Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Green treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denitrification acinetobacters and use thereof

InactiveCN102747015AReduce accumulationEasy to handleBacteriaWater contaminantsOxygenMicrobiological culture

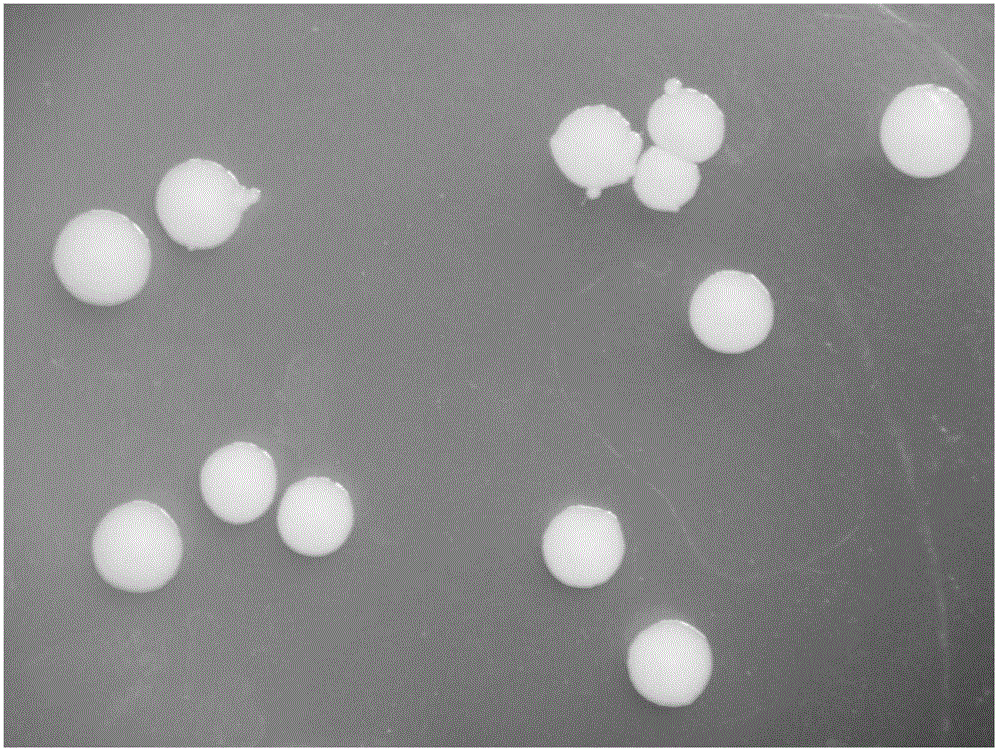

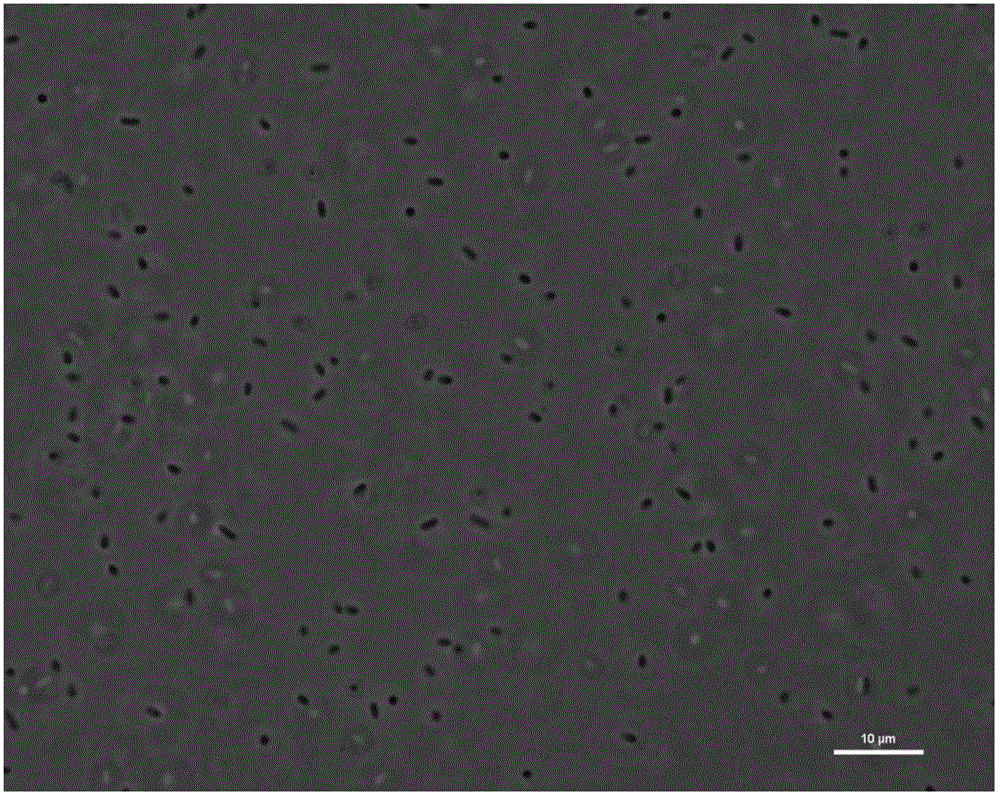

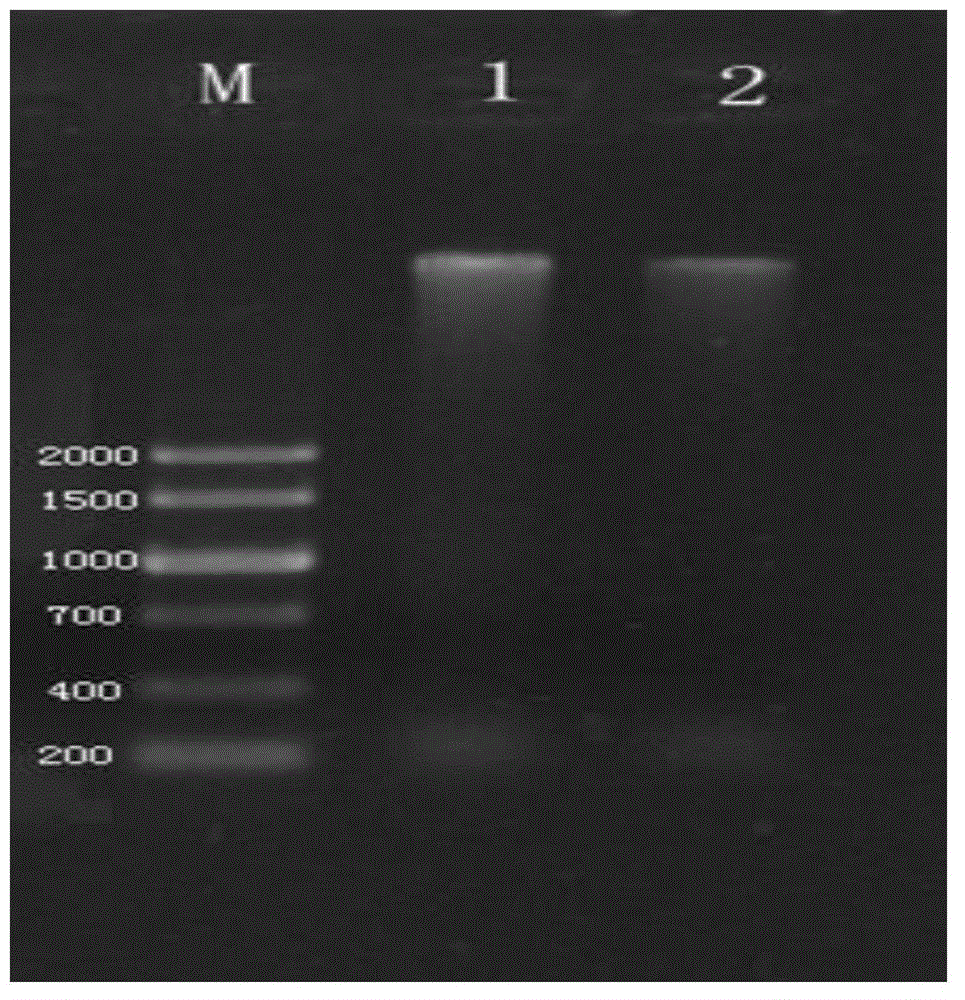

The invention relates to denitrification acinetobacters and a use thereof, and belongs to the field of environmental microbiology. The denitrification acinetobacters have a category name of Acinetobacter schindleri LN5, are preserved in the China general microbiological culture collection center of the China microbiological preservation management committee on May 30th, 2012, and has a preservation number of CGMCC No.6165. The denitrification acinetobacters have heterotrophic nitrification-aerobic denitrification functions, have high aureomycin resistance, can be used for simultaneous nitrification and denitrification (SND) treatment on nitrogen-containing sewage and especially on nitrogen and aureomycin-containing sewage, realize removal of a large part of ammonia nitrogen in nitrogen-containing sewage, realize small accumulation amounts of nitrite and nitrate nitrogen, realize nitrification-denitrification and COD removal in the same reactor, and realize environmentally-friendly, low-consumption and high-efficiency treatment on nitrogen-containing sewage.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Leaching agent for oil-containing drilling cuttings and oil-containing drilling wastes and using method of leaching agent

ActiveCN108273843ALow toxicityEasy to degradeWaste water treatment from quariesContaminated soil reclamationSolid phasesSubstance content

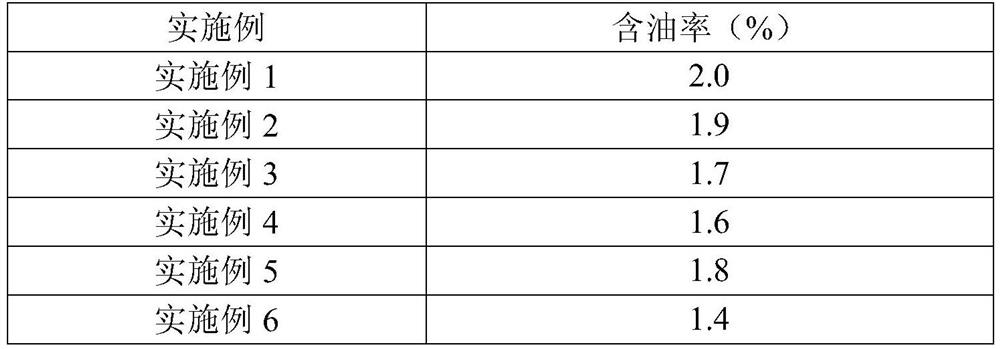

The invention provides a leaching agent for oil-containing drilling cuttings and oil-containing drilling wastes and a using method of the leaching agent. The leaching agent comprises, by volume, 80-100 parts of polyoxymethylene dimethyl ether, 0-20 parts of methyl tertiary butyl ether and 0-20 parts of petroleum ether. The using method of the leaching agent 20 parts by volume. The application method of the leaching agent comprises the steps of mixing the oil-containing drilling cuttings and / or the oil-containing drilling wastes with the leaching agent in a stirrer; stirring the mixture at a certain shearing rate for a certain period of time for leaching, standing to be subjected to solid phase natural sedimentation; and carrying out solid-liquid separation, and obtaining the oil-containingdrilling cuttings and / or the oil-containing drilling wastes subjected to deoiling treatment. According to the leaching agent for the oil-containing drilling cuttings and the oil-containing drillingwastes, the processing steps of the oil-containing drilling cuttings or the oil-containing drilling wastes can be simplified, and the processing cost can be reduced; after the oil-containing drillingcuttings or the oil-containing drilling wastes are processed, the oily substance content can be effectively reduced, and the oil-containing drilling cuttings of the oil-containing drilling waste scanreach the emission standard; and the leaching agent and emulsified diesel oil recovered by fractional distillation can be recycled, and the circulating utilization rate of the oil-based drilling fluidand the leaching agent is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Device and method for capturing and recovering carbon dioxide in flue gas

