Wetting reversal surfactant for drilling fluid

A technique of surfactant and wetting reversal, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as the drop of demulsification voltage, the reduction of oil well production, and the increase of drilling fluid loss, and achieve the goal of breaking Increased milk voltage, no effect on rheology, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

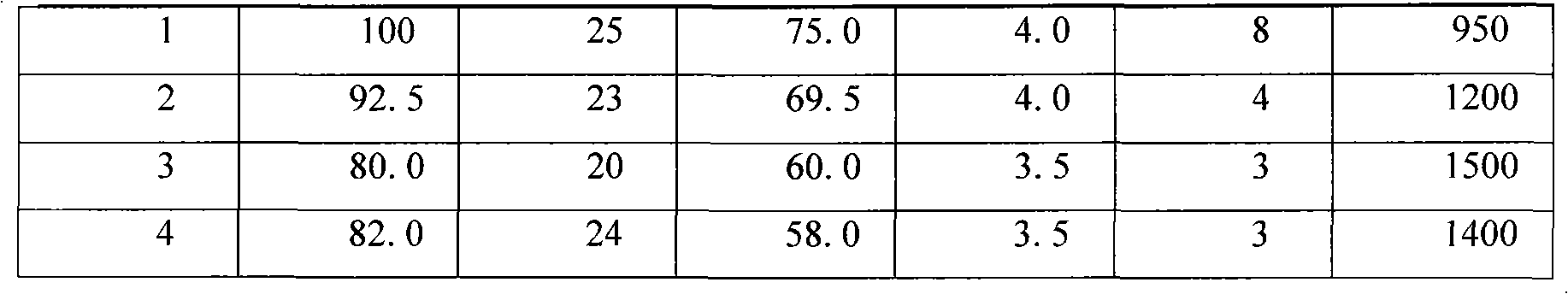

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment;

[0024] A wetting inversion surfactant for drilling fluid, the wetting inversion surfactant is made of the following ingredients by weight percentage:

[0025] Lauryltrimethylammonium Bromide 10%

[0026] Heavy Oil 15%

[0027] Fatty acids 20%

[0028] water 55%

[0029] The method for preparing the wetting and inverting surfactant for drilling fluid is: add water and dodecyltrimethylammonium bromide into a rotating high-speed stirring tank in sequence according to the above formula, then add heavy oil and fatty acid, Stir for 60 minutes and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com