Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Guaranteed anti-deformation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

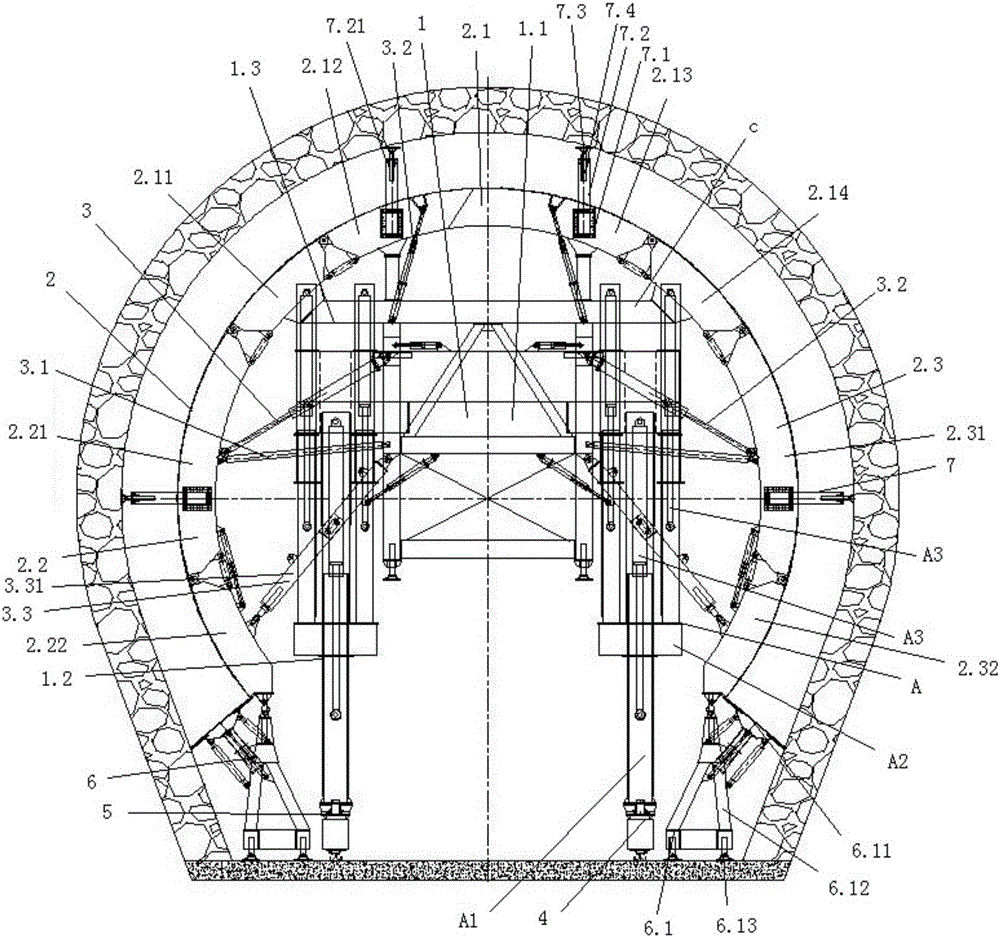

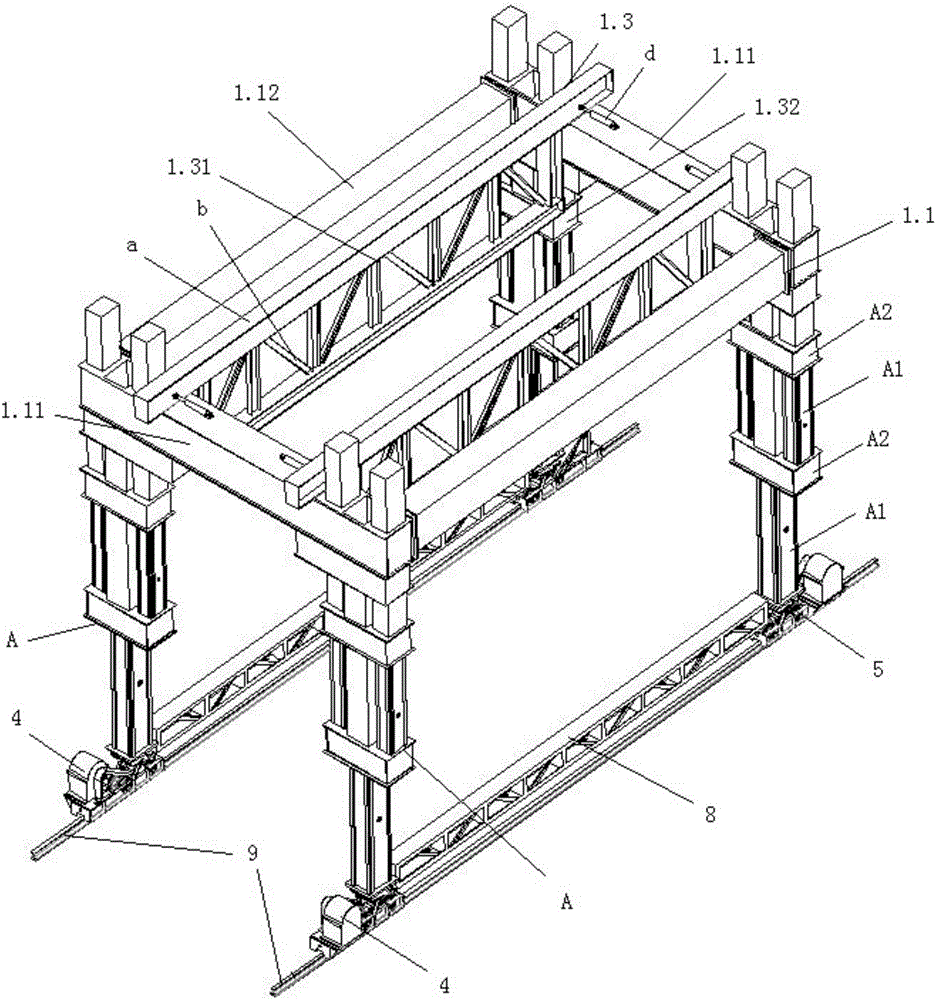

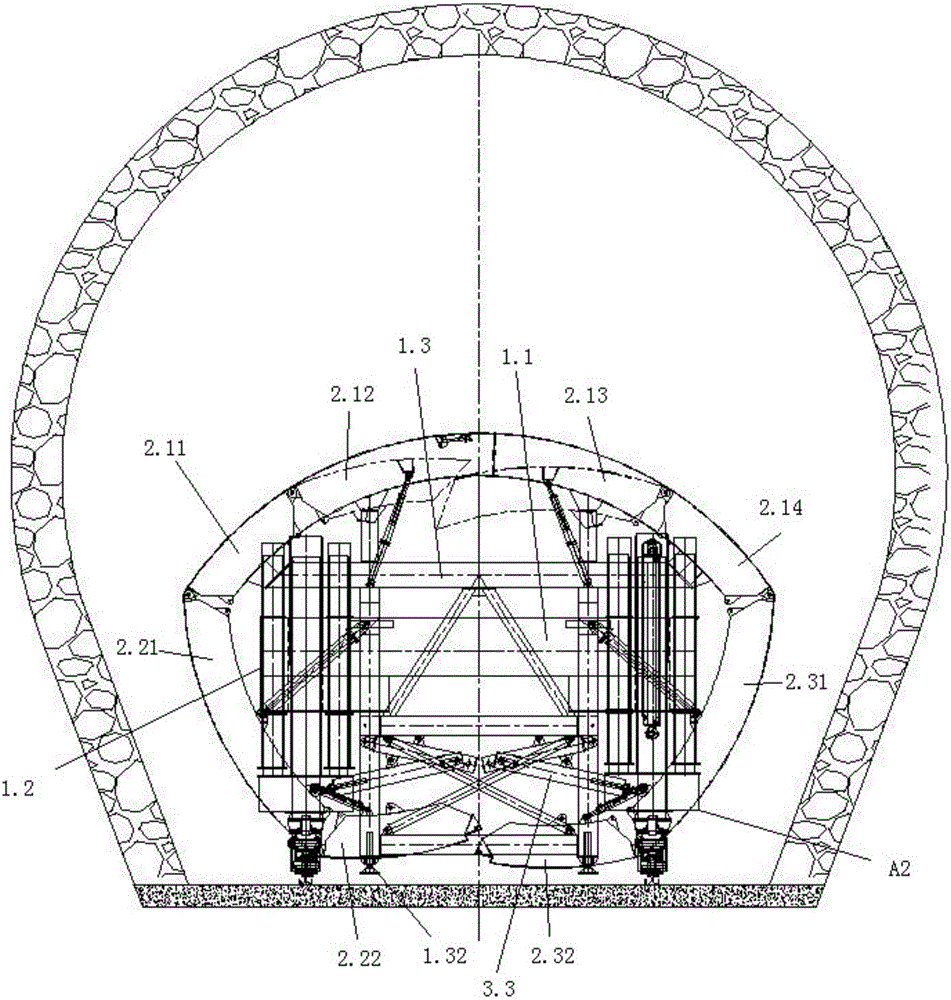

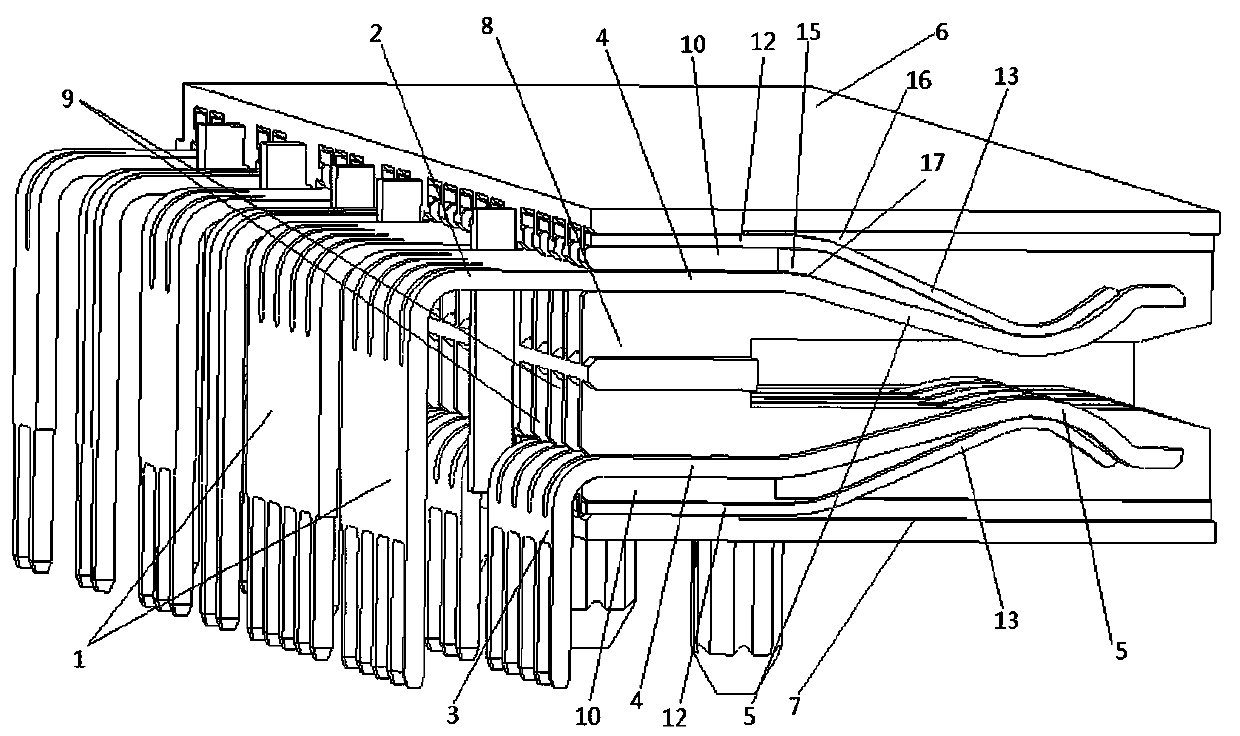

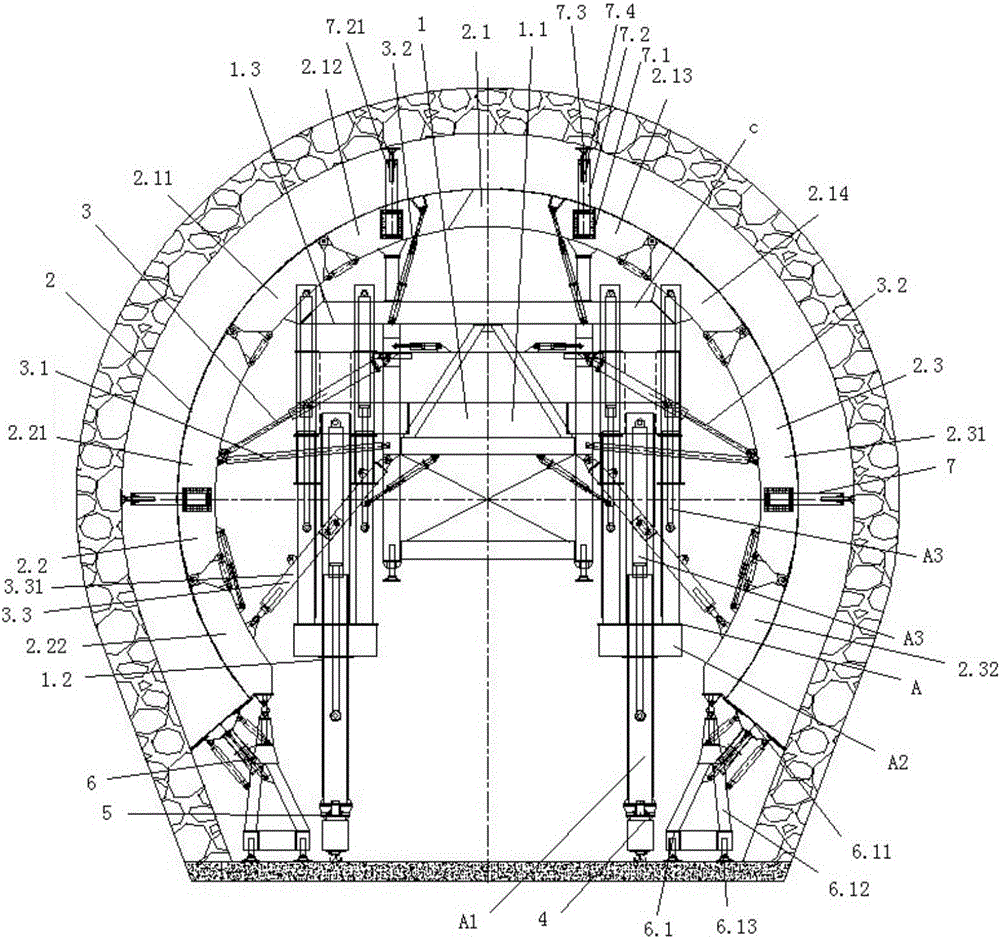

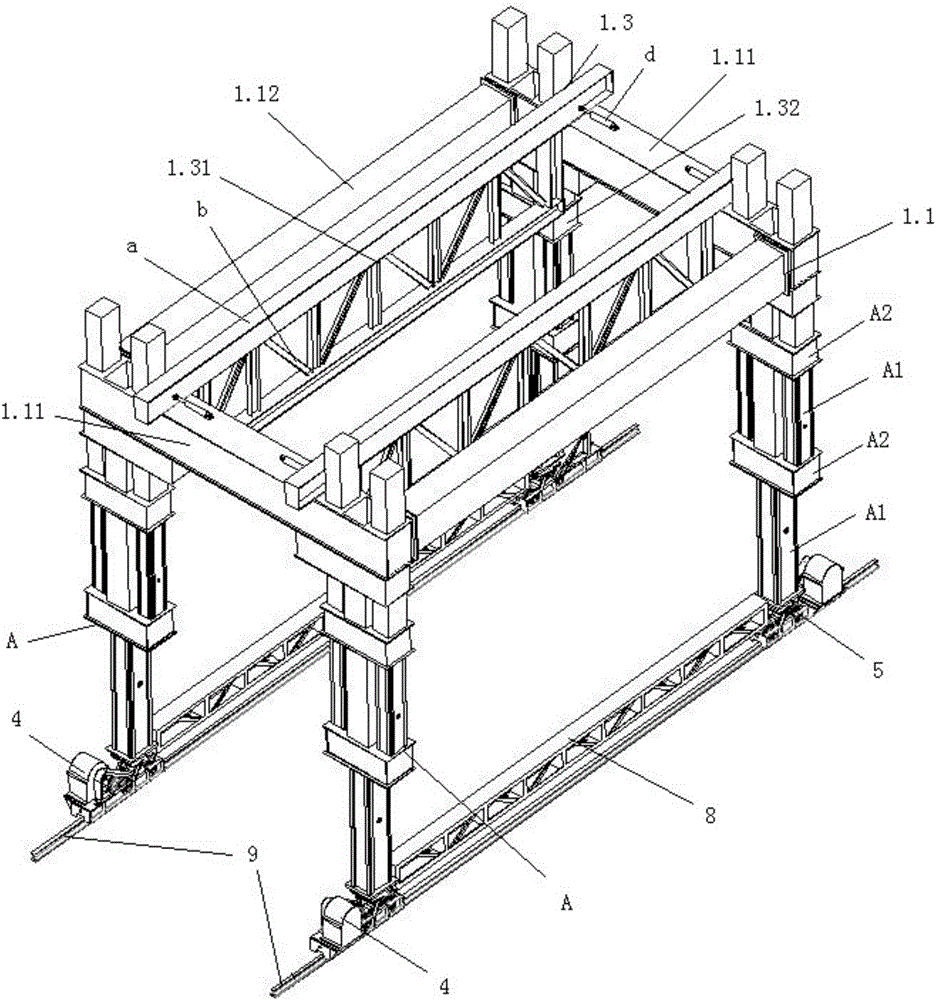

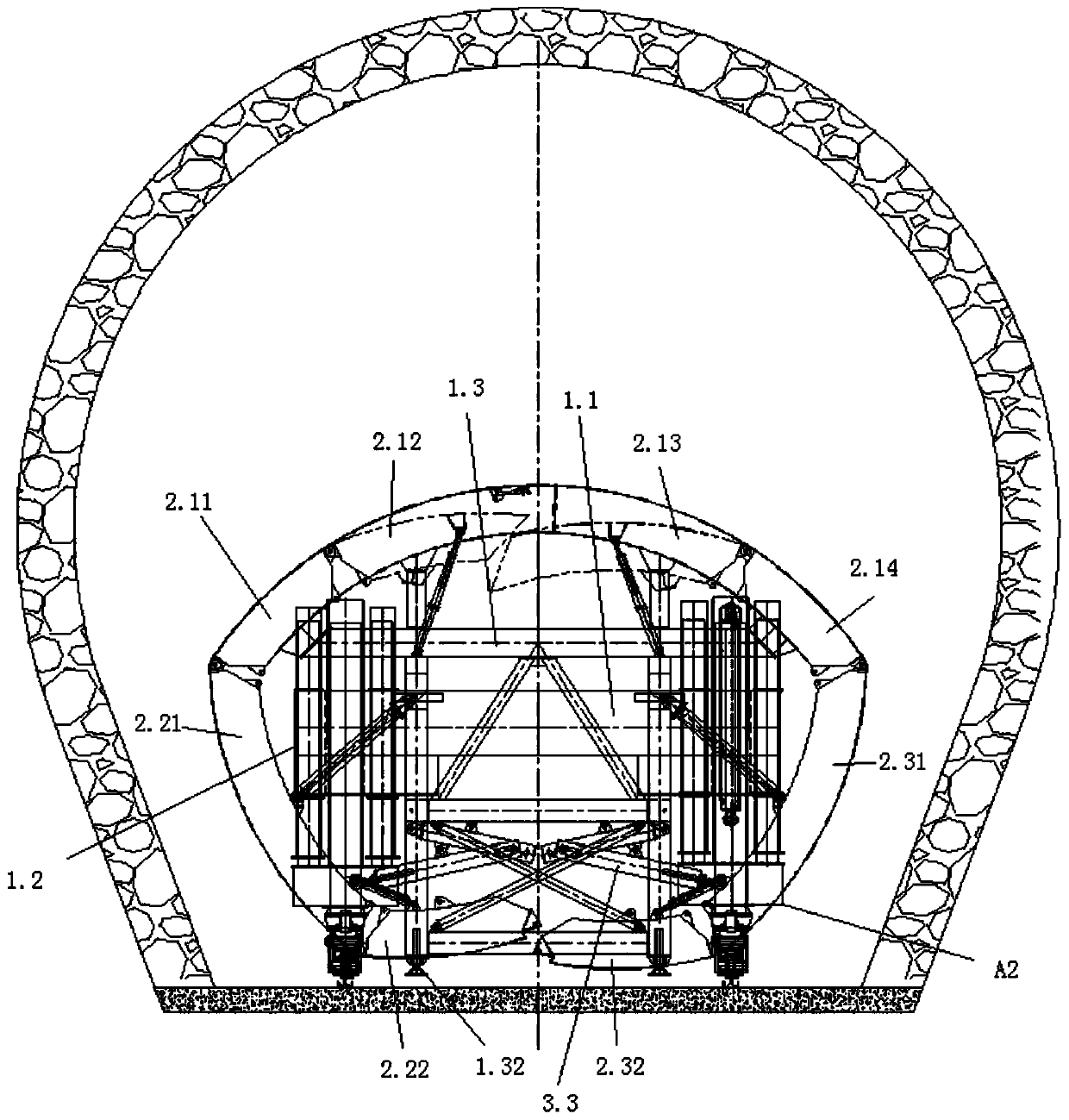

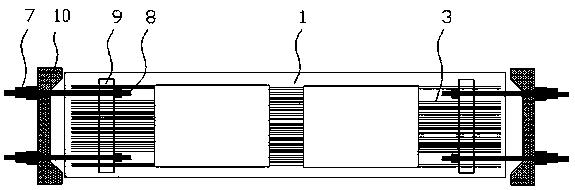

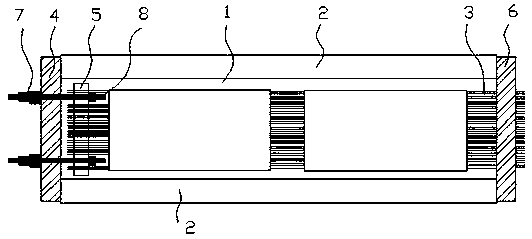

Section-variable tunnel-crossing lining trolley

ActiveCN106593472AEnsure normal walkingBig liftUnderground chambersTunnel liningHydraulic cylinderEngineering

The invention provides a section-variable tunnel-crossing lining trolley which comprises a portal system, a template system, a connecting part and a walking mechanism, wherein the portal system comprises a frame part, a jacking mechanism and a bracket part; the jacking mechanism comprises multiple sets of jacking single pieces; each of the jacking single pieces comprises a multi-level jacking part; the bracket part comprises a truss girder and an adjusting support frame for a walking mechanism; the template system comprises a top template, a left template and a right template; and the connecting part comprises a support jack and a hydraulic cylinder. The section-variable tunnel-crossing lining trolley provided by the invention has the effects that the whole structure is simple; the assembling is convenient; the jacking mechanism is in a multi-level jacking mode; the trolley not only can adapt to the construction for the tunnel sections in different heights but also can achieve higher lifting volume; the trolley can meet the requirement of constructing multiple parallel tunnels by one trolley in the manner of constructing the working tunnel; due to the design of the bracket part, the lining trolley can meet the stability requirement, and meanwhile, the structure is simplified and the whole trolley can be supported.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD +1

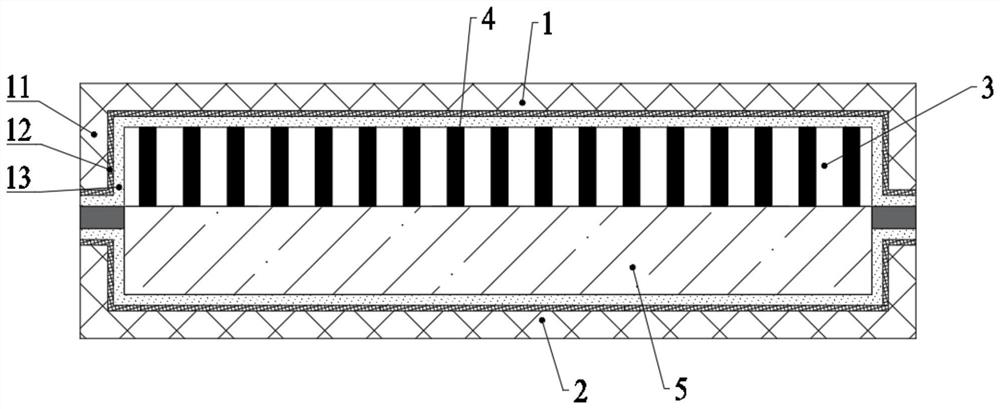

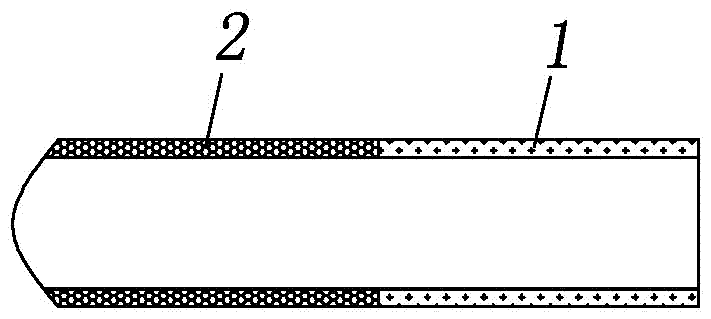

Ultrathin soaking plate with high strength and light weight

PendingCN111829380AImprove thickness uniformityImprove stabilityIndirect heat exchangersHeat exchange apparatusUltimate tensile strengthMechanical property

The invention belongs to the technical field of design and manufacturing of soaking plates, and particularly relates to an ultrathin soaking plate with high strength and light weight. The ultrathin soaking plate with high strength and light weight comprises an upper cover plate and a lower cover plate, wherein the periphery of the upper cover plate and the periphery of the lower cover plate are hermetically connected to form a sealed working medium cavity, the sealed working medium cavity is in a vacuum state and is filled with a liquid working medium, the upper cover plate and the lower coverplate are made of composite materials, the lower surface of the upper cover plate and the upper surface of the lower cover plate are concave surfaces, a plurality of support columns are arrayed in the concave surfaces, and a liquid absorbing core is arranged on the concave surface of the lower cover plate. According to the ultrathin soaking plate with high strength and light weight, the upper cover plate and the lower cover plate are both composed of three layers of composite materials, mechanical strength and deformation resistance can be guaranteed while thin plate shell materials are thinned, and mechanical properties and heat dissipation effects of the ultra-thin soaking plate in a limited space are guaranteed.

