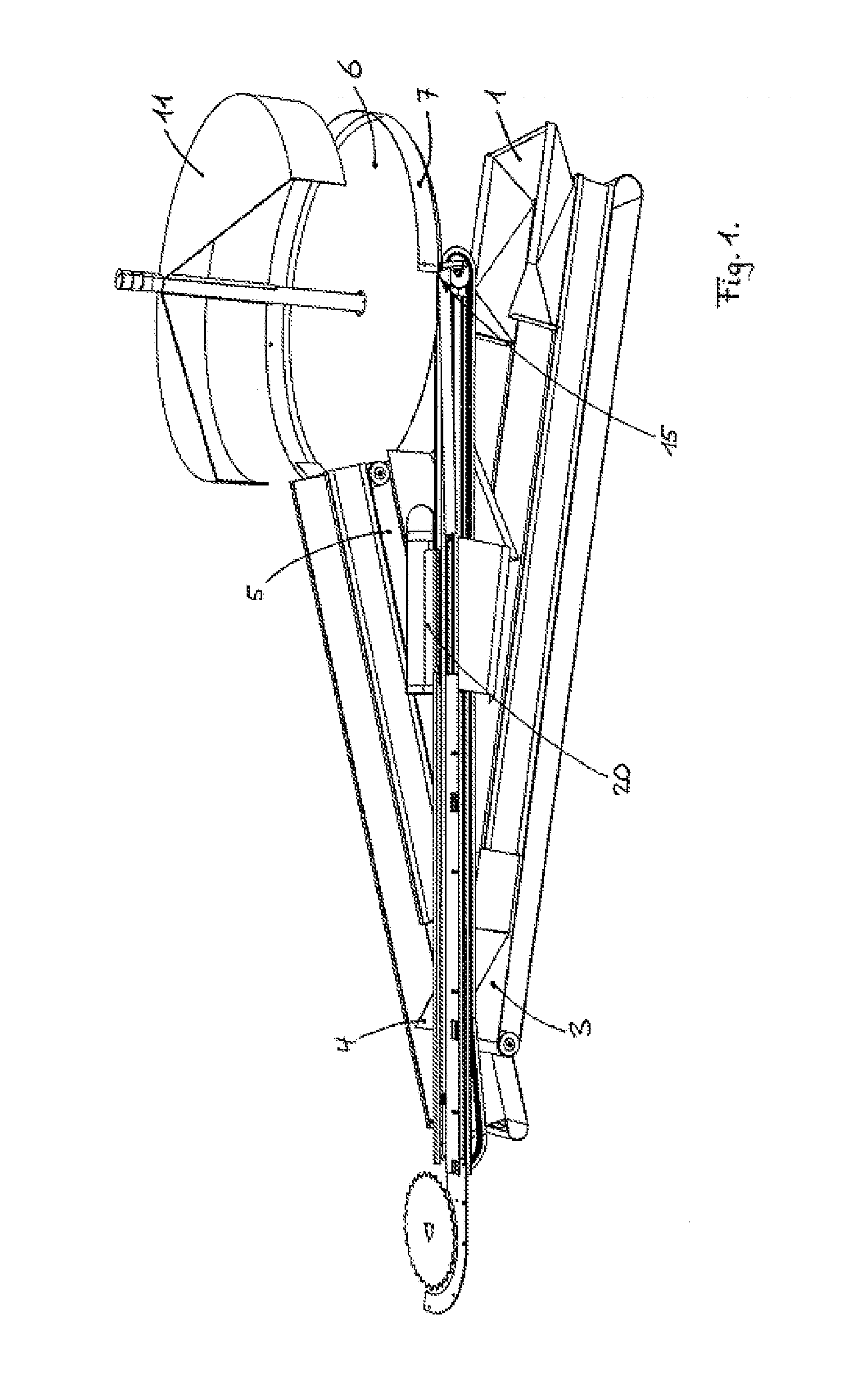

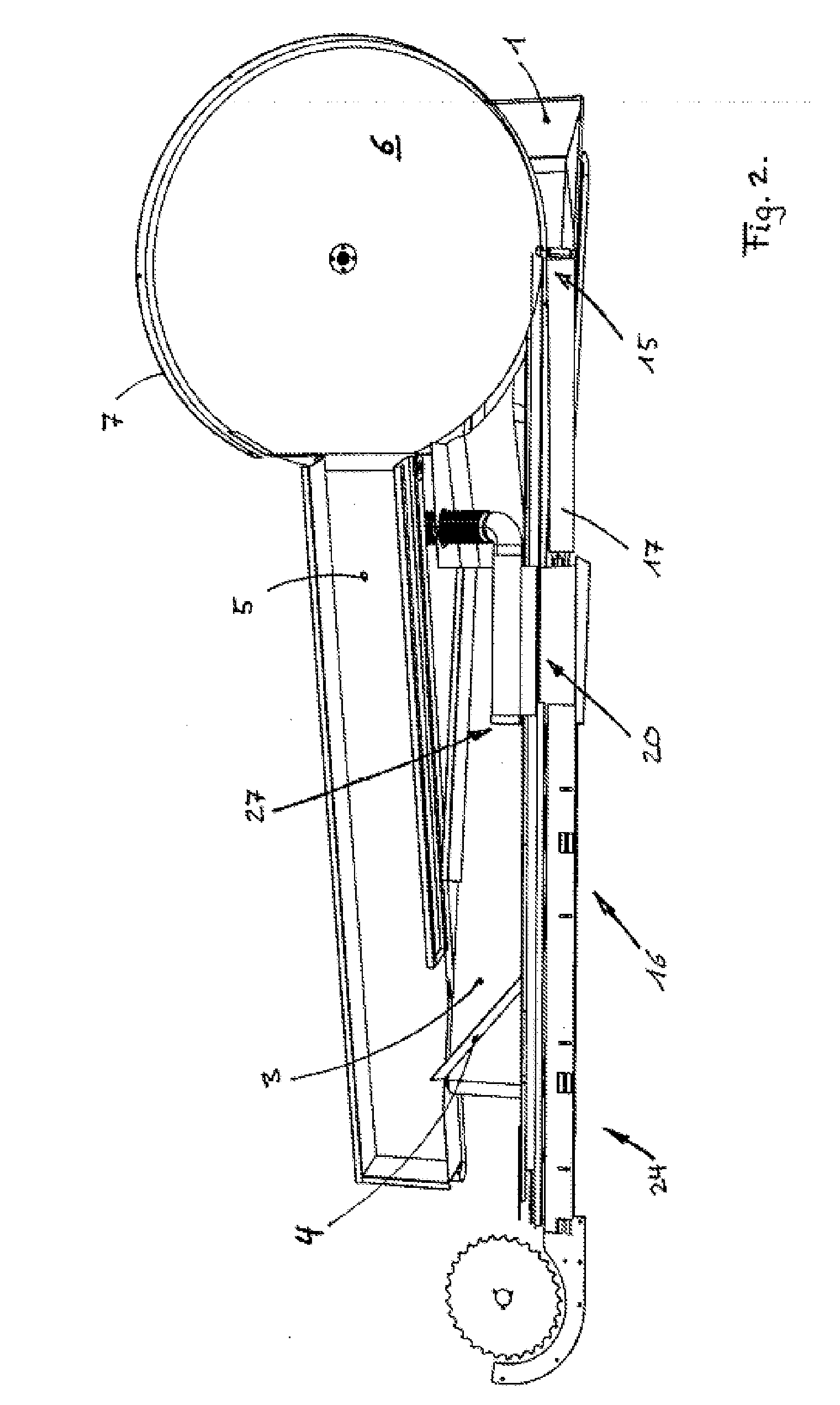

Method and apparatus for transporting articles to a station

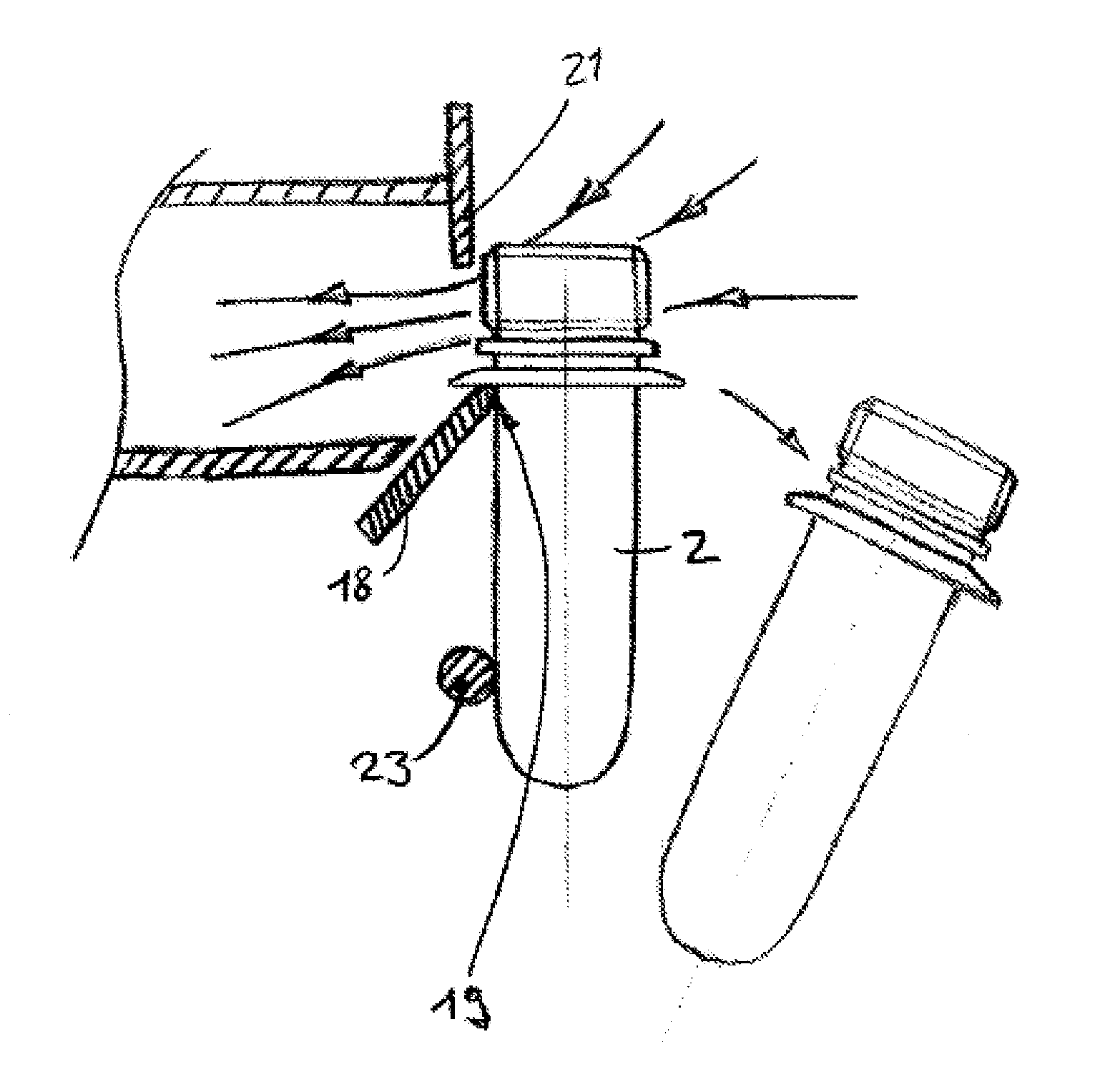

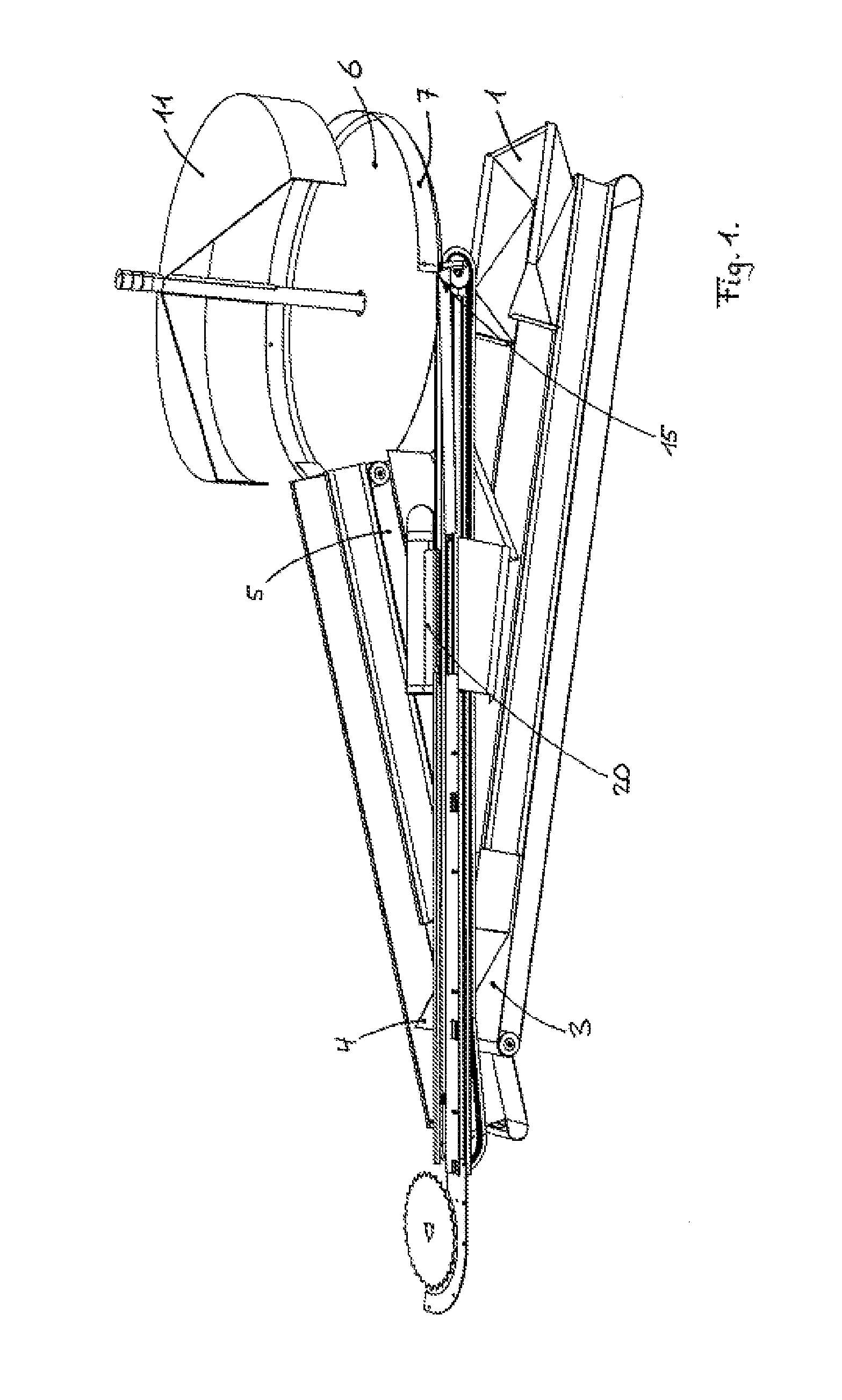