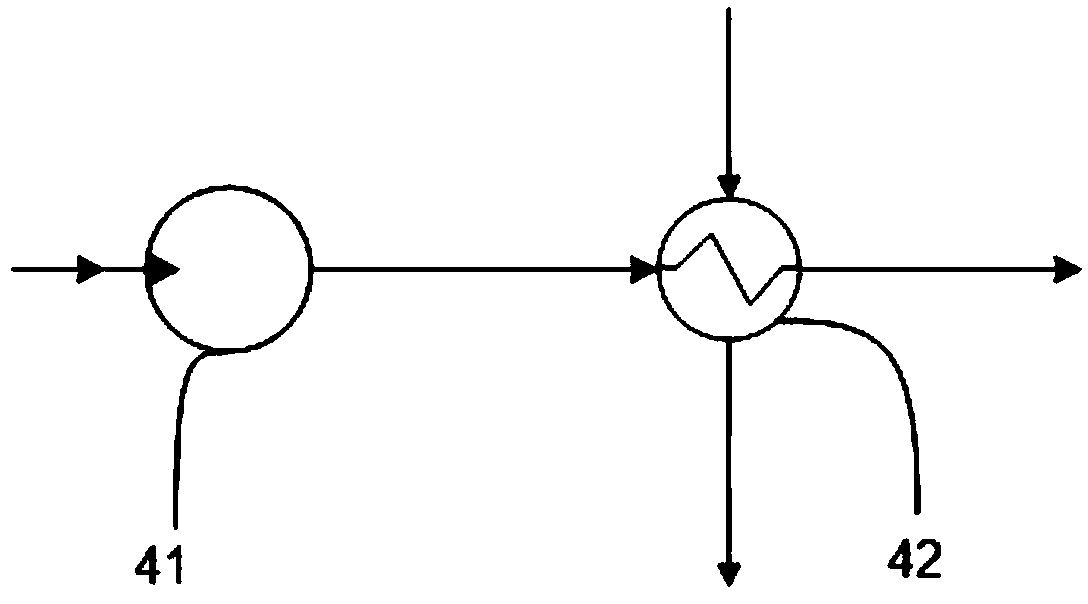

PendingCN107899377AAffect separation efficiencyAffect the degree of enrichmentCombination devicesProductsFlue gasProduct gas

The invention provides a device and method for capturing and recovering carbon dioxide in flue gas. The device comprises a flue gas treatment system, a first membrane separation unit, a second membrane separation unit and a high-pressure energy recovery device, wherein the flue gas treatment system is provided with a treatment inlet and a treatment outlet and used for treating the flue gas; the first membrane separation unit is provided with a first gas inlet, a first carbon dioxide enriched gas outlet and a first high-pressure impermeable gas outlet, and the first gas inlet is connected withthe treatment outlet; the second membrane separation unit is provided with a second gas inlet, a carbon dioxide product gas outlet and a second high-pressure impermeable gas outlet, and the second gasinlet is connected with the first carbon dioxide enriched gas outlet; the high-pressure energy recovery device is connected with the first high-pressure impermeable gas outlet and used for recoveringpressure energy of the high-pressure gas produced by the first high-pressure impermeable gas outlet. The device provided by the invention can capture CO2 in recovered flue gas more effectively.

Owner:北京集封环能科技有限责任公司

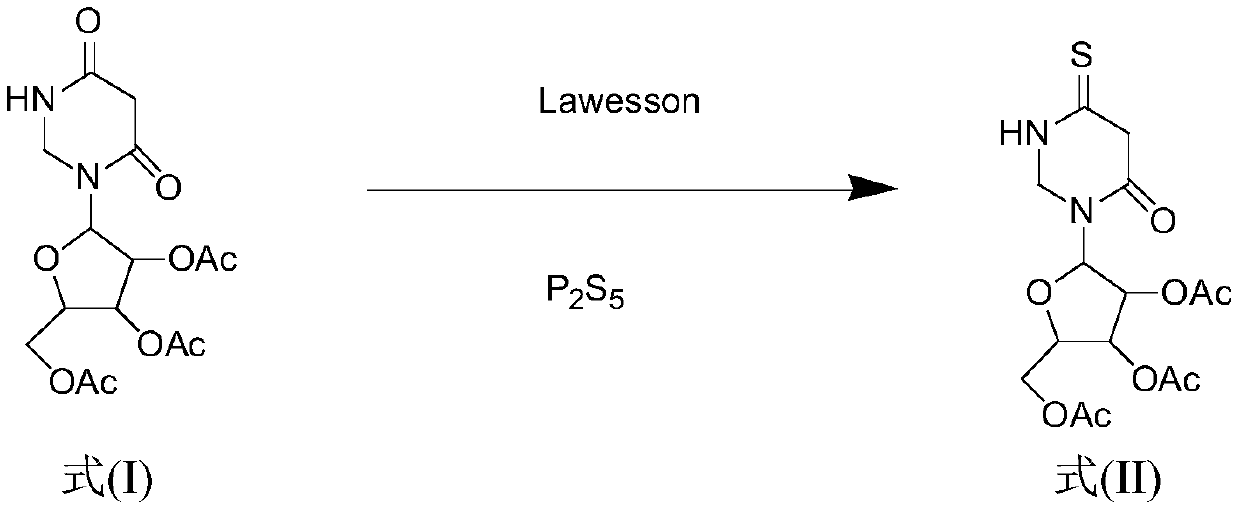

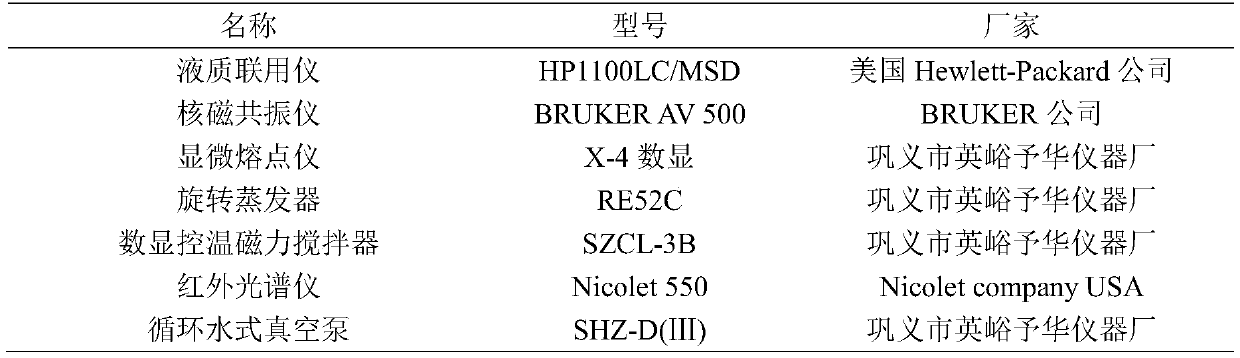

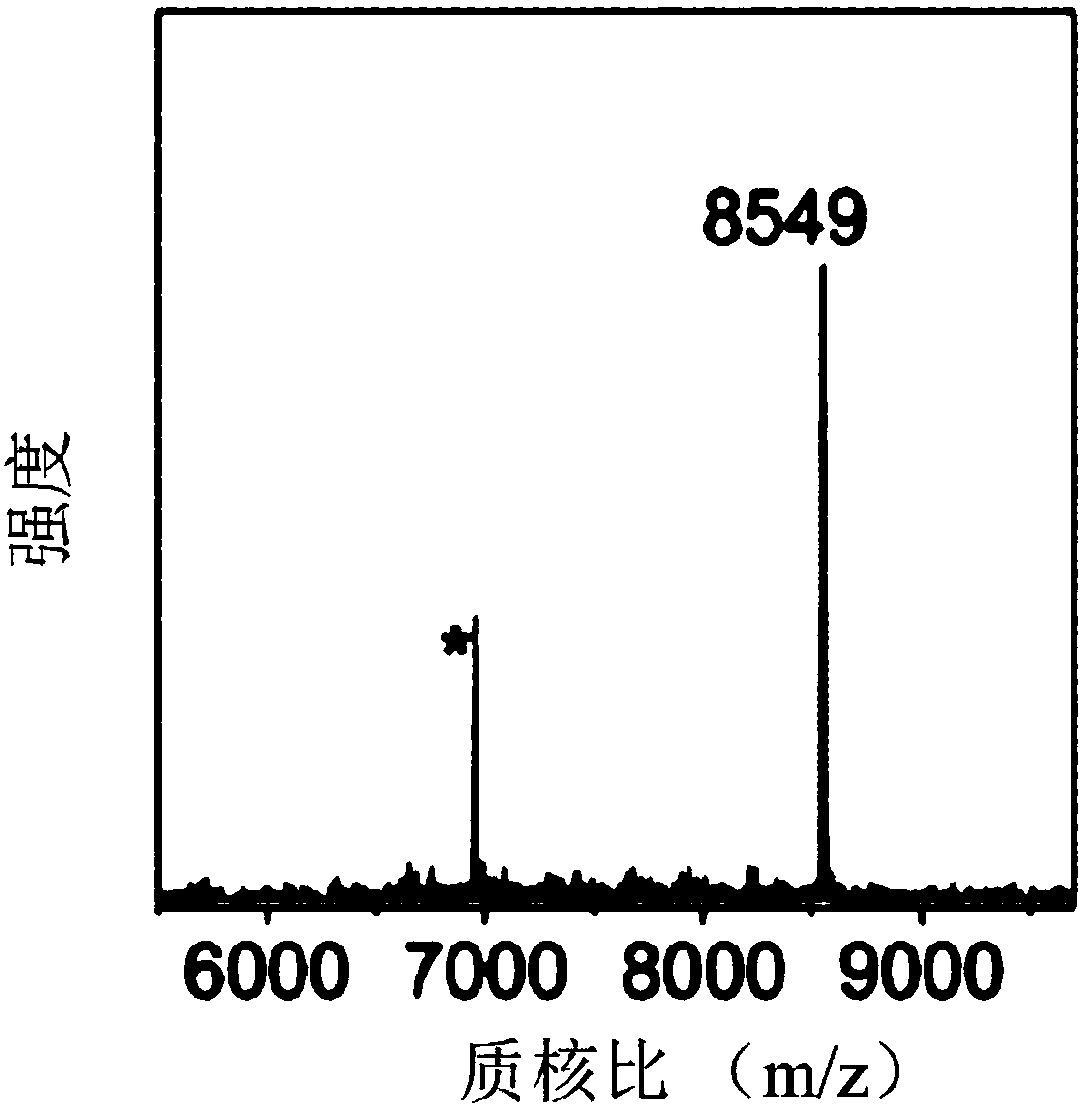

Method for synthesizing 4-S-2', 3', 5'-O-triacetyluridine

ActiveCN110204584AIncrease costShort reaction timeSugar derivativesSugar derivatives preparationChemical synthesisVulcanization