Owner:WUXI JONES TECH +3

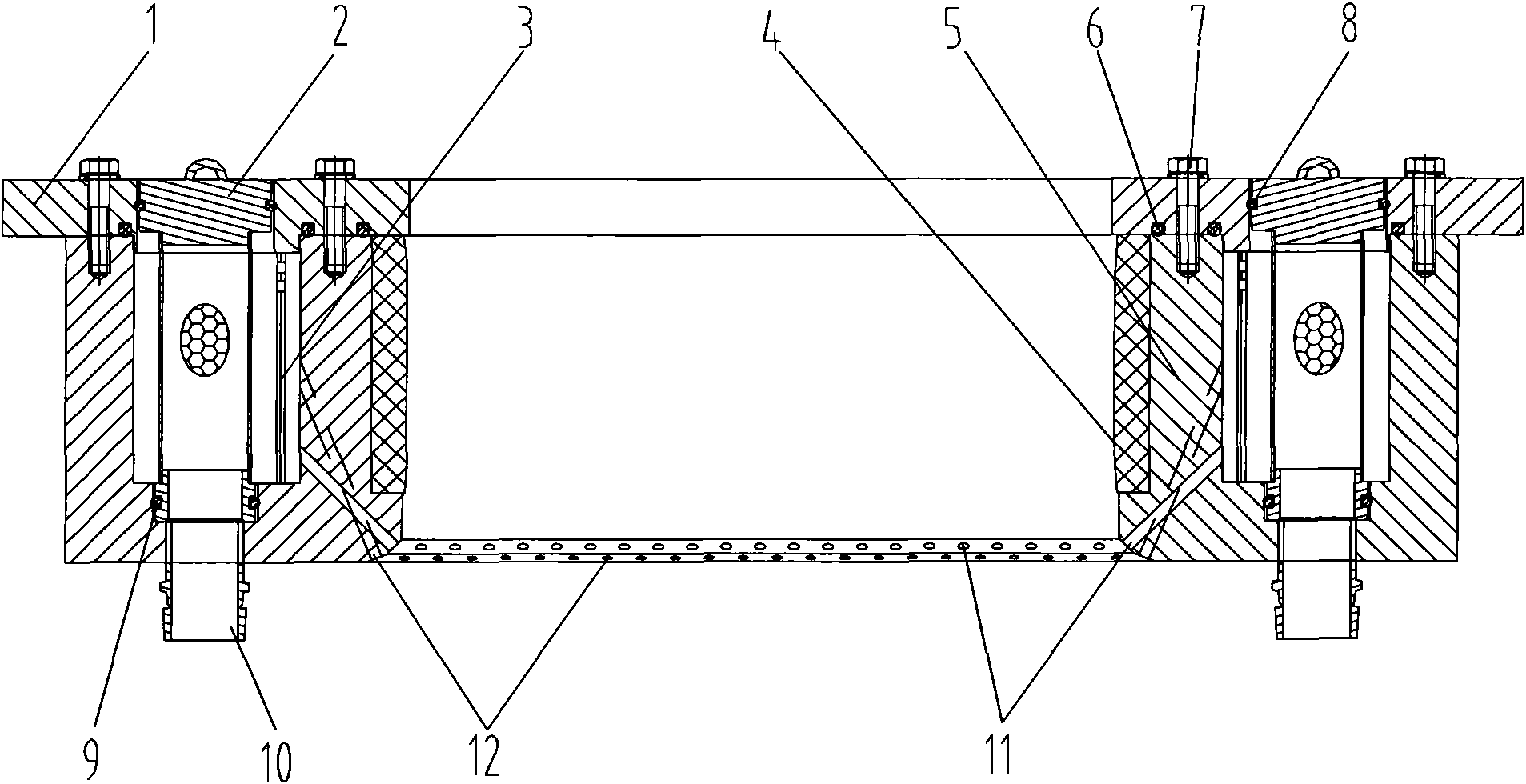

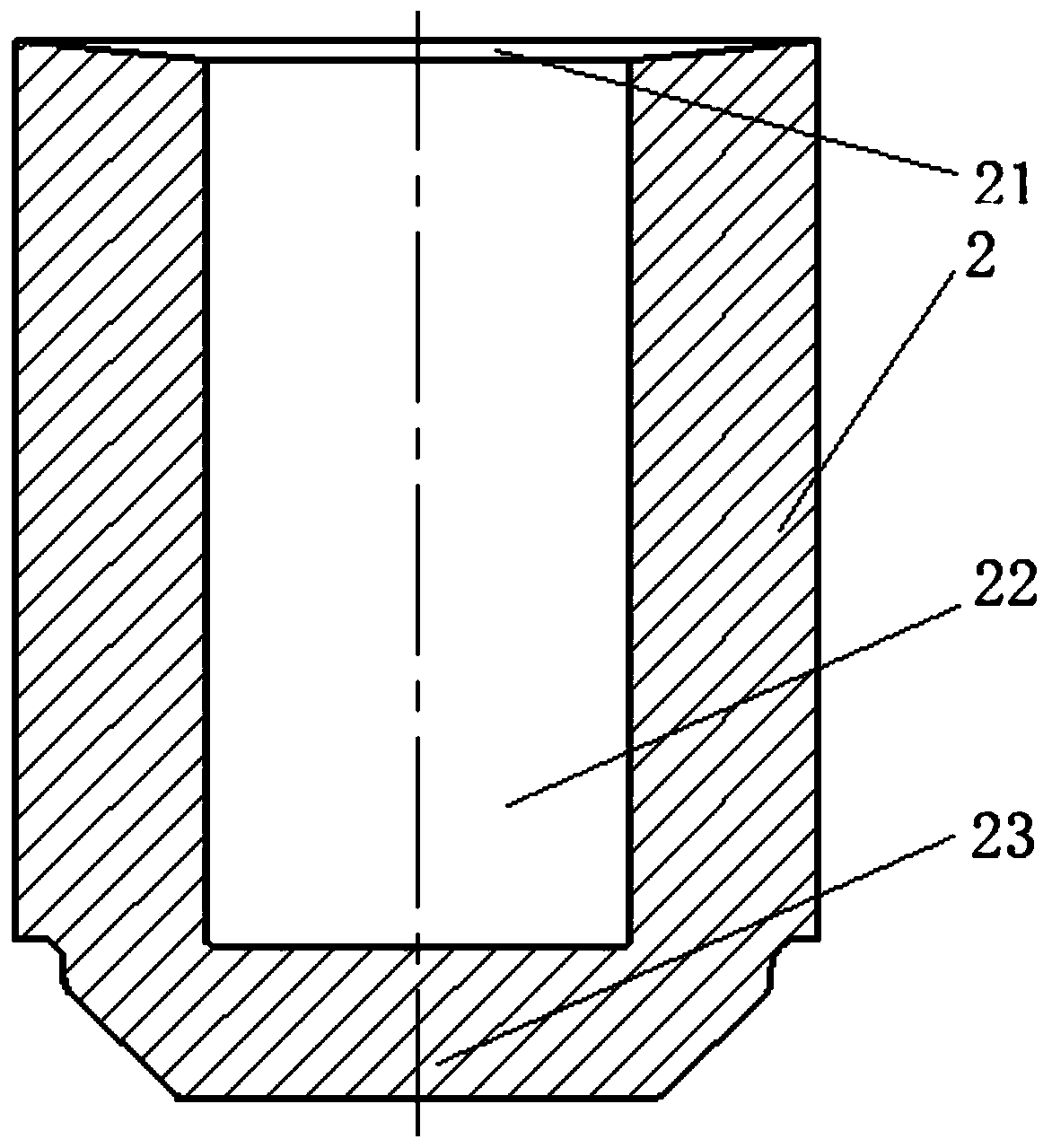

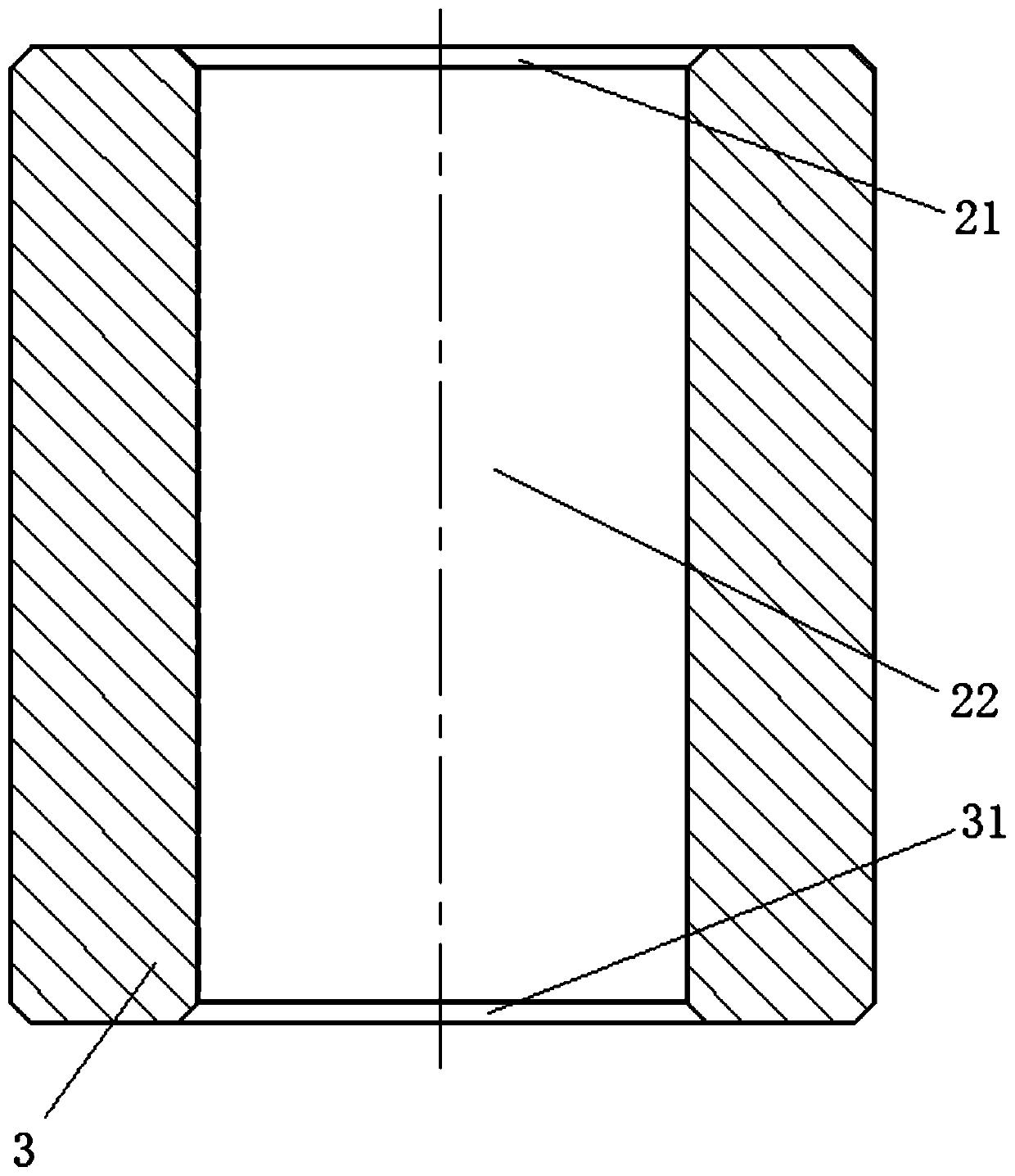

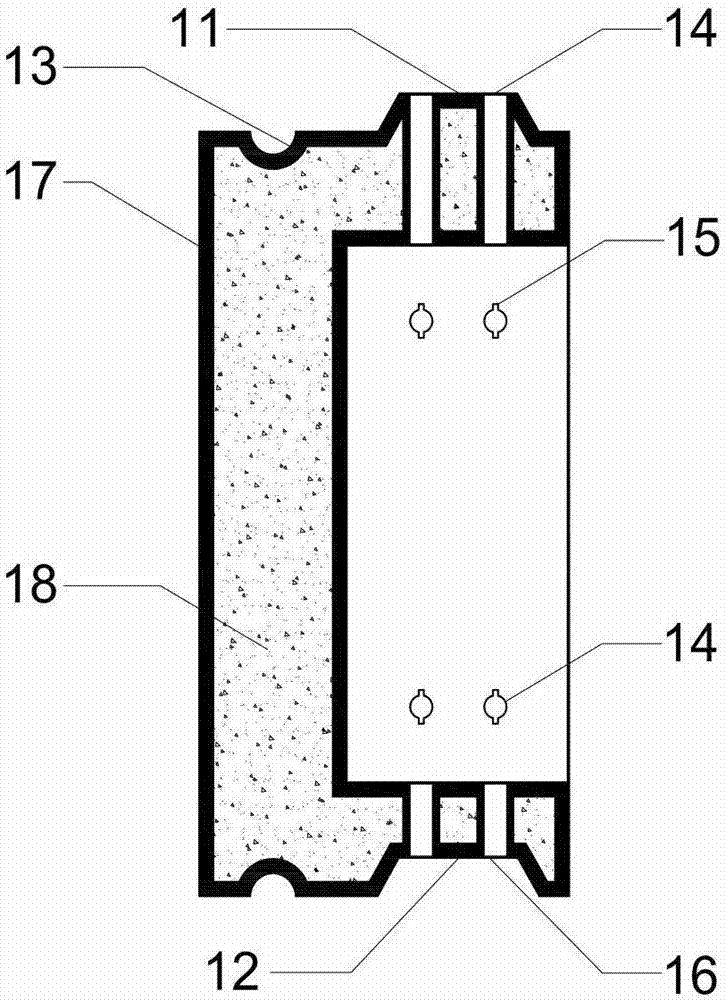

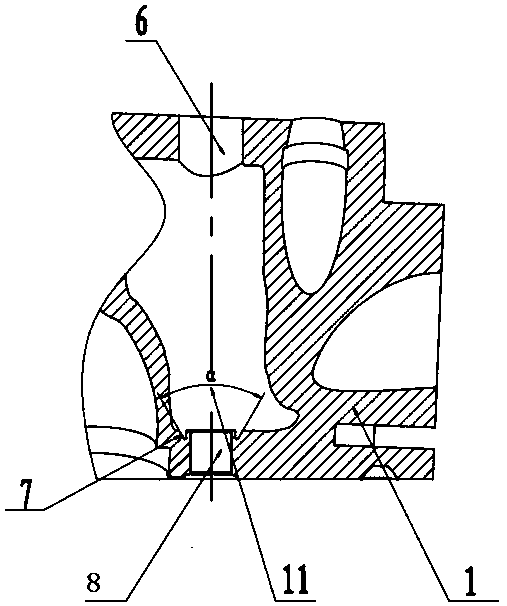

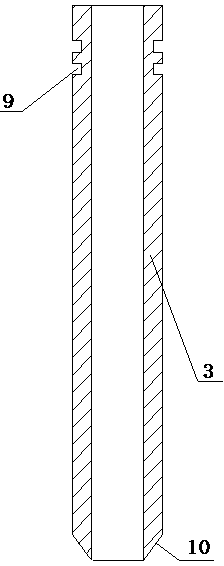

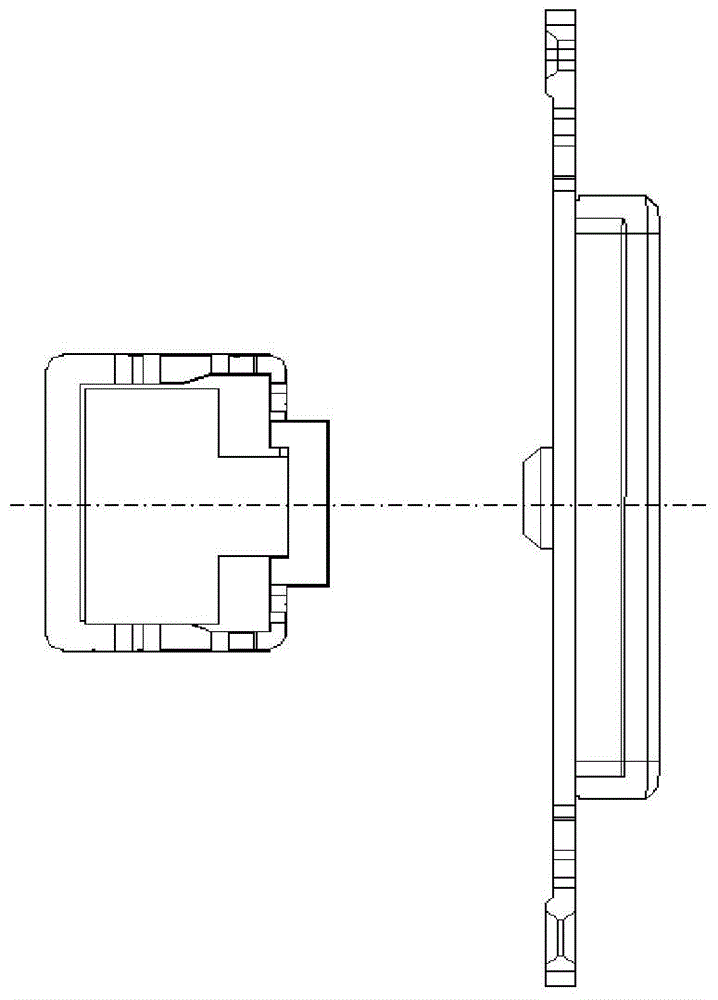

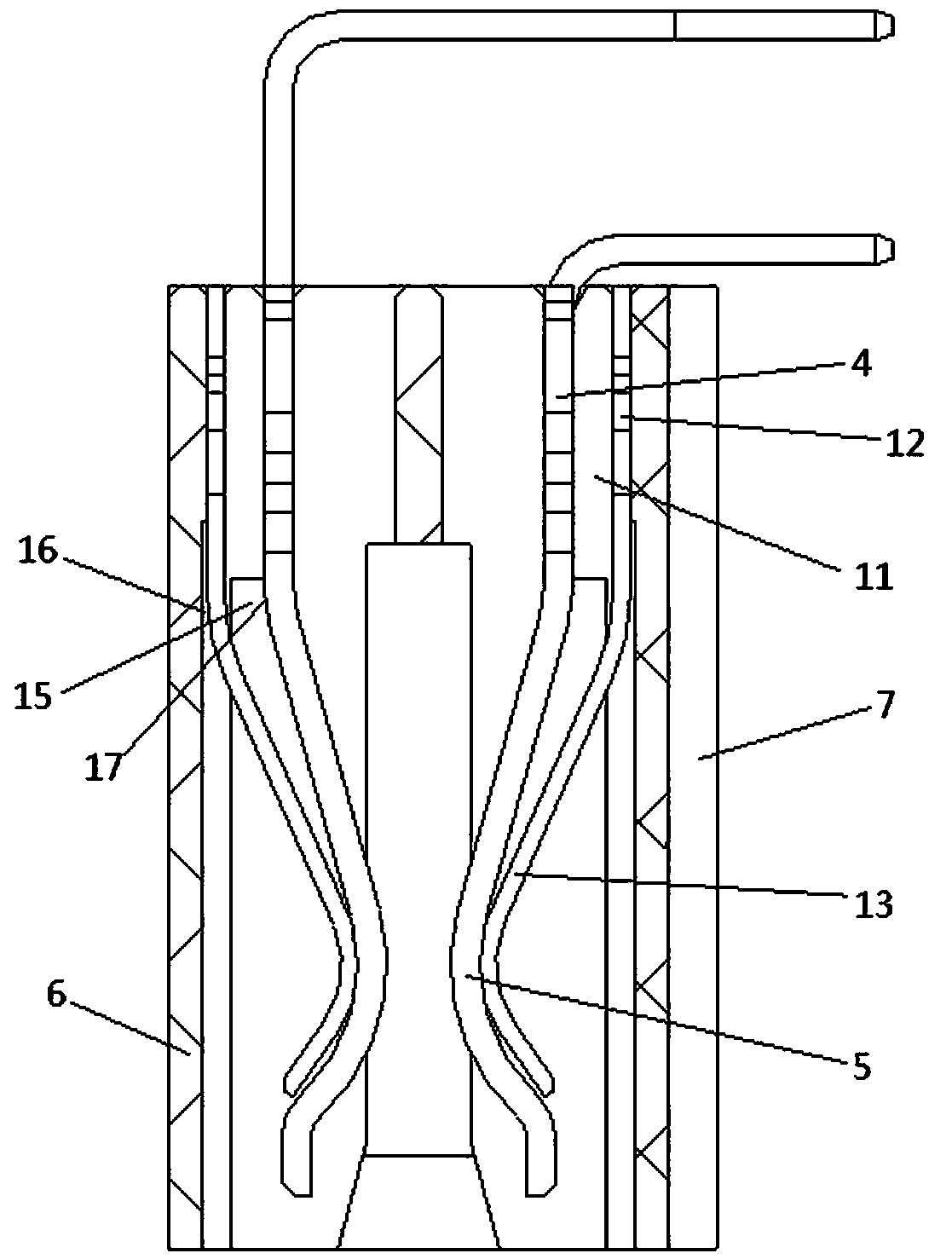

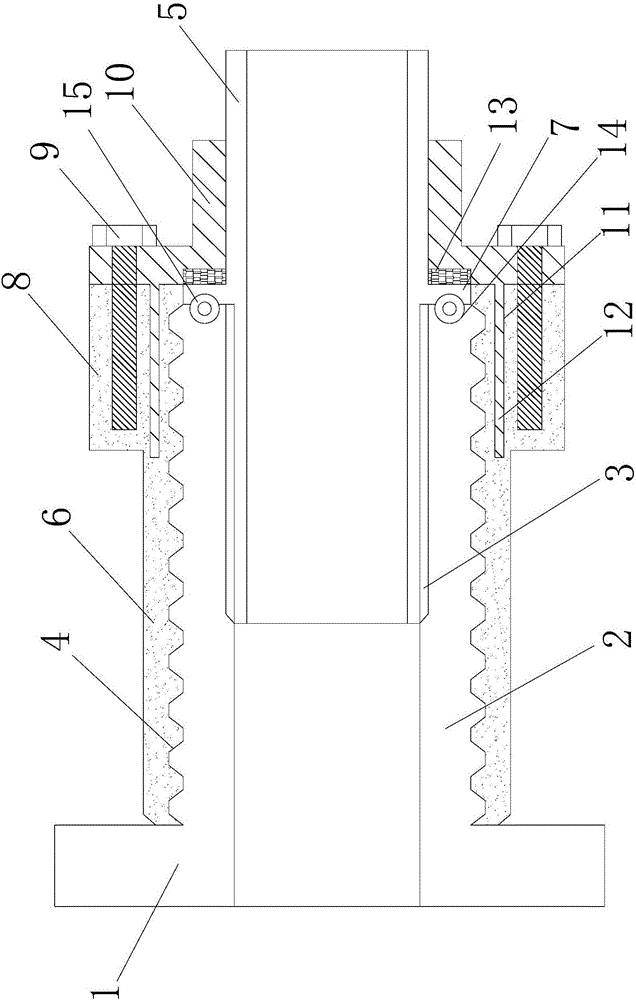

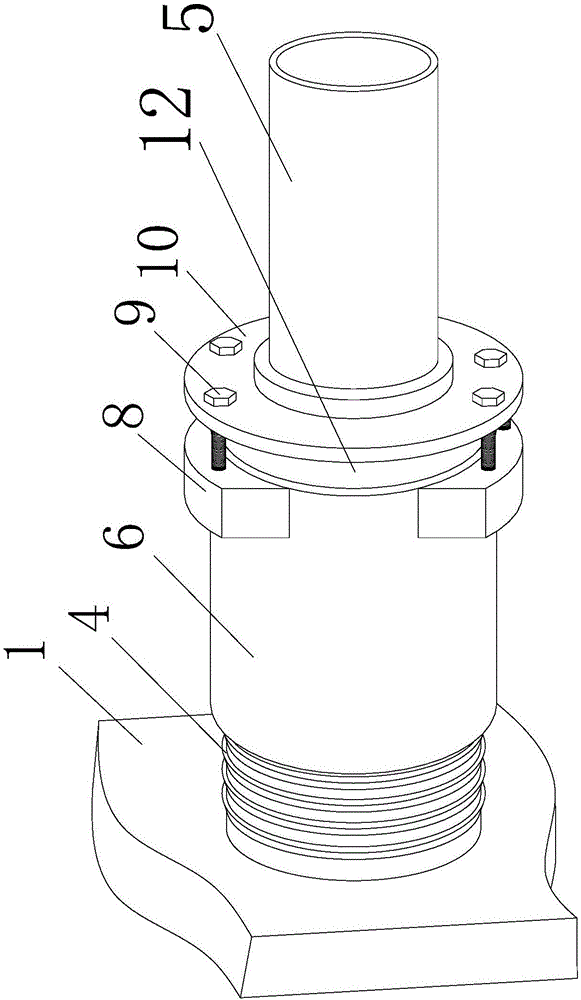

Crystallizer for semi-continuous casting of aluminum alloy

InactiveCN101829766AGuaranteed anti-deformation effectImprove deformation resistanceIngot castingGraphite

