Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve collapse retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

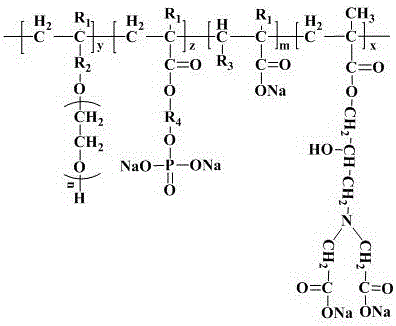

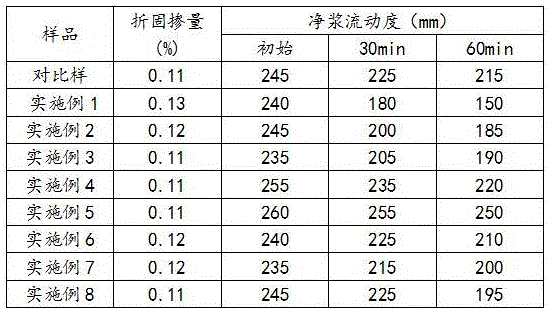

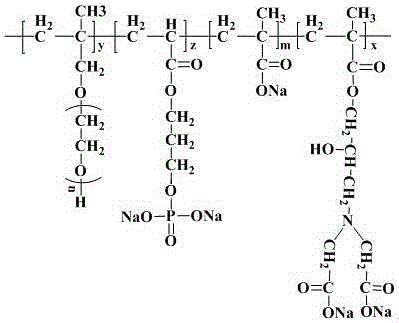

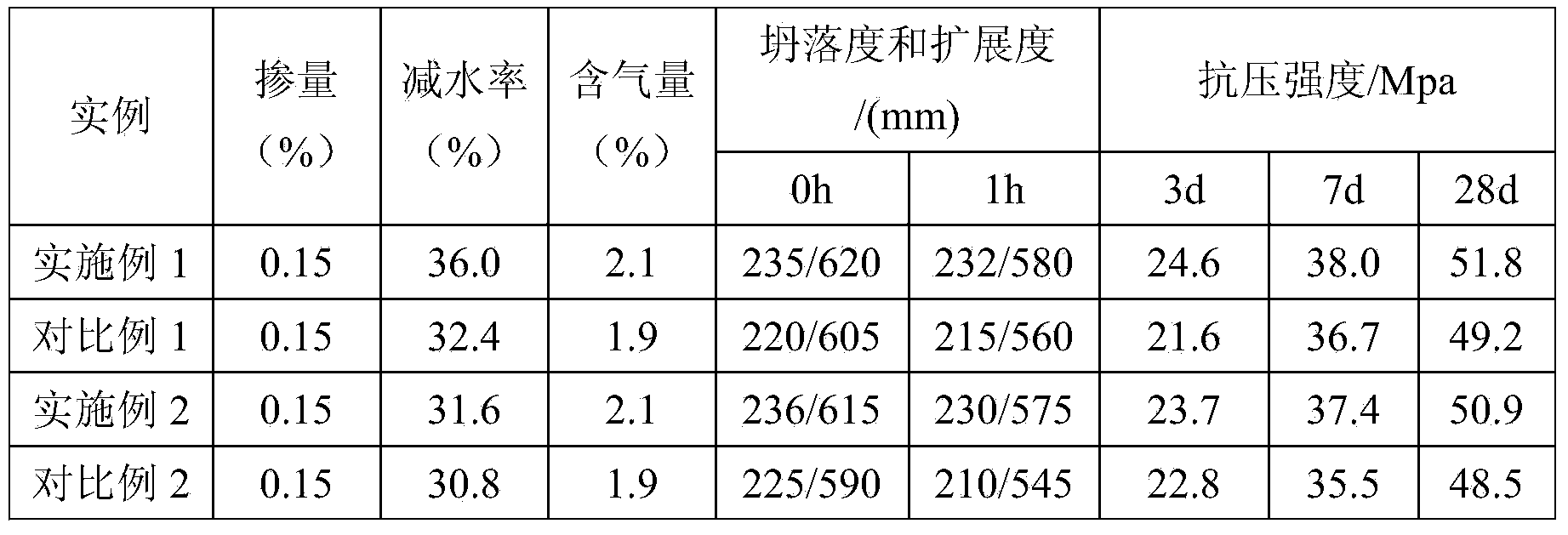

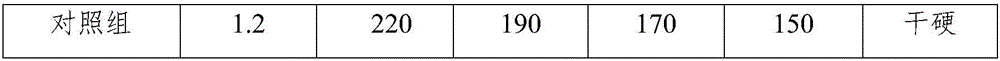

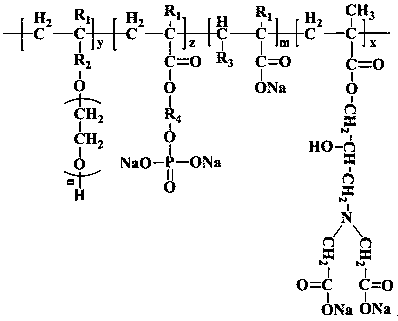

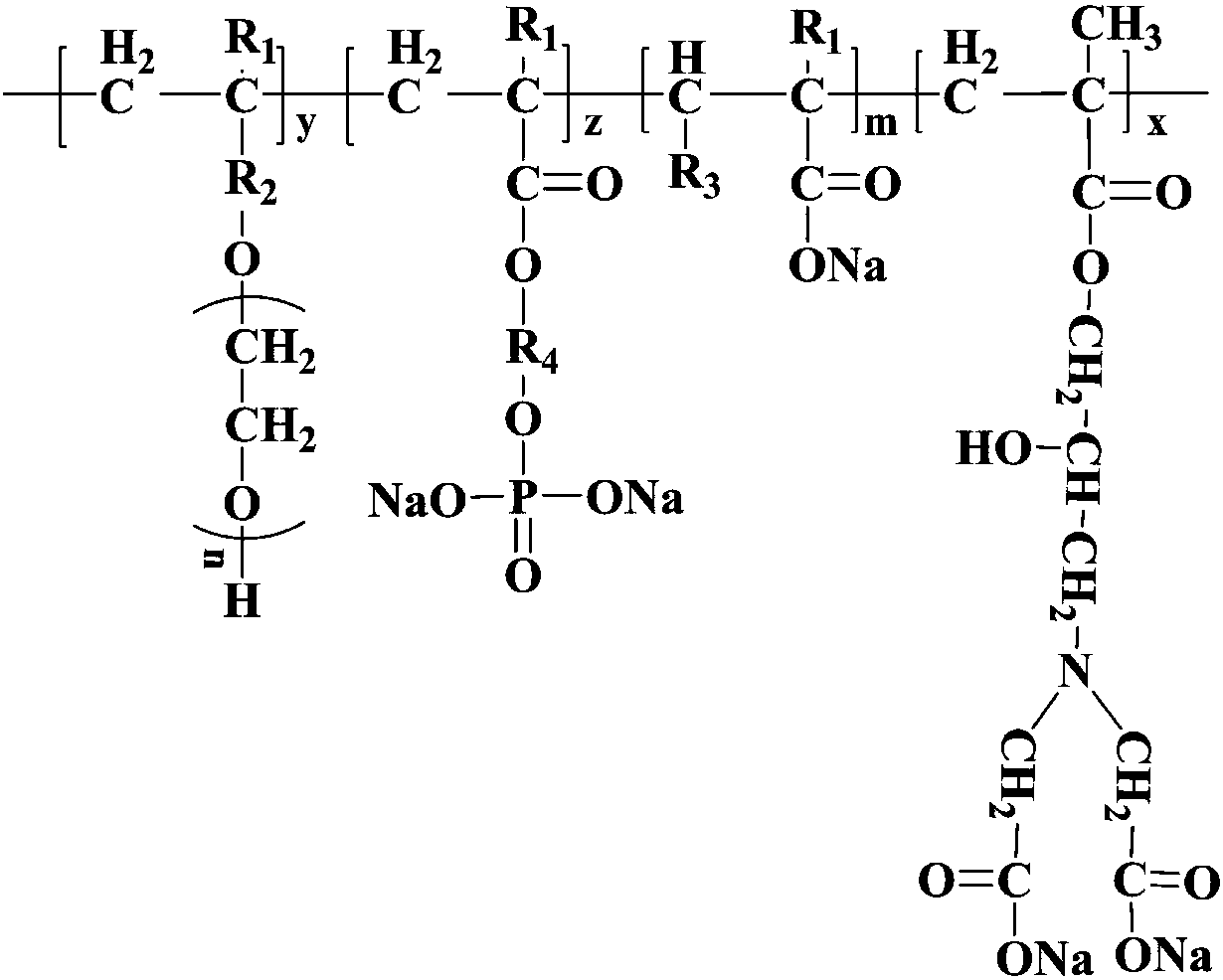

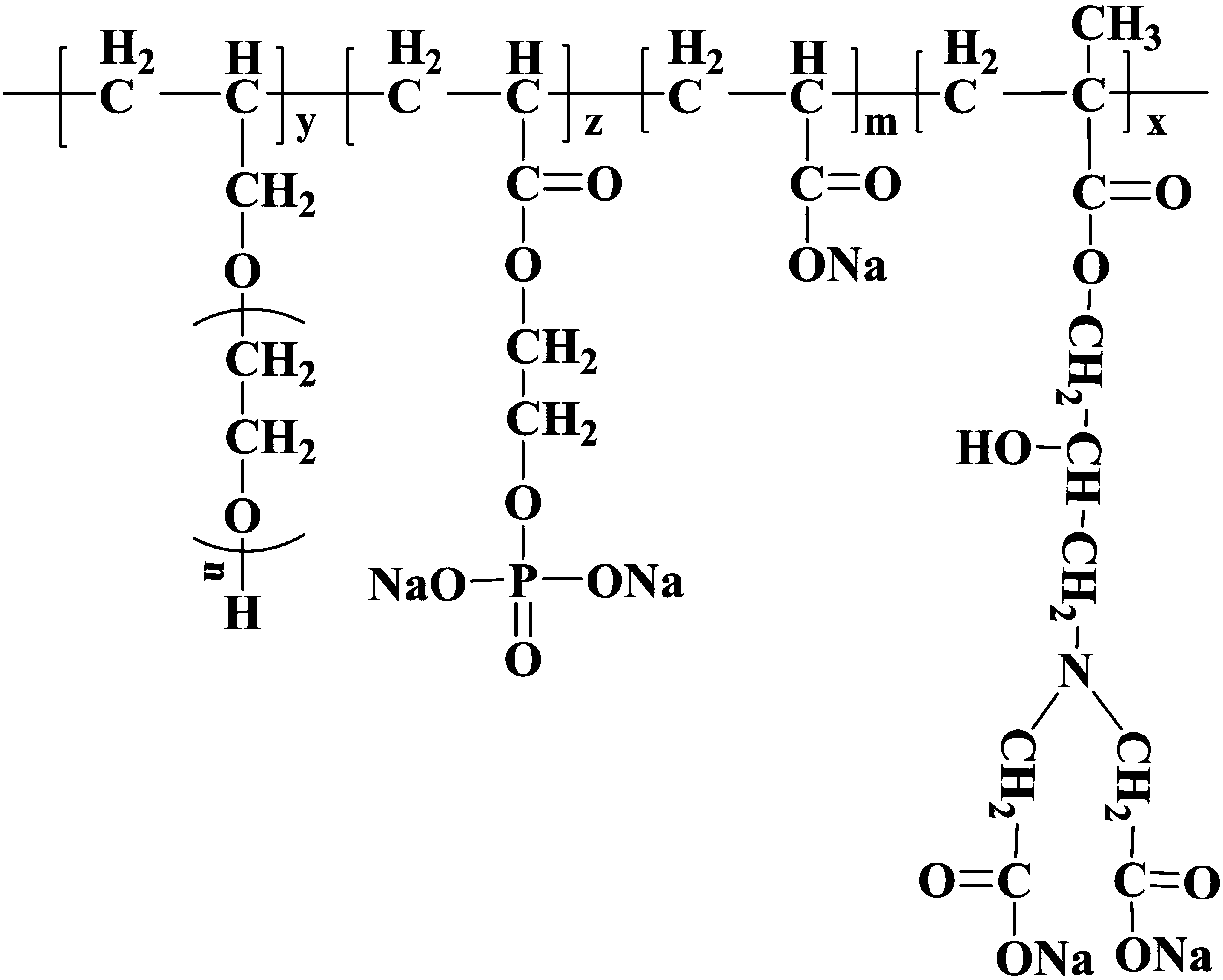

Phosphate containing high-adaptability polycarboxylate superplasticizer and preparation method thereof

The invention discloses a phosphate containing high-adaptability polycarboxylate superplasticizer and a preparation method thereof.The phosphate containing high-adaptability polycarboxylate superplasticizer is prepared through the steps that unsaturated polyether macromonomers, micromonomers, unsaturated phosphate monomers, 2-methacrylic acid-3(N,N-oxalic acid amine)-2 hydroxy propyl ester, an initiator and a chain transfer agent react with water at the temperature of 50-80 DEG C for 3-6 hours, a copolymer is obtained, then the pH value is adjusted to range from 6.0 to 7.0 with alkaline matter, and a settled solution is obtained.Compared with a polycarboxylate superplasticizer, the phosphate containing high-adaptability polycarboxylate superplasticizer has higher adsorption capacity, sulfate in cement can be effectively resisted, the