Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "High breaking voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

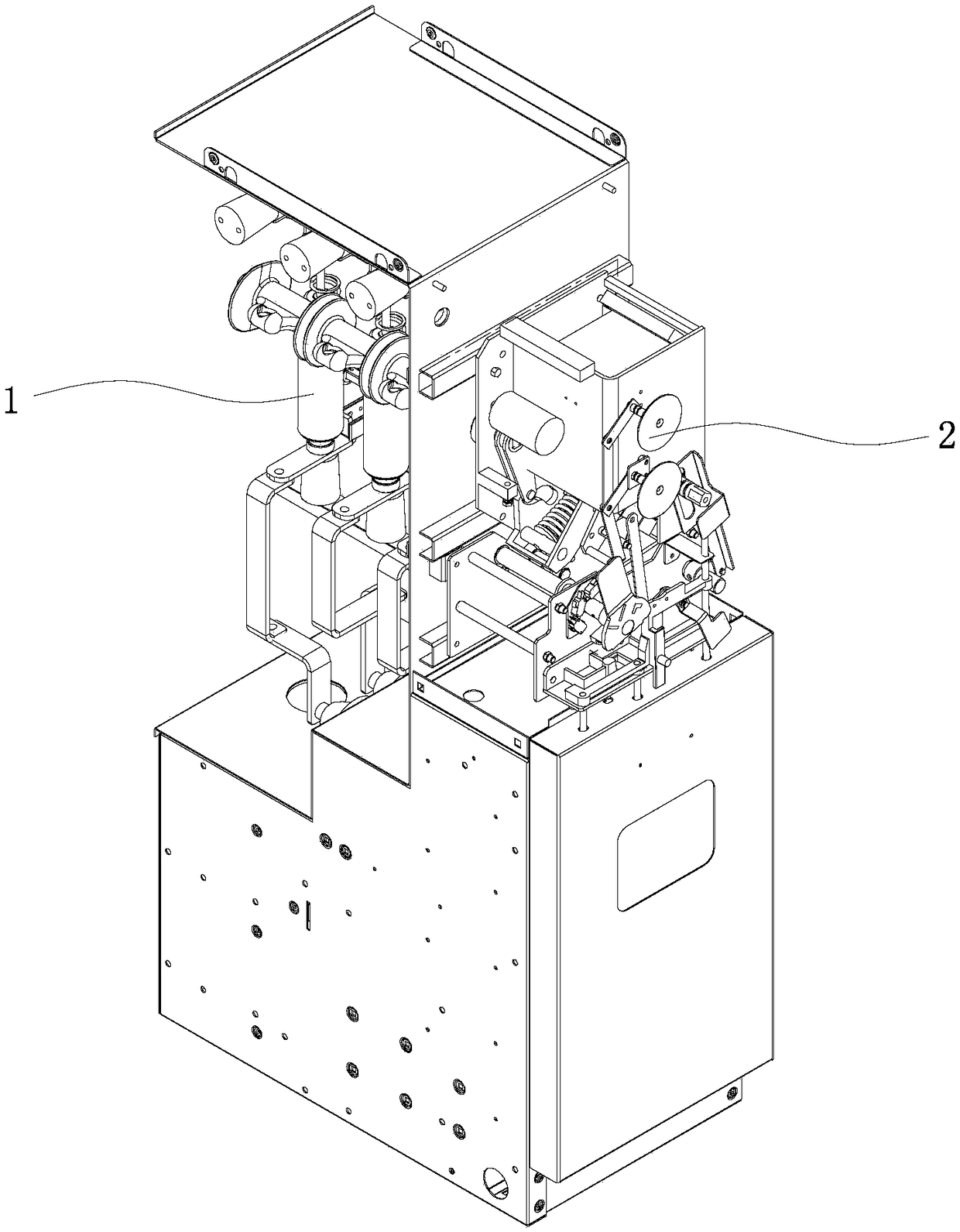

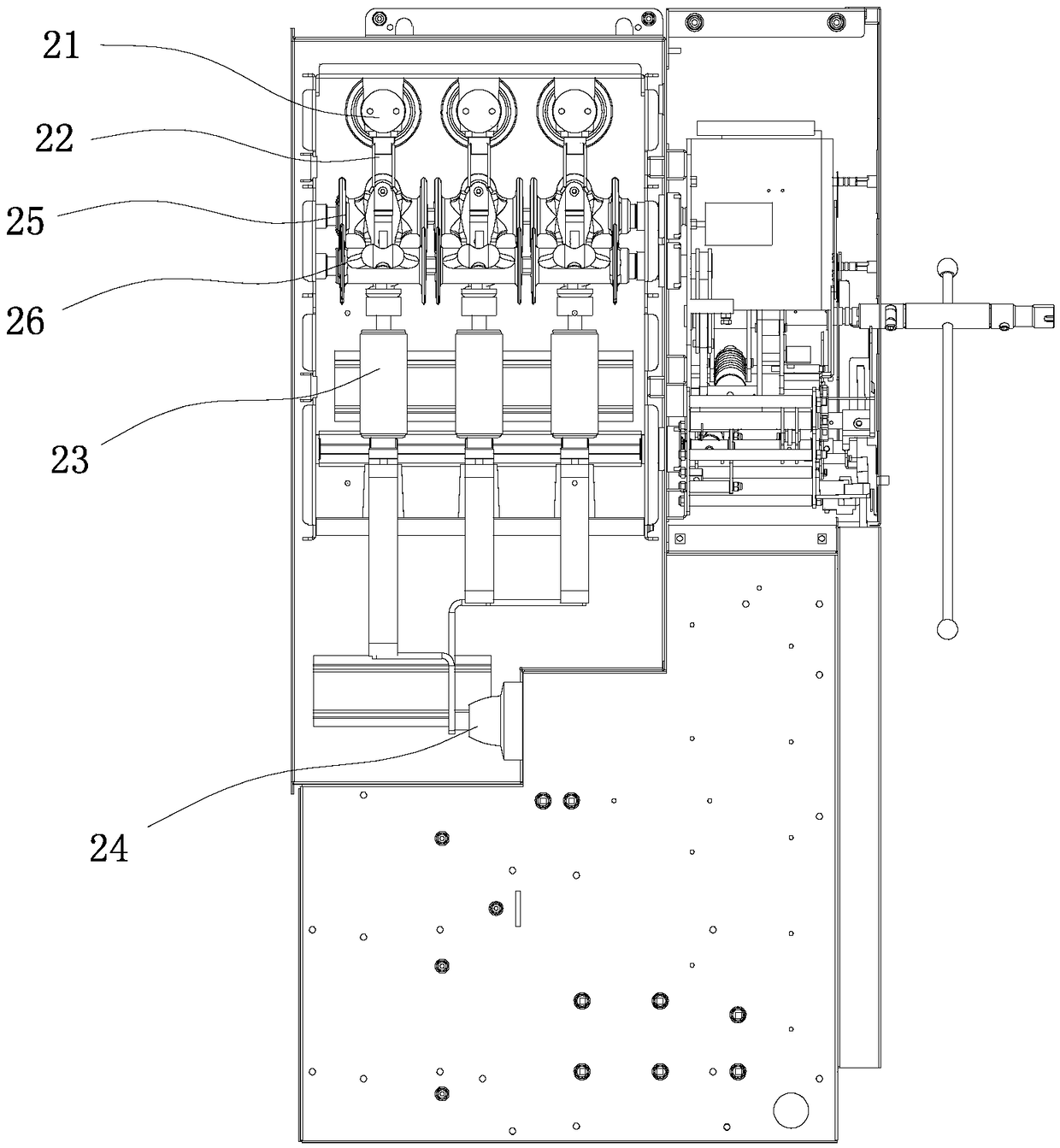

High voltage direct current breaker with multiple fractures and tandem type

InactiveCN102360991AImprove pressure equalizationHigh breaking voltageProtective switch detailsDc network circuit arrangementsOvervoltageUltra high voltage