The invention relates to a crystallizer for semi-continuous casting of aluminum alloy. A graphite lining is embedded in a cavity of a body; the body is provided with a water cavity; an upper cover is connected on the body, the bottom of the upper cover is provided with a lug boss, and the lug boss on the upper cover is matched with the water cavity of the body; the water cavity of the body is provided with two groups of cooling water holes, and the two groups of cooling water holes are distributed across; a filter is arranged in the water cavity of the body, and the upper end of the filter is fixed with the upper cover; and the bottom of the body is provided with a water inlet pipe head which is communicated with the filter. After the lug boss designed on the upper cover is assembled, the upper cover extends to the interior of the water cavity, so the crystallizer has good deformation resistance, and the service life of the whole crystallizer is prolonged; the water cavity is designed with the two groups of cooling water holes, and double rows of cross cooling water cool the ingots so as to increase watering points and cooling active regions of the cooling water on the ingots; and the filter ensures that the cooling water enters the cavity after filtering, and the filter can be directly detached on the upper cover, so the cleaning operation is simple and convenient.

Owner:苏州有色金属研究院有限公司

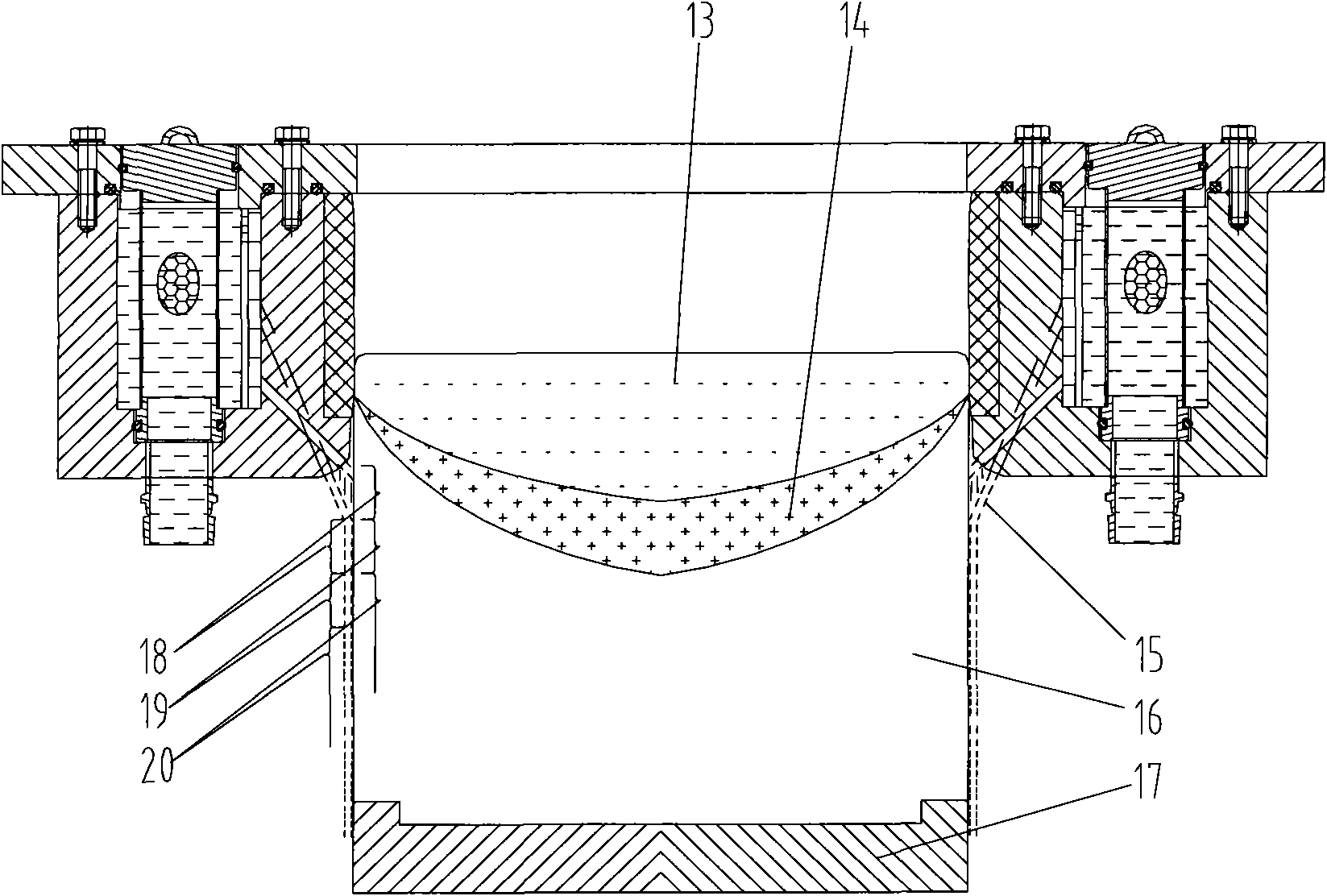

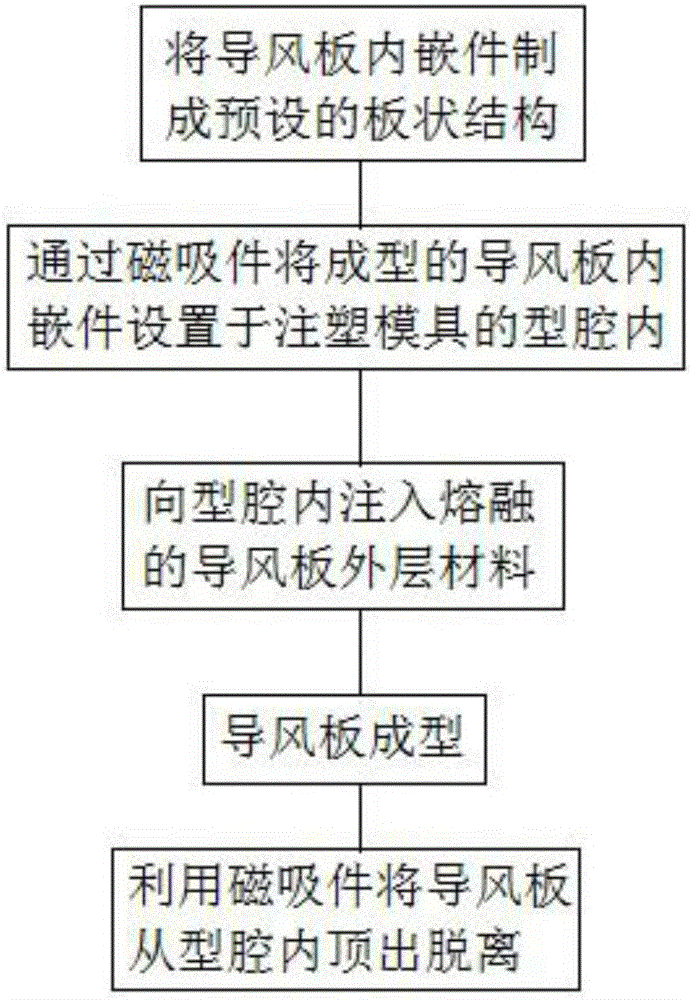

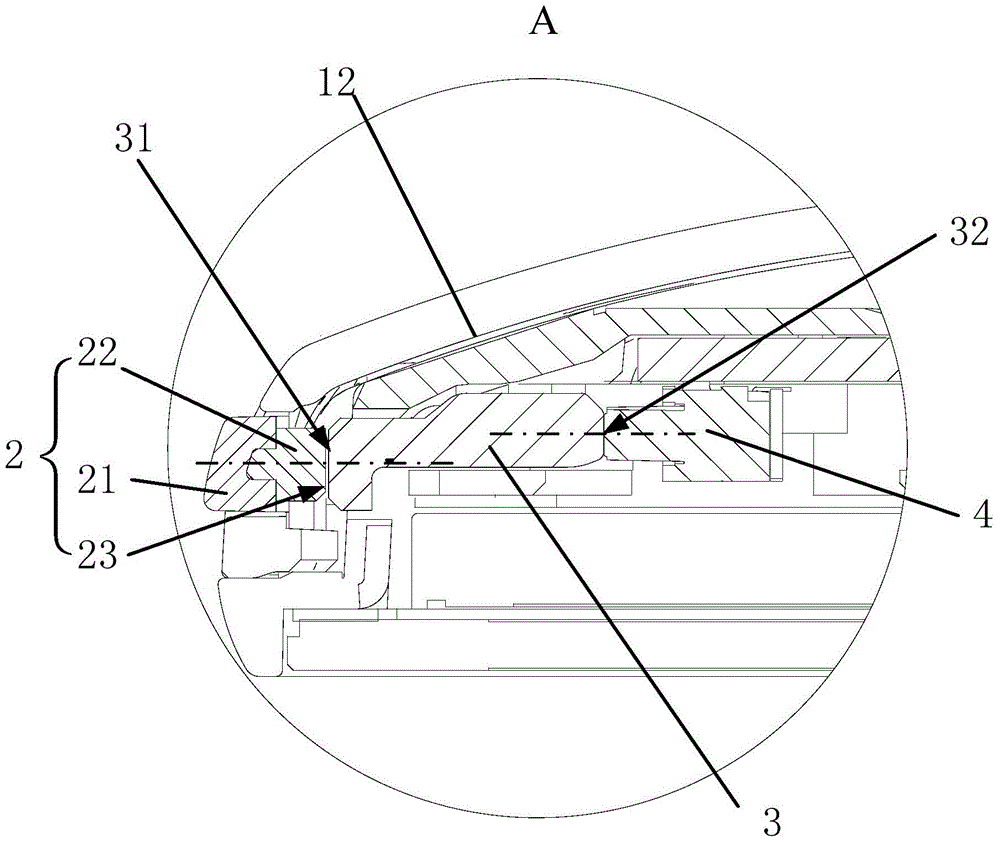

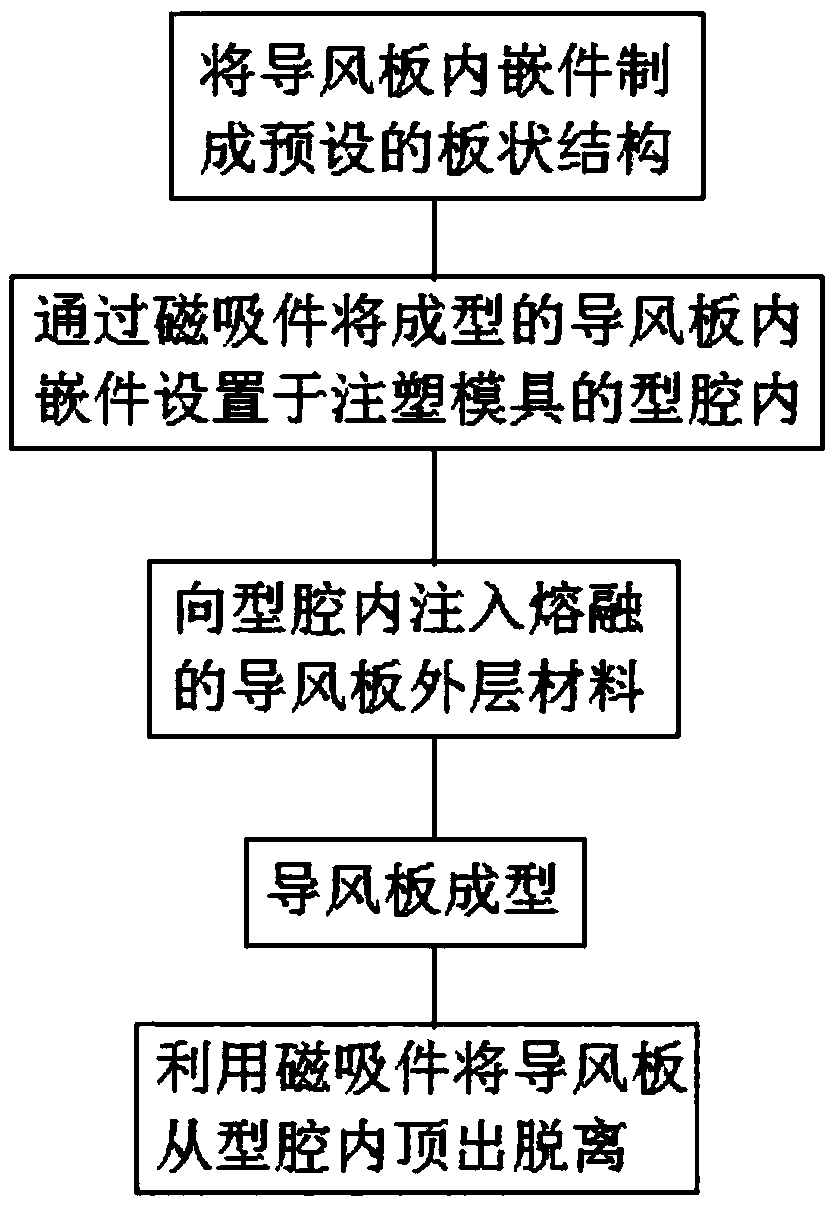

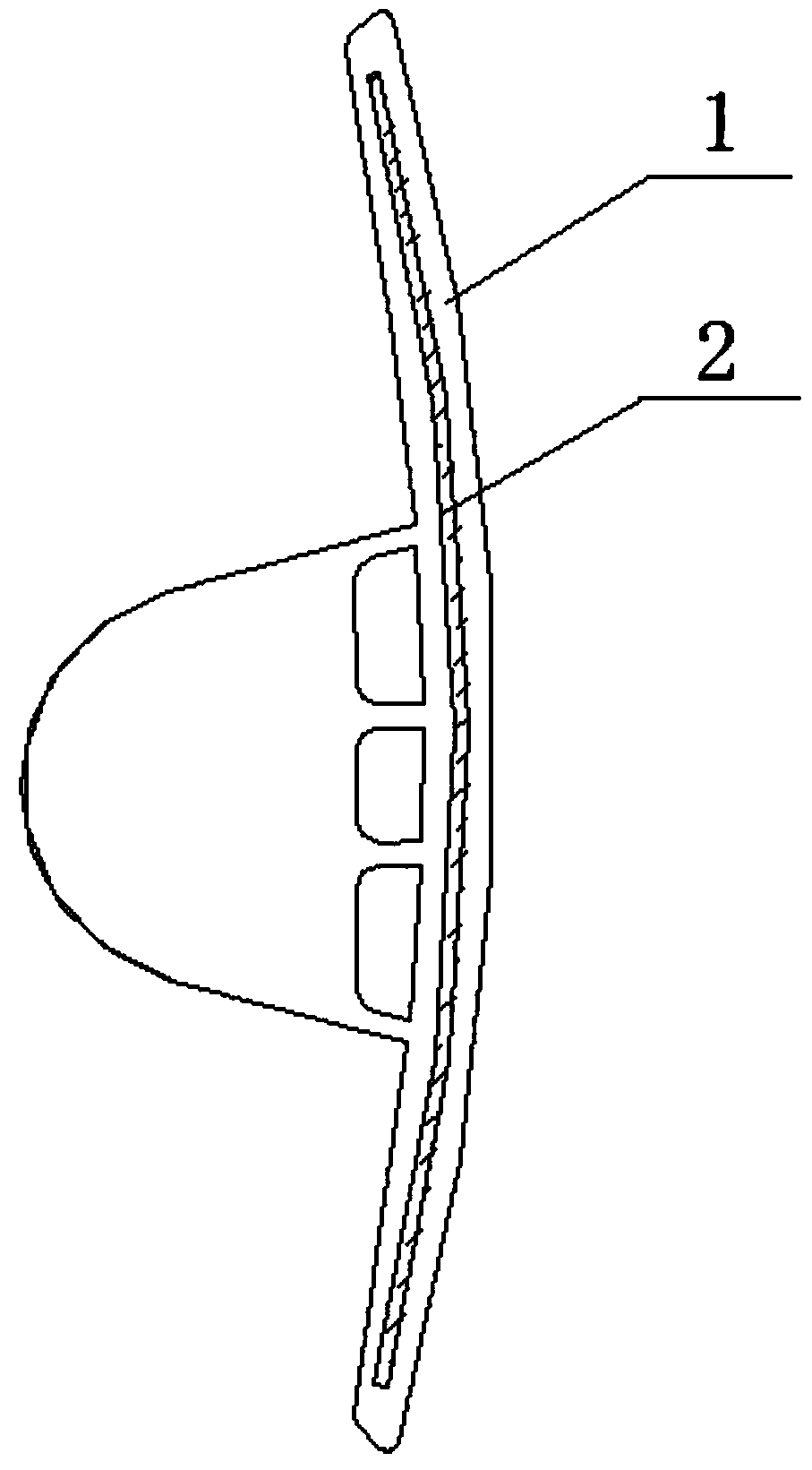

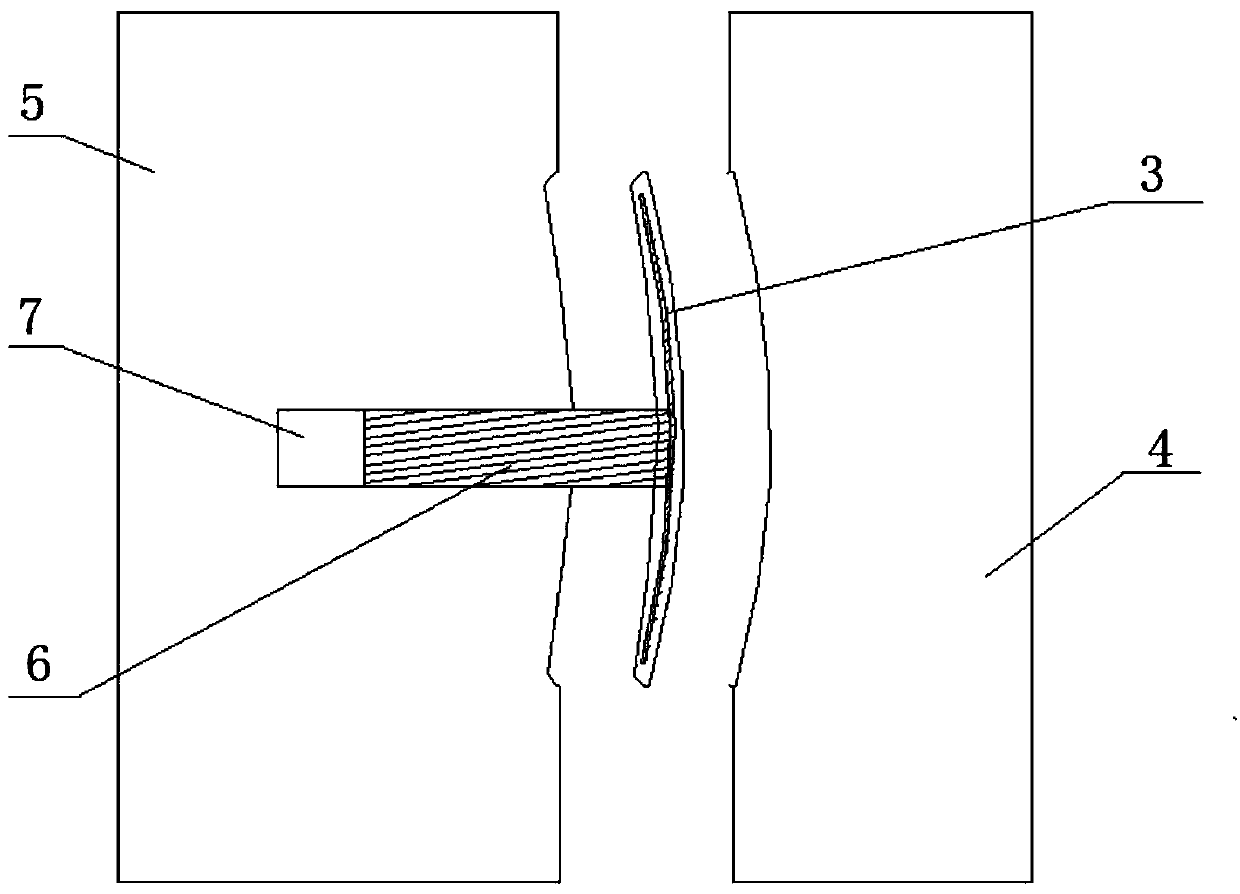

Air guide plate, injection mold and molding method

ActiveCN106003565AReduce overall thicknessSmall sizeAir-flow control membersEngineeringAluminium alloy

The invention provides an air guide plate, an injection mold and a molding method. The method comprises the following steps: a molded air guide plate insert is positioned in a molding cavity of the injection mold through a magnetic sucking piece; and a molten air guide plate outer-layer material is injected in the molding cavity, so that the outer-layer material wraps the air guide plate insert to form the air guide plate. The air guide plate adopts a sandwich layer embedding form to replace a double-layer structure form of a conventional aluminum alloy air guide plate, can only occupy less internal space of the air guide plate under the condition of guaranteeing strength and deformation resistance of the air guide plate, reduces the whole thickness of the air guide plate, and reduces the shape volume of the air guide plate.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Hollow shaft and manufacturing method thereof

InactiveCN111037244AReduce deformation resistanceDeformation resistance fully utilizedShaftsRotary machine partsManufactured materialMachining process

The invention relates to a hollow shaft and a manufacturing method thereof. The method comprises the steps that a rod is firstly subjected to warm forging, a blank with a closed end face is reverselyextruded through warm forging, the closed end face of the blank is removed through machining, and a tubular rough blank is obtained; the tubular rough blank continues to be subjected to spheroidizingannealing treatment, after being cooled, the tubular rough blank is subjected to shot blasting treatment, phosphating and saponification, then the tubular rough blank is subjected to cold forging anddrawing, and a tubular thin blank is obtained; then the tubular thin blank is milled, the irregular end face of the tubular thin blank is removed, and a tubular fine blank is obtained; and the tubularfine blank continues to be subjected to low-temperature annealing treatment, after being cooled, the tubular fine blank is subjected to shot blasting treatment, after oxide scale on the surface of the tubular fine blank is removed, radial forging is carried out, and hollow shafts of different specifications and types can be obtained according to requirements. By means of the manufacturing method,overall anti-deformation performance after part forming is guaranteed, the machining quantity of the machining process is reduced, and raw materials are saved.