The invention belongs to the field of chemical synthesis, and discloses a method for synthesizing 4-S-2', 3', 5'-O-triacetyluridine. According to the synthesis method, a compound 2', 3', 5'-O-triacetyluridine is used as a raw material, phosphorus pentasulfide and a Lawesson's reagent are combined to be used as a vulcanizing agent, 1,4-dioxane is used as a solvent for chemical reaction, and finally4-S-2', 3', 5'-O-triacetyluridine is prepared. By the method for synthesizing 4-S-2', 3', 5'-O-triacetyluridine provided by the invention, the reaction time is shortened, and moreover, the vulcanization efficiency is greatly improved. According to the synthesis method provided by the invention, the cost is reduced, the reaction aftertreatment is simple and convenient, and meanwhile, the yield ofa reaction thionucleoside compound is improved.

Owner:DALIAN UNIV

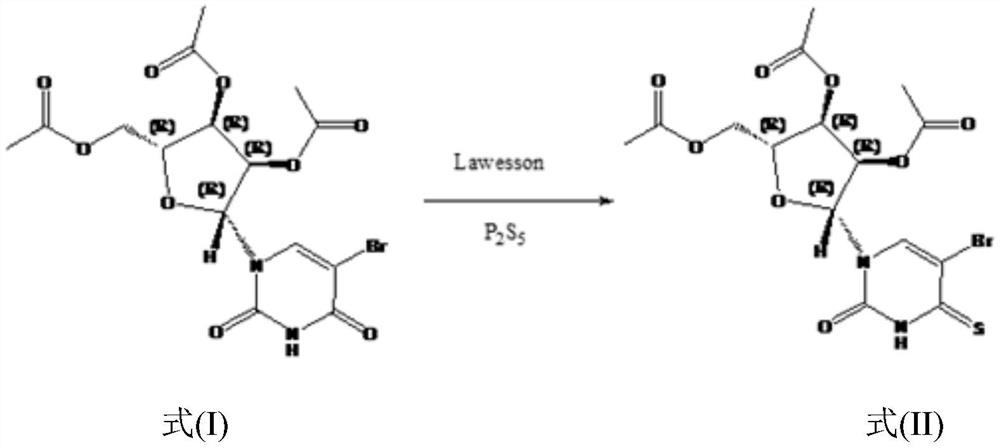

Synthesis method for 4-S-5-Br-2',3',5'-O-triacetyluridine

ActiveCN110105416AShort reaction timeImprove vulcanization efficiencySugar derivativesSugar derivatives preparationChemical synthesisChemical reaction

The invention belongs to the field of chemical synthesis and discloses a synthesis method for 4-S-5-Br-2',3',5'-O-triacetyluridine. The synthesis method comprises the steps that a compound 5-Br-2',3',5'-O-triacetyluridine serves as a raw material, phosphorus pentasulfide and a Lawesson reagent are combined to serve as a vulcanization reagent, 1,4-dioxane serves as a solvent, and a chemical reaction is carried out to finally prepare the 4-S-5-Br-2',3',5'-O-triacetyluridine. The synthesis method for the 4-S-5-Br-2',3',5'-O-triacetyluridine has the advantages that the reaction time is shortened,and the vulcanization efficiency is greatly improved. The synthesis method reduces the cost, the treatment after the reaction is simple and convenient, and meanwhile the yield of the thionucleoside compound after the reaction is increased.

Owner:DALIAN UNIV

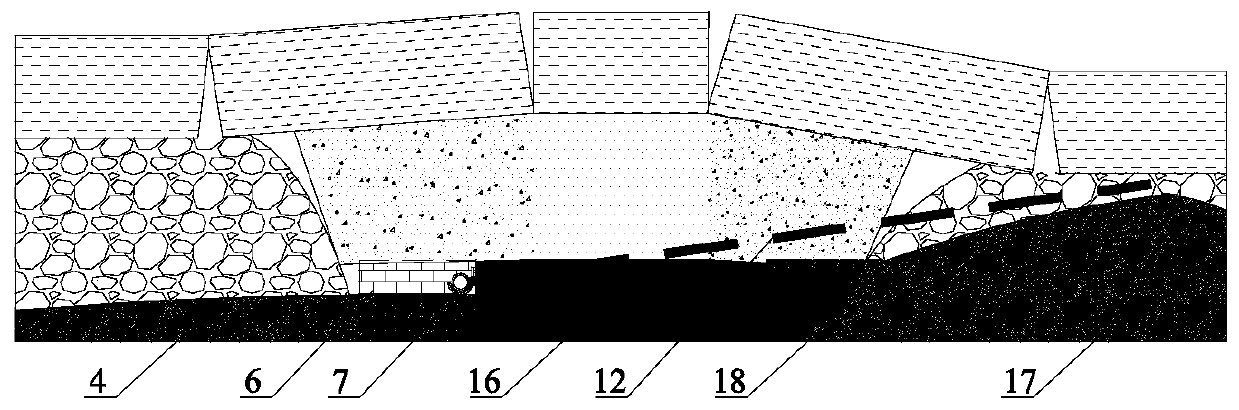

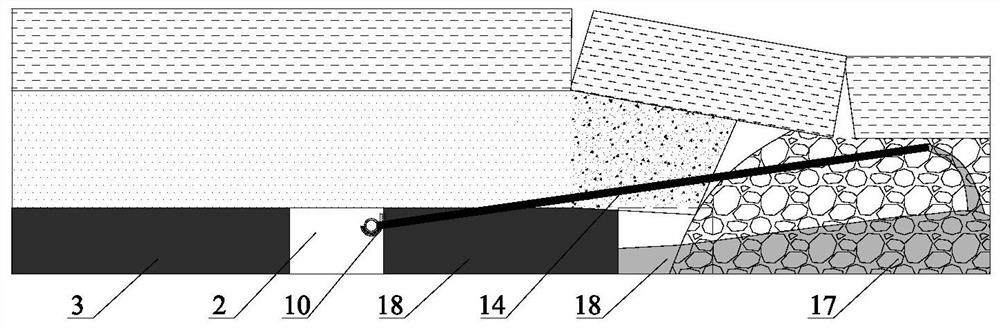

Waste rock slurry pipeline coordinated method for coal mining working face

ActiveCN111335944ALow cost emissionsDoes not affect normal productionMaterial fill-upMining engineeringCoal pillar

The invention discloses a waste rock slurry pipeline coordinated method for a coal mining working face. The method comprises the steps of drilling adjacent grouting holes in a coal pillar side of an auxiliary transportation lane every other equal distance, and placing adjacent grouting pipes; then, mounting a three-way joint at an adjacent grouting pipe on the coal pillar side of auxiliary transportation lane, and connecting a low-position grouting pipe on a pipeline hanging hook on the coal pillar side of the auxiliary transportation lane; along with the advance of the coal mining working face, performing advanced adjacent grouting on an adjacent goaf by utilizing an adjacent grouting pipe; and performing lagging low-position grouting on the goaf of the working surface by utilizing the low-position grouting pipe. According to the waste rock slurry pipeline coordinated method for the coal mining working face, waste rock can be filled to the goaf efficiently and environment-friendly with low cost without affecting normal production of coal mines.

Owner:中煤能源研究院有限责任公司

Electric coagulation decoloring method for printing and dyeing wastewater

The invention relates to an electric coagulation decoloring method for printing and dyeing wastewater. The printing and dyeing wastewater with the chroma ranging from 500 time to 1400 times and an initial pH value ranging from 6.0 to 9.0 serves as electrolyte, an electrolysis decoloring reaction is conducted in a periodical reversing pulse electrolytic cell, wherein both the positive pole and the negative pole are aluminum plates. Two adjacent electrodes of the three electrodes form one electrolysis unit, the waste water flows into a water inlet of the electrolytic cell and flows through the electrolytic cell in a gallery flowing back mode. A certain electrode current density and bath voltage are controlled, the electrolysis HRT ranges from 15 minutes to 90 minutes, and the chroma of the processed wastewater is below 50-100 times. It is found through atomic absorption detection analysis that 91.12%-97.03% of dissolved aluminum of the two poles is enriched in deposited mud, and treatment cost of each ton of water ranges from 0.3 to 0.7. Chemical agents are not added in the whole coagulation treatment process, control is simple, and the method is economical and environment-friendly.

Owner:HUBEI UNIV OF TECH

Method for recovering phosphoric acid by electrolyzing mixed acid solution

ActiveCN111020614ASolve the problem of high energy consumption and difficult process controlReduce dosagePhosphorus compoundsElectrodesOXALIC ACID DIHYDRATEO-Phosphoric Acid

The invention relates to a method for recovering phosphoric acid by electrolyzing a mixed acid solution, belonging to the field of resource recovery. The method comprises the following steps: puttingthe mixed acid solution into a product tank, wherein the mixed acid solution comprises phosphoric acid, oxyacid and organic acid; and inputting the mixed acid solution in the product tank into an electrolytic cell for cyclic electrolysis, reducing the oxyacid at the cathode of the electrolytic cell, oxidizing the organic acid at the anode of the electrolytic cell, and collecting gas generated in the cyclic electrolysis process through a gas collecting device so as to recover phosphoric acid in the mixed acid solution. The oxyacid is preferably nitric acid, nitrous acid, perchloric acid or hypochlorous acid, and the organic acid is preferably acetic acid, oxalic acid or propionic acid. According to the invention, phosphoric acid recovered through electrolysis can reach 99% or above, the technological process of treatment is simple, environmental pollution caused by direct discharge of waste acid liquid can be avoided, the additional value of products is high, and good economic benefitsand environmental benefits are achieved.