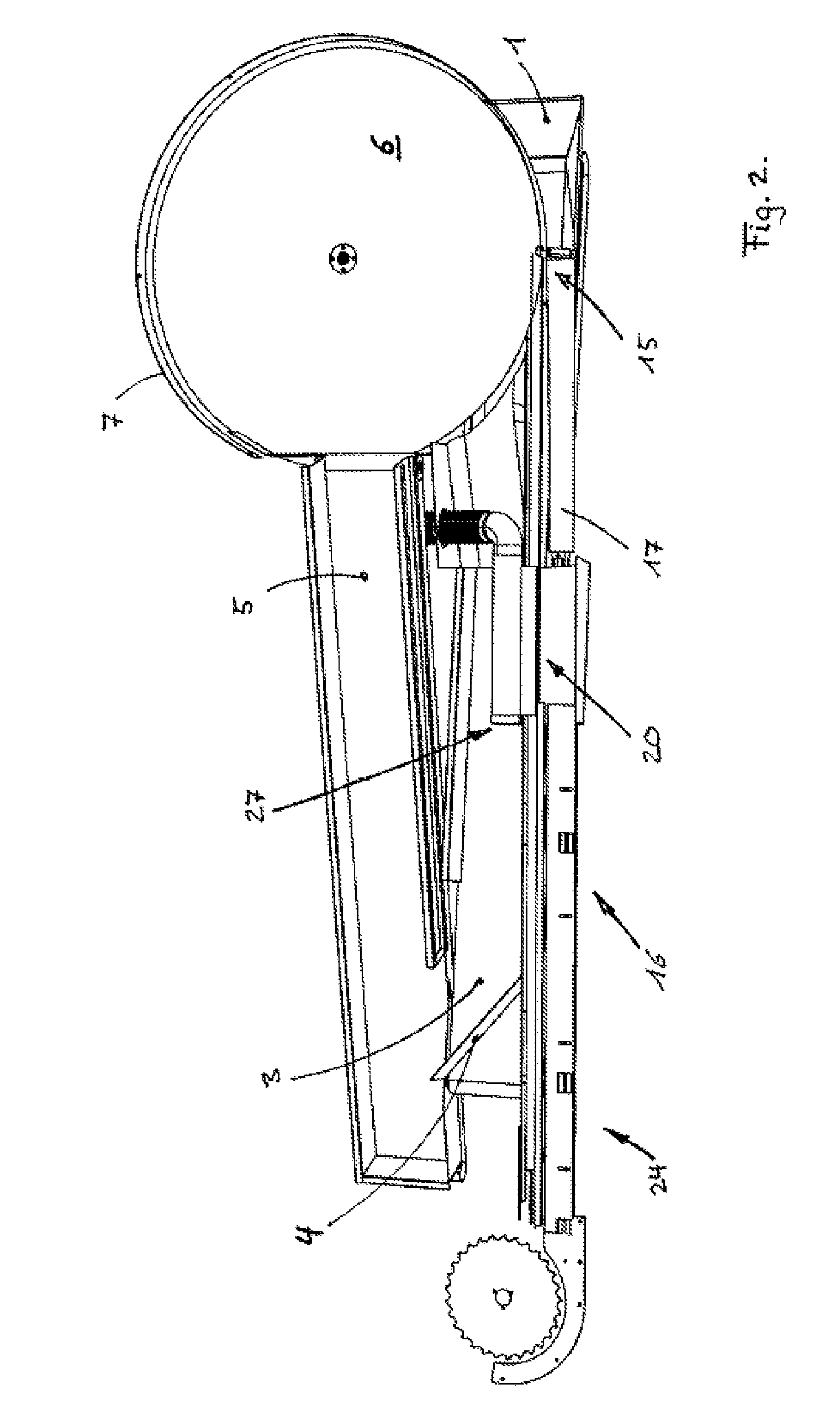

ActiveUS20140151189A1Improve dynamic responsivenessContinuous motionRollersRotary conveyorsBlow moldingEngineering

A method for transporting articles (2) to a station, in particular preforms to a blow-molding apparatus, wherein each article has a protrusion (10) and is moved along a guide (16) by a drive means (18), the article (2), along at least part of the guide (16), should be retained on an abutment (19, 21, 23), and advanced along this abutment, by an air stream.