Owner:JIANGSU SUNWAY PRECISION FORGING

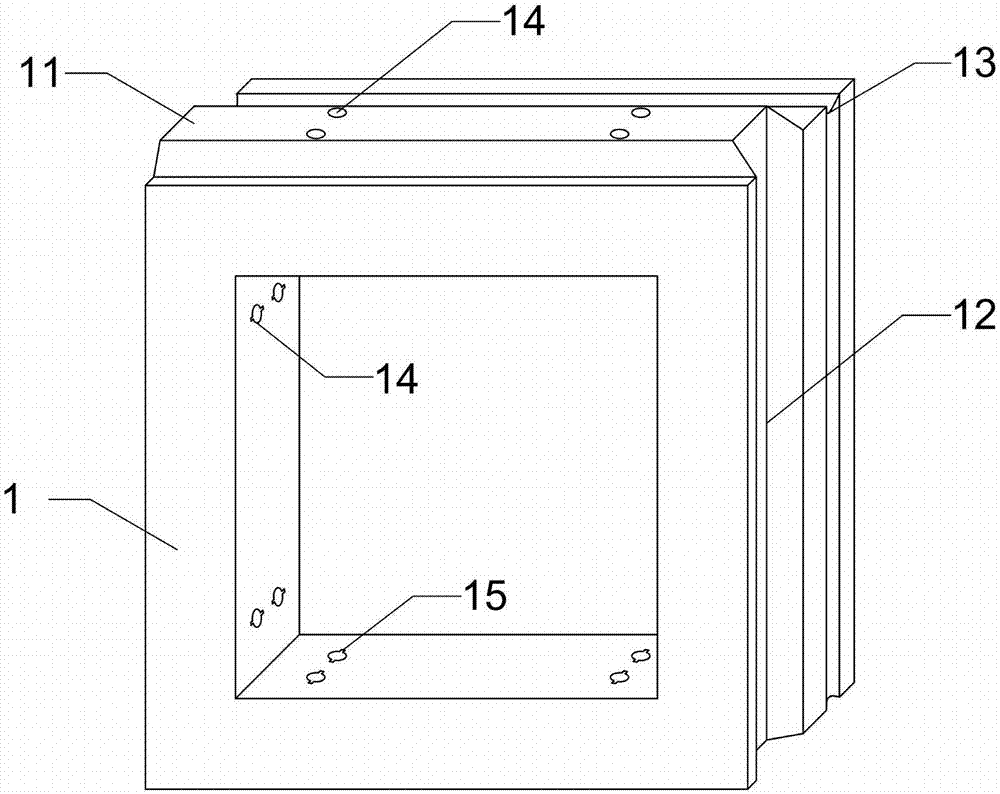

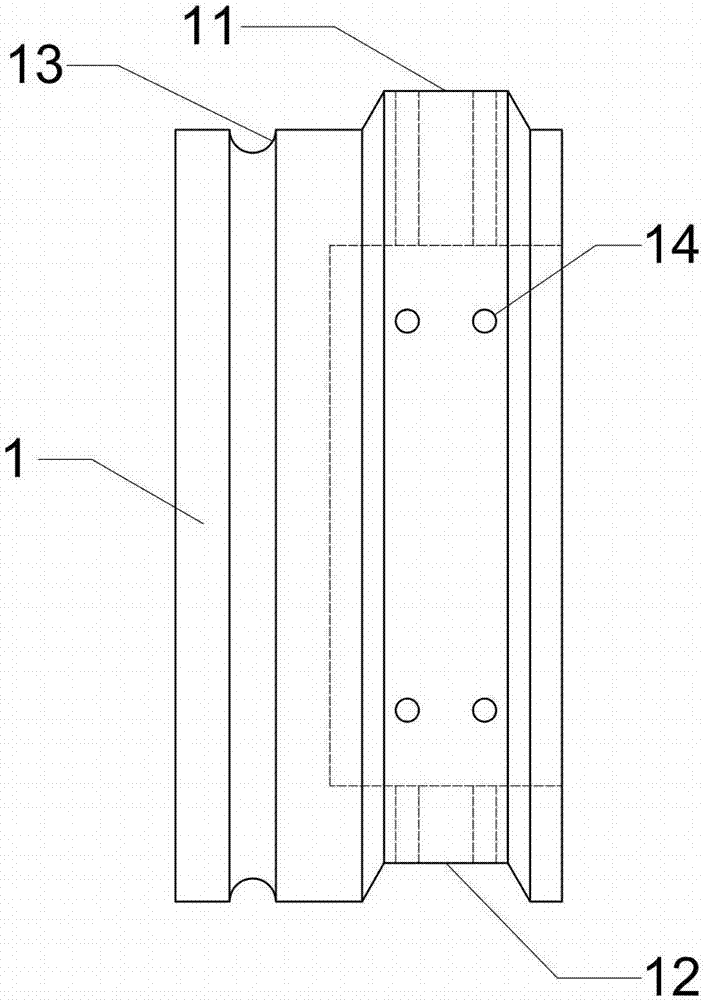

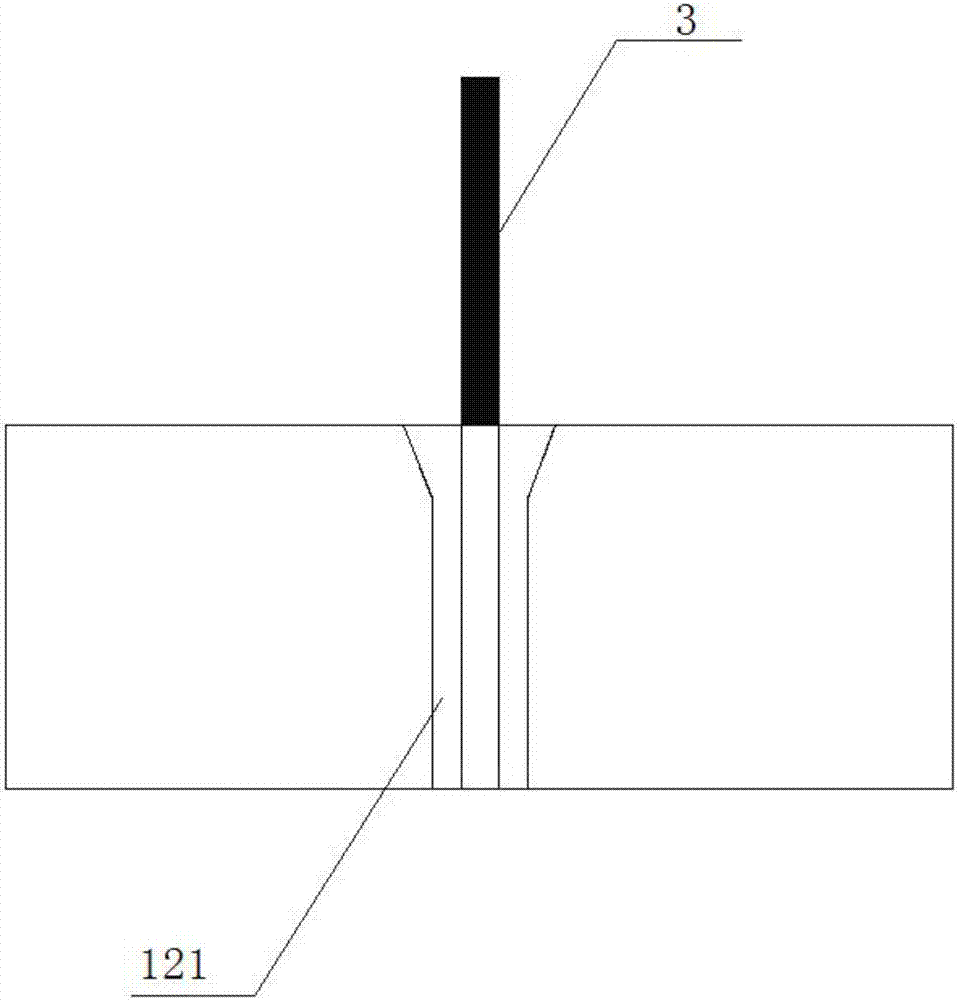

Construction method for assembled foundation pit support structure

The invention relates to a construction method for an assembled foundation pit support structure. A prefabricated reinforced concrete pile and a prefabricated box type component are mainly adopted. The prefabricated box type component comprises at least one standard piece. Trapezoid tenons 11 and trapezoid mortises 12 are formed in transverse and longitudinal connector positions of the standard pieces in a staggered manner. The prefabricated reinforced concrete pile comprises a front part 41, a rear part 42 and a pile head 43, wherein trapezoid tenons 412 and trapezoid mortises 413 are formed in the two sides of the front part in a staggered manner, and the tenons and the mortises of the prefabricated reinforced concrete pile and the tenons and the mortises of the prefabricated box type component are matched in size. A clamp support 421 used for supporting a prefabricated box type component located at the adjacent position is arranged at the position, close to the front part 41, of the rear part 42. After the whole support structure is spliced, compaction grouting is conducted on the position of a last anti-seepage grouting hole where the corresponding standard piece is arranged, and the anti-seepage grouting holes formed by the standard pieces and a pile body are fully filled with pulp from bottom to top. When it is observed that the pulp overflows out of an anti-seepage grouting hole channel of the top-layer standard piece, grouting is stopped.

Owner:TIANJIN UNIV

Battery box concealed mounting structure for Z-shaped vehicle beam pipe

ActiveCN108407592AImprove integrityHigh strengthElectric propulsion mountingCell component detailsElectricityUltimate tensile strength

The invention relates to a battery box concealed mounting structure for a Z-shaped vehicle beam pipe. The battery box concealed mounting structure comprises the vehicle beam pipe being of a hollow structure and is characterized in that the pipe wall at an end port of the vehicle beam pipe is fixedly connected with a connecting pipe, and a battery box mounting inlet is formed in the end port of thevehicle beam pipe; and a battery box is inserted and mounted from the battery box mounting inlet of the vehicle beam pipe, and a battery box mounting seat for supporting and being electrically connected with the battery box is mounted in the vehicle beam pipe. The battery box concealed mounting structure is scientific and reasonable in design, and inserting-type mounting of the battery box from the end port of the vehicle beam pipe can be achieved, so that integrity of the vehicle beam pipe is maintained, the strength and deformation resistance of the vehicle beam pipe are ensured, and the battery box concealed mounting structure has the advantages of being stable and reliable in structure and convenient to operate.

Owner:天津固德莱特科技发展有限公司

Shield tunnel segment lining structure of stratum junction section and design method

ActiveCN108571328AIncrease stiffnessAvoid failure damageUnderground chambersSustainable transportationStress concentrationEngineering

The invention discloses a shield tunnel segment lining structure of a stratum junction section and a design method. The shield tunnel segment lining structure comprises a junction section, conventional pipe sections are arranged on the two sides of the junction section, and the rigidity of a longitudinal joint bolt between every two adjacent segment rings on the junction section is higher than therigidity of each longitudinal joint bolt of the conventional pipe sections. The design method comprises the steps of establishing a longitudinal finite element numerical calculation model of a shieldtunnel, taking tunnel lining segments as concrete segments, and calculating the longitudinal sediment amount and the longitudinal deformation curve radius generated by the stratum junction section. According to the shield tunnel segment lining structure and the design method, the problem that in the prior art, the longitudinal deformation of a shield tunnel segment lining structure of the soft-hard stratum junction section is too large, the non-uniform stress is concentrated, and inter-ring longitudinal joints are damaged can be effectively solved.

Owner:SOUTHWEST JIAOTONG UNIV +1

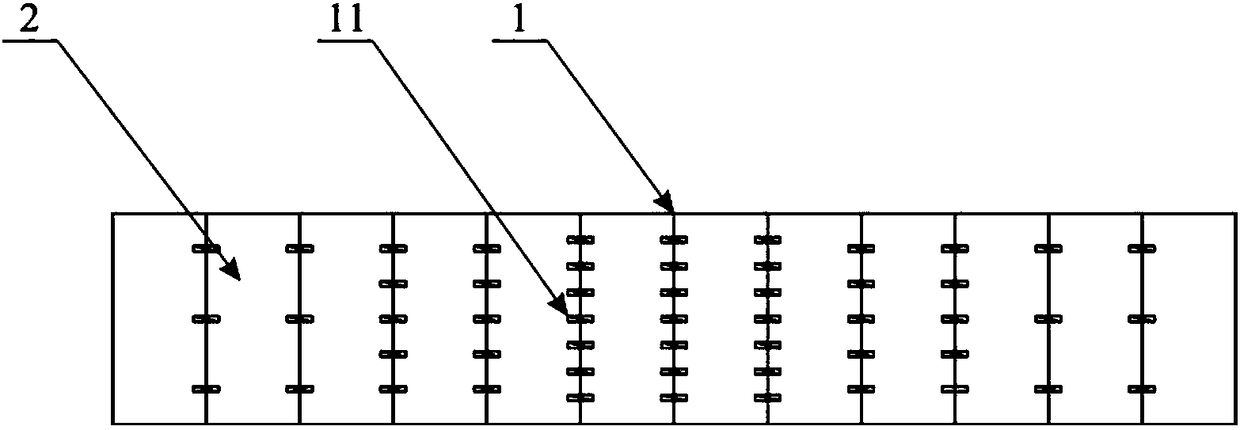

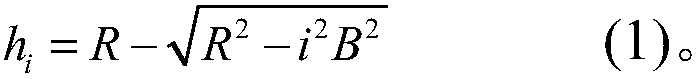

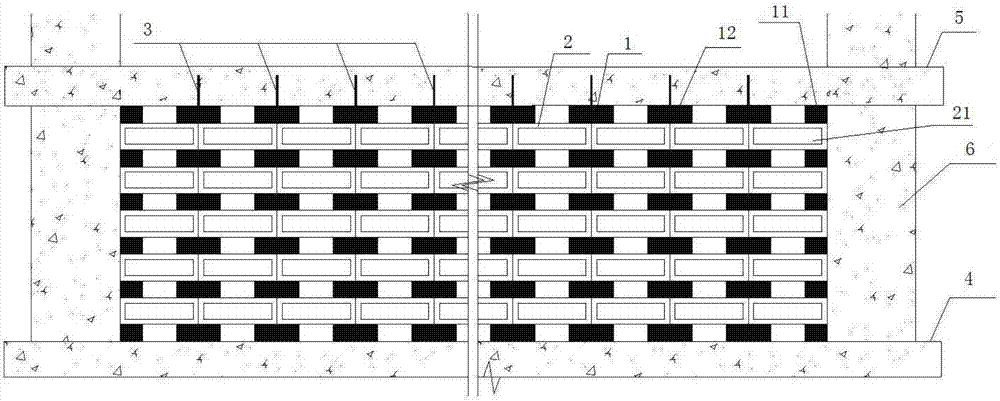

Structure-pillar free combined openwork brick wall without plastering and construction method thereof

ActiveCN107268834AGuaranteed bearing capacityGuaranteed anti-deformation effectWallsClimate change adaptationRebarHollow core

The invention discloses a structure-pillar free combined openwork brick wall without plastering and a construction method thereof. The brick wall comprises a stone layer, a concrete hollow brick block layer and steel bars which are spliced between an upper and lower two-storey beam structures, and the stone layer and the concrete hollow brick block layer are alternately spliced in an upper-and-lower mode; the stone layer consists of first stones and second stones, the first stones are arranged on two sides of a wall body and fixed with house pillars, the second stones are arranged between the two first stones on two sides of the wall body, gaps exist between the first stones and the second stones and between two adjacent second stones, and are distributed by equal spacing; the concrete hollow brick block layer is composed of a number of concrete hollow brick blocks transversely connected, the concrete hollow brick blocks located on the outermost two sides are fixed with the house pillars, the top of each steel bar is fixed to an upper layer beam structure, the bottom of each steel bar is fixed to a lower layer beam structure, and the middle of each steel bar is serially connected with the stone layer and the concrete hollow brick block layer. The wall body has no structure pillars and is beautiful on the whole, the stability of the wall body can be ensured, and the construction process is simple.

Owner:广西建工第一建筑工程集团有限公司

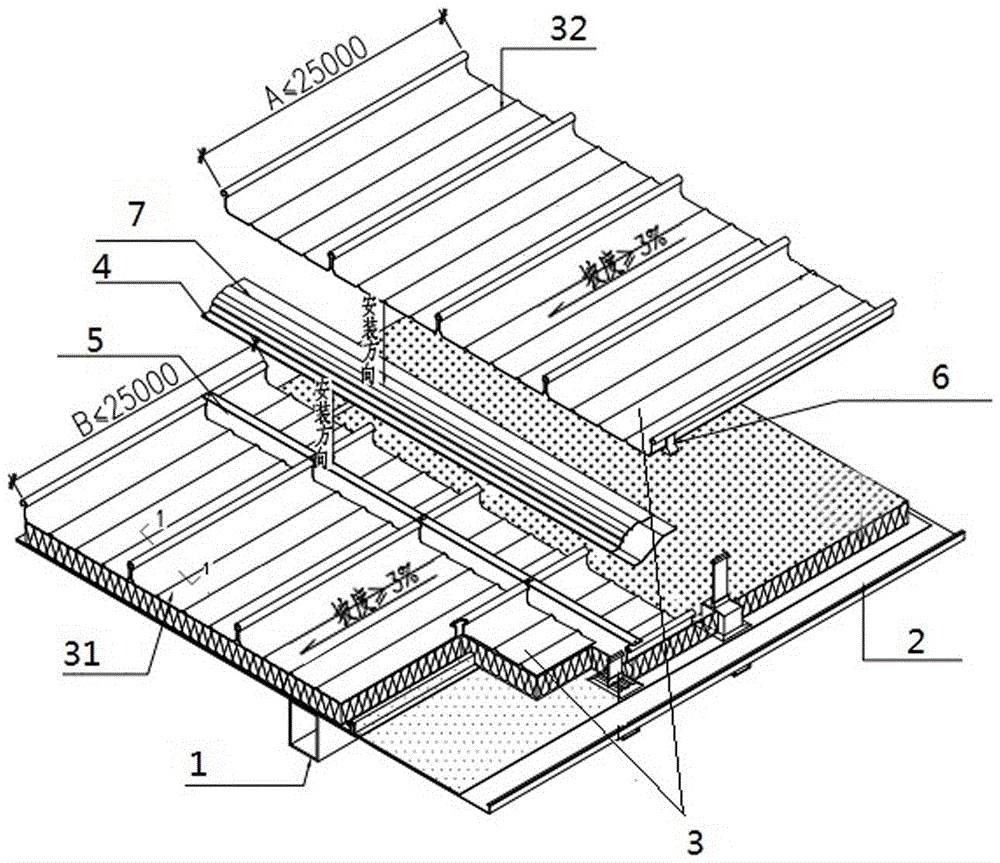

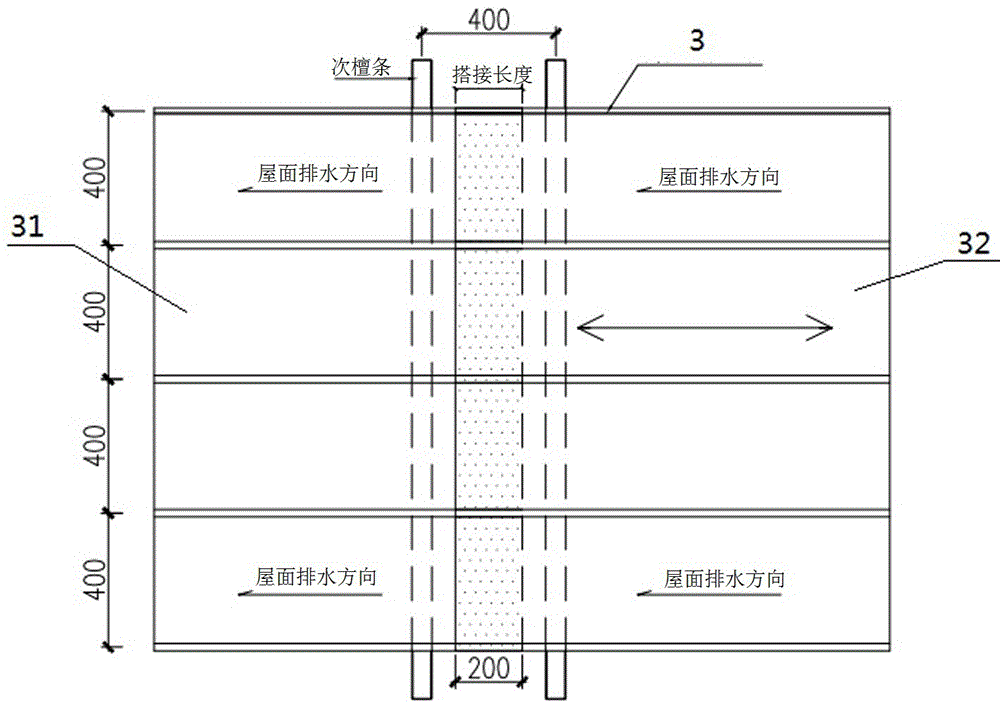

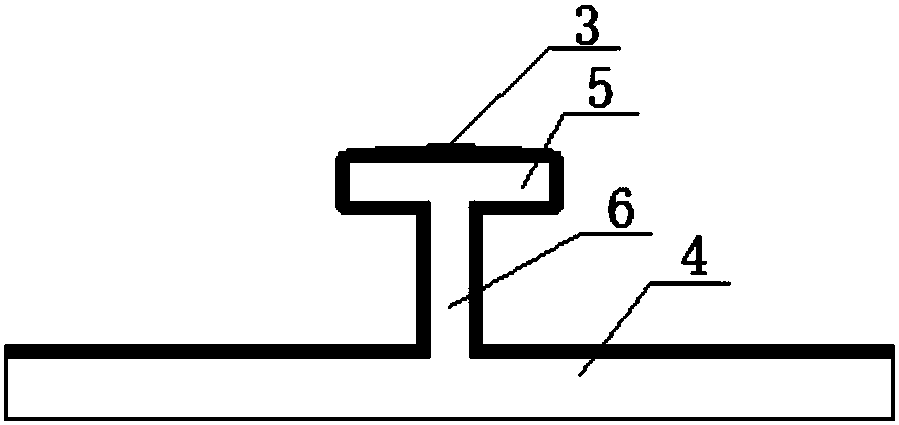

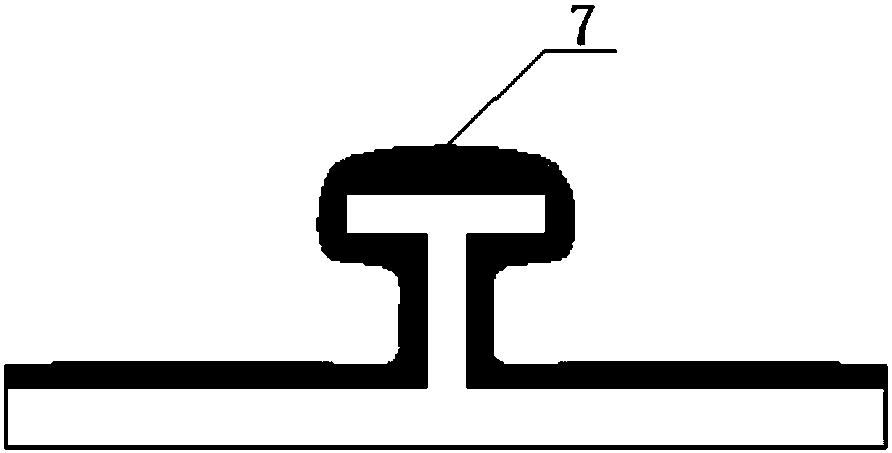

Standing seam roof having deformation resisting capability and installing process thereof

InactiveCN105952065AFirmly connectedEasy to identifyRoof covering using slabs/sheetsBuilding material handlingEngineeringRubber sheet

The invention discloses a standing seam roof having deformation resisting capability. The standing seam roof comprises a main purline, a first roof board, a second roof board and a water flashing board, wherein the second roof board is composed of a first standing seam board and a second standing seam board, the first roof board is arranged on the main purline, a first plug and a second plug are respectively arranged above the first standing seam board and below the second standing seam board, the first standing seam board and the second standing seam board are connected through the water flashing board at the lap joint position, one end of the water flashing board is fixed to the first plug of the first standing seam board, and a waterproof rubber sheet is arranged on the outer side of the water flashing board. The retractility of the standing seam roof having the deformation resisting capability can be ensured in the using process while a waterproof effect is ensured by fixing one end of the water flashing board to the first plug. In addition, the waterproof rubber sheet is further arranged on the outer side of the water flashing board, the overall waterproof performance of the roof is further improved while the retractility of the roof is ensured.