Owner:湖北永绍科技股份有限公司 +1

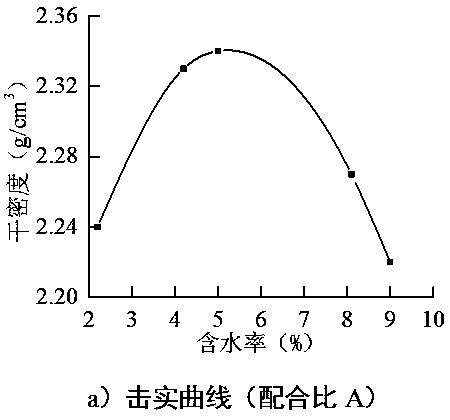

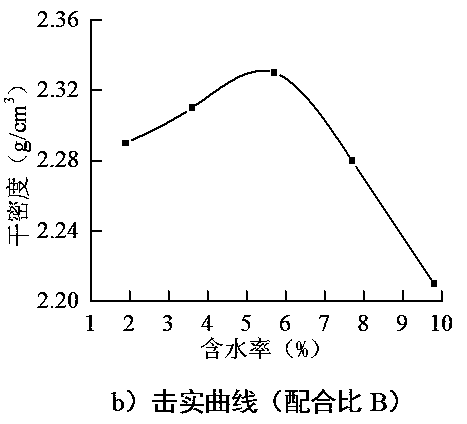

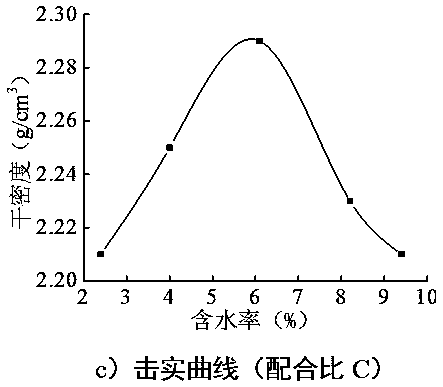

An application method of treated oil-based rock debris in an inorganic stable road base

InactiveCN109853312AReduce dosageReduce construction costsRoadwaysSolid waste managementEnvironmental indexMass ratio

The invention discloses an application method of treated oil-based rock debris in an inorganic stable road base, which is characterized by comprising the following steps: (1), treating the oil-based rock debris by adopting a waste oil-based mud rock debris resource recovery technology LRET and a thermal analysis technology, and after the detection of various treated environmental indexes is qualified, standing by; (2), checking a subbase layer before a base layer is constructed, and removing pumice stones and sundries; (3), mixing the mixture according to the following mass ratio: 52% of gravel, 12% of sand, 3-5% of cement and 31-33% of oil-based rock debris; and (4), filling the mixture on the subbase layer in a layered manner and compacting the same to finally form the road base layer. The method can be used for harmless and resourceful treatment of the oil-based rock debris; the mixture can be used as an admixture of the road base layer, thus meeting the strength requirement of theroad base layer, and effectively reducing the cement consumption required in road construction and reducing the construction cost.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

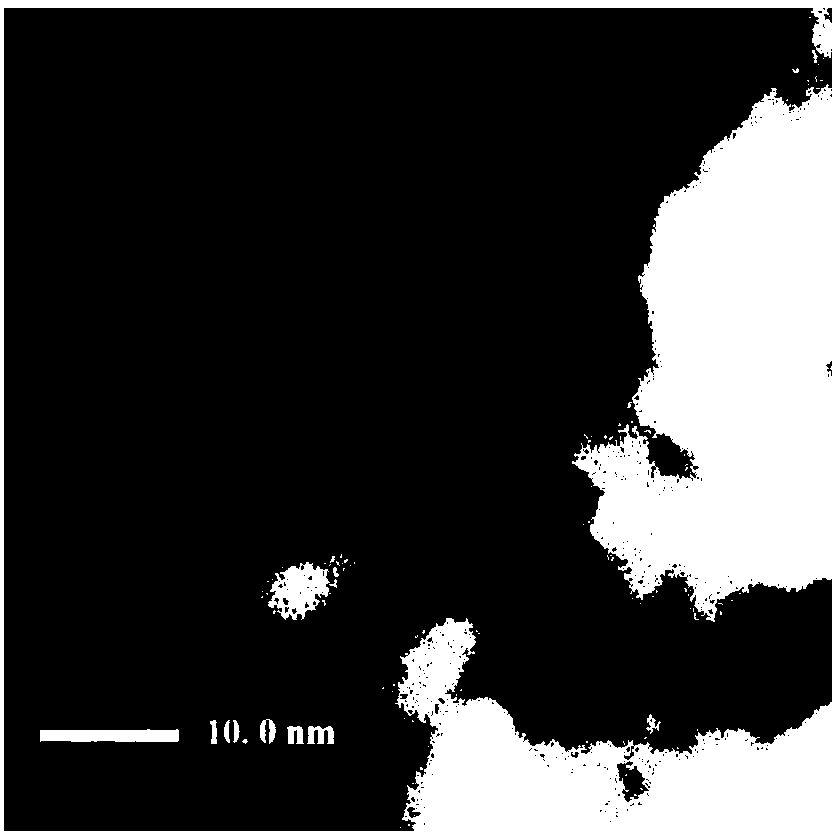

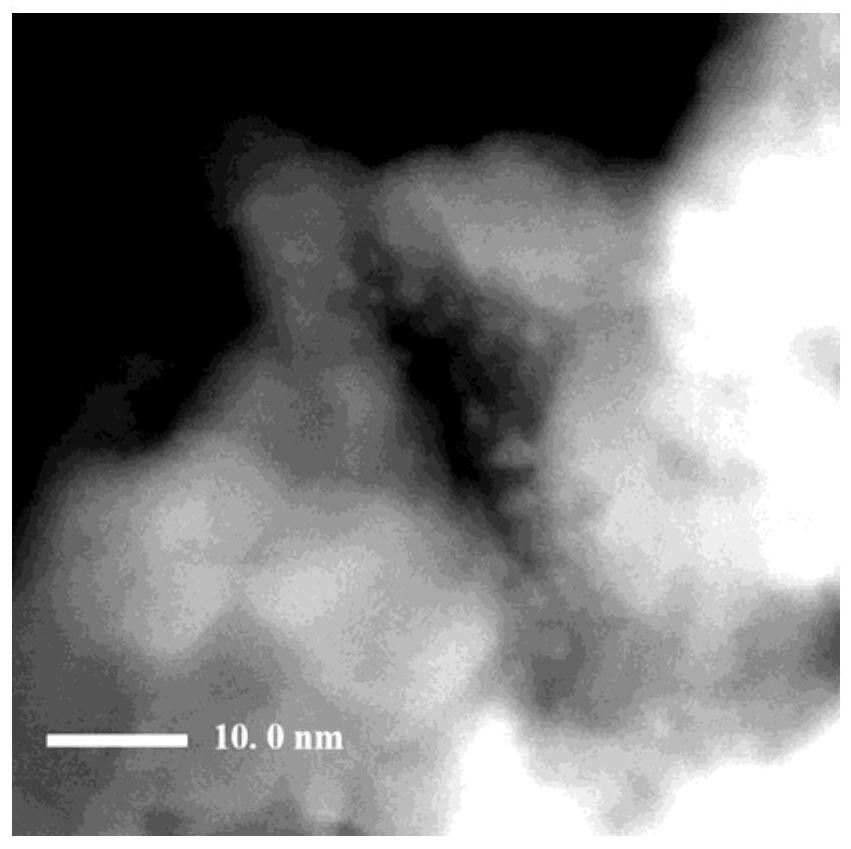

Method for treating organic ligands on surfaces of gold clusters

ActiveCN110115997ADamage structureDestruction sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsGold clusterNanoparticle

The invention relates to a method for treating organic ligands on the surfaces of gold clusters. According to the method, the surface stabilizer ligands of gold nanoparticles can be simply and efficiently treated in an environment-friendly manner, so that unsaturated coordination atoms on the surface stabilizer ligands of the gold nanoparticles are exposed, and the catalytic activity is greatly improved. The method mainly comprises the following steps of introducing water into a reactive atmosphere to activate Au-S bonds, and removing the organic ligands under a mild condition. The changes ofvibration peaks and absorption peaks before and after water treatment can be observed visibly in a Fourier infrared spectrum and an X-ray photoelectron spectrum, and these changes are matched with a result of DFT calculation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A method for reclaiming phosphoric acid from an electrolytic mixed acid solution

ActiveCN111020614BReduce dosageIncrease added valuePhosphorus compoundsElectrodesOXALIC ACID DIHYDRATEO-Phosphoric Acid

The invention relates to a method for recovering phosphoric acid by electrolyzing a mixed acid solution, belonging to the field of resource recovery. The method comprises the following steps: puttingthe mixed acid solution into a product tank, wherein the mixed acid solution comprises phosphoric acid, oxyacid and organic acid; and inputting the mixed acid solution in the product tank into an electrolytic cell for cyclic electrolysis, reducing the oxyacid at the cathode of the electrolytic cell, oxidizing the organic acid at the anode of the electrolytic cell, and collecting gas generated in the cyclic electrolysis process through a gas collecting device so as to recover phosphoric acid in the mixed acid solution. The oxyacid is preferably nitric acid, nitrous acid, perchloric acid or hypochlorous acid, and the organic acid is preferably acetic acid, oxalic acid or propionic acid. According to the invention, phosphoric acid recovered through electrolysis can reach 99% or above, the technological process of treatment is simple, environmental pollution caused by direct discharge of waste acid liquid can be avoided, the additional value of products is high, and good economic benefitsand environmental benefits are achieved.

Owner:湖北永绍科技股份有限公司 +1

A flat-plate type catalyst for photodegradation of household garbage leachate and a preparing method thereof

ActiveCN104888834AEfficient degradationImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationPhotodegradationPhotocatalytic degradation

The invention belongs to the field of environment protection and environment catalysis, and particularly relates to a non-metal-element doped modified titanium oxide catalyst used for photodegradation of household garbage leachate. The catalyst adopts household garbage pyrolysis gas as a non-metal source and a heat source to prepare the non-metal-element doped modified titanium oxide, and then the flat-plate type catalyst is prepared by mixing, rolling, coating, pleating, cutting, drying and calcinating. The catalyst is low in cost, high in photocatalytic activity, high in stability, and capable of efficiently degrading the household garbage leachate under irradiation of sun light and common lamplight, and has a good application prospect in the field of pollutant degradation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Harmless treatment method for stainless steel rolling oil sludge

PendingCN111411014AImprove cleanlinessGreen treatmentLubricant compositionProcess engineeringOil sludge

The invention relates to a harmless treatment method of stainless steel rolled oil sludge, which is characterized by sequentially comprising the following steps: 1) filtering and stirring the stainless steel rolled oil sludge to form flowing liquid; 2) primary separation: conveying the flowing liquid to a horizontal centrifuge through a slurry pump for solid-liquid primary separation; 3) secondaryseparation: conveying the rolling mixed oil subjected to primary separation into a butterfly centrifuge for solid-liquid separation again; 4) third separation: conveying the rolling oil subjected tosecond separation into a tubular centrifuge for solid-liquid separation, wherein the rolling oil obtained after three times of separation is filtered and purified for standby application, the rollingoil obtained through the treatment method is high in oil product cleanliness and can be repeatedly used, the whole treatment process is environmentally friendly and free of emission of three wastes, and the harmless treatment effect is achieved.