dispersing power of polycarboxylate is greatly improved, the phosphate structure can change the crystal morphology formed at the initial stage of ettringite, and then collapse protecting performance is improved.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

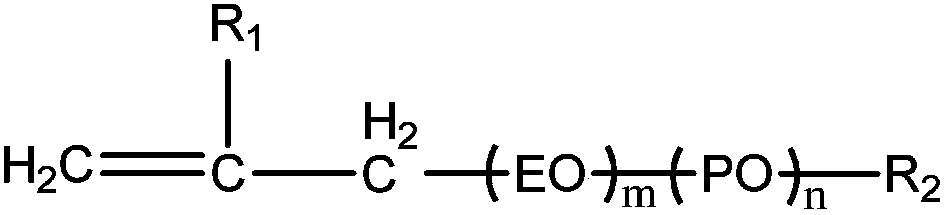

Polycarboxylate-type water reducing agent

The invention discloses a water reducing agent raw material, namely an ethylene oxide-propylene oxide ternary-block polyether macromonomer, as well as a water reducing agent prepared from the raw material. The preparation of the water reducing agent comprises the following processes: mixing iso-pentenol polyoxyethylene ether and a sodium alcoholate catalyst, heating to 80-115 DEG C and dealcoholizing; heating to 110-130 DEG C, controlling pressure to be 0.25-0.40Mpa and adding ethylene oxide; adding propylene oxide at unchanged system temperature and unchanged pressure; heating to 130-160 DEG C, controlling pressure to be 0.35-0.60Mpa, and adding ethylene oxide again; and after reaction, adding a weak acid neutralizer, thereby obtaining the ethylene oxide-propylene oxide ternary-block polyether macromonomer. Due to the use of a ternary-block system, the functional adjustment on a branched chain is easy to perform, and the adaptability and the slump loss resistance of a polycarboxylate-type water reducing agent monomer are enhanced greatly.