Owner:SHANDONG YABAITE SCI & TECH CO LTD

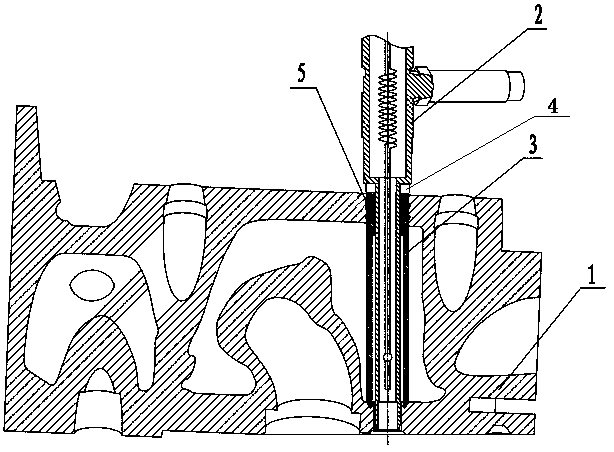

Installation structure of air cylinder drain valve of engine

PendingCN109026385ASolve Cooling ProblemsImprove reliabilityCylinder headsCylindersCombustion chamberEngineering

The invention relates to an installation structure of an air cylinder drain valve of an engine. The installation structure of the air cylinder drain valve of the engine comprises an air cylinder cover, wherein a cooling water cavity is formed in the air cylinder cover. A drain valve protective pipe is arranged in the cooling water cavity of the air cylinder cover, the upper portion of the drain valve protective pipe makes contact with the top wall of the cooling water cavity in a sealing mode through an O-shaped sealing ring, and the lower portion of the drain valve protective pipe penetratesthrough the top wall of the cooling water cavity and makes contact with the bottom wall of the cooling water cavity in a sealing mode. The drain valve is installed in the drain valve protective pipe.A valve rod of the drain valve penetrates through the drain valve protective pipe, is fixedly connected with the bottom wall of the cooling water cavity of the air cylinder cover, fixes the drain valve protective pipe through a locking washer, and communicates with a combustion chamber which is formed below the air cylinder cover. The installation structure of the air cylinder drain valve of the engine has the beneficial effects that the drain valve on the air cylinder cover is installed by penetrating through the cooling water cavity of the air cylinder cover, and therefore the cooling problem of the drain valve is solved, the working reliability of the drain valve is improved, and the service life of the drain valve is prolonged.

Owner:HENAN DIESEL ENGINE IND +1

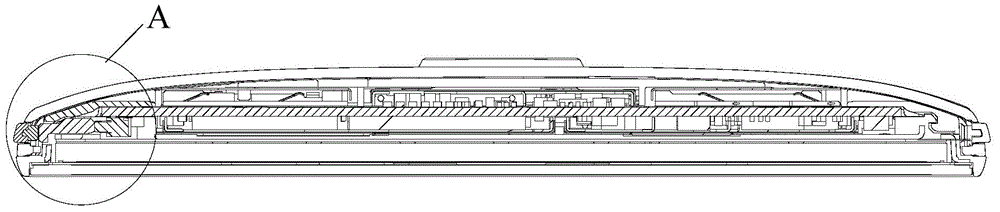

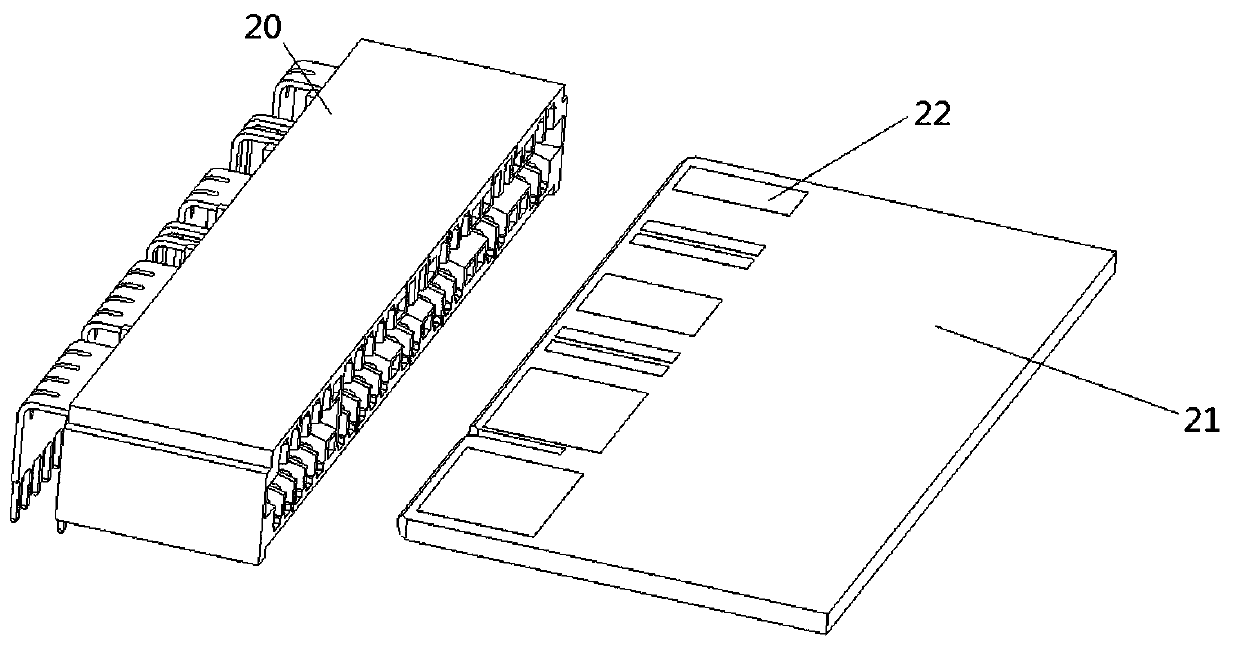

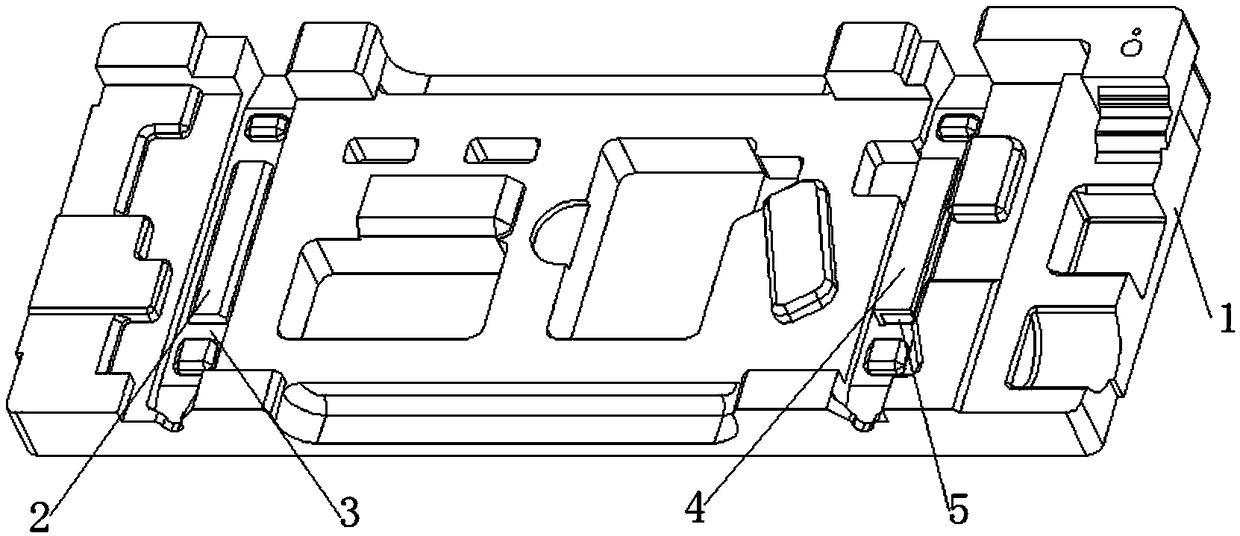

Key structure and mobile terminal

InactiveCN105632822AGuaranteed connection strengthGuaranteed anti-deformation effectElectric switchesTelephone set constructionsElectrical and Electronics engineeringEngineering

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Air deflector, injection mold and molding method

ActiveCN106003565BGuaranteed StrengthGuaranteed anti-deformation effectAir-flow control membersInterior spaceMaterials science

The invention provides an air guide plate, an injection mold and a molding method. The method comprises the following steps: a molded air guide plate insert is positioned in a molding cavity of the injection mold through a magnetic sucking piece; and a molten air guide plate outer-layer material is injected in the molding cavity, so that the outer-layer material wraps the air guide plate insert to form the air guide plate. The air guide plate adopts a sandwich layer embedding form to replace a double-layer structure form of a conventional aluminum alloy air guide plate, can only occupy less internal space of the air guide plate under the condition of guaranteeing strength and deformation resistance of the air guide plate, reduces the whole thickness of the air guide plate, and reduces the shape volume of the air guide plate.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

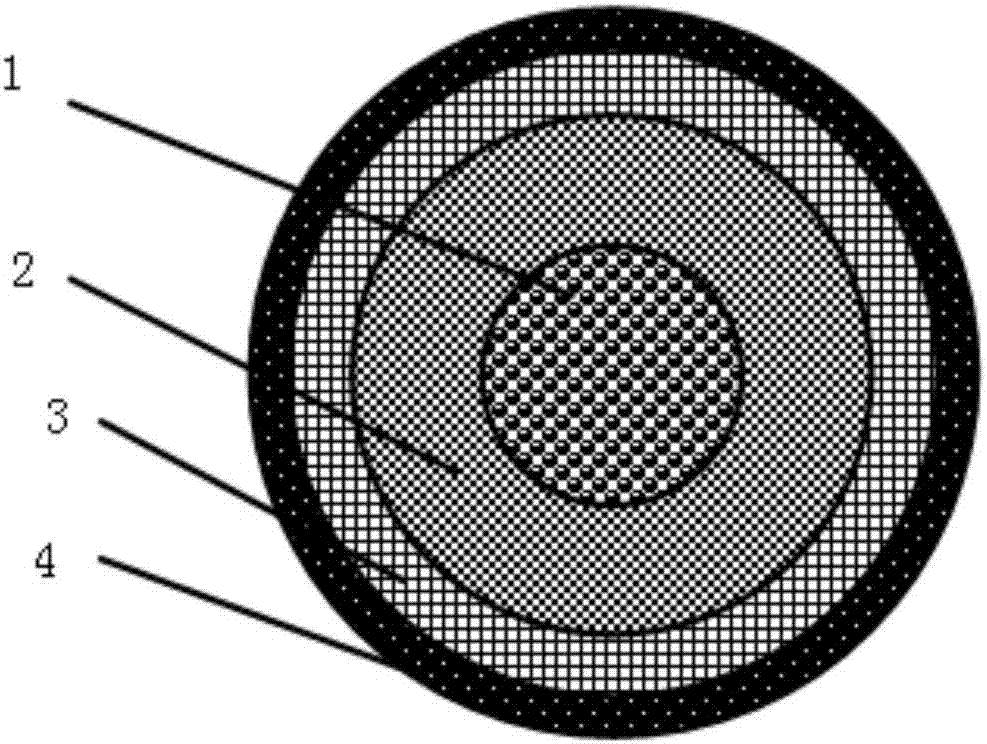

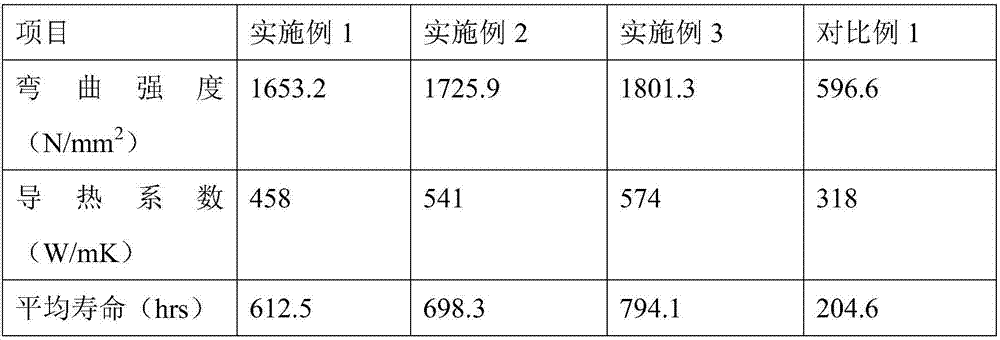

A high-toughness anti-split carbon fiber composite wire mandrel and preparation method thereof

ActiveCN106298010BHigh tensile strengthGuaranteed anti-deformation effectFlexible cablesCable/conductor manufactureFiberGlass fiber

The invention discloses a high-toughness splitting-resistant carbon fiber composite wire core rod and a preparation method. The wire core rod is made of a plurality of kinds of fiber hybrid composite materials, wherein carbon fibers are adopted as main body reinforcing fibers. The wire core rod is composed of a rigid core, a flexible layer, an anti-splitting layer and a surface wear-resistant layer which are distributed from inside to outside sequentially; the rigid core is made of a high-performance carbon fiber composite material, so that the deformation resistance of the overall core rod can be ensured; the flexible layer is made of a glass fiber composite material, so that the toughness of the core rod can achieve winding of a certain curvature; the anti-splitting layer is made of a hybrid fiber helical winding structure, so that the splitting problem of the wire core rod in a winding process can be solved; and the surface wear-resistant layer is made of a carbon fiber surface felt or a two-dimensional braided high-performance fiber mixture, so that the surface wear-resistant characteristic of the wire core rod can be ensured, and the stability of the internal structural of the wire core rod can be effectively protected. With the multi-layer structured carbon fiber composite wire core rod of the invention adopted, the comprehensive mechanical properties of a current wire steel core or a traditional composite material wire core rod can be improved, and the service life of the current wire steel core or the traditional composite material wire core rod can be effectively prolonged.

Owner:SHANDONG UNIV

Device and method for taking and storing mudstone core

PendingCN109724860AEffective preservationEasy to disassemblePreparing sample for investigationEngineeringMechanical property

The invention belongs to the field of rock mechanics experiments, and specifically discloses a device and a method for taking and storing mudstone core. The device comprises an inner cladding, an integral bracket, a conformal casting layer, and a compression spring assembly. The conformal casting layer is arranged in the metal integral bracket. The inner cladding is arranged in the conformal casting layer. The compression spring assembly is arranged between the top of the integral bracket and the inner cladding. The method comprises the following steps of: wrapping the mudstone core sample bythe inner cladding; positioning the integral bracket and the mudstone core sample; mounting the integral bracket, the compression spring assembly and the conformal casting layer; casting a solidifiedmaterial in the conformal casting layer to shape the mudstone core sample; controlling the compression spring assembly to simulate a three-way compression state of the mudstone core sample, wherein this is the storage state of the mudstone core sample; and sampling the mudstone core sample. Therefore, the taking and store of the mudstone core are completed. According to the device and the method for taking and storing the mudstone core, the physical and mechanical properties of the mudstone core sample just after exiting the hole can be maintained after long-term suspension and long-distance transportation.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

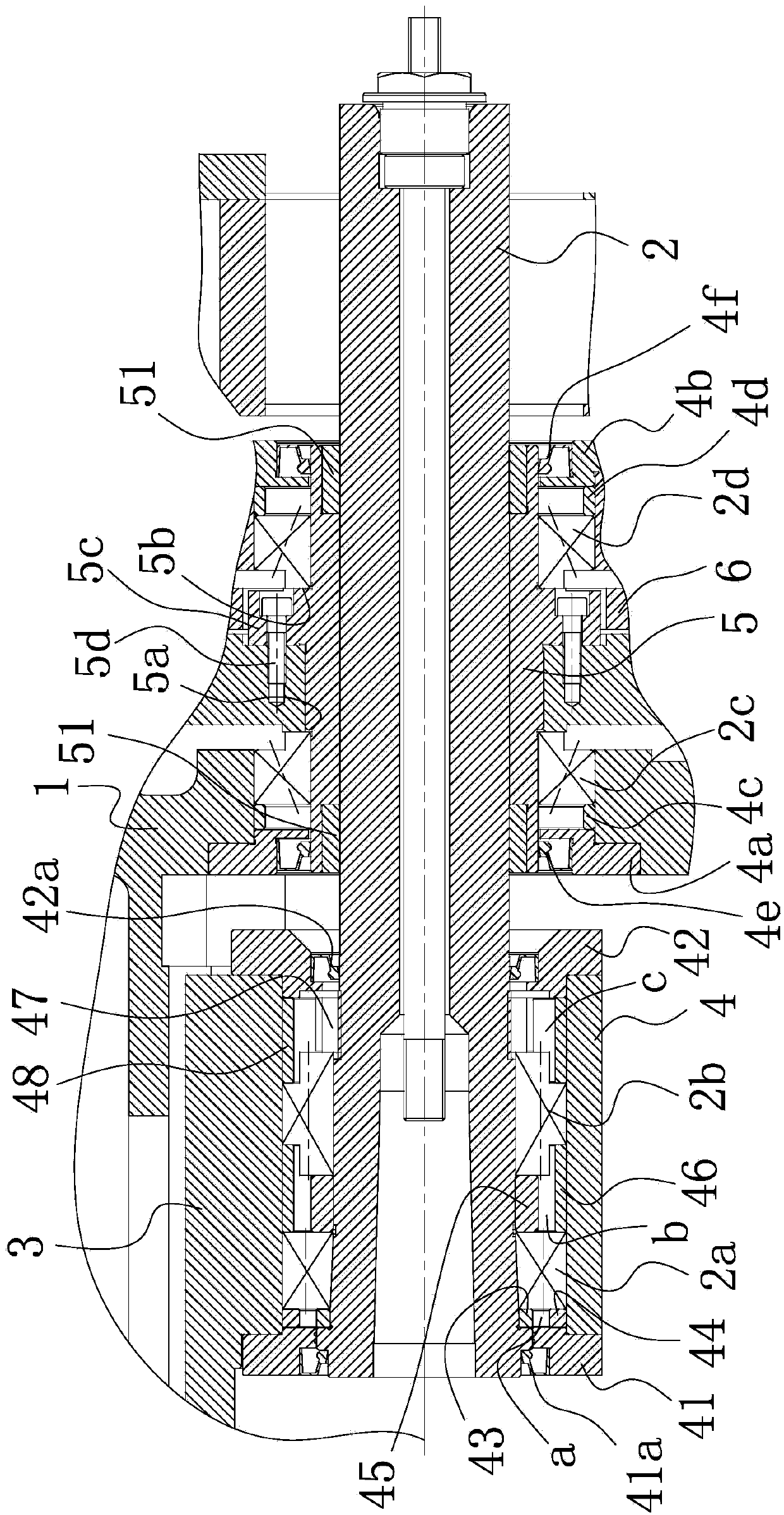

Hobbing cutter main shaft mechanism of CNC gear hobbing machine

InactiveCN103990818AReasonable designImprove structural strengthLarge fixed membersHobbingEngineering

The invention belongs to the technical field of gear hobbing machines, and particularly relates to a hobbing cutter main shaft mechanism of a CNC gear hobbing machine. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine solves the technical problems that practicability is poor in the prior art and the like. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine comprises a cutter rest shell and hobbing cutter main shaft which is arranged in the cutter rest shell in a penetrating mode and can rotate relative to the cutter rest shell, the front end of the hobbing cutter main shaft is inserted into the cutter rest shell and is arranged in a suspending mode, the tail end of the hobbing cutter main shaft penetrates through the cutter rest shell and extends out of the cutter rest shell, a first rolling structure is arranged between the cutter rest shell and the hobbing cutter main shaft, a supporting plate fixedly connected with the cutter rest shell is arranged in the cutter rest shell and is provided with a barrel-shaped locating body which is fixedly connected with the supporting plate and arranged on the periphery of the suspended end of the hobbing cutter main shaft in a sleeved mode, a second rolling structure is arranged between the hobbing cutter main shaft and the barrel-shaped locating body, and an axial locating mechanism used for preventing axial float of the hobbing cuter is further arranged between the hobbing cutter main shaft and the barrel-shaped locating body. The hobbing cutter main shaft mechanism of the CNC gear hobbing machine has the advantages of being high in structural intensity, rigidity and practicability during interrupted cutting.