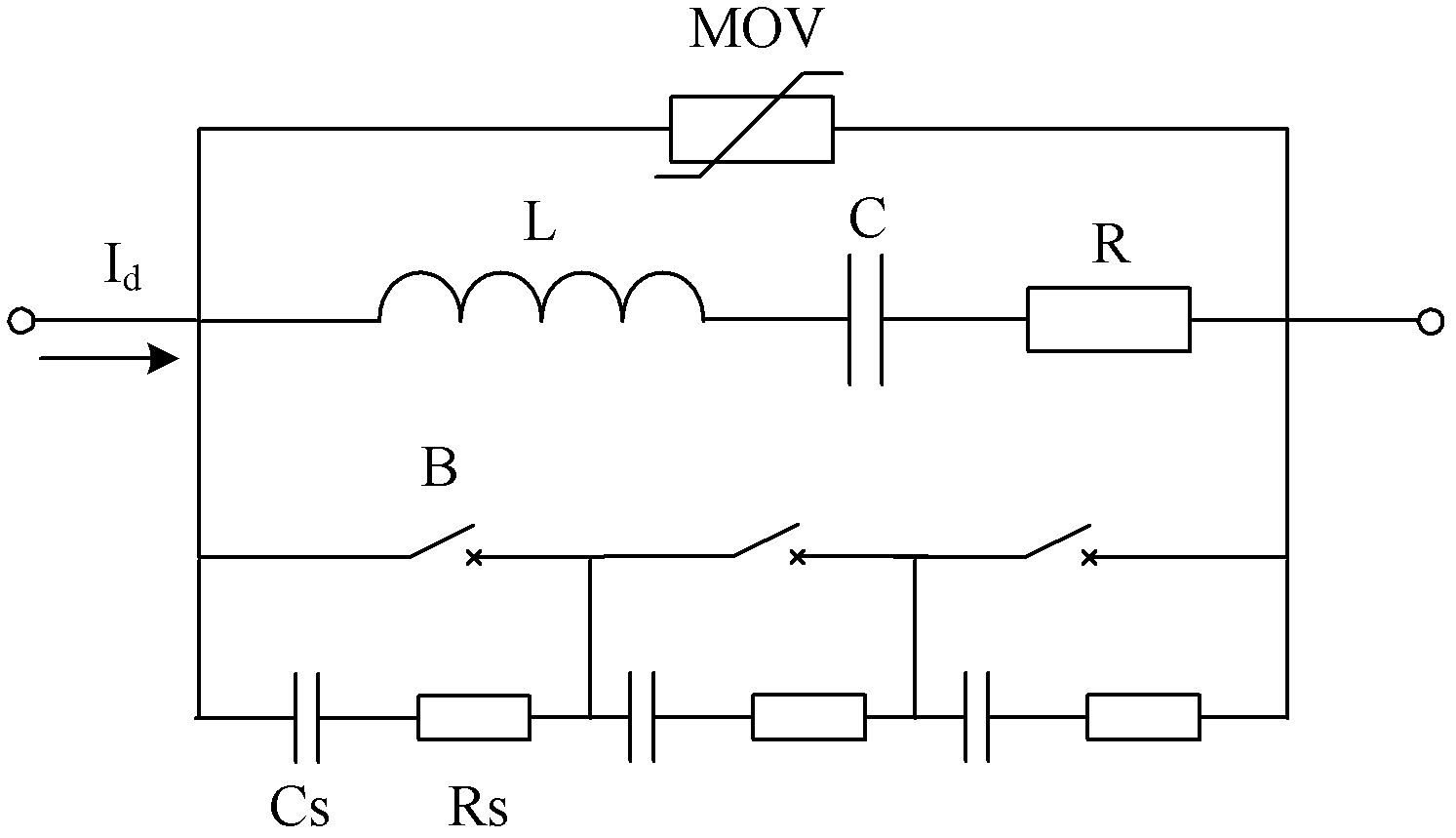

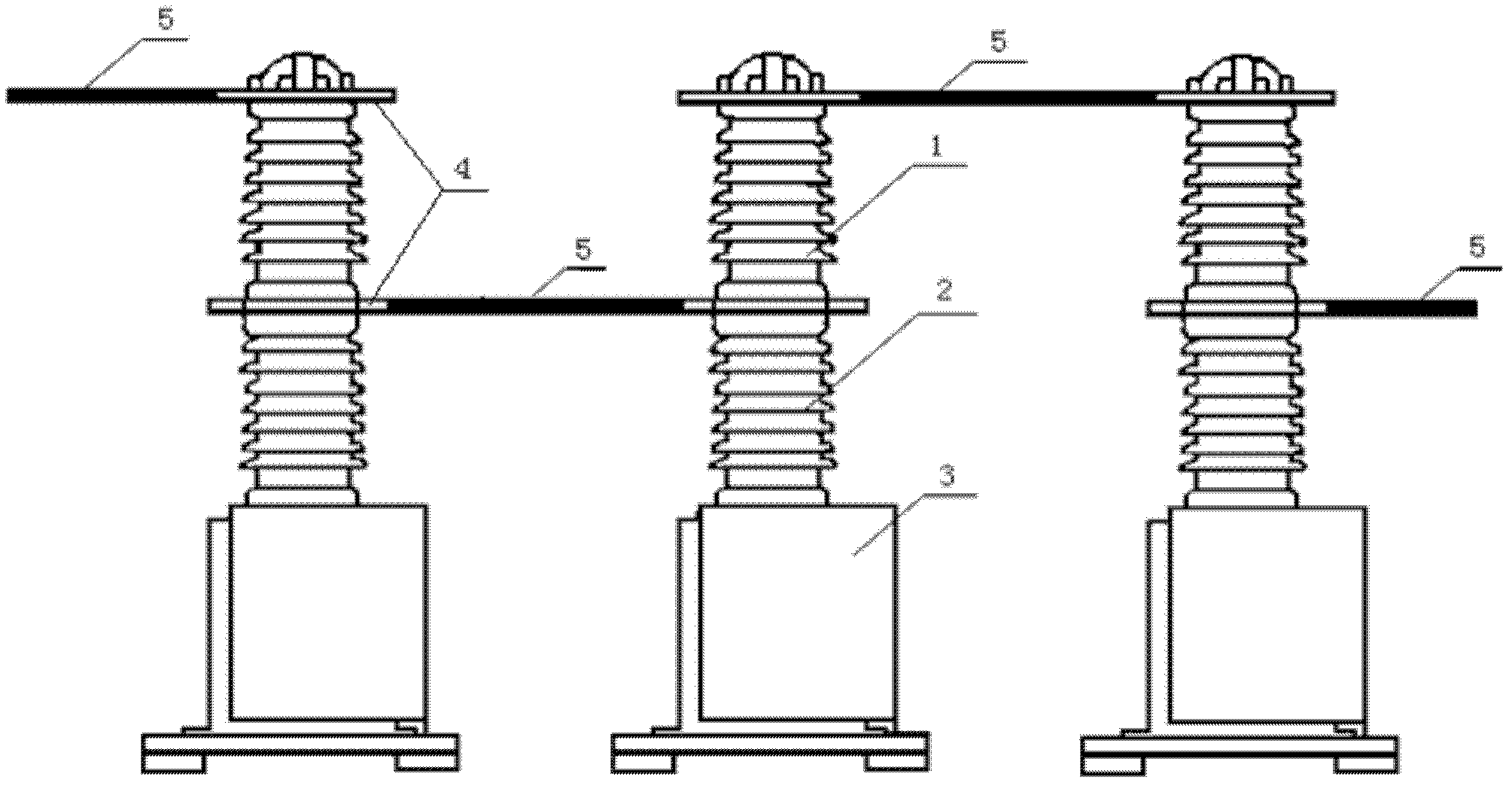

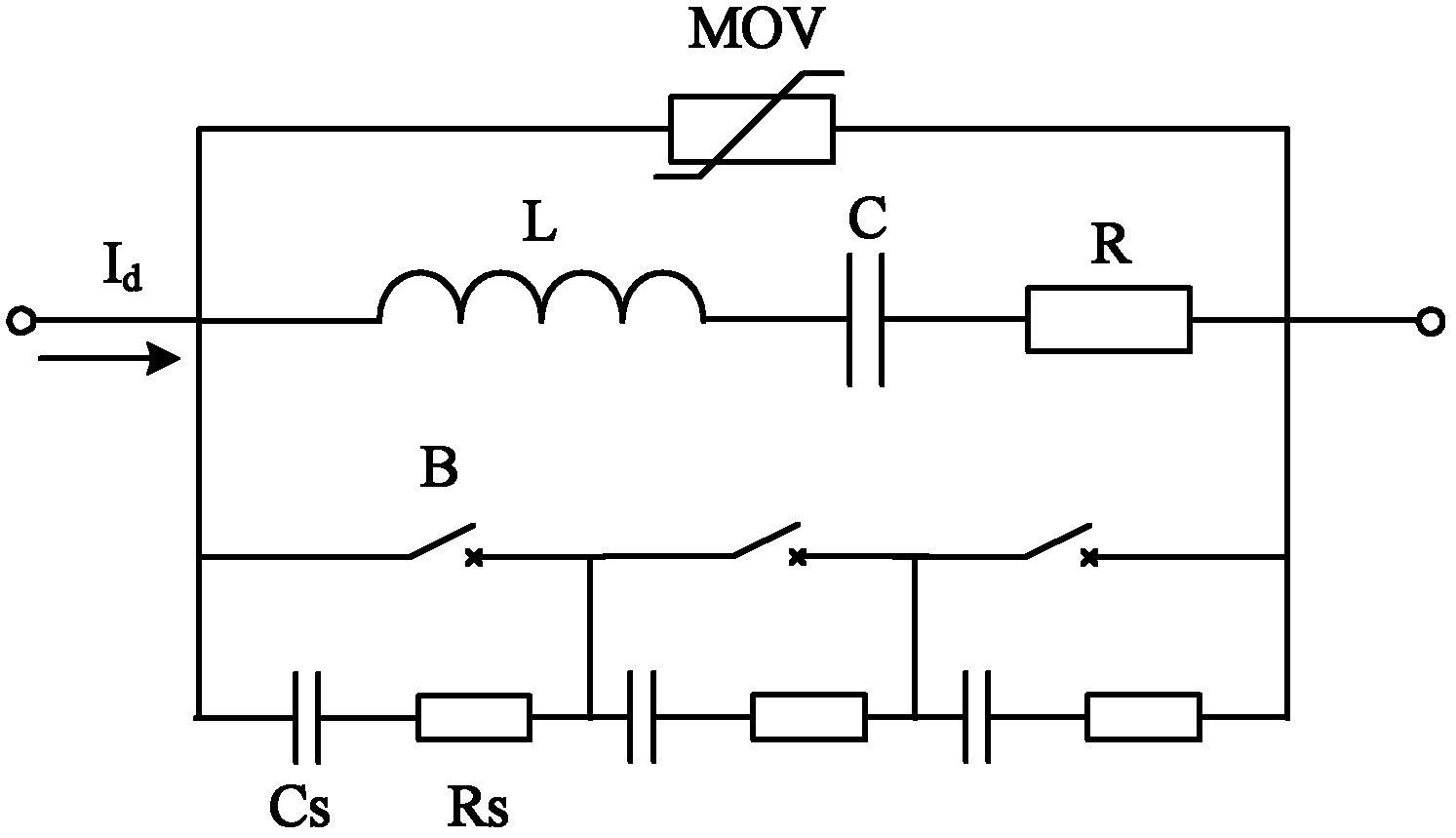

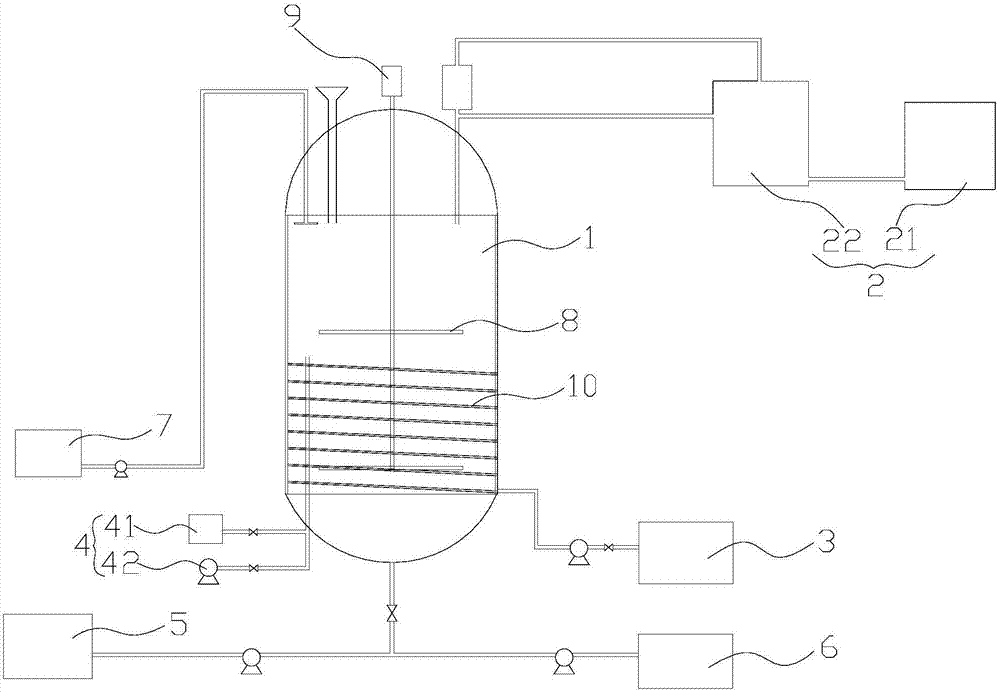

The invention relates to a high voltage direct current breaker with multiple fractures and a tandem type. The breaker comprises a multi-fracture breaker, an oscillation loop and a dissipative element. The multi-fracture breaker includes a plurality of single-phase breakers and fractures of all the single-phase breaker are in series connection through connection buses; the multi-fracture breaker is respectively in parallel connection with the oscillation loop and the dissipative element through the connection buses; and a fracture of each the single-phase breaker is respectively in parallel connection with an RC equalizer circuit. According to the invention, fractures of a plurality of single-phase breakers are in series connection so as to form a multi-fracture tandem structure; effects of high drop-out voltage, heavy drop-put current and short drop-out time and the like are realized; and demands of ultra-high voltage and extra-high voltage direct current power transmission projects can be completely met. In addition, the oscillation loop in the invention is used for generating oscillation currents; the dissipative element is used for absorbing line energy and restricting overvoltages after currents are switched off; and the RC damping circuit is used for improving equalizing voltages between fractures of all the single-phase breakers.

