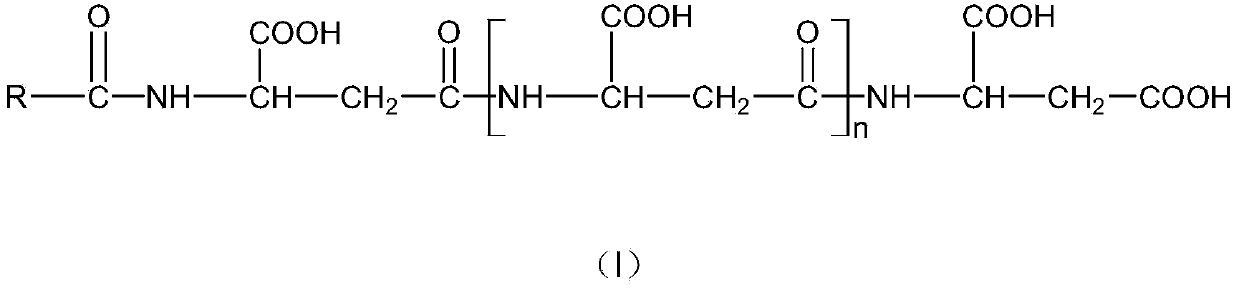

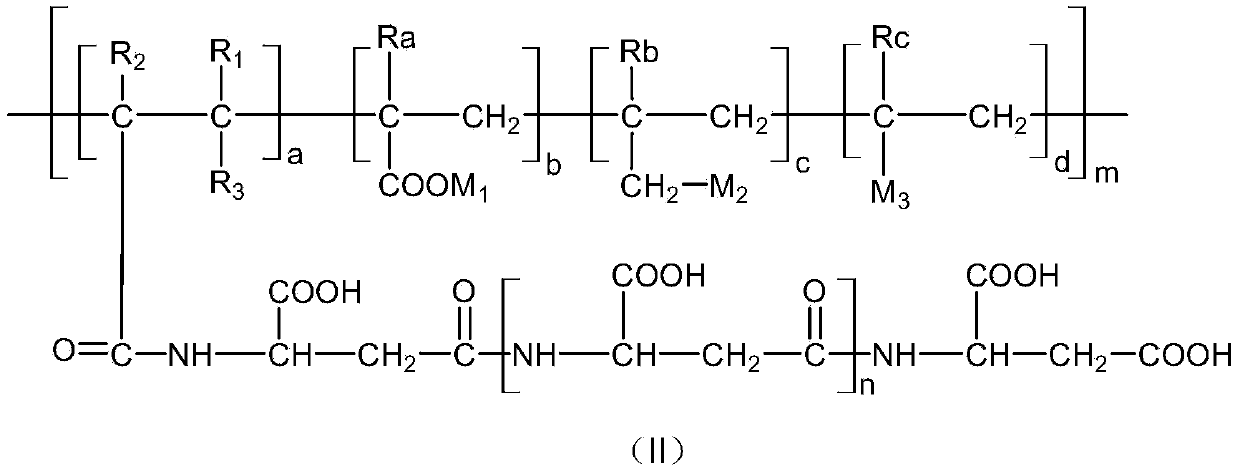

Retarding and plastic-retaining type polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in its preparation, and has the field of polycarboxylate water reducing agent with retarding plasticity and plasticity, which can solve problems such as difficulties in retarding plasticity and plasticity, and achieve improvement in retarding plasticity and plasticity. Effect and effect of water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] step 1

[0095] Mix 400g of polyaspartic acid (number-average molecular weight 4000) and 20g of methacrylic acid in water, stir and heat up to 45°C, and add 20g of DMAP solution (1wt%) and 5g of EDC solution (1wt%) dropwise at a constant speed using a constant-flow pump , the dropping time is 30-60 minutes, and the reaction is continued for 60-120 minutes after the dropping is completed. Carboxylic acid amidated monomers of polyaspartic acid were synthesized. In order to improve the reaction yield, a small amount of pyridine can be added as an acid-binding agent.

[0096] The prepared product was analyzed by high-performance liquid chromatography, and the monomer conversion rate was greater than 95%. When the reaction temperature was high, a suitable amount of hydroquinone and other polymerization inhibitors could be added to avoid self-polymerization of unsaturated carboxylic acid monomers.

[0097] step 2

[0098] Add 200g of the amidation product of polyasparti...

Embodiment 2

[0101] step 1

[0102] Add 300g of polyaspartic acid with a molecular weight of 3000 and 15g of acrylic acid into the reaction vessel, add an appropriate amount of distilled water, stir and raise the temperature to 45°C, and start to add 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene dropwise 20g of amine (EDC) solution and 5g of 4-dimethylaminopyridine (DMAP) solution, the solution concentration is 1wt%, the dropwise addition time is 30-60min, continue to react for 60min-120min after dropping, stop heating.

[0103] The polyaspartic acid amidation products were analyzed by infrared spectroscopy. Polyaspartic at 760cm -1 There is an absorption peak at the N-H bond in the secondary amine group, which is the characteristic peak of the out-of-plane bending vibration of the N-H bond, while in the polyaspartic acid amidation product, this peak basically disappears, which proves that the polyaspartic acid and the carboxyl group have amide Chemical reaction, and the reaction is ...

Embodiment 3

[0107] step 1

[0108] Add 400g of polyaspartic acid with a molecular weight of 4000 and 20g of methacrylic acid into the reaction vessel, add an appropriate amount of distilled water, stir and raise the temperature to 45°C, and start to add 1-(3-dimethylaminopropyl)-3-ethyl carbon Diimine (EDC) solution 20g and 4-dimethylaminopyridine (DMAP) solution 5g, the solution concentration is 1wt%, the dropwise addition time is 30-60min, continue to react for 60min-120min after the dropwise addition, stop heating.

[0109] step 2

[0110] Add 200g of the above-prepared amidation product of polyaspartic acid and allyl polyethylene glycol (APEG) with a molecular weight of 2400 into the reaction vessel, add 200g of distilled water, stir and heat up to 70-80°C. Add 55g of maleic anhydride, and start dropping 30g (10wt%) of the initiator sodium persulfate aqueous solution and 40g of the 5wt% solution of the chain transfer agent mercaptoacetic acid at the same time. The dropping time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com