Owner:浙江嘉力宝精机股份有限公司

a connector

ActiveCN105762546BGuaranteed anti-deformation effectCoupling device detailsEngineeringElectrical and Electronics engineering

Owner:中航光电(广东)有限公司

Heat pipe and preparation method thereof

ActiveCN107121001AHigh hardnessHigh strengthIndirect heat exchangersHeat exchange apparatusBoron nitrideEngineering

The invention relates to the technical field of heat pipes, and provides a heat pipe. The heat pipe comprises a pipe shell, a pipe core and working liquid, wherein the pipe core is arranged on the inner wall of the pipe shell, the working liquid is sealed in the pipe shell, the pipe shell comprises a white corundum section and a boron nitride section which are integrally formed, the white corundum section is 1 / 2 to 5 / 6 of the length of the pipe shell, and the boron nitride section is 1 / 6 to 1 / 2 of the length of the pipe shell. The invention further provides a preparation method of the heat pipe. The heat pipe provided by the invention has the advantage of difficulty in deformation, the heat transfer performance of the heat pipe can be effectively improved, the service life of the heat pipe is prolonged, and additionally, the invention provides the preparation method of the heat pipe.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

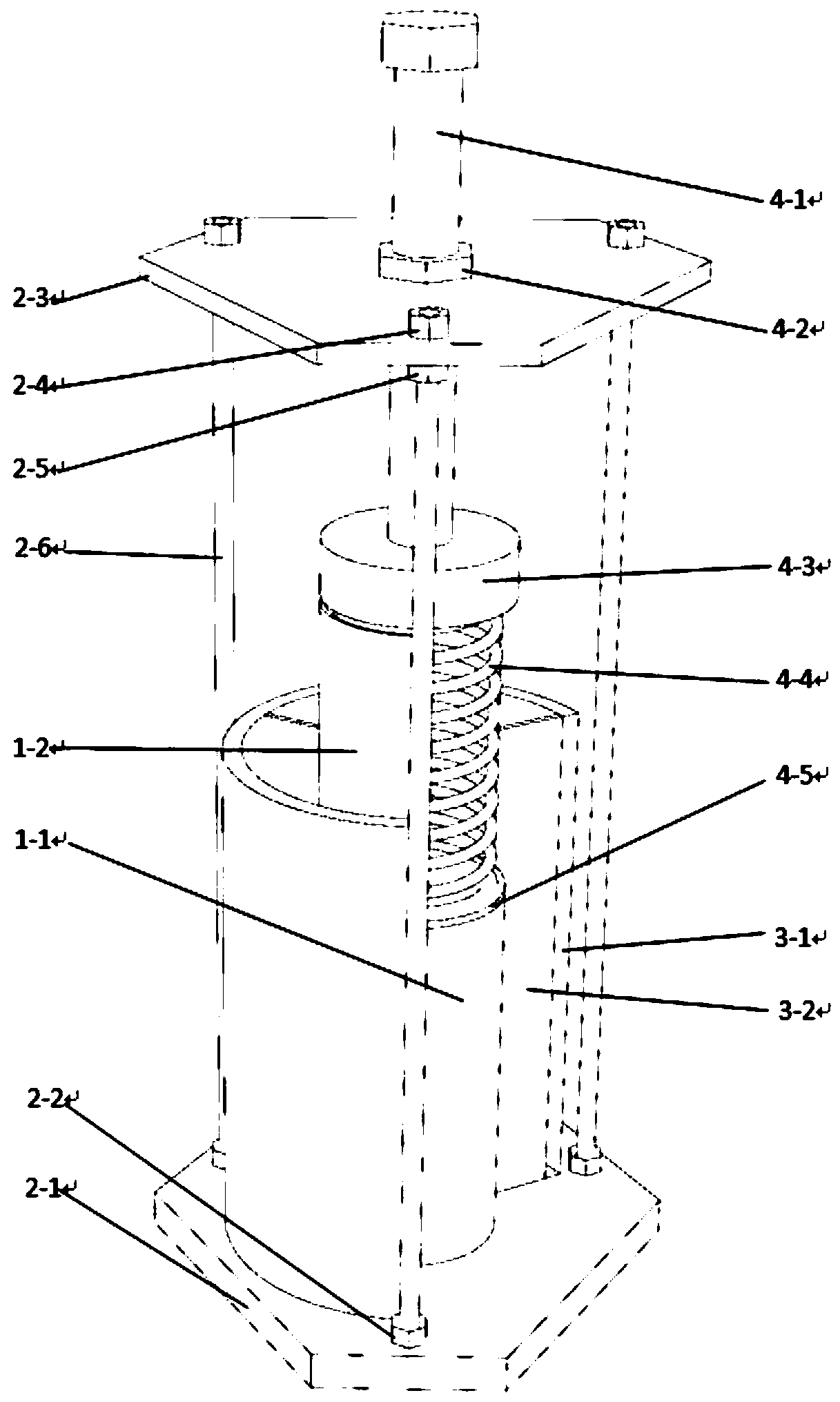

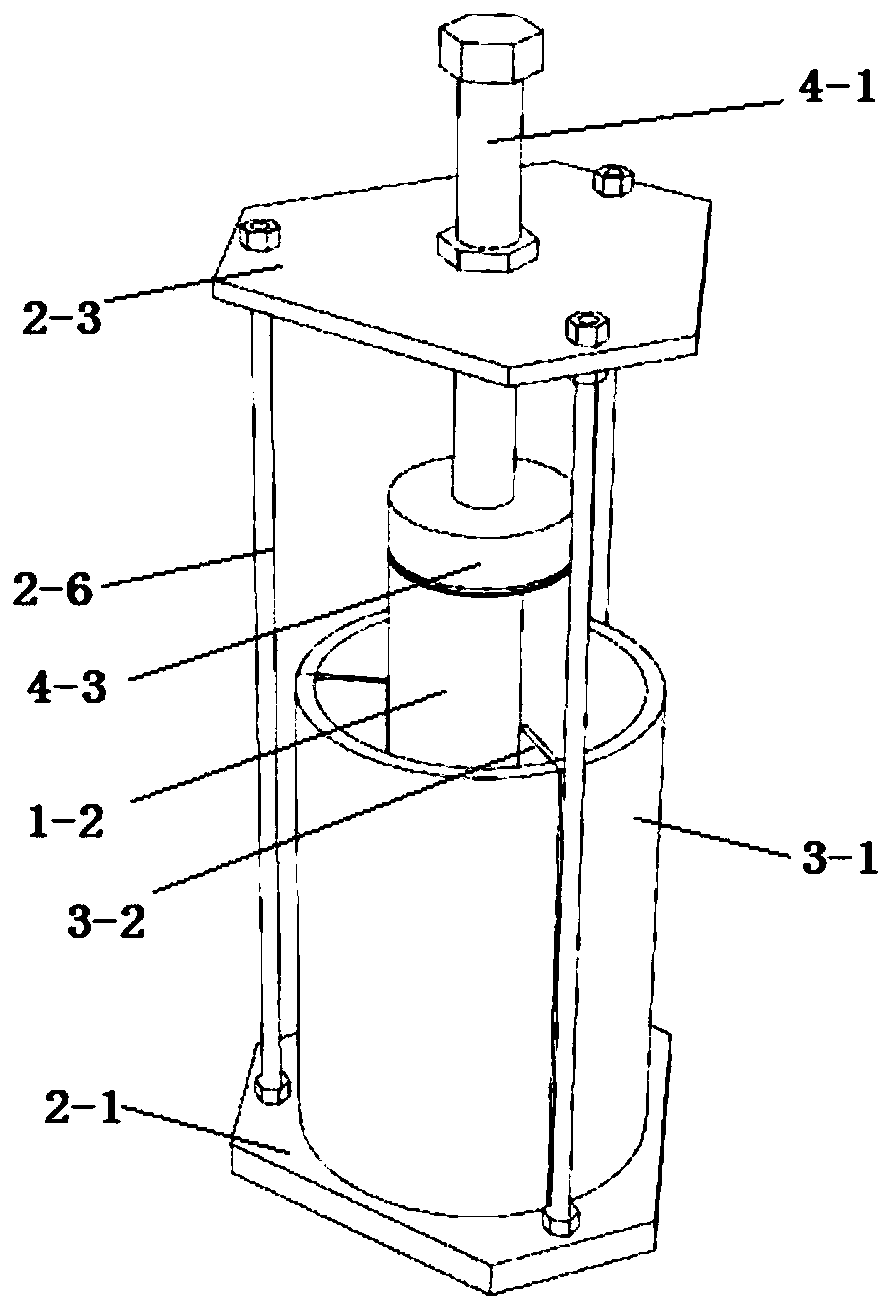

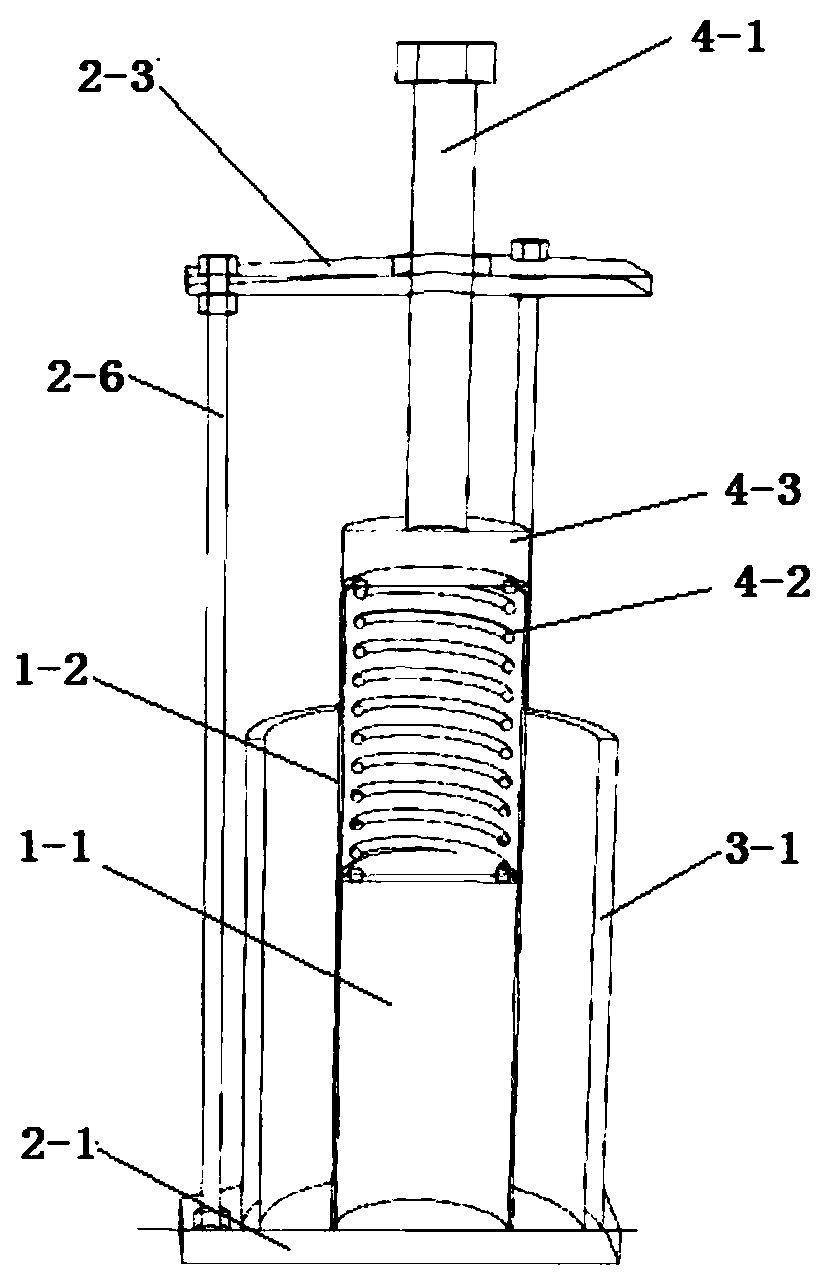

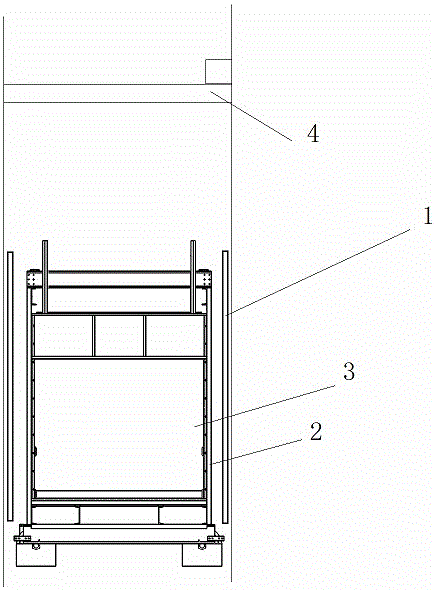

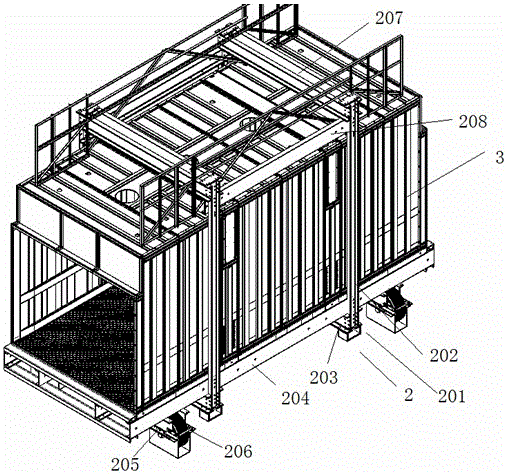

Large-tonnage automobile loading elevator

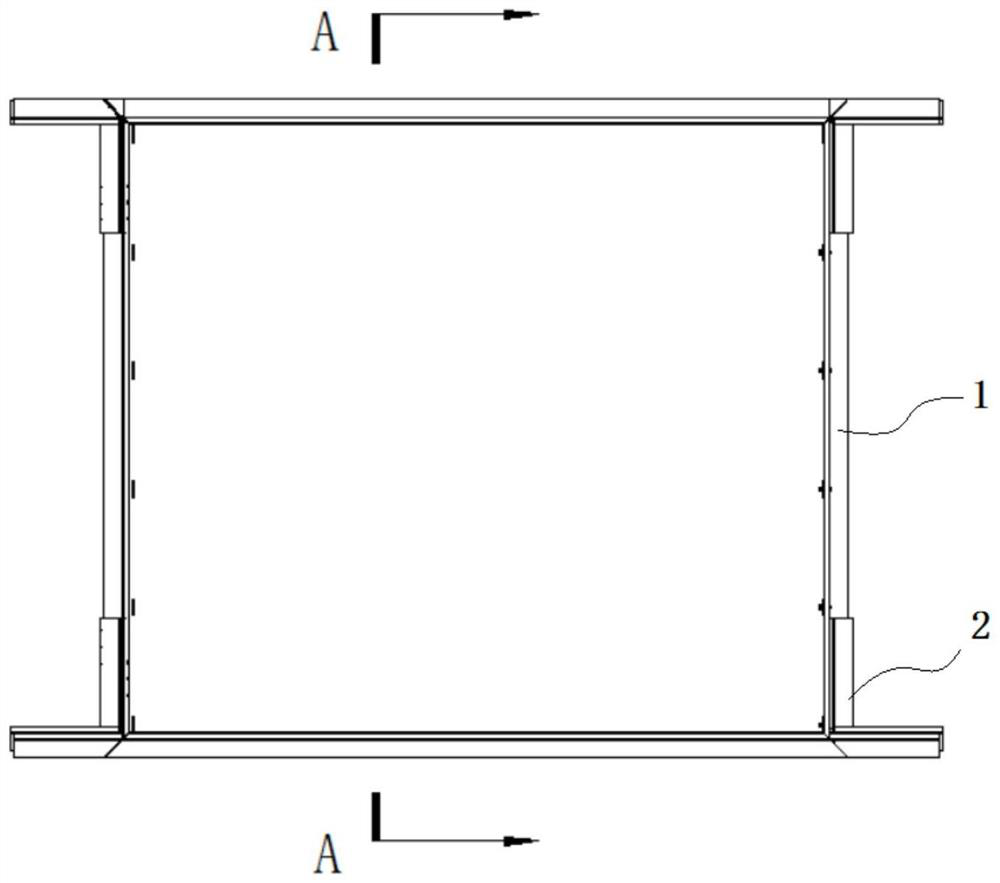

ActiveCN106516944AGuaranteed carrying capacityGuaranteed anti-deformation effectElevatorsBuilding liftsAutomobile platformStructural engineering

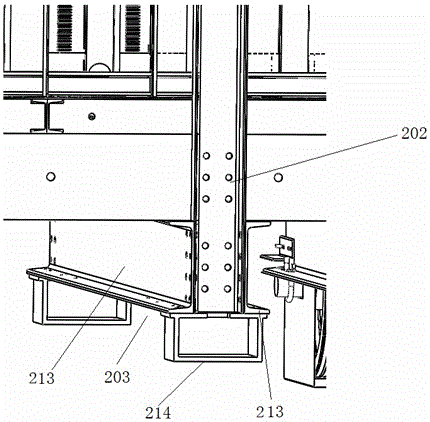

The invention discloses a large-tonnage automobile loading elevator. The elevator comprises two guide rails (1) arranged in a well, a car platform bracket structure (2) is arranged on the guide rails (1) and is provided with an elevator car (3), and a machine room arrangement structure (4) is arranged above the well. The car platform bracket structure (2) comprises two straight beam frames (201) matched with the guide rails (1), the straight beam frames (201) comprise straight beams (202) matched with the guide rails, lower beams (203) are arranged below the straight beams (202), bases (204) are arranged on the lower beams (203), the elevator car (3) is fixed to the bases (204), car platform wheel lower beams (205) are fixed below the bases (204), car top wheels (206) are arranged at the two ends of each car platform wheel lower beam (205), upper beams (207) are arranged above the straight beams (202), and connection beams (208) are arranged between the two sets of upper beams (207).

Owner:WEIBO ELEVATOR

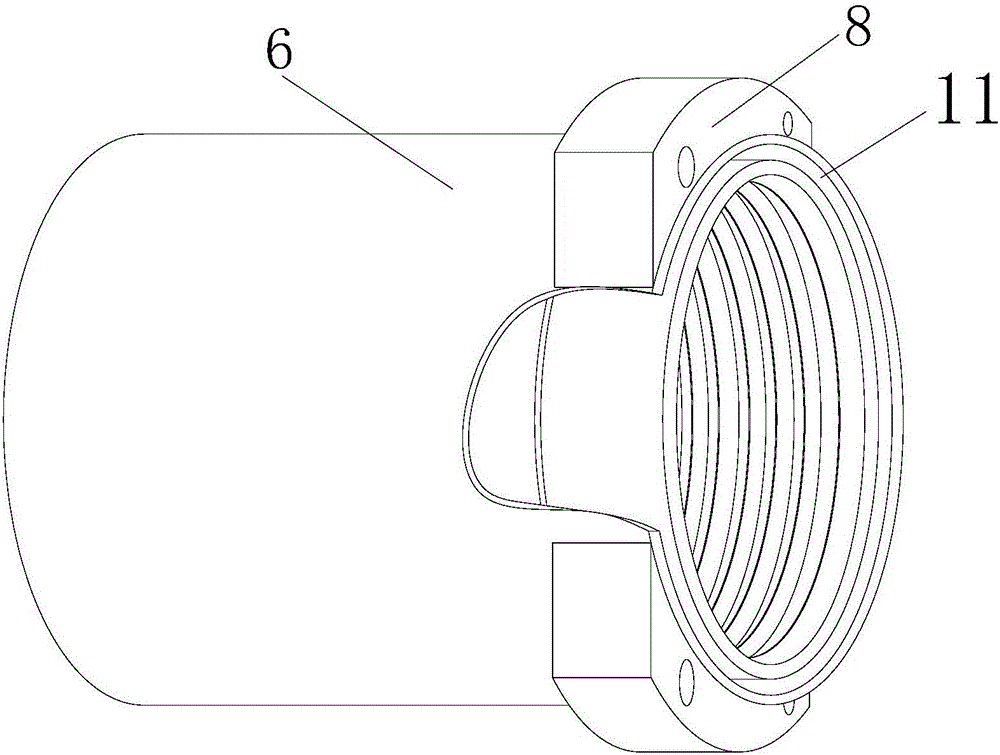

Connection structure for water collection tank and water collection pipe

InactiveCN106287045AEasy connectionEasy to disassembleSleeve/socket jointsFoundation engineeringAgricultural engineeringWater pipe

The invention discloses a connection structure for a water collection tank and a water collection pipe. The connection structure comprises a water collection tank body, a water inlet, a water collection pipe body, an outer sleeve and fastening rings. The right side of the water collection tank body is provided with the water inlet. The water collection pipe body is connected to the inner side of the water inlet through an inner spline. The outer sleeve is installed on the outer side of the water inlet through a thread groove. The top and the bottom of the end, far away from the water collection tank body, of the outer side of the outer sleeve are each provided with a connection block. The fastening rings are fixed to the right sides of the connection blocks through bolts. According to the provided connection structure for the water collection tank and the water collection pipe, the outer sleeve is installed on the outer side of the water inlet through the thread groove, the fastening rings are connected through matching of the bolts, thus the water collection pipe body and the water inlet can be fixedly connected through the fastening rings, the traditional connection mode that the water collection tank and the water collection pipe are bonded through foam adhesive, then nonwovens are wound and fixation is conducted through iron wires is replaced effectively, and thus connection between the water collection pipe and the water collection tank is simpler and more convenient.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