Owner:NINGBO BAOXIN STAINLESS STEEL

Vertical distribution structure applicable to treatment of oil-containing drillings in offshore oil-gas development

PendingCN108119075AReduce energy consumptionEvenly heatedFlushingEnvironmental resistanceSmall footprint

The invention belongs to the field of environmental protection of offshore oil-gas fields and particularly provides a vertical distribution structure applicable to treatment of oil-containing drillings in offshore oil-gas development. The vertical distribution structure comprises three parts, namely a vertical hammer mill assembly, an electromagnetic heating system, a sealing and supporting system. The oil-containing drillings enters the vertical hammer mill assembly by a feeding channel, and a transmission shaft drives radial hammer mill blade and axial hammer mill blades to rotate, so that solid phases in the oil-containing drillings are continuously hammer-milled and crushed, further the hammer-milling heat is generated, and the oil-liquid diffusion distance is reduced; simultaneously,due to the electromagnetic heating system, the temperature of a vertical hammer-mill drum body is increased, so that under the compounding action of hammer-milling heat and electromagnetic heating, the oil liquid in the oil-containing drillings is vaporized and separated; a heat-insulating layer wrapping outside the vertical hammer-mill drum body can inhibit heat loss effectively. The vertical distribution structure provided by the invention solves the defects and shortages of other structures well, has the advantages of small occupied area, high treatment efficiency and low energy consumption, high-efficiency and safe treatment of the oil-containing drillings are realized and the environmental protection requirements of green development of the offshore oil-gas development is met.

Owner:SOUTHWEST PETROLEUM UNIV

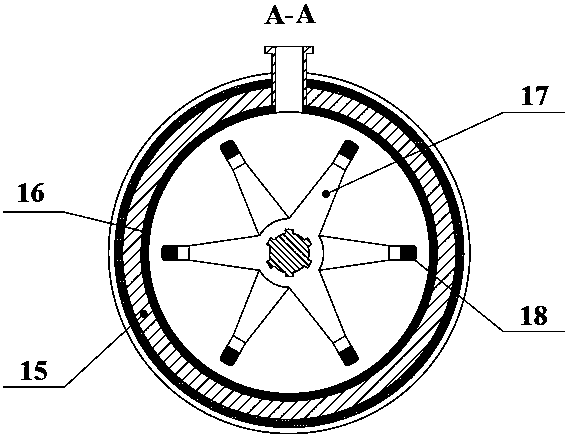

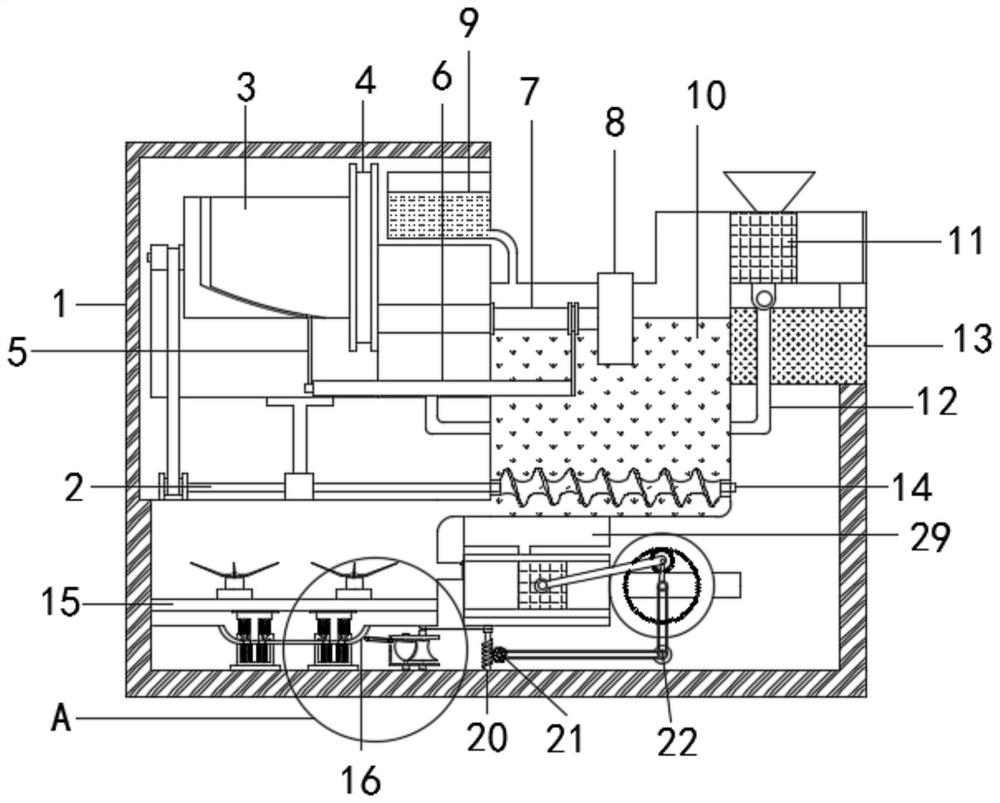

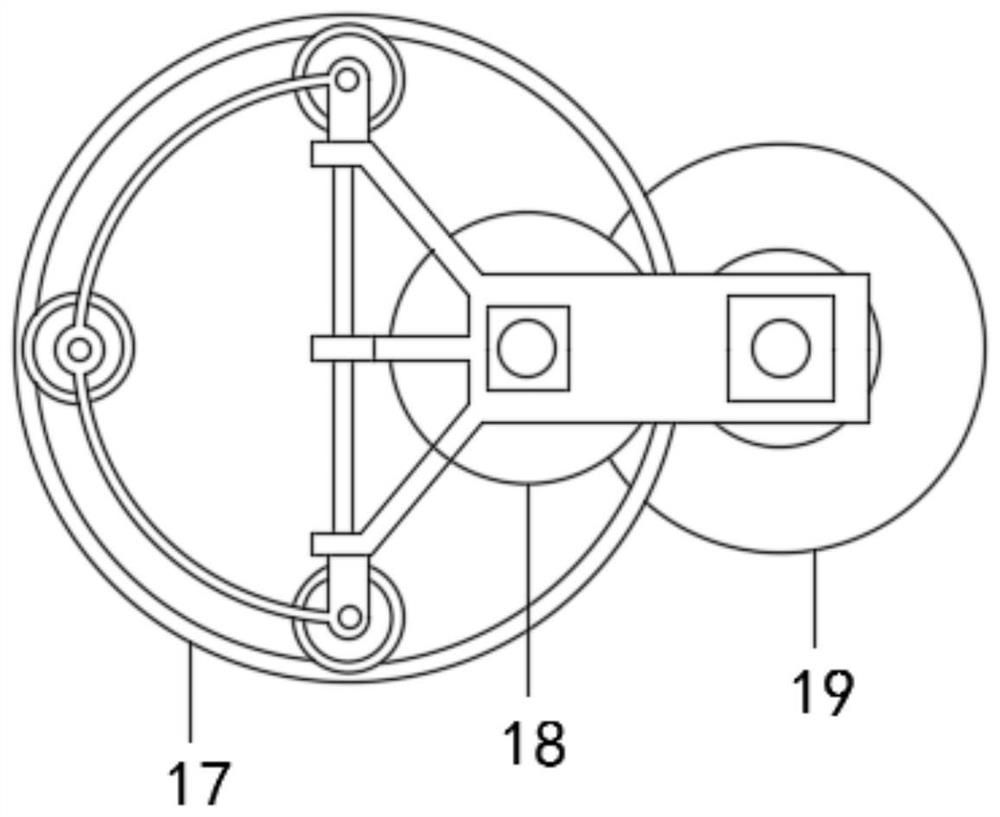

Energy-saving and environment-friendly biotechnology rural domestic garbage treatment device

InactiveCN113714244AImprove utilization efficiencySave resourcesSolid waste disposalGrain treatmentsOil contentRefuse Disposals

The invention relates to the technical field of garbage treatment, and discloses an energy-saving and environment-friendly biotechnology rural domestic garbage treatment device. The energy-saving and environment-friendly biotechnology rural domestic garbage treatment device comprises a box body, the left side of the box body is rotationally connected with a driving shaft, a water tank is arranged above a rotating rod, a speed change ring is arranged on the lower right portion of a sliding plate, and the right side of the speed change ring is in transmission connection with a convex body. The right side of the convex body is in transmission connection with a concave body, the right side of the concave body is in transmission connection with a threaded rod, biological flora liquid is arranged above a piston. According to the energy-saving and environment-friendly biotechnology rural domestic garbage treatment device, the driving shaft rotates to drive a rotating plate to slide and rotate at the same time to drive oil floating in a garbage can to enter an oil collecting tank, the oil and water in garbage are separated, and the environment is protected; the oil content is reduced in the garbage recycling process, the garbage utilization efficiency is higher, the speed change ring drives the concave body to change the speed, a push-pull column drives the piston to move, the piston enables the biological bacterium liquid and the garbage to be mixed, and therefore the use amount of the biological bacterium liquid is controlled according to the garbage gravity, resources are saved, and the environment is protected.

Owner:魏帅

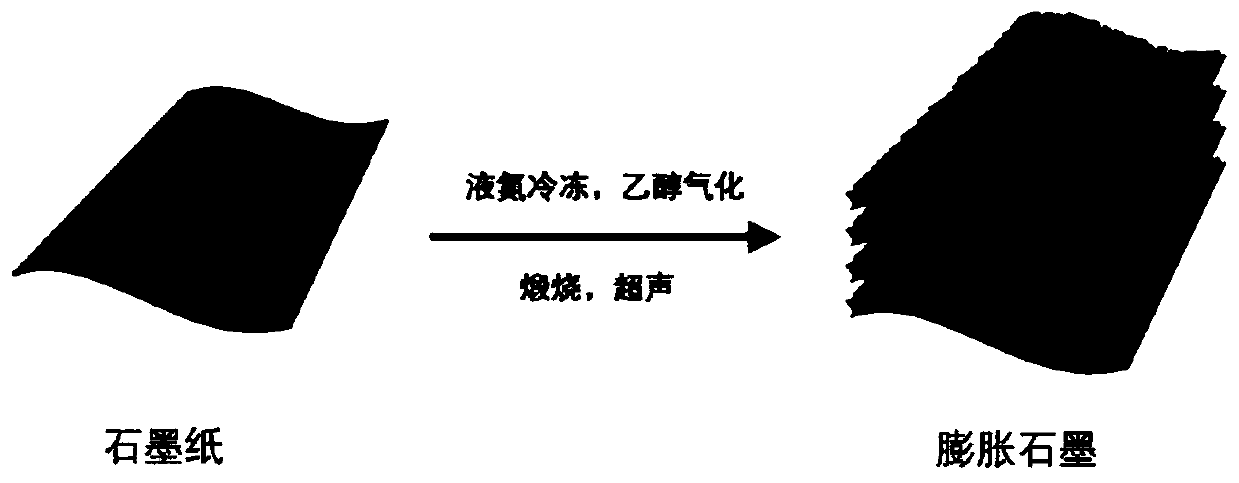

A kind of expanded graphite electrode for the electrochemical removal of heavy metal ions in wastewater and its preparation method and application

ActiveCN110182908BEasy to handleGreen treatmentWater contaminantsWater/sewage treatment using germicide/oligodynamic-processGraphite electrodeWastewater

The invention discloses an expanded graphite electrode used for electrochemical removal of heavy metal ions in waste water, a preparation method and application thereof. First, the graphite paper was cut to a suitable size, ultrasonically cleaned in acid, alkali and ultrapure water for one hour each, and then dried. Then, soak the pretreated graphite paper in liquid nitrogen for 5-30min, and then quickly immerse the frozen graphite paper into the ethanol solution. At room temperature, liquid nitrogen molecules vaporize rapidly, and instantly expand in the graphite paper sheet to expand the graphite paper into three-dimensional expanded graphite. Furthermore, the expanded graphite was calcined at 700° C. for 1 h, and ultrasonicated in ethanol for 30 minutes. Finally, it is used as an electrode after being rinsed with a large amount of ultrapure water and dried. The obtained three-dimensional expanded graphite electrode has good conductivity, and heavy metal ions in wastewater can be efficiently removed by electrochemical reduction.