Owner:WUHAN UNIV OF TECH

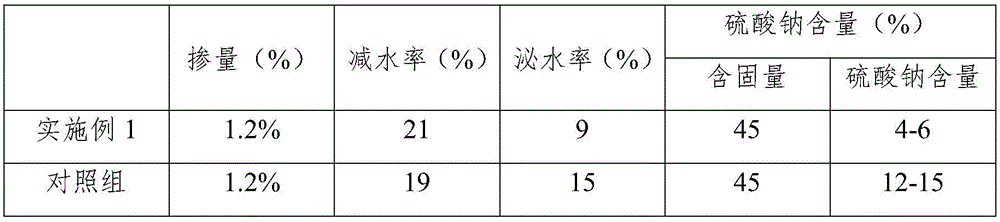

Papermaking black liquor modified sulfamate high efficiency water reducer and preparation method thereof

The invention discloses a papermaking black liquor modified sulfamate high efficiency water reducer. The high efficiency water reducer is prepared from, by weight, 130-140 parts of sodium sulfanilate, 30-60 parts of a papermaking black liquor, 12-30 parts of sulfur dioxide, 50-70 parts of phenol, 150-180 parts of formaldehyde, 15-30 parts of a 30% liquid alkali, 9-13 parts of urea, and 200-360 parts of water. A preparation method of the high efficiency water reducer comprises the following steps: sulfonating the papermaking black liquor with sulfur dioxide, adding the sulfonated papermaking black liquor to a sodium sulfanilate, urea and phenol mixed alkaline solution, adding formaldehyde in a dropwise manner, and carrying out a condensation reaction to prepare the papermaking black liquor modified sulfamate high efficiency water reducer. The high efficiency water reducer prepared in the invention has the advantages of obvious reduction of the slump loss and the water segregation phenomenon of concrete, increase of the slump retaining property, workability improvement, low production cost, environmental pollution reduction, realization of full utilization of the papermaking black liquor, and reduction of the recycling cost.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

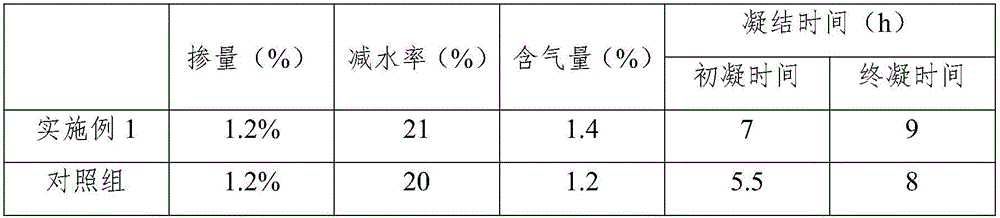

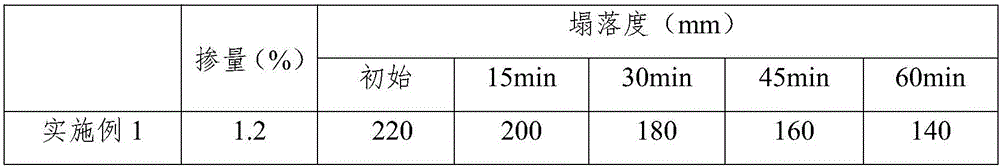

A kind of concrete viscosity modifier and preparation method thereof

The invention discloses a concrete viscosity regulating agent and a preparation method thereof. The concrete viscosity regulating agent is a ternary polymer prepared through free radical polymerization of monomer GMA-IDA prepared from glycidyl methacrylate and iminodiacetic acid, acrylic acid (AA) or methacrylic acid, and cationic monomer. The concrete viscosity regulating agent is novel in structure, reasonable in design, and simple and safe in production process; conditions are easily controllable; organic solvents polluting the environment are not used in production; and the concrete viscosity regulating agent is a green environment-friendly water-soluble polymer and is easy for industrial production. The concrete viscosity regulating agent has good compatibility with concrete additives like a polycarboxylate superplasticizer, can substantially improve workability of concrete, inhibits the phenomenon of water segregation and separation of concrete in an early stage, improves slump loss resistance of the concrete and has certain anti-mud effect.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

Polycarboxylate-type water reducer monomer polyether and preparation method for midbody thereof

The invention discloses a polycarboxylate-type water reducer monomer polyether and a preparation method for a midbody thereof. The preparation method for the polycarboxylate-type water reducer monomer polyether midbody, provided by the invention, comprises the steps of mixing an enol initiator with water content of less than 0.05% with a catalyst and reacting under the temperature of below 35 DEG C and under a nitrogen bubbling condition, wherein stirring is not required in the mixing and reaction processes of the enol initiator and the catalyst. According to the preparation method for the polycarboxylate-type water reducer monomer polyether midbody, provided by the invention, the content of the side reactant can be obviously reduced, the damage to the device can be reduced, the production process is safe, the operation method is simple and convenient and the prepared polycarboxylate-type water reducer monomer polyether contains few impurities.

Owner:SHANGHAI DONGDA CHEM

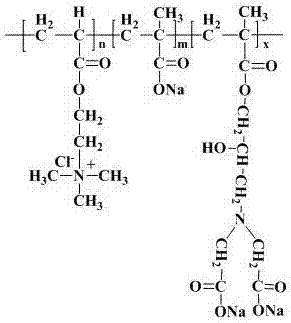

Modified naphthalene-series water reducer and preparation method thereof

The invention discloses a modified naphthalene-series water reducer and a preparation method thereof. The water reducer comprises 90-110 parts of industrial naphthalene, 40-60 parts of washing oil, 175-185 parts of sulfuric acid and 90-92 parts of formaldehyde. In the production process of the water reducer, wash oil is creatively added for performing modification on naphthalenesulfonic acid, and the water reducer is prepared through steps of naphthalene dissolving, sulfonation, hydrolysis, condensation, neutralization and the like. According to the modified naphthalene-series water reducer, the cost is reduced, also the collapse-preventing effect of the finished product on concrete is improved, thus the workability, the pumpability and the non-air-entraining property of concrete are improved, and the production efficiency is improved.

Owner:FUQING YONGCHUN CONCRETE ADMIXTURE

Low-cost modified naphthalene-based superplasticizer with high slump-keeping property and preparation method thereof

The invention discloses a low-cost modified naphthalene-based superplasticizer with high slump-keeping property and a preparation method thereof. The superplasticizer is prepared from the following components in parts by weight: 120-130 parts of industrial naphthalene oil, 50-60 parts of 80% petroleum waste phenol residue, 100-120 parts of concentrated sulphuric acid, 40-80 parts of formaldehyde, 80-100 parts of 30% alkaline solution, 20-40 parts of 35% papermaking black liquor, 12-20 parts of sulphur dioxide and a right amount of water. The prepared superplasticizer is low in production cost, the preparation method is simple and short in period, the problem that cost of naphthalene-based chemical modification is always high is solved, mixed concrete is relatively soft, does not adhere to bottom and has better workability and slump-keeping property, and bleeding ratio is low, so that concrete reinforcement effect is obvious.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

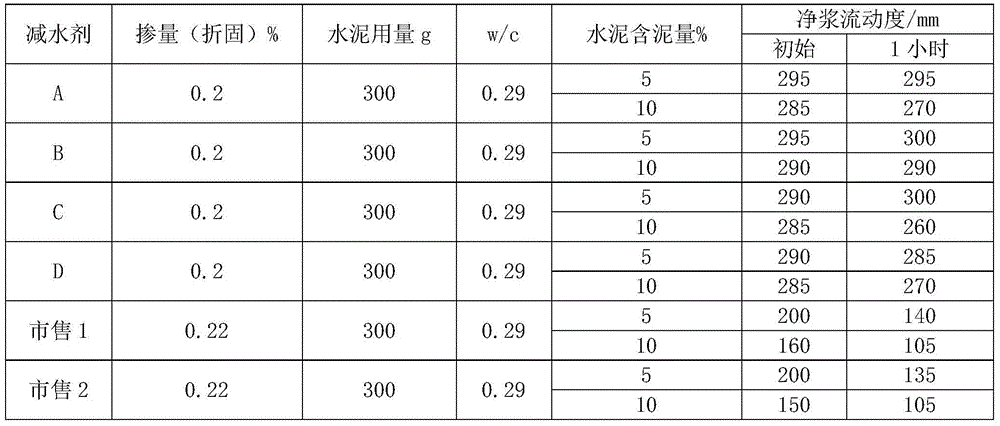

Sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent and preparation method thereof

InactiveCN109593167AImprove collapse retentionGood retarding effectPotassium persulfateNuclear chemistry

The invention discloses a sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent. The water reducing agent is a copolymer formed by polymerizing sorbitol acrylate citric acid,acrylic acid, an unsaturated polyether macromonomer, an initiator and a chain transfer agent through a free radical copolymerization reaction; the unsaturated polyether macromonomer is one or two ofallyl polyoxyethylene ether, methylallyl alcohol polyoxyethylene ether and isoamylene polyoxyethylene ether; the initiator is at least one of hydrogen peroxide, ammonium persulfate and potassium persulfate, or any one of hydrogen peroxide, ammonium persulfate and potassium persulfate in combination with at least one of ascorbic acid, sodium formaldehyde sulfoxylate and ferrous sulfate; the chain transfer agent is at least one of mercaptopropionic acid, thioglycolic acid, mercaptoethanol, mercaptoethylamine, sodium methallyl sulfonate, sodium hypophosphite and sodium allylsulfonate. According to the sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent, a hydration film can be generated on the surface of cement particles, and the slump retaining capability of the water reducing agent and the adaptability to the mechanical sand of different flooring materials and the retarding effect on the concrete can be further improved.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

Mud-resistant polycarboxylate superplasticizer

The invention belongs to the technical field of design and manufacture of concrete admixtures and particularly relates to mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer is made of, by weight, 60-90 parts of polyethylene glycol dimethacrylate, 20-40 parts of sodium dodecyl benzene sulfonate, 10-15 parts of carboxylic acid derivatives, 1-3 parts of thiocarbamide, 5-15 parts of potassium permanganate, 5-15 parts of chain transfer agent, 150-263 parts of deionized water and 5-15 parts of 30% sodium hydroxide. Concrete prepared from the polycarboxylate superplasticizer made according to the method is excellent in slump constant keeping capability and wide in mud content application range of sand and gravel materials, and concrete construction in southern Xinjiang is technically guaranteed.