Owner:CHINA ELECTRIC POWER RES INST +1

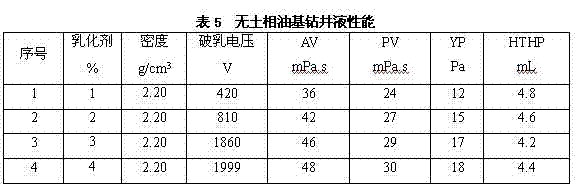

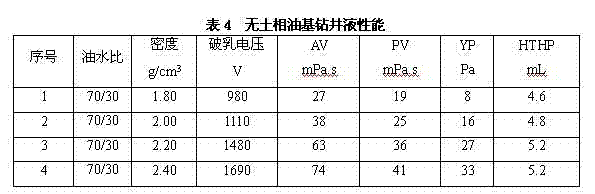

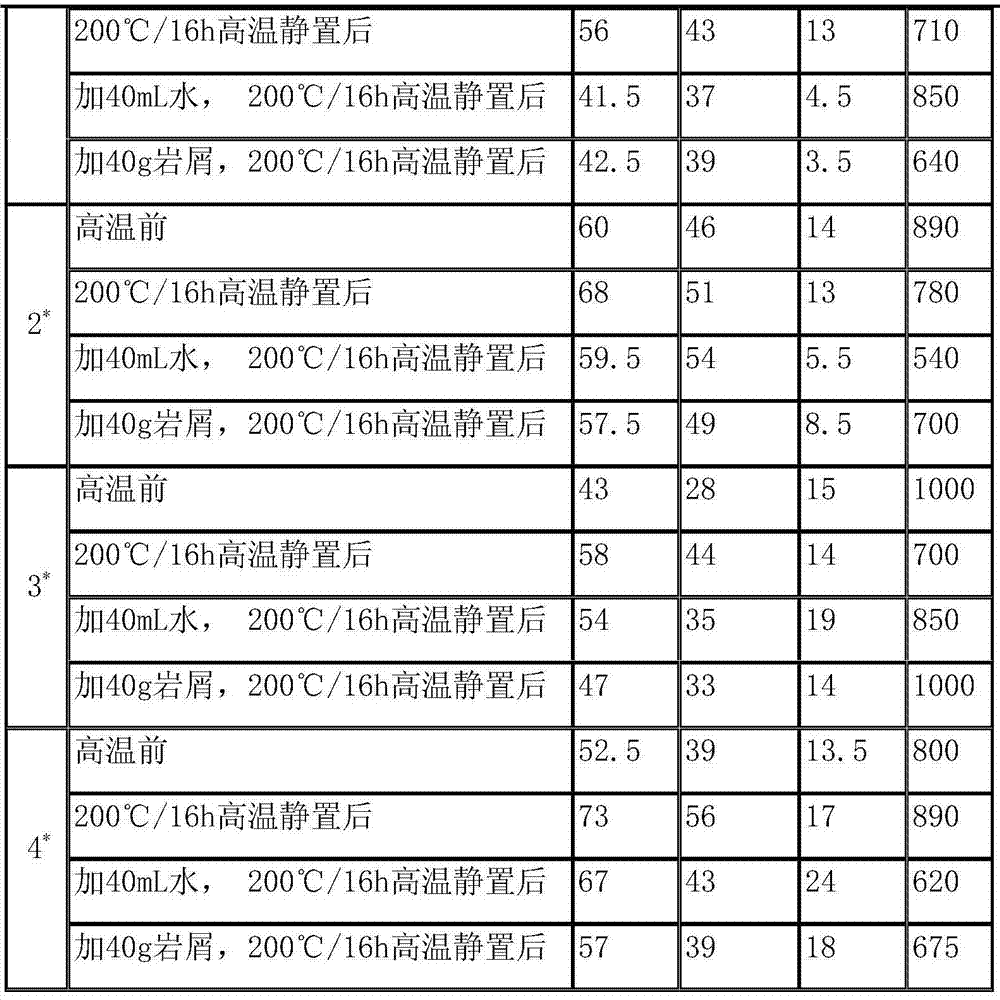

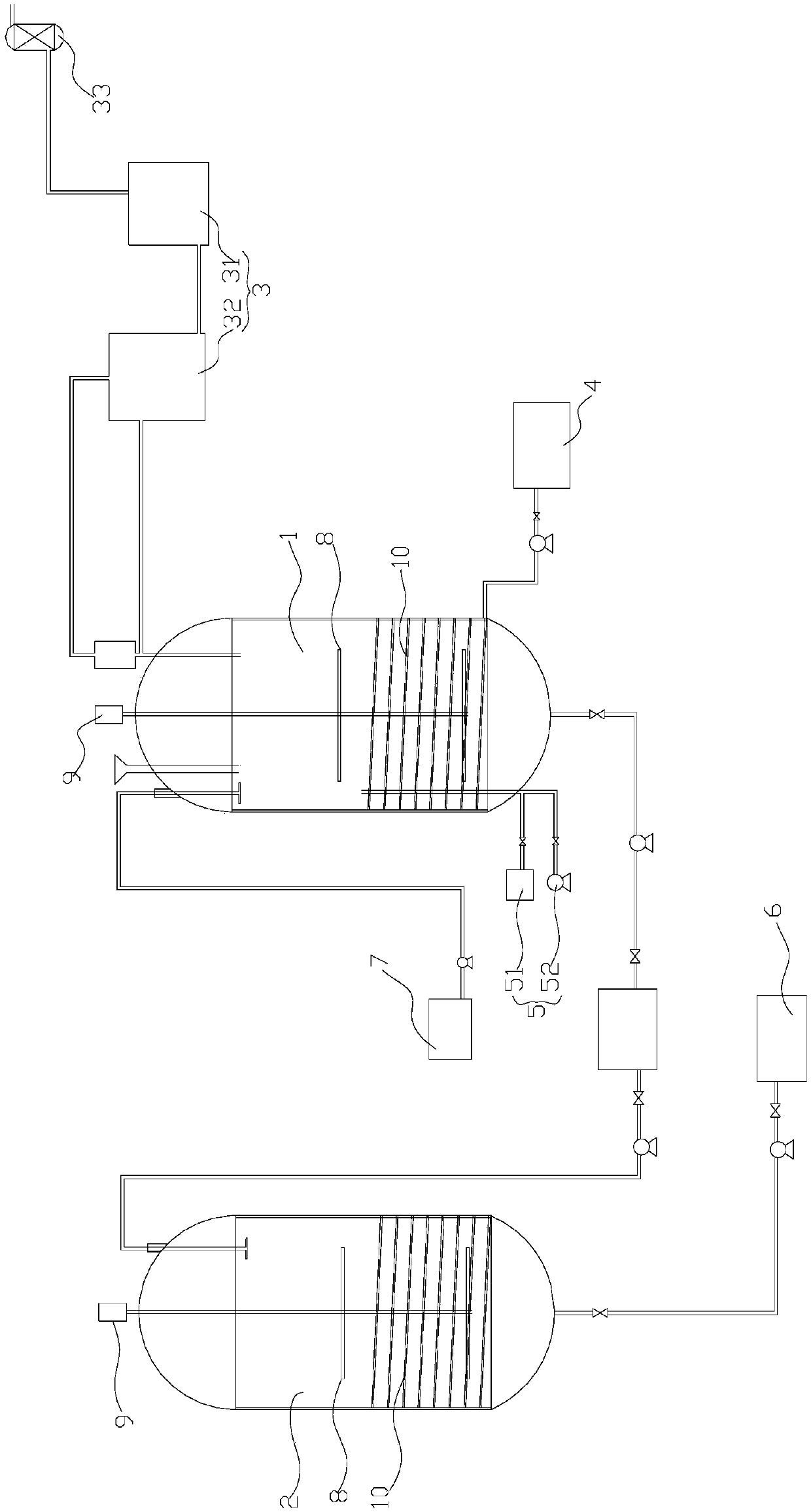

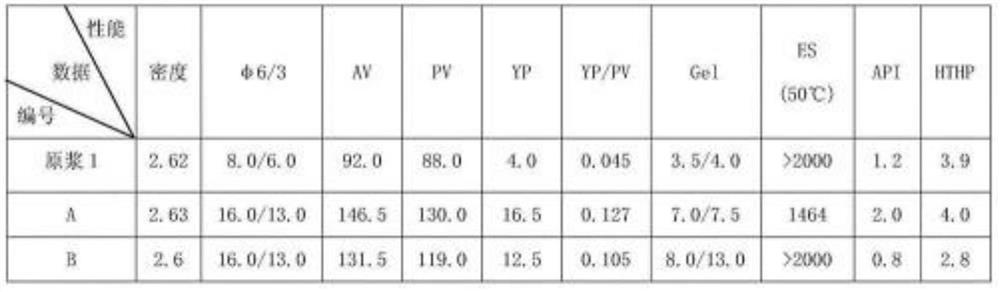

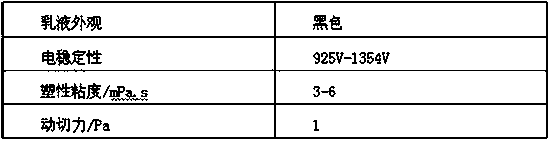

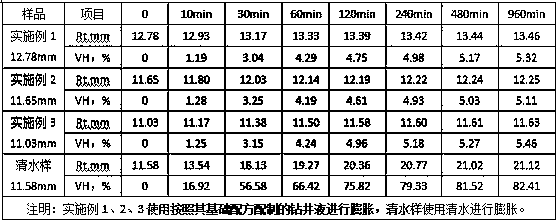

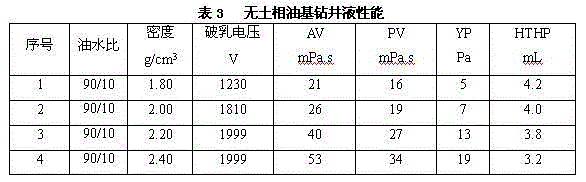

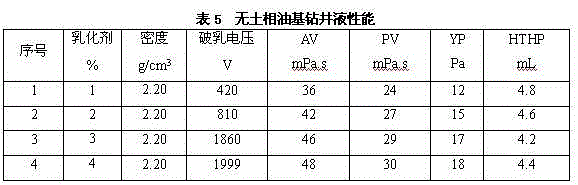

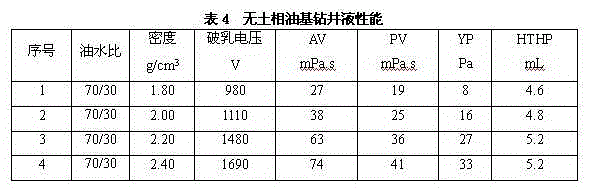

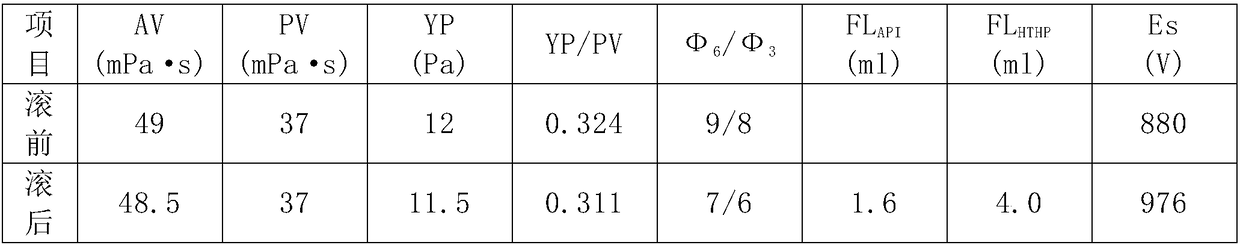

Soil-phase-free oil-based drilling fluid

ActiveCN103788934AStrong electrical stabilityHigh breaking voltageDrilling compositionSoil scienceHigh density

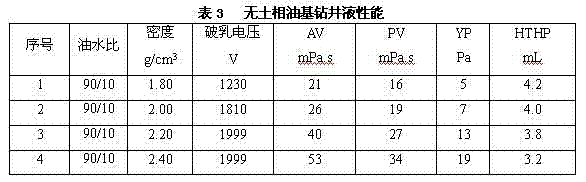

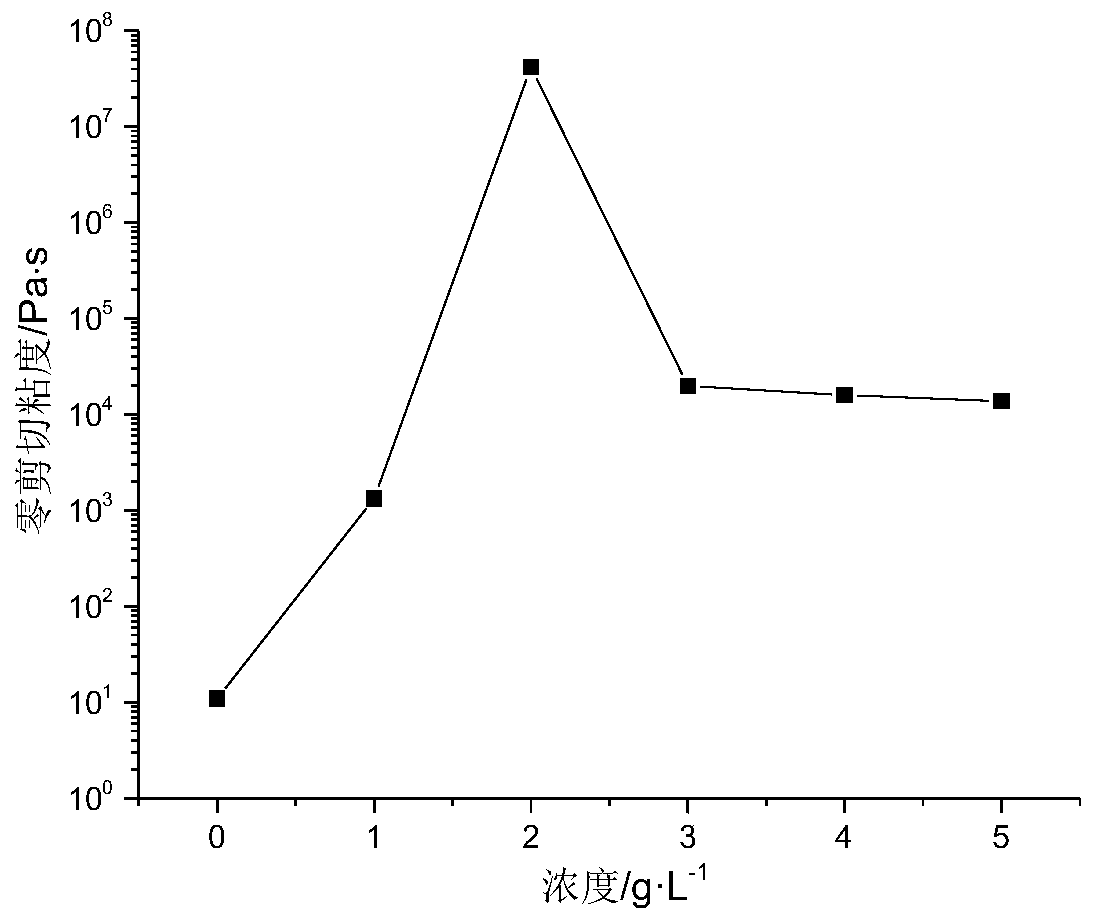

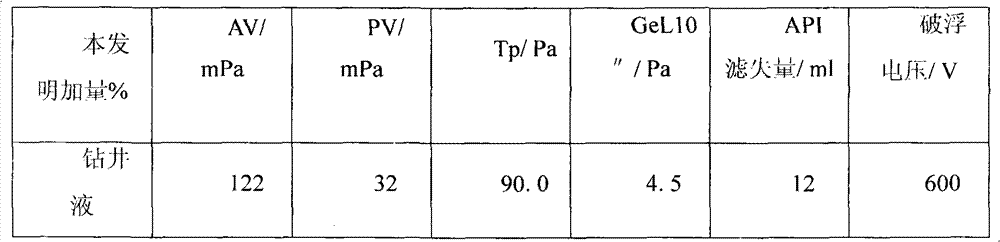

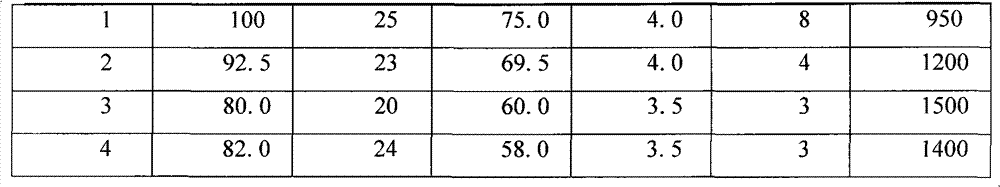

The invention relates to a soil-phase-free oil-based drilling fluid. The soil-phase-free oil-based drilling fluid is prepared from the following raw materials in percentage by weight: 50-85 percent of base oil, 5-30 percent of CaCl2 saline, 1-4 percent of composite type emulsifier G326-HEM, 1-5 percent of filtrate reducer G328, 0.5-3 percent of alkalinity conditioning agent, 0.5-3 percent of tackifier, 0.2-2 percent of viscosifier and the balance of barite. According to the soil-phase-free oil-based drilling fluid, the demulsification voltage is higher than 800V, and the temperature resistance of higher than 180 DEG C is achieved; the formula is simple, the field operation and maintenance are convenient, and the soil-phase-free oil-based drilling fluid has good rheological property in the absence of a wetting agent under the condition of high density; the system is widely applicable to the base oil and can be used in mineral oil or gaseous oil; and a novel method is provided for lowering the well leakage loss of the oil-based drilling fluid, the cost of the drilling fluid is also remarkably lowered, good economic and social benefits are obtained, and thus the soil-phase-free oil-based drilling fluid is worthy of popularization and application.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Nb-a1 alloy powder for electrolytic capacitors, method for manufacturing nb-a1 alloy powder, and electrolytic capacitor

InactiveUS20060114644A1High dielectric constantReduce leakage currentElectrolytic capacitorsAlloyElectrolytic capacitor

The present invention provides an Nb—Al alloy powder for electrolytic capacitors. The powder is useful in manufacturing a component of an electrolytic capacitor which has a high capacitance and dielectric constant and which includes stable dielectric layers. The powder includes particles, which are covered with dielectric layers when the powder is processed into an anode of an electrolytic capacitor. The particles have dendritic microstructures principally containing NbAl3, Nb2Al, Nb3Al, or Nb and matrices containing Al or eutectic structures containing at least two selected from the group consisting of NbAl3, Nb2Al, Nb3Al, and Nb. The eutectic structures or the matrices surround the dendritic microstructures.

Owner:CBMM ASIA

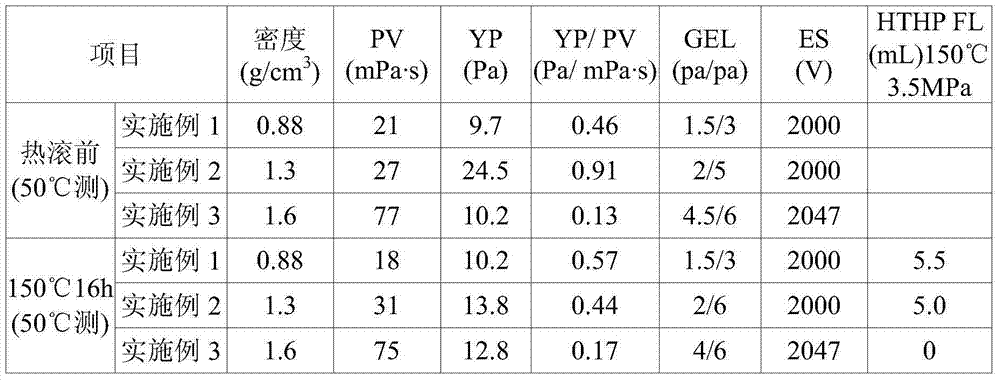

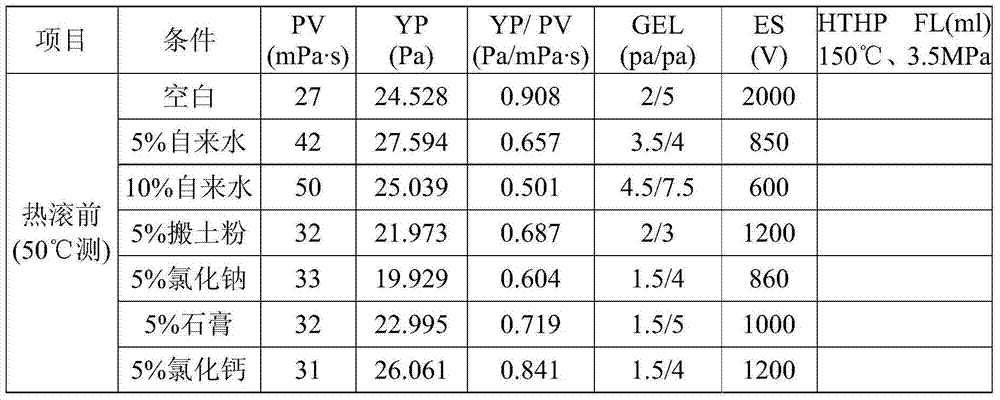

Plant oil-based drilling fluid and preparation method thereof

The invention provides a plant oil-based drilling fluid and a preparation method thereof. The plant oil-based drilling fluid comprises plant oil, a saline solution and a treating agent, wherein the volume ratio of the plant oil to the saline solution is (80:20) to (95:5); the treating agent comprises an emulsifier, a wetting agent, organic soil and a filtrate reducer. Based on 100mL of plant oil and saline solution, the content of the emulsifier is 2.5-3.5g, content of the wetting agent is 0.5-0.8g, the content of the organic soil is 0.5-2g and content of the filtrate reducer is 3-5g; the density of the drilling fluid is 0.88-1.6g / cm<3>. As the selected base oil is plant oil in the natural biologic chain, the plant oil-based drilling fluid provided by the invention can be biodegraded and further has the advantages of good emulsion stability, low high-temperature and high-pressure filter loss and good water-resisting, soil-resisting, salt calcium-resisting and gypsum pollution-resisting capacities.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Wetting reversal surfactant for drilling fluid

The invention discloses a wetting reversal surfactant for drilling fluid. The wetting reversal surfactant is characterized by comprising the following components in percentage by weight: 10 percent of dodecyltrimethylammonium bromide, 15 percent of heavy oil, 20 percent of fatty acid and 55 percent of water. The surfactant does not have influence on the performance of the drilling fluid and has positive charges so as to be mutually absorbed to a hydrophilic rock layer around an oil well with negative charges; the surfactant is adhered to a rock core through a cationic surfactant; the wetting reversal surfactant is covered by a hydrophobic lipophilic group layer; and thus the hydrophilic rock layer is reversed into a lipophilic hydrophobic rock layer to fulfill the aim of replenishing oil and stopping water.