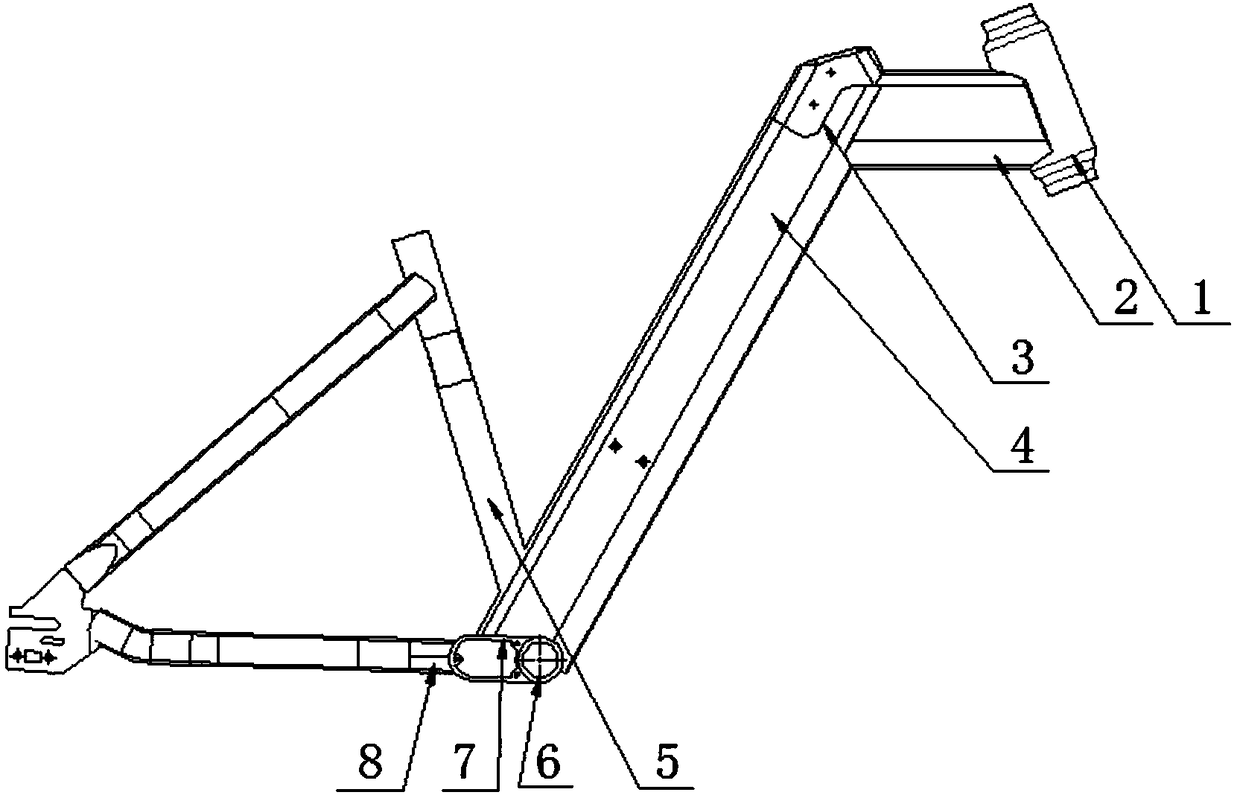

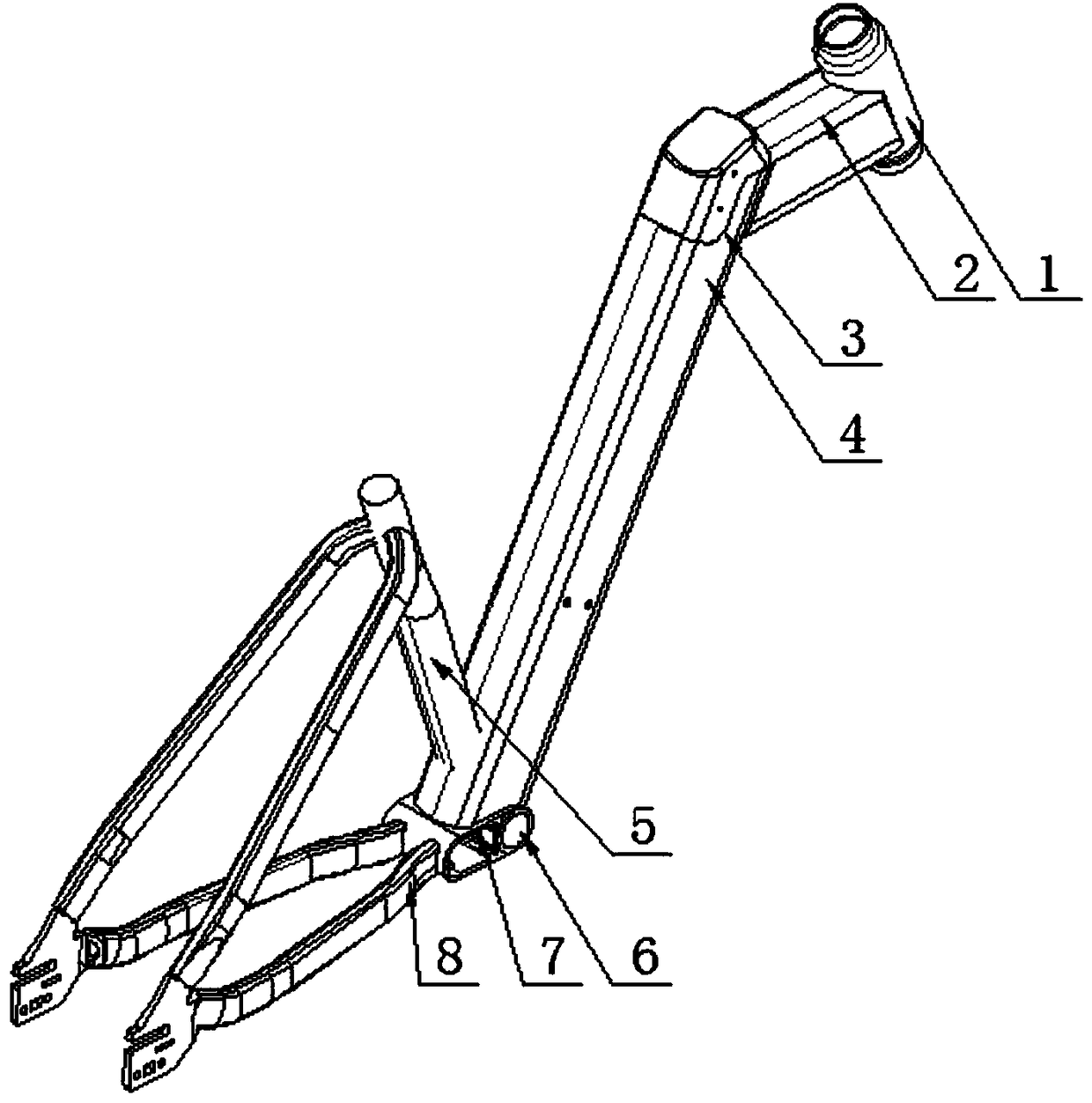

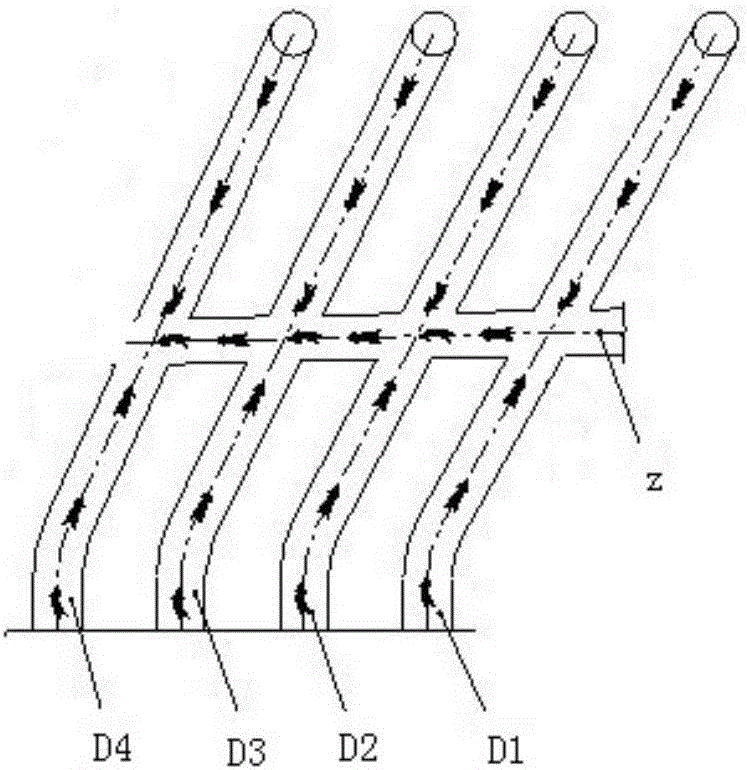

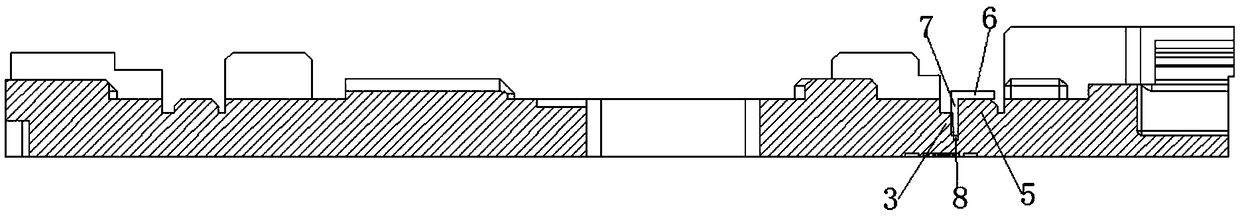

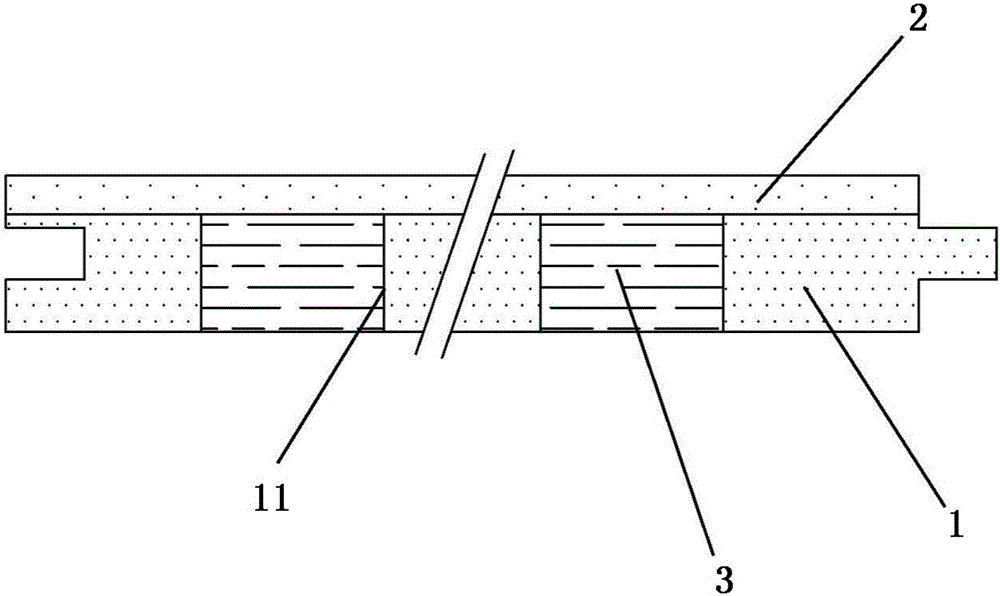

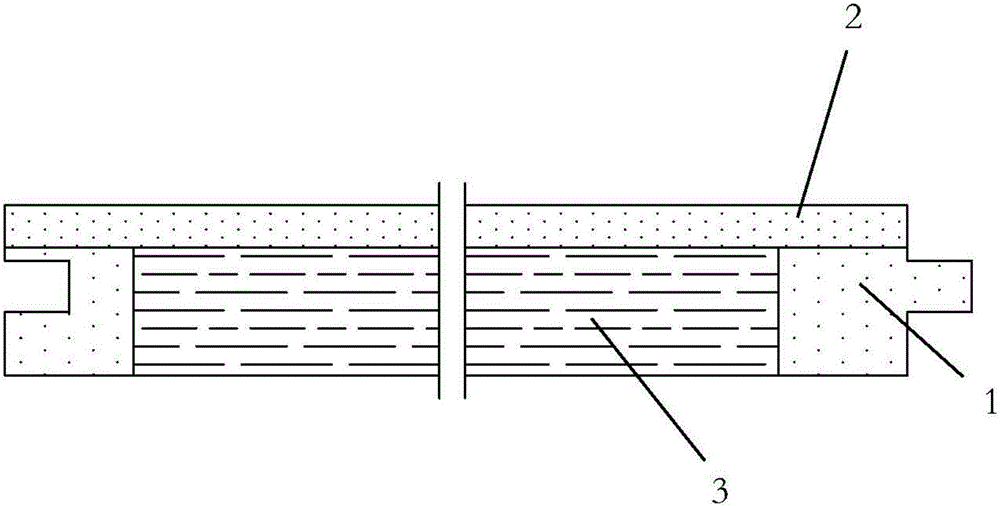

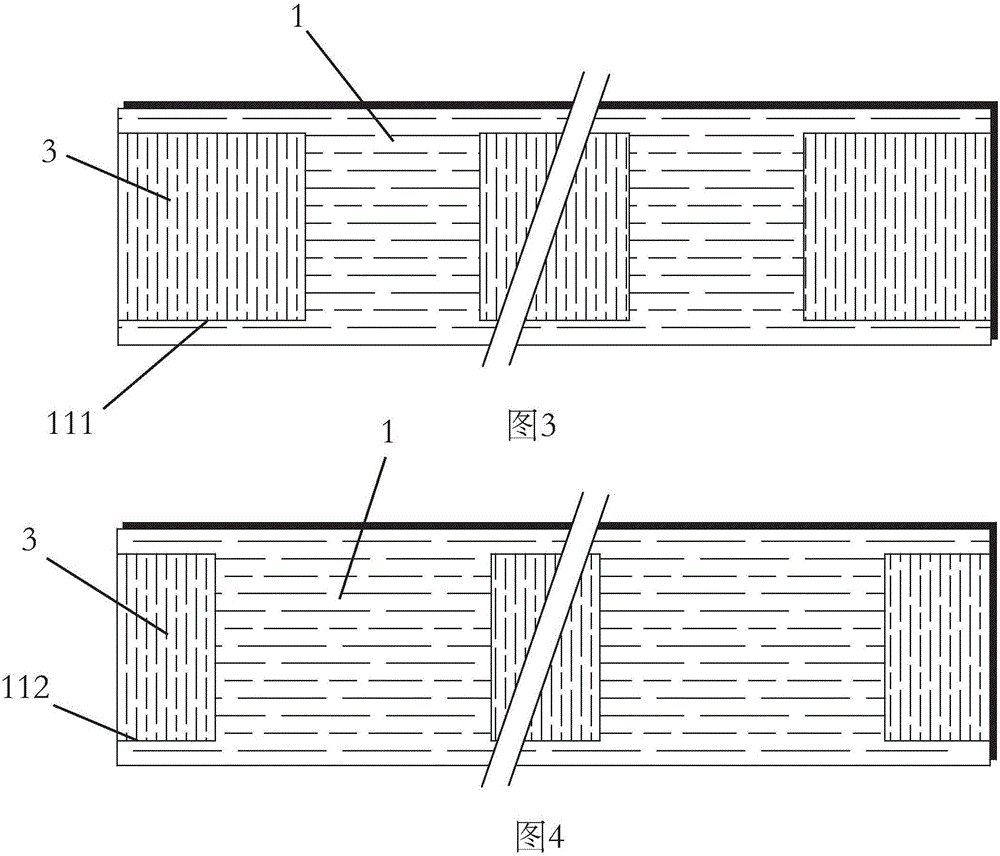

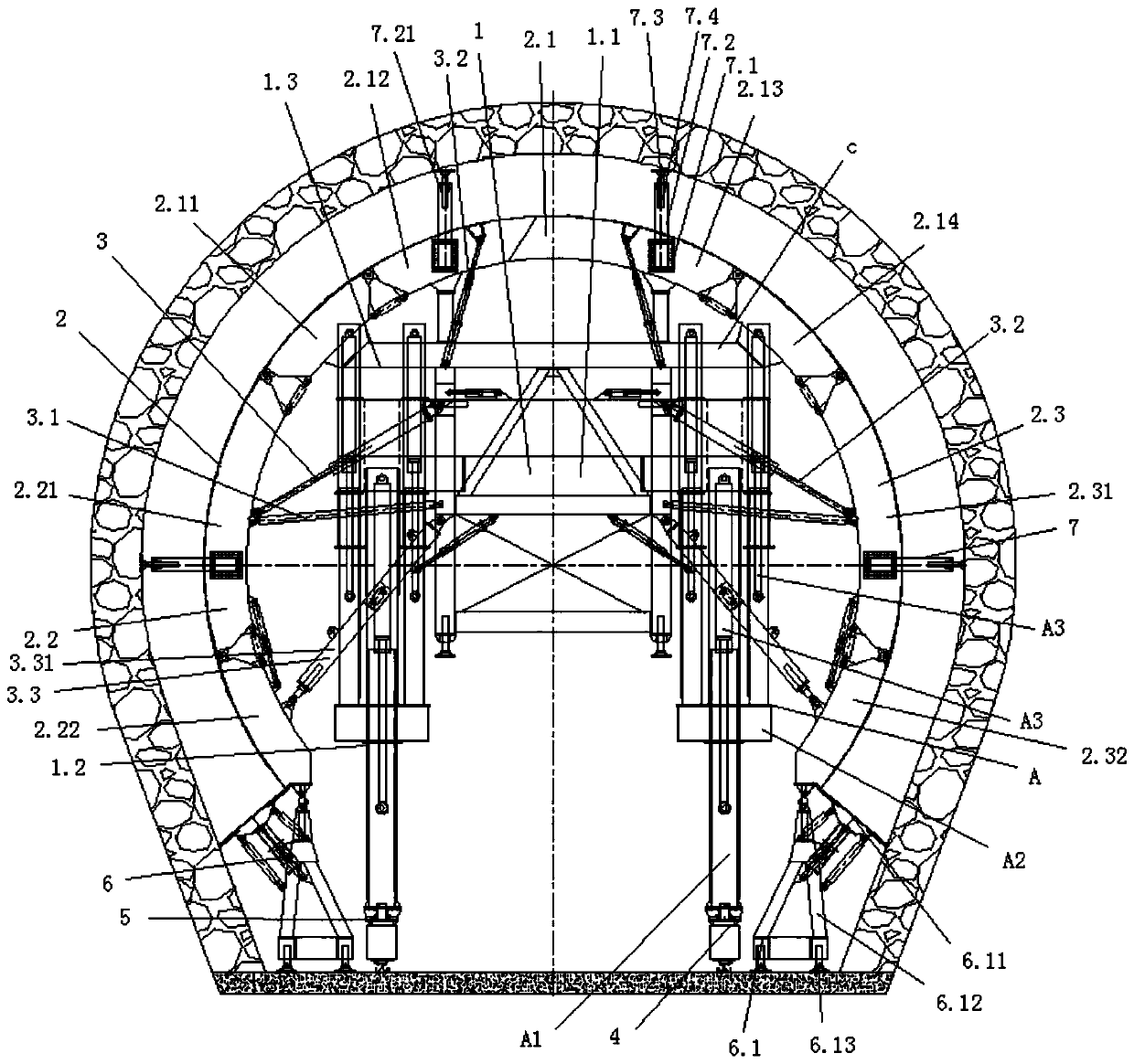

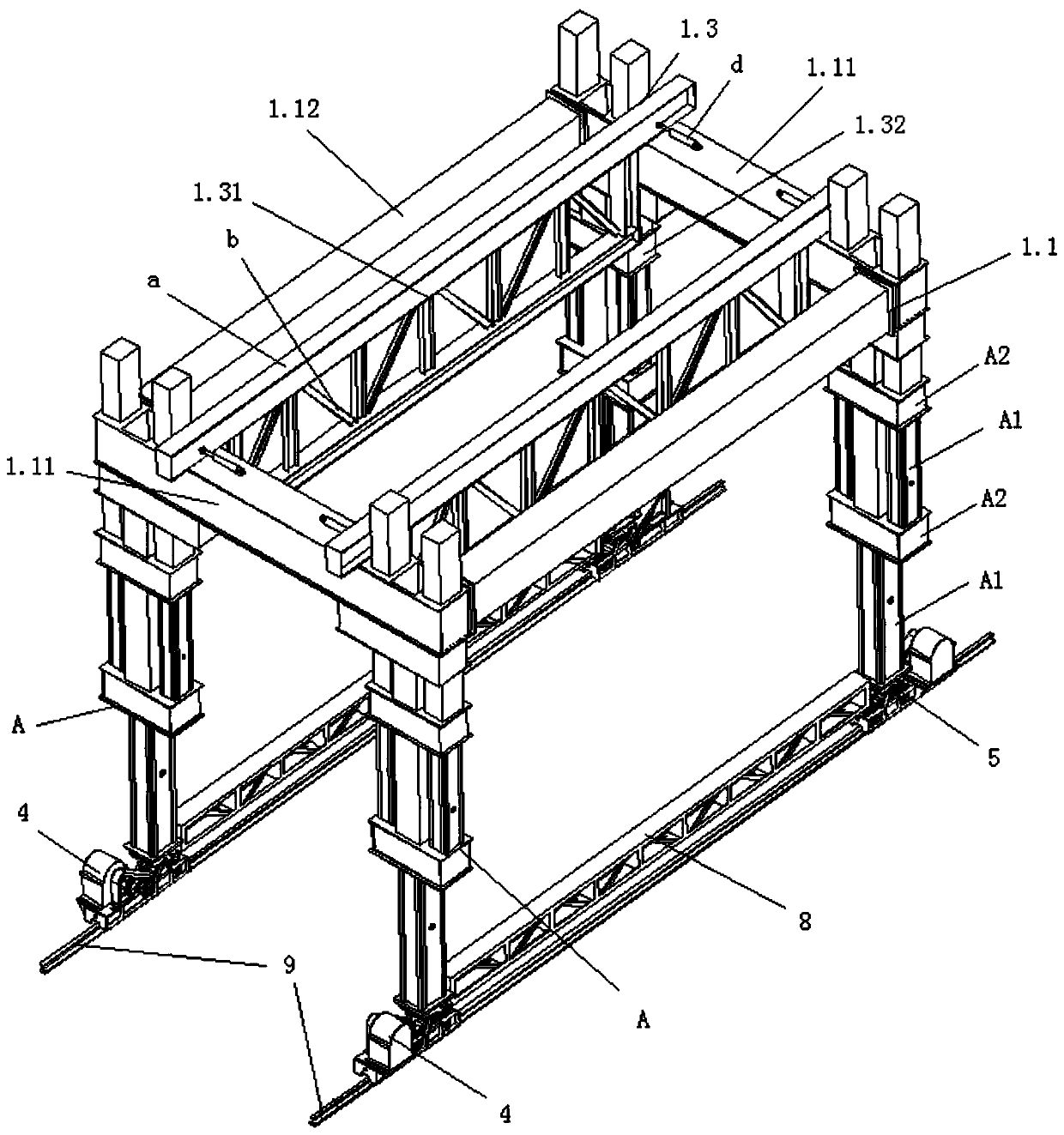

Construction method of tunnels and tunnel lining trolley adopting same

ActiveCN106837379AReduce in quantityMeet construction needsUnderground chambersTunnel liningEngineeringBuilding construction

The invention provides a construction method of tunnels. The construction method specifically comprises the following steps that (1), a lining trolley is assembled; (2), the lining trolley travels into a master cave to conduct lining construction; (3), after master cave construction is completed, first conversion of the lining trolley is conducted, and the lining trolley travels into a next master cave through a branch cave; (4), second conversion of the lining trolley is conducted, and the lining trolley after second conversion conducts lining construction; and (5), the step (3) and the step (4) are repeated to construct the multiple master caves, third conversion of the lining trolley is conducted, and lining construction of the tunnels is completed. By adoption of the construction method, the technical step is concise, the construction requirements of the multiple tunnels which are arranged side by side are met by one trolley, and labor cost and device cost are reduced. The invention further discloses the tunnel lining trolley. The tunnel lining trolley has the effects that the overall structure is concise, and assembling is convenient; and the trolley has a large lifting quantity, and the double requirements of master cave lining and smooth passing of short branch caves are met.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

Chassis packaging device for household appliance

PendingCN109160088AReduce deformationImprove extrusion resistancePackaging vehiclesContainers for machinesEngineeringChassis

The invention provides a chassis packaging device for household appliance. The chassis packaging device comprises a bearing base and a reinforcing device, wherein the bearing base comprises a body, the body is provided with at least one base foot part being arranged at the corresponding position of base feet of a chassis of the household appliance, and at least one of the base foot parts includesa bearing base foot part corresponding to the bearing side of the household appliance; the reinforcing device is arranged on the bearing base foot part and used for making contact with the corresponding base foot; and the stiffness of the reinforcing device is higher than that of the base foot parts. The reinforcing device is arranged on the bearing base foot part, corresponding to the bearing side of the household appliance, of the bearing base, meanwhile the stiffness of the reinforcing device is higher than that of the base foot parts, when the bearing base is extruded, the overall anti-extrusion capacity of the bearing base is enhanced because of the existence of the reinforcing device, and the chassis is not prone to deformation; especially, when the household appliance falls off, extrusion external force suffered by the chassis is less than the external force when the reinforcing device is not added, and the degree of chassis deformation caused by falling off is reduced.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

Double-layer solid wood composite floor and preparation method thereof

ActiveCN105888187AThe problem of non-uniform cutting deformationIncreased longitudinal deformation resistanceCovering/liningsFlooringSolid woodPulp and paper industry

The invention provides a double-layer solid wood composite floor and a preparation method thereof. The double-layer solid wood composite floor comprises a surface plate and a back plate. Multiple through holes are formed in the back plate in a hollowed-out mode. A glue layer is arranged between the surface plate and the back plate, hot pressing is conducted, a double-layer wood plate structure is formed, wood grain directions of the surface plate and the back plate are identical, and wood blocks perpendicular to grain of the surface plate and grain of the back plate and corresponding to the contours of the through holes are embedded into the through holes. By means of the double-layer solid wood composite floor, glue layers are reduced, only one glue layer is used, and the emission amount of harmful gas is reduced. The wood blocks with perpendicular middle grain are embedded, longitudinal strength is greatly improved, and the big-width floor can be machined. The problems that double-layer solid wood composite floors are poor in deformation and stress resisting capacity, traditional three-layer or multi-layer composite wood floors are provided with too many glue layers, and excessive harmful gas is released are solved.

Owner:FUSONG JINLONG WOOD GRP CO LTD +4

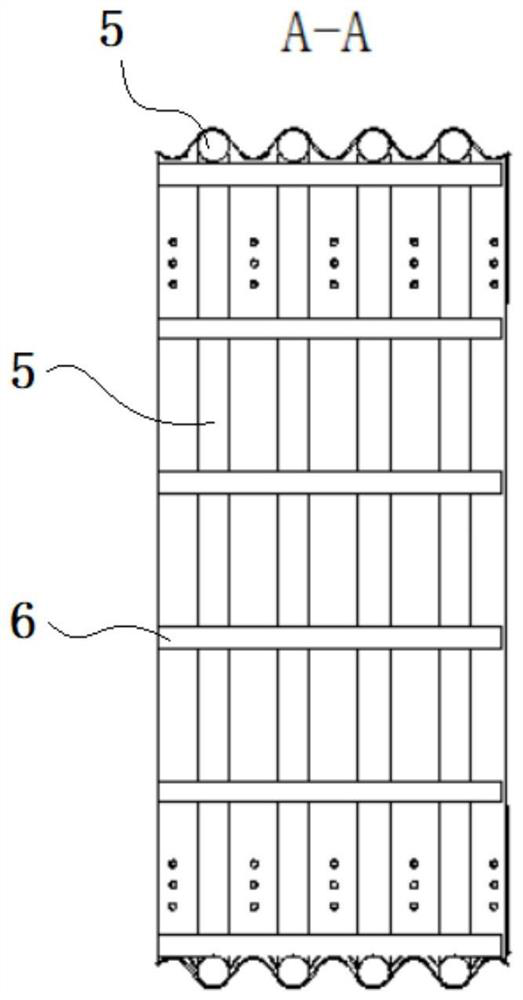

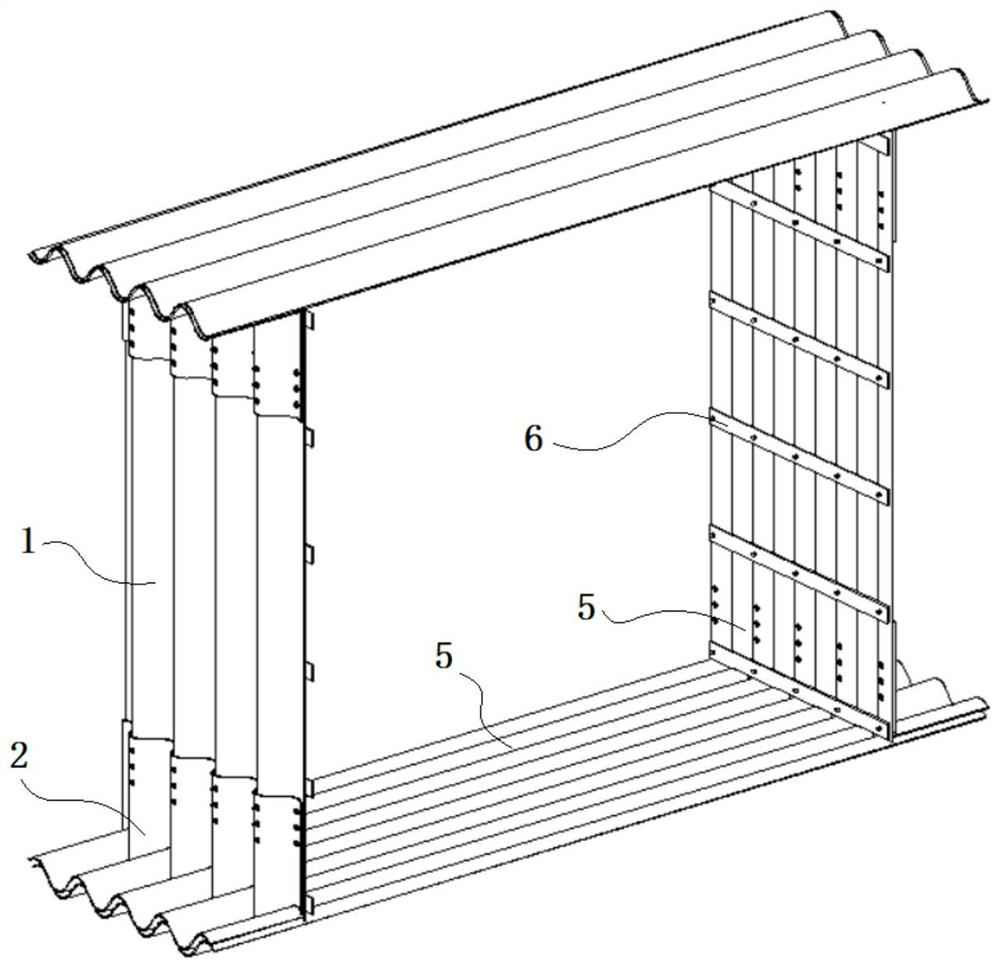

Reinforced corrugated plate box culvert structure

PendingCN114293488AGuaranteed StrengthGuaranteed anti-deformation effectGround-workArchitectural engineeringCivil engineering

The invention relates to a reinforced corrugated plate box culvert structure which comprises a plurality of jointed board units, the multi-face jointed board units are sequentially and vertically connected through connecting pieces to form a closed box culvert structure, the reinforced corrugated plate box culvert structure comprises an upper jointed board unit, a lower jointed board unit, a left jointed board unit and a right jointed board unit, each jointed board unit comprises a steel corrugated plate, a reinforcing pipe and a fixing transverse plate, and the reinforcing pipes are arranged in wave troughs of the steel corrugated plate; the reinforcing pipes on the adjacent splicing plate units are perpendicularly connected in an abutting mode, all the reinforcing pipes form an inner reinforcing frame in a box culvert shape, and the multiple fixing transverse plates are transversely fixed to the inner walls of the steel corrugated plates to fix the reinforcing pipes. According to one embodiment, the inner reinforcing frames are arranged in the box culvert structure, the inner reinforcing frames abut against one another through the high-strength reinforcing pipes so as to share radial and transverse deformation pressure borne by the jointed board units in the culvert, and the strength, the deformation resistance and the anti-seismic effect of the box culvert are guaranteed.