Owner:INTRAVIS GESELLSCHAFT FUR LIEFERUNGEN & LEISTUNGEN VON BILDGEBENDEN & BILDVERARBEITENDEN ANLAGEN & VERFAHREN MBH

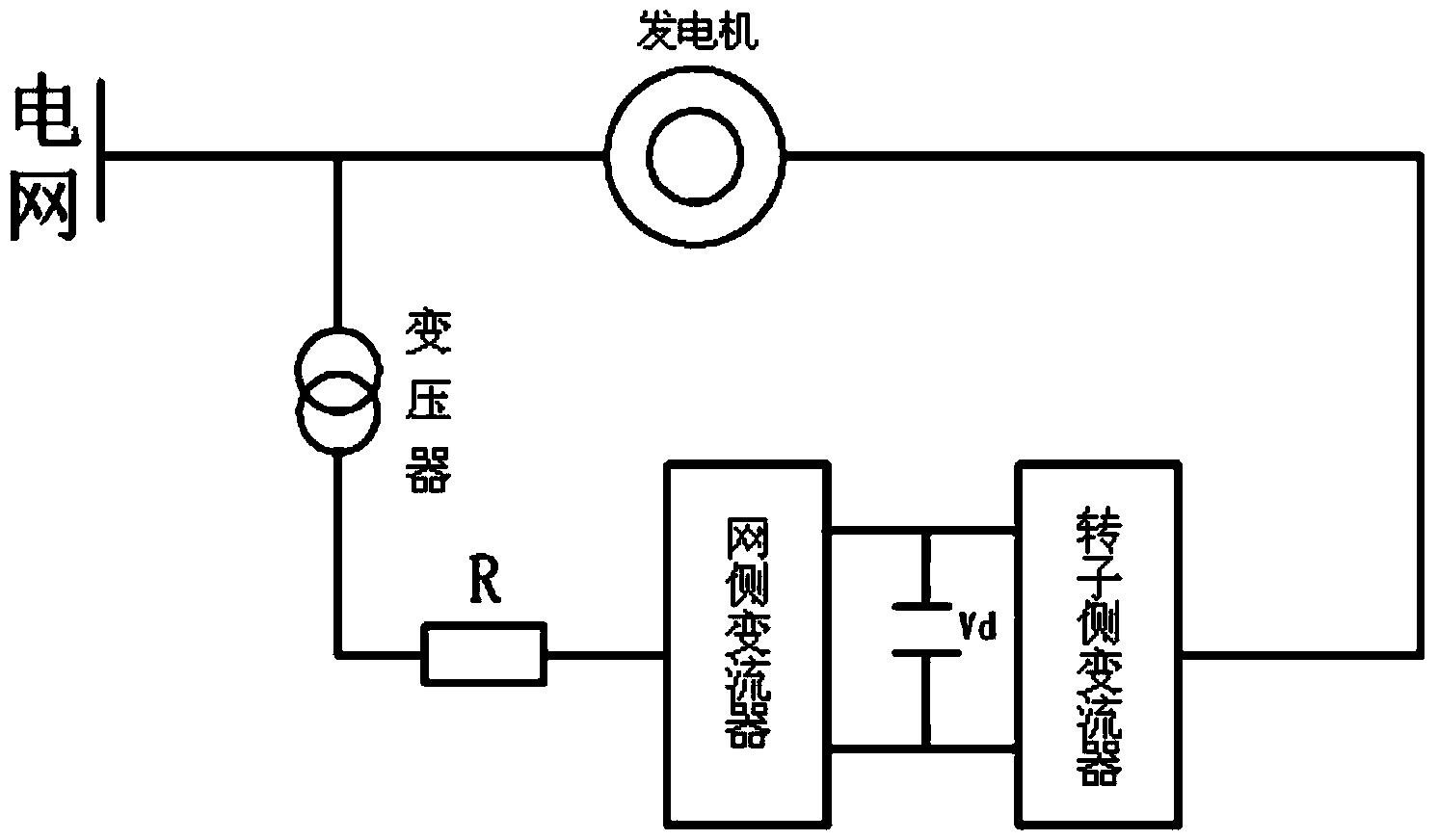

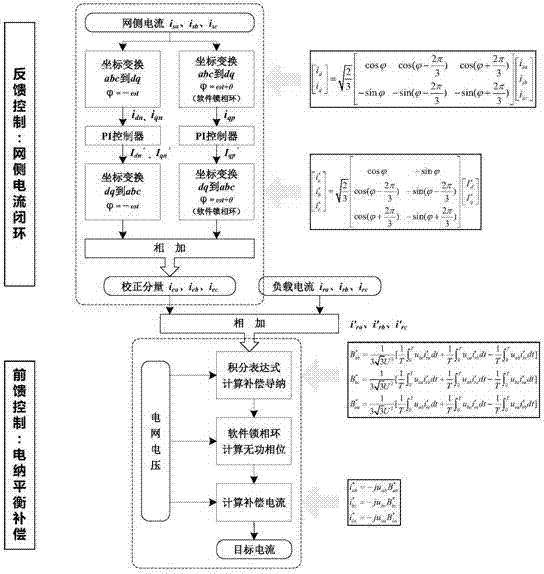

Control method for doubly-fed wind generator converters

InactiveCN103684173ASimplify the control problemGood control effectElectronic commutation motor controlVector control systemsPower gridRotor side converter

The invention relates to a control method for doubly-fed wind generator converters. The converters are doubly-fed converters, and the converters comprise the rotor side converter connected with a generator rotor and the grid side converter connected with a power grid, the grid side converter is controlled through a voltage orientation vector of the power grid, and the rotor side converter is controlled through an orientation vector of a stator field. The problems that according to an existing method, active power and reactive power decoupling control can not be performed on an alternating-current excitation generator rapidly, and the control mode is complex are solved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Redundantly actuated parallel machine tool body

InactiveCN106965153AGood mechanical transmissionImprove dynamic responsivenessProgramme-controlled manipulatorEngineeringMachine tool

A redundantly actuated parallel machine tool body is suitable for various fields of machining, cutting, measuring and the like. The problem that a series machine tool is poor in rigidity and low in flexibility is solved. The machine tool comprises a rack, linear movement assemblies, connecting rod assemblies and a workbench assembly. One end of the first connecting rod assembly, one end of the second connecting rod assembly, one end of the third connecting rod assembly, one end of the fourth connecting rod assembly, one end of the fifth connecting rod assembly and one end of the sixth connecting rod assembly are fixedly connected with a sliding block of the first linear movement assembly, a sliding block of the first linear movement assembly, a sliding block of the second linear movement assembly, a sliding block of the third linear movement assembly, a sliding block of the fourth linear movement assembly, a sliding block of the fifth linear movement assembly and a sliding block of the sixth linear movement assembly, the other end of the first connecting rod assembly, the other end of the second connecting rod assembly, the other end of the third connecting rod assembly, the other end of the fourth connecting rod assembly, the other end of the fifth connecting rod assembly and the other end of the sixth connecting rod assembly are connected with a first U-shaped connector, the second U-shaped connector, the third U-shaped connector, the fourth U-shaped connector, the fifth U-shaped connector and the sixth U-shaped connector in the workbench assembly through cross shafts, and a hooke joint is formed. The sliding blocks do linear movement along guide rails to drive connecting rods to move, motion input on a workbench is achieved, and three-freedom-degree motion of two rotation and one translation is achieved.

Owner:BEIJING JIAOTONG UNIV

Two-motor variable-frequency speed control system considering efficiency optimization and decoupling control method thereof

InactiveCN102969948AGood dynamic response performanceEliminate the effects ofMultiple dynamo-electric motors speed regulationLeast squares support vector machineFlux linkage

The invention discloses a two-motor variable-frequency speed control system considering efficiency optimization and a decoupling control method thereof. The system comprises a two-motor variable-frequency speed control system body and a least squares support vector machine (LSSVM) inverse system which are connected in series to form a pseudo-linear compound system. The LSSVM inverse system and a closed loop controller jointly form an LSSVM inverse controller. The decoupling control method comprises the steps of building a mathematical model of the two-motor variable-frequency speed control system body considering motor rotor magnetic linkage and performing reversibility analysis; designing the LSSVM inverse system consisting of an LSSVM and an integrator and using the LSSVM inverse system as a feedforward controller to be connected with an original system in series to obtain the pseudo-linear compound system and achieve approximate linearity and decoupling of the two-motor variable-frequency speed control system body; using a proportion integration differentiation (PID) controller as an additional controller to achieve closed loop control; and adopting rotor magnetic linkage optimization based on a motor loss model to achieve decoupling control of the two-motor variable-frequency speed control system considering efficiency optimization.

