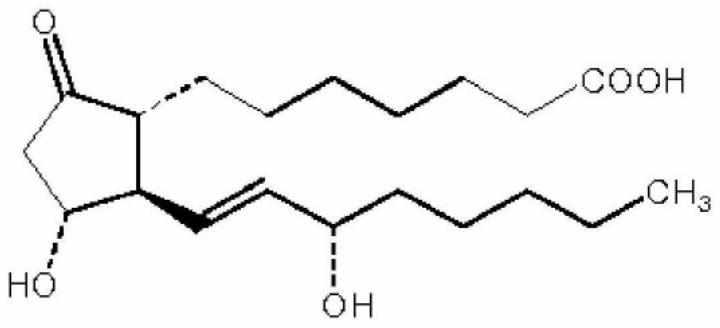

A kind of prostaglandin-containing fat emulsion and preparation method thereof

A prostaglandin and fat emulsion technology, which is applied in the field of medicine, can solve the problems of easy decomposition of prostaglandins, increase the difficulty of distribution, clinical management and use, and achieve the effects of improving drug quality, ensuring emulsification stability, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

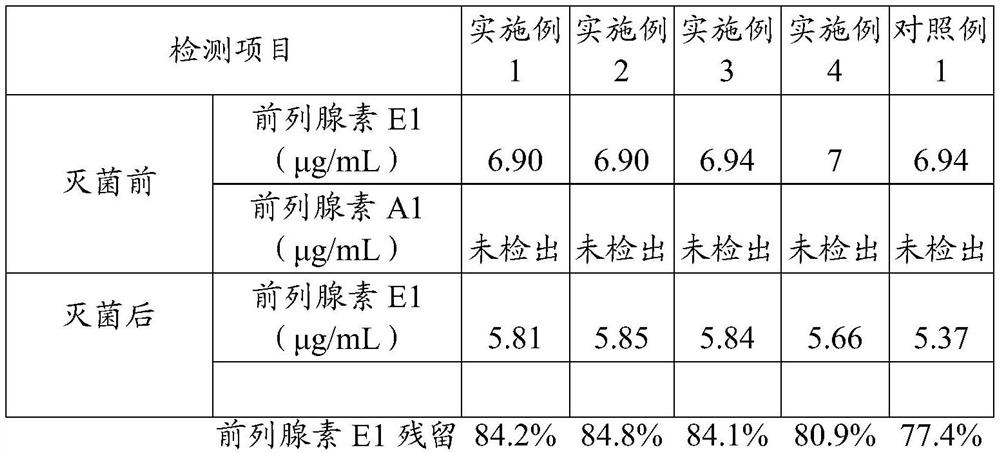

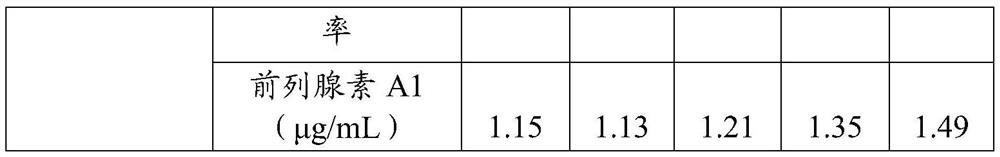

Embodiment 1

[0077] Take 100g of soybean oil, heat it to 80°C, add 7mg of prostaglandin E1, stir to dissolve, then add 17.86g of lecithin (PC) and 36mg of phosphatidylglycerol (PG) (PC:PG is about 99.8:0.2), stir dispersed to obtain an oil phase;

[0078]Take 22.1g of glycerin for injection and add it to an appropriate amount of water for injection, stir and dissolve, then heat to 80°C to prepare the water phase;

[0079] Mix and stir the oil phase and the water phase, add water for injection to 1000ml, enter a high-pressure homogenizer for homogenization treatment, the homogenization pressure is 750bar / 100bar, homogenize 4 times, and the homogenization temperature is 50°C to obtain a uniform emulsion. Use hydrochloric acid or sodium hydroxide to adjust its pH value to 5.5, fill the emulsion into an ampoule bottle, fill it with nitrogen and seal it, and keep it in a rotary sterilizer at 121°C for 8 minutes to obtain a fat emulsion containing prostaglandin

Embodiment 2

[0081] Take 100g of soybean oil, heat it to 80°C, add 7mg of prostaglandin E1, stir to dissolve it, then add 17.87g of lecithin and 27mg of phosphatidylglycerol (PC:PG about 99.85:0.15), stir and disperse to obtain an oil phase ;

[0082] Take 22.1g of glycerin for injection and add it to an appropriate amount of water for injection, stir and dissolve, then heat to 80°C to prepare the water phase;

[0083] Mix and stir the oil phase and the water phase, add water for injection to 1000ml, enter a high-pressure homogenizer for homogenization treatment, the homogenization pressure is 750bar / 100bar, homogenize 4 times, and the homogenization temperature is 50°C to obtain a uniform emulsion. Adjust the pH to 5.5 using hydrochloric acid or sodium hydroxide. The emulsion was filled in ampoules, filled with nitrogen and sealed, and kept in a rotary sterilizer at 121° C. for 8 minutes to obtain a prostaglandin-containing fat emulsion.

Embodiment 3

[0085] Take 100g of soybean oil, heat it to 80°C, add 7mg of prostaglandin E1, stir to dissolve it, then add 17.85g of lecithin and 45mg of phosphatidylglycerol (PC:PG about 99.75:0.25), stir and disperse to obtain the oil phase ;

[0086] Take 22.1g of glycerin for injection and add it to an appropriate amount of water for injection, stir and dissolve, then heat to 80°C to prepare the water phase;

[0087] Mix and stir the oil phase and the water phase, add water for injection to 1000ml, enter a high-pressure homogenizer for homogenization treatment, the homogenization pressure is 750bar / 100bar, homogenize 4 times, and the homogenization temperature is 50°C to obtain a uniform emulsion. Use hydrochloric acid or sodium hydroxide to adjust the pH to 5.5, fill the emulsion into an ampoule, fill it with nitrogen and seal it, and keep it in a rotary sterilizer at 121°C for 8 minutes to obtain a prostaglandin-containing fat emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com