Owner:SICHUAN ZHENGRONG IND +1

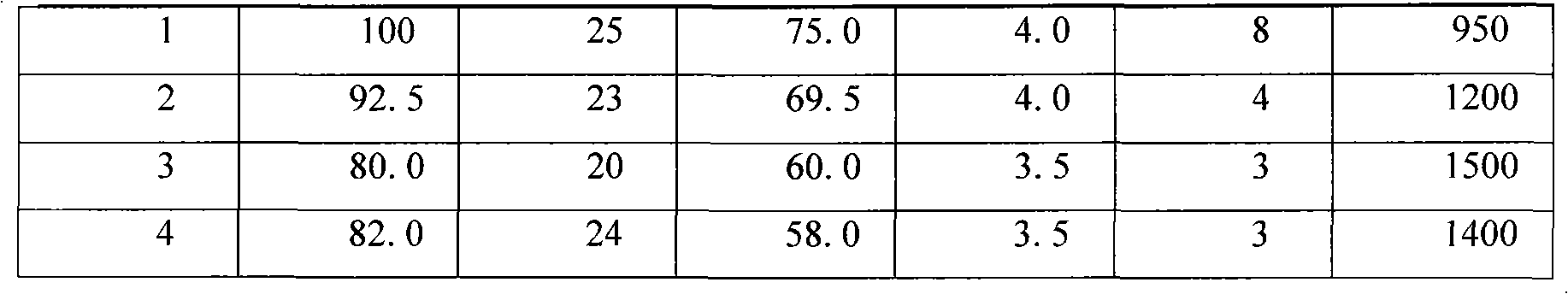

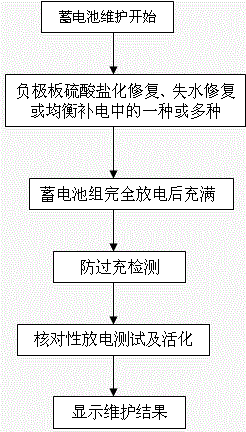

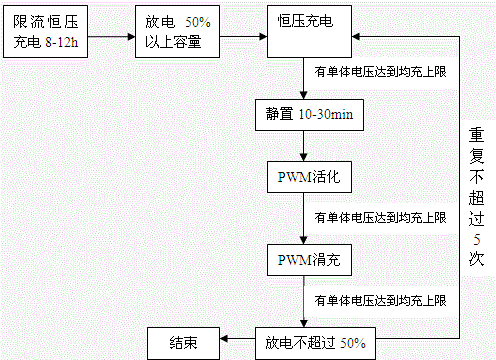

Apparatus and method for online maintenance of valve regulated sealed lead acid storage battery

InactiveCN105428732AHigh breaking voltagePrevent dehydrationSecondary cells charging/dischargingTrickle chargingPulse charge

The present invention discloses an apparatus and a method for online maintenance of a valve regulated sealed lead acid storage battery. According to the present invention, the backward battery in the storage battery pack is repaired by using a semi-offline technology, cyclic charging, pulse charging, low current trickle charging and other ways; and with the method of the present invention, the storage battery can not depart from the online backup status, the backward storage battery is subjected to maintenance by using the charging device of the user and the loading, and the occurrence of the phenomenon that the severe overcharge is generated during the storage battery pack so as to cause the storage battery dehydration can be avoided by using the semi-offline mode so as to prolong the service life of the storage battery.

Owner:NANNING GUORUI ELECTRONICS TECH CO LTD

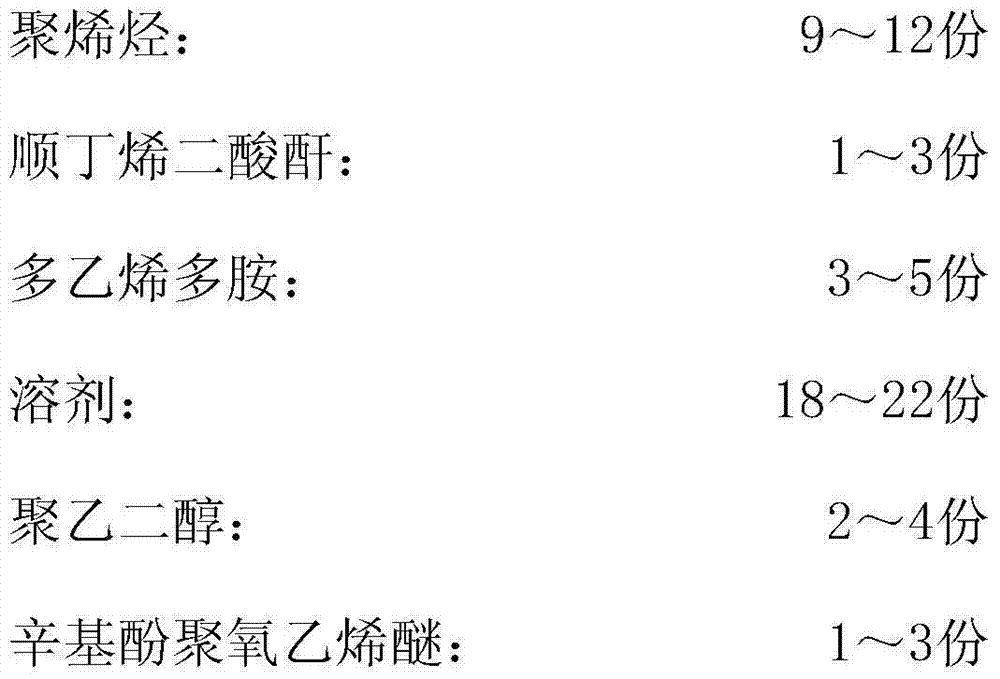

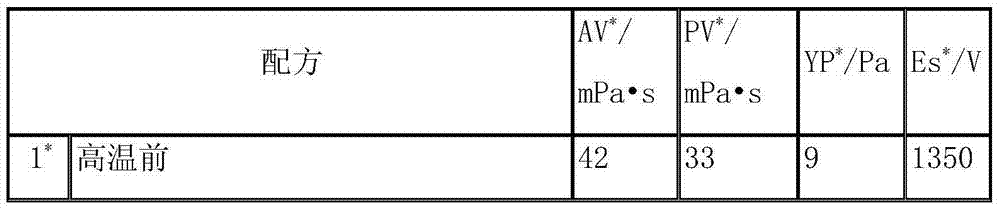

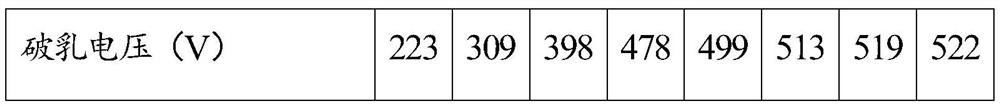

High-temperature-resistant oil-base drilling fluid emulsifier and preparation method thereof

ActiveCN104263328AHigh breaking voltageGuaranteed emulsification stabilityDrilling compositionWater in oilPolyethylene polyamine

The invention discloses a high-temperature-resistant oil-base drilling fluid emulsifier which is prepared by reacting the following components in parts by weight: 9-12 parts of polyolefin, 1-3 parts of maleic anhydride, 18-22 parts of xylene, 3-5 parts of polyethylene polyamine, 2-4 parts of polyethyleneglycol and 1-3 parts of octyl phenol polyethenoxy ether. The invention also discloses a preparation method of the emulsifier. The emulsifier has better emulsifying effect on the water-in-oil drilling fluid system which uses diesel and white oil as continuous phases, has superhigh high-temperature resistance, can keep high emulsion-breaking voltage of the oil-base drilling fluid at the high temperature of 200 DEG C or so, and can enduringly ensure the emulsifying stability, rheological property and pollution resistance of the oil-base drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-temperature emulsifier applied to oil-based drilling fluids and preparation method of high-temperature emulsifier

PendingCN107828391AReduce the number of additionsReduce the amount addedDrilling compositionPetroleum oilMineral oil

The invention discloses a high-temperature emulsifier applied to oil-based drilling fluids and a preparation method of the high-temperature emulsifier, and belongs to the technical field of petroleumdrilling fluids. The high-temperature emulsifier comprises, by mass, 10-45% of fatty acid amide, 30-60% of oxidized fatty acid, 10-30% of Malay acidized tall oil fatty acid, 5-20% of rheological property regulators and 10-30% of mineral oil. The total percentage of the raw materials is 100%. The preparation method includes mixing the fatty acid amide with the oxidized fatty acid, the Malay acidized tall oil fatty acid, the rheological property regulators and the mineral oil, stirring the raw materials at the temperature of 60 DEG C for 1-2 hours of reaction, and discharging the mixture to obtain the high-temperature emulsifier. The high-temperature emulsifier has the advantages of high temperature resistance, high demulsification voltage, low filter loss, capability of stabilizing a drilling fluid system, low adding amount, convenience and effectiveness in use, convenience in popularization and application, and the like. The preparation method has the advantages of simple procedure andstep, convenience in production and greatly reduced production cost.

Owner:联技精细材料(珠海)有限公司

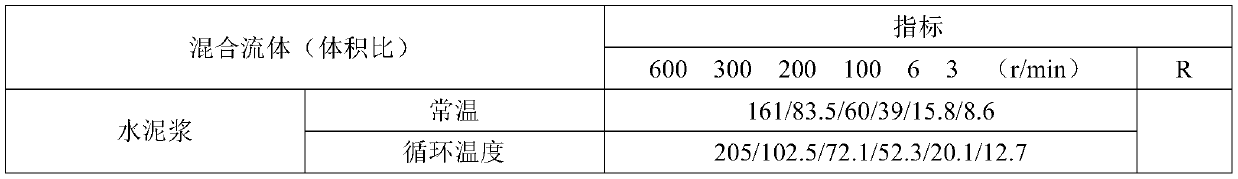

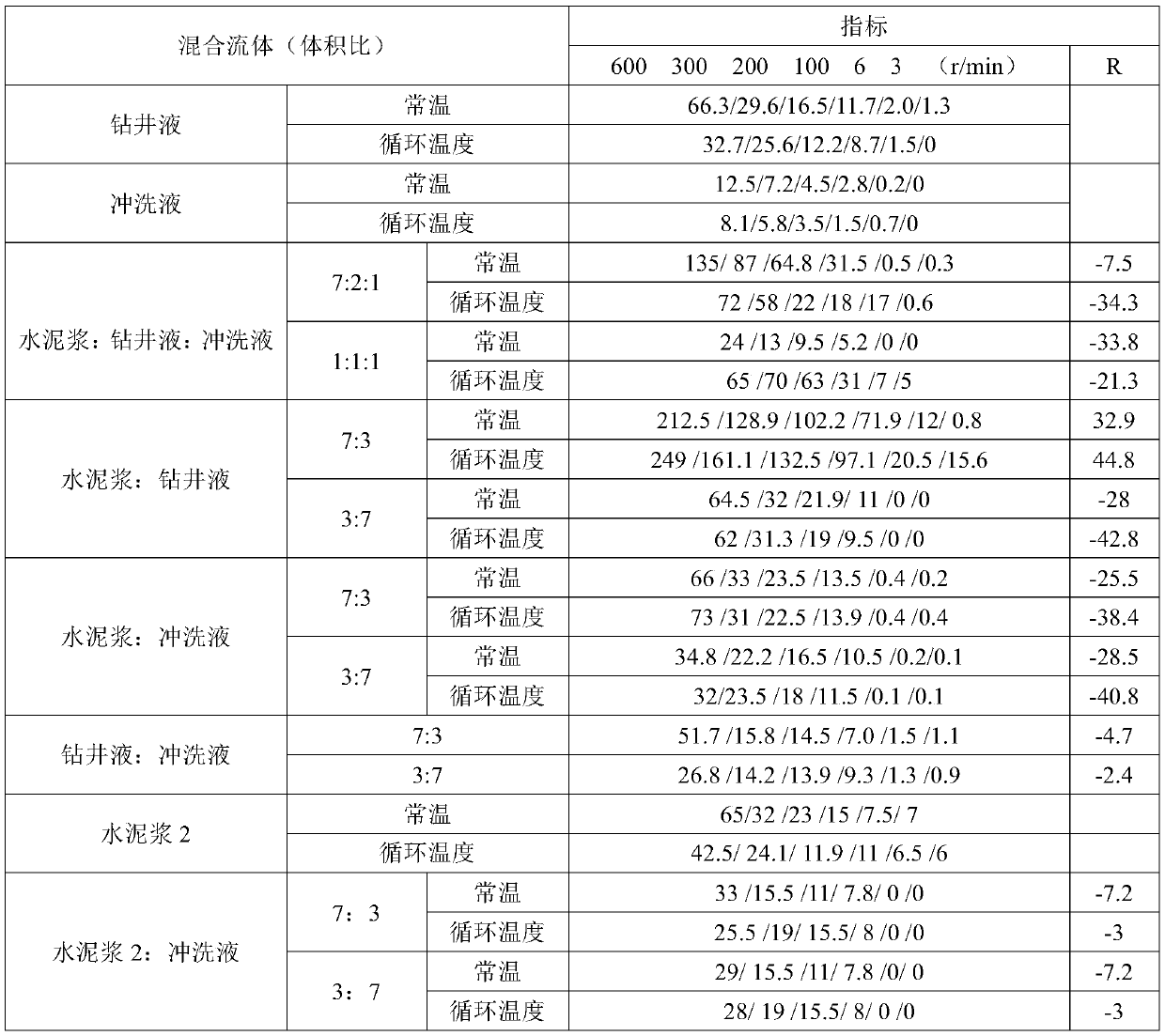

Well cementation flushing fluid for oil-based drilling fluid and preparation method and use method of well cementation flushing fluid

InactiveCN110846013AImprove securitySimple recipeFlushingDrilling compositionActive agentDioxyethylene Ether

The invention discloses a well cementation flushing fluid for oil-based drilling fluid as well as a preparation method and a use method of the well cementation flushing fluid. The well cementation flushing fluid comprises fresh water, a nonionic surfactant I, a nonionic surfactant II, a normal salt cosolvent and an acidic salt cosolvent, wherein the nonionic surfactant I is a fatty alcohol-polyoxyethylene ether nonionic surfactant, and the nonionic surfactant II is a nonylphenol polyoxyethylene ether nonionic surfactant; the nonionic surfactant II has good emulsifying property, and an hydrophilic base end is easily adsorbed on the surfaces of an oil-water interface, a sleeve and a well wall; the non-ionic surfactant I is used as a main agent of the flushing fluid, has good wettability, foamability, detergency and emulsifying power, has relatively high degreasing capacity, hard water resistance, is easy to biodegrade and has good compatibility; the normal salt cosolvent and the acidic salt cosolvent are used for assisting dissolution of the two nonionic surfactants, and meanwhile, the elution capacity of the well cementation flushing fluid on drilling fluid and oil-based mud cake isenhanced; safety is high, the formula is simple, cost is low, and environment friendliness is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

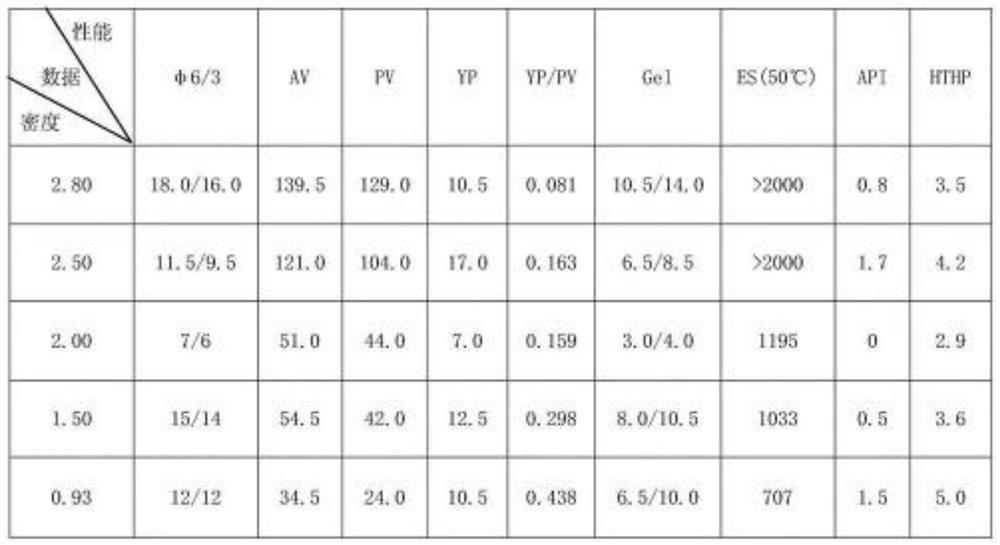

High-temperature-resistant ultrahigh-density oil-based drilling fluid and preparation method thereof

ActiveCN112538341AImprove rheologyGood settlement stabilityDrilling compositionHigh densityManganese

The invention provides a high-temperature-resistant ultrahigh-density oil-based drilling fluid and a preparation method thereof. The high-temperature-resistant ultrahigh-density oil-based drilling fluid comprises a base fluid and a weight adjusting agent. The base fluid comprises the following components in percentage by mass: 15-35% of base oil, 0.05-1.50% of a tackifier, 0.05-1.50% of a suspension enhancer, 1.05-13% of an emulsifier, 20-75% of lime, 1-10% of a filtrate reducer, 1-10% of a bridge plugging agent and 0.05-3% of a wetting agent. The weight adjusting agent comprises a calcium chloride aqueous solution and a weighting agent. The weighting agent comprises barite, micro-manganese ore powder and micro-ilmenite powder. The oil-based drilling fluid has the characteristics of high temperature resistance, high density, strong stability and excellent rheological property, and can meet the development requirements of ultrahigh-pressure and ultrahigh-temperature stratums.

