Lead ion repairing material for soil remediation and preparation method thereof

A remediation material and soil remediation technology, applied in the field of soil remediation, can solve problems such as low treatment efficiency of lead ion content, and achieve the effects of improving the content of migratory lead ions, increasing the content of nitrogen, and preventing detonation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

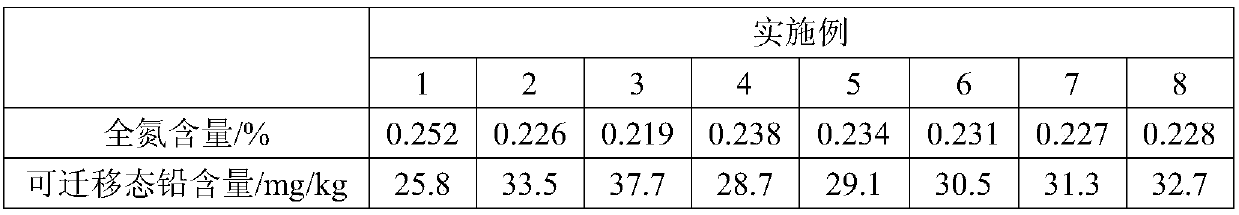

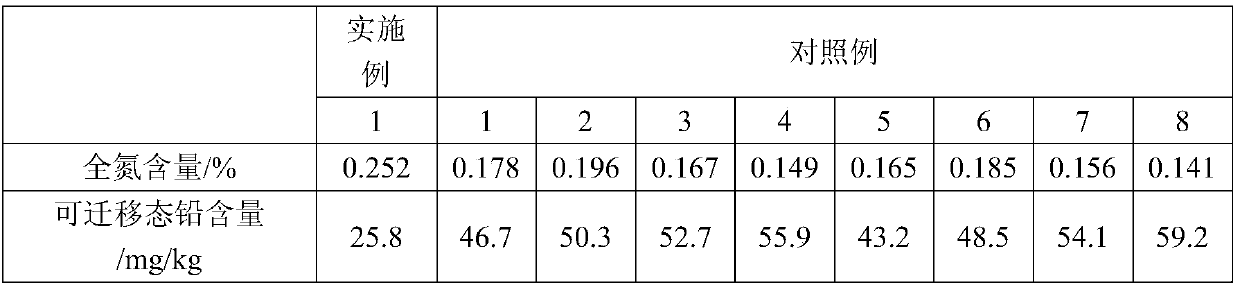

Examples

Embodiment 1

[0022] A kind of lead ion remediation material for soil remediation, its preparation method comprises the following steps:

[0023] (1), Weigh 33 parts of acrylic acid, 9.5 parts of isooctyl acrylate, 2.3 parts of urea, 0.9 parts of Sr-10 emulsifier, 26 parts of water, 43 parts of ethanol and 0.25 parts of ammonium persulfate and add them to the reaction kettle. 115r / min, maintain the reaction temperature of the system at 45°C for 35min, raise the temperature of the reactor to 75°C for 1.5h, add 6.9 parts of urea to the reactor in 6 times and continue the reaction for 1.5h while maintaining the above reaction conditions. The product was filtered, ultrasonically washed 3 times with 500mL methanol, 3 times ultrasonically washed with 500mL ethanol, and vacuum-dried at 49°C and -0.08MPa for 13min to obtain urea-modified polyacrylic acid;

[0024] (2), Weigh 23 parts of polylactic acid, 4.9 parts of lignin and 1.3 parts of maleic anhydride and add them to the open mill, keep the te...

Embodiment 2

[0029] A kind of lead ion remediation material for soil remediation, its preparation method comprises the following steps:

[0030](1), Weigh 33 parts of acrylic acid, 5 parts of isooctyl acrylate, 1.5 parts of urea, 0.3 parts of Sr-10 emulsifier, 21 parts of water, 35 parts of ethanol and 0.1 part of ammonium persulfate and add them to the reaction kettle. 115r / min, maintain the reaction temperature of the system at 45°C for 35min, raise the temperature of the reactor to 69°C for 3h, add 4.5 parts of urea to the reactor in 6 times and continue the reaction for 1.5h while maintaining the above reaction conditions, the product After filtration, ultrasonic washing with 500 mL of methanol for 3 times, ultrasonic washing with 500 mL of ethanol for 3 times, and vacuum drying at 49 °C and -0.08 MPa for 13 min, urea-modified polyacrylic acid was obtained;

[0031] (2), Weigh 23 parts of polylactic acid, 3 parts of lignin and 0.5 part of maleic anhydride and add them to the open mill,...

Embodiment 3

[0036] A kind of lead ion remediation material for soil remediation, its preparation method comprises the following steps:

[0037] (1), Weigh 33 parts of acrylic acid, 14 parts of isooctyl acrylate, 4.25 parts of urea, 2 parts of Sr-10 emulsifier, 35 parts of water, 49 parts of ethanol and 0.5 part of ammonium persulfate and add them to the reaction kettle. 115r / min, maintain the reaction temperature of the system at 45°C for 35min, raise the temperature of the reactor to 91°C for 0.5h, add 12.75 parts of urea to the reactor in 6 times and continue the reaction for 1.5h under the above reaction conditions. The product was filtered, ultrasonically washed 3 times with 500mL methanol, 3 times ultrasonically washed with 500mL ethanol, and vacuum-dried at 49°C and -0.08MPa for 13min to obtain urea-modified polyacrylic acid;

[0038] (2), take 23 parts of polylactic acid, 6 parts of lignin and 3 parts of maleic anhydride and add them to the open mill, maintain the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com