Owner:ZHEJIANG UNIV

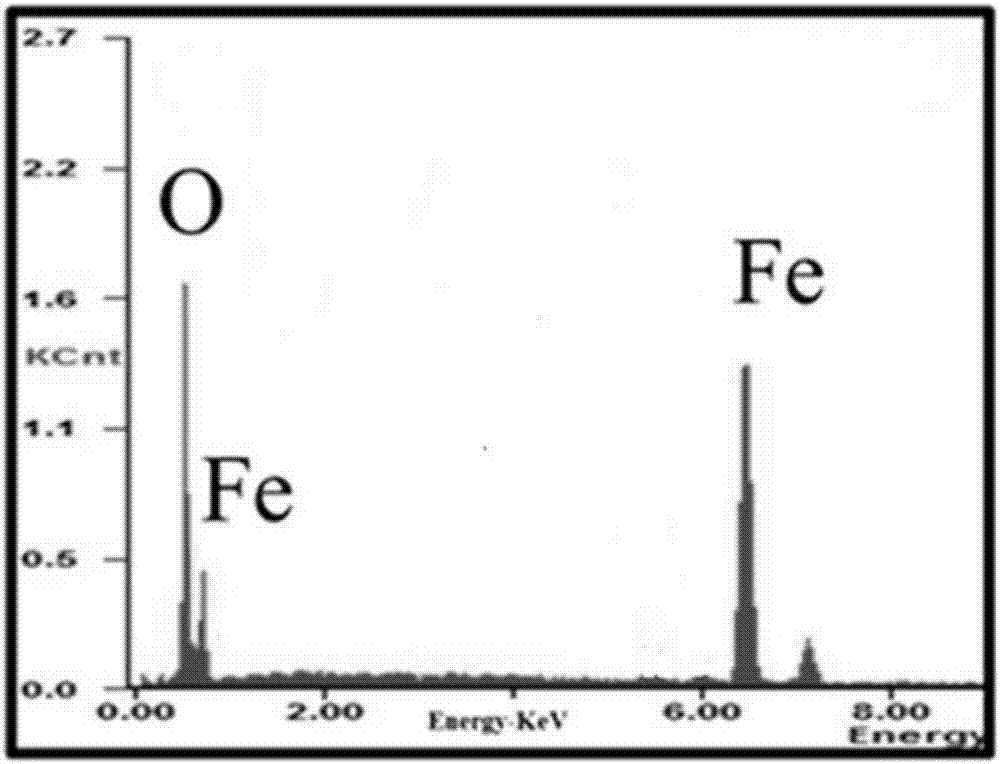

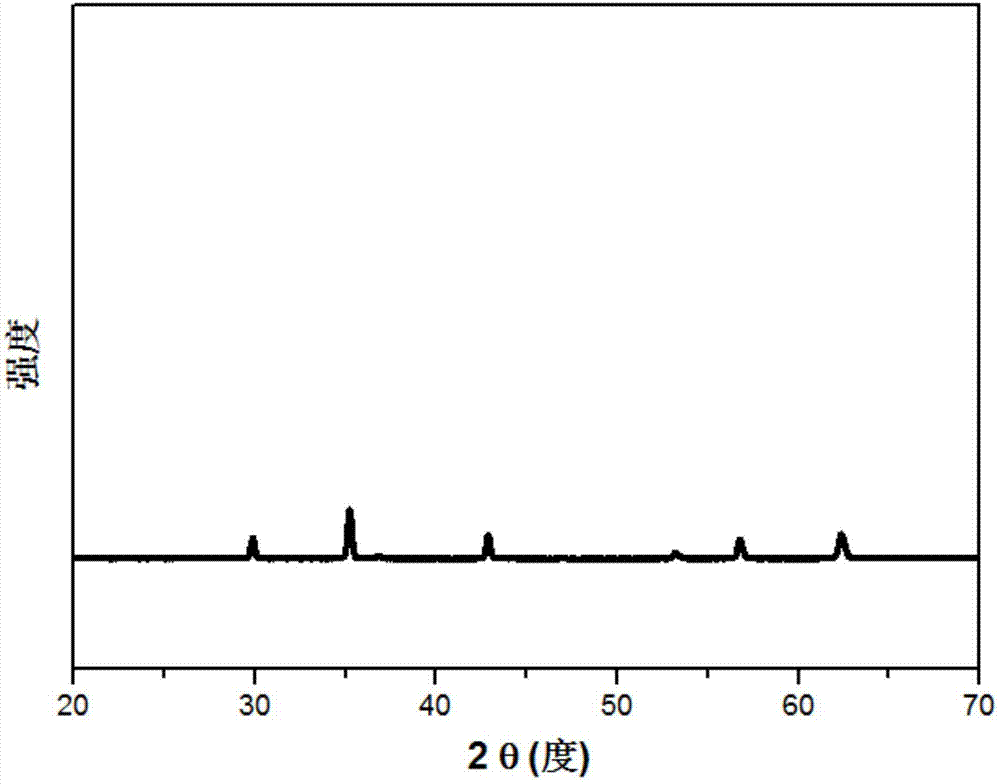

Environment-friendly nano material for automobile tail gas nitric oxide catalysis purification and preparation method of environment-friendly nano material

ActiveCN107253737AEasy to makeSave raw materialsMaterial nanotechnologyDispersed particle separationNitric oxideMaterials science

The invention discloses an environment-friendly nano material gamma-Fe2O3 for automobile tail gas nitric oxide catalysis purification and a preparation method of the environment-friendly nano material, and belongs to the technical field of environment-friendly purification material preparation. The environment-friendly nano material comprises gamma-phase Fe2O3 particles, and the sizes of the particles are within 23-228 nm. The preparation method comprises the following steps: by taking iron wires which are smooth and clean in surface as a raw material, putting the iron wires into 80 mL of a mixed solution, wherein the mixed solution comprises 5-15 mL of absolute ethyl alcohol, 33.6g-44.8g of KOH and the balance of deionized water; performing hydrothermal reaction for 24-48 hours at 270-290 DEG C, further performing ultrasonic treatment for 9-20 hours, filtering, soaking and stirring for 2-5 hours in a 10-25% ammonium hydroxide solution, and further soaking and stirring for 1-6 minutes in a 2-6% hydrochloric acid solution; washing with deionized water, drying, and calcining, thereby obtaining the environment-friendly nano material. The environment-friendly nano material is low in preparation cost, cheap in raw material, green in treatment process, free of complex instrument or equipment, and relatively good in market prospect in automobile tail gas nitric oxide NOx catalysis.

Owner:海南省环境科学研究院

Method for producing edible food package paper with bean peel as raw material

ActiveCN101413226BRaise the ratioReduce energy consumptionNon-fibrous pulp additionPulp beating/refining methodsCelluloseSoybean hulls

The invention discloses a method for producing edible food packaging paper with soybean hull as a raw material. The method comprises the following steps: the soybean hulls are subject to superfine comminution, are treated by pressurization for 20 minutes to 2 hours under the pressure of between 130 and 320kPa, and are cooled; an enzymatic reaction is performed under the conditions that the mass concentration of soybean hull powder is between 1 and 25 percent, the mass ratio of cellulose to the soybean hull powder is between 0.1 to 1 and 10 to 1, the temperature is between 25 and 70 DEG C, andthe rotating speed is between 50 and 350rpm; the reaction is terminated when the hydrolysis degree of the reaction reaches between 5 and 20 percent; a filtrate is vacuum concentrated and decolorized by hydrogen peroxide, and then a food thickener and a food plasticizer are added for stirring evenly; the ultrasonic degassing is performed for 30 to 120 minutes after the beating; the filtrate is placed into a mold for molding; and the edible food packaging paper is obtained through drying at a temperature of between 55 and 70 DEG C. The method has green raw material and chloride-free environment-friendly process, has no discharge of acid liquids or alkaline liquids, provides a new approach for the utilization of high added values of biomass resources, and also provides broad prospect for thedevelopment of special paper.