Owner:XINJIANG DELAND

Preparation method of polycarboxylate superplasticizer

The invention discloses a preparation method of a polycarboxylate superplasticizer. The method relates to the technical field of concrete admixture preparation, and comprises the following two stages:a first stage: under a stirring condition, adding acrylic acid, vitamin C, mercaptopropionic acid, a methylallyl polyoxyethylene ether monomer and ammonium persulfate into a reactor, heating to 60 DEG C+ / -5 DEG C, and carrying out heat preservation to react for 1 hour to 5 hours; then, adding a defoaming agent, an air entraining agent, a thickening agent and a corrosion remover into the reactor,and uniformly stirring; a second stage: adding a retarder and water into a substance obtained in the first stage, and uniformly stirring. According to the preparation method of the polycarboxylate superplasticizer provided by the invention, the vitamin C used as one of reaction raw materials is added, so that the product polycarboxylate superplasticizer is modified, and a water reducing effect andan anti-collapse effect are improved.

Owner:广西鸿志新材料有限公司

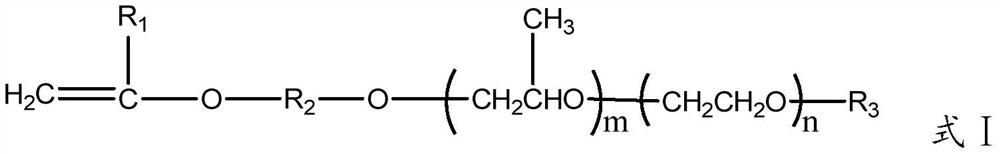

Unsaturated polyether alcohol and polycarboxylate water reducer prepared by same

The invention relates to an unsaturated polyether alcohol. A method comprises: adding unsaturated amine into a reactor, after nitrogen gas replacement, continuously adding epoxy olefin, at reaction pressure of 0.001-1.0MPa and reaction temperature of 40-120 DEG C, after charging, performing curing and degassing treatment, pressing phosphonitrile catalyst into the reactor by nitrogen gas, charging the nitrogen gas after vacuumizing, continuously charging epoxy ethylene oxide at reaction pressure of 0.001-1.0MPa and reaction temperature of 40-120 DEG C, after charging, performing the curing and degassing treatment, cooling and filtering to obtain the unsaturated polyether alcohol. The unsaturated polyether alcohol has a comb structure and an amino functional group, a polycarboxylate water reducer prepared by the unsaturated polyether alcohol is improved by 30 percent or more than 30 percent in early strength and 10 percent or more than 10 percent in collapsing retention.

Owner:NANJING HONGBAOLI POLYURETHANE

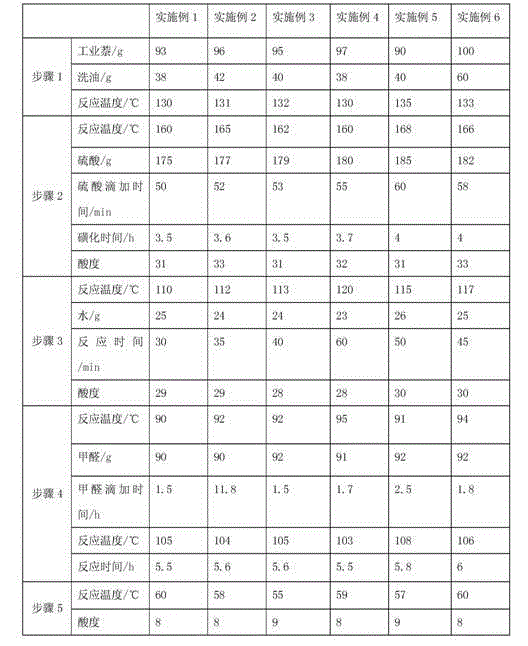

Lignosulfonate modified sulfamic acid series high-efficiency water reducer and preparation method thereof

InactiveCN103965417BReduce manufacturing costSolve the phenomenon of segregation and bleedingSuperplasticizerPhenol

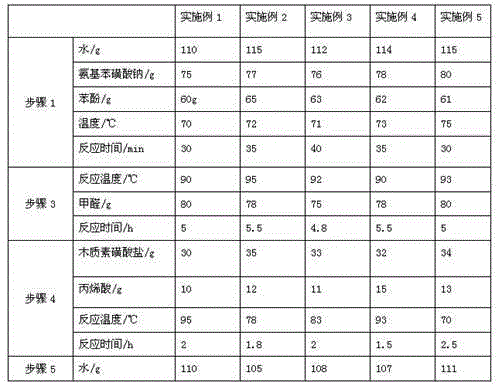

The invention discloses a preparation method of a lignosulfonate-modified aminosulfonic acid series high-efficiency water reducer, which uses sodium aminobenzenesulfonate, phenol, and formaldehyde as reactants, sodium hydroxide as an adduct, and formaldehyde as polycondensation Lignosulfonate and acrylic acid are copolymers, and through the stages of dissolution, addition, polycondensation and copolymerization, a lignosulfonate-modified sulfamic acid-based high-efficiency water reducer is obtained. The invention overcomes the shortcoming that the sulfamic acid-based superplasticizer is too sensitive to the dosage, improves the water retention and adaptability, reduces the production cost of the sulfamic acid-based high-efficiency water-reducer, and broadens the range of lignosulfonate. application range.

Owner:FUQING YONGCHUN CONCRETE ADMIXTURE

Preparation method of slump-proof polycarboxylate superplasticizer

ActiveCN108084358ALower melting temperatureLow reaction temperatureBulk polymerizationTransport time

The invention provides a preparation method of a slump-proof polycarboxylate superplasticizer. The slump-proof polycarboxylate superplasticizer is prepared by bulk polymerization. The preparation method comprises the steps of (1) mixing polyoxyethylene polyoxypropylene ether and polyoxyethylene ether, stirring well at controlled temperature of 40-60 DEG C, and adding an initiator and a mixture ofunsaturated carboxylic acid, unsaturated carboxylates and a chain transfer agent; (2) curing for 0.5-1 hour after completion of step (1), and cooling to obtain the slump-proof polycarboxylate superplasticizer. The bulk polymerization is performed at relatively low temperature, the conditions are mild, operability is high, and the synthesized polycarboxylate superplasticizer has high water-reducingproperty. The polycarboxylate superplasticizer prepared herein is in liquid state at normal temperature, having an effective concentration of 100% and good stability of storage performance; the polycarboxylate superplasticizer is applicable to long-range transport and use; the polycarboxylate superplasticizer has excellent slump-proof performance; the problem can be solved that concrete slumps due to high temperature and long transport time; the polycarboxylate superplasticizer has a promising industrial application prospect.