Owner:PETROCHINA CO LTD

An ultra-high density oil-based drilling fluid

ActiveCN105623628BImprove emulsion stabilityImprove rheologyDrilling compositionUltra high pressureHorizontal wells

Owner:成都西油华巍科技有限公司 +1

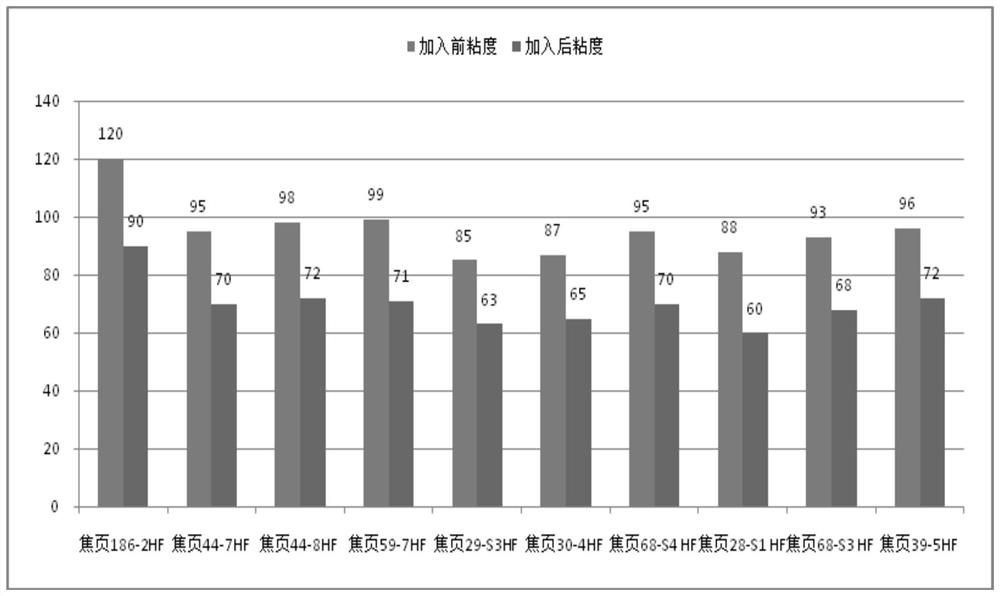

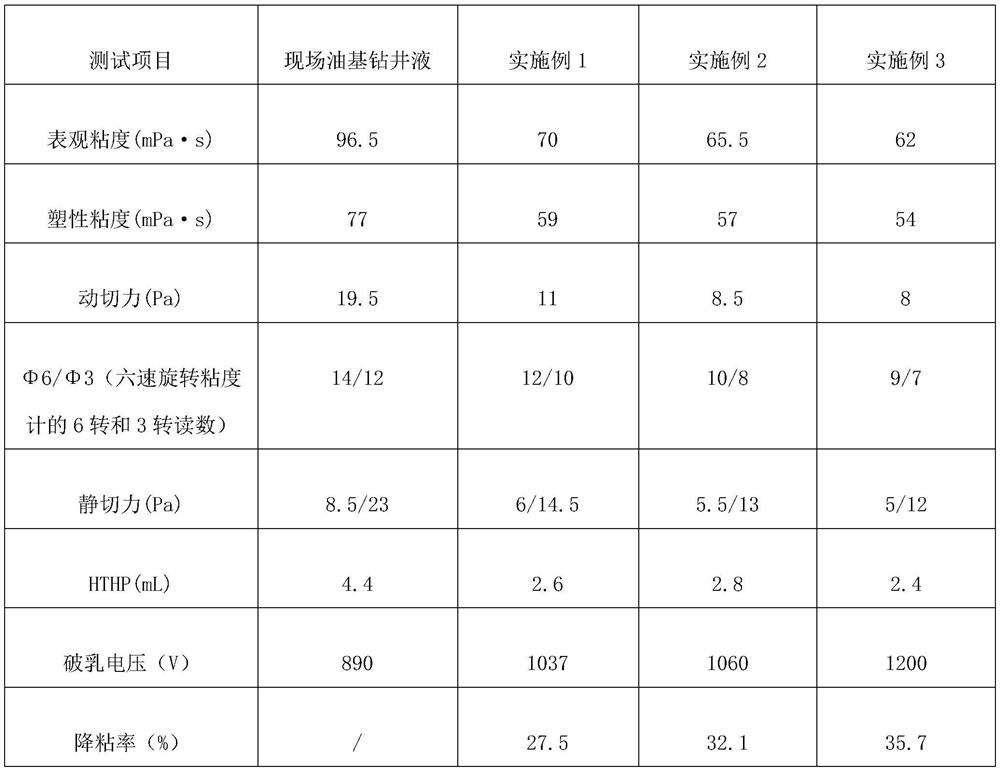

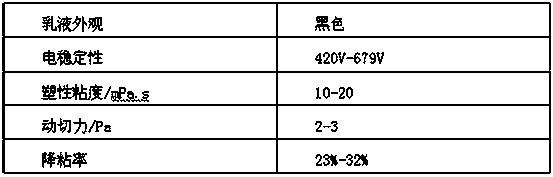

Oil-based drilling fluid viscosity reducer as well as preparation method and application thereof

The invention discloses an oil-based drilling fluidviscosity reducer. The viscosity reducer comprises the following components in parts by weight: 50-100 parts of solvent oil, 5-50 parts of a surfactant, 1-20 parts of a penetrating agent and 1-10 parts of a stabilizer. The oil-based drilling fluid viscosity reducer provided by the invention can significantly reduce the viscosity and shearing forceof the oil-based drilling fluid, improve the fluidity of the oil-based drilling fluid, reduce the circulating pump pressure, and realize the cyclic utilization of the oil-based drilling fluid; and the high-temperature resistance is excellent, the cost is low, and the economic value is high. The invention further discloses a preparation method and application of the oil-based drilling fluid viscosity reducer. The preparation method has the advantages of being simple in process, convenient to operate and beneficial to industrial production. The oil-based drilling fluid viscosity reducer is applied to the oil-based drilling fluid, the viscosity reduction rate can be effectively increased, and the circulating pump pressure is reduced.

Owner:中石化石油工程技术服务有限公司 +2

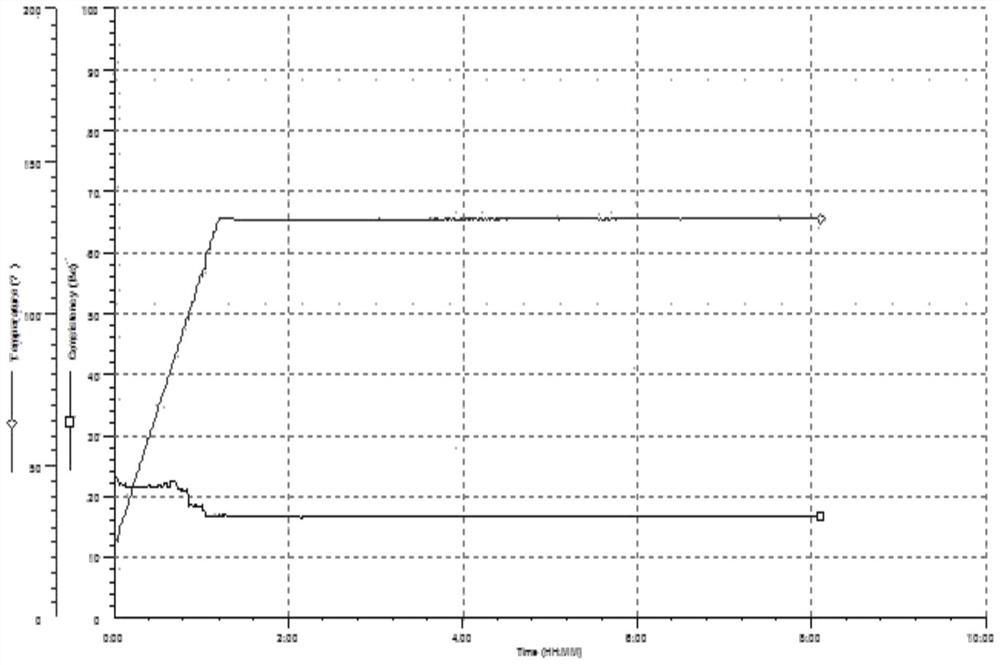

Oil-based spacer fluid for well cementation and cementing and preparation method thereof

ActiveCN112375551AEasy constructionHigh breaking voltageDrilling compositionPhysical chemistryWell cementing

The invention relates to the technical field of oil-based spacer fluid, and particularly relates to oil-based spacer fluid for well cementation and cementing and a preparation method thereof. The oil-based spacer fluid for well cementation and cementing comprises a weighting material, a wetting agent, organic soil, oil, a suspending agent, a dispersing agent, a polymer fluid loss agent, an emulsifying agent and water. The preparation method comprises the five steps, a first mixture, a second mixture and a third mixture are sequentially obtained, and finally, the oil-based spacer fluid for wellcementation and cementing is obtained. By adjusting the oil-water ratio of the spacer fluid, pollution of the oil-based drilling fluid is reduced, and finally the purposes of simplifying cementing construction, improving the success rate and reducing the cost in the oil-based drilling fluid environment are achieved. According to the invention, oil is adopted as a main mixed liquid, and the interface wettability of the oil after being mixed with the oil-based drilling fluid and cement paste is changed under the combined action of the oil and the matched additives and emulsifiers, so that the technical indexes such as compatibility, stability and density of the oil-based drilling fluid, the spacer fluid and the cement paste are improved, and the technical requirements of well cementation and cement injection can be met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Emulsifier, preparation method thereof and oil-based drilling fluid

The invention provides a preparation method of an emulsifier. The emulsifier is prepared from C4-C10 amino-containing carboxylic acid, C2-C10 dibasic acid, C3-C18 aliphatic amine and C12-C18 monobasicacid through a reaction. The emulsifier with a dendritical structure is prepared from the specific raw materials, the heat resisting property of the emulsifier can reach 220 DEG C, the emulsifier hasbetter emulsion stability and stability ratio, flowability of a drilling fluid can be improved by the emulsifier, demulsification voltage can be increased, and site operation demands can be met better. The invention further provides the emulsifier prepared with the method and an oil-based drilling fluid containing the emulsifier.

Owner:中石化石油工程技术服务有限公司 +1

Emulsifier for oil-based drilling fluid

InactiveCN111826133AStrong anti-pollutionEasy to useDrilling compositionCarboxyl radicalPtru catalyst

The invention discloses an emulsifier for an oil-based drilling fluid. The emulsifier is prepared from the following raw materials in parts by weight: 40-50 parts of an emulsifier base solution, 25-30parts of an anti-fouling emulsion and 10-15 parts of white oil, an emulsifier base solution is prepared in the preparation process; the emulsifier base solution takes tall oil fatty acid as a raw material, converts carboxyl in the tall oil fatty acid into acyl chloride under the action of triphosgene, reacts with ammonia to amidate the tall oil fatty acid; furthermore, bis (1, 5-cyclooctadiene) nickel is used as a catalyst, a carbon-nitrogen bond on amide is cut off and methanol is taken as a nucleophilic reagent, the tall oil fatty acid is further esterified after amidation to obtain an emulsifier base solution, the emulsifier base solution is further treated to obtain the emulsifier, after the emulsifier is mixed with the oil-based drilling fluid, the demulsification voltage of an oil-based system can be increased, and the emulsifier also has a relatively strong anti-pollution effect, greatly improves the temperature resistance of the oil-based system, and is stable in performance and simple to use.

Owner:ANHUI LUHAI PETROLEUM AUX TECH

Preparation method of inert dilution agent for oil-based drilling fluid

The invention relates to a preparation method of an inert dilution agent for an oil-based drilling fluid. According to the technical scheme, the preparation method comprises the following steps that 1, low-viscosity synthetic base oil is added in a beaker with a stirrer and a thermometer, and a reaction is carried out at the 50-90 DEG C for 3-6 hours, and then heating is stopped; 2, an emulsifyingagent is added into the reactor in the step 1, and stirring is conducted 3-6 hours; 3, a filtrate reducer, a wetting agent, an alkalinity regulating agent and a calcium chloride water solution are mixed in a ratio and then added into the reactor in the step 1, and stirring is conducted for 6-8 hours; 4, the mixture in the reactor is stirred at a high speed, a reaction is carried out at the temperature of 50-90 DEG C for 3-6 hours, cooling is conducted until to the room temperature, an emulsion is formed, and the emulsion is the inert dilution agent for the oil-based drilling fluid. The preparation method has the advantages that under the condition that the inhibitive ability and the shear thinning performance of the oil-based drilling fluid are not changed, the plastic viscosity can be reduced, and the drilling fluid obtained before and after addition of the inert dilution agent cannot affect construction safety even in the construction process.