Owner:SOUTH CHINA UNIV OF TECH

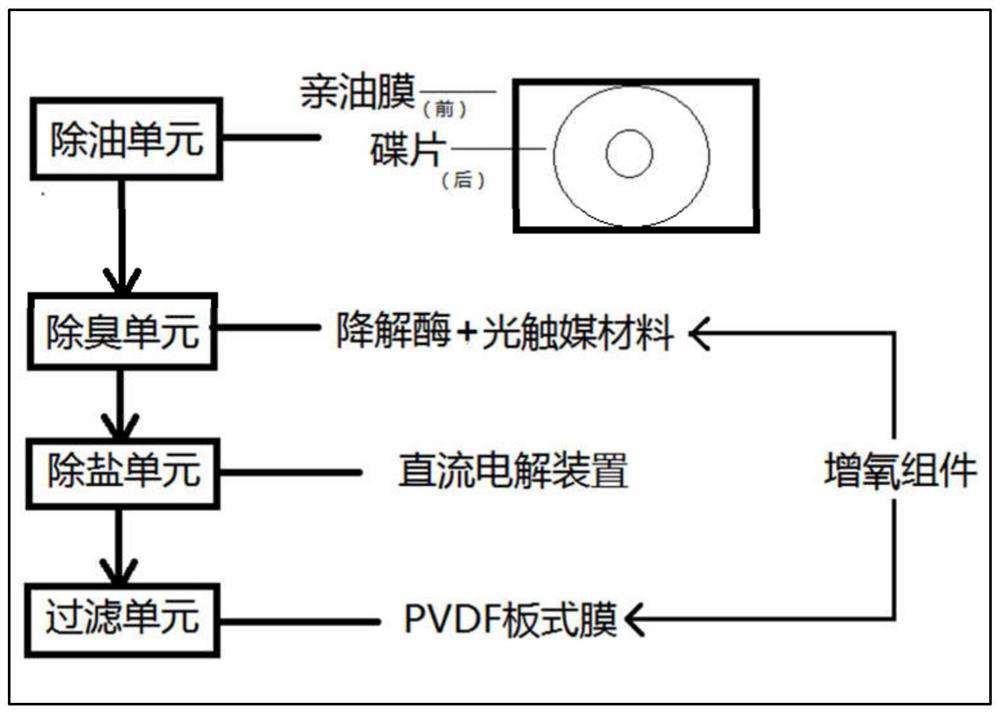

Process treatment method and system for oil-water separation and desalination of garbage

InactiveCN112605093AEasy to handleGreen treatmentTransportation and packagingSolid waste disposalElectrolysisFiltration

The invention belongs to the technical field of garbage treatment, and particularly relates to a process treatment method and system for oil-water separation and desalination of garbage. The method comprises the following steps of 1) oil removal treatment: comprising combining a micron-sized oleophylic membrane with a disc, and removing oil in an oil absorption and rotation combined manner; 2) deodorization treatment: comprising conducting deodorization on the oil-removed garbage by adopting a degrading enzyme and a photocatalyst material; 3) desalination treatment: comprising conducting desalting and heavy metal removing by adopting a direct-current electrolysis mode; and (4) filtering and collecting: comprising filtering the treated garbage through a PVDF (Polyvinylidene Fluoride) plate-type membrane, and carrying out oxygenation treatment. By combining the oil removal treatment mode, the deodorization mode and the desalination mode with the PVDF plate-type membrane filtration and water drainage mode, separation of oil and water in garbage can be realized, peculiar smell is reduced, 30-40% of reduction is realized, and compared with the traditional technology, the method of the invention has the advantages of greenness, high efficiency, high utilization rate, recyclability, cost reduction and the like.

Owner:广州市凯卫莎环保科技有限公司

Expanded graphite electrode for electrochemical removal of heavy metal ion in wastewater and preparation method and application of expanded graphite electrode

ActiveCN110182908AEasy to handleGreen treatmentWater contaminantsWater/sewage treatment using germicide/oligodynamic-processGraphite electrodeRoom temperature

The invention discloses an expanded graphite electrode for electrochemical removal of heavy metal ions in wastewater and a preparation method and application of the expanded graphite electrode. The preparation method comprises the following steps: firstly, cutting graphite paper into an appropriate size, performing ultrasonic cleaning for one hour separately in an acid, an alkali and ultrapure water in sequence, and performing drying; secondly, soaking the pretreated graphite paper into liquid nitrogen for 5-30 minutes; rapidly soaking frozen graphite paper into an ethanol solution, wherein liquid nitrogen molecules are gasified rapidly and expanded instantaneously in graphite paper layers at the room temperature, and then the graphite paper is expanded into three-dimensional expanded graphite; furthermore, calcining the expanded graphite at 700 DEG C for one hour, and performing ultrasonic treatment for 30 minutes in ethanol; and finally washing the expanded graphite with a great dealof ultrapure water, and performing drying, so as to obtain an electrode. The obtained three-dimensional expanded graphite electrode has good conductivity, and heavy metal ions in wastewater can be efficiently removed through electrochemical reduction.

Owner:ZHEJIANG UNIV

A method for treating organic ligands on the surface of gold atom clusters

ActiveCN110115997BNo pollution in the processEasy to operateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsGold clusterNanoparticle

A method for treating organic ligands on the surface of gold clusters. This method can be green, environmentally friendly, simple and efficient to treat the surface stabilizer ligands of gold nanoparticles to expose unsaturated coordination atoms, thereby greatly improving catalytic activity. This method mainly involves passing water into the reaction atmosphere, activating the Au-S bond, and removing the organic ligand under mild conditions. The changes in vibration peak and absorption peak positions before and after water treatment can be observed intuitively in Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy. These changes are also consistent with the results of DFT calculations.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of 4-s-5-br-2', 3', 5'-o-triacetyl uridine synthesis method

ActiveCN110105416BShort reaction timeImprove vulcanization efficiencySugar derivativesSugar derivatives preparationChemical synthesisPhosphorus pentasulfide

Owner:DALIAN UNIV

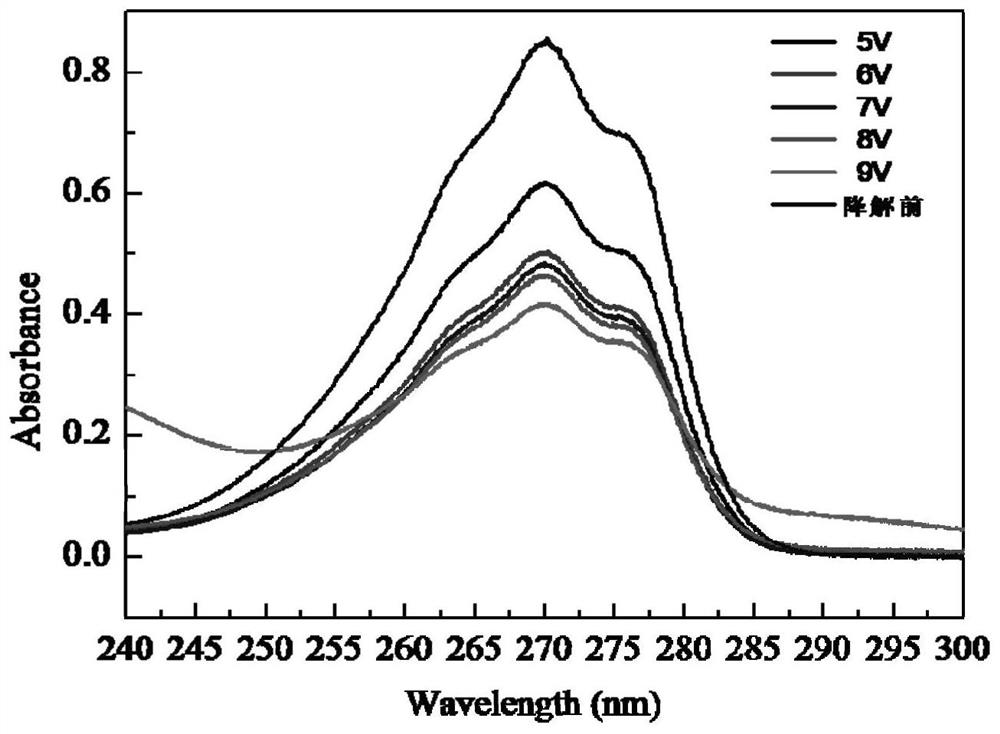

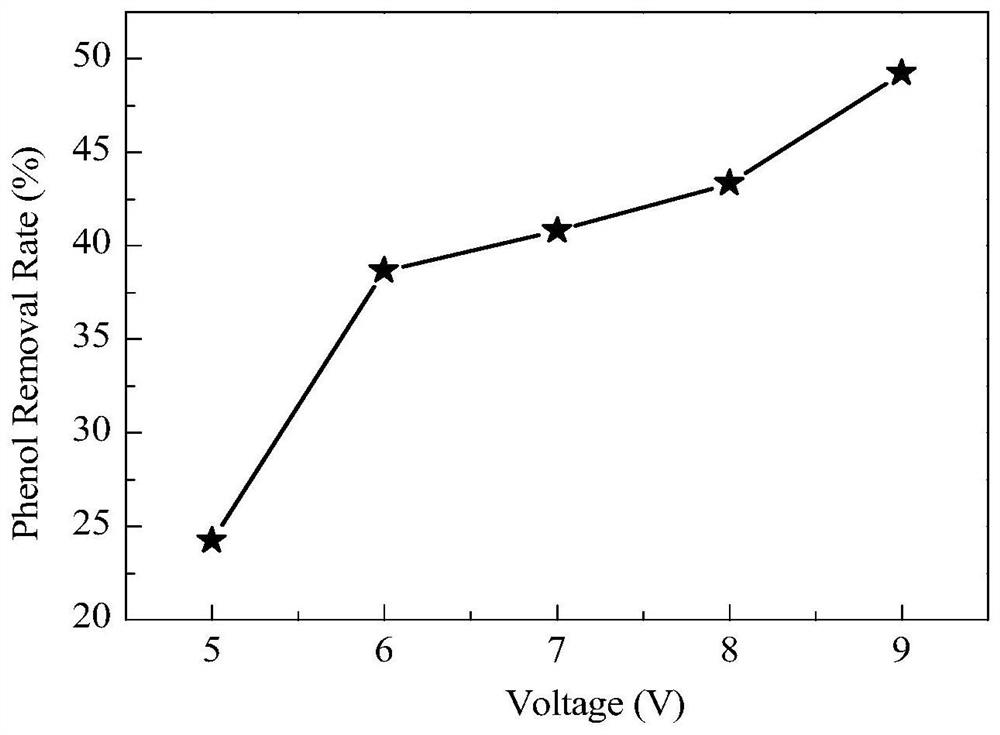

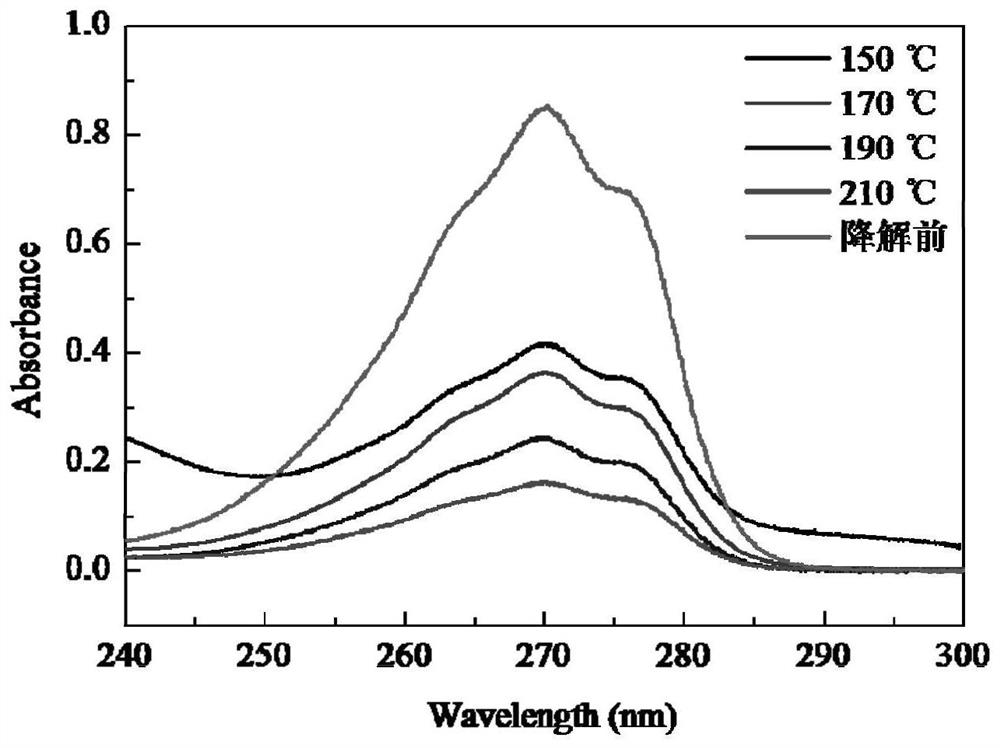

A kind of phenol wastewater treatment method

ActiveCN110655257BAchieve degradationIdeal degradation rateWater contaminantsWater/sewage treatmentElectrolysisElectrical battery

