Preparation method of polycarboxylate superplasticizer

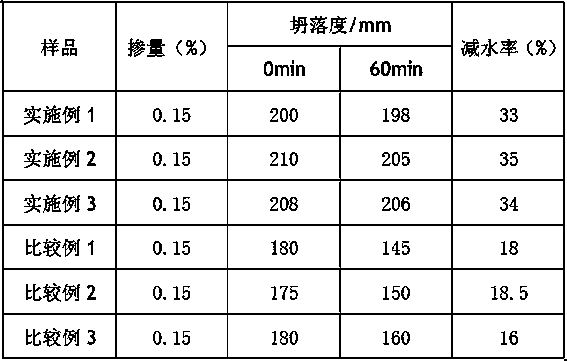

A technology of water reducing agent and polycarboxylic acid, applied in the field of preparation of polycarboxylate water reducing agent, can solve the problems of small water reducing rate, large change of slump with time and high dosage, and achieves the improvement of air entrainment function, Improve the slump retention effect and avoid the effect of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 - the preparation method of polycarboxylate water reducer

[0016] It includes the following two stages:

[0017] The first stage: under stirring conditions, add 1.5kg acrylic acid, 0.1kg vitamin C, 2kg thiopropionic acid, 20kg methallyl polyoxyethylene ether monomer and 0.5kg ammonium persulfate into the reactor, and heat to 60°C, keep warm for 5 hours; then, add 0.1kg defoamer, 0.1kg air-entraining agent, 0.1kg thickener, 0.1kg preservative to the reactor, and stir evenly;

[0018] The second stage: add 0.1kg retarder and 2.9kg water to the material obtained in the first stage, and stir evenly.

Embodiment 2

[0019] Embodiment 2 - the preparation method of polycarboxylate water reducer

[0020] It includes the following two stages:

[0021] The first stage: under stirring conditions, add 2kg acrylic acid, 0.5kg vitamin C, 4kg thiopropionic acid, 30kg methallyl polyoxyethylene ether monomer and 1kg ammonium persulfate to the reactor, and heat to 130 ℃, heat preservation reaction for 1 hour; then, add 0.05kg defoamer, 0.05kg air-entraining agent, 0.05kg thickener, 0.05kg preservative to the reactor, and stir evenly;

[0022] The second stage: add 0.05kg retarder and 3.7kg water to the material obtained in the first stage, and stir evenly.

Embodiment 3

[0023] Embodiment 3 - the preparation method of polycarboxylate water reducer

[0024] It includes the following two stages:

[0025] The first stage: under stirring conditions, add 1.8kg acrylic acid, 0.4kg vitamin C, 3kg thiopropionic acid, 26kg methallyl polyoxyethylene ether monomer and 0.8kg ammonium persulfate into the reactor, and heat to 80°C, keep warm for 4 hours; then, add 0.06kg defoamer, 0.06kg air-entraining agent, 0.06kg thickener, 0.06kg preservative to the reactor, and stir evenly;

[0026] The second stage: add 0.06kg retarder and 3.2kg water to the material obtained in the first stage, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com