Owner:中石化石油工程技术服务有限公司 +2

Water-in-oil releasing liquid and production method thereof

ActiveCN105018059AAdjustment improves the ability to suspend bariteImproved ability to suspend bariteDrilling compositionOil waterAmmonium bromide

The present invention relates to a water-in-oil releasing liquid and a production method thereof. The production method sequentially comprises: (1) preparing raw materials, wherein the raw materials comprise, by weight, 200 parts of water, 680 parts of diesel oil, 10-20 parts of oleic acid, 20-25 parts of slaked lime, 20-30 parts of a wetting reversion agent dodecyl trimethyl ammonium bromide, 60-70 parts of a solid emulsifier SN-1, 10-20 parts of an anti-sloughing agent FT-1, 20-30 parts of a fast penetrant T, and 20-65 parts of barium sulfate; and (2) pouring the diesel oil into a high speed stirring tank, adding the solid emulsifier SN-1 under the 20000 rpm stirring condition to stir for 15-20 min, adding the water, stirring for 20-30 min so as to make oil and water be completely emulsified, sequentially adding the oleic acid, the slaked lime, the anti-sloughing agent FT-1, the wetting reversion agent and the barium sulfate, stirring, finally adding the fast penetrant T, and stirring for 30-40 min so as to obtain the water-in-oil releasing liquid.

Owner:中石化石油工程技术服务有限公司 +1

Modified fatty acid type primary emulsion for high-temperature-resistant oil based drilling fluid and preparation method of modified fatty acid type primary emulsion

ActiveCN105315973AReduce high temperature and high pressure filtration lossHigh practical valueDrilling compositionEmulsionFatty acid

The invention discloses a modified fatty acid type primary emulsion for high-temperature-resistant oil based drilling fluid and a preparation method of the modified fatty acid type primary emulsion. The modified fatty acid type primary emulsion for the high-temperature-resistant oil based drilling fluid consists of the following components: dicarboxylic anhydride, fatty acid and epoxy chloropropane, wherein the mass ratio of dicarboxylic anhydride to fatty acid is 1:20-1:30, and the mass of the epoxy chloropropane accounts for 15-25% of the mass of the fatty acid. The modified fatty acid type primary emulsion disclosed by the invention is obtained by modifying the fatty acid, has stronger emulsifying capacity and high temperature resistance, and has an effect of reducing the high-temperature high-pressure filtration losses of the oil based drilling fluid at the same time.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low-cost emulsifying agent applied to oil-based drilling fluid and preparation method thereof

PendingCN107987811AReduce the number of additionsImprove stabilityDrilling compositionEmulsionPetroleum

The invention discloses a low-cost emulsifying agent applied to an oil-based drilling fluid and a preparation method thereof, and belongs to the technical field of petroleum drilling fluids. The low-cost emulsifying agent comprises the following raw materials in percentages by weight: 45% to 70% of oxidized fatty acid, 15% to 40% of malefic tall oil fatty acid, 5% to 30% of oleic acid and 1% to 5%of octadecyl sodium alkyl benzene sulfonate, wherein the total weight percentage of the raw materials is 100%. The preparation method comprises the following steps: mixing oxidized fatty acid, malefic tall oil fatty acid, oleic acid and octadecyl sodium alkyl benzene sulfonate, carrying out a stirring reaction at the temperature of 60 DEG C for 1 to 2 h, and discharging to obtain the low-cost emulsifying agent. The emulsifying agent disclosed by the invention has the advantages of low cost, high emulsion-breaking voltage, low filter loss and the like, a drilling fluid system can be stable, and the emulsifying agent is small in additive amount and convenient and effective to use and is convenient for popularization and application. The preparation method disclosed by the invention is simple in working procedures, simple in steps and convenient in production, and the production cost is greatly reduced.

Owner:联技精细材料(珠海)有限公司

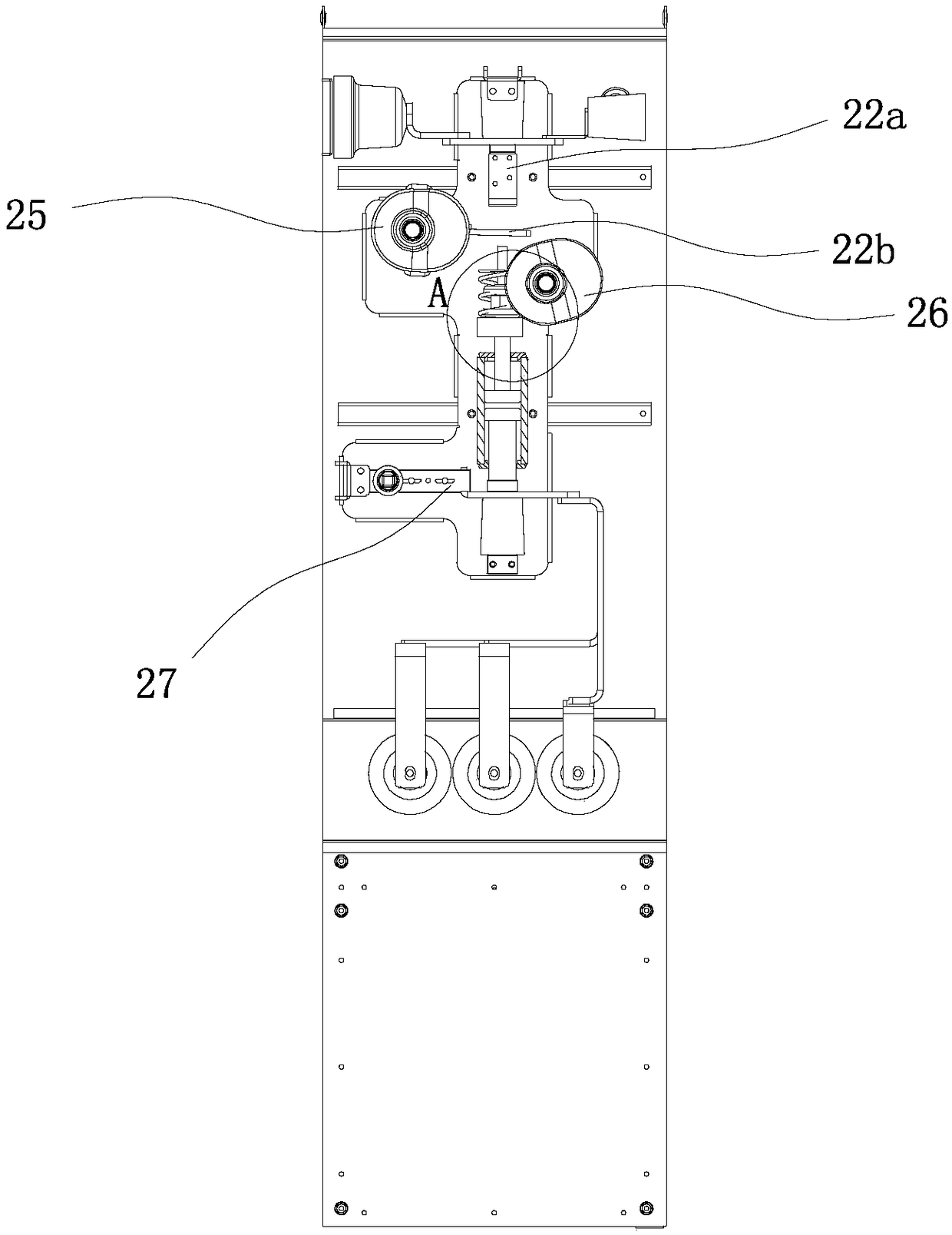

A breaking method for isolation linkage vacuum load switch

ActiveCN109166746BHigh breaking voltageNot easy to arcElectric switchesControl theoryMechanical engineering