Owner:JIANGSU UNIV OF SCI & TECH

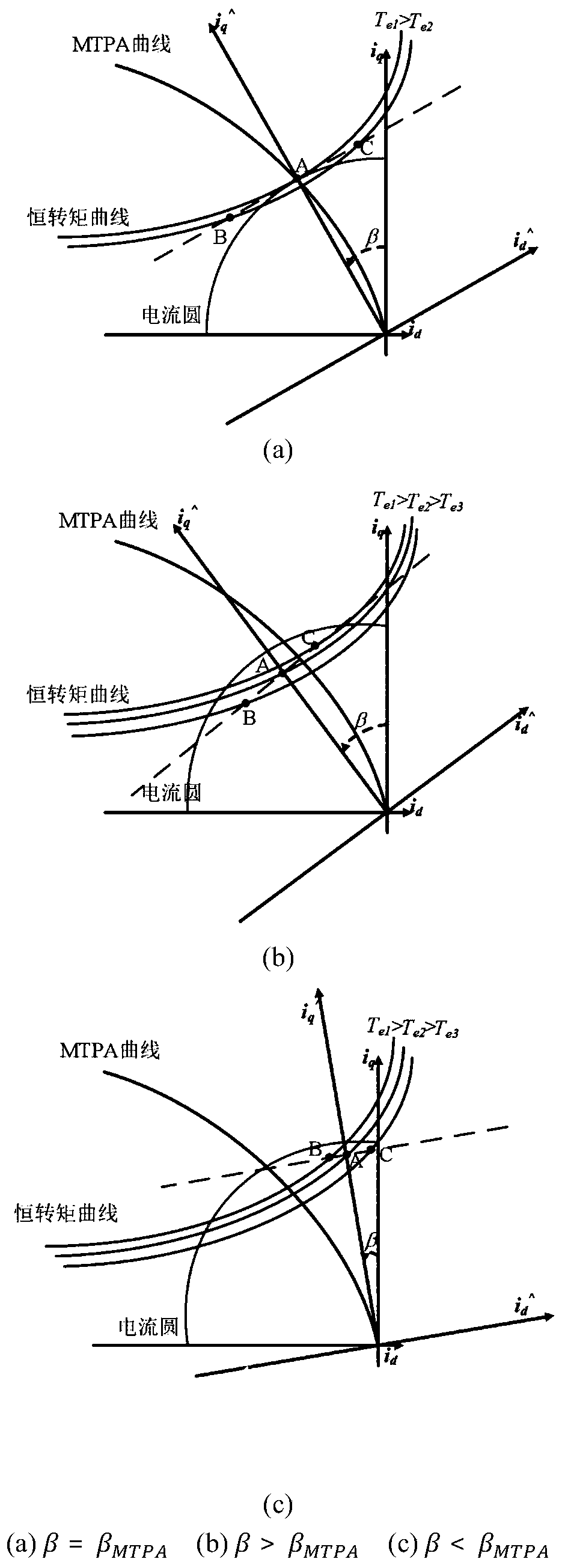

Permanent magnet synchronous motor control method based on virtual signal injection and gradient descent method

ActiveCN110336504AAchieve precise trackingRealize seamless switchingElectronic commutation motor controlAC motor controlPermanent magnet synchronous motorStator current vector

The invention discloses a permanent magnet synchronous motor control method based on a virtual signal injection and gradient descent method. In the real-time control process of a permanent magnet synchronous motor, a virtual signal is injected under a coordinate system, an angle reference value of a stator current vector is obtained by utilizing a virtual signal injection method and a gradient descent method, a reference value of a stator current vector axial component is obtained by adopting a torque compensation calculation method, a stator current vector reference value under a d-q coordinate system is further obtained by coordinate transformation, and a gradient value under the coexistence of the maximum current torque ratio control and weak magnetic control is corrected and controlled, so that seamless switching between the maximum current torque ratio control and the weak magnetic control is achieved. According to the invention, the gradient expression is corrected by introducingvoltage feedback, seamless switching between the maximum current torque ratio control and the weak magnetic control can be achieved, the rotating speed range is wide, complex signal processing is notrequired, and the dynamic response performance is good.

Owner:ZHEJIANG UNIV

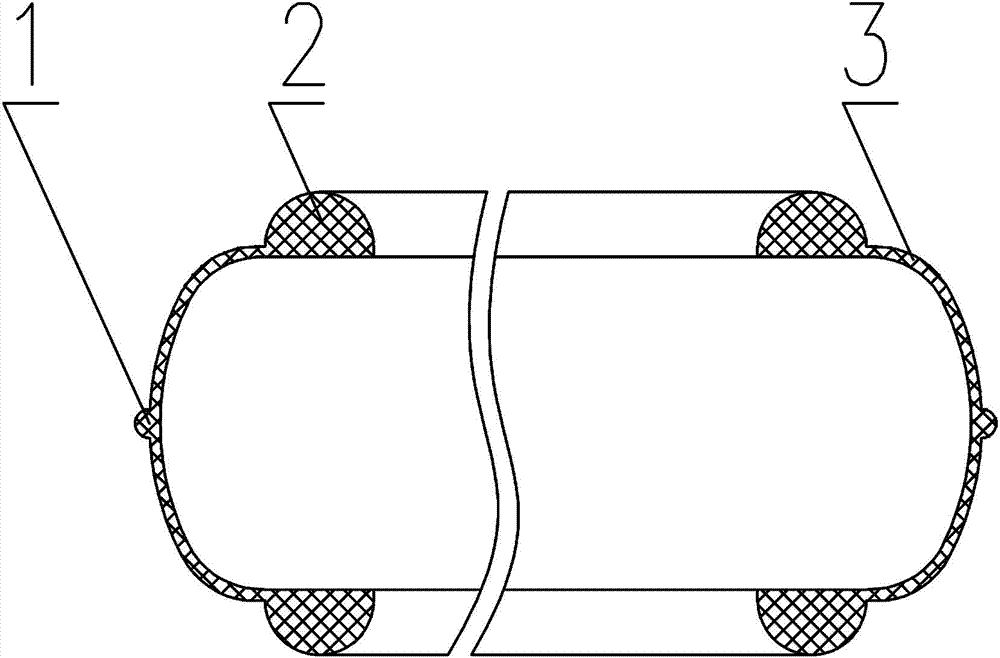

Reciprocating movement type internal pressure compensation sealing piece

ActiveCN102954225AReduce frictionImprove dynamic responsivenessEngine sealsPiston ringsEngineeringInternal pressure

The invention discloses a reciprocating movement type internal pressure compensation sealing piece which comprises a cylinder body and an end cover, wherein a middle piston is arranged between a first piston and a second piston; the edge of the middle piston is provided with an annular sealing piece; the upper and lower ends of the annular sealing piece are provided with raised positioning parts; the outer side of the middle of the annular sealing piece are provided with a raised sealing part which is matched with an inner wall of the cylinder body; grooves matched with the raised sealing part are formed in the first piston and the second piston; and a sealing cavity is formed between the annular sealing piece and the middle piston. According to the reciprocating movement type internal pressure compensation sealing piece, the sealing cavity formed between the sealing piece and the middle piston is utilized and is matched with a one-way valve, and a medium can be filled in and discharged from the cavity according to a gap between the sealing piece and the cylinder body and the working pressure during the operation, so that an optimal sealing state is achieved. A sealing medium with pressure is injected and is matched with a dynamic compensation function of self-elongation of a sealing material, so that a dynamic sealing effect is achieved.

