Air deflector, injection mold and molding method

A molding method and injection mold technology, applied in the direction of air flow control components, etc., can solve the problems of thick air deflector, poor user experience, heavy weight, etc., and achieve the effect of reducing the overall volume and overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

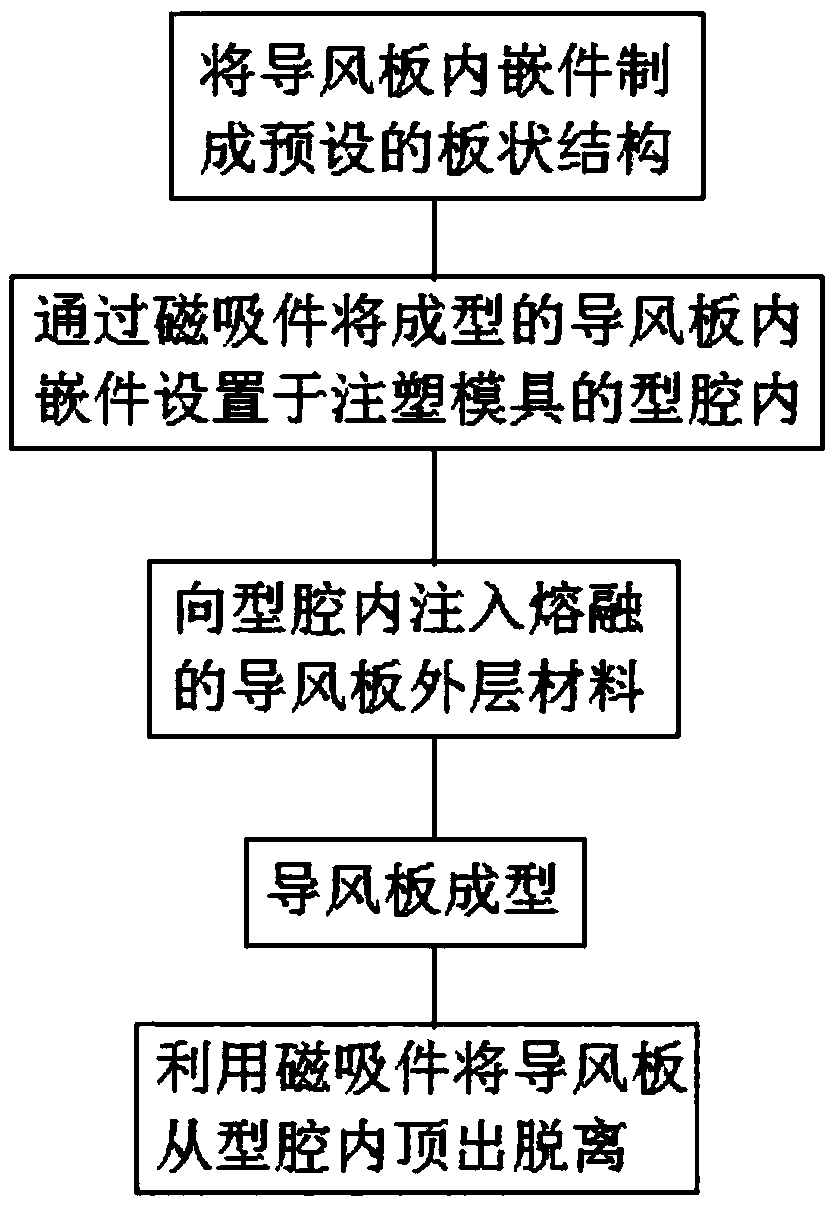

Method used

Image

Examples

Embodiment Construction

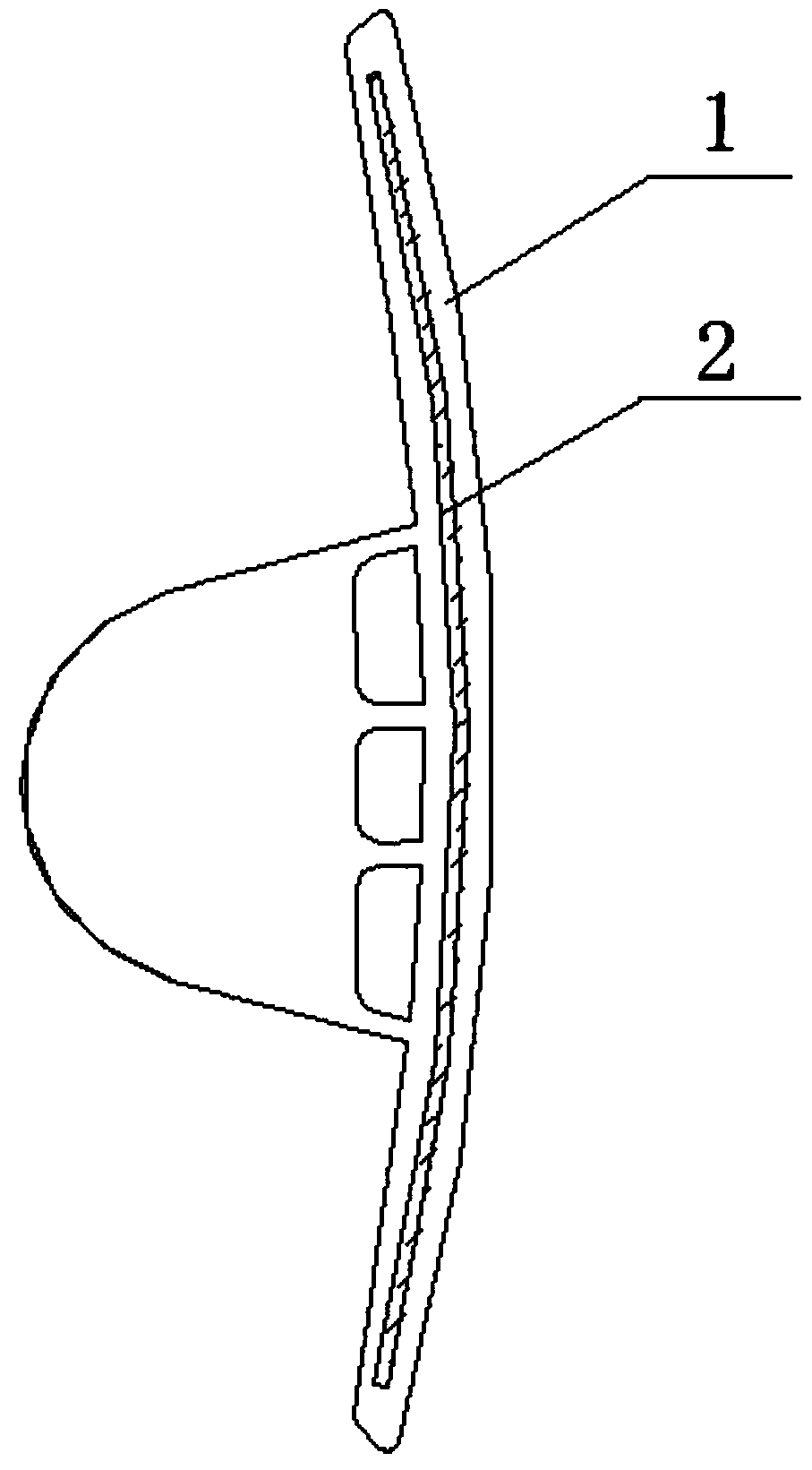

