High-efficiency polycarboxylic acid water-reducing composite agent and production device thereof

A production device and technology of polycarboxylate, applied in the field of concrete admixture, can solve the problems of unreliable effect, unsatisfactory polymerization effect, environmental protection and other problems of polycarboxylate water reducer, achieve good promotion value and market prospect, and reliable performance , the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

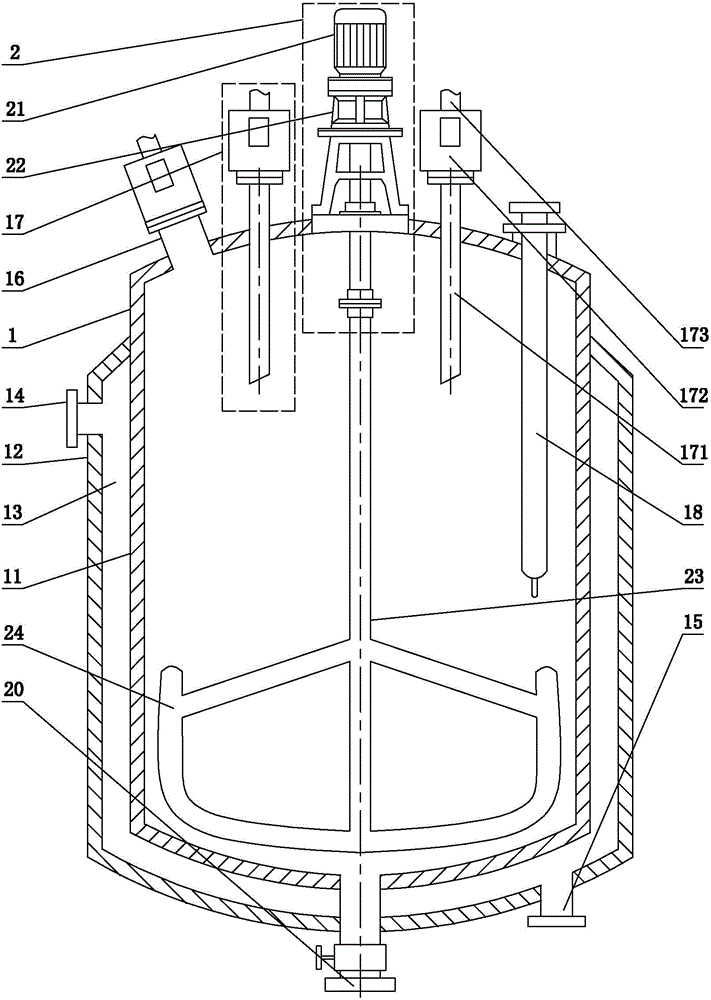

Image

Examples

Embodiment 1

[0023] Example 1: 28% of polycarboxylate water reducer, 3% of cellulose ether, 0.3% of sodium lauryl sulfate, 3% of methacrylic acid, 2% of nano silicon dioxide, 0.5% of sodium lignosulfonate, 0.3% of polyether JCYX7, 0.3% of sodium nitrite, 2% of triethanolamine, and the balance of water were sent to the compounding tank for compounding, and the high-efficiency polycarboxylate water-reducing compound was prepared after stirring evenly.

[0024] Polycarboxylate superplasticizer is to send maleic anhydride, allyl polyoxyethylene ether sulfate, and sodium methacrylate sulfonate into the synthetic enamel reaction kettle at a ratio of 1:3:2.5, and the reaction temperature is 88°C. Configure the initiator (ammonium persulfate and potassium persulfate to account for 4% of the monomer weight after mixing) into a 10% aqueous solution, add it dropwise to the kettle for 1 hour, and feed nitrogen into the kettle. React for 2 hours, raise the temperature to 5°C for aging, continue to reac...

Embodiment 2

[0025] Example 2: 31% polycarboxylate water reducer, 3.5% cellulose ether, 0.35% sodium lauryl sulfate, 3.5% propylene-benzene nano core-shell emulsion, 3% nano silicon dioxide, lignin sulfonic acid 0.6% of sodium, 0.35% of polyether JCYX7, 0.35% of sodium nitrite, 2.5% of triethanolamine, and the balance of water were respectively sent into the compounding tank for compounding, and the high-efficiency polycarboxylate water-reducing compound agent was obtained after stirring evenly.

[0026] Polycarboxylate superplasticizer is to send maleic anhydride, allyl polyoxyethylene ether sulfate, and sodium methacrylate sulfonate into the synthetic enamel reaction kettle at a ratio of 1:3:2.5, and the reaction temperature is 93°C. Configure the initiator (ammonium persulfate and potassium persulfate to account for 4% of the monomer weight after mixing) into a 12.5% aqueous solution, add it dropwise to the kettle for 1 hour, and feed nitrogen into the kettle. React for 2 hours, raise...

Embodiment 3

[0027] Example 3: 34% of polycarboxylate water reducer, 4% of cellulose ether, 0.4% of sodium lauryl sulfate, 4% of propylene-benzene nano-core-shell emulsion, 3.5% of nano-silicon dioxide, and lignosulfonic acid 0.65% sodium, 0.4% polyether JCYX7, 0.4% sodium nitrite, 3% triethanolamine, and the balance water were sent to the compounding tank for compounding, and the high-efficiency polycarboxylate water-reducing compound agent was prepared after stirring evenly.

[0028] Polycarboxylate superplasticizer is to send maleic anhydride, allyl polyoxyethylene ether sulfate, and sodium methacrylate sulfonate into the synthetic enamel reaction kettle at a ratio of 1:3:2.5, and the reaction temperature is 98°C. Configure the initiator (ammonium persulfate and potassium persulfate to account for 4% of the weight of the monomer after mixing) into a 15% aqueous solution, add it dropwise to the kettle for 2 hours, and feed nitrogen into the kettle. After the addition of materials, React ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com