Owner:CHINA THREE GORGES UNIV

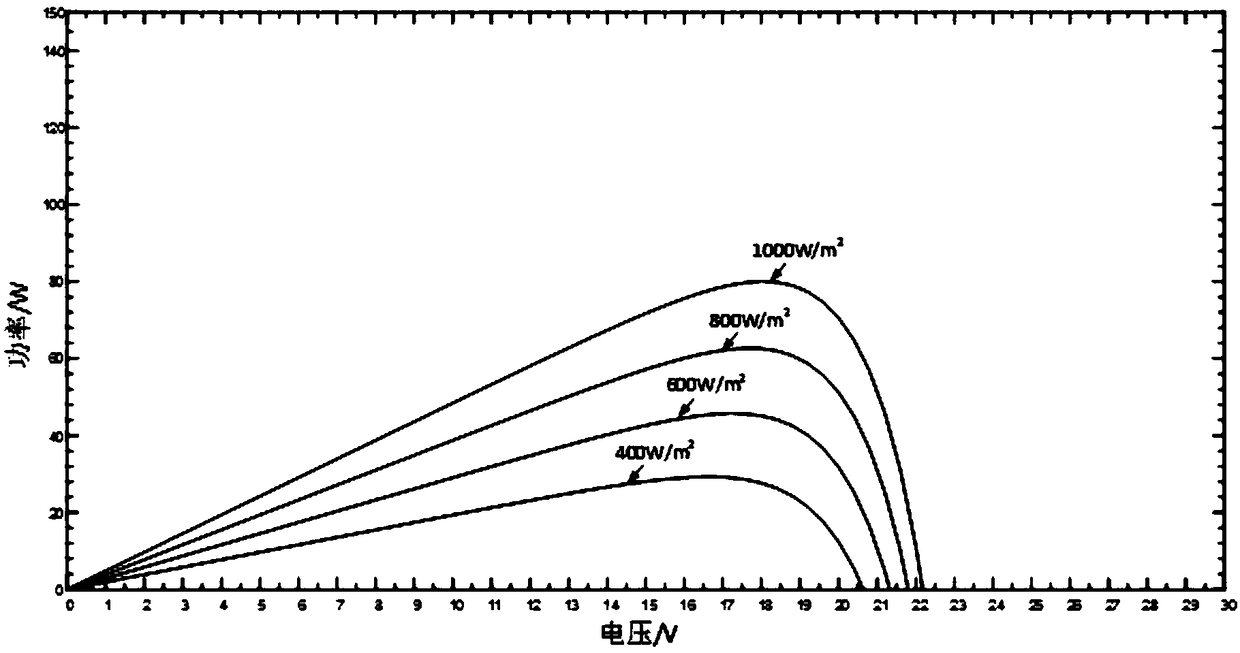

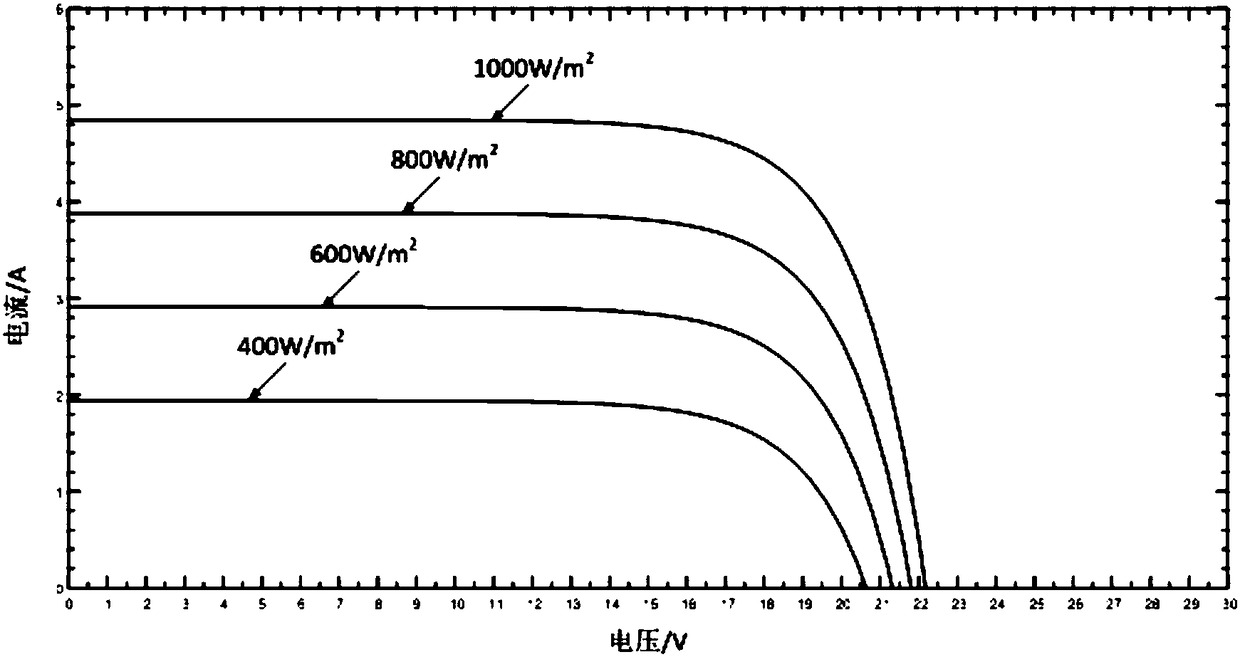

Maximum power point tracking method based on adaptive fuzzy control

InactiveCN108803771AFast trackingStable trackingPhotovoltaic energy generationAdaptive controlFuzzy control systemMaximum power principle

The invention discloses a maximum power point tracking method based on adaptive fuzzy control. The method comprises the following steps of 1) determining an input variable and an output variable of afuzzy controller; 2) summarizing control rules of the fuzzy controller; 3) determining fuzzification and anti-fuzzification methods; 4) determining relevant parameters such as the division of disclosure domains, quantization factors and the like. An adaptive fuzzy control MPPT method has fast tracking speed and good dynamic response performance, has almost no fluctuation after reaching a steady state, and can track the maximum power point of a photovoltaic array stably and efficiently. Under the condition of disturbance of system parameters such as illumination intensity, ambient temperature and the like, new working points can be quickly found, and a system is kept stable; the ability of a solar photovoltaic system to resist external factors is strengthened, the system parameters are confirm and simple, and energy waste is reduced.

Owner:NANJING UNIV OF SCI & TECH

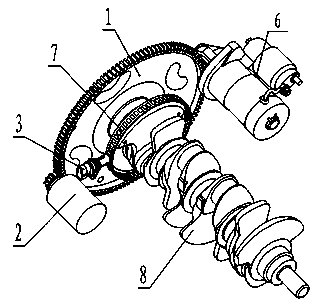

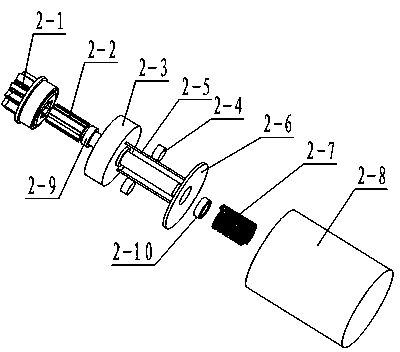

Crankshaft position limiting system after flameout of automobile engine

ActiveCN103388527AImprove dynamic responsivenessReduce fuel consumptionMachines/enginesEngine componentsLocking mechanismDrive shaft

The invention relates to a crankshaft position limiting system after flameout of an automobile engine, aiming at solving the problem that the engine cannot be quickly started up. The crankshaft position limiting system comprises an engine flywheel, a crankshaft position locking mechanism, a crankshaft position sensor, a crankshaft signal panel and an ECU (Engine Control Unit). The crankshaft position locking mechanism comprises a locking gear, a transmission shaft, a locking wheel, an electromagnetic valve, a traction pushrod, a traction disc, a return spring and an engine body shell. The locking gear is installed at the front end of the transmission shaft. The transmission shaft is assembled with the locking wheel. The electromagnetic valve is arranged at the front of the traction disc. The traction disc is fixedly assembled with the rear end of the traction pushrod. The front end of the traction pushrod penetrates through the locking wheel and then is assembled with the locking gear. The return spring is sheathed in the inner chamber of the engine body shell. The crankshaft position limiting system after the flameout of the automobile engine has the characteristics of simple structure and stable performance, the improvement of quick response performance of vehicle power is facilitated, the engine can be flamed out when the vehicle is stopped for waiting, and not only can the oil consumption of the vehicle be reduced, but also the emission of tail gas can be reduced.