Owner:XIAN CENTURY METAL STRUCTURE CO LTD

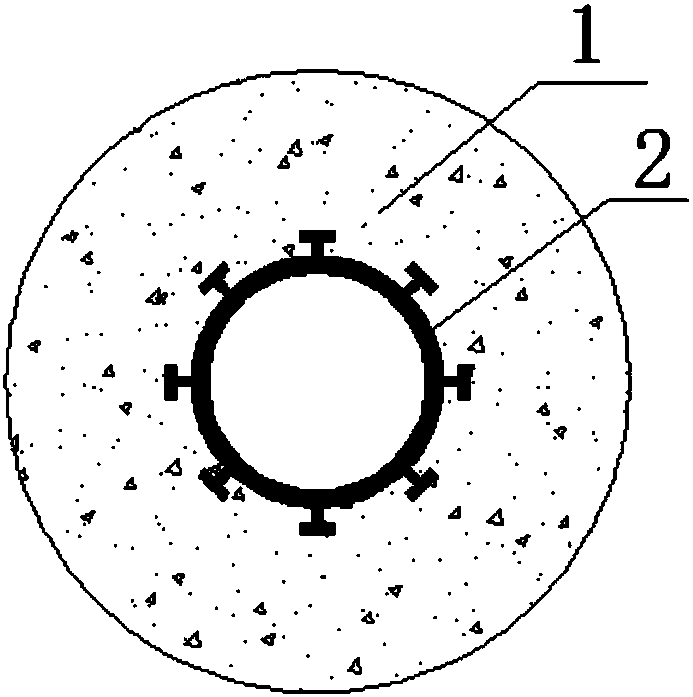

Concrete tube with lining water-absorption expansion plastic sheet

InactiveCN108662302ACorrosion resistantAging resistantCorrosion preventionPipe protection against corrosion/incrustationPlastic materialsPlastic film

The invention relates to a concrete tube with a lining water-absorption expansion plastic sheet. The concrete tube comprises a lining water-absorption expansion plastic sheet and a concrete structurelayer wrapped around the outer side of the lining water-absorption expansion plastic sheet, the lining water-absorption expansion plastic sheet is prepared from two or more layers of high-molecular plastic materials, and is divided into a base body layer and a water-absorption expansion layer, the base body layer is arranged on the inner side, the water absorption expansion layer is arranged on the outer side, and anchoring structures are distributed and arranged on the outer side of the lining water-absorption expansion plastic sheet. The anchoring structures extend into the concrete structure layer, so that the lining water-absorption expansion plastic sheet and the concrete structure layer are firmly combined, and better sealing performance is achieved; and the anchoring structures consist of connecting sections and anchoring sections, the connecting sections are directly connected with the lining water-absorption expansion plastic sheet, and the anchoring sections are directly connected with the connecting sections. Compared with the prior art, the concrete tube has the advantages of being good in sealing effect, long in service life, good in anti-corrosion effect and low in maintenance cost, so that the service life of the concrete tube can be obviously prolonged by 10-20 years.

Owner:SHANGHAI QINGYUAN PIPE TECH

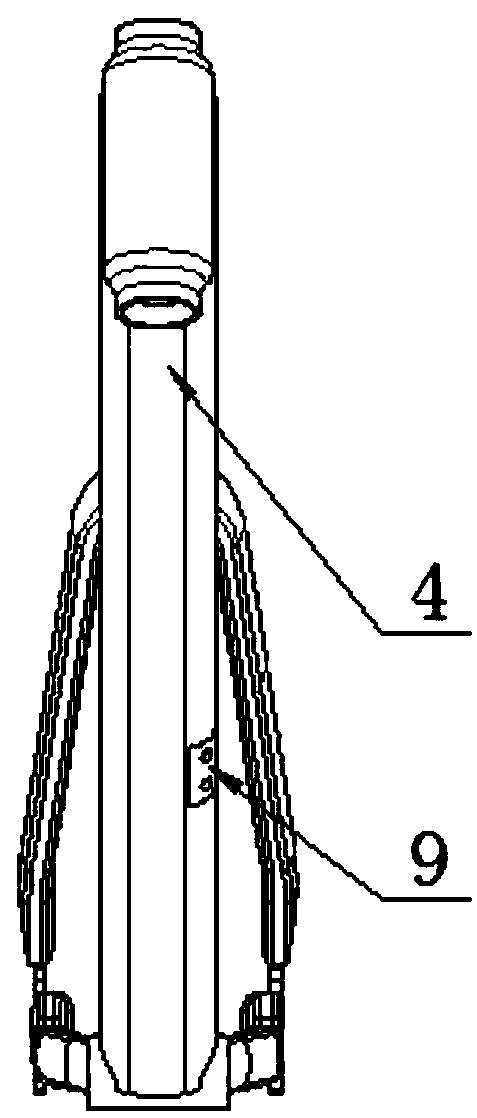

A lining trolley suitable for the construction of main tunnels and branch tunnels in parallel tunnels

ActiveCN106593472BEnsure normal walkingBig liftUnderground chambersTunnel liningHydraulic cylinderArchitectural engineering

The invention provides a section-variable tunnel-crossing lining trolley which comprises a portal system, a template system, a connecting part and a walking mechanism, wherein the portal system comprises a frame part, a jacking mechanism and a bracket part; the jacking mechanism comprises multiple sets of jacking single pieces; each of the jacking single pieces comprises a multi-level jacking part; the bracket part comprises a truss girder and an adjusting support frame for a walking mechanism; the template system comprises a top template, a left template and a right template; and the connecting part comprises a support jack and a hydraulic cylinder. The section-variable tunnel-crossing lining trolley provided by the invention has the effects that the whole structure is simple; the assembling is convenient; the jacking mechanism is in a multi-level jacking mode; the trolley not only can adapt to the construction for the tunnel sections in different heights but also can achieve higher lifting volume; the trolley can meet the requirement of constructing multiple parallel tunnels by one trolley in the manner of constructing the working tunnel; due to the design of the bracket part, the lining trolley can meet the stability requirement, and meanwhile, the structure is simplified and the whole trolley can be supported.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD +1

Permeable asphalt and improved construction method thereof

PendingCN113817330AExtended service lifeIncrease viscosityPaving reinforcementsPaving gutters/kerbsRoad surfaceMaterials science

The invention relates to the technical field of asphalt pavement construction methods, and discloses permeable asphalt and an improved construction method thereof.The permeable asphalt is characterized in that 1, rubber powder and an HVA high-viscosity modifier are used for conducting composite modification on asphalt, and the cohesiveness of the asphalt is improved; and 2) the permeable asphalt is heated to 180 DEG C to enable the permeable asphalt to be in a flowing state, and respectively 6%, 8%, 10% and 12% of micro-particle HVA high-viscosity modifiers are added into the permeable asphalt. According to the permeable asphalt and the improved construction method thereof, the influence of water damage on the service life of an asphalt pavement can be reduced, the service life of the pavement can be greatly prolonged, the viscosity of the asphalt can be greatly improved by doping the micro-particle HVA modifier and a proper amount of rubber powder, and the high and low temperature resistance and the fatigue resistance of an asphalt mixture can be comprehensively improved; and the use stability of the permeable asphalt pavement in a high-temperature region and a cold region is improved, and the junked tires are combined with the permeable asphalt pavement, so that the pavement performance can be improved, and the environmental pressure caused by the junked tires can be relieved.

Owner:SUZHOU GOLD MANTIS GREEN LANDSCAPE LIMITED

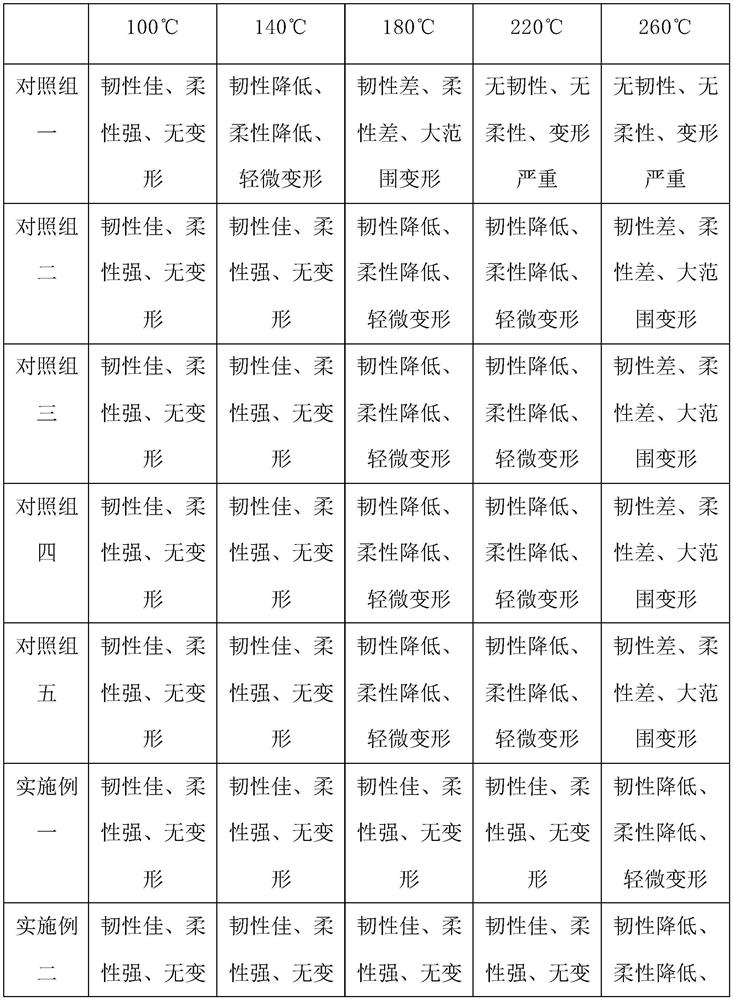

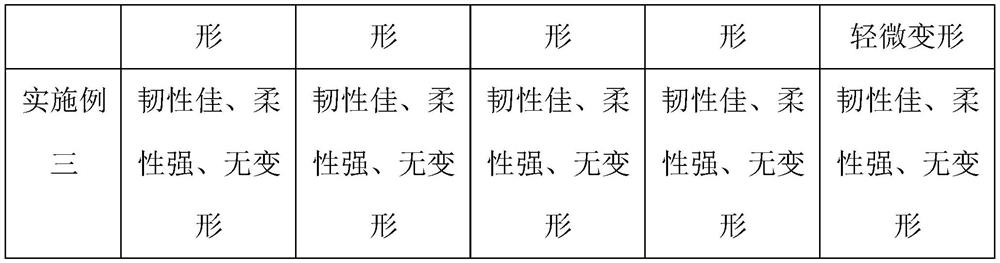

Glue solution for coating television circuit board and preparation method of glue solution

ActiveCN113046009AImprove protectionAvoid dryness and hardeningNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceHexagonal boron nitride

The invention discloses a glue solution for coating a television circuit board and a preparation method of the glue solution, and particularly relates to the technical field of circuit board glue solutions. The glue solution comprises a component A liquid and a component B. The component A liquid comprises epoxy resin, a curing agent, pyrolytic graphite, nano silicon dioxide and an organic solvent; and the component B liquid comprises polyurethane, a curing accelerator, nano cellulose, hexagonal boron nitride microchips and an organic solvent. The heat-resistant and high-temperature-resistant performance of the glue solution can be effectively improved, the toughness and flexibility of the glue solution in a high-temperature environment and the protection effect on a circuit board can be effectively guaranteed, the glue solution can be prevented from being dried up and hardened in the high-temperature environment when the circuit board is coated with the glue solution, double modification treatment can be effectively combined on the basis of effectively guaranteeing the performance of epoxy resin, on the basis of effectively ensuring the self performance of polyurethane, double modification treatment can be compounded, and the heat resistance and stability of the component A liquid and the component B liquid can be effectively enhanced.

Owner:青岛汇元海泰电子有限公司

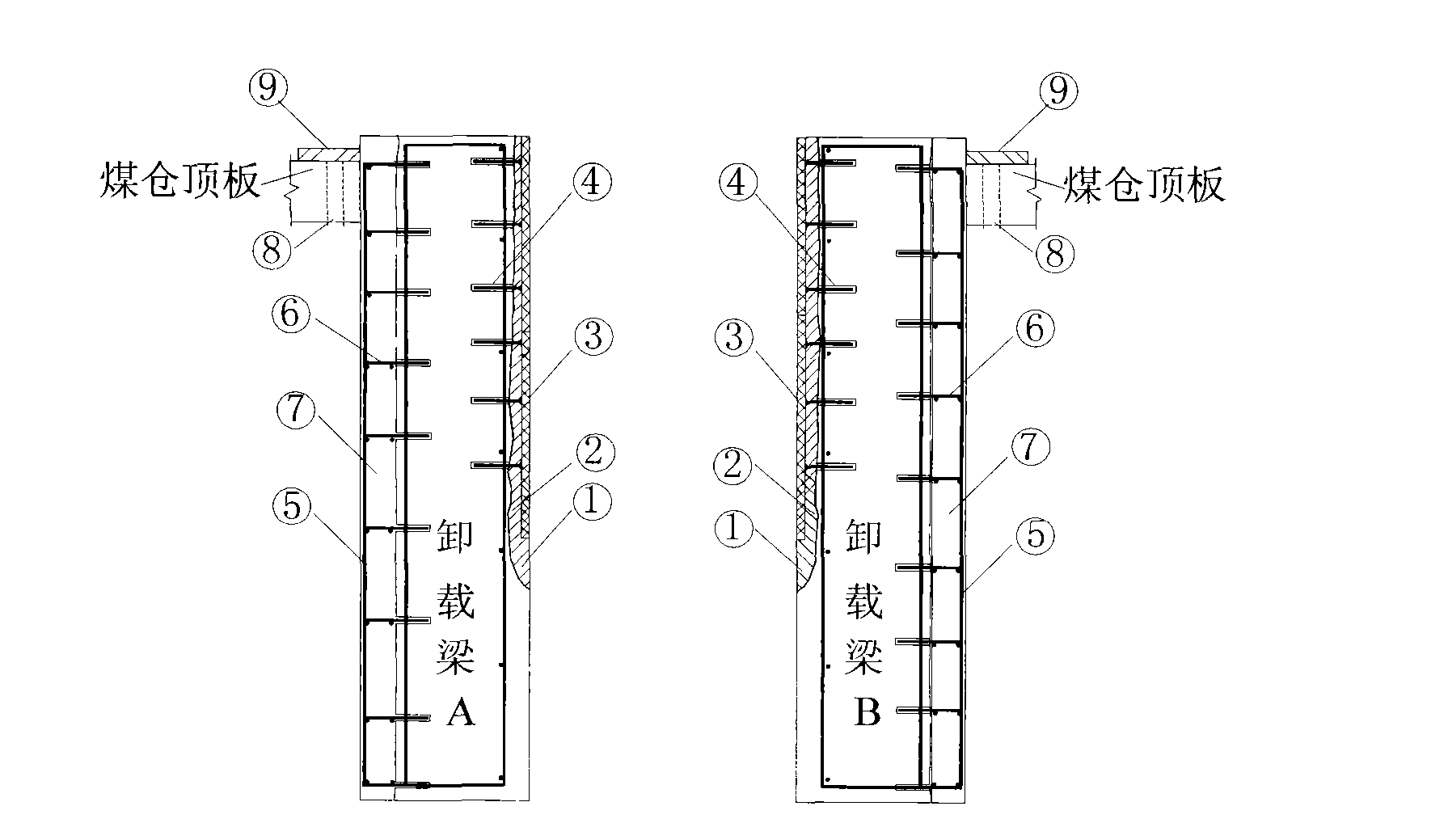

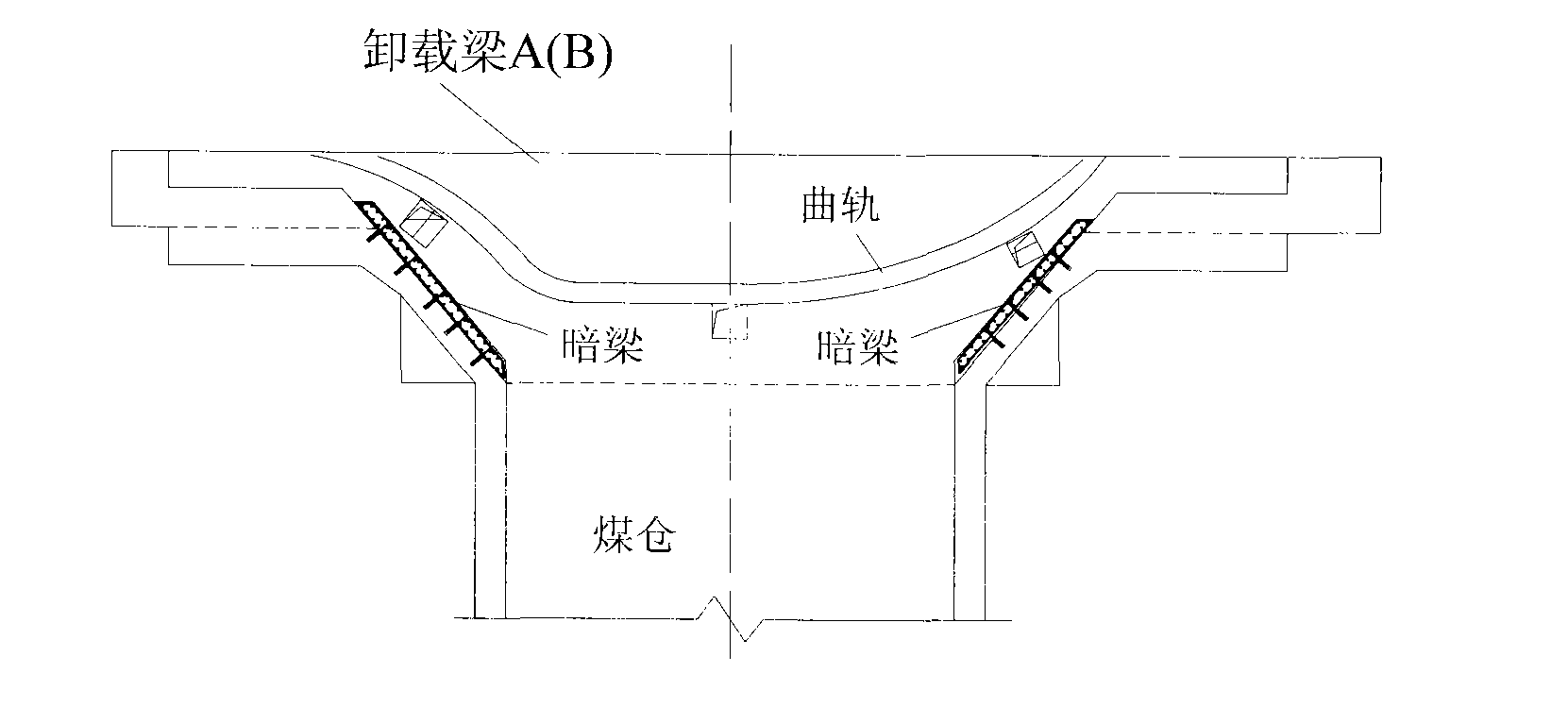

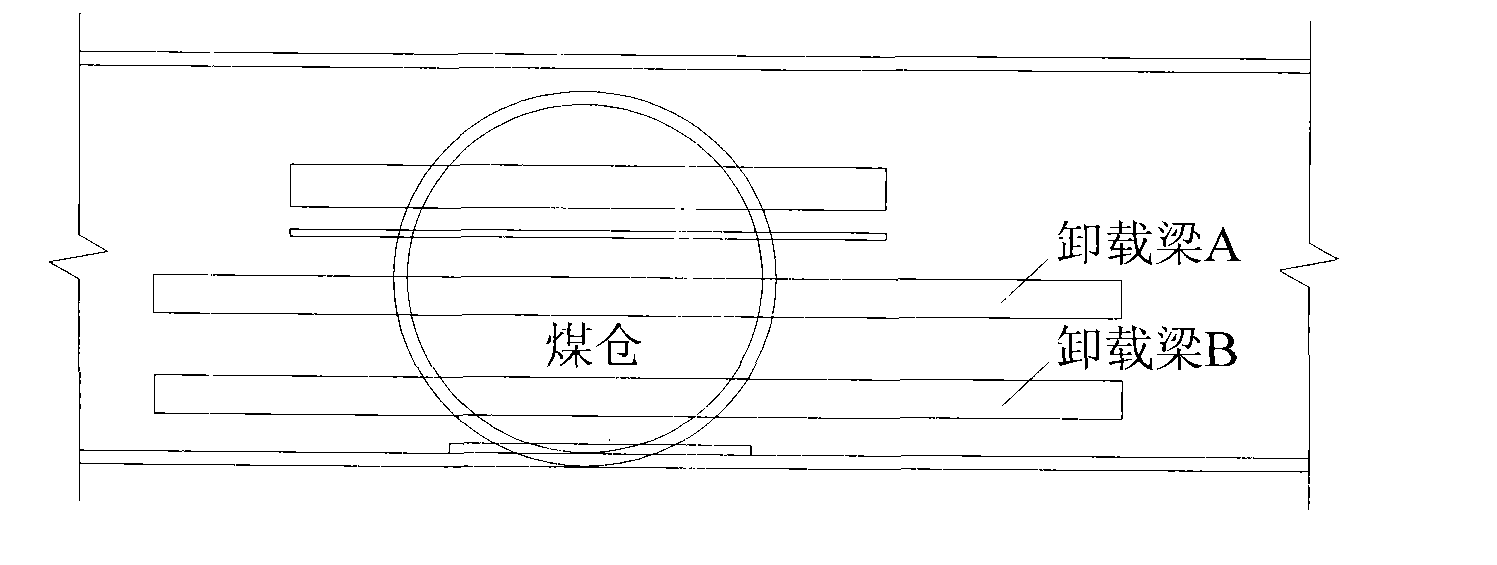

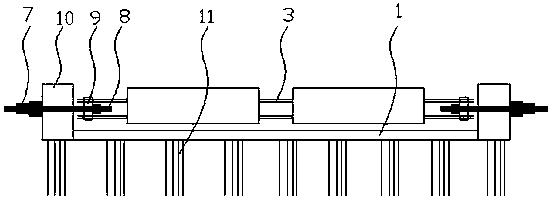

Method for reinforcing unloading beams of unloading station of coal mine

InactiveCN103061528BGuaranteed carrying capacityGuaranteed anti-deformation effectBuilding repairsReinforced concreteRebar

Owner:CHINA UNIV OF MINING & TECH

A pre-tensioned prefabricated beam pedestal

Owner:CHINA RAILWAY 23RD BUREAU GRP RAILTRANSIT ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com