Owner:JIAHUA CHEM MAOMING

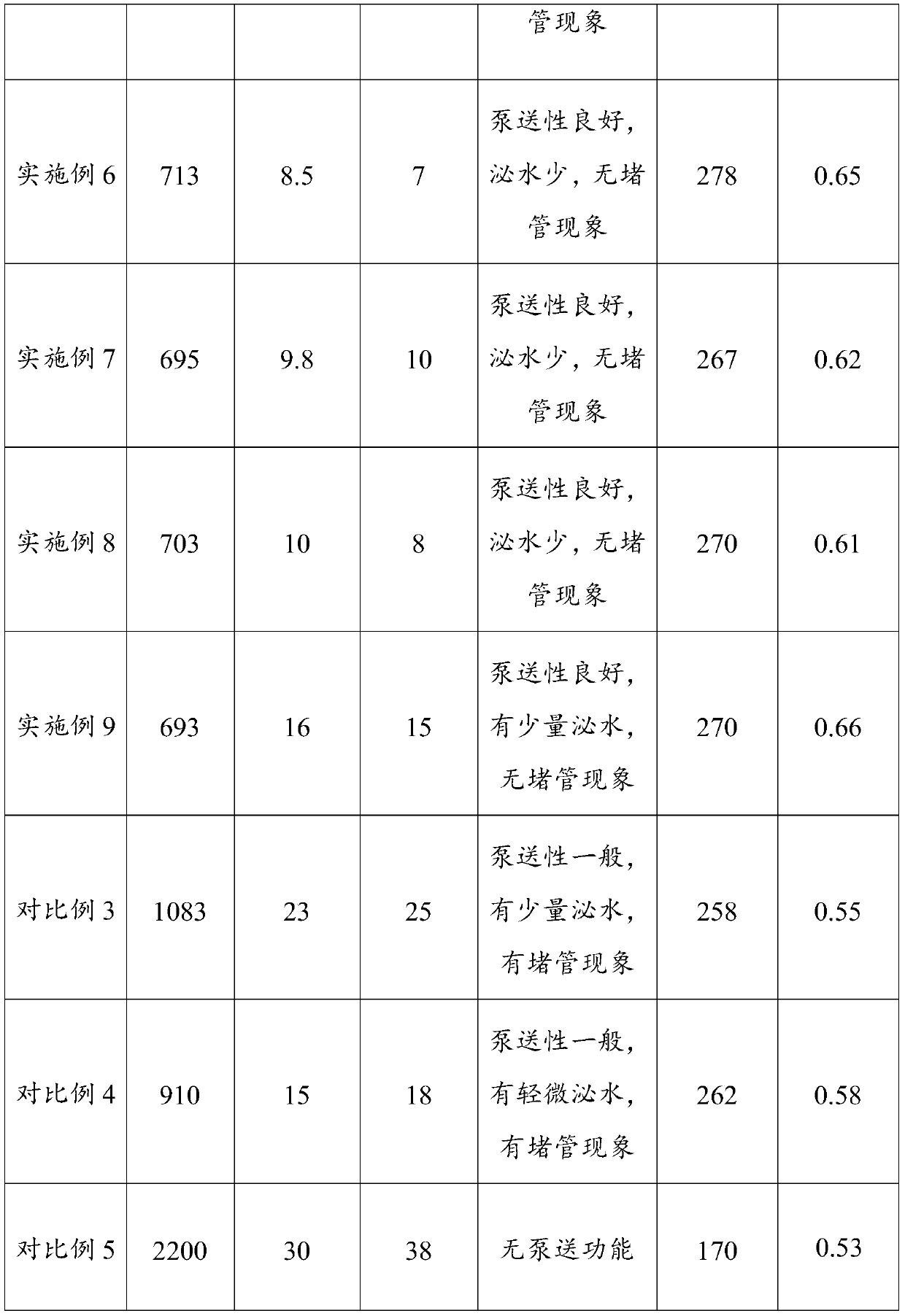

Polycarboxylic acid dispersing agent, phosphogypsum slurry, and preparation methods and applications of polycarboxylic acid dispersing agent and phosphogypsum slurry

The invention provides a polycarboxylic acid dispersing agent, a phosphogypsum slurry, and preparation methods and applications of the polycarboxylic acid dispersing agent and the phosphogypsum slurry, wherein the polycarboxylic acid dispersing agent comprises the following raw materials: VOPEG, and the VOPEG is a mixture of 4-hydroxybutyl vinyl polyoxyethylene ether and 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether. According to the invention, by adding VOPEG, the activity matching degree of the VOPEG and a micromolecular monomer acrylic acid is good based on the copolymerizationactivity of the high-activity double bonds linked with oxygen atoms in the VOPEG, and the positions of the double bonds are not isomerized, so that the side chain comb-shaped structure of the synthesized polycarboxylic acid dispersing agent is stretched, and the degree of freedom is good; and the polycarboxylic acid dispersing agent has dispersing function and also has functions of viscosity reduction, good collapse prevention performance and bleeding resistance, reduces the risk of the pipe blockage of a phosphogypsum slurry in a long-distance pumping process when the polycarboxylic acid dispersing agent is applied to the phosphogypsum slurry, and can adapt to different types of phosphogypsum backfill materials.

