Crystallizer for semi-continuous casting of aluminum alloy

A crystallizer and semi-continuous technology, which is applied in the field of aluminum alloy semi-continuous casting, can solve the problems affecting the quality of the ingot, the cooling strength is not high, the structure of the ingot is coarse, etc. The effect of improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

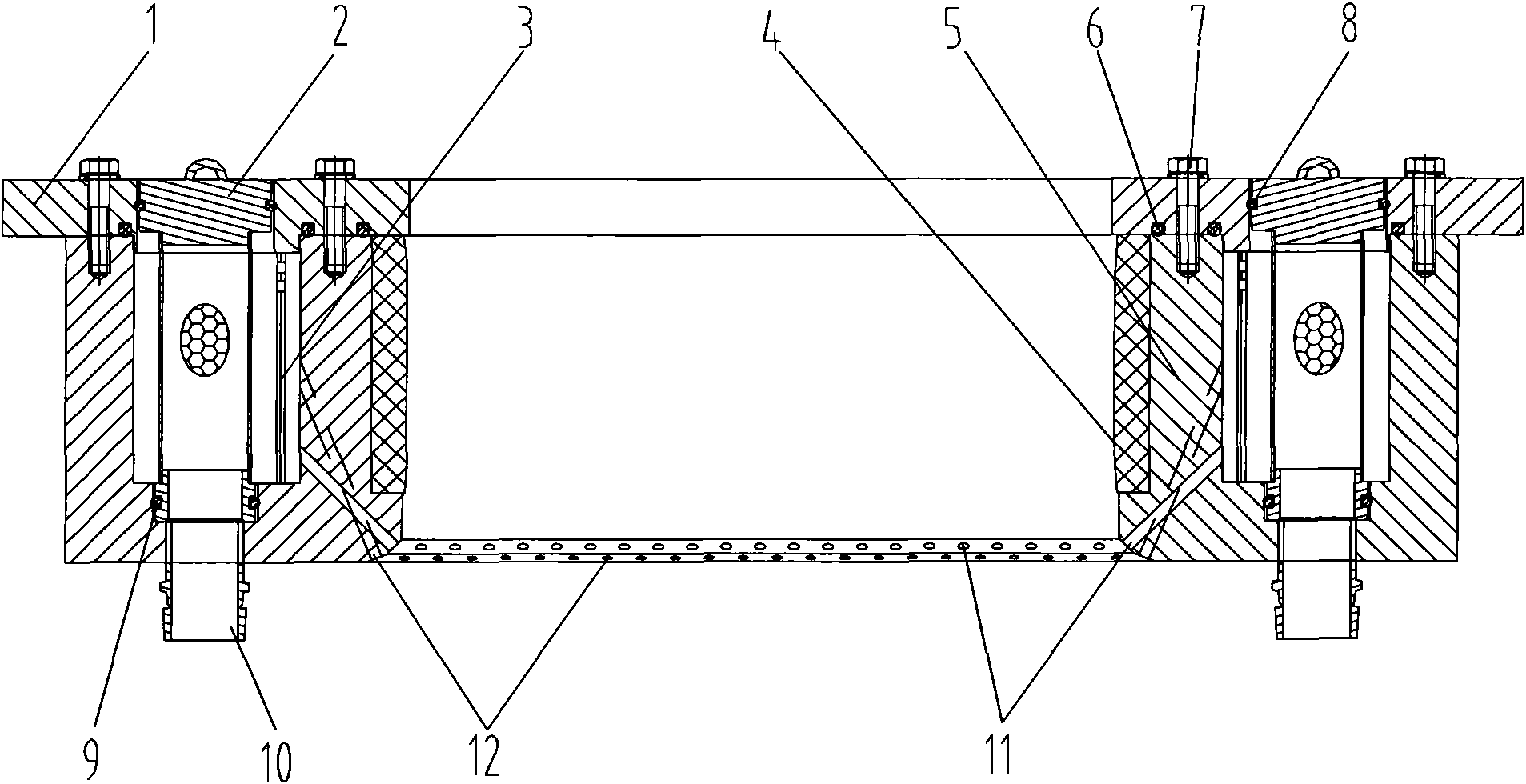

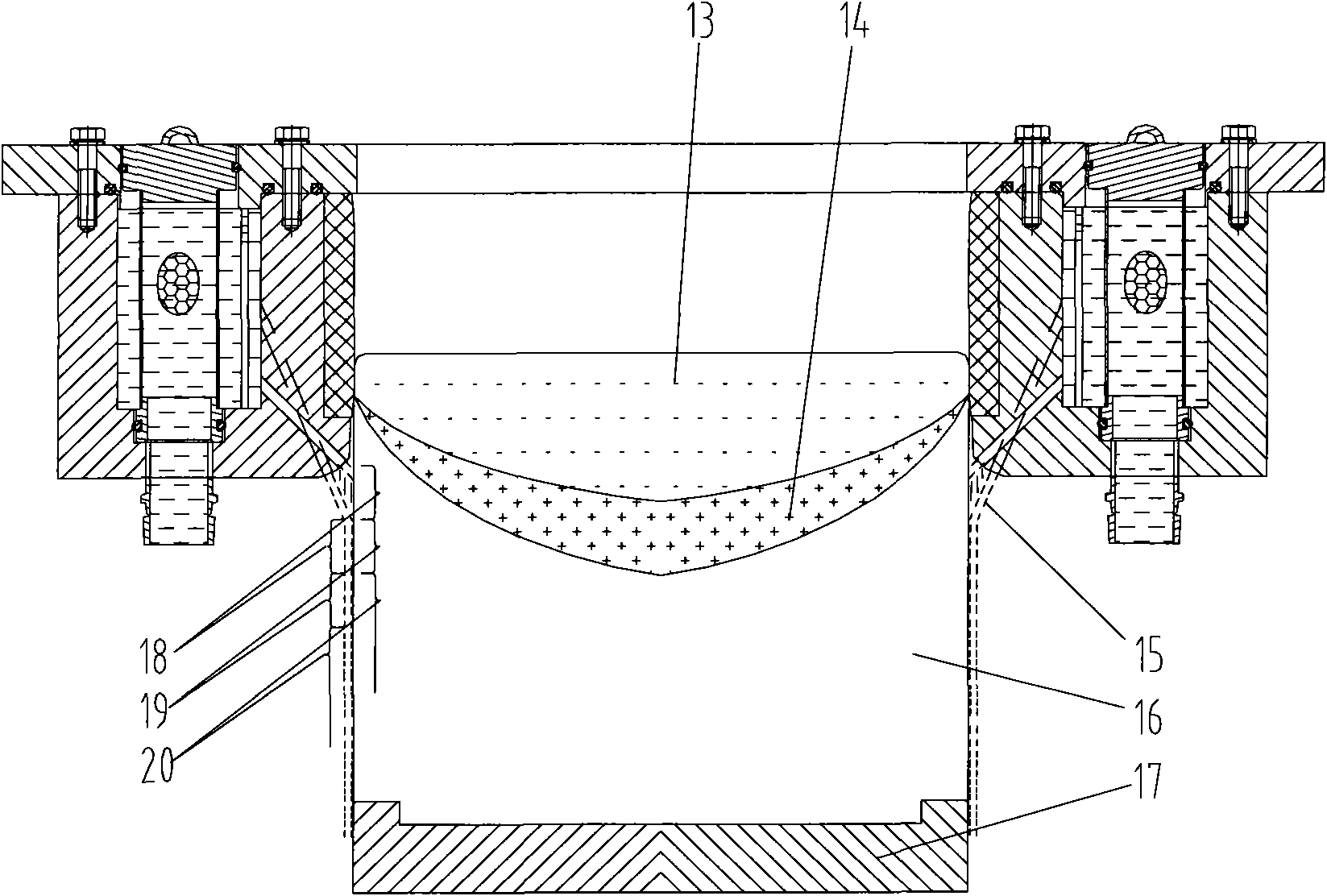

[0020] like figure 1 As shown, a crystallizer for aluminum alloy semi-continuous casting includes a body 5 and an upper cover 1, the inner cavity of the body 5 is embedded with a graphite lining 4, and the graphite lining 4 has a symmetrical structure up and down, and the upper cover 1 is passed through bolts 7 Connected to the main body 5 and sealed by the sealing strip 6, the main body 5 is provided with a water chamber, the bottom of the upper cover 1 is provided with a boss, the boss on the upper cover is matched with the water chamber of the main body, and the water chamber of the main body is provided with Two groups of cooling water holes, that is, the first group of cooling water holes 11 and the second group of cooling water holes 12, the first group of cooling water holes 11 and the second group of cooling water holes 12 are distributed in a crossing manner, and the hole spacing of the two groups of cooling water holes At 10-14mm, the diameter of the two groups of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com