Enhanced polycarboxylic acid system concrete reducing agent and preparation method therefor

A polycarboxylate-based concrete technology, applied in the field of concrete, can solve the problems of formaldehyde not being environmentally friendly, potential safety hazards, complex preparation process of melamine high-efficiency water reducer, etc., and achieve the effects of good adaptability, enhanced strength, and dense arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

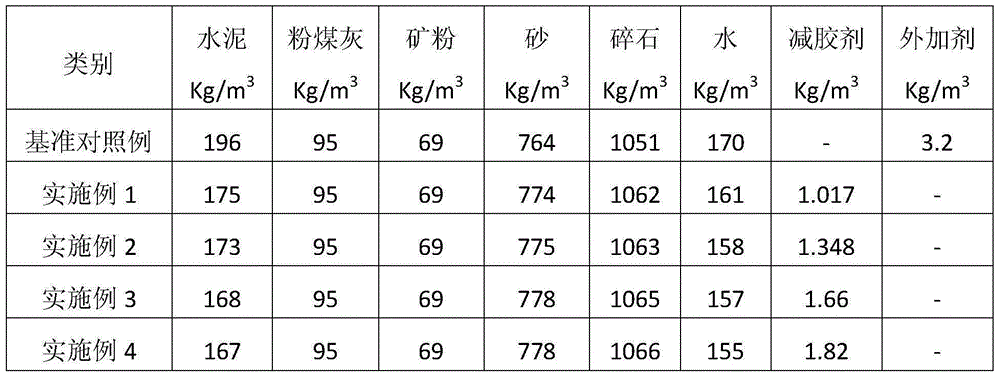

Embodiment 1

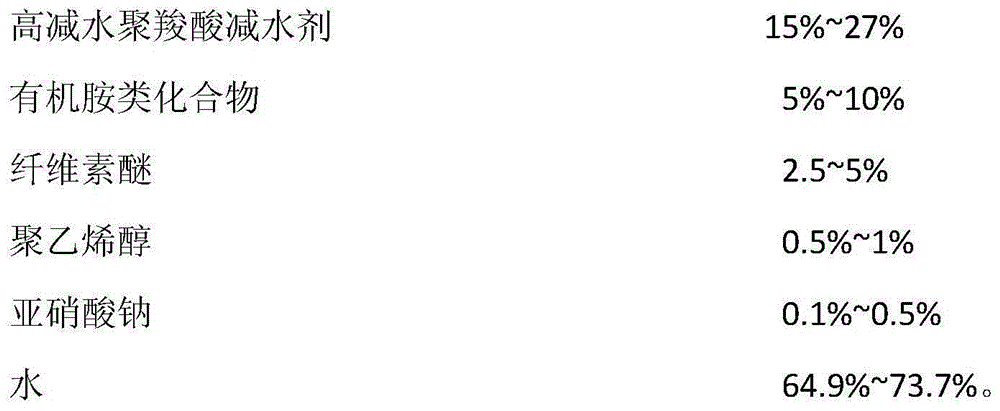

[0020] Step (1): the preparation of a kind of reinforced polycarboxylate concrete reducer:

[0021] 22% of methallyl polyoxyethylene ether (number-average molecular weight: 1400) polycarboxylate water reducer, 9% N-hydroxyethyl ethylenediamine, 2.5% methyl cellulose, polycarbonate with a molecular weight of 18000 1% vinyl alcohol, 0.2% sodium nitrite and 65.3% water were stirred at 20°C for 4 hours to obtain a reinforced concrete reducer.

[0022] Step (2): Add the above-mentioned reinforced concrete gel reducer with a solid content of 0.3% of the mass of the cementitious material into the concrete, and perform standard curing for 3d, 7d, and 28d.

Embodiment 2

[0024] Step (1): the preparation of a kind of reinforced polycarboxylate concrete reducer:

[0025] 17% of methallyl polyoxyethylene ether (number average molecular weight: 5000) polycarboxylate water reducer, 5% of N,N,N',N'-tetrahydroxyethylethylenediamine, carboxymethyl 3% cellulose, 0.8% polyvinyl alcohol with a molecular weight of 20000, 0.5% sodium nitrite and 73.7% water were stirred at 26°C for 3 hours to obtain a reinforced concrete reducer.

[0026] Step (2): Add the above-mentioned reinforced concrete reducer with a solid content of 0.4% of the mass of the cementitious material into the concrete, and perform standard curing for 3d, 7d, and 28d.

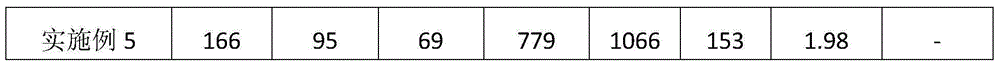

Embodiment 3

[0028] Step (1): the preparation of a kind of reinforced polycarboxylate concrete reducer:

[0029] The methallyl polyoxyethylene ether (number average molecular weight is 8000) polycarboxylate superplasticizer 15%, N-hydroxyethyl ethylenediamine 10%, hydroxyethyl cellulose 3%, molecular weight 25000 0.5% polyvinyl alcohol, 0.1% sodium nitrite and 71.4% water were stirred at 32°C for 2.5 hours to obtain a reinforced concrete reducer.

[0030] Step (2): Add the above-mentioned reinforced concrete reducer with a solid content of 0.5% of the mass of the cementitious material into the concrete, and perform standard curing for 3d, 7d, and 28d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com