High-temperature-resistant oil-base drilling fluid emulsifier and preparation method thereof

An oil-based drilling fluid, high temperature resistance technology, applied in the field of oil drilling, can solve the problems of large gap, poor high temperature emulsification effect, large addition amount, etc., to achieve strong high temperature resistance ability, ensure emulsion stability, and good emulsification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

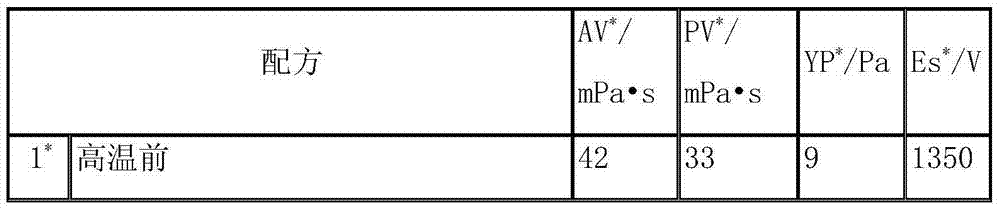

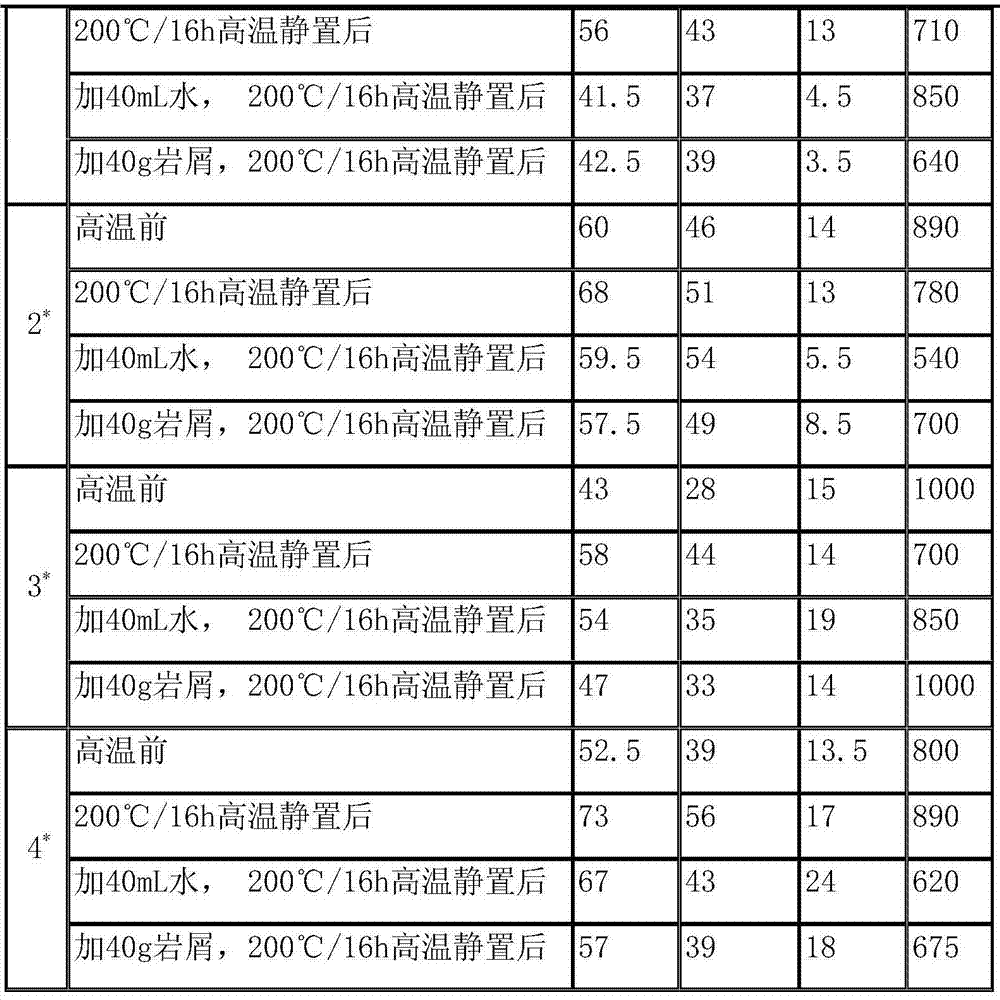

Embodiment 1

[0018] (1) Dissolve 9 parts of polyisobutylene (molecular weight 1000-1200) and 2 parts of maleic anhydride in 22 parts of solvent xylene, add to the reaction kettle, heat to 150°C, pressurize to 0.6MPa with nitrogen, Reaction 8h, obtain polyisobutylene succinic anhydride;

[0019] (2) Reduce the temperature in the reactor to room temperature and release the pressure, add 4 parts of polyethylene polyamine, raise the temperature to 110°C, and react for 6 hours under normal pressure, so that polyethylene polyamine and polyisobutylene succinic anhydride undergo condensation reaction;

[0020] (3) Heating up to 150° C. to recover the solvent by distillation under normal pressure. After the distillation is completed, the temperature is raised to 200° C. to recover unreacted reactants by distillation, and the obtained product is polyolefin succinimide, the primary product of the emulsifier;

[0021] (4) Evenly mix the primary product of the emulsifier with 4 parts of polyethylene gl...

Embodiment 2

[0023] (1) Dissolve 12 parts of polyisobutylene (molecular weight 1000-1200) and 1 part of maleic anhydride in 20 parts of solvent xylene, add to the reaction kettle, heat to 160 ° C, pressurize to 0.7 MPa with nitrogen, Reaction 10h, obtain polyisobutylene succinic anhydride;

[0024] (2) Reduce the temperature in the reactor to room temperature and release the pressure, add 3 parts of polyethylene polyamine, heat up to 120°C, and react for 5 hours under normal pressure, so that polyethylene polyamine and polyisobutylene succinic anhydride undergo condensation reaction;

[0025] (3) Heating up to 155° C. to distill and recover the solvent under normal pressure. After the distillation is completed, the temperature is raised to 205° C. to distill and recover the unreacted reactants. The product obtained is polyolefin succinimide, the primary product of the emulsifier;

[0026] (4) Uniformly mix the primary product of the emulsifier with 3 parts of polyethylene glycol and 3 part...

Embodiment 3

[0028] (1) Dissolve 10 parts of polyisobutylene (molecular weight 1000-1200) and 3 parts of maleic anhydride in 18 parts of solvent xylene, add to the reaction kettle, heat to 160 °C, pressurize to 0.5 MPa with nitrogen, Reaction 9h, obtain polyisobutylene succinic anhydride;

[0029] (2) Reduce the temperature in the reactor to room temperature and release the pressure, add 5 parts of polyethylene polyamine, raise the temperature to 130°C, and react for 4 hours under normal pressure, so that polyethylene polyamine and polyisobutylene succinic anhydride undergo condensation reaction;

[0030] (3) Heating up to 155° C. to distill and recover the solvent under normal pressure. After the distillation is completed, the temperature is raised to 205° C. to distill and recover the unreacted reactants. The product obtained is polyolefin succinimide, the primary product of the emulsifier;

[0031] (4) Evenly mix the primary product of the emulsifier with 2 parts of polyethylene glycol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com