Polycarboxylic acid dispersing agent, phosphogypsum slurry, and preparation methods and applications of polycarboxylic acid dispersing agent and phosphogypsum slurry

A technology of polycarboxylic acid and dispersant, which is applied in mining equipment, earth square drilling, filling, etc. It can solve the problems of poor slump performance, easy pipe plugging, high viscosity, etc., achieve good slump performance and improve dispersion performance , the effect of good activity matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

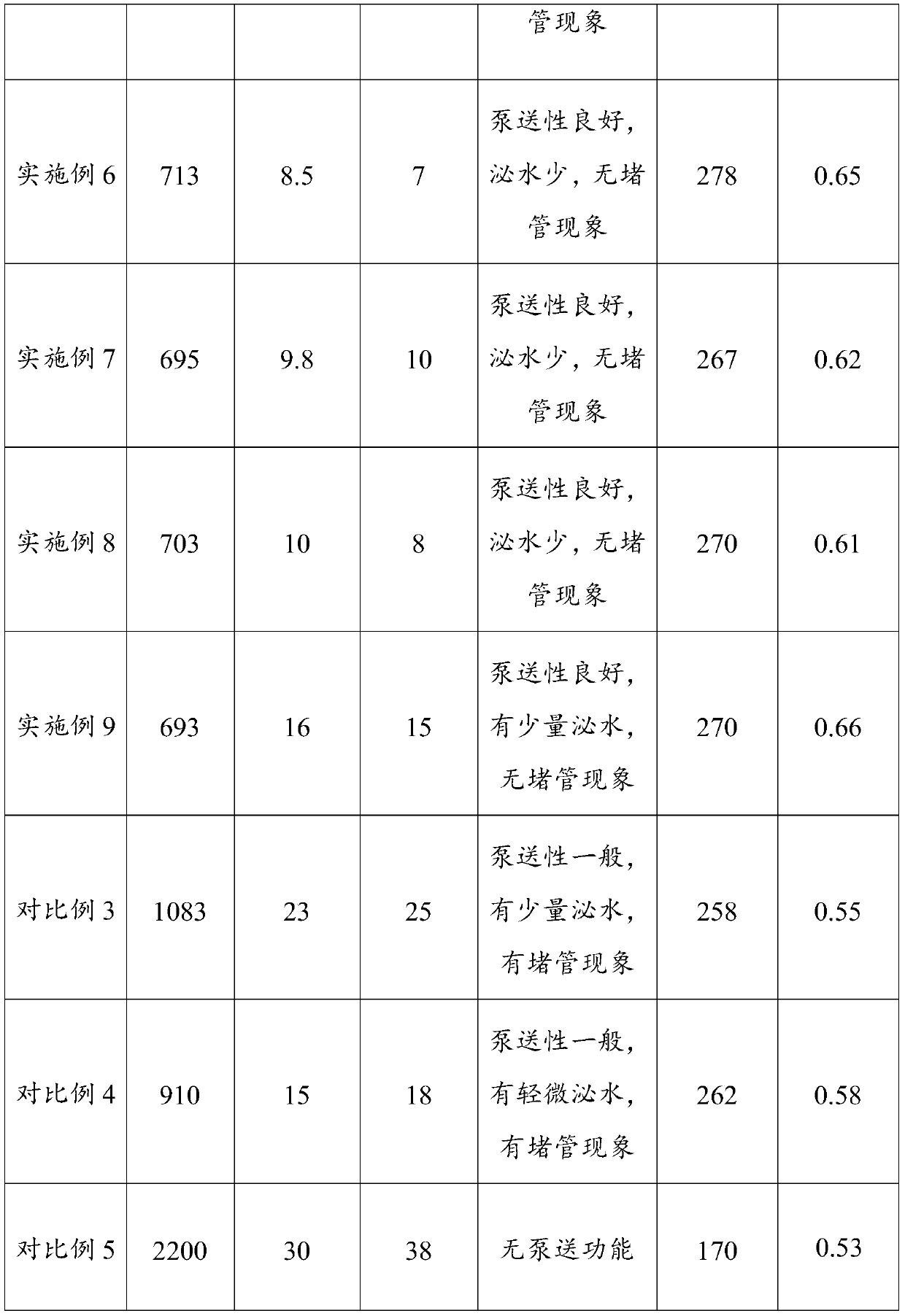

Examples

Embodiment 1

[0049] The present embodiment provides a kind of polycarboxylic acid dispersant and preparation method thereof, specifically comprises the following steps:

[0050] The configuration of the mixed aqueous solution of acrylic acid and chain transfer agent: dissolve 5kg of acrylic acid and 0.25kg of chain transfer agent mercaptoethanol in 32kg of water, mix well, and set aside;

[0051] Configuration of the reducing agent aqueous solution: dissolve 0.1kg of reducing agent-modified white powder in 1kg of water, mix well, and set aside;

[0052] Dissolve 30kg of VOPEG (number-average molecular weight: 1200) in 25kg of water, then add 0.5kg of hydrogen peroxide as an oxidizing agent, and after stirring evenly, add the above-mentioned mixed aqueous solution of acrylic acid and chain transfer agent dropwise within 30 minutes at 15°C; then within 40 minutes Add the above reducing agent aqueous solution dropwise; after reacting for 1 hour, add sodium hydroxide for neutralization to obta...

Embodiment 2

[0054] The present embodiment provides a kind of polycarboxylic acid dispersant and preparation method thereof, specifically comprises the following steps:

[0055] The configuration of the mixed aqueous solution of acrylic acid and chain transfer agent: dissolve 8kg of acrylic acid and 0.2kg of chain transfer agent sodium methylpropanesulfonate in 30kg of water, mix well, and set aside;

[0056] Configuration of the reducing agent aqueous solution: dissolve 0.2kg of reducing agent vitamin C in 3kg of water, mix well, and set aside;

[0057] Dissolve 35kg of VOPEG (number average molecular weight: 1000) in 30kg of water, then add 0.3kg of ammonium persulfate as an oxidant, after stirring evenly, add the mixed aqueous solution of the above-mentioned acrylic acid and chain transfer agent dropwise within 35min at 10°C; then within 50min Add the above reducing agent aqueous solution dropwise; after reacting for 1 hour, add sodium hydroxide for neutralization to obtain the polycarb...

Embodiment 3

[0059] The present embodiment provides a kind of polycarboxylic acid dispersant and preparation method thereof, specifically comprises the following steps:

[0060] The configuration of the mixed aqueous solution of acrylic acid and chain transfer agent: dissolve 6kg of acrylic acid and 0.3kg of chain transfer agent mercaptopropionic acid in 30kg of water, mix well, and set aside;

[0061] The configuration of the reducing agent aqueous solution: dissolve 0.15kg reducing agent modified hanging white block in 2kg water, mix well, and set aside;

[0062] Dissolve 34kg of VOPEG (number average molecular weight: 5000) in 25kg of water, then add 0.3kg of oxidant hydrogen peroxide, after stirring evenly, add the above mixed aqueous solution of acrylic acid and chain transfer agent dropwise within 45min at 12°C; then within 60min Add the above reducing agent aqueous solution dropwise; after reacting for 1 hour, add sodium hydroxide for neutralization to obtain the polycarboxylic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com