Owner:佳化化学(上海)有限公司

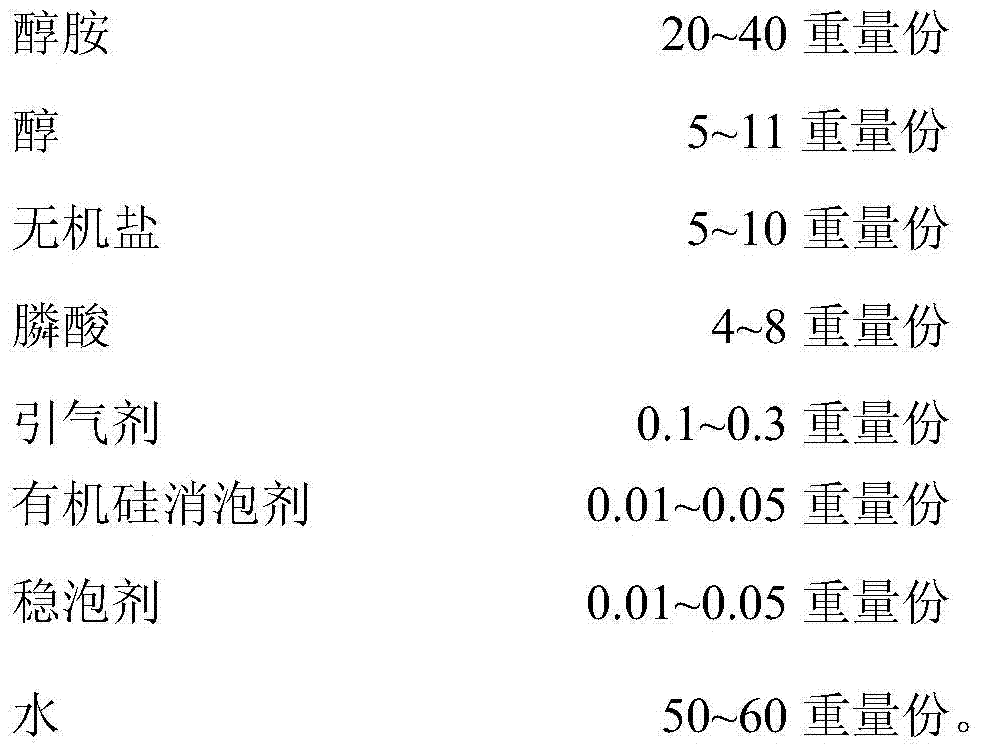

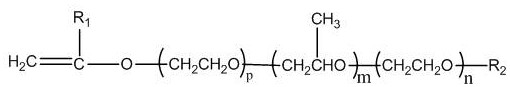

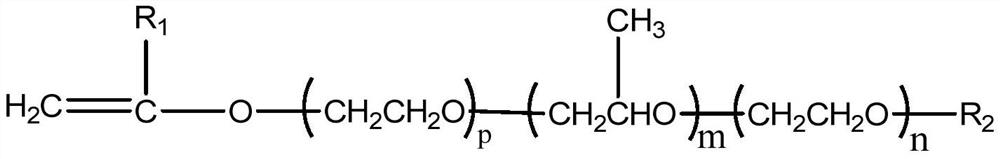

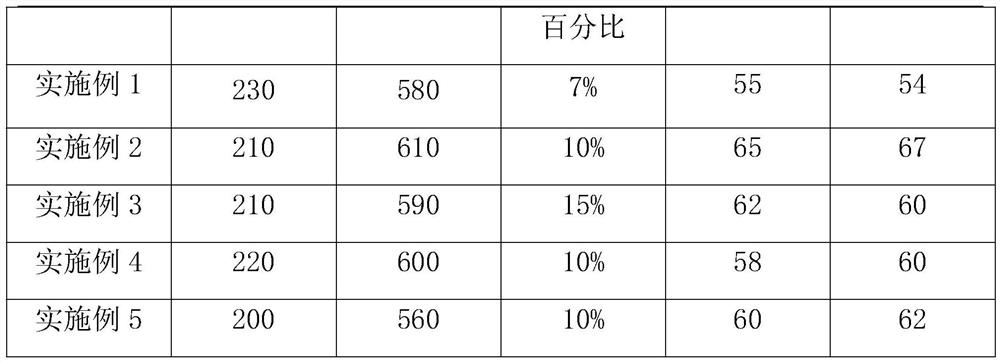

A kind of concrete synergist and preparation method thereof

The invention discloses a concrete synergist and a preparation method thereof. The raw materials are composed of the following components by weight: 20-40 parts by weight of alcohol amine, 6-12 parts by weight of alcohol, 5-10 parts by weight of inorganic salt, phosphine 4-12 parts by weight of acid, 0.05-0.3 parts by weight of air-entraining agent, 0.01-0.05 parts by weight of silicone defoamer, 0.01-0.05 parts by weight of foam stabilizer and 35-60 parts by weight of water, wherein the alcohol amine is monoethanol One or both of diisopropanolamine, aminoethylethanolamine or N,N‑diethylpropanolamine, the alcohol is at least one of diethylene glycol and 1,5‑pentanediol, inorganic salt Potassium pyrophosphate or sodium pyrophosphate. The concrete synergist of the invention has the advantages of non-toxic finished products, uniform dispersion, simple process, no pollution, low energy consumption, easy industrial production, and can effectively improve the workability and slump retention of concrete and increase the strength of concrete. By reducing the amount of cement, the hydration reaction efficiency of cement in concrete can be effectively improved.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Silyl ether-terminated polyether, preparation method thereof and high-efficiency mud-resistant water reducing agent

ActiveCN111286021AIncrease steric hindranceLow water solubilityBulk chemical productionPolymer scienceOrganosolv

The invention provides silyl ether-terminated polyether, a preparation method thereof and a high-efficiency mud-resistant water reducing agent. The preparation method comprises the following steps: 1)under a stirring condition, adding a polyether raw material into an organic solvent, and dissolving; 2) adding imidazole, stirring and dissolving; and 3) adding a silyl ether protective agent, and reacting to obtain the silyl ether-terminated polyether. Compared with the prior art, the silyl ether-terminated polyether has advantages that silyl ether substances are used for terminating hydroxyl groups of methyl allyl polyoxyethylene ether HPEG, 4-hydroxybutyl vinyl polyoxyethylene ether VPEG and the like so that the whole PEG chain terminal has a certain hydrophobicity, and the terminal grouphas a large volume so as to effectively prevent the PEG chain from penetrating into the soil, such that the excellent mud resistance is represented.

Owner:安徽海螺材料科技股份有限公司

Mud resistant polycarboxylate superplasticizer and preparation method thereof

The invention relates to a mud resistant polycarboxylate superplasticizer and a preparation method thereof. The mud resistant polycarboxylate superplasticizer is prepared from the following ingredients in percentage by weight: 10 to 20 percent of alcohol alkoxylate, 10 to 20 percent of acrylic esters, 5 to 10 percent of double bond-containing organic silicon, 0.5 to 3 percent of a sodium pyrosulfite mud-resistant modifier, 5 to 10 percent of a charged colloid, 1 to 5 percent of active organic acid and the balance of deionized water. By using the formula, the polycarboxylate superplasticizer with excellent stress resistance and slump retaining performance can be prepared.

Owner:南京福盛新材料有限公司

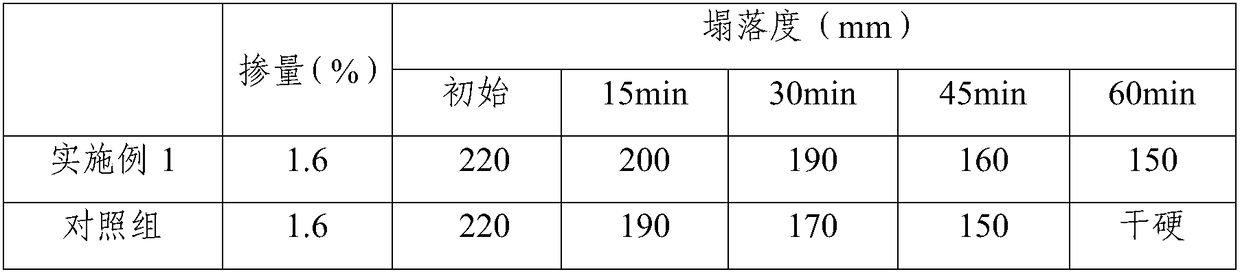

A kind of phosphate-containing high adaptability polycarboxylate water reducing agent and preparation method thereof

The invention discloses a phosphate containing high-adaptability polycarboxylate superplasticizer and a preparation method thereof.The phosphate containing high-adaptability polycarboxylate superplasticizer is prepared through the steps that unsaturated polyether macromonomers, micromonomers, unsaturated phosphate monomers, 2-methacrylic acid-3(N,N-oxalic acid amine)-2 hydroxy propyl ester, an initiator and a chain transfer agent react with water at the temperature of 50-80 DEG C for 3-6 hours, a copolymer is obtained, then the pH value is adjusted to range from 6.0 to 7.0 with alkaline matter, and a settled solution is obtained.Compared with a polycarboxylate superplasticizer, the phosphate containing high-adaptability polycarboxylate superplasticizer has higher adsorption capacity, sulfate in cement can be effectively resisted, the dispersing power of polycarboxylate is greatly improved, the phosphate structure can change the crystal morphology formed at the initial stage of ettringite, and then collapse protecting performance is improved.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

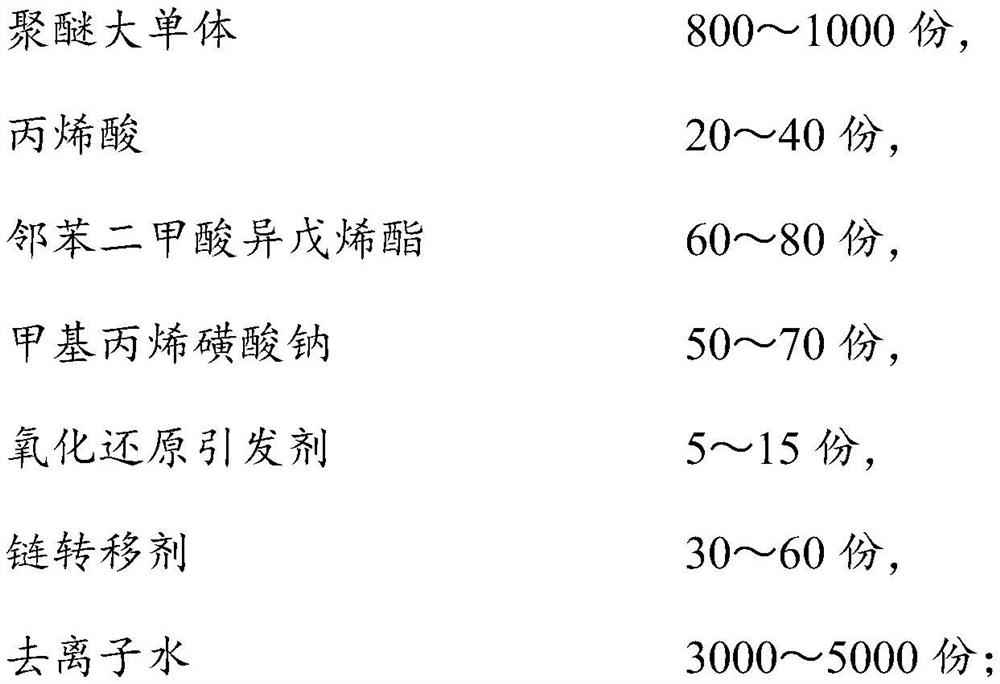

Slow-release high-slump-retaining type water reducing agent and preparation method thereof

The invention relates to the technical field of water reducing agents, in particular to a slow-release high-slump-retaining water reducing agent and a preparation method thereof. Comprising the following raw materials in parts by mass: 800-1000 parts of a polyether macromonomer, 20-40 parts of acrylic acid, 60-80 parts of isopentene phthalate, 50-70 parts of sodium methallyl sulfonate, 5-15 parts of a redox initiator, 30-60 parts of a chain transfer agent and 3000-5000 parts of deionized water. The water reducing agent slowly releases carboxyl and sulfonic acid groups in an alkaline environment of concrete, the fluidity of the concrete is kept for a long time, the ester group hydrolysis speed is lower, long-time slow release can be achieved, good slow release and high collapse protection performance are achieved, meanwhile, the later adsorption-dispersion capacity of the polycarboxylic acid water reducing agent is improved, and the service life of the water reducing agent is prolonged. Therefore, the slump loss of the concrete is slowed down.

