Construction method for assembled foundation pit support structure

A foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of poor rigidity and deformation resistance, non-recyclable use, and poor seepage prevention, so as to ensure deformation resistance and save energy. Engineering materials, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0056] Now in conjunction with above-mentioned each accompanying drawing example, further set forth the present invention.

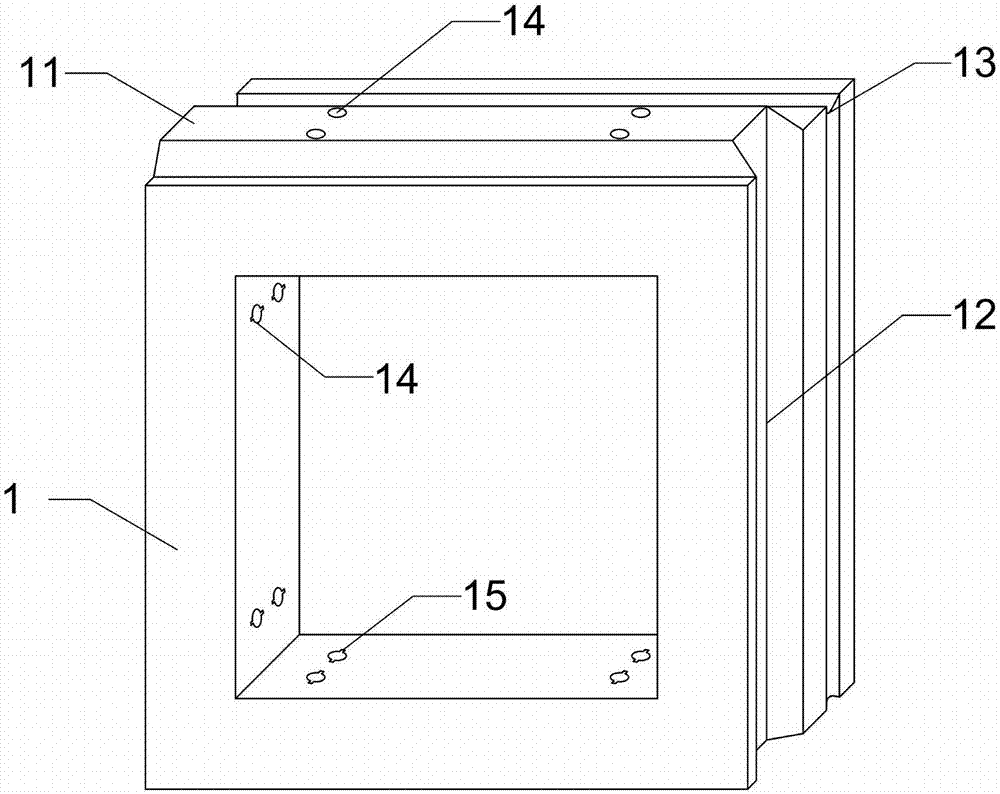

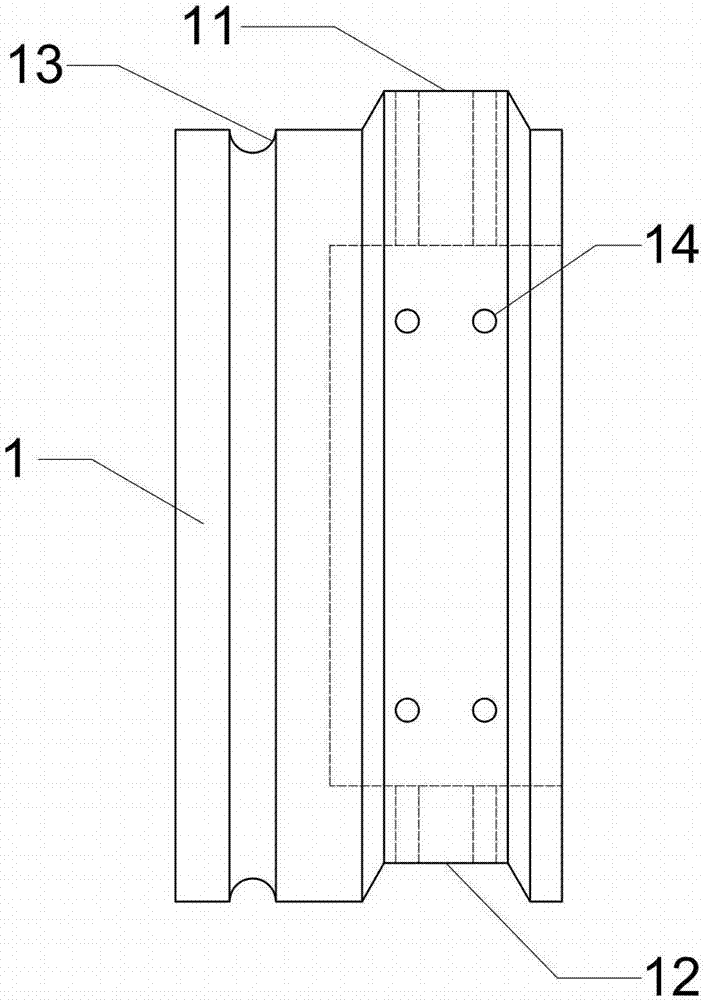

