Emulsifier for oil-based drilling fluid

An oil-based drilling fluid and emulsifier technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor anti-fouling performance of emulsifiers, inability of emulsifiers to work, and reduced efficacy of emulsifiers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

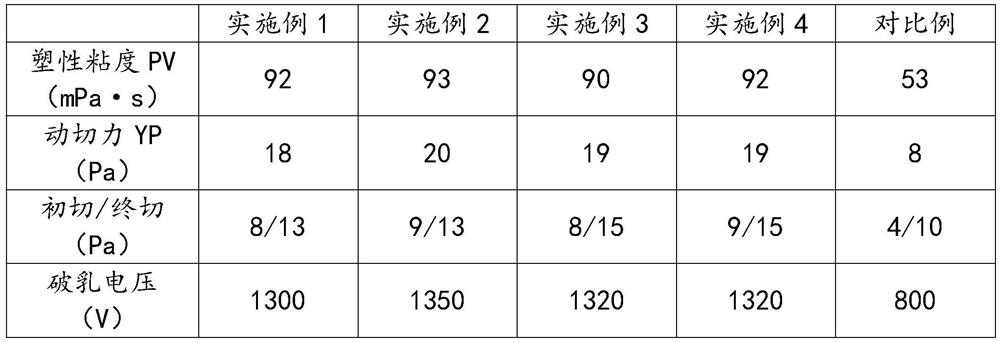

Examples

Embodiment 1

[0031] The emulsifier for oil-based drilling fluid is made of the following raw materials in parts by weight: 40 parts of emulsifier base fluid, 25 parts of antifouling emulsion, and 10 parts of white oil;

[0032] The emulsifier is made by the following steps:

[0033] Step S1: Add white oil into the stirred tank at a rotation speed of 300r / min and a temperature of 25°C, stir, add an emulsifier base liquid, and stir for 15 minutes to obtain the first mixed liquid;

[0034] Step S2: Add the first mixed solution prepared in step S1 into a stirred tank at a rotation speed of 200r / min and a temperature of 25°C, stir and add milk antifouling emulsion, and stir for 20 minutes to prepare the second mixed solution ;

[0035] Step S3: The second mixed solution prepared in step S2 was ultrasonically treated for 5 minutes at a frequency of 40 kHz to prepare an emulsifier.

[0036] Described emulsifier base liquid is made by following steps:

[0037]Step A1: Mix pyridine and triethyla...

Embodiment 2

[0047] The emulsifier for oil-based drilling fluid is made of the following raw materials in parts by weight: 43 parts of emulsifier base fluid, 27 parts of antifouling emulsion, and 12 parts of white oil;

[0048] The emulsifier is made by the following steps:

[0049] Step S1: Add white oil into the stirred tank at a rotation speed of 300r / min and a temperature of 25°C, stir, add emulsifier base liquid, and stir for 15 minutes to obtain the first mixed liquid;

[0050] Step S2: Add the first mixed solution prepared in step S1 into a stirred tank at a rotation speed of 200r / min and a temperature of 25°C, stir and add milk antifouling emulsion, and stir for 20 minutes to prepare the second mixed solution ;

[0051] Step S3: The second mixed solution prepared in step S2 was ultrasonically treated for 5 minutes at a frequency of 40 kHz to prepare an emulsifier.

[0052] Described emulsifier base liquid is made by following steps:

[0053] Step A1: Mix pyridine and triethylami...

Embodiment 3

[0063] The emulsifier for oil-based drilling fluid is made of the following raw materials in parts by weight: 48 parts of emulsifier base fluid, 28 parts of antifouling emulsion, and 13 parts of white oil;

[0064] The emulsifier is made by the following steps:

[0065] Step S1: Add white oil into the stirred tank at a rotation speed of 400r / min and a temperature of 30°C, stir, add an emulsifier base liquid, and stir for 20 minutes to obtain the first mixed liquid;

[0066] Step S2: Add the first mixed solution prepared in step S1 into a stirred tank at a rotation speed of 300r / min and a temperature of 30°C, stir and add milk antifouling emulsion, and stir for 30 minutes to prepare the second mixed solution ;

[0067] Step S3: The second mixed solution prepared in step S2 was subjected to ultrasonic treatment for 10 min at a frequency of 50 kHz to obtain an emulsifier.

[0068] Described emulsifier base liquid is made by following steps:

[0069] Step A1: Mix pyridine and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com