Gantry type lifting shuttle

A shuttle car and gantry-type technology, which is applied in the field of transportation equipment, can solve the problems of high cost, complex structure, and inability to automatically put goods into shelves, etc., and achieve the effect of high stability and guaranteed carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

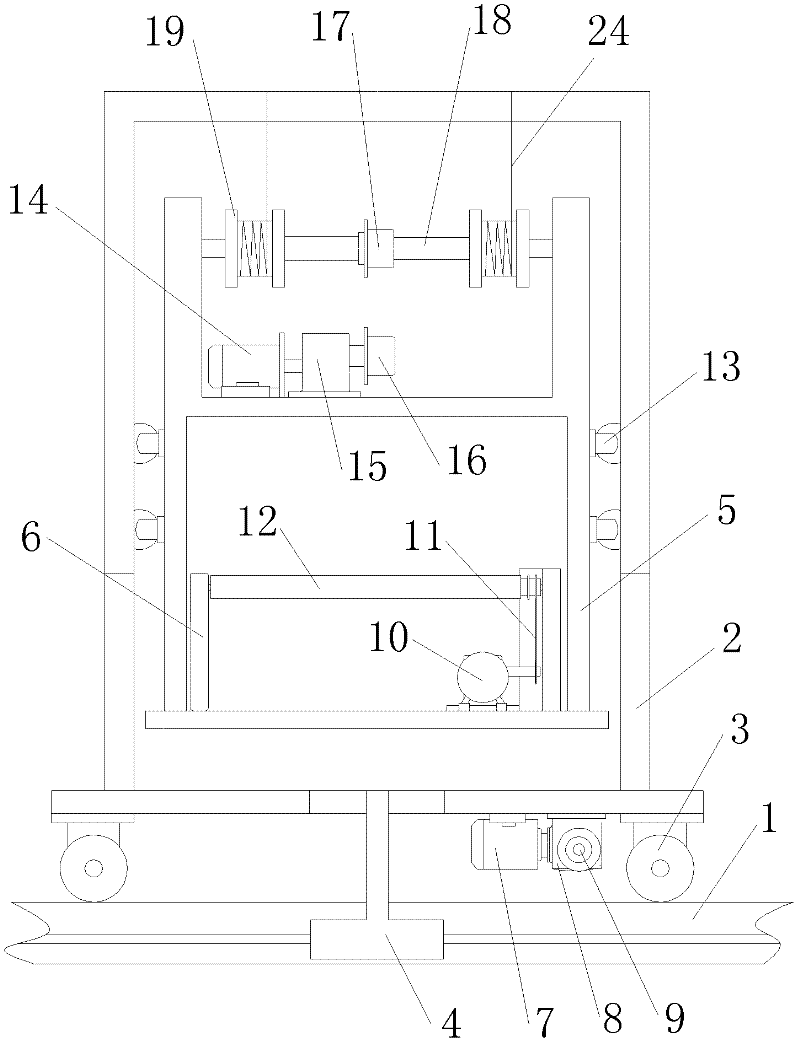

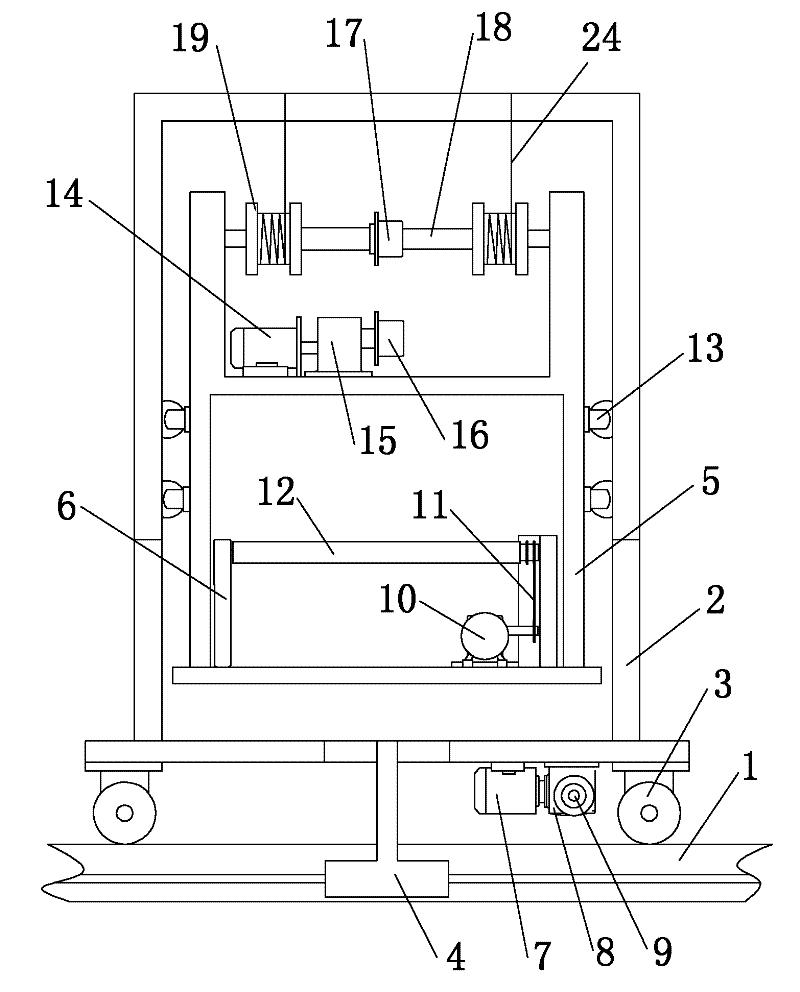

[0017] Such as figure 1 with figure 2 As shown, the gantry-type lifting shuttle vehicle of the present invention includes a gantry frame 2, a running mechanism, a lifting mechanism and a conveying mechanism, the running mechanism is installed on the bottom of the gantry frame 2, the lifting mechanism is installed in the gantry frame 2, and the conveying mechanism is installed on the lifting mechanism. bottom of the body. The lifting mechanism cooperates with the gantry frame 2 through the guide wheels 13, and the running mechanism cooperates with the track 1 through the stabilizing wheels 22, so that the whole shuttle is fixed on the ground and can only reciprocate in the horizontal direction.

[0018] The traveling mechanism mainly includes a traveling wheel 3, a stabilizing wheel 22, a traveling wheel shaft 21 and a traveling drive mechanism. The bottom of the gantry frame 2 is respectively equipped with a walking wheel shaft 21 by a bearing 23 front and back, and two wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com