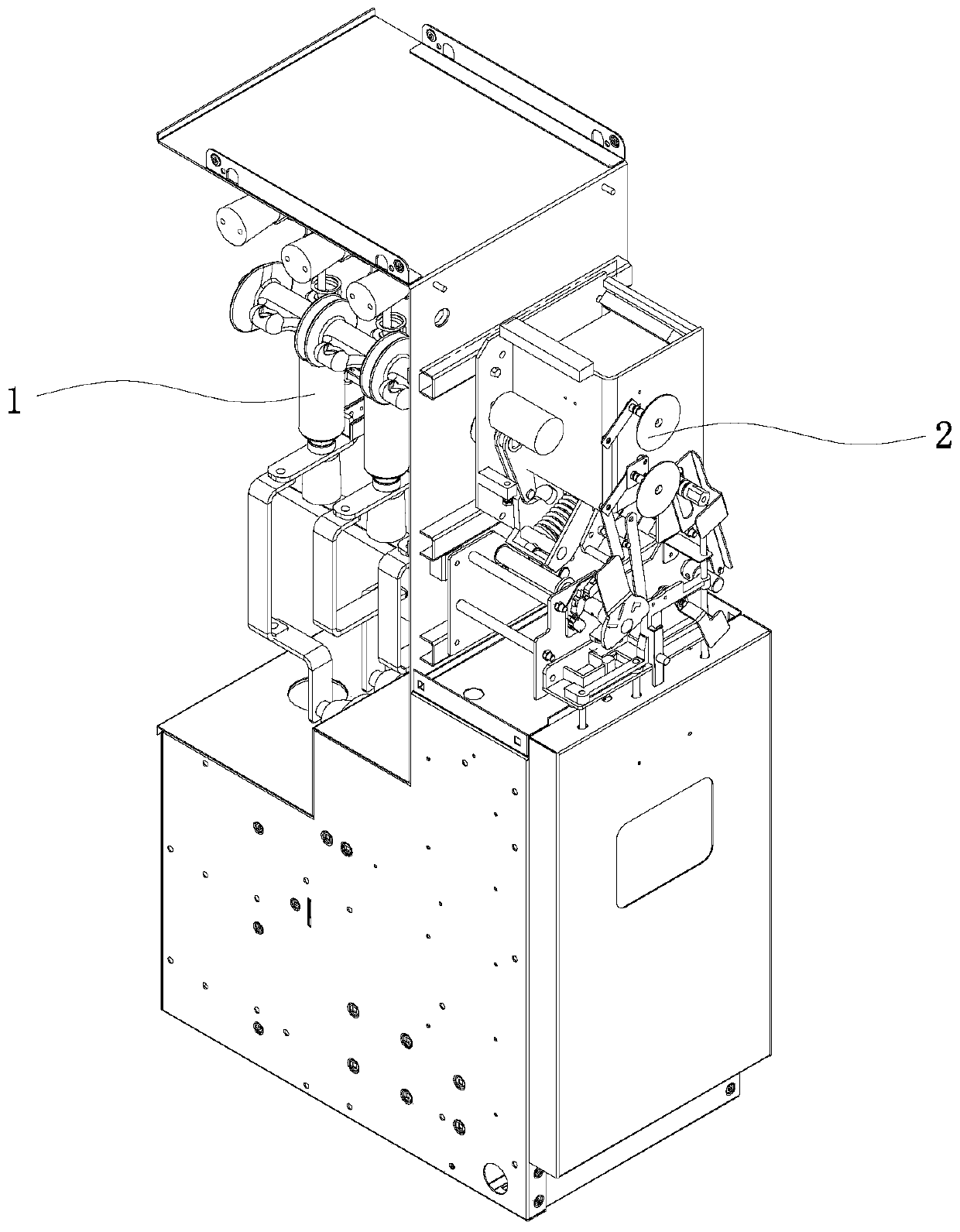

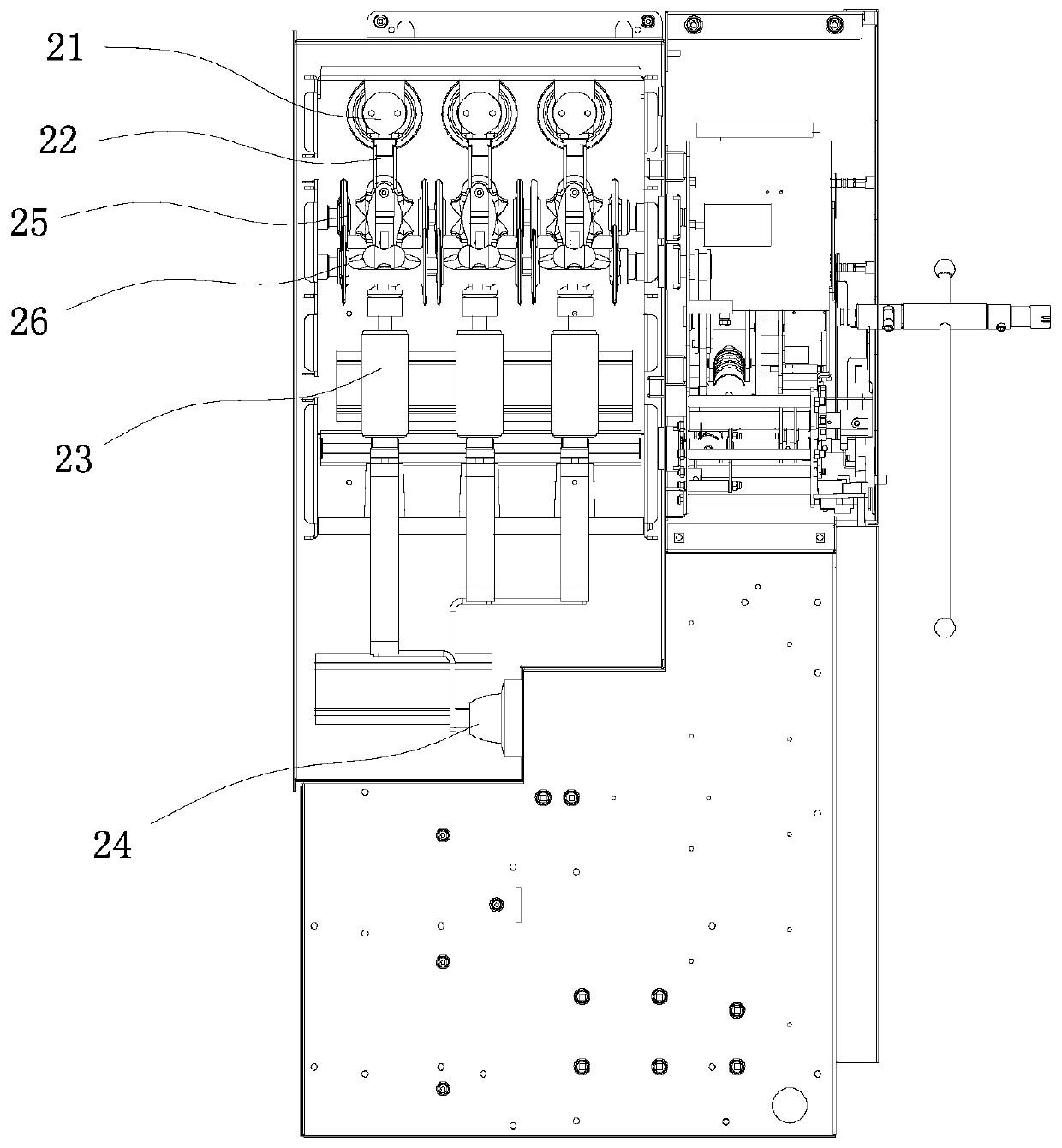

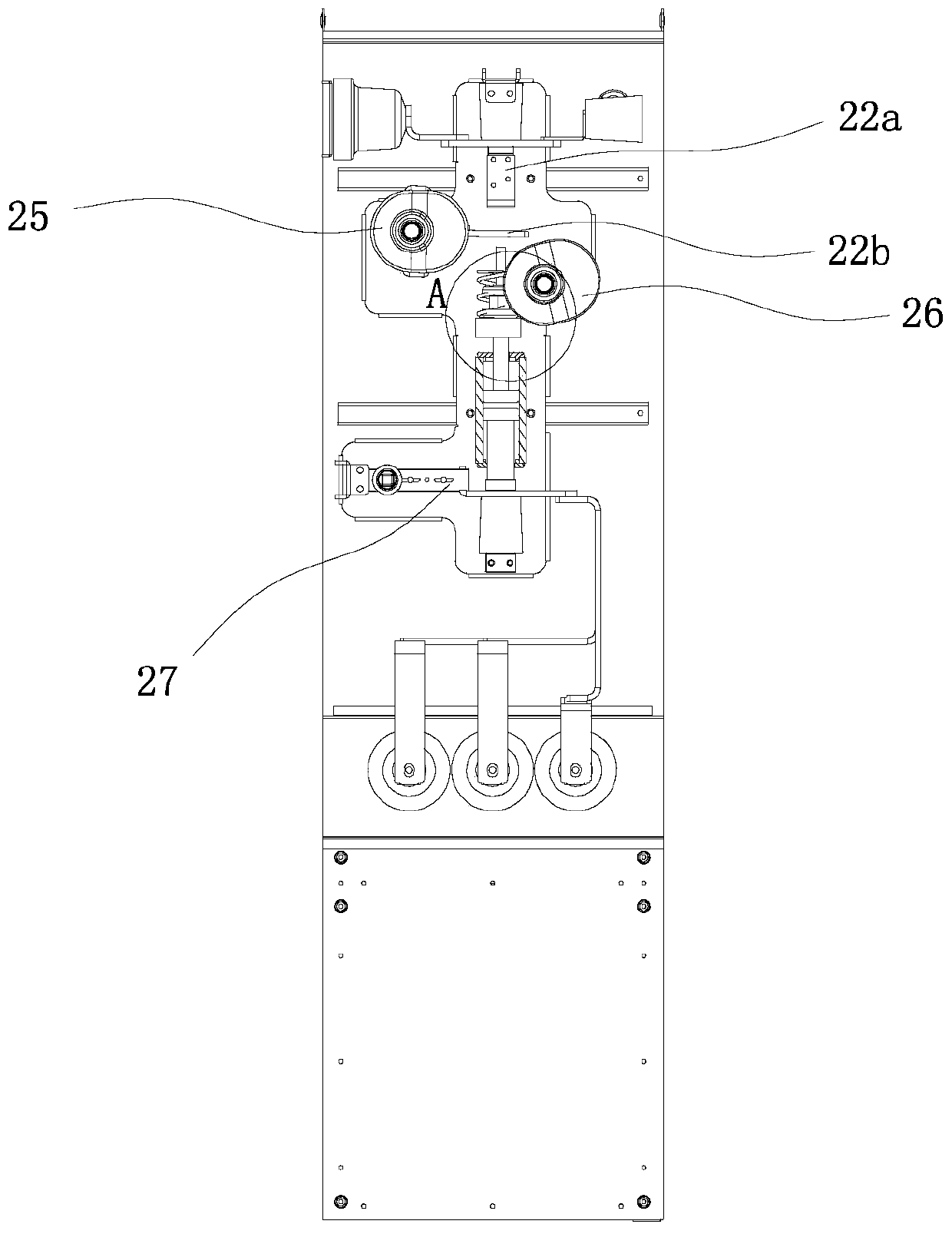

The invention discloses a breaking and closing method of an isolation linkage vacuum load switch. The inlet and outlet ends of the load switch are provided with an isolation switch and a vacuum arc extinguisher. The first rotor is used for controlling the isolation switch to be turned on and off, the second rotor is used for controlling the vacuum arc extinguisher to be turned on and off, and theoperating mechanism is used for controlling the isolation switch and the vacuum arc extinguisher to be linked. Vacuum interrupter closes after disconnector closes for T time; The operating mechanism also controls the opening action of the disconnector and the opening action of the vacuum interrupter. The vacuum load switch has a high interrupting voltage, which meets the requirements of high voltage level. The vacuum load switch has a high interrupting voltage. The disconnector and vacuum arc extinguisher are interconnected, and the load switch is not easy to start arc. The breaks of the disconnector and the vacuum interrupter can be closed in several milliseconds, and the vacuum interrupter can be closed safely after the arc generated by the transient state of the disconnector is quicklyextinguished.

Owner:珠海沃顿电气有限公司

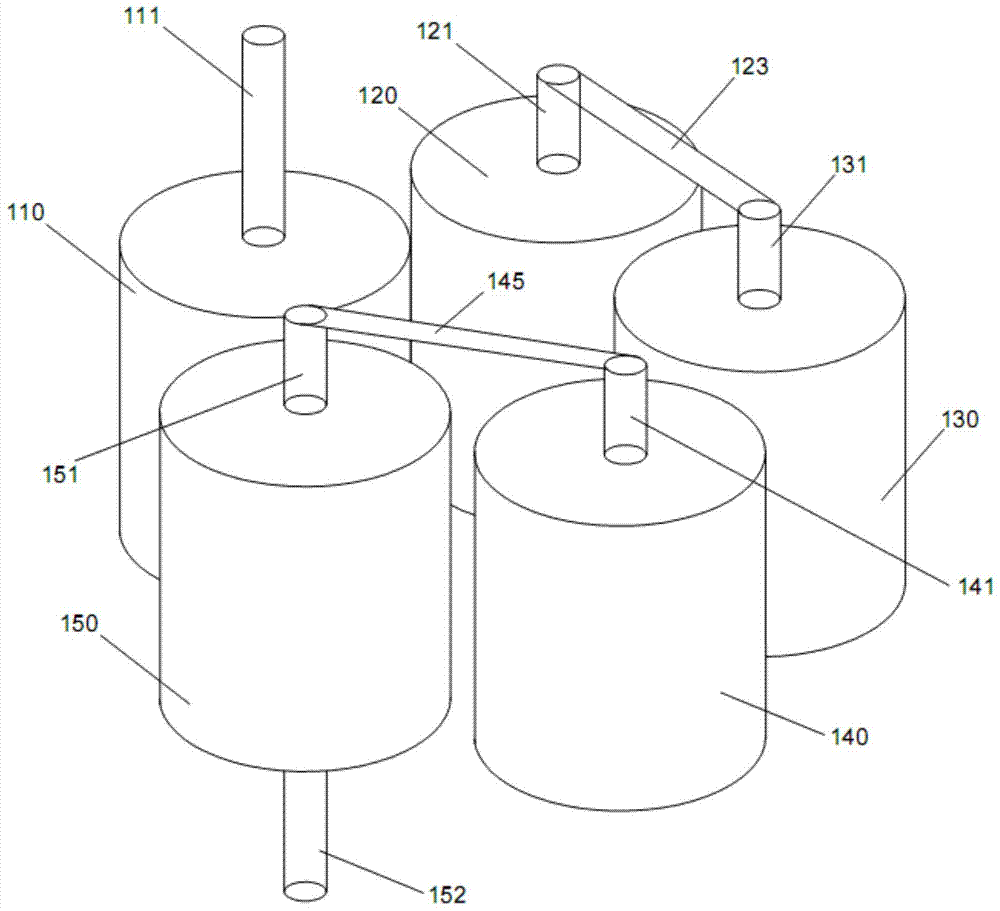

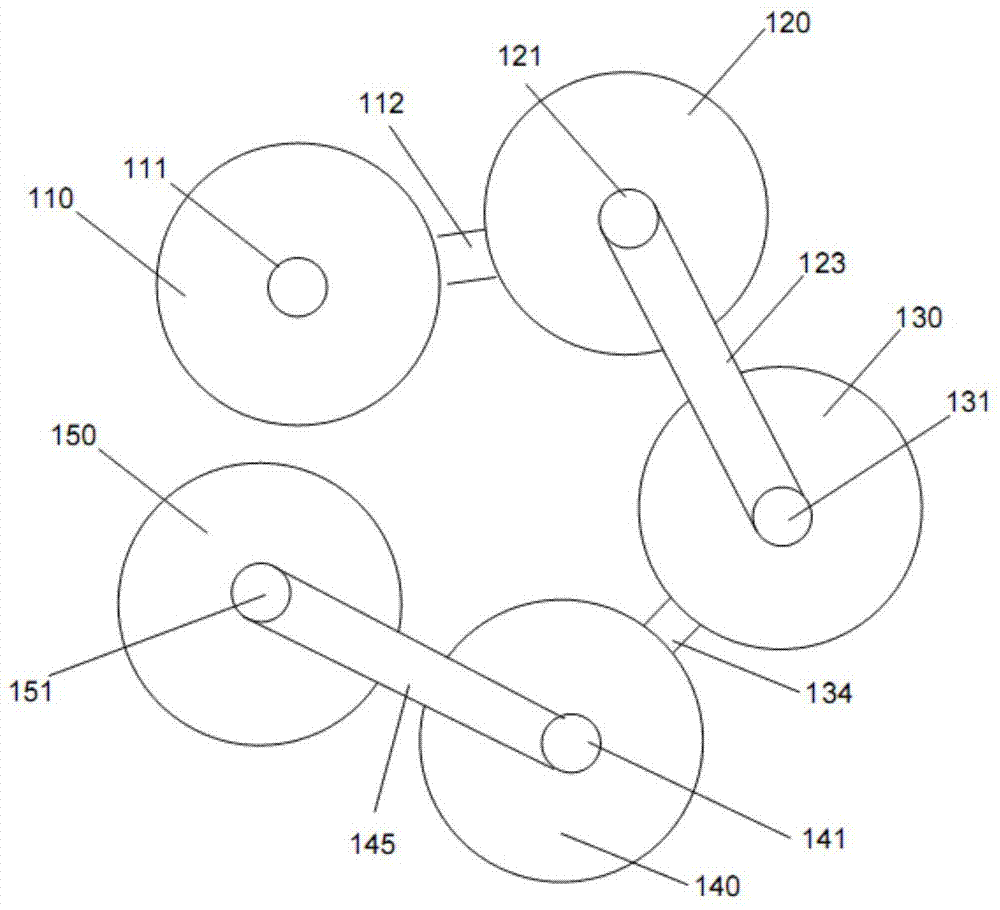

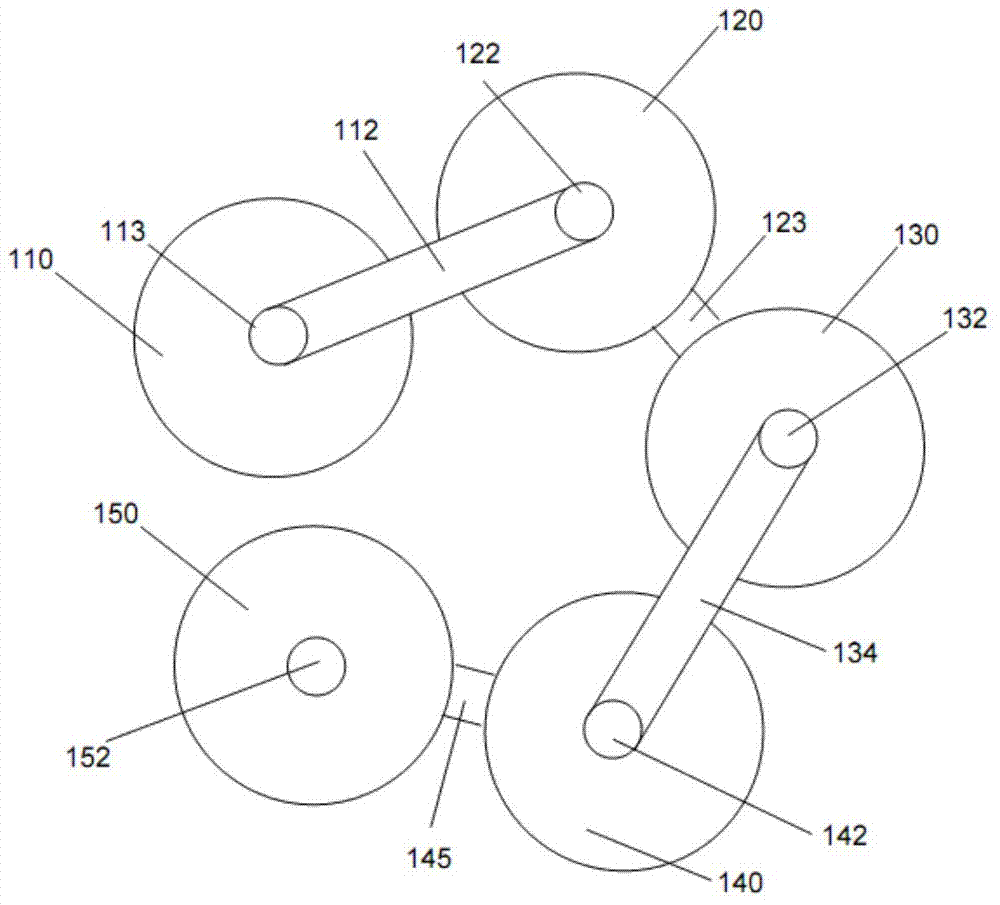

A multi-break HVDC circuit breaker

ActiveCN105244208BArc current is smallShort arcing timeElectric switchesDc circuit breakerHigh-voltage direct current

The invention discloses a multi-break high-voltage direct current breaker. The breaker comprises an arc extinguishing chamber array, linkage plates and a driving mechanism, wherein the arc extinguishing chamber array is formed through arranging several same arc extinguishing chambers; the linkage plates are arranged on two ends of the arc extinguishing chamber array in parallel, and the linkage plates are fixedly connected to moving conducting rods of the arc extinguishing chambers; the driving mechanism is connected to the linkage plates. By using the multi-break high-voltage direct current breaker, a technical problem that a high voltage direct current is not easy to break is solved; breaking performance is high and an effect breaking voltage grade of the direct current breaker is increased.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

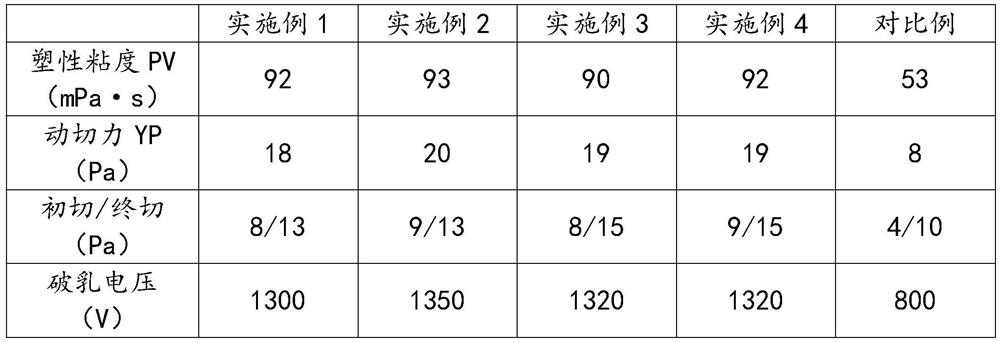

A kind of emulsified drilling fluid with high density and low oil-water ratio for shale horizontal well

ActiveCN106566496BHigh breaking voltageHigh densityDrilling compositionEthylenediamineHorizontal wells

The invention discloses an emulsion drilling fluid with high density and low oil-water ratio for a shale horizontal well. The emulsion drilling fluid is prepared from raw materials in parts by weight as follows: 180 parts of 3# white oil, 120 parts of a 30% calcium chloride solution, 2-5 parts of a main emulsifier, 4-8 parts of an auxiliary emulsifier, 12-18 parts of a reversible emulsifier, 5-10 parts of calcium oxide, 2-5 parts of organic soil, 3-8 parts of a blocking agent, 0.5-3 parts of an extracting agent, 6-12 parts of calcium carbonate and 0-800 parts of barytes, wherein the main emulsifier is prepared from tall oil fatty acid and maleic anhydride, the auxiliary emulsifier is prepared from high-level fatty acid salt and high-level fatty acid polyol ester, the reversible emulsifier is prepared from methyl 9-octadecenoate and hydroxyethyl ethylenediamine, and the extracting agent is prepared from styrene, methyl methacrylate and hexadecyl acrylate. The oil-water ratio is 6:4, and the emulsion drilling fluid has higher inhibition dispersibility and blocking capacity, good lubricating property and good heat-resisting property and can be suitable for meeting the drilling requirement of a horizontal section of the shale deep well.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Ceramic insulating shell of arc-resistant components and processing implementation technology

InactiveCN110556255AExtended service lifeWork lessElectric switchesAlternating currentElectric control

The invention discloses a ceramic insulating shell of a contactor, a relay, a circuit breaker and a switch, and particularly relates to a device ceramic insulating shell which has a strong arc ablation resistance, can be welded in a metallized and sealed manner, and has the functions of high dielectric strength, high breakdown voltage, high temperature resistance, acid and alkali resistance, highstrength and the like. The shell and the structure are applied to an electric control device, the on-off voltage direct current of the traditional electric control device can reach 600VDC or above, the alternating current of the traditional electric control device can reach 800VAC or above, and the safety and environmental adaptability indexes of the device can be greatly improved.