The invention relates to a method for treating phenol wastewater. The method comprises: (1) a step of vaporizing phenol waste water with heat energy provided by a solar concentrating heat collection device to form phenol water vapor; and (2) a step of electrolytically oxidizing the phenol water vapor with electric energy provided by a photovoltaic cell . The present invention realizes the degradation of vapor state phenol for the first time, and degrades phenol in the vapor phase to achieve an ideal degradation rate of phenol; in addition, the activated molecules in the excited state with high energy content can undergo less intermediate incomplete oxidation The products are oxidized to carbon dioxide and water with simultaneous production of hydrogen. The invention does not introduce any other form of energy during the electrolysis period, realizes the utilization of the full spectrum of solar energy, breaks the limitation of the traditional photovoltaic method on the utilization of sunlight, truly achieves the purpose of environmental friendliness, and realizes on the basis of energy saving The degradation of phenol wastewater is achieved, which provides a new direction for the green and efficient treatment of industrial organic wastewater.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for treating oily sewage through solar STEP light-heat-electricity coupling

ActiveCN114590859AImprove utilization efficiencyImprove degradation efficiencyWater/sewage treatment by irradiationGeneral water supply conservationElectrochemistryHeat energy

The invention provides a method for treating oily sewage through solar STEP photo-thermal-electric coupling, which comprises the following steps of: providing heat energy by using a photo-thermal effect of solar energy, providing electric energy by using a photo-electric effect, and carrying out constant-current electrolysis on the oily sewage in an electrolytic tank with a cathode and an anode; wherein the temperature of the electrolytic tank ranges from 20 DEG C to 90 DEG C, and the current of the constant-current electrolysis ranges from 50 mA to 90 mA. According to the invention, solar energy is used as a green energy source, and under the synergistic effect of solar electrochemistry, photocatalysis and solar heat, on the basis of improving the utilization rate of solar energy, the reaction path of the oil-containing wastewater of the oil field is further optimized, the energy source is saved, and the degradation efficiency of the oil-containing wastewater of the oil field is greatly improved.

Owner:NORTHEAST GASOLINEEUM UNIV

Leaching agent for oily drilling cuttings and oily drilling waste and method of use thereof

ActiveCN108273843BReduce processing costsReduce contentWaste water treatment from quariesContaminated soil reclamationWell drillingEther

The invention provides a leaching agent for oily drilling cuttings and oily drilling waste and its application method. The leaching agent comprises: 80-100 parts by volume of polyoxymethylene dimethyl ether, 0-20 parts by volume of methyl tert-butyl ether, and 0-20 parts by volume of petroleum ether. The method of using the leaching agent is as follows: mix oily drill cuttings and / or oily drilling waste with the leaching agent in a mixer; stir for a certain period of time at a certain shear rate for leaching, and let the solid phase settle naturally Finally, solid-liquid separation, after drying, oily drilling cuttings and / or oily drilling waste after deoiling treatment are obtained. The leaching agent of the present invention can simplify the treatment steps and cost of oily drilling cuttings / oily drilling waste, and after the oily drilling cuttings / oily drilling waste is treated, the content of oily substances can be effectively reduced and the oily substance content can be achieved to meet the discharge standard. Moreover, the leaching agent and emulsified diesel oil recovered by fractional distillation can be recycled, which greatly improves the recycling rate of oil-based drilling fluid and leaching agent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A flat-plate photodegradation domestic waste leachate catalyst and preparation method thereof

ActiveCN104888834BEfficient degradationImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystPhotocatalytic degradation

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Denitrification acinetobacters and use thereof

InactiveCN102747015BReduce accumulationEasy to handleBacteriaWater contaminantsMicrobiological cultureBacteroides species

The invention relates to denitrification acinetobacters and a use thereof, and belongs to the field of environmental microbiology. The denitrification acinetobacters have a category name of Acinetobacter schindleri LN5, are preserved in the China general microbiological culture collection center of the China microbiological preservation management committee on May 30th, 2012, and has a preservation number of CGMCC No.6165. The denitrification acinetobacters have heterotrophic nitrification-aerobic denitrification functions, have high aureomycin resistance, can be used for simultaneous nitrification and denitrification (SND) treatment on nitrogen-containing sewage and especially on nitrogen and aureomycin-containing sewage, realize removal of a large part of ammonia nitrogen in nitrogen-containing sewage, realize small accumulation amounts of nitrite and nitrate nitrogen, realize nitrification-denitrification and COD removal in the same reactor, and realize environmentally-friendly, low-consumption and high-efficiency treatment on nitrogen-containing sewage.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A collaborative filling method for gangue slurry pipeline in coal mining face

ActiveCN111335944BLow cost emissionsDoes not affect normal productionMaterial fill-upMining engineeringCoal pillar

Owner:中煤能源研究院有限责任公司

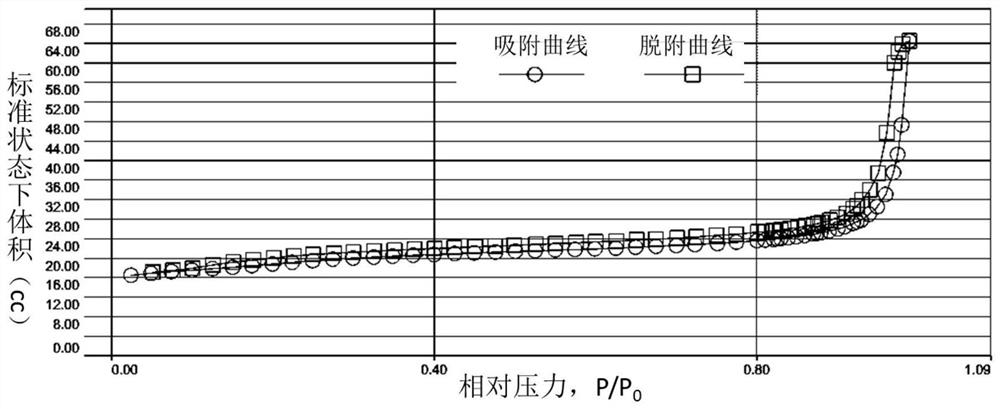

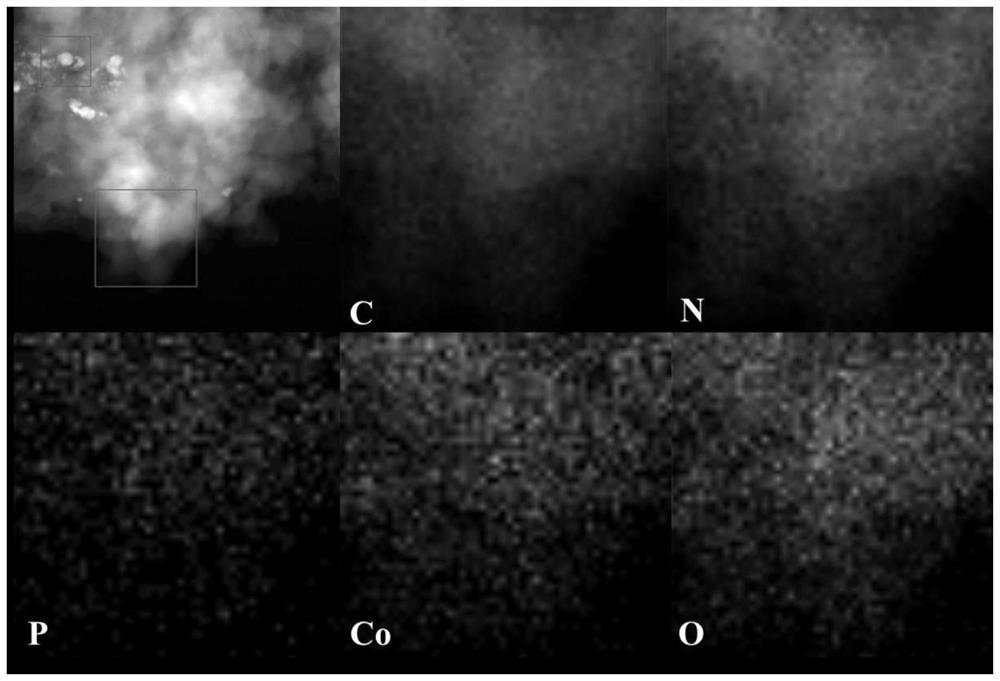

Nitrogen-and-phosphorus co-doped carbon-based cobalt catalyst and preparation method thereof, and synthetic method of saturated aliphatic primary amine

ActiveCN113441166AImprove cycle stabilityHigh selectivityOrganic compound preparationCatalyst activation/preparationCarbon layerPtru catalyst

The invention provides a nitrogen-and-phosphorus co-doped carbon-based cobalt catalyst and a preparation method thereof, and a synthesis method of saturated aliphatic primary amine. The nitrogen-and-phosphorus co-doped carbon-based cobalt catalyst comprises 0.5-15% of cobalt, 0.1-5% of phosphorus and 1-10% of nitrogen. The carbon-based cobalt catalyst has good catalytic hydrogenation activity, the nitrogen-doped carbon layer of the carbon-based cobalt catalyst has alkalinity, and the carbon layer has a coating structure, so the catalyst is high in stability, has relatively high catalytic activity and catalytic selectivity for synthesis of saturated aliphatic primary amine, and is wide in application prospect.

Owner:JIANGSU YANGNONG CHEM GROUP

Preparation process of nanometer RE oxide particle

ActiveCN101066775BGreen treatmentEasy to operateRare earth metal compoundsBulk chemical productionAlcoholOrganosolv

The present invention provides preparation process of nanometer RE fluoride particle. Alcohol solution of RE compound is dispersed in fluorine-containing ionic liquid, and the ionic liquid is heated to decompose and to produce fluorine ion combined with RE ion, so as to prepare great amount of nanometer RE fluoride particles in homogeneous shape. The prepared nanometer particles have size of 50-200 nm and may find wide application in biology, catalyst, lubricant, analysis, optics and other fields. The present invention completes reaction in a green solvent system, and is environment friendly.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com