Redundantly actuated parallel machine tool body

A machine tool and parallel technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low degree of freedom and poor stiffness, and achieve the effect of improving the bearing capacity, eliminating the singular configuration, and meeting the requirements of high-precision motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in conjunction with accompanying drawings.

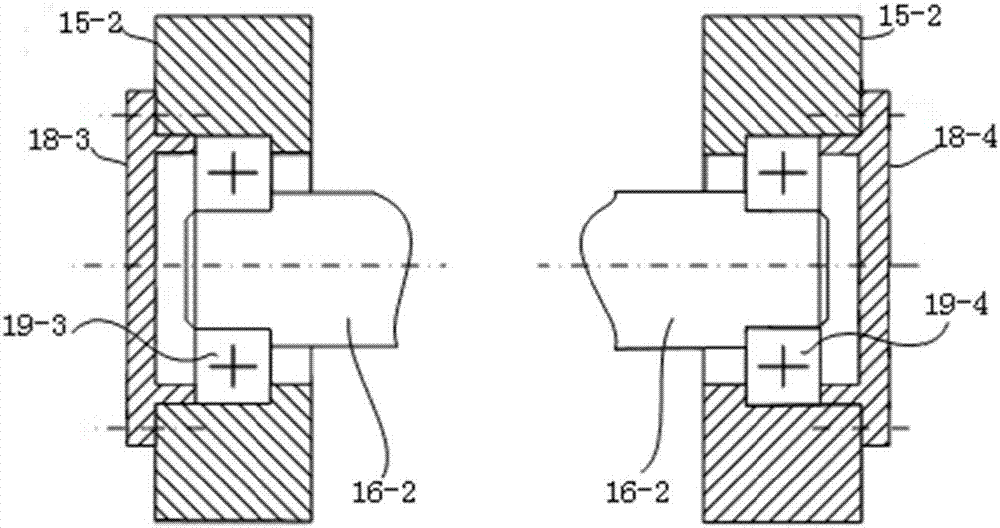

[0068] A redundantly driven parallel machine tool body, such as figure 1 As shown, the machine tool includes: frame 1, first to sixth linear moving assemblies 2-1, 2-2, 2-3, 2-4, 2-5, 2-6, first to sixth connecting rods Assemblies 3-1, 3-2, 3-3, 3-4, 3-5, 3-6, bench assembly 6.

[0069] The first to sixth guide rail frames 9-1, 9-2, 9-3, 9-4, 9-5, 9-6 are respectively fixed and connected to six supports 4-1, 4-2, 4-3, 4-4, 4-5, 4 on the frame 1 by screws -6 in;

[0070] Such as Figure 5 As shown, the first linear movement assembly 2-1 includes: a motor 7-1, a coupling 8-1, a guide rail frame 9-1, a first guide rail 10-1 and a second guide rail 10-2, and a lead screw 11- 1. Slider 12-1, baffle 13-1, first and second baffle bearings 14-1, 14-2;

[0071] Connections between the components that make up the first linear movement assembly:

[0072] Lead screw 11-1 and slider 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com