Owner:宜兴市伊特瓷件厂

A vacuum load ring network cabinet which is isolated and linked

ActiveCN109243883AHigh breaking voltageImprove safety and reliabilitySwitchgear arrangementsHigh-tension/heavy-dress switchesElectricityRing network

The invention discloses a vacuum load ring network cabinet which is isolated and linked, The switching mechanism comprises a first wiring terminal, an isolating switch, a vacuum interrupter and a second wiring terminal which are electrically connected in turn. The switching mechanism further comprises a first rotor for controlling the on-off of the isolating switch and a second rotor for controlling the on-off of the vacuum interrupter. The operating mechanism is simultaneously connected to the first rotor and the second rotor. The operating mechanism is used to control the linkage between thedisconnector and the vacuum interrupter. The vacuum load switch has a high interrupting voltage, which meets the requirements of high voltage level. The vacuum load switch has a high interrupting voltage. Disconnector and vacuum arc extinguisher are interconnected, vacuum load switch is not easy to start arc; The breaks of disconnector and vacuum interrupter can be closed in millisecond order. After the arc produced by transient closing of disconnector is quickly extinguished, the vacuum interrupter can be closed safely, and the vacuum load switch has higher safety and reliability.

Owner:珠海沃顿电气有限公司

A soil-free oil-based drilling fluid

ActiveCN103788934BStrong electrical stabilityHigh breaking voltageDrilling compositionSocial benefitsSoil science

The invention relates to a soil-free oil-based drilling fluid, which is prepared from the following raw materials in weight percentage: 50-85% of base oil, 5-30% of CaCl2 brine, and compound emulsifier G326-HEM? 1~4%, fluid loss reducer G328? 1~5%, alkalinity regulator .5~3%, viscosifier 0.5~3%, cutting agent 0.2~2%, and the rest is barite. The demulsification voltage of the soil-free oil-based drilling fluid provided by the invention is higher than 800V, and the temperature resistance is higher than 180°C. rheology; the system is widely adaptable to base oil and can be used for mineral oil or gas oil; it provides a new method for reducing lost circulation loss of oil-based drilling fluid, and at the same time significantly reduces the cost of drilling fluid and obtains good economic and social benefits Benefits are worth popularizing and applying.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

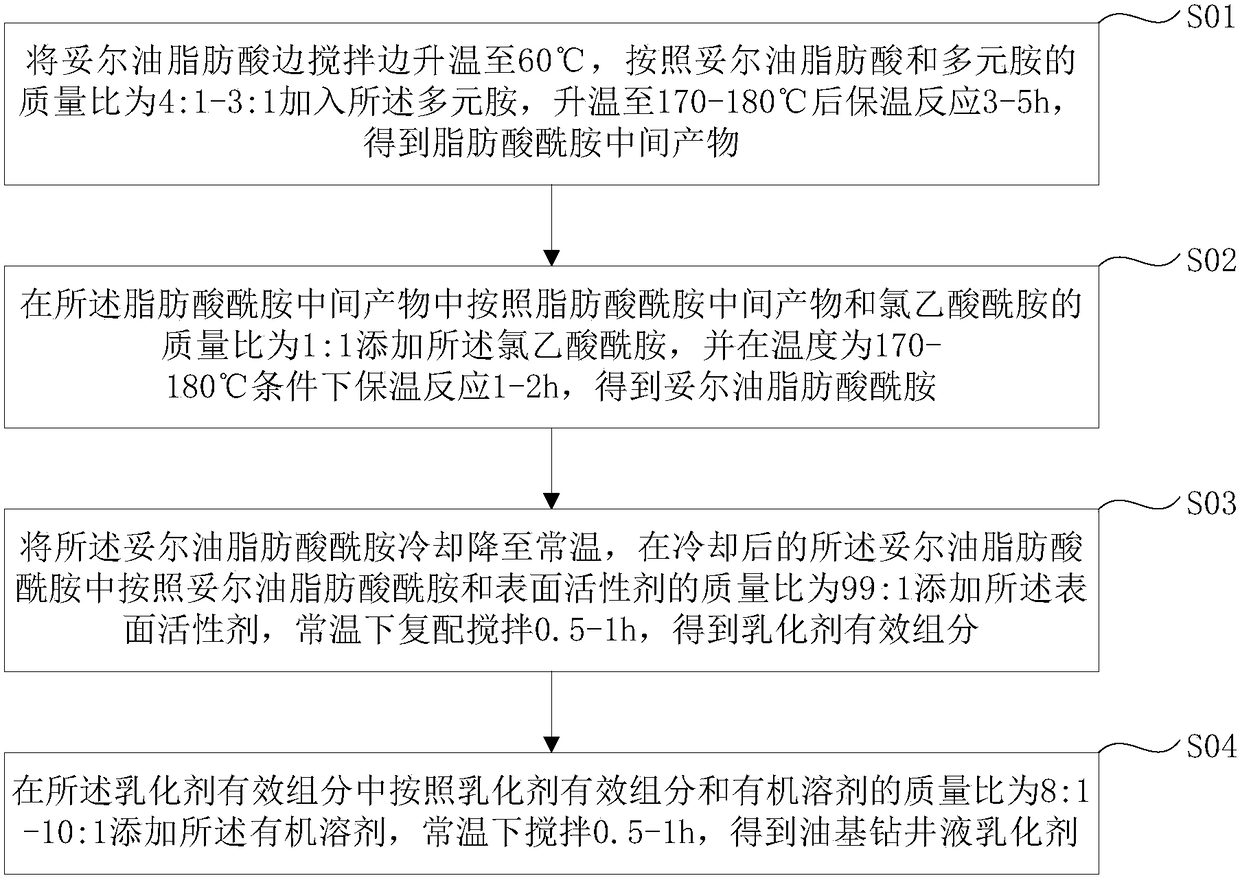

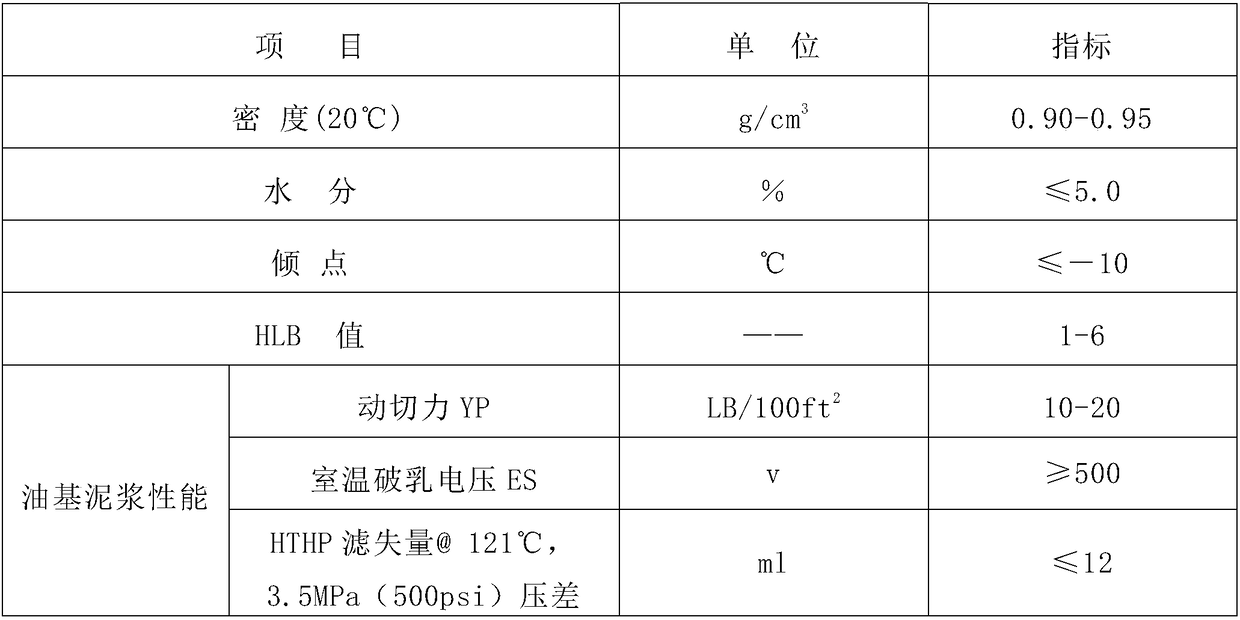

A kind of emulsifier based on oil-based drilling fluid and preparation method thereof

ActiveCN105907382BHigh breaking voltageReduce the number of additionsDrilling compositionOrganic solventEmulsion

The invention provides an emulsifying agent based on oil-based drilling fluid. The emulsifying agent contains tall oil fatty acid, polyamine, chloroactic acid amide, surfactants and organic solvents. Meanwhile, the invention also provides a preparation method of the emulsifying agent based on oil-based drilling fluid. The emulsifying agent based on oil-based drilling fluid provided by the invention is an integral emulsifying agent; the characteristics of emulsion stability and high emulsion breaking voltage are realized; the emulsifying agent can reduce the addition times and the addition quantity of the emulsifying agents in the drilling fluid, so that the drilling cost can be reduced; the integral emulsifying agent has the advantages that the in-site operation, particularly the system maintenance difficulty can be reduced; further, the occurrence of complicated conditions is reduced; the use is convenient and effective. The preparation method of the emulsifying agent based on oil-based drilling fluid provided by the invention has the advantages that the production process is simple; the cost is low.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of modified epoxy asphalt particle, water-in-oil drilling fluid and preparation method thereof

ActiveCN110922773BImprove high temperature resistanceGuaranteed electrical stabilityWorking-up pitch/asphalt/bitumen by chemical meansDrilling compositionPolymer scienceFirming agent

The invention discloses a modified epoxy asphalt particle, a water-in-oil base drilling fluid and a preparation method thereof. The components of the modified epoxy asphalt particles of the present invention include: modified asphalt, epoxy resin, and curing agent, wherein the components of the modified asphalt include: matrix asphalt, organic acid anhydride, SBR mother liquor, and crosslinking agent. The modified epoxy asphalt particle of the present invention not only has a small particle size, but also has a certain elastic deformation ability, and has excellent high temperature resistance. The drilling fluid has good rheological properties and high temperature and high pressure fluid loss reduction effect when used at high temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

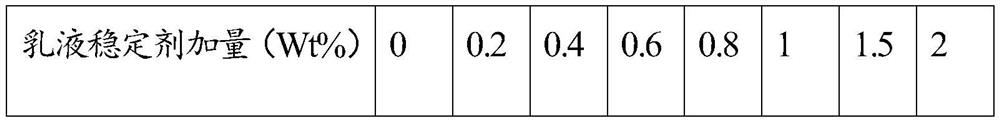

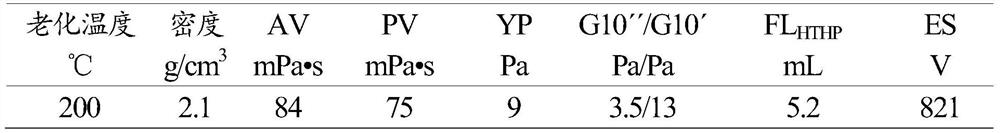

Composite emulsifier for ultrahigh-temperature-resistant water-in-oil emulsion drilling fluid and drilling fluid

ActiveCN113652213AGuaranteed emulsification stabilityImprove emulsion stabilityDrilling compositionOil emulsionFiltration

The invention discloses a composite emulsifier for an ultrahigh-temperature-resistant water-in-oil emulsion drilling fluid and the drilling fluid, and the composite emulsifier comprises the following raw materials in parts by weight: 2.0-5.0 parts of a main emulsifier, 1.0-4.0 parts of an auxiliary emulsifier and 0.2-2 parts of an emulsion stabilizer. Under ultrahigh temperature and high density, the main emulsifier can form a close packing composite film with viscoelasticity on an oil-water interface of a drilling fluid system and can maintain the emulsion stability of the drilling fluid system, and the auxiliary emulsifier can reduce the tension of the oil-water interface, interact with the main emulsifier and assist the main emulsifier to improve the emulsion stability of the drilling fluid system. By adding the emulsion stabilizer, the strength of an interfacial film can be remarkably improved, and the emulsion stability of the water-in-oil emulsion drilling fluid is improved, so that the system sedimentation stability, the drilling fluid filtration loss and other properties are improved.

Owner:中国石油集团西部钻探工程有限公司青海钻井公司 +1

Copolymer and its application and oil-based drilling fluid stabilizer and its preparation method and oil-based drilling fluid

ActiveCN108467483BImprove emulsion stabilityGood settlement stabilityDrilling compositionPolyamine CompoundWell drilling

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Wetting reversal surfactant for drilling fluid

ActiveCN101974320BControl performanceRegulatory performanceDrilling compositionFatty acidSURFACTANT BLEND

The invention discloses a wetting reversal surfactant for drilling fluid. The wetting reversal surfactant is characterized by comprising the following components in percentage by weight: 10 percent of dodecyltrimethylammonium bromide, 15 percent of heavy oil, 20 percent of fatty acid and 55 percent of water. The surfactant does not have influence on the performance of the drilling fluid and has positive charges so as to be mutually absorbed to a hydrophilic rock layer around an oil well with negative charges; the surfactant is adhered to a rock core through a cationic surfactant; the wetting reversal surfactant is covered by a hydrophobic lipophilic group layer; and thus the hydrophilic rock layer is reversed into a lipophilic hydrophobic rock layer to fulfill the aim of replenishing oil and stopping water.

Owner:SICHUAN ZHENGRONG IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com