High temperature resistant oil-based drilling fluid emulsifier and preparation method thereof

An oil-based drilling fluid and emulsifier technology, applied in the field of oil drilling, can solve the problems of poor high-temperature emulsification effect, large gap, and large amount of addition, and achieves the ability to ensure emulsification stability, good emulsification, and strong high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

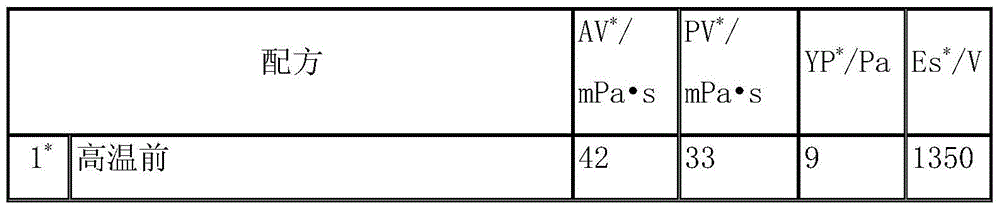

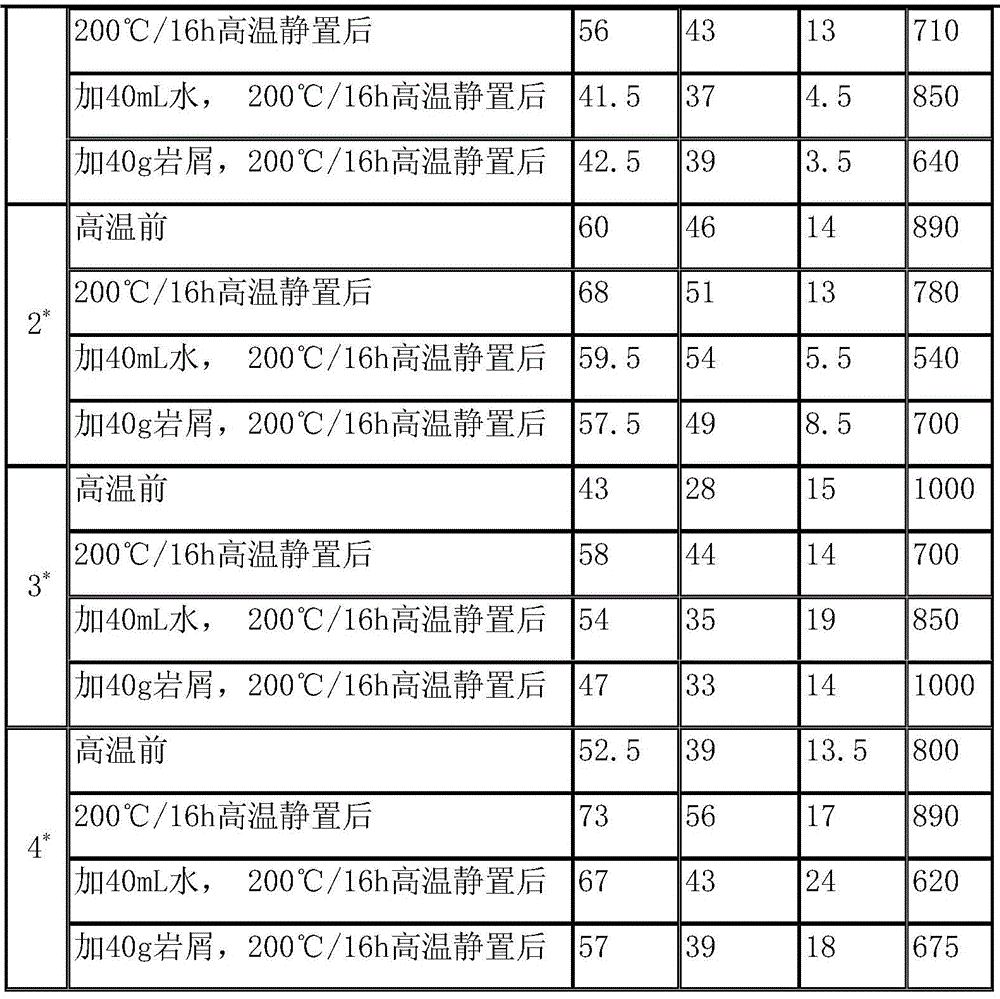

Embodiment 1

[0021] (1) Dissolve 9 parts of polyisobutylene (molecular weight 1000-1200) and 2 parts of maleic anhydride in 22 parts of solvent xylene, add to the reaction kettle, heat to 150°C, pressurize to 0.6MPa with nitrogen, Reaction 8h, obtain polyisobutylene succinic anhydride;

[0022] (2) Reduce the temperature in the reactor to room temperature and release the pressure, add 4 parts of polyethylene polyamine, raise the temperature to 110°C, and react for 6 hours under normal pressure, so that polyethylene polyamine and polyisobutylene succinic anhydride undergo condensation reaction;

[0023] (3) Heating up to 150° C. to recover the solvent by distillation under normal pressure. After the distillation is completed, the temperature is raised to 200° C. to recover unreacted reactants by distillation, and the obtained product is polyolefin succinimide, the primary product of the emulsifier;

[0024] (4) Evenly mix the primary product of the emulsifier with 4 parts of polyethylene gl...

Embodiment 2

[0026] (1) Dissolve 12 parts of polyisobutylene (molecular weight 1000-1200) and 1 part of maleic anhydride in 20 parts of solvent xylene, add to the reaction kettle, heat to 160 ° C, pressurize to 0.7 MPa with nitrogen, Reaction 10h, obtain polyisobutylene succinic anhydride;

[0027] (2) Reduce the temperature in the reactor to room temperature and release the pressure, add 3 parts of polyethylene polyamine, heat up to 120°C, and react for 5 hours under normal pressure, so that polyethylene polyamine and polyisobutylene succinic anhydride undergo condensation reaction;

[0028] (3) Heating up to 155° C. to distill and recover the solvent under normal pressure. After the distillation is completed, the temperature is raised to 205° C. to distill and recover the unreacted reactants. The product obtained is polyolefin succinimide, the primary product of the emulsifier;

[0029] (4) Uniformly mix the primary product of the emulsifier with 3 parts of polyethylene glycol and 3 part...

Embodiment 3

[0031] (1) Dissolve 10 parts of polyisobutylene (molecular weight 1000-1200) and 3 parts of maleic anhydride in 18 parts of solvent xylene, add to the reaction kettle, heat to 160 °C, pressurize to 0.5 MPa with nitrogen, Reaction 9h, obtain polyisobutylene succinic anhydride;

[0032] (2) Reduce the temperature in the reactor to room temperature and release the pressure, add 5 parts of polyethylene polyamine, raise the temperature to 130°C, and react for 4 hours under normal pressure, so that polyethylene polyamine and polyisobutylene succinic anhydride undergo condensation reaction;

[0033] (3) Heating up to 155° C. to distill and recover the solvent under normal pressure. After the distillation is completed, the temperature is raised to 205° C. to distill and recover the unreacted reactants. The product obtained is polyolefin succinimide, the primary product of the emulsifier;

[0034] (4) Evenly mix the primary product of the emulsifier with 2 parts of polyethylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com