Owner:GREAT WALL MOTOR CO LTD

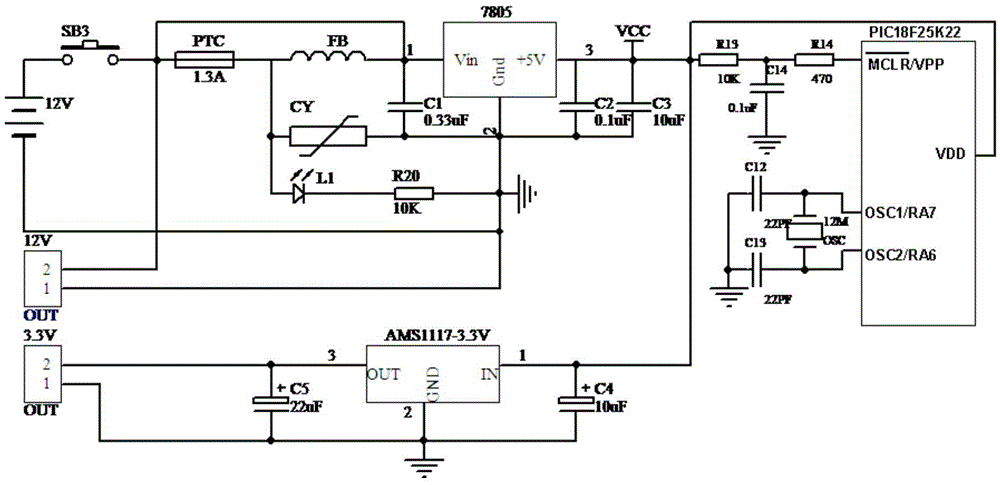

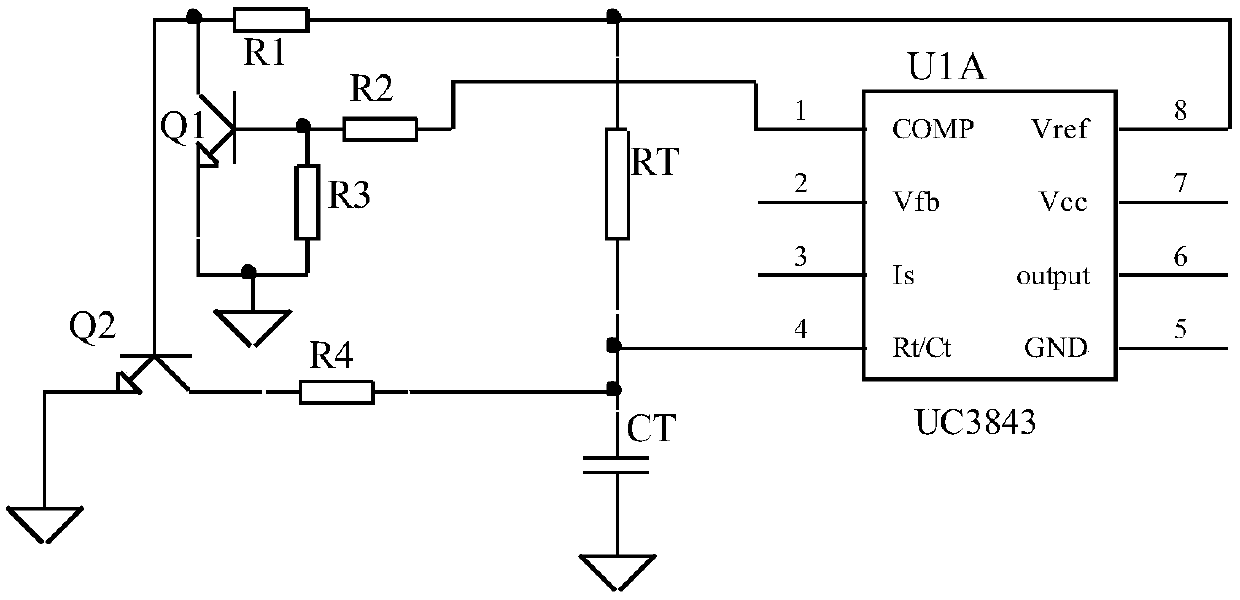

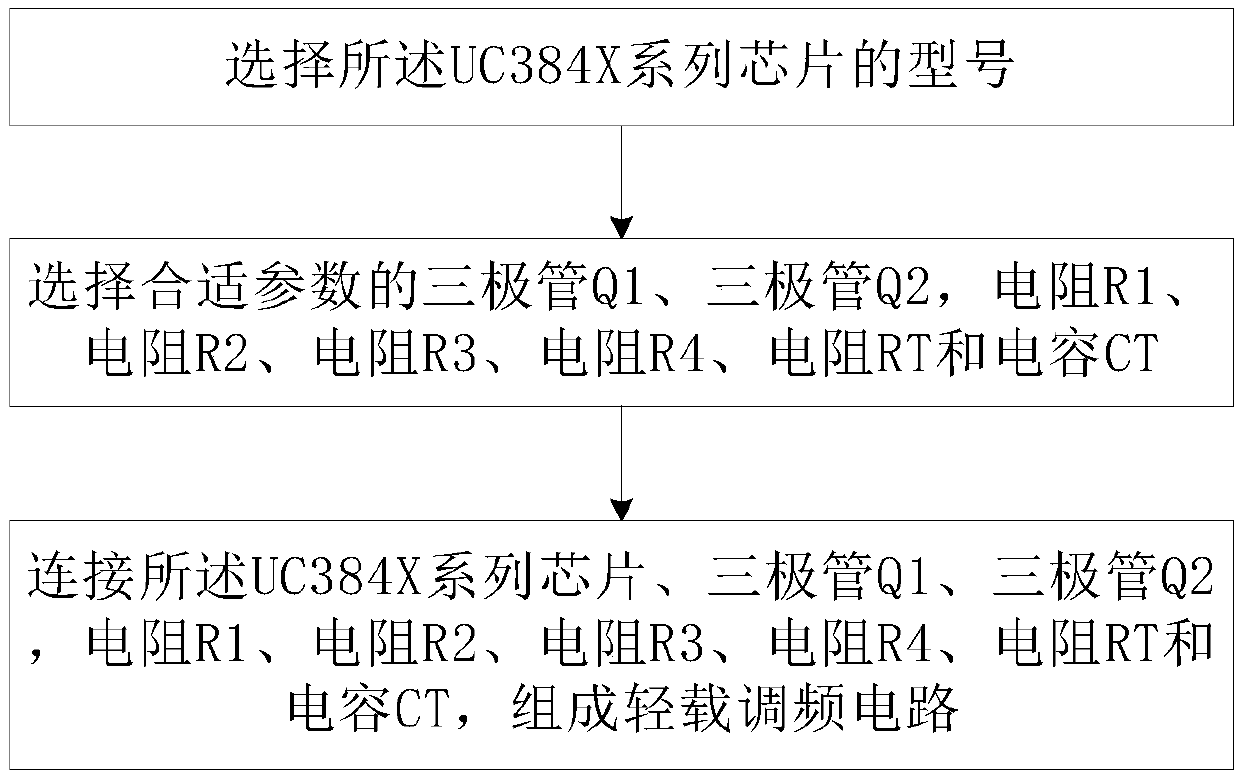

A switching power frequency conversion control circuit applied to a new energy vehicle and a design method thereof

ActiveCN109104074ASimple structureNovel and reasonable designPower conversion systemsNew energyEngineering

The invention discloses a switching power frequency conversion control circuit applied to a new energy vehicle, comprising a UC384X series chip, a transistor Q1, a transistor Q2, a resistor R3, a resistor RT and a capacitor CT, wherein one end of the resistor RT and the capacitor CT connected in series is connected with the eighth pin of the UC384X series chip. The terminals of the resistor RT andthe capacitor CT are connected to the fourth pin of the UC384X series chip, and are connected to the collector of the transistor Q2 through the resistor R4. The base of the transistor Q2 and the collector of the transistor Q1 are connected to the eighth pin of the UC384X series chip through the resistor R1. The base of transistor Q1 is connected to the first pin of UC384X series chip through resistor R2. The invention also discloses a design method of the switching power supply frequency conversion control circuit applied to a new energy vehicle. The circuit has the advantages of high workingreliability and high frequency modulation response speed, and can greatly improve the overall efficiency of the switching power supply.

Owner:NORTHWEST A & F UNIV

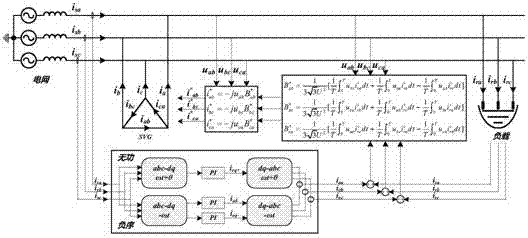

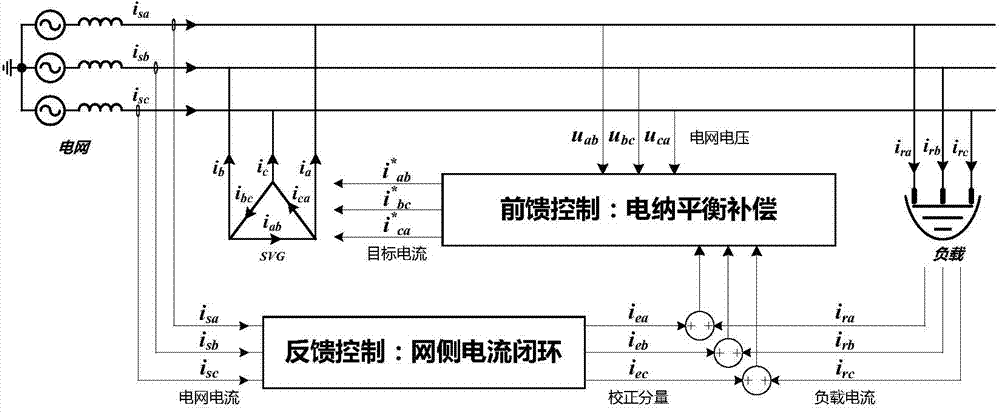

Circulation control method for angle joint chain SVG (static var generator)

ActiveCN103944171AFast dynamic responseImprove dynamic responsivenessFlexible AC transmissionPolyphase network asymmetry elimination/reductionLoop controlCompensation effect

Disclosed is a circulation control method for an angle joint chain SVG (static var generator). A circulation control system comprises a feed-forward controller with the susceptance balance principle and a feedback controller with a grid-side current closed loop, so that a chain SVG device can perform reactive power and negative sequence compensation for a three-phase