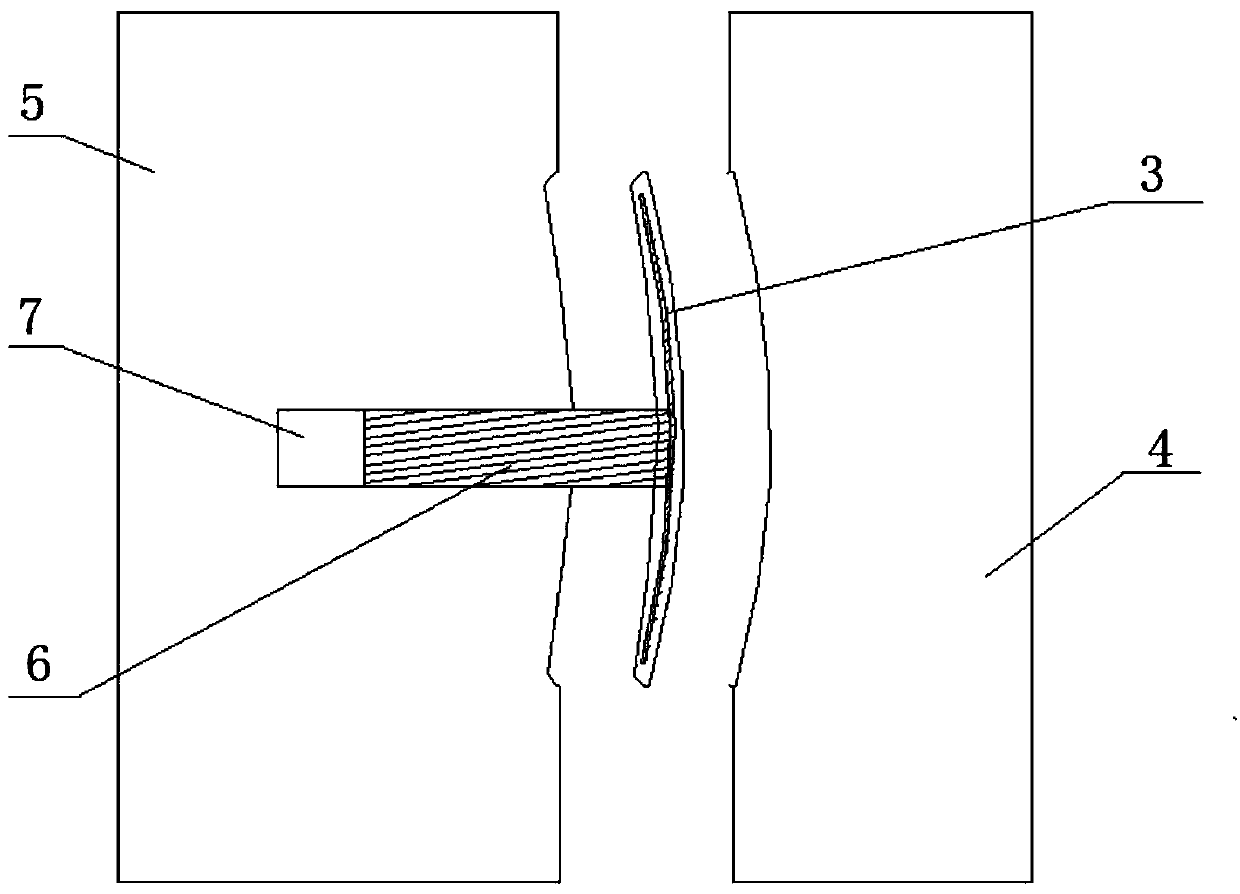

[0021] In order to clearly illustrate the solutions of the present invention, preferred embodiments are given below and described in detail with reference to the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the application or use of the present disclosure. It should be understood that in all the drawings, corresponding reference numerals indicate the same or corresponding parts and features.

[0022] Aiming at the problems of the low strength of the all-plastic air deflector in the prior art and the excessive volume of the aluminum alloy plastic double-layer structure air deflector, the present invention provides an air deflector, which includes an embedded part and a package. Cover the outer periphery of the inner insert. The conventional aluminum alloy plastic double-layer mechanism wind deflector is embedded on the side, part of the surface of the aluminum alloy or plastic is still exposed to the outside, and in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com