Method for reinforcing unloading beams of unloading station of coal mine

A technology of unloading beams and unloading stations, which is applied in building maintenance, construction, building construction, etc., can solve the problems of easy occurrence of repetition, deformation of unloading beams, and high cost, so as to increase the ability to resist surrounding rock pressure, high reliability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

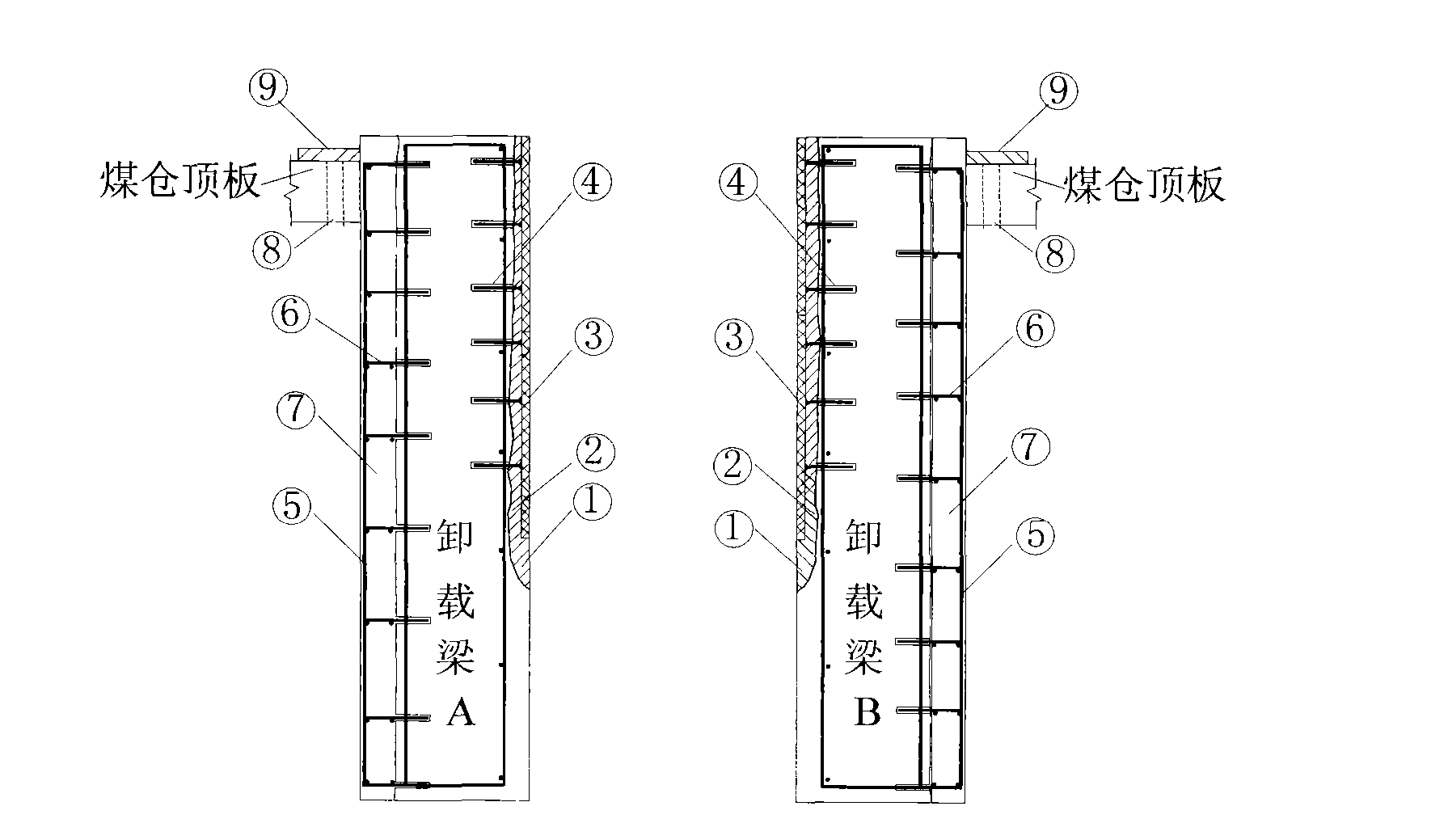

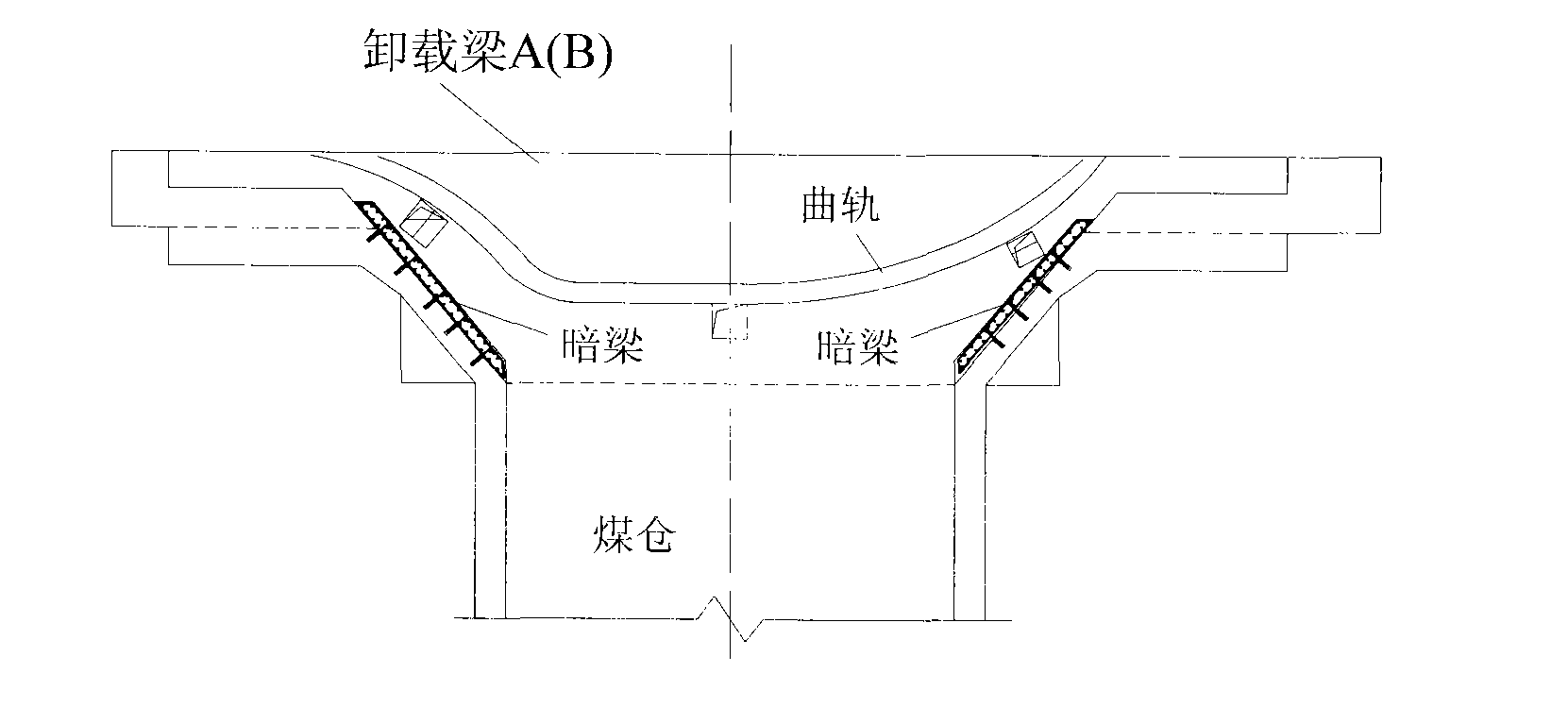

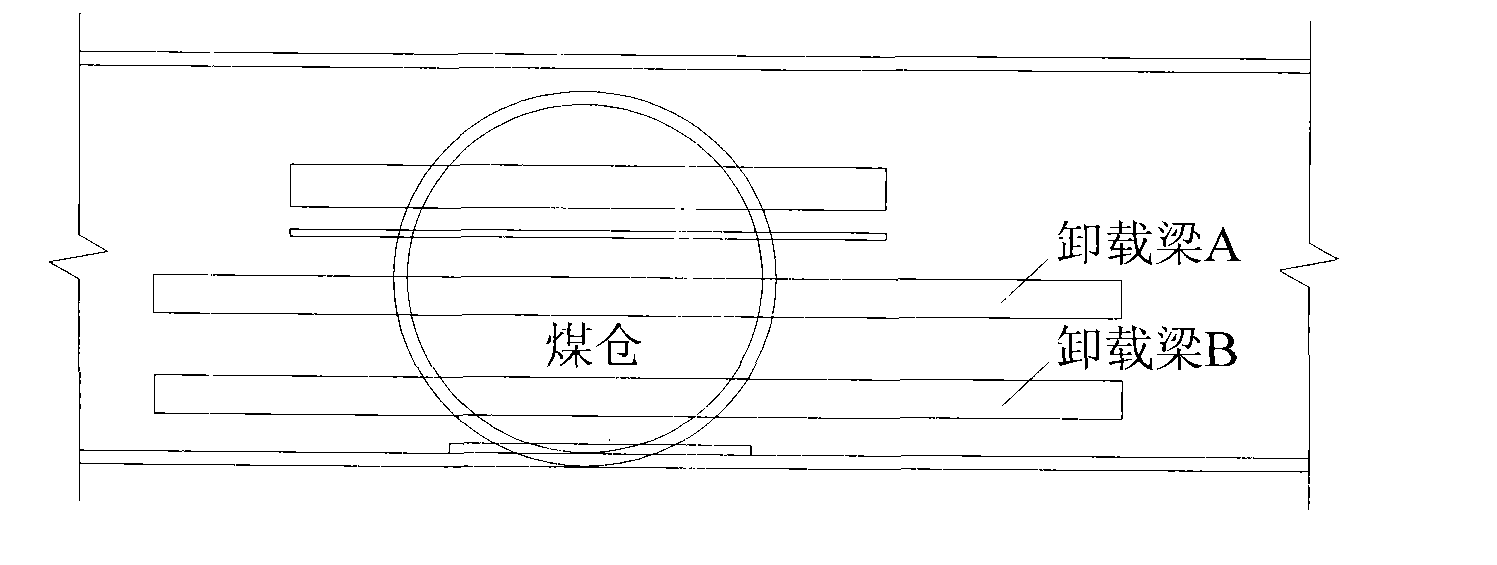

[0025] Attached below Figures 1 to 3 An embodiment of the present invention is further described:

[0026] The invention provides a coal mine unloading station unloading beam reinforcement method, such as figure 1 As shown, taking the two ends of the unloading curved rail as the reference point and the unloading curved rail as the reference line, chisel away the excess concrete ① on the inside of the unloading beams A and B to meet the distance between the steel plates after adding steel plates and pouring grout Meet the design requirements for the distance between mine cars; figure 1 As shown, the outer sides of the unloading beams A and B are chiseled, the reinforcement holes are drilled and steel bars are implanted ⑥, the new beam reinforcement ⑤ is bound, the formwork is supported, and the high-strength non-shrinkage grouting material ⑦ is poured to increase the section width of the original unloading beams A and B. Thereby improving the bearing capacity and deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com