Silyl ether-terminated polyether, preparation method thereof and high-efficiency mud-resistant water reducing agent

A technology of polyether and silicon ether, which is applied in the field of high-efficiency mud-resistant superplasticizers, can solve problems such as poor slump retention and reduced water-reducing rate of superplasticizers, and achieve improved slump retention performance, improved mud resistance, and reduced penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation method of the polyether end-capping of silicon ether, comprises the following steps:

[0042] 1) Methallyl polyoxyethylene ether (HPEG) is measured by the national standard hydroxyl value measurement method to measure the molar amount of hydroxyl groups per 100 grams of the sample. Oxyethylene ether (HPEG) was added to acetonitrile with 5 times the mass of HPEG, and dissolved;

[0043] 2) Add imidazole which is 1.3 times the amount of hydroxyl substances contained in methallyl polyoxyethylene ether and stir for 30 minutes until fully dissolved;

[0044] 3) At 2°C, add tert-butyldiphenylsilyl trifluoromethanesulfonate with 1.2 times the amount of the hydroxyl substance in 3 separate additions, the same amount is added for three times, with an interval of 10 minutes between each addition. After the addition is completed, react at room temperature for 20 hours. That is, the polyether terminated with silicon ether was spin-dried for later use.

Embodiment 2

[0046] A high-efficiency mud-resistant water reducer, prepared by using the silicon ether-terminated polyether prepared in the above embodiment 1, specifically:

[0047] 1) Under the condition of 25°C, take 0.08 mol of uncapped HPEG and 0.02 mol of silyl ether-capped HPEG prepared in Example 1, dissolve them in water 1.2 times the total mass of uncapped HPEG and silyl ether-capped HPEG, and stir to make After the bottom solution is dissolved and clarified, add 2.0% of the total mass of hydrogen peroxide of unblocked HPEG and silicon ether-capped HPEG and ferrous sulfate of 0.01% of the total mass of uncapped HPEG and silicon ether-capped HPEG. After dissolving completely, the above solution as a primer;

[0048] 2) Preparation of material A and material B: Material A is 0.35 moL of acrylic acid dissolved in water that is 4 times the mass of acrylic acid, and material B is mercaptopropionic acid and 0.8% of the total mass of unblocked HPEG and silicon ether-capped HPEG. 0.4% o...

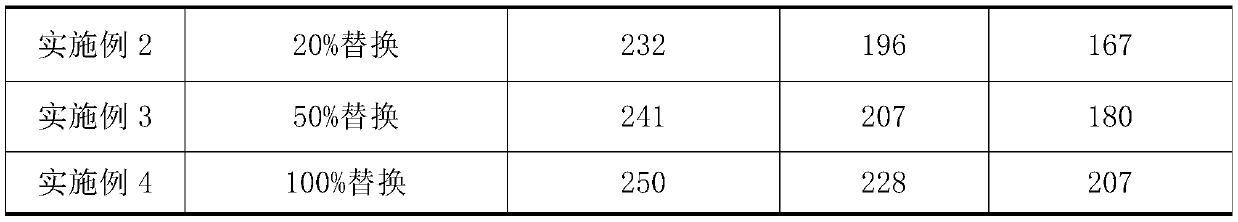

Embodiment 3

[0051] A high-efficiency mud-resistant water reducer, prepared by using the above-mentioned silicone ether-terminated polyether, specifically:

[0052] Change 0.08moL unblocked EPEG and 0.02moL silyl ether-capped EPEG prepared in Example 1 into 0.05moL uncapped EPEG and 0.05moL silyl ether-capped EPEG prepared in Example 1; others are the same as in the examples 2. A 50% replacement synthetic water reducer mother liquor was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com