Owner:何武顺

Polycarboxylate superplasticizer with nano size and preparation method thereof

PendingCN114716623AOptimize structure sizeImprove performanceSolid waste managementMeth-Superplasticizer

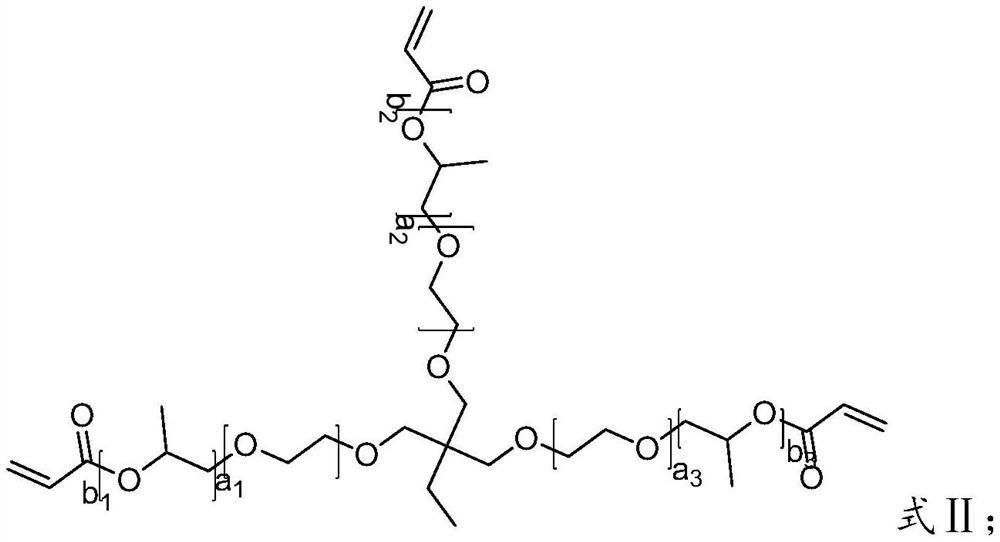

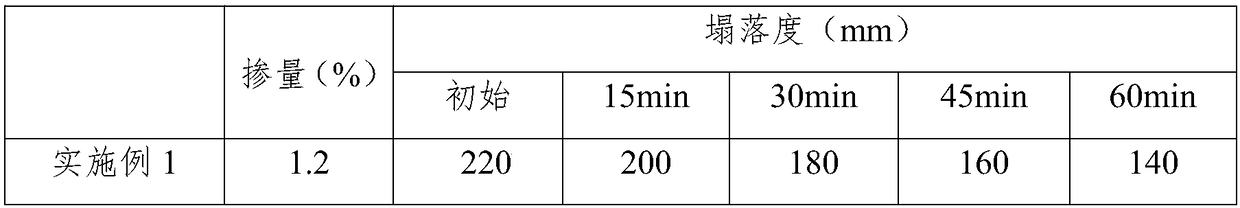

The invention belongs to the technical field of preparation of concrete admixtures, and particularly relates to a polycarboxylic acid water reducing agent with a nanometer size and a preparation method thereof. The preparation method comprises the following steps: (1) preparing hydroxyalkyl vinyl-terminated polyoxypropylene polyoxyethylene ether; (2) preparing trimethylolpropane polyoxyethylene polyoxypropylene ether triacrylate; (3) preparing a template agent; and (4) preparing the polycarboxylic acid water reducing agent with nano size, and limiting the specific preparation steps of the template agent and the polycarboxylic acid water reducing agent. According to the method, hydroxyalkyl-terminated vinyl polyoxypropylene polyoxyethylene ether and trimethylolpropane polyoxyethylene polyoxypropylene ether triacrylate can optimize the main chain structure and the particle size of the water reducing agent under the action of a specific template agent, the particle size of the obtained water reducing agent is 60-80 nm, and the dispersion index is 1.01-1.02; meanwhile, the obtained water reducing agent has relatively good comprehensive performance, such as excellent water reducing rate, collapse resistance and workability, and particularly, the collapse resistance is remarkably improved.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

A low-cost and high-slump modified naphthalene-based high-efficiency water reducer and its preparation method

The invention discloses a low-cost modified naphthalene-based superplasticizer with high slump-keeping property and a preparation method thereof. The superplasticizer is prepared from the following components in parts by weight: 120-130 parts of industrial naphthalene oil, 50-60 parts of 80% petroleum waste phenol residue, 100-120 parts of concentrated sulphuric acid, 40-80 parts of formaldehyde, 80-100 parts of 30% alkaline solution, 20-40 parts of 35% papermaking black liquor, 12-20 parts of sulphur dioxide and a right amount of water. The prepared superplasticizer is low in production cost, the preparation method is simple and short in period, the problem that cost of naphthalene-based chemical modification is always high is solved, mixed concrete is relatively soft, does not adhere to bottom and has better workability and slump-keeping property, and bleeding ratio is low, so that concrete reinforcement effect is obvious.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

Crosslinking type polycarboxylic acid water reducing agent and preparation method thereof

PendingCN114736341AControllable reaction rateGentle and steady exothermSolid waste managementComposite materialEther

The invention belongs to the technical field of preparation of concrete admixtures, and particularly relates to a cross-linked polycarboxylic acid water reducer and a preparation method thereof. The method comprises the following steps: (1) preparing hydroxyalkyl vinyl-terminated polyoxypropylene polyoxyethylene ether; (2) preparing trimethylolpropane polyoxyethylene polyoxypropylene ether triacrylate; and (3) carrying out free radical polymerization reaction on the hydroxyalkyl-terminated vinyl polyoxypropylene polyoxyethylene ether and trimethylolpropane polyoxyethylene polyoxypropylene ether triacrylate to prepare the cross-linking type polycarboxylic acid water reducing agent. In the polymerization process, the reaction rate is controllable, heat release is mild and stable, the phenomena of local implosion and the like caused by high temperature in the polymerization reaction process are avoided, the reaction speed can be stably controlled, and the polycarboxylic acid water reducer with high water reducing rate, high slump retention, good wrapping property and excellent workability is obtained under the condition of normal temperature. And moreover, the preparation method of the water reducing agent is suitable for most production lines.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

A paper-making black liquor modified sulfamate high-efficiency water reducer and its preparation method

The invention discloses a papermaking black liquor modified sulfamate high efficiency water reducer. The high efficiency water reducer is prepared from, by weight, 130-140 parts of sodium sulfanilate, 30-60 parts of a papermaking black liquor, 12-30 parts of sulfur dioxide, 50-70 parts of phenol, 150-180 parts of formaldehyde, 15-30 parts of a 30% liquid alkali, 9-13 parts of urea, and 200-360 parts of water. A preparation method of the high efficiency water reducer comprises the following steps: sulfonating the papermaking black liquor with sulfur dioxide, adding the sulfonated papermaking black liquor to a sodium sulfanilate, urea and phenol mixed alkaline solution, adding formaldehyde in a dropwise manner, and carrying out a condensation reaction to prepare the papermaking black liquor modified sulfamate high efficiency water reducer. The high efficiency water reducer prepared in the invention has the advantages of obvious reduction of the slump loss and the water segregation phenomenon of concrete, increase of the slump retaining property, workability improvement, low production cost, environmental pollution reduction, realization of full utilization of the papermaking black liquor, and reduction of the recycling cost.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