unbalance load under the condition of asymmetric grid voltage. Grid-side current closed loop control is characterized in that residual reactive power and negative sequence components in compensated grid-side current are detected and respectively subjected to proportional integral control under a synchronous rotating reference frame, so that the residual components are gradually reduced to zero, and the influence caused by grid voltage unbalance on reactive power and negative sequence compensation effects is automatically compensated. The circulation control method combines feed-forward control with feedback control, so that the SVG device can keep fast and dynamic response, achieve fine stable compensation effects and resist the influence caused by grid voltage unbalance.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

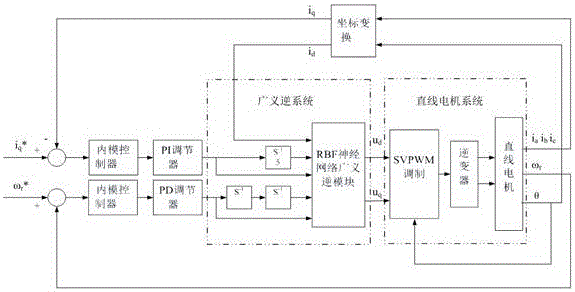

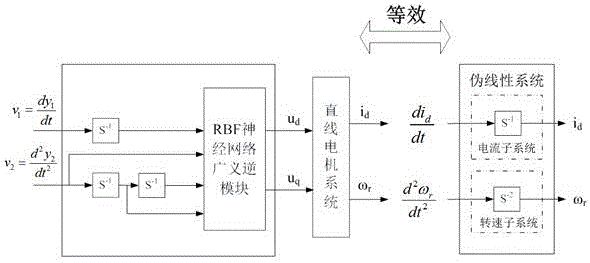

RBF neural network generalized inverse internal model control method of linear motor

ActiveCN106130431ASuperior key performanceAchieve linearizationElectronic commutation motor controlAC motor controlGeneralized inverseLinearization

The invention discloses an RBF neural network generalized inverse internal model control method of a linear motor. A generalized inverse system of a permanent magnet linear motor free of an accurate mathematical model is approached through an RBF neural network; and the generalized inverse system is connected with a permanent magnet linear motor system in series, so that linearization and decoupling of a permanent magnet linear motor control system are achieved; and through correction on a decoupled pseudo linear system through inner model control, the key properties of the control accuracy, the dynamic response capability, the robustness and the like of the permanent magnet linear motor control system are more excellent.

Owner:SUQIAN COLLEGE

Method and apparatus for transporting articles to a station

ActiveUS9561614B2Improve dynamic responsivenessContinuous motionConveyorsConveyor partsBlow moldingEngineering

Owner:INTRAVIS GESELLSCHAFT FUR LIEFERUNGEN & LEISTUNGEN VON BILDGEBENDEN & BILDVERARBEITENDEN ANLAGEN & VERFAHREN MBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com