Composite emulsifier for ultrahigh-temperature-resistant water-in-oil emulsion drilling fluid and drilling fluid

A technology for emulsified drilling fluid and compound emulsifier, applied in the field of petroleum drilling engineering, can solve the problems of less research, settlement stability and rheological property control of water-in-oil emulsion drilling fluid performance, emulsification stability, settlement stability and filtration. In order to improve the strength of the interface membrane, improve the settlement stability of the system and the filtration performance of drilling fluid, improve the settlement stability and the filtration performance of high temperature and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

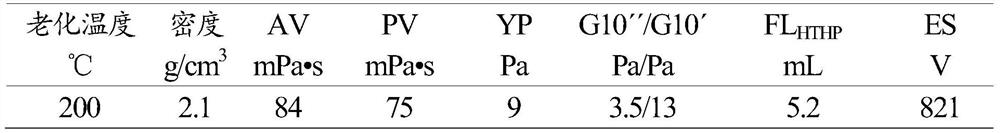

[0089] The present invention also provides a preparation method of the ultra-high temperature resistant water-in-oil emulsified drilling fluid, specifically, comprising the following steps:

[0090] S1. Add organic soil, main emulsifier, auxiliary emulsifier, emulsion stabilizer, cutting agent and acid-base regulator to the oil phase in sequence, stir at high speed to make it fully dispersed, and stir for 5 minutes after adding each component Add the next one, the high-speed stirring rate is 11000r / min;

[0091] S2. Continue to add the water phase under high-speed stirring conditions to fully emulsify the system. The high-speed stirring time is not less than 10 minutes, and the high-speed stirring rate is 11000r / min;

[0092] S3. Add fluid loss reducer, ultrafine particles and weighting agent in sequence. After each component is added, it must be stirred for 5 minutes before adding the next one. The stirring rate is 11000r / min. The resulting mixed liquid is water-in-oil emulsi...

Embodiment 1

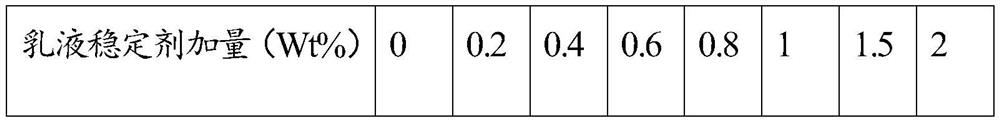

[0096] Embodiment 1 Effect evaluation of compound emulsifier

[0097] The volume ratio of the oil phase (0# diesel oil) to the water phase (20Wt% calcium chloride aqueous solution) is 8:2, in terms of mass percentage, when adding 1.5% of the main emulsifier and 1% of the auxiliary emulsifier, the emulsion stabilizer (PEG-30 dipolyhydroxystearate) is added in an amount of 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1%, 1.5%, and 2%, and the effects are shown in Table 1.

[0098] Table 1

[0099] Addition amount of emulsion stabilizer (Wt%) 0 0.2 0.4 0.6 0.8 1 1.5 2 Demulsification voltage (V) 213 302 388 468 495 508 515 519

Embodiment 2

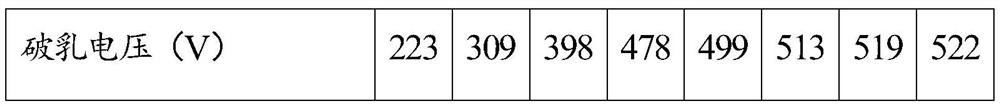

[0100] Embodiment 2 The effect evaluation of compound emulsifier

[0101] The volume ratio of the oil phase (0# diesel oil) to the water phase (20Wt% calcium chloride aqueous solution) is 9:1, in terms of mass percentage, when adding 2% of the main emulsifier and 1% of the auxiliary emulsifier, the emulsion stabilizer (PEG-30 dipolyhydroxystearate) is added in an amount of 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1%, 1.5%, and 2%, and the effects are shown in Table 2.

[0102] Table 2

[0103]

[0104]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com