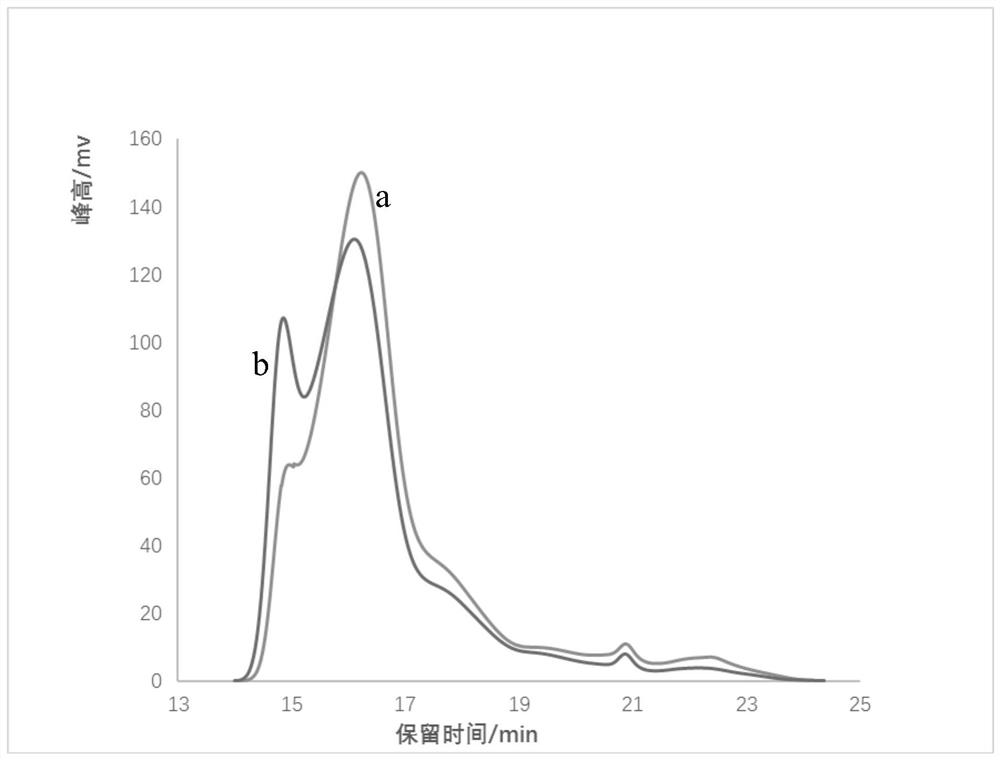

A kind of polycarboxylate water reducing agent and preparation method thereof

The invention belongs to the technical field of concrete admixture preparation, and in particular relates to a polycarboxylate water reducer and a preparation method thereof. The method comprises (1) preparing hydroxyethyl-terminated vinyl polyoxypropylene polyoxyethylene ether; (2) preparing polycarboxylate water reducer; the double-ended vinyl ether small monomers contain alkoxy groups and Contains double bonds; preferably, the vinyl ether monomer is ethylene glycol divinyl ether and / or diethylene glycol divinyl ether. The content of ultra-high molecular weight copolymer in the polycarboxylate water reducer prepared by the method is reduced, the relative molecular weight distribution is normal distribution, the molecular weight distribution is narrow, and there are almost no strong polar ultra-high molecular weight by-products; The reaction rate is controllable, the heat release is mild and stable, avoiding the local detonation phenomenon caused by high temperature during the polymerization reaction, and the monomer conversion rate can be increased to more than 95%.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

DSD acid waste liquid modified superplasticizer

The invention concretely relates to a DSD acid waste liquid modified superplasticizer. The superplasticizer includes the following raw materials, by weight: 50-60 parts of a naphthalene-based superplasticizer, 150-300 parts of DSD acid industrial waste liquid, 10-20 parts of an initiator, and 5-15 parts of a chain transfer agent. The DSD acid waste liquid modified superplasticizer provided by theinvention can effectively utilize waste and has obvious reinforcing effect on concrete.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

A kind of preparation method of collapsible polycarboxylate water reducer

The invention provides a preparation method of a collapse-preserving polycarboxylate water-reducer, which is prepared by bulk polymerization, which specifically includes the following steps: (1) polyoxyethylene polyoxypropylene Mix the ether and polyoxyethylene ether, control the temperature to 40-60°C, stir evenly, then add the initiator, and the mixture of unsaturated carboxylic acid, unsaturated carboxylic acid ester and chain transfer agent; (2) the step (1 ) after the completion of aging for 0.5 to 1 hour, lowering the temperature to obtain a slump-preserving polycarboxylate superplasticizer. The bulk polymerization reaction is carried out at a relatively low temperature, the conditions are mild, and the operability is strong. The synthesized polycarboxylate water reducer has high water reducing performance. The polycarboxylate water reducer prepared by the above method is liquid at normal temperature, the effective concentration is 100%, the storage performance is stable, and it is suitable for long-distance transportation and use; The problem of concrete collapse caused by long transportation time has broad prospects for industrial application.

Owner:JIAHUA CHEM MAOMING

A modified lignosulfonate water reducer and its preparation method

The invention relates to the technical field of water reducers, specifically a modified lignosulfonate water reducer and a preparation method thereof, comprising, in parts by weight: 30-50 parts of bagasse, 40-60 parts of formic acid solution, and chloroacetic acid solution 40-60 parts, 5-8 parts of tea polyphenols, 1-4 parts of betaine, 0.2-0.6 parts of methyl methacrylate, 2-7 parts of sulfonating agent, the water reducing agent of the present invention can Water reduction within a certain range, high fluidity of cement slurry, multiple reactive points, good water reduction effect, good air bubble performance, high slump retention, water reduction rate as high as 50%, and the dosage is generally 0.08‑0.13%. Good performance, stable storage effect, long-term storage will not cause the stability of the water reducing agent to decrease, the effective components of the water reducing agent will be lost or the water reducing agent will fail.

Owner:贵州凯襄新材料有限公司

Concrete with synergist and preparation method thereof

The invention provides a synergist-containing concrete, which is made of the following raw materials in weight percentage: 10-20% of cement, 25-30% of fly ash, 6-9% of silica fume, and 0.1-0.2% of synergist , the first part of water 4‑6%, coarse aggregate 10‑25%, fine aggregate 10‑25%, water reducing agent 1‑2.5%; synergist is made of the following raw materials by weight: triethanolamine 20‑ 35 parts, 1‑5 parts of sodium tripolyphosphate, 2‑4 parts of tetraethylenepentamine, 2‑3 parts of sodium tungstate, 5‑10 parts of sodium pyrophosphate, 5‑15 parts of allylamine, the second part of water 20‑25 servings. The raw materials of the present invention cooperate with each other to obtain a synergist-containing concrete that reduces the amount of cement, reduces the cost, and ensures that the concrete has better working performance and mechanical performance.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

A kind of anti-mud type polycarboxylate water reducer and preparation method thereof

The invention relates to a mud-resistant polycarboxylate water-reducer and a preparation method thereof, which comprises the following components in weight percent: 10-20% of isomeric alcohol polyoxyethylene ether, 10-20% of acrylic acid ester, bis 5~10% of key organic silicon, 0.5~3% of sodium pyrosulfite anti-mud modifier, 5~10% of charged colloid, 1~5% of active organic acid and the balance are deionized water; the present invention can Preparation of polycarboxylate superplasticizer with excellent stress resistance and slump retention.

Owner:南京福盛新材料有限公司

A kind of preparation method of petroleum waste phenol slag modified sulfamate high-efficiency water reducer

The invention discloses a waste petroleum phenolic residue modified sulfamate high-efficiency water reducing agent and a preparation method thereof. The waste petroleum phenolic residue modified sulfamate high-efficiency water reducing agent is prepared from the following components in parts by weight: 130-140 parts of sodium sulfanilate, 100-200 parts of 80% waste petroleum phenolic residues, 30-60 parts of concentrated sulfuric acid, 50-60 parts of phenol, 150-180 parts of formaldehyde, 15-30 parts of 30% liquid caustic soda, 1-10 parts of dodecyl diphenyl ether sodium disulfonate and 180-260 parts of water. The waste petroleum phenolic residue modified sulfamate high-efficiency water reducing agent disclosed by the invention is low in production cost, the slump loss and the bleeding phenomenon of concrete can be remarkably reduced, the slump resistance can be improved, the peaceability can be improved, a remarkable concrete reinforcing effect can be achieved, and the social and economic benefits are remarkable.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com