Copolymer and its application and oil-based drilling fluid stabilizer and its preparation method and oil-based drilling fluid

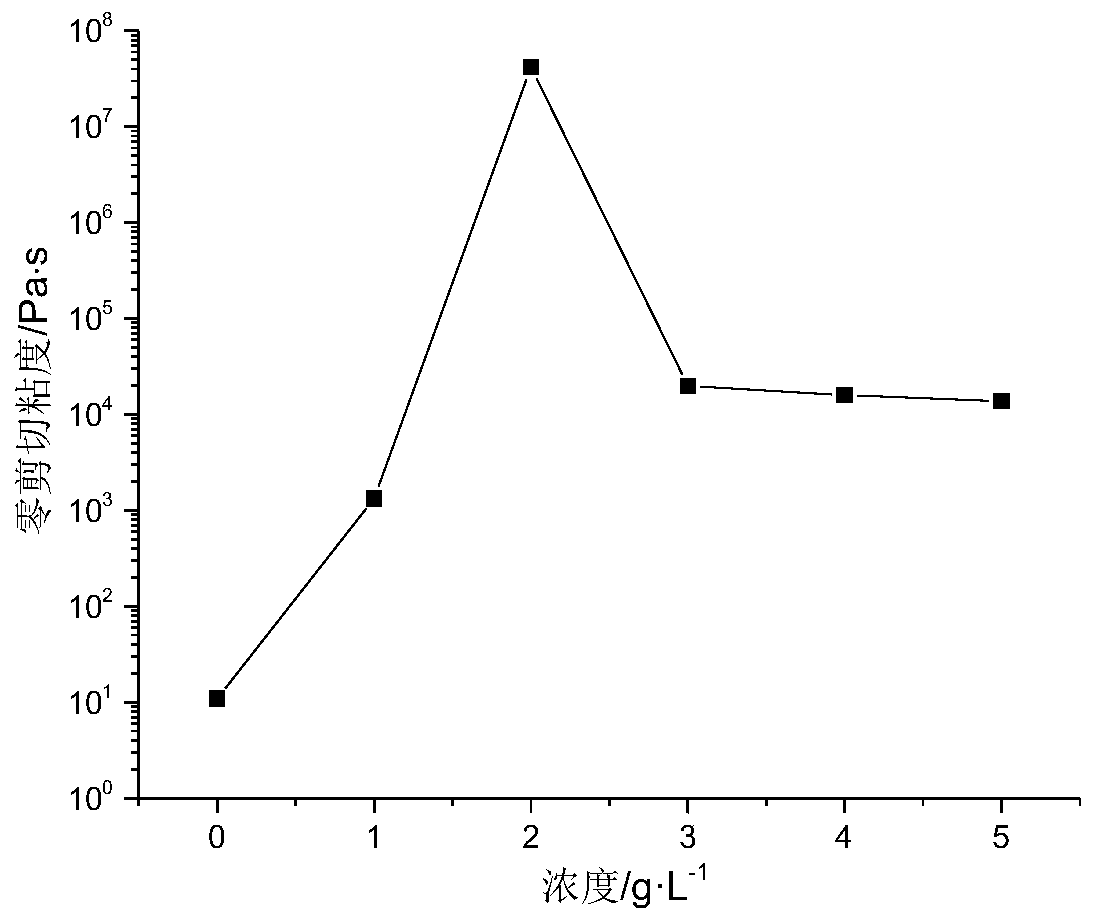

A technology of oil-based drilling fluid and copolymer, which is applied in the field of oil-based drilling fluid, can solve the problems of poor stability of oil-based drilling fluid, etc., and achieve the effects of cleaning the wellbore, improving the stability of the settlement, and improving the stability of the emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The fourth aspect of the present invention provides a kind of preparation method of oil-based drilling fluid stabilizer, wherein, the preparation method comprises:

[0027] (1) fatty acid and fatty acid polymer are mixed and dissolved;

[0028] (2) performing the first reaction at 150-200° C. after mixing the mixture obtained in step (1) with the polyamine compound;

[0029] (3) Cool the reaction product obtained in step (2) to 20-35°C and mix it with diacid and / or dianhydride, and then carry out the second reaction at 150-200°C;

[0030] And optionally, after cooling the reaction product of the second reaction to 50-70° C., it is mixed with unsaturated fatty acid for dilution.

[0031] In the present invention, preferably, the molar ratio of fatty acid, fatty acid polymer, polyamine compound, diacid and / or dianhydride is 1:1-3:0.1-0.5::0.03-0.1, preferably 1:2 -2.5: 0.2-0.4: 0.03-0.05.

[0032] In the present invention, in order to further improve the performance ef...

Embodiment 1

[0044] (1) Mix oleic acid and dimerized fatty acid (purchased from Shanghai Zhipu Chemical Co., Ltd., trade mark is DMA-1080) to fully dissolve the dimerized fatty acid;

[0045](2) Mix the mixture obtained in step (1) with tetraethylenepentamine, react for 6 hours under the condition of an oil bath at 170°C, and remove the moisture generated by the reaction during the reaction;

[0046] (3) After the above reaction is completed, cool the system to 20°C, add adipic acid, raise the temperature to 170°C at a rate of 10°C / min, and react for 4 hours.

[0047] (4) After the reaction is finished, the reaction product is cooled to 60° C., and the same volume of oleic acid as the product is added for dilution.

[0048] Among them, the molar ratio of oleic acid, dimer fatty acid, tetraethylenepentamine and adipic acid is 1:2.5:0.3:0.05. Stabilizer A1 was obtained.

Embodiment 2

[0050] (1) Mix linolenic acid and dimerized fatty acid (purchased from Shanghai Zhipu Chemical Co., Ltd., brand name is DMA-1080) to fully dissolve the dimerized fatty acid;

[0051] (2) Mix the mixture obtained in step (1) with triethylenediamine, and react for 8 hours under the condition of an oil bath at 150° C., and remove the moisture generated by the reaction during the reaction;

[0052] (3) After the above reaction is completed, cool the system to 30°C, add maleic anhydride, raise the temperature to 150°C at a rate of 15°C / min, and react for 3 hours.

[0053] (4) After the reaction is finished, the reaction product is cooled to 60° C., and the same volume of oleic acid as the product is added for dilution.

[0054] Among them, the molar ratio of oleic acid, dimer fatty acid, triethylenediamine and maleic anhydride is 1:2:0.2:0.03. Stabilizer A2 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com