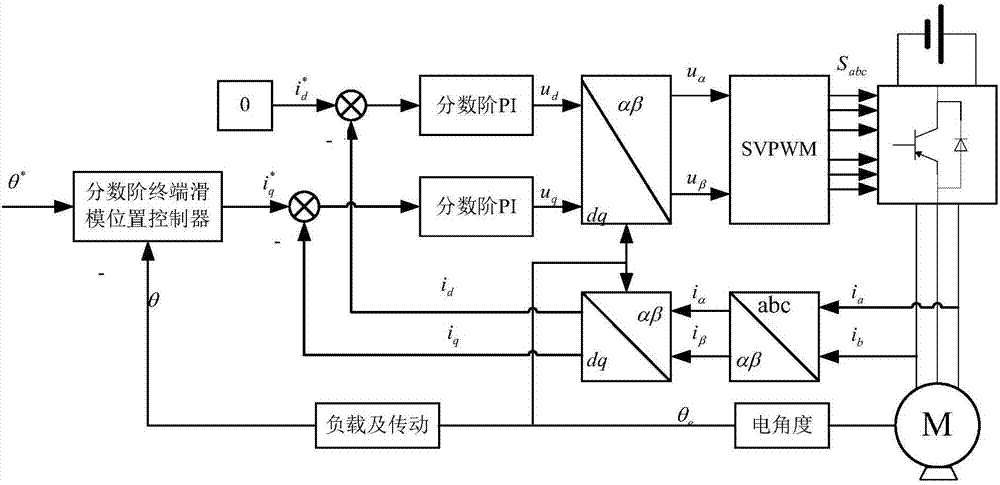

Follow-up control method by means of fractional-order quick terminal sliding mode control

A terminal sliding mode, fractional-order technology, applied in general control systems, adaptive control, control/regulation systems, etc., can solve problems such as less-than-expected follow-up performance and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

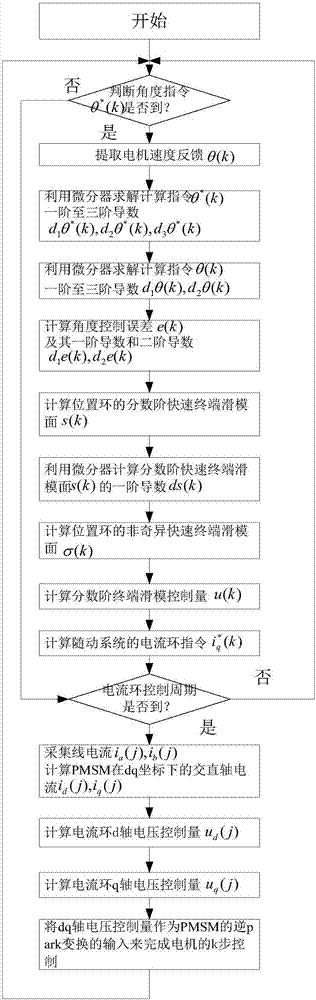

[0072] Scheme of the present invention has following steps:

[0073] (1) Judgment angle command θ * (k) Is it there? Yes, enter step (2), otherwise just enter step (11), k is the step number of angle control;

[0074] (2) Extract the follow-up angle feedback θ(k), T sp is the follow-up angle control period;

[0075] (3) Use the differentiator to solve the calculation instruction θ * (k) First to third derivative d 1 θ * (k),d 2 θ * (k),d 3 θ * (k):

[0076]

[0077]

[0078]

[0079]

[0080]

[0081]

[0082] in, is the sliding surface θ * (k-1) estimation error; are θ * (k) and its first-order, second-order, and third-order estimated values; are the first-order, second-order, third-order, and fourth-order gains of the differential esti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com