Crosslinking type polycarboxylic acid water reducing agent and preparation method thereof

A polycarboxylic acid, cross-linked technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of difficult control of polymerization speed, poor product stability, high equipment requirements, etc., to avoid local explosion Polymerization, excellent workability, and good wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The specific embodiment provides a preparation method of a cross-linked polycarboxylate water reducer, comprising the following steps:

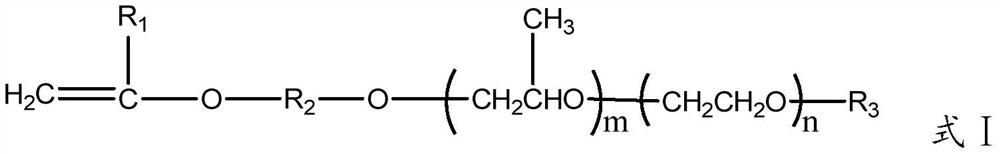

[0068] (1) Preparation of hydroxyalkyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether

[0069] Take unsaturated alcohol as the starting agent, put it into the autoclave, add alkali catalyst to mix, pass nitrogen to replace, add propylene oxide in an oxygen-free environment to control the reaction temperature to be 100-130 ° C, after the reaction is complete Add ethylene oxide, after the reaction of ethylene oxide is complete, the reaction kettle is cooled down, acid is added to neutralize the reaction, and the pH is adjusted to 6-7 to obtain hydroxyalkyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether.

[0070] (2) Preparation of trimethylolpropane polyoxyethylene polyoxypropylene ether triacrylate

[0071] (1) in the reaction kettle, add trihydroxypropane and alkali catalyst, replace the air in ...

Embodiment 1

[0076] This embodiment provides a cross-linked polycarboxylate water reducer and a preparation method thereof. The preparation method includes the following steps:

[0077] (1) Preparation of hydroxyalkyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether

[0078]100g of ethylene glycol monovinyl ether and 0.25g of sodium hydroxide were added to the autoclave, and after three times of nitrogen replacement, stirring was started, and the temperature of the reactor was raised to 110°C, and 160g of ring was fed into the reactor under an oxygen-free environment. Oxypropane, ripening reaction for 1h, after the reaction is complete, add 2000g of ethylene oxide to the reaction kettle, and ripen for 1h. After the reaction of ethylene oxide is complete, the reaction kettle is cooled to 90 ℃, and acetic acid is added to carry out the neutralization reaction. The pH reaches 6-7 to obtain hydroxyalkyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether with a...

Embodiment 2

[0086] This embodiment provides a cross-linked polycarboxylate water reducer and a preparation method thereof. The preparation method includes the following steps:

[0087] (1) Preparation of hydroxyalkyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether

[0088] Take 100g of ethylene glycol monovinyl ether and 0.25g of sodium hydroxide and add it to the autoclave. After replacing it with nitrogen three times, start stirring. Propane, ripening reaction for 1h, after the reaction is complete, add 2000g of ethylene oxide to the reaction kettle, and ripen for 1h, after the reaction of ethylene oxide is complete, reduce the temperature in the reaction kettle to 90 ℃, add acetic acid, and carry out the neutralization reaction, The pH of the product is adjusted to 6-7 to obtain hydroxyethyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether with an average molecular weight of 2000; wherein, ethylene oxide and propylene oxide are added to the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com