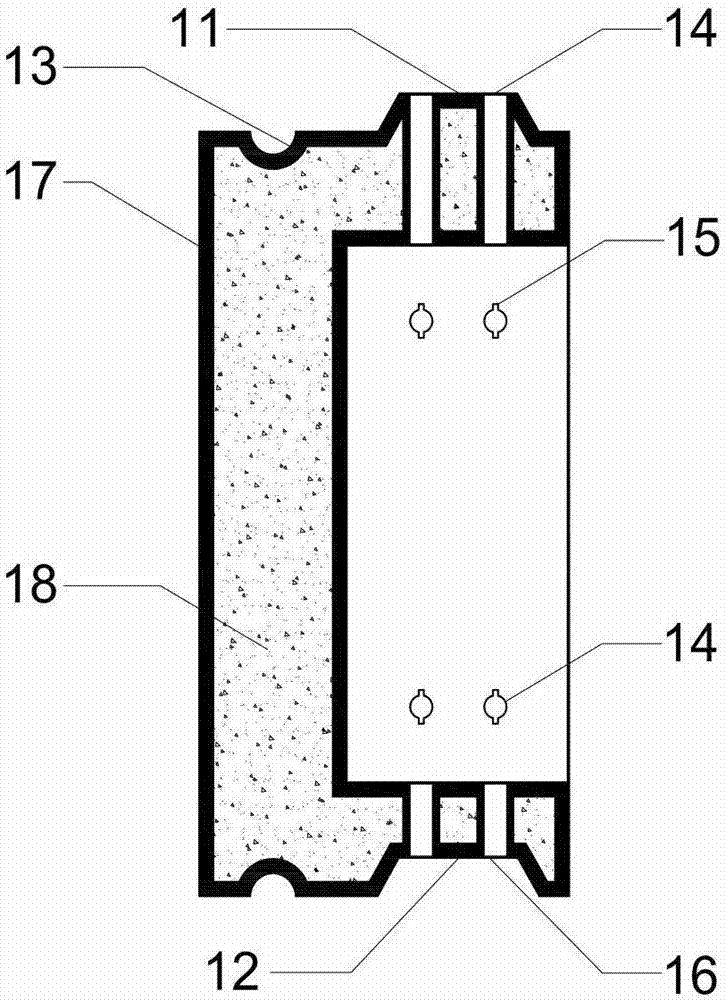

[0057] Such as Figure 1 to Figure 5 As shown, on the one hand, considering the simplification of transportation and assembly, and the excavation depth of each soil layer, it is desirable to use smaller standard pieces; The number of joints, the total length of the joints and the number of bolts, and the shortened construction period in order to reduce the number of assembly times, etc., hope to use larger standard pieces. Considering the actual engineering, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com