Standing seam roof having deformation resisting capability and installing process thereof

A technology with anti-deformation ability and upright seaming, applied in the field of manufacturing, can solve the problems of roof waterproof performance and expansion performance, affecting the service life of the roof, etc., and achieve the effect of prolonging life, improving quality, and improving waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

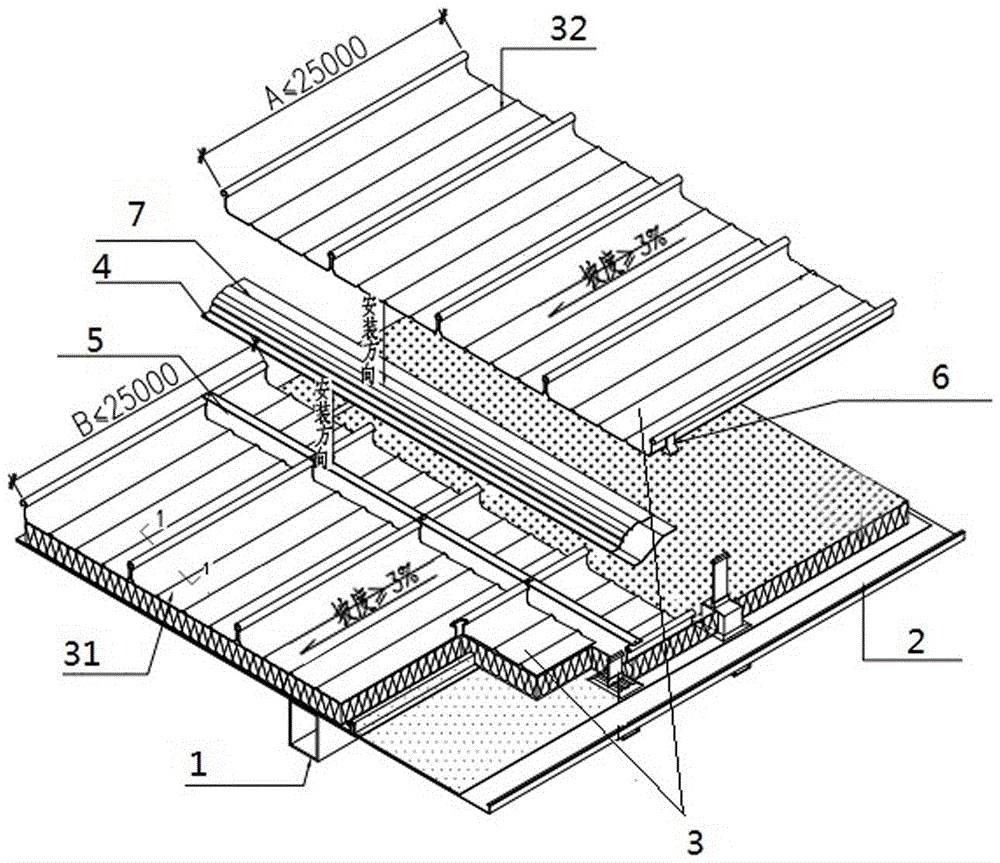

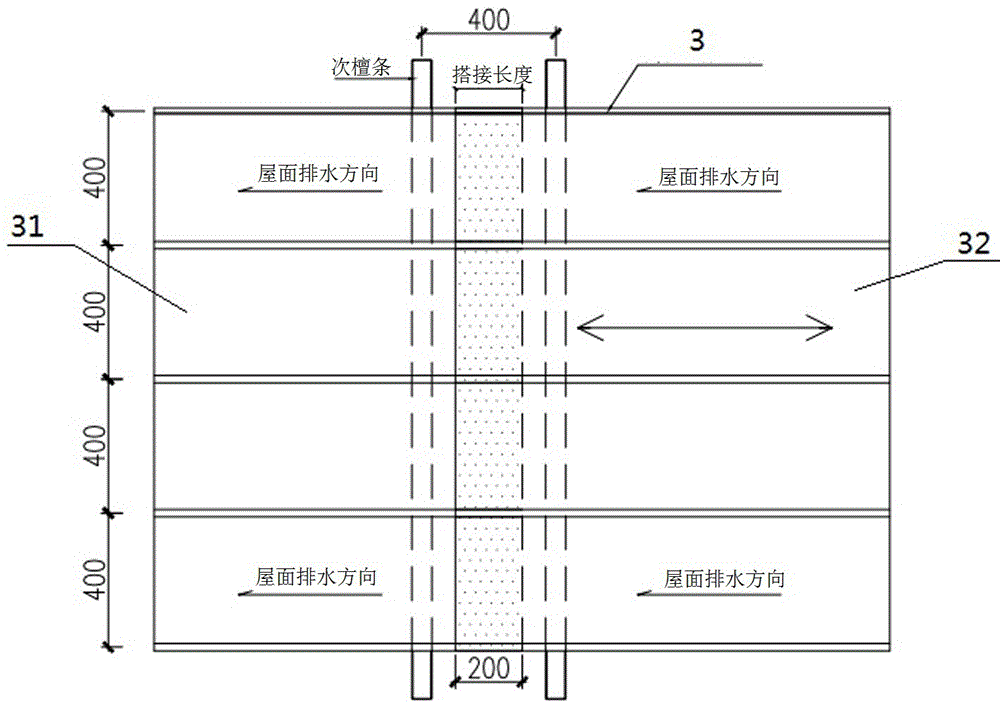

[0033] As shown in the figure, a standing seam roof with anti-deformation ability includes: main sandalwood bar 1, first roof panel 2, second roof panel 3 and flashing panel 4, wherein the second roof panel 3 is composed of a first upright seam plate 31 and a second upright seam plate 32;

[0034] The relationship between the above components is as follows:

[0035] The first roof panel 2 is arranged on the main slat 1, the first standing seam panel 31 and the second standing seam panel 32 are connected to the first roof panel 2 through a connecting piece, and the The top of the first standing seam 31 and the bottom of the second standing seam 32 are respectively provided with a first plug 5 and a second plug 6, and the first standing seam 31 and the second standing seam 32 The lap joints are connected by a flashing board 4, one end of the flashing board 4 is fixed on the first plug 5 of the first standing seam board 31, and the outer side of the flashing board 4 is provided ...

Embodiment 2

[0042] An installation process of a standing seam roof with anti-deformation capability described in this embodiment, wherein the structure of the standing seam roof is the same as that in Embodiment 1.

[0043] As shown in the figure, a standing seam roof with anti-deformation ability includes: main sandalwood bar 1, first roof panel 2, second roof panel 3 and flashing panel 4, wherein the second roof panel 3 is composed of a first upright seam plate 31 and a second upright seam plate 32;

[0044] The relationship between the above components is as follows:

[0045] The first roof panel 2 is arranged on the main slat 1, the first standing seam panel 31 and the second standing seam panel 32 are connected to the first roof panel 2 through a connecting piece, and the The top of the first standing seam 31 and the bottom of the second standing seam 32 are respectively provided with a first plug 5 and a second plug 6, and the first standing seam 31 and the second standing seam 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com